Manufacturing Process of Stealth Unmanned Aerial Vehicle Exhaust Nozzles Based on Carbon Fiber-Reinforced Silicon Carbide Matrix Composites

Abstract

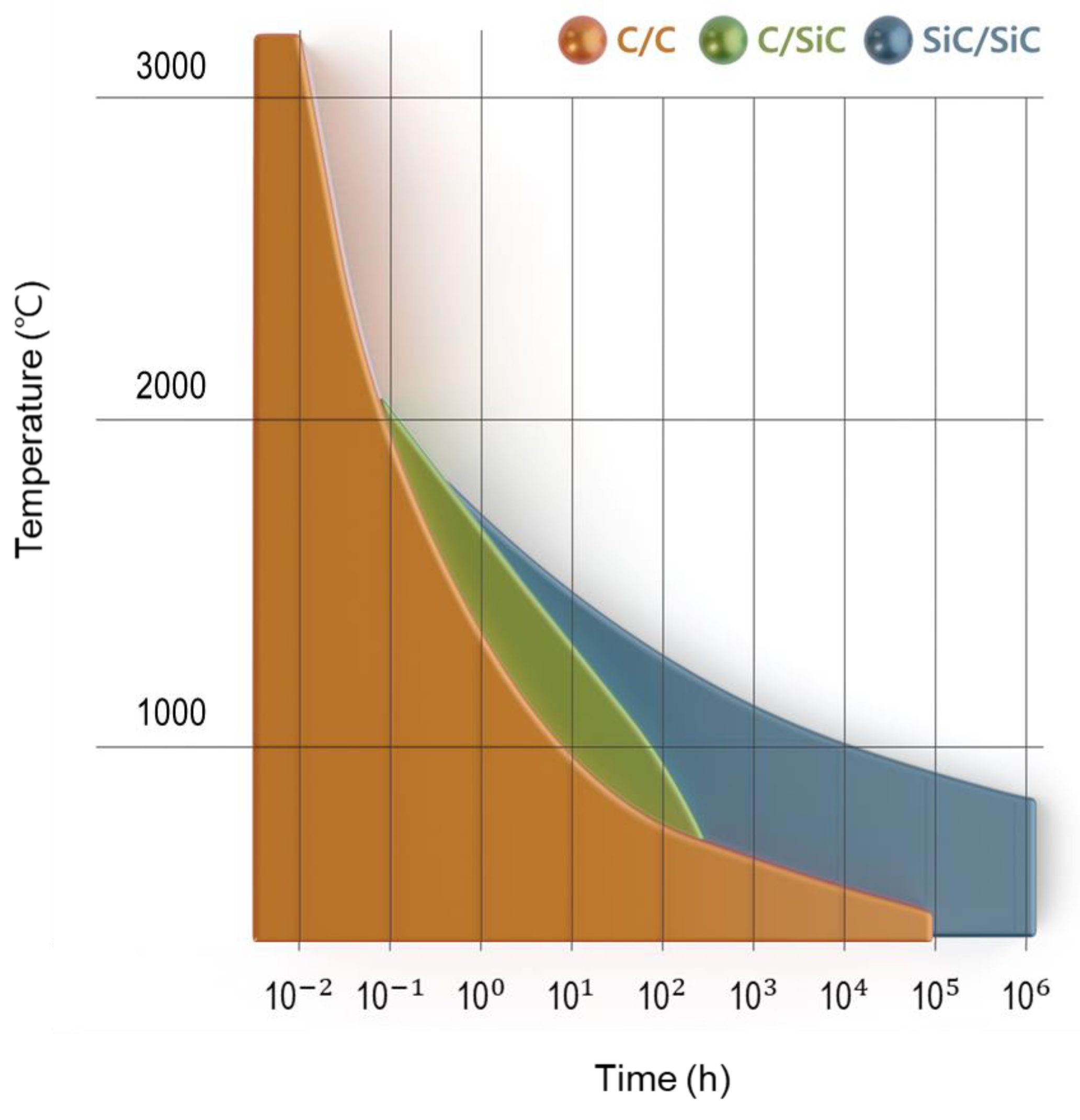

1. Introduction

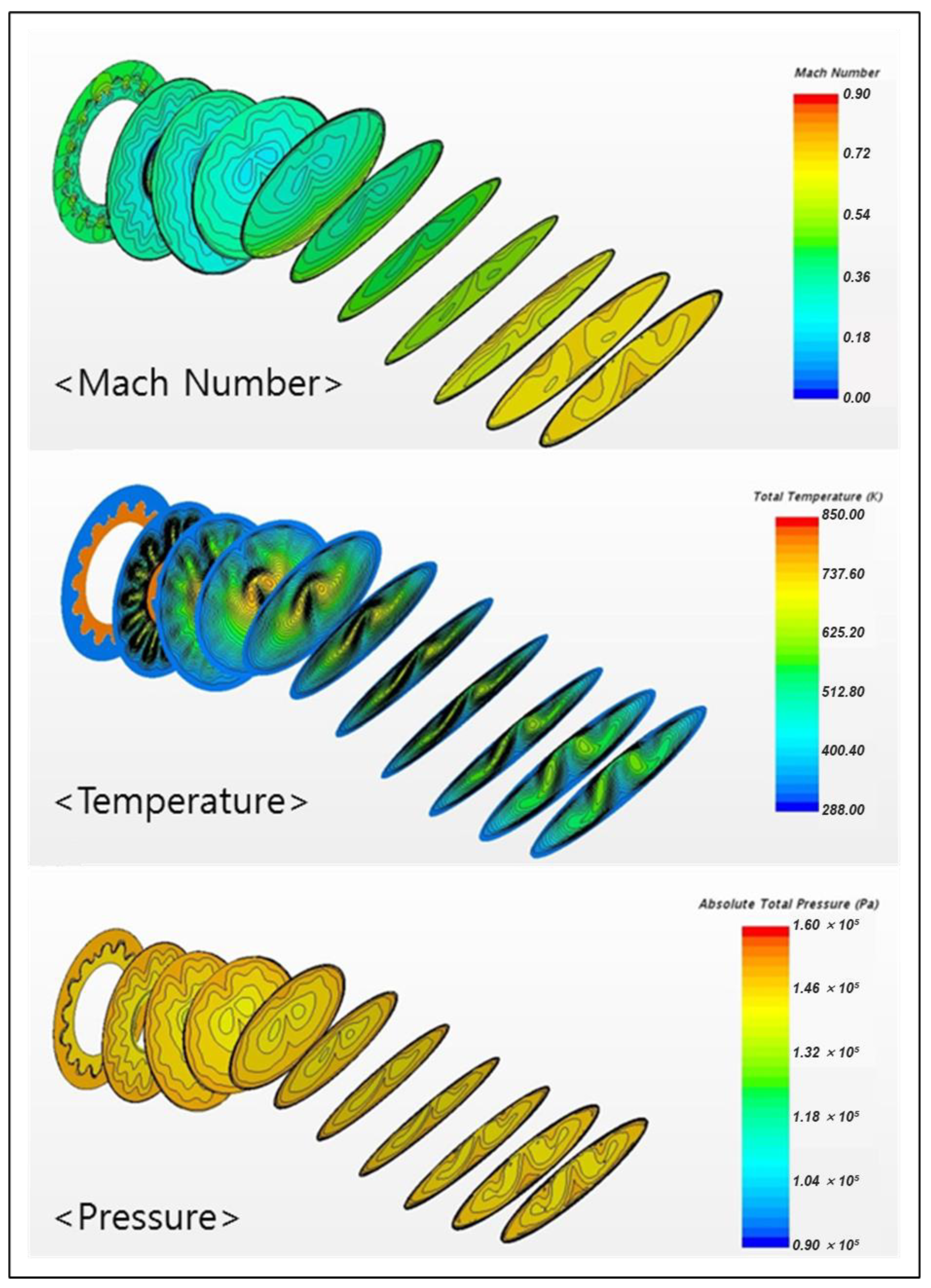

2. Development of the Manufacturing Process for High-Temperature, Low-Observable Composite Engine Exhaust Nozzles for UAVs

2.1. Fabrication of the PMC Preform

2.1.1. Materials

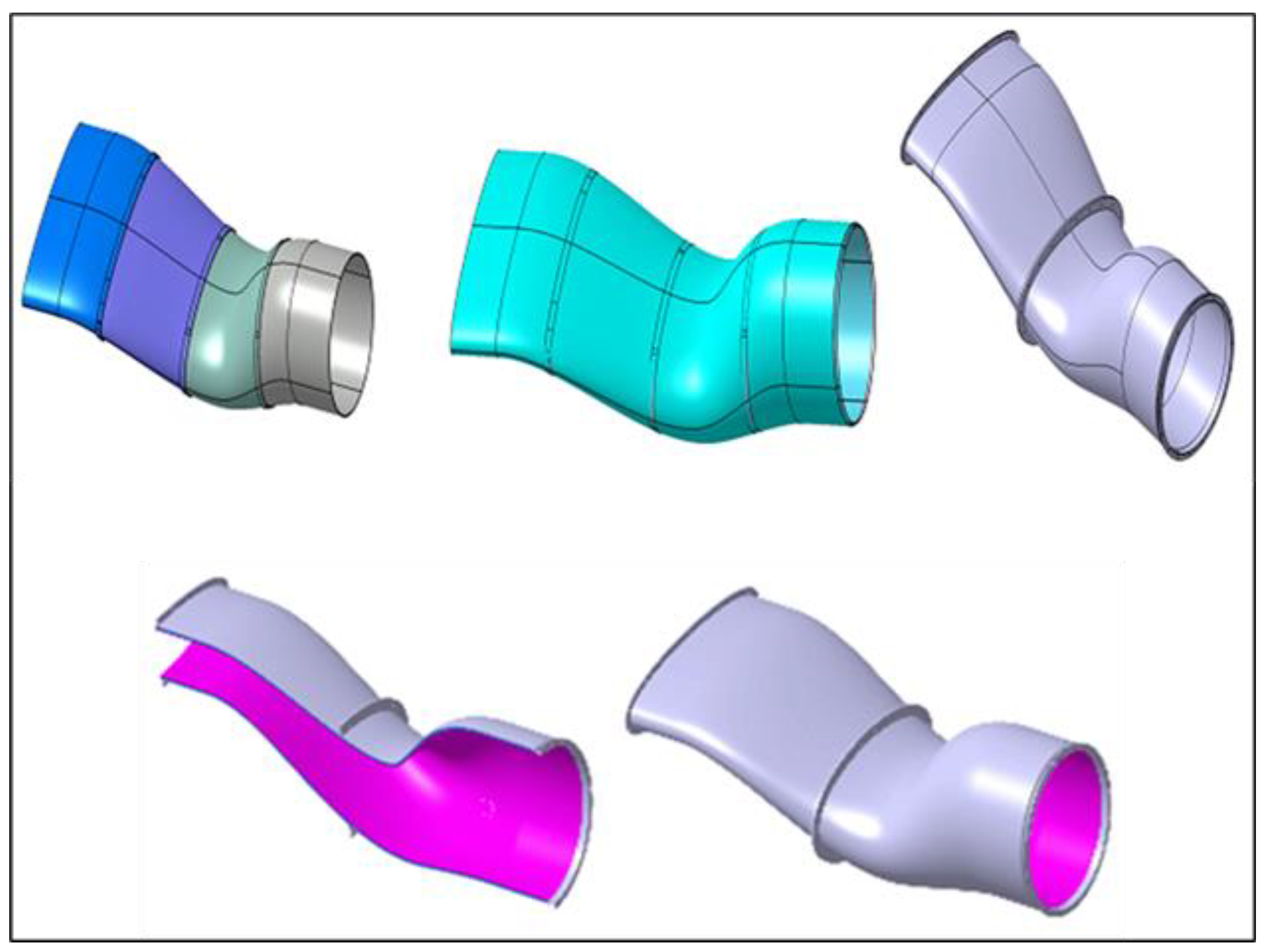

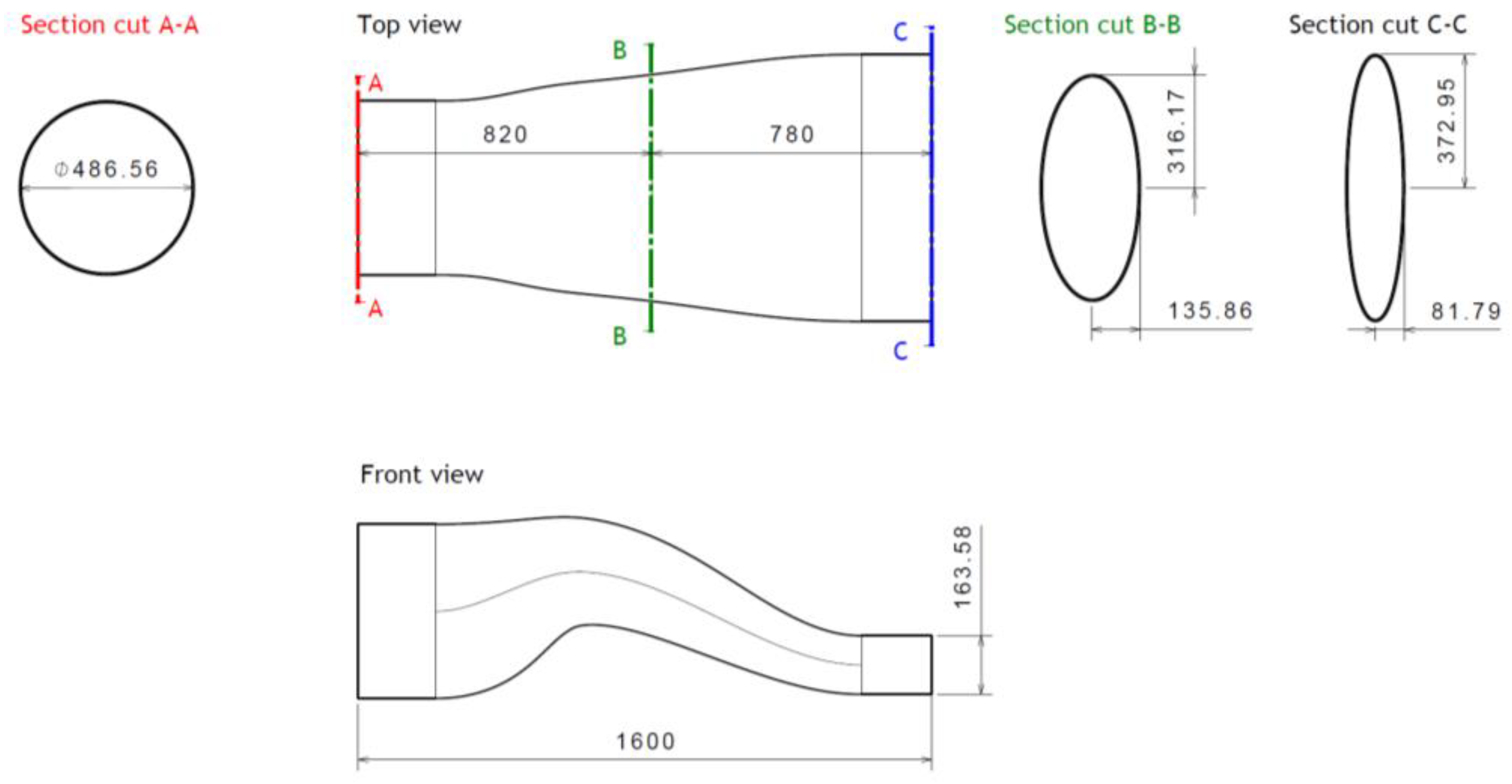

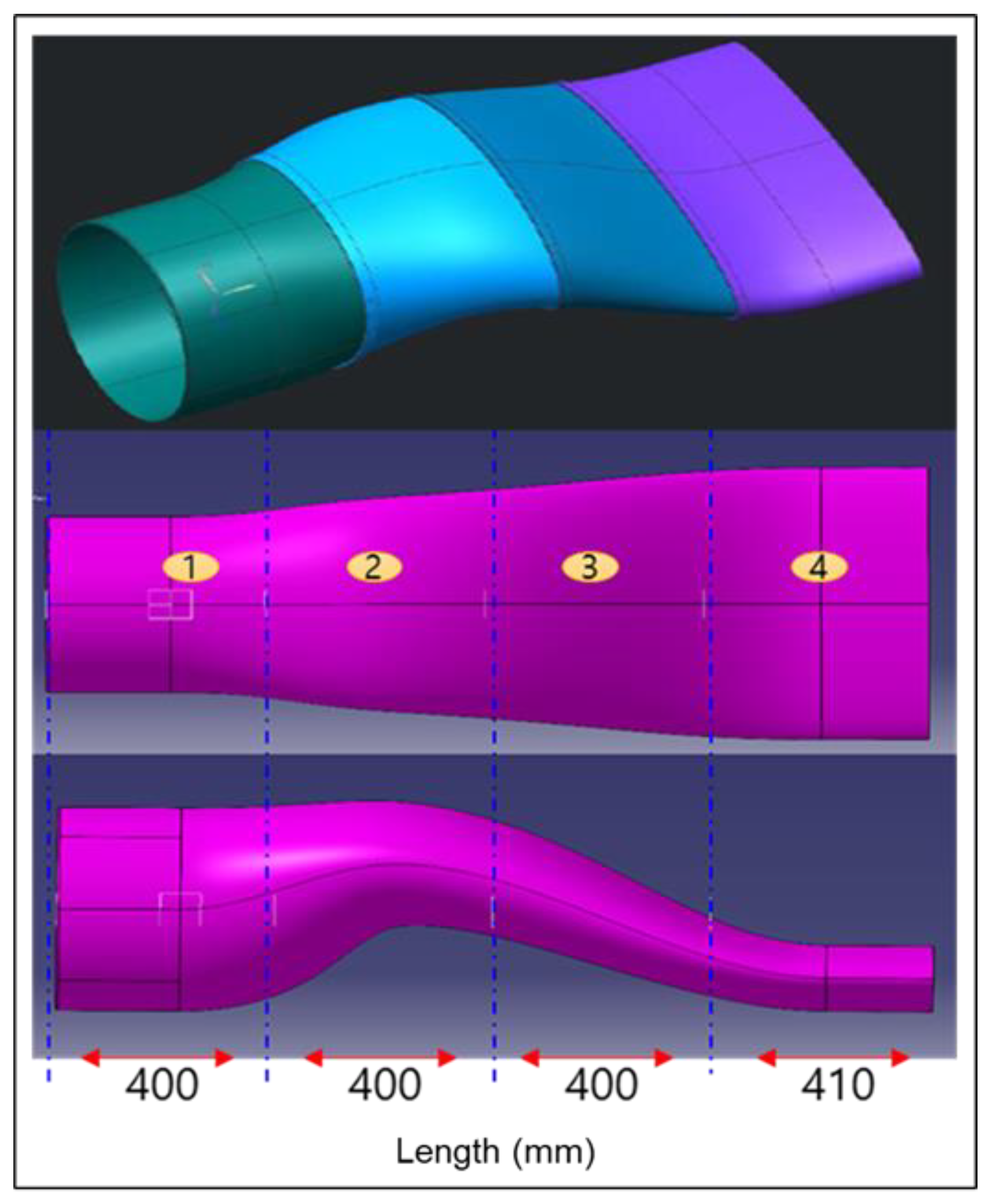

2.1.2. Preform Design According to Nozzle Geometry

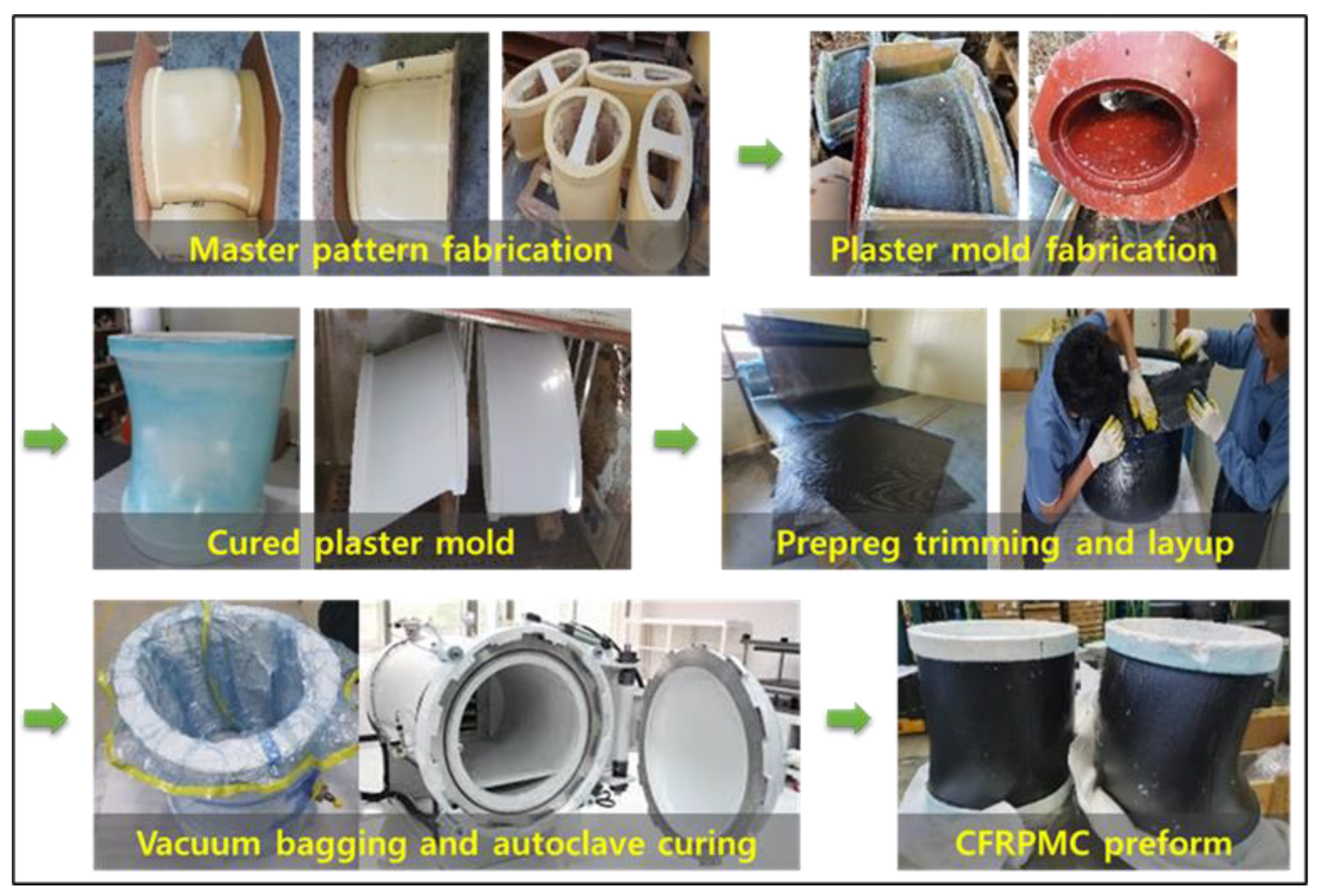

2.1.3. CFRPMC Preform Fabrication

2.2. Fabrication Process of the C/SiC

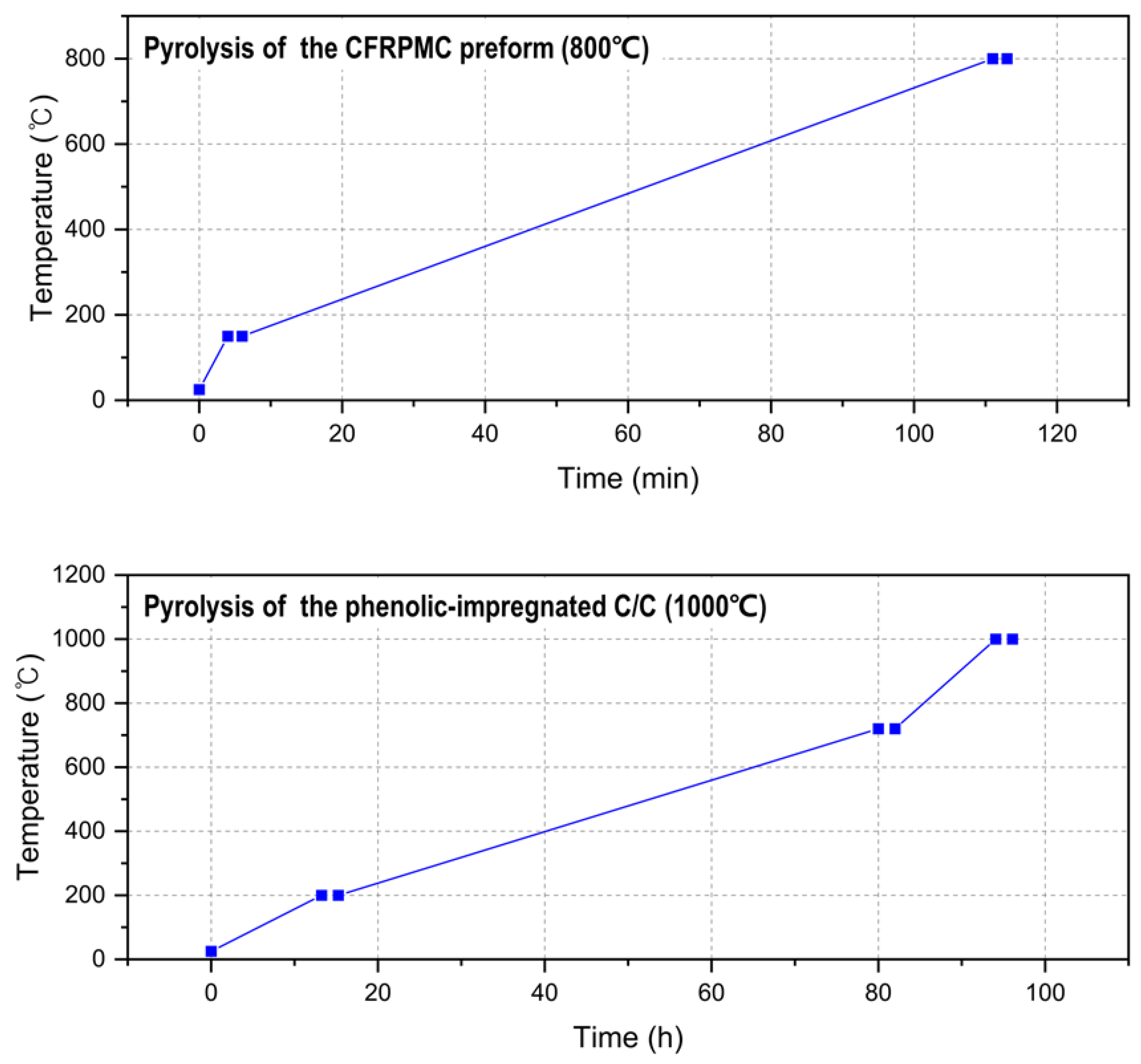

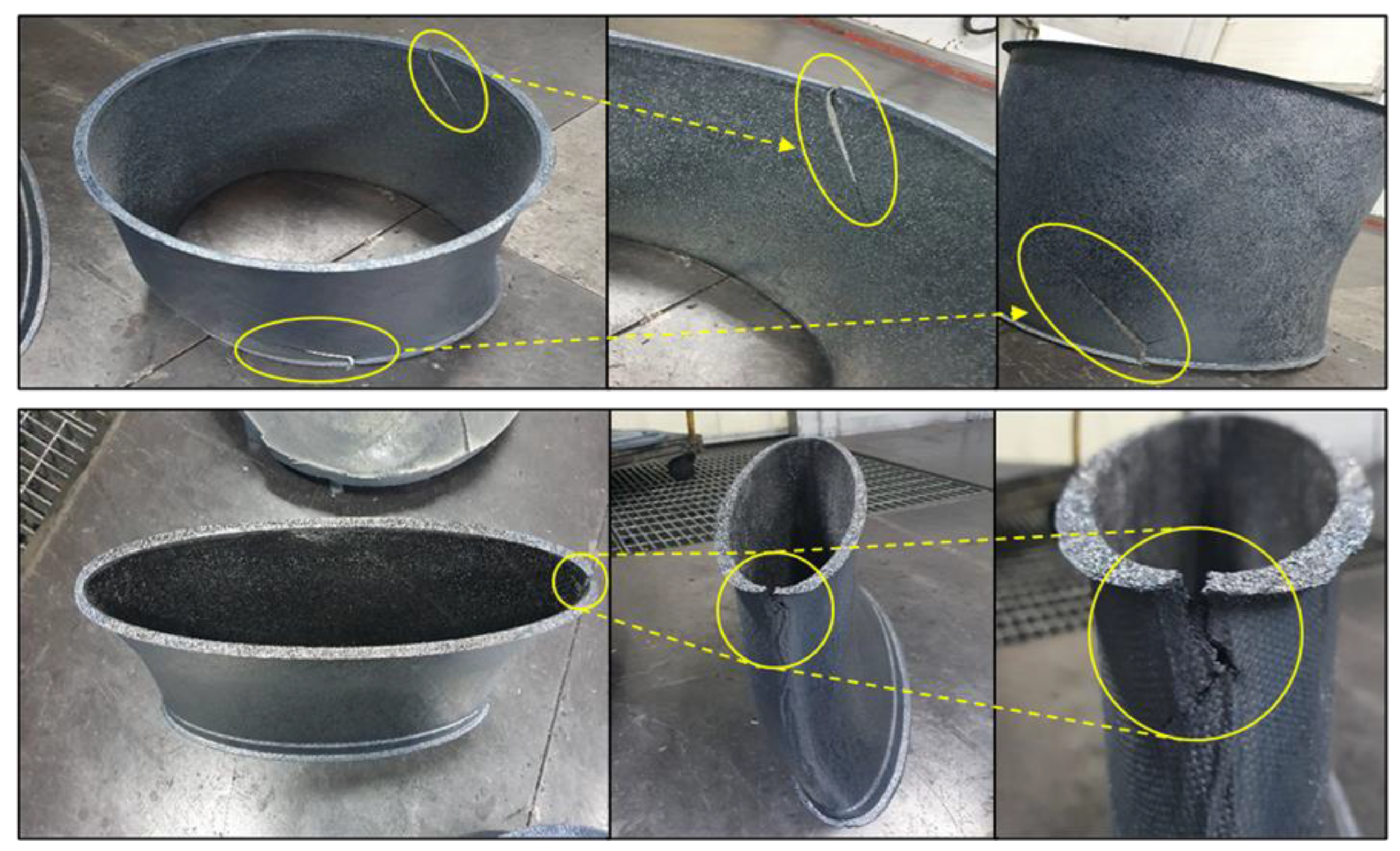

2.2.1. Pyrolysis of the CFRPMC Preform and Densification of the C/C

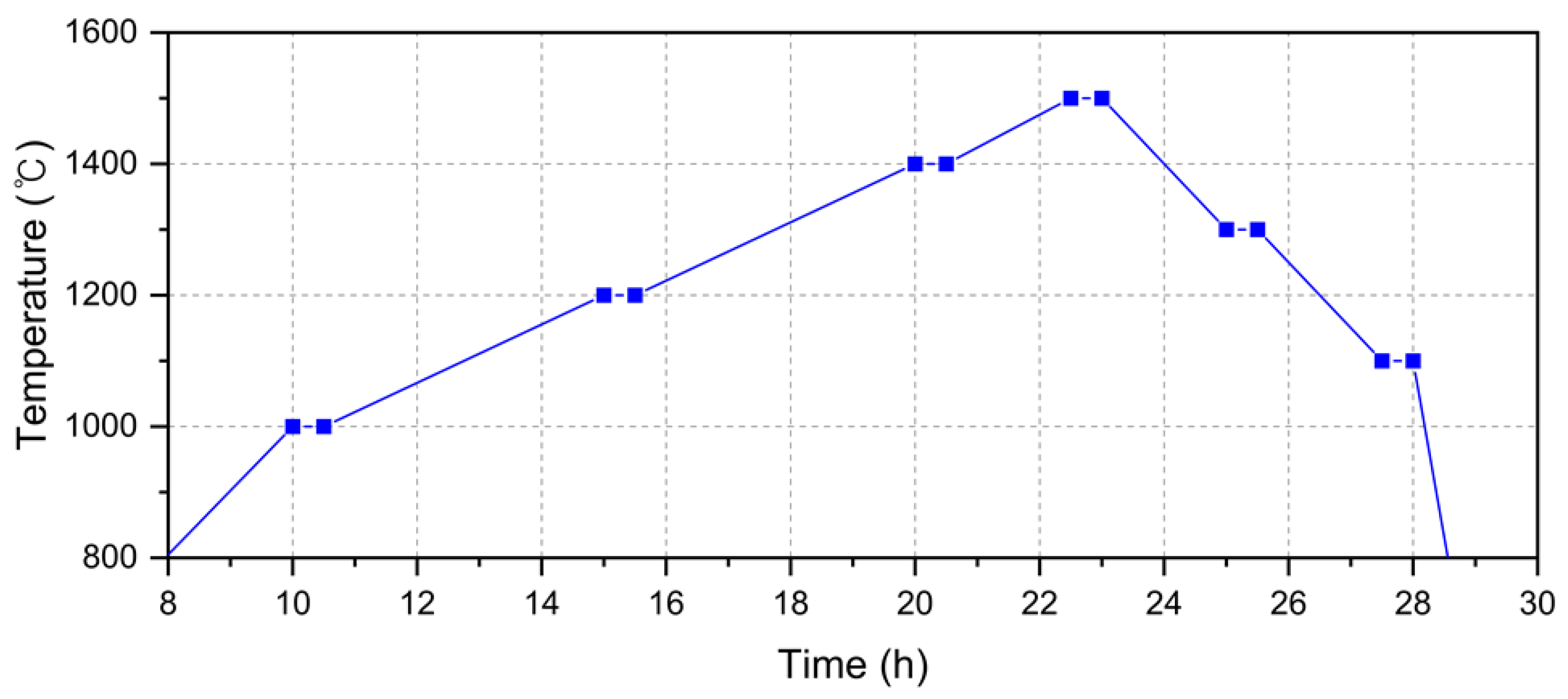

2.2.2. Heat Treatment of the Densified C/C Preform and the LSI Process

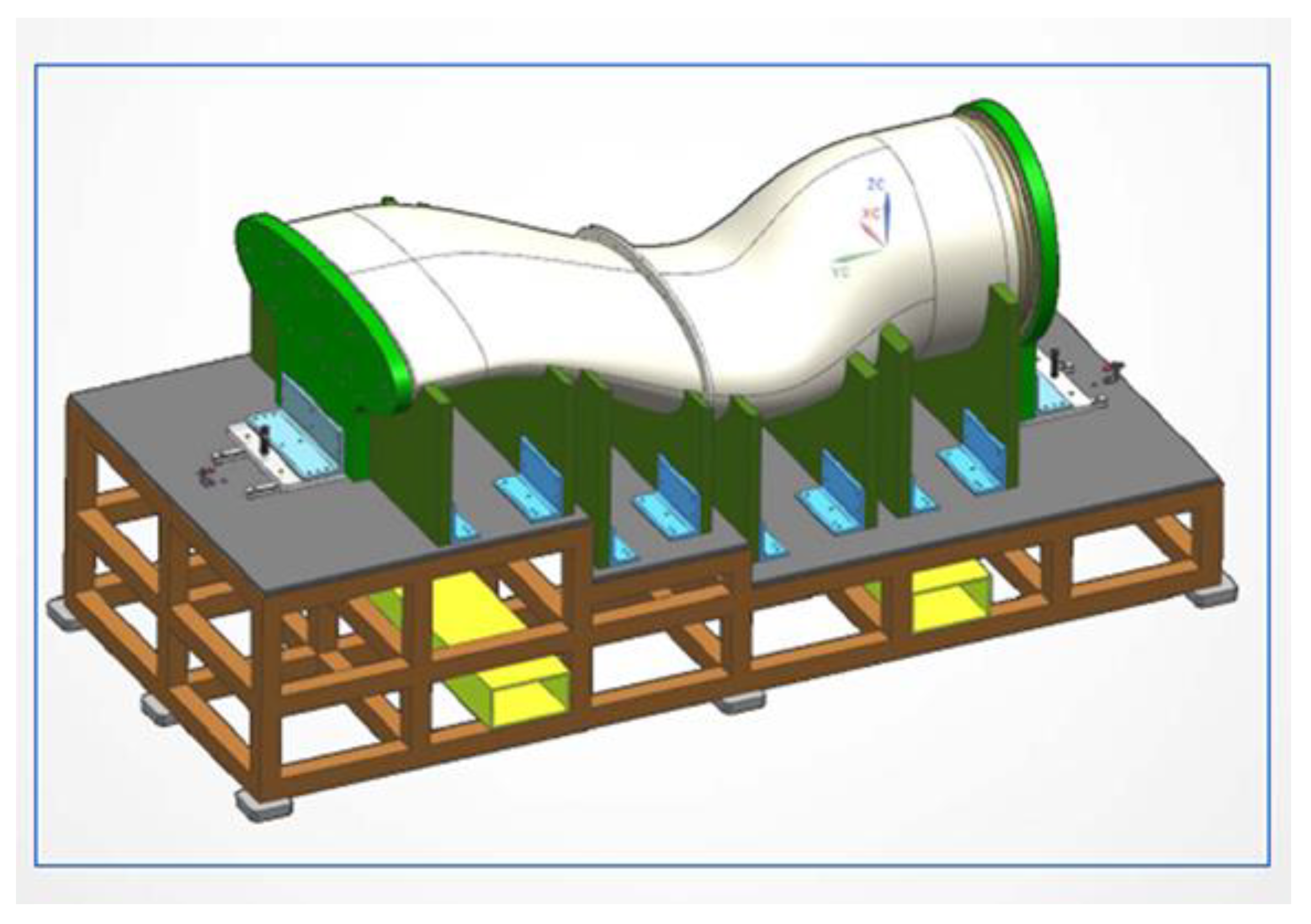

2.3. Multilayer Exhaust Nozzle Fabrication

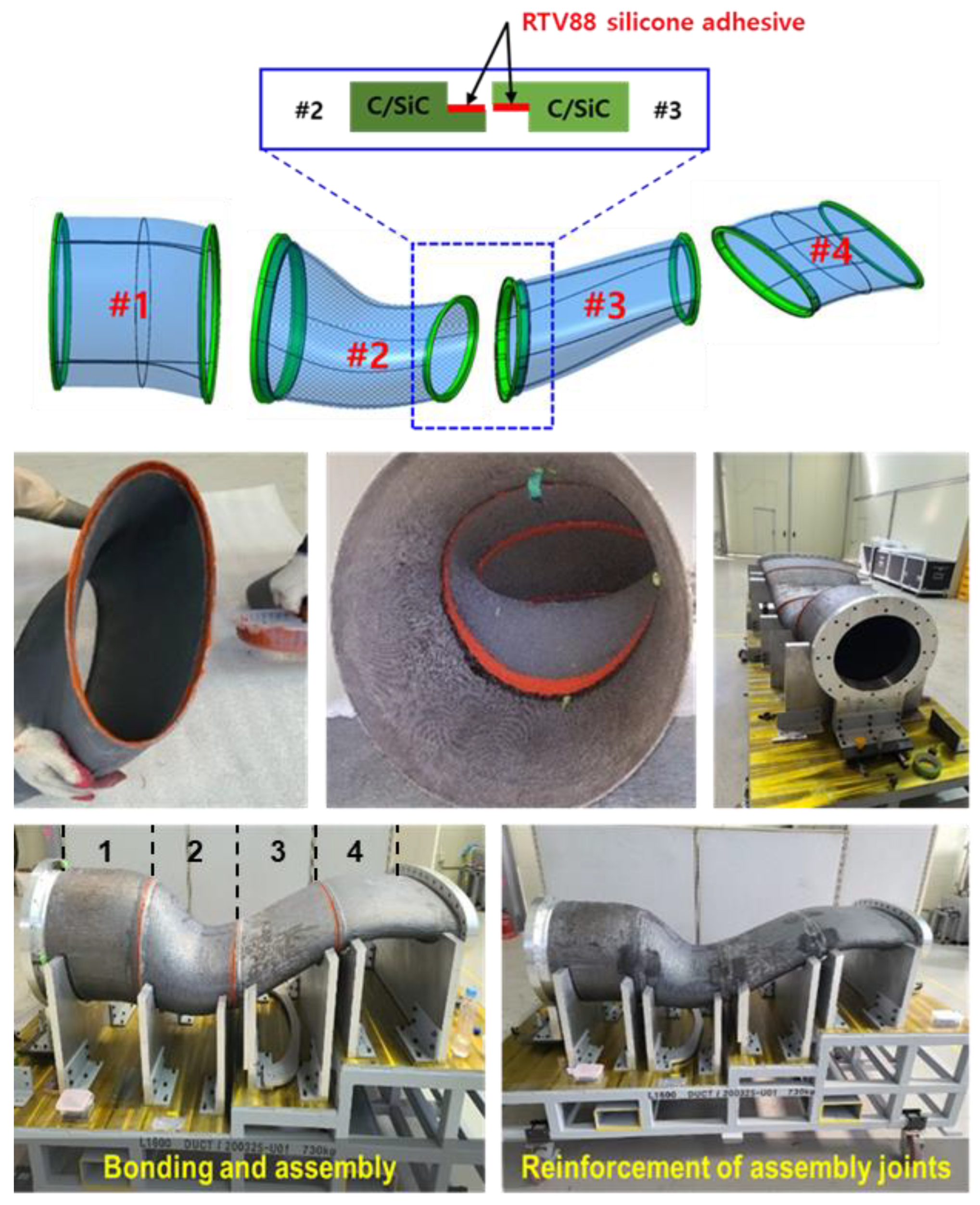

2.3.1. Assembly and Bonding of Segmented C/SiC Nozzle Parts

2.3.2. Thermal Insulation and Outer Reinforcement Layer Forming

2.3.3. Integration with the UAV Turbofan Engine

3. Test Results and Discussion

3.1. Physical and Mechanical Properties of C/SiCs

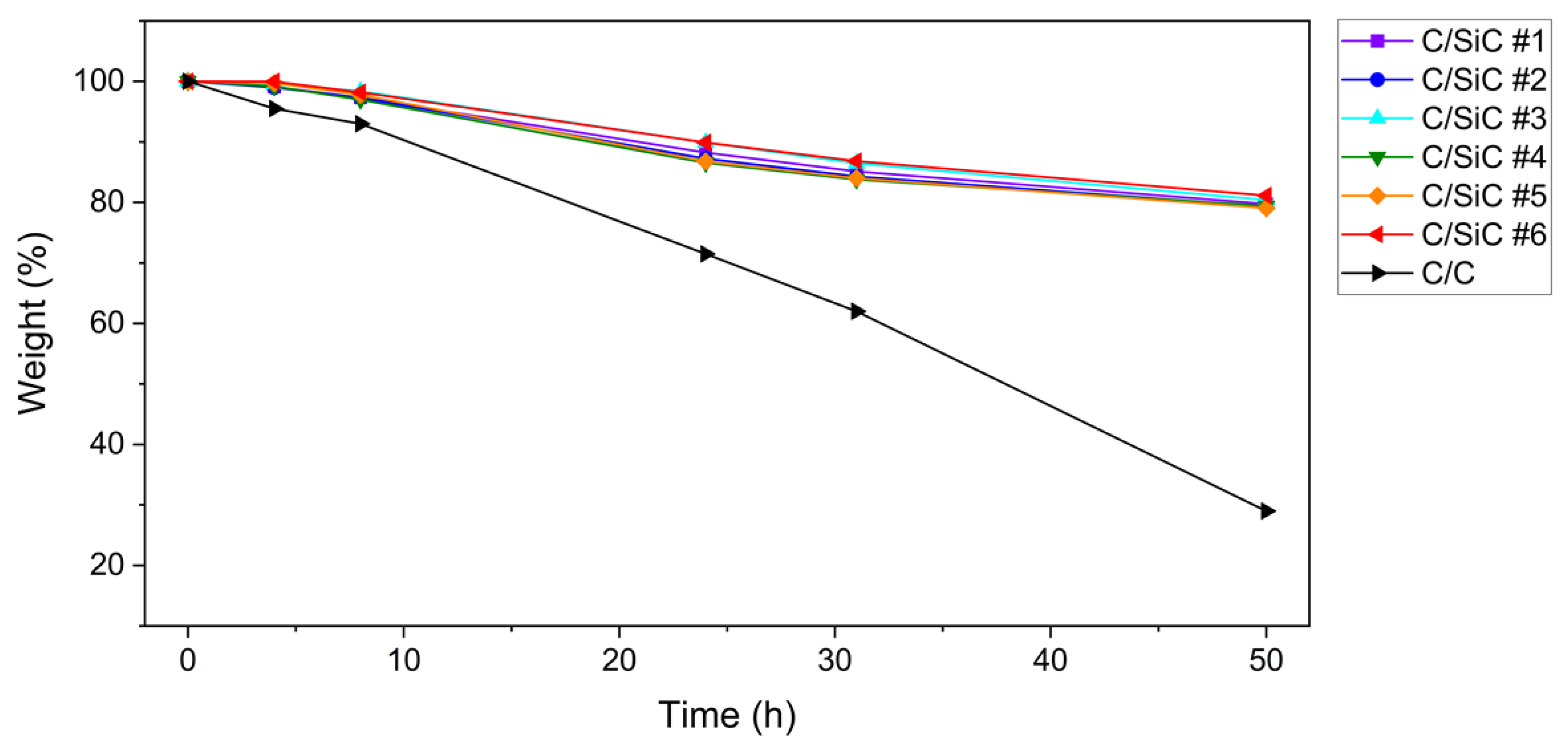

3.2. Oxidation and Ablation Resistance Tests

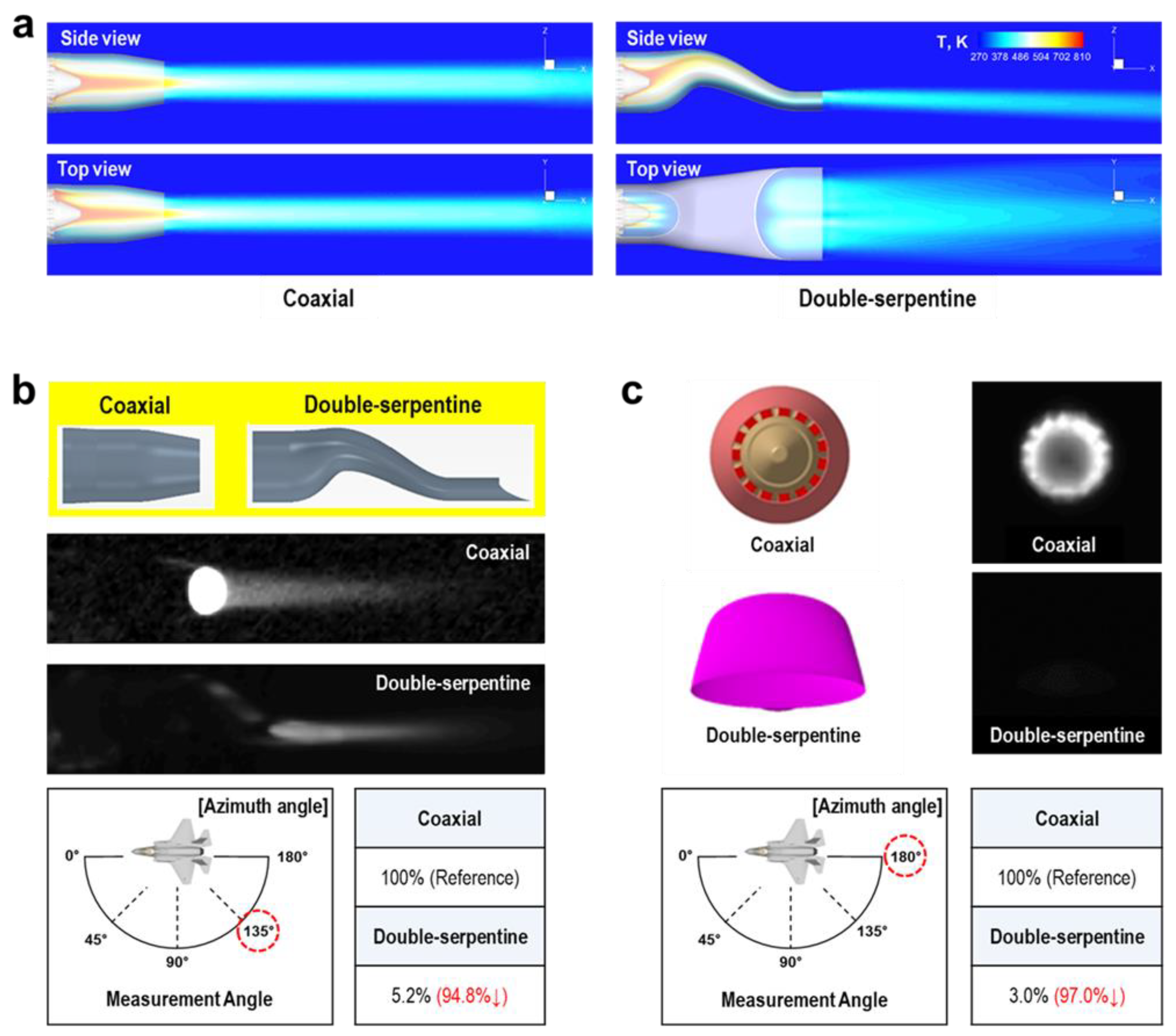

3.3. IR-Signature Measurement Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DS | Double-serpentine |

| UAV | Unmanned aerial vehicle |

| C/SiC | Carbon fiber-reinforced silicon carbide matrix composite |

| PMC | Polymer matrix composite |

| CFRPMC | Carbon fiber-reinforced polymer matrix composite |

| C/C | Carbon fiber-reinforced carbon matrix composite |

| SiC/SiC | Silicon carbide fiber-reinforced silicon carbide matrix composite |

| LSI | Liquid silicon infiltration |

| PAN | Polyacrylonitrile |

| CTE | Coefficient of thermal expansion |

References

- Li, M.; Chen, J.; Feng, X.; Qu, F.; Bai, J. An efficient adjoint method for the aero-stealth shape optimization design. Aerosp. Sci. Technol. 2021, 118, 107017. [Google Scholar] [CrossRef]

- Bo, L.; Wang, Q.; Hu, H. Multidisciplinary design optimization of axisymmetric exhaust systems: Integrating aerodynamic performance and infrared stealth capabilities. Inter. J. Therm. Sci. 2025, 208, 109462. [Google Scholar] [CrossRef]

- Lee, C.; Choi, S.M. Study on the Effects of Aft Deck Geometry on Plume Shield Ratio. Inter. J. Aeronaut. Space Sci. 2025, 26, 1–12. [Google Scholar] [CrossRef]

- Shi, J.; Zhou, L.; Xu, J.; Shi, J.; Wang, Z. Experimental Study on Infrared Radiation Characteristics and Matching Performance of Low-Observable Nozzles. J. Propuls. Power 2024, 40, 354–367. [Google Scholar] [CrossRef]

- Kim, S.J.; Kim, Y.R.; Kim, Y.; Kim, M.H.; Lee, M. 2D exhaust nozzle with multiple composite layers for IR signature suppression. Results Phys. 2020, 19, 103395. [Google Scholar] [CrossRef]

- Guo, B.-F.; Wang, Y.-J.; Cao, C.-F.; Qu, Z.-H.; Song, J.; Li, S.-N.; Gao, J.-F.; Song, P.; Zhang, G.-D.; Shi, Y.-Q.; et al. Large-Scale, Mechanically Robust, Solvent-Resistant, and Antioxidant MXene-Based Composites for Reliable Long-Term Infrared Stealth. Adv. Sci. 2024, 11, 2309392. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, J.; Wang, Z.; Wang, Y.; Jin, X.; Li, P.; Liu, P.; Chen, K.; Yang, L.; Fan, X. Thermal shock resistance and failure mechanisms of high temperature resistant radar and infrared compatible stealth coatings. Surf. Coat. Technol. 2023, 465, 129613. [Google Scholar] [CrossRef]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Sengupta, P.; Manna, I. Advanced High-Temperature Structural Materials for Aerospace and Power Sectors: A Critical Review. Trans. Indian Inst. Met. 2019, 72, 2043–2059. [Google Scholar] [CrossRef]

- Bencivengo, R.; Stoica, A.I.; Leonov, S.B.; Gulotty, R. Experimental Characterization of C–C Composite Destruction Under Impact of High Thermal Flux in Atmosphere and Hypersonic Airflow. Aerospace 2025, 12, 43. [Google Scholar] [CrossRef]

- Han, M.; Zhou, C.; Silberschmidt, V.V.; Bi, Q. Oxidation behaviour and residual mechanical properties of carbon/carbon composites. Carbon Lett. 2023, 33, 1241–1252. [Google Scholar] [CrossRef]

- Fu, Z.; Pang, A.; Luo, H.; Zhou, K.; Yang, H. Research progress of ceramic matrix composites for high temperature stealth technology based on multi-scale collaborative design. J. Mater. Res. Technol. 2022, 18, 2770–2783. [Google Scholar] [CrossRef]

- Guo, G.; Ye, F.; Cheng, L.; Li, Z.; Zhang, L. A novel porous carbon synthesized to serve in the preparation of highly dense and high-strength SiC/SiC by reactive melt infiltration. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107839. [Google Scholar] [CrossRef]

- Yilmaz, S.; Theodore, M.; Ozcan, S. Silicon carbide fiber manufacturing: Cost and technology. Compos. Part B Eng. 2024, 269, 111101. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, T.; Kang, W.; Xing, X.; Wu, S.; Gou, Y. Synthesis of Polytitanocarbosilane and Preparation of Si–C–Ti–B Fibers. Processes 2023, 11, 1189. [Google Scholar] [CrossRef]

- Wang, J.; Lin, M.; Xu, Z.; Zhang, Y.; Shi, Z.; Qian, J.; Qiao, G.; Jin, Z. Microstructure and mechanical properties of C/C–SiC composites fabricated by a rapid processing method. J. Eur. Ceram. Soc. 2009, 29, 3091–3097. [Google Scholar] [CrossRef]

- Yao, X.Y.; Li, W.; Feng, G.H. Effect of C/C preform density on oxidation properties of C/C-SiC composites. IOP Conf. Ser. Mater. Sci. Eng. 2020, 733, 012012. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Xiong, X.; Ye, Z.; Long, Q.; Wang, J.; Li, T.; Liu, C. Microstructure and Ablation Behavior of C/C-SiC-(ZrxHf1−x)C Composites Prepared by Reactive Melt Infiltration Method. Materials 2023, 16, 2120. [Google Scholar] [CrossRef]

- Xu, C.; Yi, F.; Meng, S.; Huo, Y.; Han, X.; Yang, Q. Compressive experimental method and properties of C/C composites under ultra-high temperature environment. J. Eur. Ceram. Soc. 2022, 42, 4702–4711. [Google Scholar] [CrossRef]

- Gauthier, M.M. Carbon-Carbon Composites. Eng. Mater. Handb. Desk Ed. 1995, 48, 1094–1111. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.-Y.; Gong, S.-K.; Xu, H.-B.; Guo, H.-B. High-temperature oxidation resistance of Si-coated C/SiC composites. Rare Met. 2024, 43, 4566–4572. [Google Scholar] [CrossRef]

- DiCarlo, J.A.; Yun, H.M.; Morscher, G.N.; Bhatt, R.T. SiC/SiC Composites for 1200 °C and Above. In Handbook of Ceramic Composites; Bansal, N.P., Ed.; Springer: Boston, MA, USA, 2005; pp. 77–98. [Google Scholar]

- Liu, X.; Li, L. Design, Fabrication and Testing of Aeroengine Ceramic-Matrix Composite Components, 1st ed.; Springer: Singapore, 2024. [Google Scholar]

- Patel, M.; Saurabh, K.; Prasad, V.V.B.; Subrahmanyam, J. High temperature C/C–SiC composite by liquid silicon infiltration: A literature review. Bull. Mater. Sci. 2012, 35, 63–73. [Google Scholar] [CrossRef]

- Cheng, L.; Xu, Y.; Zhang, L.; Yin, X. Oxidation behavior of three dimensional C/SiC composites in air and combustion gas environments. Carbon 2000, 38, 2103–2108. [Google Scholar] [CrossRef]

- Cramer, C.L.; Yoon, B.; Lance, M.J.; Cakmak, E.; Campbell, Q.A.; Mitchell, D.J. Additive Manufacturing of C/C-SiC Ceramic Matrix Composites by Automated Fiber Placement of Continuous Fiber Tow in Polymer with Pyrolysis and Reactive Silicon Melt Infiltration. J. Compos. Sci. 2022, 6, 359. [Google Scholar] [CrossRef]

- Gallegos, I.; Varshney, V.; Kemppainen, J.; Odegard, G.M. Revealing nanoscale mechanisms of pyrolysis at phenolic resin/carbon fiber interface. J. Mater. Sci. 2025, 60, 5106–5124. [Google Scholar] [CrossRef]

- Souza, W.; Garcia, K.; Dollinger, C.; Pardini, L. Electrical Behavior of Carbon Fiber/Phenolic Composite during Pyrolysis. Mater. Res. 2015, 18, 1209–1216. [Google Scholar] [CrossRef]

- Seers, B.; Tomlinson, R.; Fairclough, P. Residual stress in fiber reinforced thermosetting composites: A review of measurement techniques. Polym. Compos. 2021, 42, 1631–1647. [Google Scholar] [CrossRef]

- Chen, X.; Cheng, G.; Zhang, J.; Guo, F.; Zhou, H.; Liao, C.; Wang, H.; Zhang, X.; Dong, S. Residual stress variation in SiCf/SiC composite during heat treatment and its effects on mechanical behavior. J. Adv. Ceram. 2020, 9, 567–575. [Google Scholar] [CrossRef]

- Knauf, M.W.; Przybyla, C.P.; Shade, P.A.; Park, J.-S.; Ritchey, A.J.; Trice, R.W.; Pipes, R.B. In situ characterization of residual stress evolution during heat treatment of SiC/SiC ceramic matrix composites using high-energy X-ray diffraction. J. Am. Ceram. Soc. 2021, 104, 1424–1435. [Google Scholar] [CrossRef]

- Kong, C.; Sun, Z.; Niu, X.; Song, Y. Analytical model of elastic modulus and coefficient of thermal expansion for 2.5D C/SiC composite. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2013, 28, 494–499. [Google Scholar] [CrossRef]

- Ge, H.; Zhang, L.; Zhang, H.; Wang, F.; Gao, X.; Song, Y. Cyclic Ablation Properties of C/SiC-ZrC Composites. Aerospace 2024, 11, 432. [Google Scholar] [CrossRef]

| Tensile Strength (GPa) | Tensile Modulus (GPa) | Elongation (%) | Density (g/cm3) | Filament Diameter (μm) |

|---|---|---|---|---|

| 5.5 | 250 | 2.2 | 1.8 | 7.0 |

| Areal Density (g/m2) | Prepreg Thickness (mm) | Prepreg Width (mm) | Resin Content (%) | Resin Solids Content (%) |

|---|---|---|---|---|

| 209 ± 13 | 0.23 ± 0.2 | 1020 ± 15 | 35 ± 5 | 60 ± 3 |

| Curing Temperature (°C) | Cooling Temperature (°C) | Pressure (kPa) | Heating Rate (°C/min) | Curing Time (h) |

|---|---|---|---|---|

| 150 ± 5 | 65 | 276 ± 35 | 1.5 | 2 |

| Tensile Strength (MPa) | Compressive Strength (MPa) | Thermal Conductivity (W/(m·K)) | Density (g/cm3) | Coefficient of Thermal Expansion (K−1) | |

|---|---|---|---|---|---|

| 25 °C | 300 °C | ||||

| 108.67 ± 4.04 | 242.33 ± 24.68 | 7.06 | 7.98 | 1.72 | 1.088 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, B.-J.; Kim, J.W.; Lee, M.Y.; Park, J.K.; Cho, N.C.; Baek, C.W. Manufacturing Process of Stealth Unmanned Aerial Vehicle Exhaust Nozzles Based on Carbon Fiber-Reinforced Silicon Carbide Matrix Composites. Aerospace 2025, 12, 600. https://doi.org/10.3390/aerospace12070600

Kim B-J, Kim JW, Lee MY, Park JK, Cho NC, Baek CW. Manufacturing Process of Stealth Unmanned Aerial Vehicle Exhaust Nozzles Based on Carbon Fiber-Reinforced Silicon Carbide Matrix Composites. Aerospace. 2025; 12(7):600. https://doi.org/10.3390/aerospace12070600

Chicago/Turabian StyleKim, Byeong-Joo, Jae Won Kim, Man Young Lee, Jong Kyoo Park, Nam Choon Cho, and Cheul Woo Baek. 2025. "Manufacturing Process of Stealth Unmanned Aerial Vehicle Exhaust Nozzles Based on Carbon Fiber-Reinforced Silicon Carbide Matrix Composites" Aerospace 12, no. 7: 600. https://doi.org/10.3390/aerospace12070600

APA StyleKim, B.-J., Kim, J. W., Lee, M. Y., Park, J. K., Cho, N. C., & Baek, C. W. (2025). Manufacturing Process of Stealth Unmanned Aerial Vehicle Exhaust Nozzles Based on Carbon Fiber-Reinforced Silicon Carbide Matrix Composites. Aerospace, 12(7), 600. https://doi.org/10.3390/aerospace12070600