Analytical Shaping of a Rocket Nose as a Stage of Preliminary Aerodynamic Modification

Abstract

1. Introduction

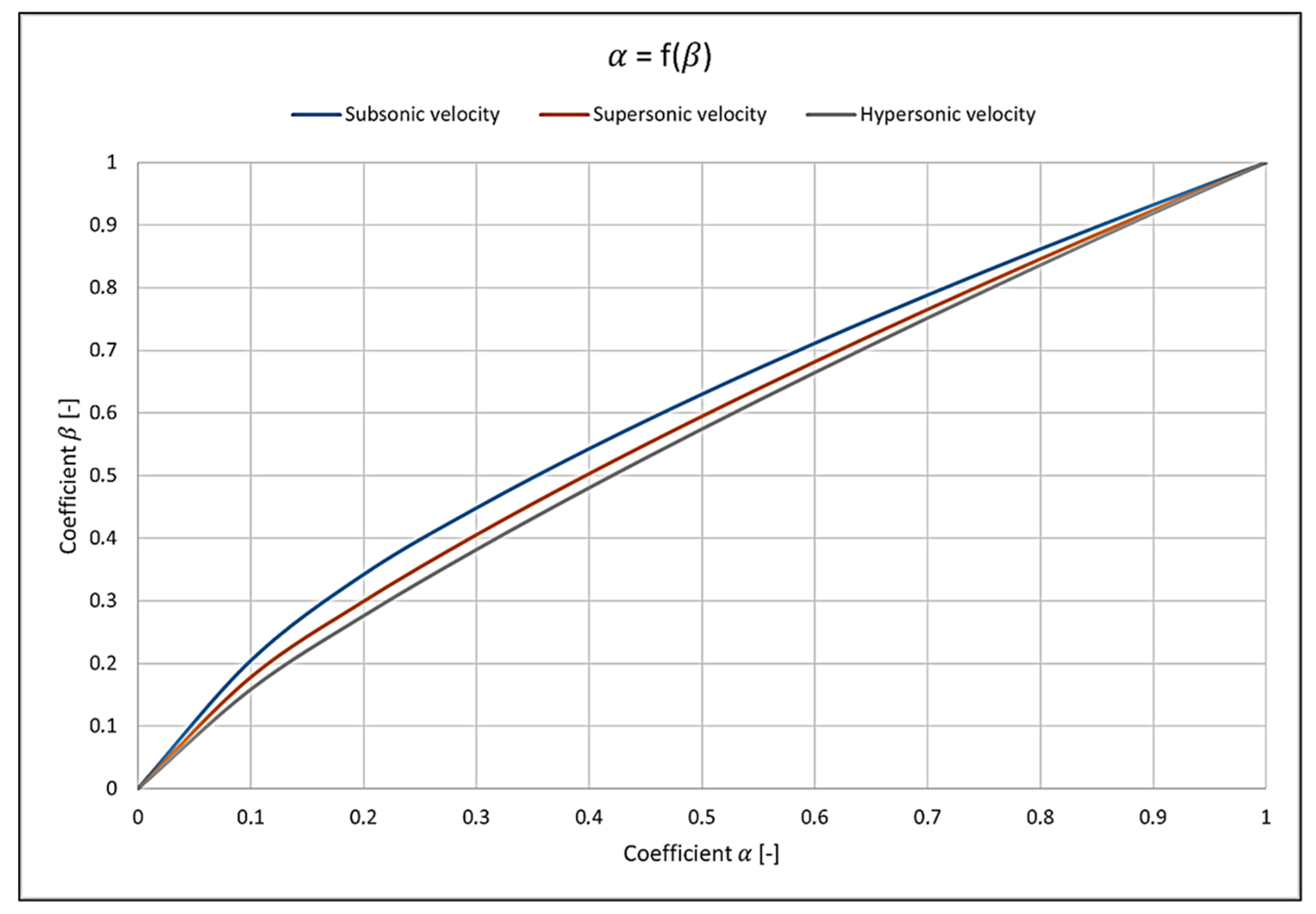

2. Mathematical Model to Minimize the Drag Coefficient of the Rocket Front and Its Internal Volume

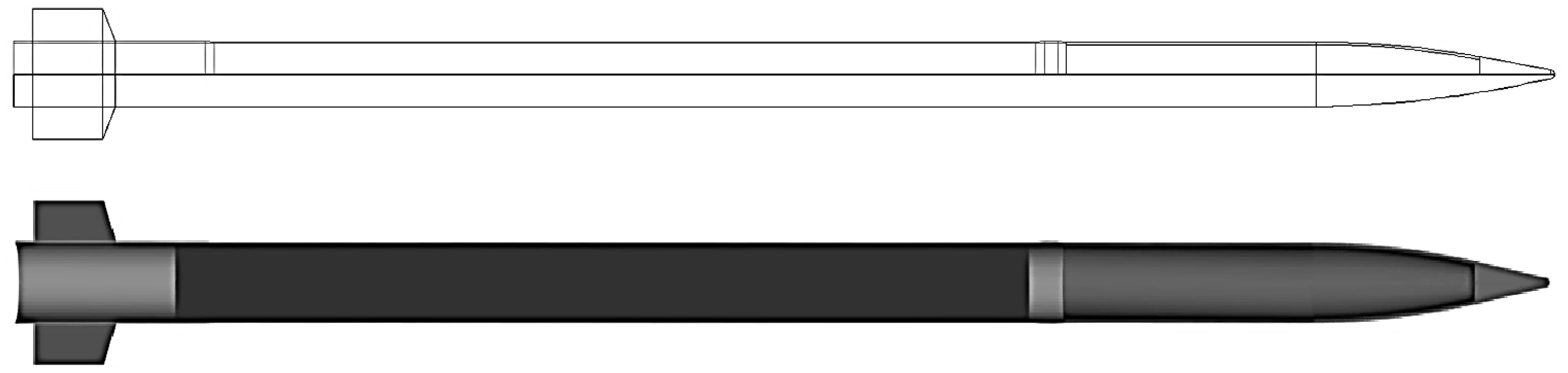

- Aerodynamic forebody shape—this part has an increasing section for ;

- The cylindrical part of the rocket with a length of ;

- Although the rear section of rockets is usually shaped as a truncated cone to reduce base drag, this particular missile lacks such a configuration.

2.1. The Minimization of the Aerodynamic Drag of a Missile

- : This is the drag resistance per unit length;

- : This is the dynamic air pressure, expressed as , where is the air density, and is the missile’s velocity;

- : This is a function that describes the shape of the missile’s nose profile as a function of its coordinate , which is the distance along the missile’s axis;

- : This is the derivative of the function , i.e., the slope of the nose profile at point ;

- Integration along the length of the missile’s nose (from to , where is the length of the missile’s nose).

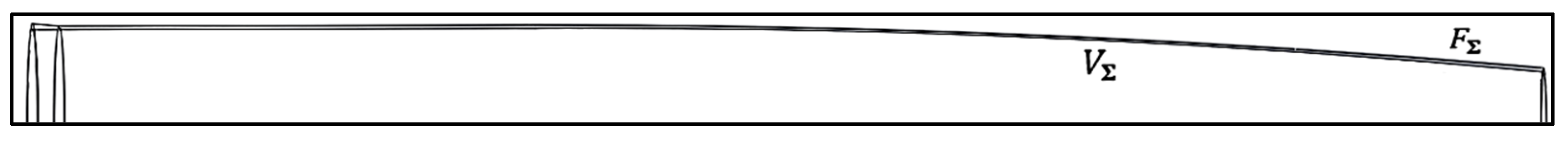

2.2. Determination of the Internal Volume of the Designed Missile

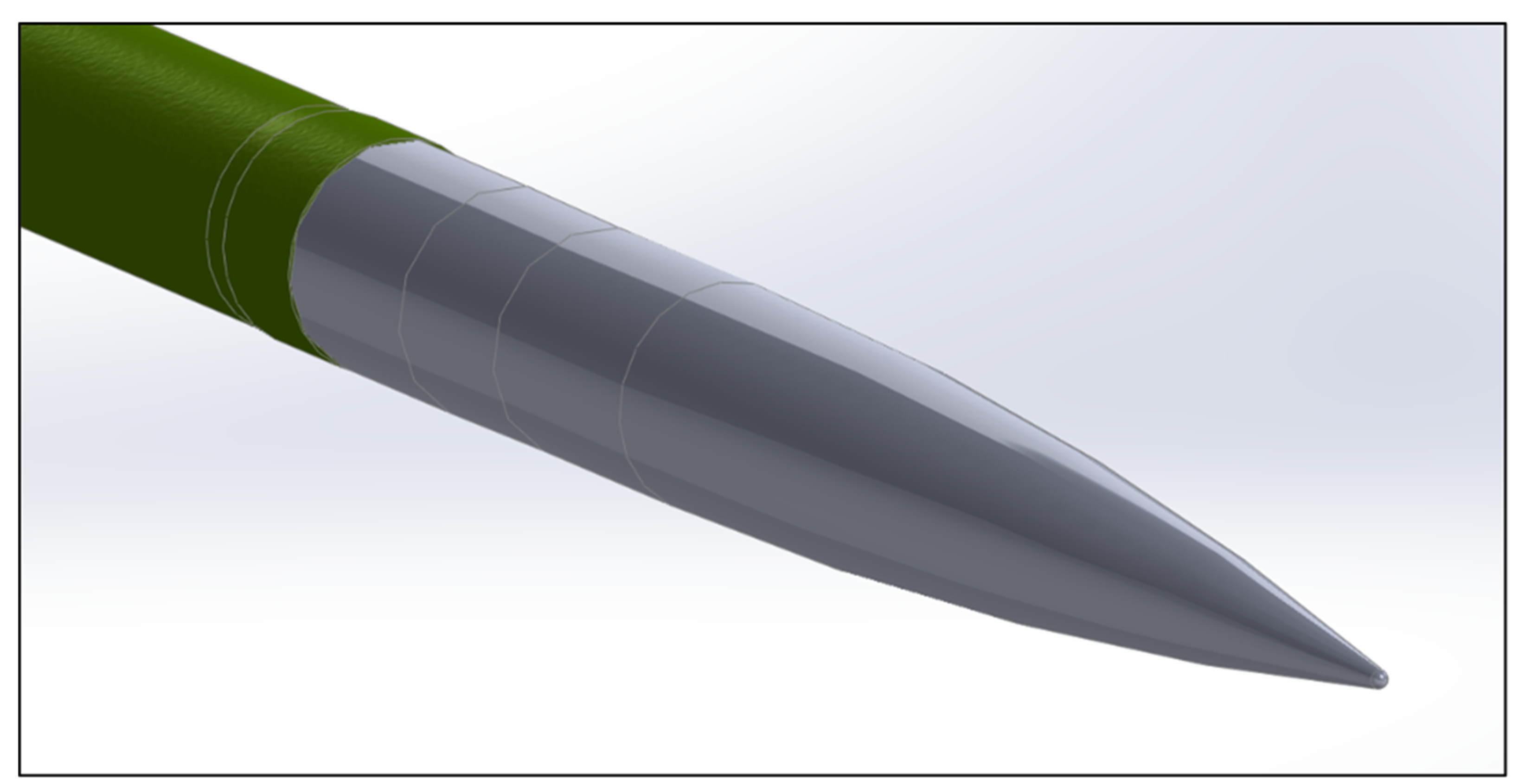

3. Shaping the Outline of the Missile Face for the Guided Version

3.1. Determination of the Shape of the New Aerodynamic Contour for the Guided Missile

- Point A: At this point, it is necessary to bring the two elements seamlessly together. One of the simplest solutions is to introduce a curve tangent to both contours.

- Point B: At this point, the streamline curve breaks down quite a bit. However, this is “not a problem” for the rocket, as it is possible to introduce a spherical outline tangent to the aerodynamic streamline at this point. Alternatively, in most cases of military rockets, various devices are used, such as a supersonic cone, fuse, camera, etc. In summary, this location is not a problem in the analysis of the forward streamline curve.

- Zone I: The front zone of the rocket (conical part).

- Zone II: The zone proper that is the subject of the following analysis.

- Zone III: The body of the rocket.

3.2. Determination of the Volume of the New Aerodynamic Contour in the Design Space for the Control System

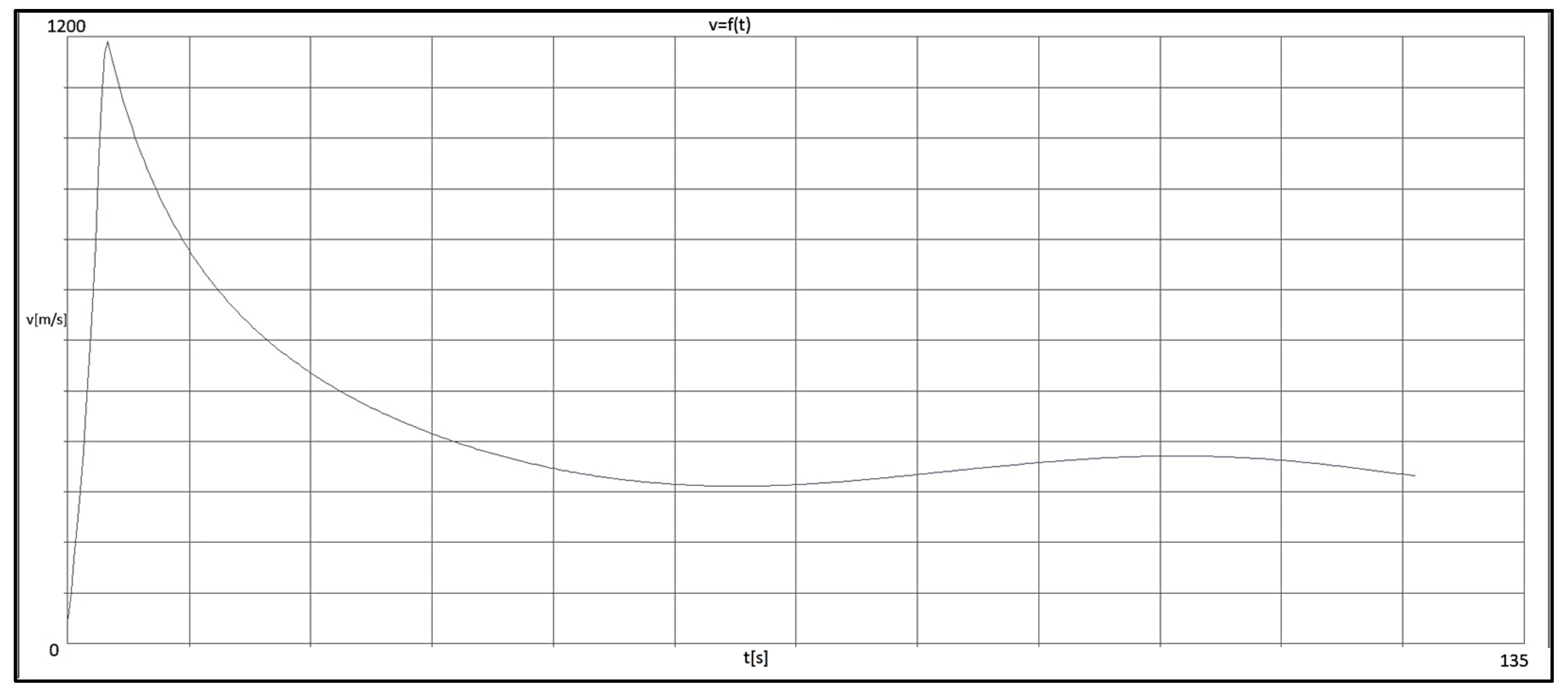

4. Missile Aerodynamics Analysis

- Meteorological parameters:

- Air temperature: 21.2 °C;

- Atmospheric pressure: 1026 hPa;

- Relative humidity: 65%;

- Wind speed: 2.6 m/s (5 knots);

- Wind direction: northeast (NE).

- Initial rocket parameters:itial rocket parameters:

- Rocket temperature: 20 °C;

- Initial velocity: 300 m/s (according to engine specifications);

- Launch angle: 55°.

- Instrumentation and measurement methods:

- Data analysis:

5. Description of the Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Budiyono, A.; Rachman, H. Proportional guidance and CDM control synthesis for a short-range homing surface–to–air missile. J. Aerosp. Eng. 2012, 25. [Google Scholar] [CrossRef]

- Hong, D.; Kim, M. Sungsu Park Study on reinforcement learning-based missile guidance law. Appl. Sci. 2020, 10, 6567. [Google Scholar] [CrossRef]

- Li, K.; Yang, S.; Zhao, L. Three-loop autopilot of spinning missiles. J. Aerosp. Eng. 2013, 228, 1195–1201. [Google Scholar] [CrossRef]

- Makowski, M.; Sienicki, K.; Motyl, K. Visualization of flight rocket missile in the environment Matlab/Simulink with the use of the Flightgear. Mechanik 2015, 7, 487–496. [Google Scholar] [CrossRef][Green Version]

- Bużantowicz, W.; Pietrasieński, J. Dual-control missile guidance: A simulation study. J. Theor. Appl. Mech. 2018, 56, 727–739. [Google Scholar] [CrossRef]

- Dębecki, A.; Dubiel, S.; Konstrukcja Rakiet, C., III. Podstawy Projektowania Charakterystyki Aerodynamiczne i Optymalne Programy Lotu Rakiet; WAT: Warszawa, Poland, 1988. [Google Scholar]

- Szklarski, A.; Głębocki, R.; Jacewicz, M. Impact point prediction guidance parametric study for 155 mm rocket assisted artillery missile with lateral thrusters. Arch. Mech. Eng. 2020, 67, 31–56. [Google Scholar] [CrossRef]

- Zygmunt, B.; Motyl, K. Symulacja komputerowa balistyki 122 mm pocisku rakietowego ze zmodernizowanym zespołem napędowym. Probl. Mechatroniki Uzbroj. Lot. Inżyniera Bezpieczeństwa 2016, 7, 53–72. [Google Scholar] [CrossRef]

- Li, K.; Yang, S.; Zhao, L. Stability of spinning missiles with an acceleration autopilot. J. Guid. Control. Dyn. 2012, 35, 774–786. [Google Scholar] [CrossRef]

- Hu, S.; Wang, J.; Wang, Y.; Tian, S. Stability limits for the velocity orientation autopilot of rolling missiles. IEEE Access 2021, 9, 9504563. [Google Scholar] [CrossRef]

- Sreeja, S.; Hablani, H.B. Precision Munition Guidance and Moving Target Position Estimation. In Proceedings of the AIAA SciTech, AIAA Guidance, Navigation and Control Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Xu, Y.; Wang, Z.; Gao, B. Six-degree-of-freedom digital simulation for missile guidance and control. Math. Probl. Eng. 2015, 2015, 829473. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Q.; Zhang, X.; Zhang, H.; Zhang, F. Field-to-View Constrained Integrated Guidance and Control for Hypersonic Homing Intercepting Supersonic Maneuvering Targets. Aerospace 2022, 9, 640. [Google Scholar] [CrossRef]

- Trzun, Z.; Vrdoljak, M. Monte Carlo simulation of missile trajectories dispersion due to imperfectly manufactured warhead. In Proceedings of the 31st DAAAM International Symposium on Intelligent Manufacturing and Automation, Mostar, Bosnia and Herzegovina, 21–24 October 2020. [Google Scholar] [CrossRef]

- Wu, P.; Yuan, W.; Ji, L.; Zhou, L.; Zhou, Z.; Feng, W.; Guo, Y. Missile aerodynamic shape optimization design using deep neural networks. Aerosp. Sci. Technol. 2022, 126, 107640. [Google Scholar] [CrossRef]

- Şumnu, A.; Güzelbey, İ.H.; Öğücü, O. Aerodynamic Shape Optimization of a Missile Using a Multiobjective Genetic Algorithm. Int. J. Aerosp. Eng. 2020, 2020, 1528435. [Google Scholar] [CrossRef]

- Li, Y.; Yi, L.; Ao, Y.; Ma, L.; Wang, Y. Simulation analysis the aerodynamic characteristics of variable sweep wing missile. J. Phys. Conf. Ser. ICAACE 2020, 1570, 012073. [Google Scholar] [CrossRef]

- Kumar, R.; Mishra, P.R. Analysis of different shape of missile nose configuration. Int. J. Adv. Res. Innov. Ideas Educ. IJARIIE 2024, 10, 438–447. [Google Scholar]

| Missile Flight Characteristics | Values | Physical Units | |

|---|---|---|---|

| Flight time to target | 70 ÷ 120 | ||

| Length of the missile | 2671 | ||

| Caliber | 0.1 | ||

| Angle of throw | 10 ÷ 55 | ||

| Launch mass of the missile | 62.6 | ||

| Initial velocity | 290 | ||

| Maximum flight speed | 1375 | ||

| Coordinate of the position of the center of mass at the time of launch | 1679 | ||

| Coordinate after fuel burnout | 1656 | ||

| Range | 28 ÷ 42 |

| Test Set | Launch Angle (°) | Range (km) | Max. Velocity (m/s) |

|---|---|---|---|

| Missile 1 (pre-modification) | 41.9 | ||

| Missile 1 (post-modification) | 44.5 | ||

| Missile 2 (pre-modification) | 41.4 | ||

| Missile 2 (post-modification) | 44.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szklarski, A.; Głębocki, R. Analytical Shaping of a Rocket Nose as a Stage of Preliminary Aerodynamic Modification. Aerospace 2025, 12, 594. https://doi.org/10.3390/aerospace12070594

Szklarski A, Głębocki R. Analytical Shaping of a Rocket Nose as a Stage of Preliminary Aerodynamic Modification. Aerospace. 2025; 12(7):594. https://doi.org/10.3390/aerospace12070594

Chicago/Turabian StyleSzklarski, Adrian, and Robert Głębocki. 2025. "Analytical Shaping of a Rocket Nose as a Stage of Preliminary Aerodynamic Modification" Aerospace 12, no. 7: 594. https://doi.org/10.3390/aerospace12070594

APA StyleSzklarski, A., & Głębocki, R. (2025). Analytical Shaping of a Rocket Nose as a Stage of Preliminary Aerodynamic Modification. Aerospace, 12(7), 594. https://doi.org/10.3390/aerospace12070594