Transient Temperature Evaluation and Thermal Management Optimization Strategy for Aero-Engine Across the Entire Flight Envelope

Abstract

1. Introduction

2. Methodology

2.1. The Heat Transfer Analysis Based on the Finite Volume Method

2.2. Thermal Analysis of Multi-Stage Components

2.3. Thermal Analysis of High-Temperature Components

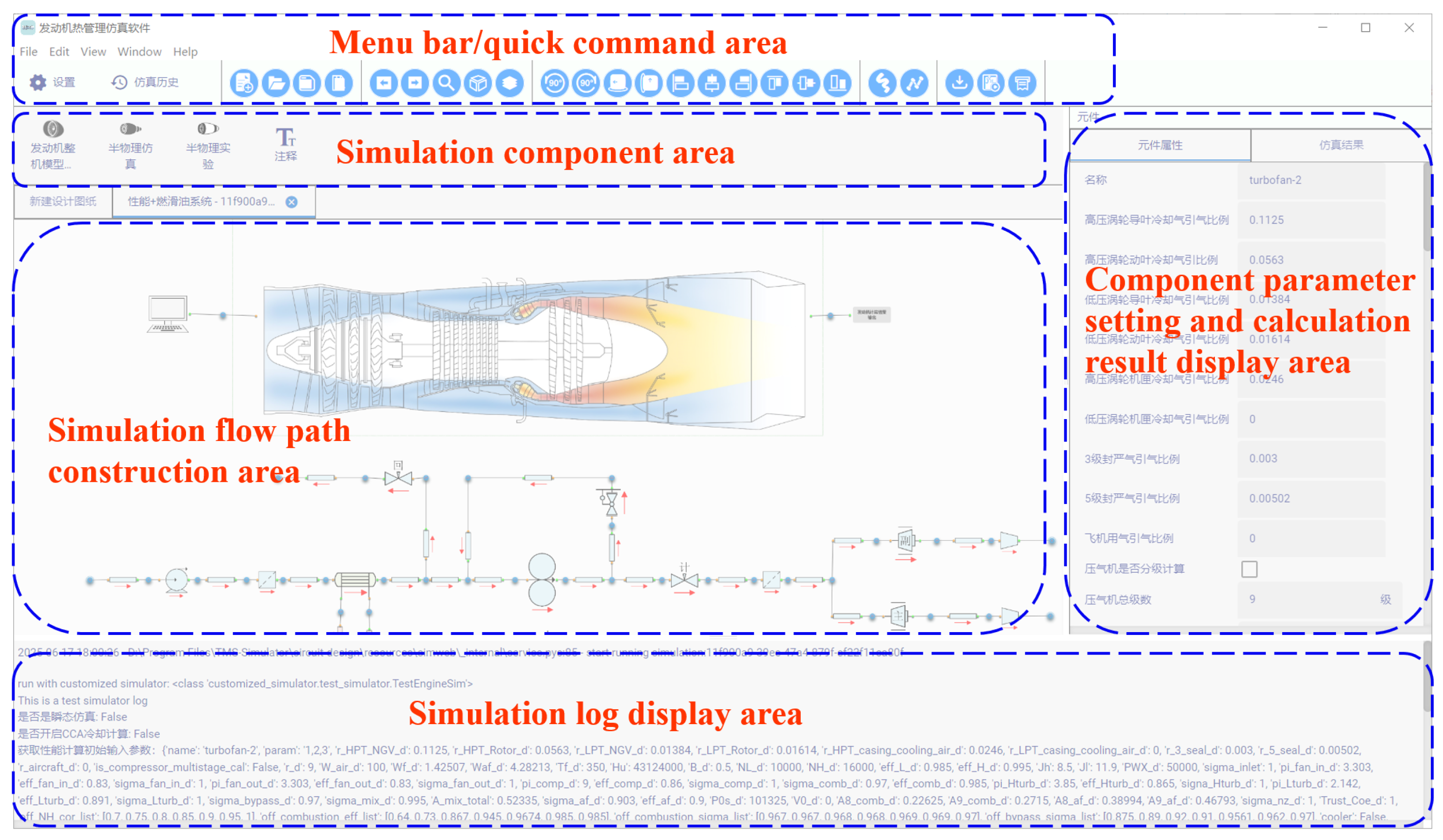

3. Model and Verification

3.1. Model Description

3.2. Accuracy Verification

4. Results and Discussions

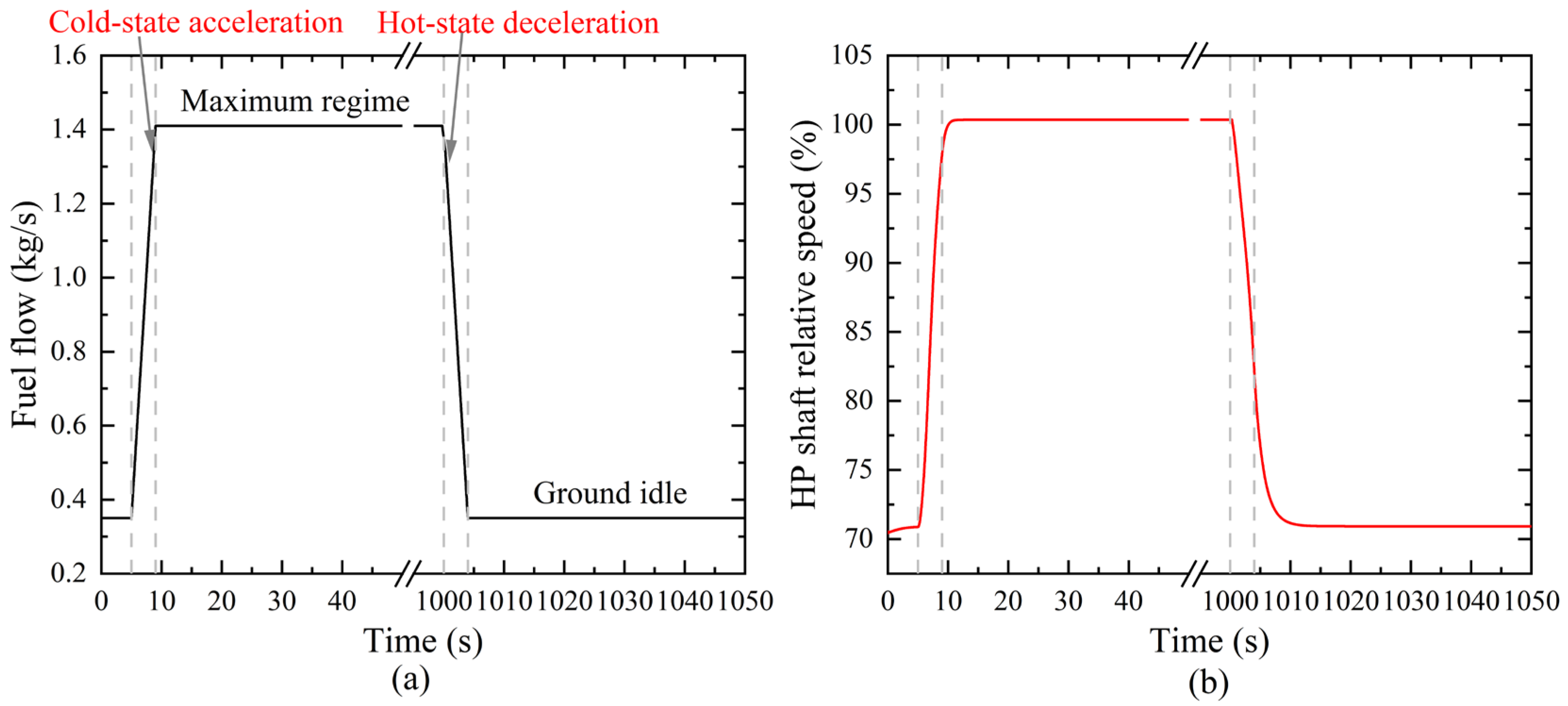

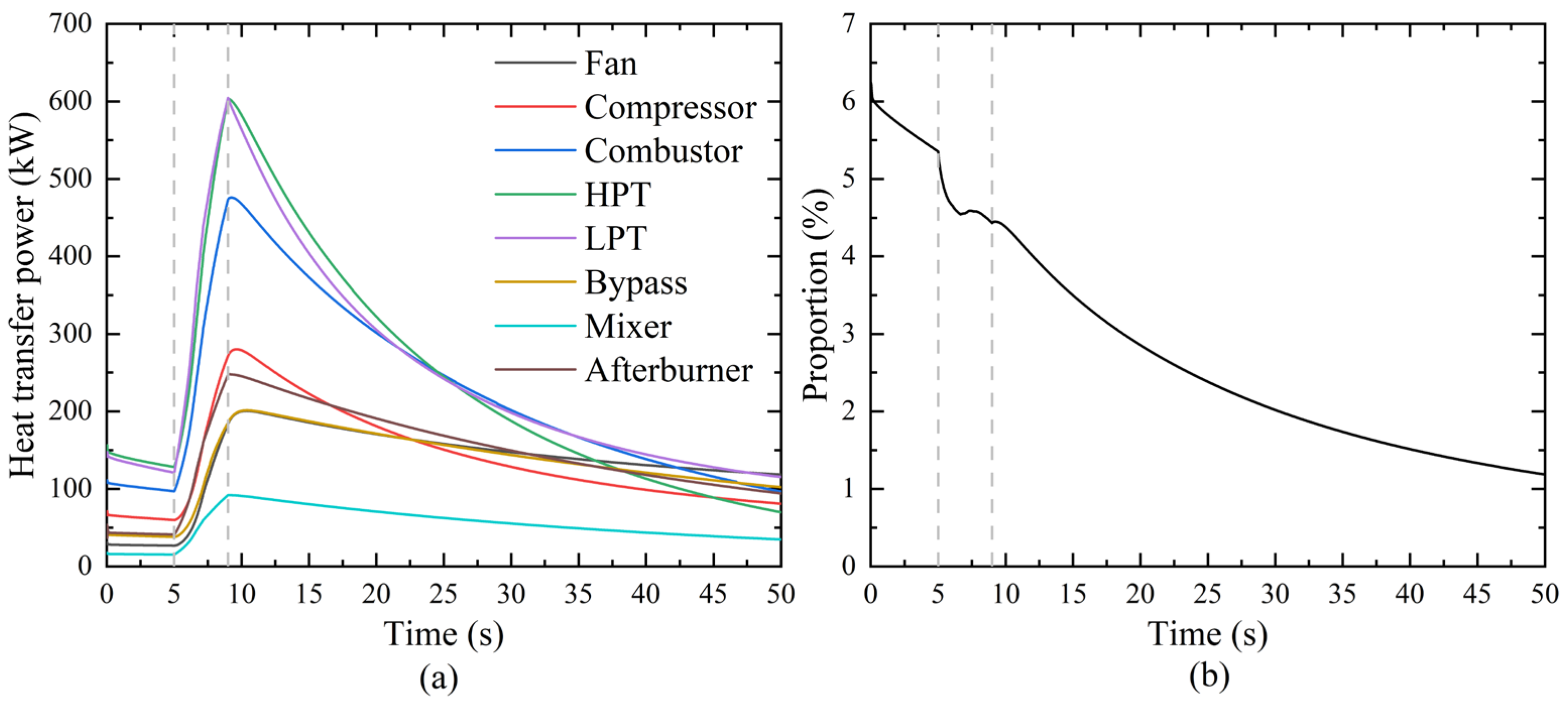

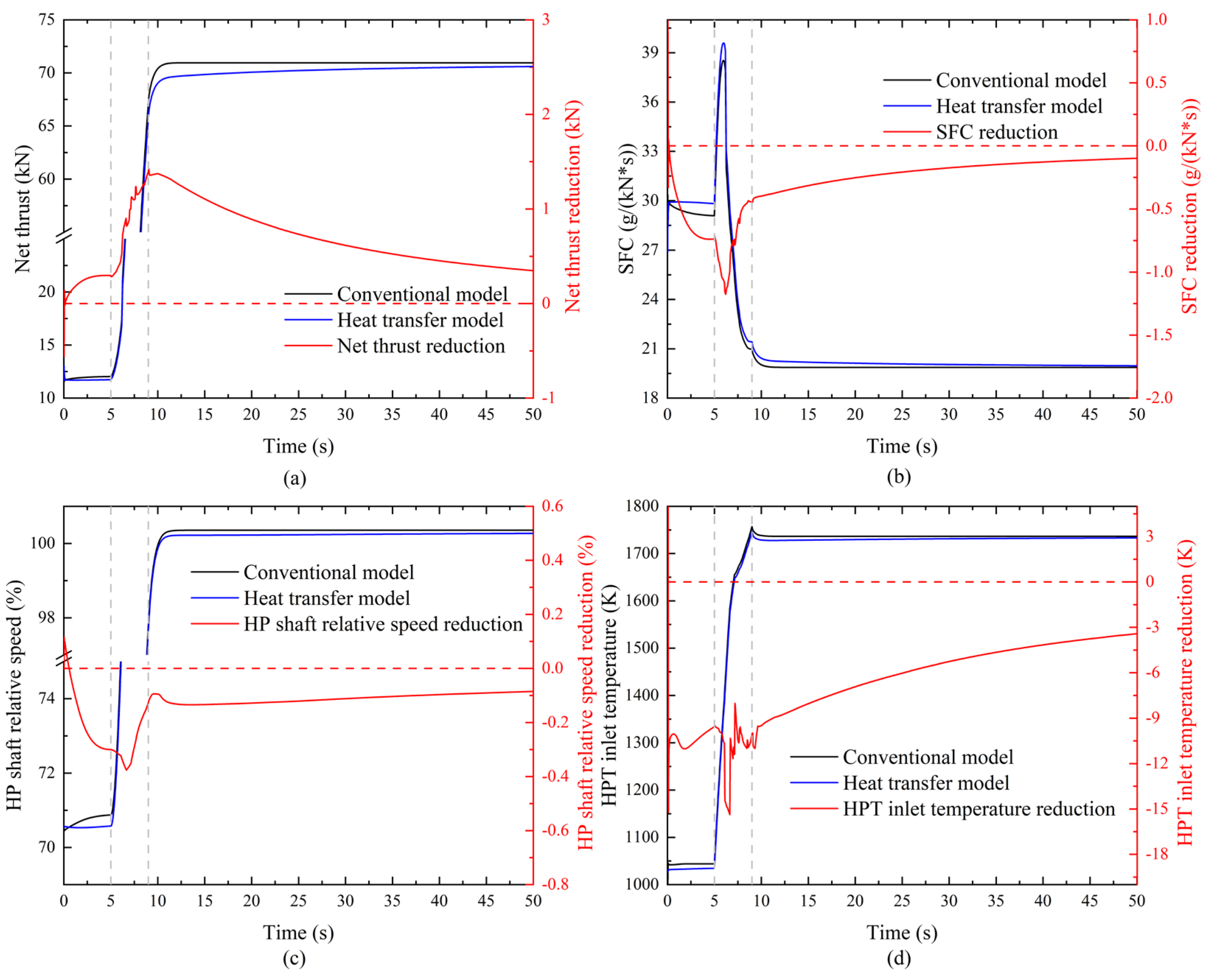

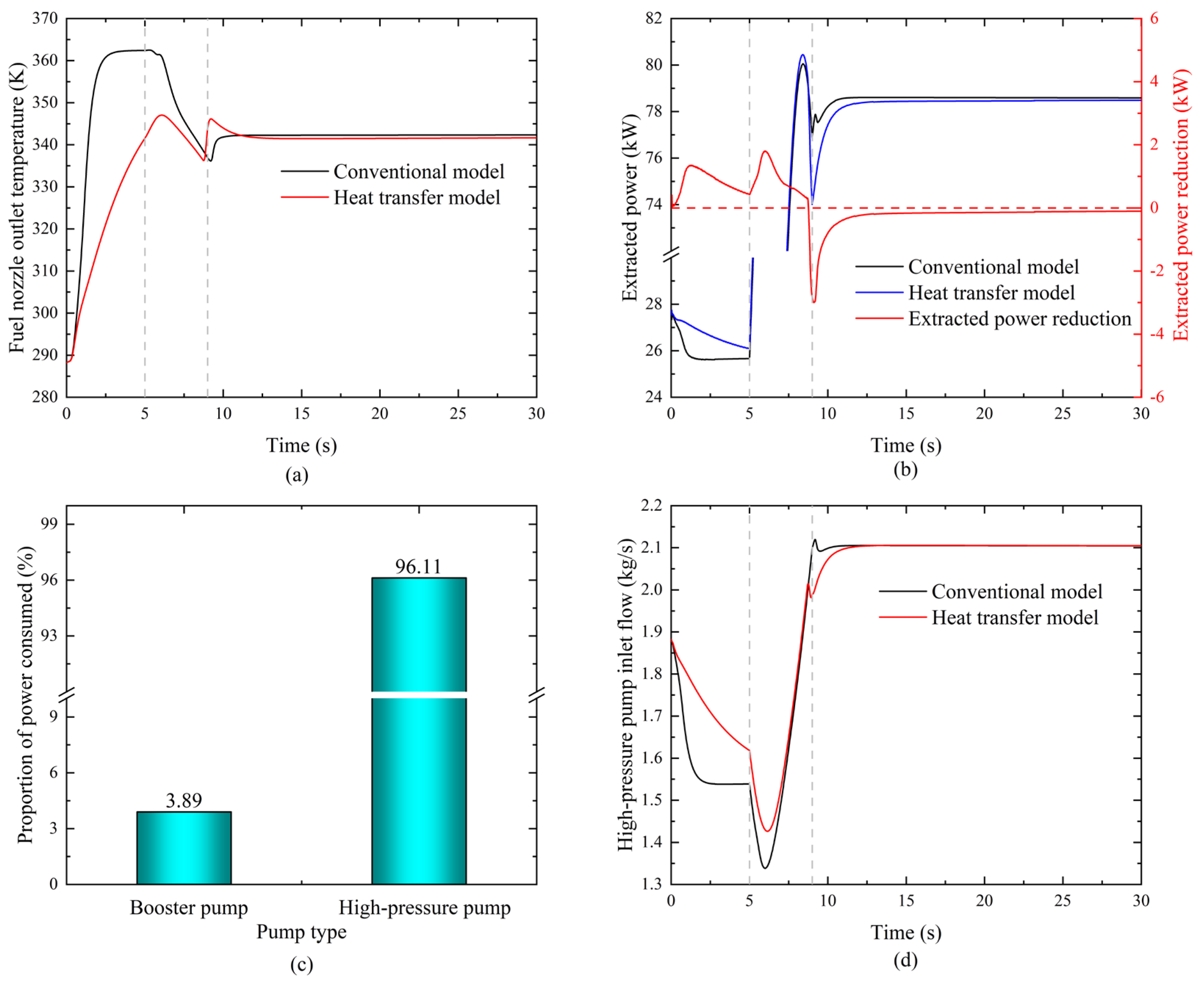

4.1. The Impact of Heat Transfer

4.1.1. Cold-State Acceleration

4.1.2. Hot-State Deceleration

4.2. Heat Transfer Analysis Under Full Flight Mission

4.2.1. Heat Transfer Analysis of Aero-Engine Performance

4.2.2. Heat Transfer Analysis of Fuel System

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Energy (J) | |

| H | Altitude (m) |

| Ma | Mach number |

| Heat (J) | |

| Temperature (K) | |

| Component volume () | |

| Output power (W) | |

| Specific heat capacity () | |

| Convective heat transfer coefficient () | |

| Specific enthalpy of the fluid (J/kg) | |

| Coefficient of thermal conductivity () | |

| Mass flow rate of fuel (kg/s) | |

| Heat flux density () | |

| Time (s) | |

| Time step size (s) | |

| Dimension of the control volume in the x direction | |

| Dimension of the control volume in the y direction | |

| Abbreviations | |

| FVM | Finite volume method |

| HP | High-pressure |

| HPT | High-pressure turbine |

| LPT | Low-pressure turbine |

| SFC | Specific fuel consumption |

| Greek symbols | |

| Density () | |

| Emissivity | |

| Absorptivity | |

| Stefan–Boltzmann constant | |

| Subscript | |

| CV | Control volume |

| EM | Metal components of the engine |

| c | Cooling air |

| f | Fluid |

| g | Gas |

| w | Solid wall |

| in | Inlet |

| out | Outlet |

| ref | Reference value |

Appendix A

| Description | Calculation |

| Forced convection in duct [26] | |

| is the hydraulic diameter of the duct; is the flow cross sectional area of the duct; is the wetted perimeter of the duct; is the Reynolds number; is the mass flow rate of fluid; is the dynamic viscosity of fluid; is the Prandtl number; is the constant pressure specific heat capacity of fluid; is the thermal conductivity of fluids; is the length of the duct; is the dynamic viscosity of fluid at wall temperature; is the convective heat transfer coefficient | |

| Forced convection of rotating disk [12] | |

| is the Reynolds number; is the fluid density; is the angular velocity of disk; is the rotation radius of the disk; is the dynamic viscosity of fluid; is the Prandtl number; is the constant pressure specific heat capacity of fluid; is the thermal conductivity of fluids; is the convective heat transfer coefficient | |

| Forced convection on the outer surface of the blade [32] | |

| is the Reynolds number; is the fluid density; is the blade perimeter; is the rotation radius of the blade; is the dynamic viscosity of fluid; is the fluid inlet velocity; is the fluid outlet velocity; is the fluid inlet geometric angle; is the fluid outlet geometric angle; is the Prandtl number; is the constant pressure specific heat capacity of fluid; is the thermal conductivity of fluids; is the convective heat transfer coefficient; is the qualitative dimensions of the blade | |

| Forced convection on the inner surface of the blade [32] | |

| is the hydraulic diameter of the duct; is the flow cross sectional area of the inner surface; is the wetted perimeter of the inner surface; is the Reynolds number; is the mass flow rate of fluid; is the dynamic viscosity of fluid; is the Prandtl number; is the constant pressure specific heat capacity of fluid; is the thermal conductivity of fluids; is the convective heat transfer coefficient | |

| Forced convection on the inner/outer surface of the flame tube [23] | Inner surface: Outer surface: |

| is the flame tube diameter; is the flame tube cross-sectional area; is the convective heat transfer coefficient with air; is the convective heat transfer coefficient with air; is the mass flow rate of air; is the mass flow rate of gas; is the dynamic viscosity of gas; is the thermal conductivity of gas; is the dynamic viscosity of air; is the thermal conductivity of air |

References

- Liang, C.; Suo, D.; Sun, M. A Review on the Key Technologies of the Sixth Generation Fighter Engines in the US. Aeroengine 2016, 42, 93–97. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Liu, X.; Shen, C.; Zhang, H.; Xiong, K. Recent active thermal management technologies for the development of energy-optimized aerospace vehicles in China. Chin. J. Aeronaut. 2021, 34, 1–27. [Google Scholar] [CrossRef]

- Cheng, R.; Zhang, Z.; Chen, Z. Technical characteristics and implementation of the fourth-generation jet fighter engines. Acta Aeronaut. Astronaut. Sin. 2019, 40, 6–15. [Google Scholar]

- Van Heerden, A.S.J.; Judt, D.M.; Jafari, S.; Lawson, C.P.; Nikolaidis, T.; Bosak, D. Aircraft thermal management: Practices, technology, system architectures, future challenges, and opportunities. Prog. Aerosp. Sci. 2022, 128, 100767. [Google Scholar] [CrossRef]

- Doman, D.B. Fuel Flow Topology and Control for Extending Aircraft Thermal Endurance. J. Thermophys. Heat Transf. 2018, 32, 35–50. [Google Scholar] [CrossRef]

- Huang, G.P.; Doman, D.B.; Rothenberger, M.J.; Hencey, B.; DeSimio, M.P.; Tipton, A.; Sigthorsson, D.O. Dimensional Analysis, Modeling, and Experimental Validation of an Aircraft Fuel Thermal Management System. J. Thermophys. Heat Transf. 2019, 33, 983–993. [Google Scholar] [CrossRef]

- Huang, P.G.; Doman, D.B. Thermal Management of Single- and Dual-Tank Fuel-Flow Topologies Using an Optimal Control Strategy. J. Therm. Sci. Eng. Appl. 2018, 10, 041019. [Google Scholar] [CrossRef]

- Yang, Y.; Nikolaidis, T.; Pilidis, P. Quasi-2D thermal network based heat soakage model for gas turbine transient performance modification. Appl. Therm. Eng. 2024, 241, 122340. [Google Scholar] [CrossRef]

- Visser, W.P.J.; Dountchev, I.D. Modeling Thermal Effects on Performance of Small Gas Turbines. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; V001T01A014. [Google Scholar] [CrossRef]

- Fawke, A.J.; Saravanamuttoo, H.I.H. Digital computer simulation of the dynamic response of a twin-spool turbofan with mixed exhausts. Aeronaut. J. 1973, 77, 471–478. [Google Scholar] [CrossRef]

- Maccallum, N.R.L. The Performance of Turbojet Engines during the ‘Thermal Soak’ Transient. In Proceedings of the Institution of Mechanical Engineers, Conference Proceedings (Vol. 184, No. 7, pp. 23-29); Sage Publications, Sage UK: London, UK, 1969. [Google Scholar] [CrossRef]

- Naylor, P. Gas Turbine Transient Performance: Heat Soakage Modelling. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2004. [Google Scholar]

- LI, Z. Aircraft Engine Transient Performance Modelling with Heat Soakage Effects. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2019. [Google Scholar]

- Chapman, J.W.; Guo, T.-H.; Kratz, J.L.; Litt, J.S. Integrated Turbine Tip Clearance and Gas Turbine Engine Simulation. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Kratz, J.L.; Culley, D.E.; Chapman, J.W. Approximation of Engine Casing Temperature Constraints for Casing Mounted Electronics. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Wang, T.; Xuan, Y.; Han, X. Investigation on hybrid thermal features of aero-engines from combustor to turbine. Int. J. Heat Mass Transf. 2023, 200, 123559. [Google Scholar] [CrossRef]

- Yang, S.; Gou, W.; Lin, Y.; Xu, X.; Shi, B.; Liang, X. Steady State Simulation Program of Aero-Engine Thermal Management System. In Proceedings of the 6th China Aeronautical Science and Technology Conference, Wuzhen, China, 26–27 September 2023; Springer Nature: Singapore, 2024. [Google Scholar]

- Sizhao, K.; Xiuzhi, X.I.; Bo, L.I. Simulation and analysis of temperature of aviation engine fuel system based on Flowmaster software. J. Aerosp. Power 2020, 35, 722–731. [Google Scholar] [CrossRef]

- Liu, J.; Li, M.; Zhang, T.; Wang, Y.; Cao, Z.; Shao, W.; Chen, Q. Optimization of the aero-engine thermal management system with intermediate cycle based on heat current method. Appl. Therm. Eng. 2024, 237, 121793. [Google Scholar] [CrossRef]

- Oba, D.; Gonda, Y. Fuel System with Variable Speed Pump to Improve Thermal Management Ability for Aircraft Engines. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V006T06A025. [Google Scholar] [CrossRef]

- Oppenheimer, M.W.; Sigthorsson, D.; Doman, D.B. Extending Aircraft Thermal Endurance by Fuel Pump Sizing. In Proceedings of the 2018 AIAA Guidance, Navigation, and Control Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Tao, W. Numerical Heat Transfer, 2nd ed.; Xi’an Jiaotong University Press: Xi’an, China, 2001. [Google Scholar]

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion: Alternative Fuels and Emissions; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Chen, F.P.; Chen, Y.C.; Song, K.R.; Li, Y.S. Study on the Influence of Heat Transfer Effect on Performance Simulation of Engine Transition State. In Proceedings of the 2019 IEEE 10th International Conference on Mechanical and Aerospace Engineering (ICMAE), Brussels, Belgium, 22–25 July 2019. [Google Scholar] [CrossRef]

- Walsh, P. Gas Turbine Performance; Blackwell Publishing: Oxford, UK, 2004. [Google Scholar]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- Wang, B.; Xuan, Y. An improved WSGG model for exhaust gases of aero engines within broader ranges of temperature and pressure variations. Int. J. Heat Mass Transf. 2019, 136, 1299–1310. [Google Scholar] [CrossRef]

- Yang, S.; Lin, Y.; Yu, H.; Xu, X.; Liang, X. Analysis of the hot fuel return characteristics for a fuel thermal management system with multiple temperature limit points. J. Tsinghua Univ. 2024, 64, 841–851. [Google Scholar] [CrossRef]

- Gou, W.; Yang, S.; Lin, Y.; Shao, F.; Liang, X.; Shi, B. Dynamic blade tip clearance control of aero-engine by the integration of cooling air with fuel thermal management system. Appl. Therm. Eng. 2025, 261, 125042. [Google Scholar] [CrossRef]

- Young, J.B.; Wilcock, R.C. Modeling the Air-Cooled Gas Turbine: Part 2—Coolant Flows and Losses. J. Turbomach. 2002, 124, 214–221. [Google Scholar] [CrossRef]

- Morioka, N.; Oyori, H. Fuel System Design for the More Electric Engine. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June, 2012. [Google Scholar] [CrossRef]

- Cao, Y.; Tao, Z.; Xu, G. Aero-Engine Heat Transfer; Beihang University Press: Beijing, China, 2005. [Google Scholar]

| Parameters | Value |

|---|---|

| Air mass flow rate (kg/s) | 100 |

| LPC pressure ratio | 3.3 |

| LPC isentropic efficiency | 0.83 |

| HPC pressure ratio | 9 |

| HPC isentropic efficiency | 0.86 |

| Combustion efficiency | 0.987 |

| Combustor exit temperature (K) | 1730 |

| HPT isentropic efficiency | 0.87 |

| LPT isentropic efficiency | 0.89 |

| Low-pressure shaft speed (RPM) | 10,000 |

| High-pressure shaft speed (RPM) | 16,000 |

| Net thrust (kN) | 70.9 |

| Specific fuel consumption (g/(kN·s)) | 20.11 |

| Calculation Parameters | Value | Unit |

|---|---|---|

| Combustor outlet temperature | 1700 | K |

| Turbine inlet pressure | 34 | bar |

| Coolant supply temperature | 867 | K |

| Coolant supply pressure | 34 | bar |

| Coolant/mainstream flowrate ratio | 0.145 | |

| Average temperature of the blade (Literature result) | 1045.5 | K |

| Average temperature of the blade (Model result) | 1070.6 | K |

| Relative error | 2.4 | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gou, W.; Yang, S.; Liu, K.; Lin, Y.; Liang, X.; Shi, B. Transient Temperature Evaluation and Thermal Management Optimization Strategy for Aero-Engine Across the Entire Flight Envelope. Aerospace 2025, 12, 562. https://doi.org/10.3390/aerospace12060562

Gou W, Yang S, Liu K, Lin Y, Liang X, Shi B. Transient Temperature Evaluation and Thermal Management Optimization Strategy for Aero-Engine Across the Entire Flight Envelope. Aerospace. 2025; 12(6):562. https://doi.org/10.3390/aerospace12060562

Chicago/Turabian StyleGou, Weilong, Shiyu Yang, Kehan Liu, Yuanfang Lin, Xingang Liang, and Bo Shi. 2025. "Transient Temperature Evaluation and Thermal Management Optimization Strategy for Aero-Engine Across the Entire Flight Envelope" Aerospace 12, no. 6: 562. https://doi.org/10.3390/aerospace12060562

APA StyleGou, W., Yang, S., Liu, K., Lin, Y., Liang, X., & Shi, B. (2025). Transient Temperature Evaluation and Thermal Management Optimization Strategy for Aero-Engine Across the Entire Flight Envelope. Aerospace, 12(6), 562. https://doi.org/10.3390/aerospace12060562