On-Orbit Functional Verification of Combustion Science Experimental System in China Space Station

Abstract

1. Introduction

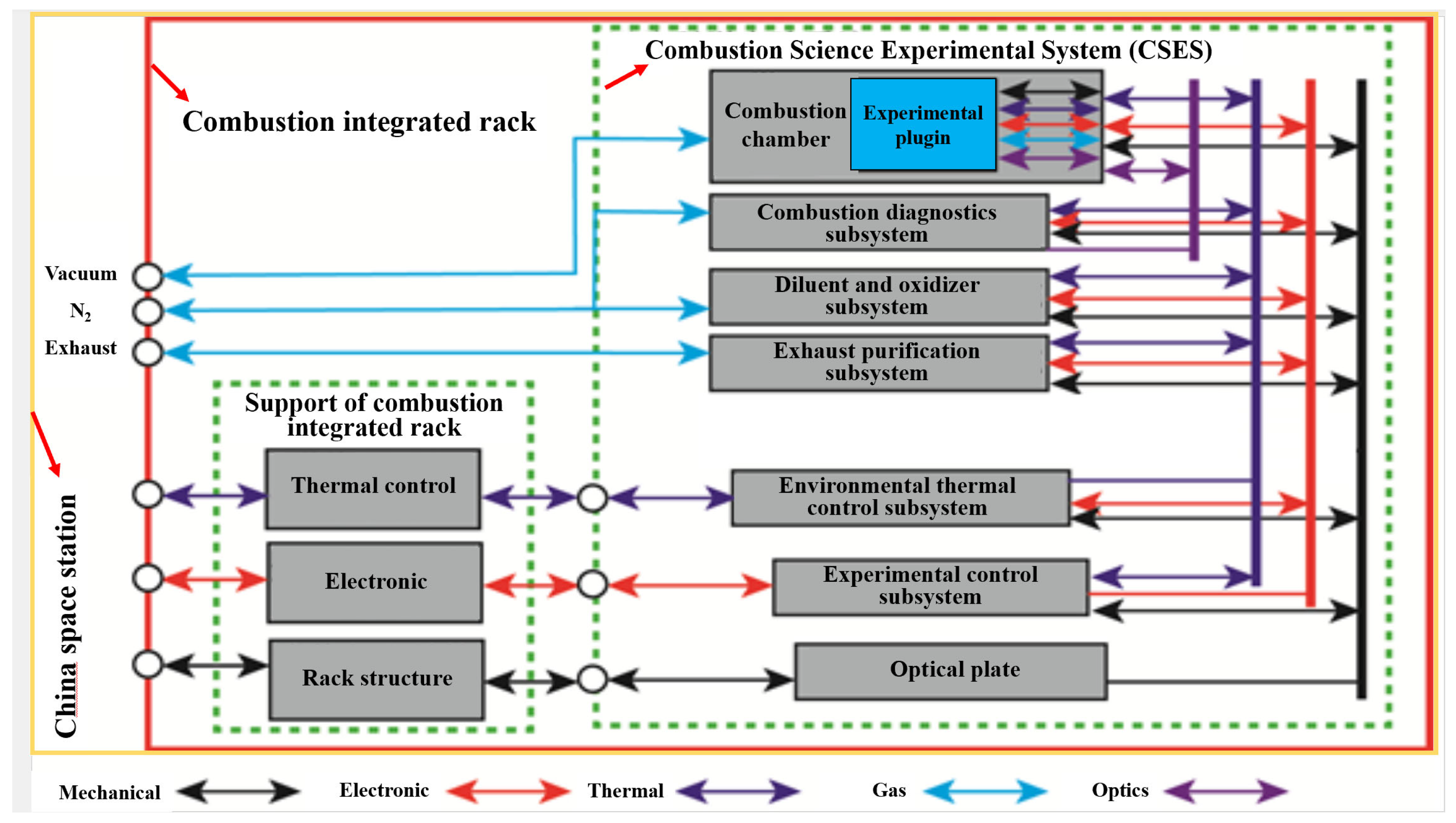

2. Combustion Science Experimental System

2.1. Composition of the CSES

- The optical plate serves as the structural backbone of the system. Integrated mechanically with the rack, it supports the installation of key components.

- The combustion chamber provides a sealed and isolated environment for combustion experiments. As a central hub, it connects experimental plugins to the platform. Additionally, eight optical windows located at the center of the chamber enable observations.

- The diluent and oxidizer subsystem is responsible for storing and managing high-pressure oxygen and inert gasses, as well as integrating nitrogen resources from the CSS. Based on the required atmosphere configuration, it delivers gas reactants into the chamber at specified flow rates with precision.

- Modular experimental plugins are installed within the chamber to provide ignition, fuel supply, and signal acquisition functions for combustion experiments.

- The combustion diagnostics subsystem employs non-contact measurement techniques to capture critical experimental data. It comprises eight optical devices, which are in one-to-one correspondence with the eight observation windows arranged circumferentially around the combustion chamber. Additionally, this subsystem supports the integration of additional diagnostic equipment through standardized interfaces.

- The exhaust purification subsystem collects various combustion byproducts. These byproducts undergo compositional analysis and real-time recycling cleaning to ensure safe release.

- The experimental control subsystem manages power distribution and data communication. Power at 100 V and 28 V is received and distributed to scientific instruments via a power conversion unit equipped with gigabit Ethernet and RS422 interfaces.

- During the operation, an environmental thermal control subsystem ensures safe equipment operation through a combined air-cooling and water-cooling approach.

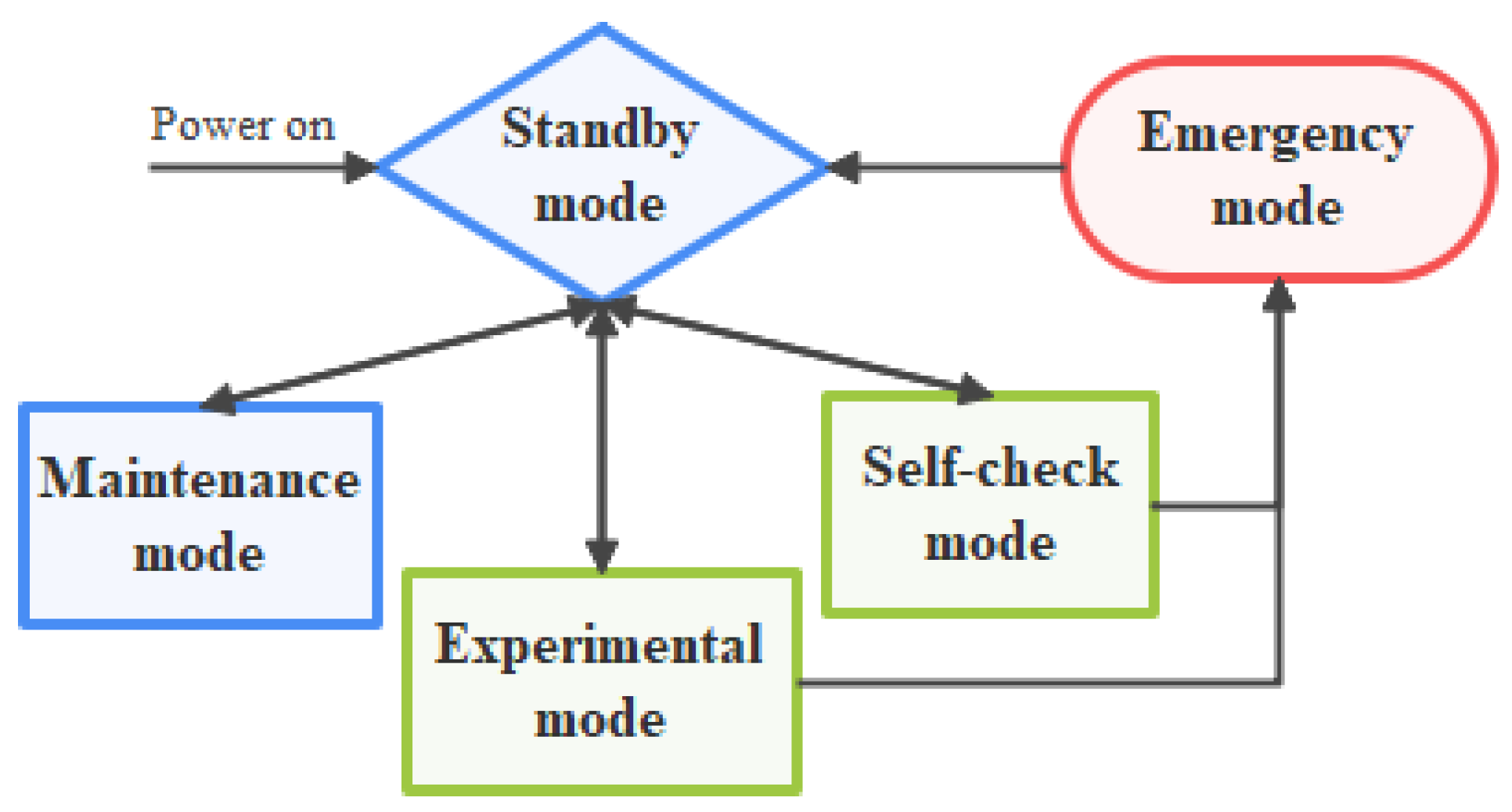

2.2. Operation Principle of the CSES

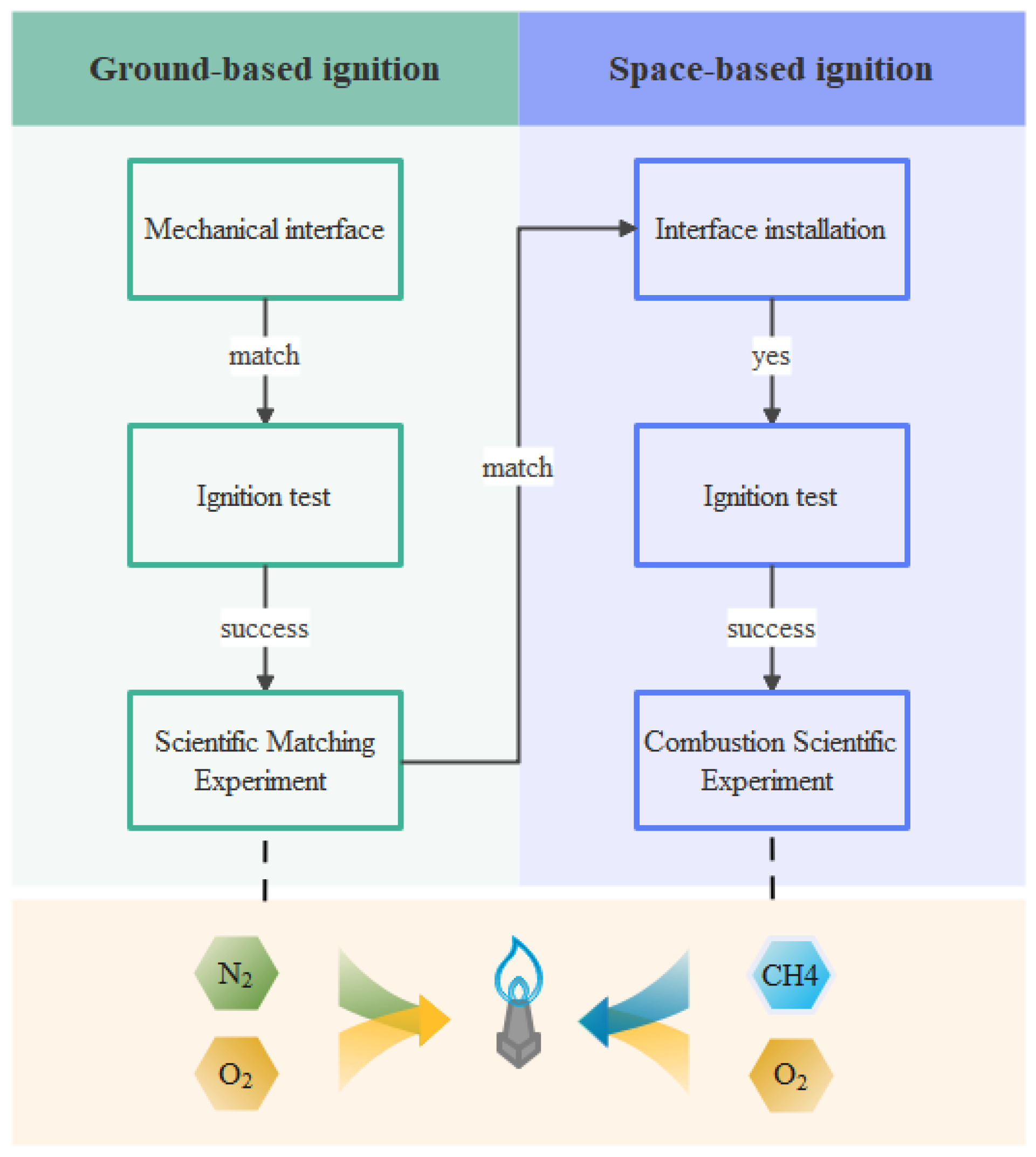

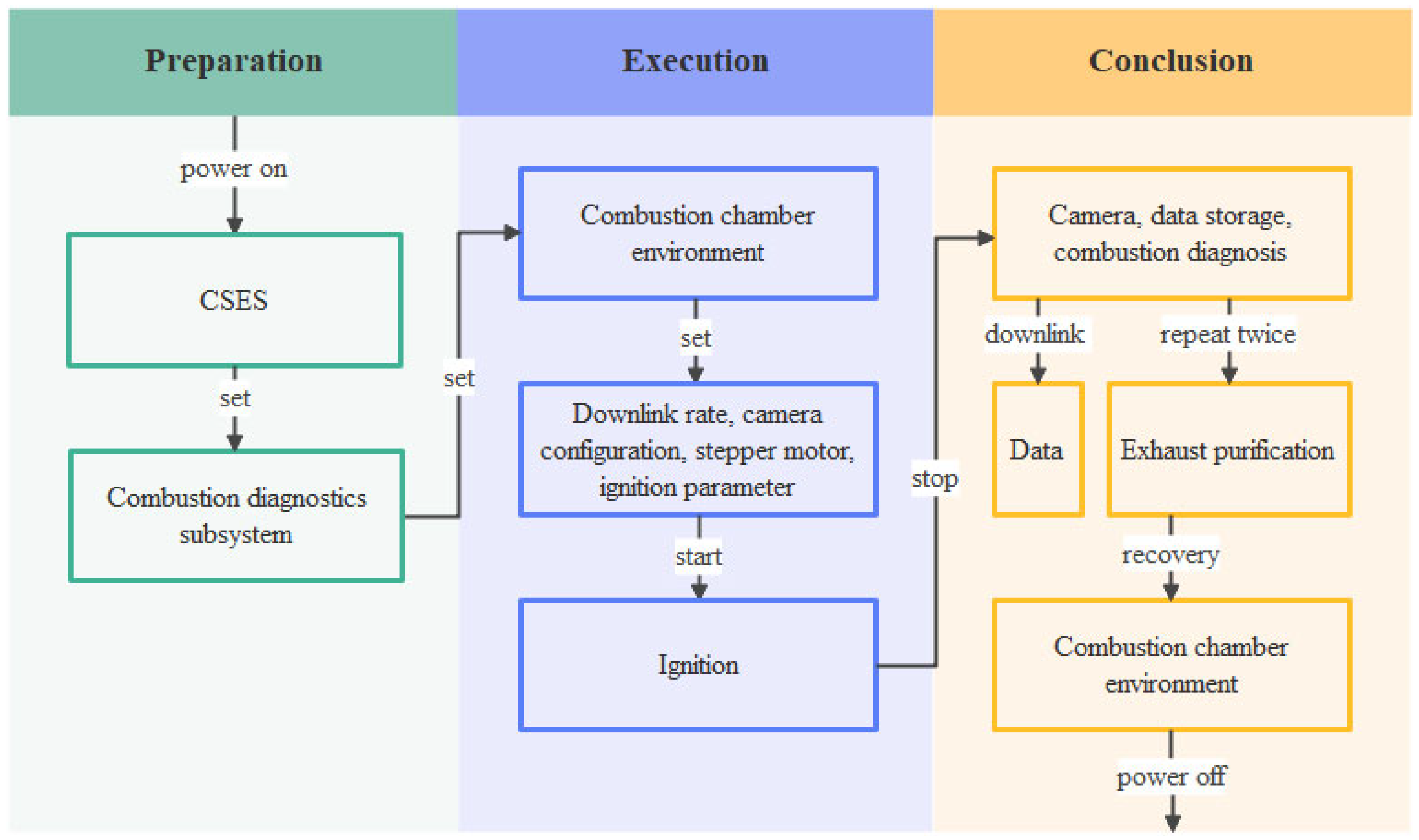

2.3. Procedure of Combustion Experiment in the CSES

3. Technical Indicator of the CSES

3.1. Physical Structure

3.2. Information Interface

3.3. Power Supply

3.4. Combustion Diagnostics

3.5. Safety and Reliability

3.6. Ergonomics

3.7. Capabilities Comparison

4. Primary Functions Verification of the CSES

4.1. Gas Supply and Configuration

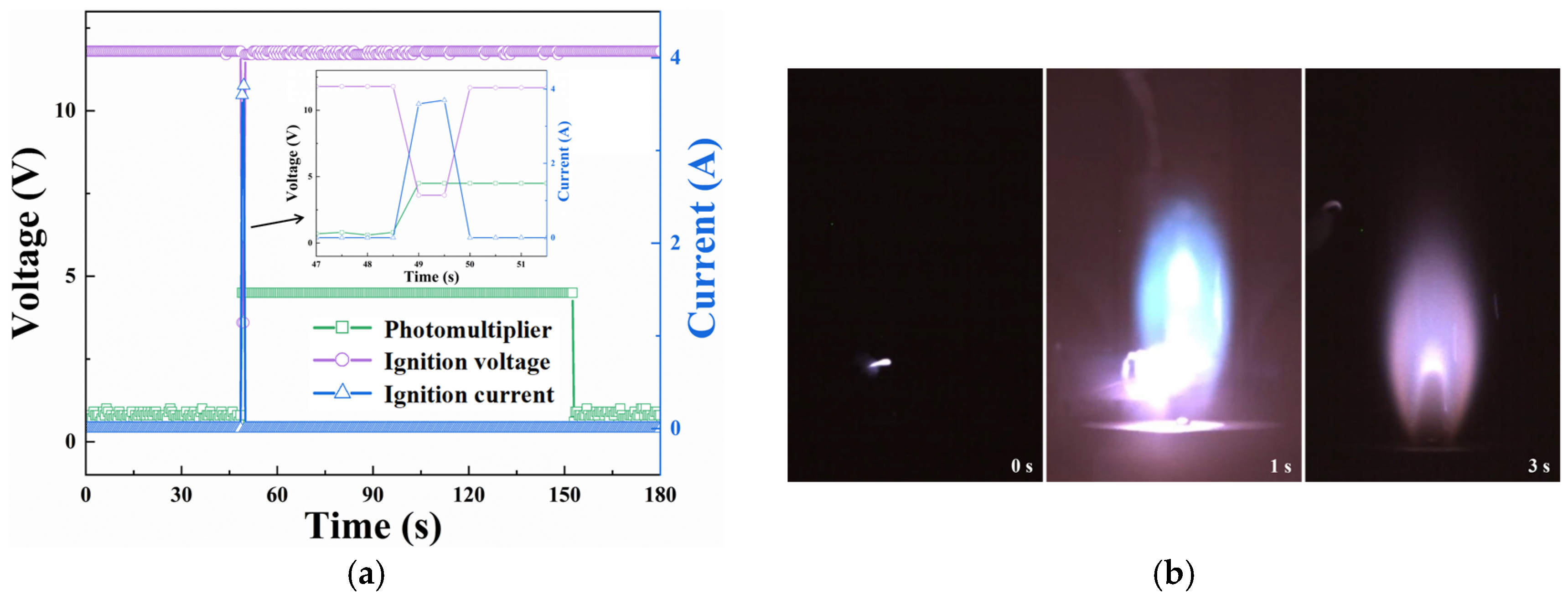

4.2. Fuel Gas Ignition and Combustion

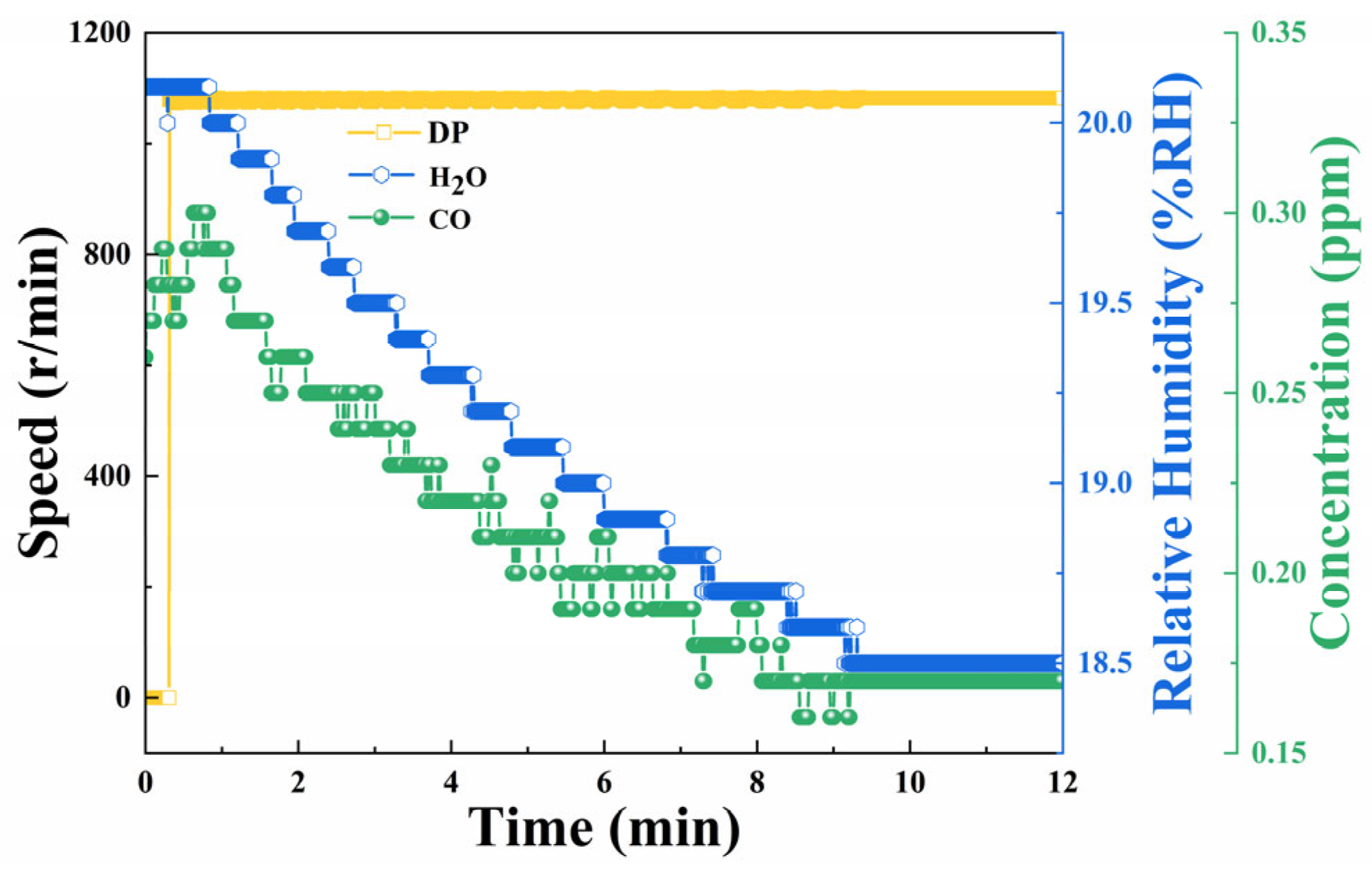

4.3. Filtering and Analysis of Exhaust Gasses

4.4. Exhaust Gas Emission and Vacuum Control

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Correa, S.M. Power Generation and Aeropropulsion Gas Turbines: From Combustion Science to Combustion Technology. Symp. Int. Combust. 1998, 27, 1793–1807. [Google Scholar] [CrossRef]

- Fernandez-Pello, A.C. Micropower Generation Using Combustion: Issues and Approaches. Proc. Combust. Inst. 2002, 29, 883–899. [Google Scholar] [CrossRef]

- Sehra, A.K.; Whitlow, W. Propulsion and Power for 21st Century Aviation. Prog. Aerosp. Sci. 2004, 40, 199–235. [Google Scholar] [CrossRef]

- Kohse-Höinghaus, K. Combustion, Chemistry, and Carbon Neutrality. Chem. Rev. 2023, 123, 5139–5219. [Google Scholar] [CrossRef] [PubMed]

- Aldushin, A.P.; Matkowsky, B.J.; Schult, D.A. Buoyancy Driven Filtration Combustion. Combust. Sci. Technol. 1997, 125, 283–349. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, K.H. Combustion-Induced Buoyancy Effects of an Axisymmetric Reactive Plume. Proc. Combust. Inst. 2000, 28, 1989–1995. [Google Scholar] [CrossRef]

- Bar-Ilan, A.; Rein, G.; Walther, D.C.; Fernandez-Pello, A.C.; Torero, J.L.; Urban, D.L. The Effect of Buoyancy on Opposed Smoldering. Combust. Sci. Technol. 2004, 176, 2027–2055. [Google Scholar] [CrossRef]

- King, M.K.; Ross, H.D. Overview of the NASA Microgravity Combustion Program. AIAA J. 1998, 36, 1337–1345. [Google Scholar] [CrossRef][Green Version]

- Wu, C.; Xiao, Y.; Wang, S.; Zhu, F. Horizontal Flame Spread over Thin Solids in Reduced Buoyancy Environments. Combust. Flame 2022, 240, 112008. [Google Scholar] [CrossRef]

- Huang, X.; Nakamura, Y.; Urban, D. Introduction to Special Issue on Spacecraft Fire Safety. Fire Technol. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Jomaas, G.; Torero, J.L.; Eigenbrod, C.; Niehaus, J.; Olson, S.L.; Ferkul, P.V.; Legros, G.; Fernandez-Pello, A.C.; Cowlard, A.J.; Rouvreau, S.; et al. Fire Safety in Space–beyond Flammability Testing of Small Samples. Acta Astronaut. 2015, 109, 208–216. [Google Scholar] [CrossRef]

- Friedman, R.; Sacksteder, K. Science and Technology Issues in Spacecraft Fire Safety. In 25th AIAA Aerospace Sciences Meeting; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 12–15 January 1987. [Google Scholar]

- Li, N.; Deng, H.; Xu, Z.; Yan, M.; Wei, S.; Sun, G.; Wen, X.; Gan, H.; Wang, F. Effect of Oxygen-Rich Combustion on Flame Propagation of Syngas in a Half-Open Pipe at Elevated Temperatures. J. Therm. Sci. 2024, 33, 1920–1934. [Google Scholar] [CrossRef]

- Li, D.; Wen, Y.; Liu, Y.C.; Wang, S. On the Transition Modes and Mechanisms for Laminar to Turbulent Lifted Jet Diffusion Flames at Normal- and Micro-Gravity. Combust. Flame 2024, 260, 113269. [Google Scholar] [CrossRef]

- Nakamura, Y.; Usuki, T.; Wakatsuki, K. Novel Fire Extinguisher Method Using Vacuuming Force Applicable to Space Habitats. Fire Technol. 2020, 56, 361–384. [Google Scholar] [CrossRef]

- Torikai, H. Extinguishing Characteristics of a Pool Fire with a Rubber Balloon Filled with Inert Gases. Fire Technol. 2020, 56, 385–399. [Google Scholar] [CrossRef]

- Takahashi, J.; Fujita, O.; Ito, K. The Effect of Irradiation Angle on Laser Ignition of Cellulose Sheet in Microgravity. Proc. Combust. Inst. 2005, 30, 2311–2317. [Google Scholar] [CrossRef]

- Protsch, R.W. EUROTUBE-SAAR: A European Drop Shaft Facility. Adv. Space Res. 1991, 11, 119–121. [Google Scholar] [CrossRef]

- Olson, S.L. Piloted Ignition Delay Times of Opposed and Concurrent Flame Spread over a Thermally-Thin Fuel in a Forced Convective Microgravity Environment. Proc. Combust. Inst. 2011, 33, 2633–2639. [Google Scholar] [CrossRef]

- Roslon, M.; Olenick, S.; Zhou, Y.Y.; Walther, D.C.; Torero, J.L.; Fernandez-Pello, A.C.; Ross, H.D. Microgravity Ignition Delay of Solid Fuels in Low-Velocity Flows. AIAA J. 2001, 39, 2336–2342. [Google Scholar] [CrossRef]

- van Wynsberghe, E.; Turak, A. Station-Keeping of a High-Altitude Balloon with Electric Propulsion and Wireless Power Transmission: A Concept Study. Acta Astronaut. 2016, 128, 616–627. [Google Scholar] [CrossRef]

- Olson, S.L.; Hegde, U.; Bhattacharjee, S.; Deering, J.L.; Tang, L.; Altenkirch, R.A. Sounding rocket microgravity experiments elucidating diffusive and radiative transport effects on flame spread over thermally thick solids. Combust. Sci. Technol. 2004, 176, 557–584. [Google Scholar] [CrossRef]

- Olson, S.L.; Ferkul, P.V. Microgravity Flammability Boundary for PMMA Rods in Axial Stagnation Flow: Experimental Results and Energy Balance Analyses. Combust. Flame 2017, 180, 217–229. [Google Scholar] [CrossRef]

- Olson, S.L.; Kashiwagi, T.; Fujita, O.; Kikuchi, M.; Ito, K. Experimental Observations of Spot Radiative Ignition and Subsequent Three-Dimensional Flame Spread over Thin Cellulose Fuels. Combust. Flame 2001, 125, 852–864. [Google Scholar] [CrossRef]

- Urban, D.L.; Ferkul, P.; Olson, S.; Ruff, G.A.; Easton, J.; T’ien, J.S.; Liao, Y.-T.T.; Li, C.; Fernandez-Pello, C.; Torero, J.L.; et al. Flame Spread: Effects of Microgravity and Scale. Combust. Flame 2019, 199, 168–182. [Google Scholar] [CrossRef]

- Xue, T.; Liang, D.; Pang, W.; Shen, D.; Niamat, A.; Liu, J.; Zhou, J. Ignition and Combustion of Metal Fuels under Microgravity: A Short Review. FirePhysChem 2022, 2, 340–356. [Google Scholar] [CrossRef]

- Dittus, H. Drop Tower ‘Bremen’: A Weightlessness Laboratory on Earth. Endeavour 1991, 15, 72–78. [Google Scholar] [CrossRef]

- Rojas-Alva, U.; Jomaas, G. A Historical Overview of Experimental Solid Combustion Research in Microgravity. Acta Astronaut. 2022, 194, 363–375. [Google Scholar] [CrossRef]

- Matsumoto, K.; Fujii, T.; Suzuki, K.; Segawa, D.; Kadota, T. Laser-Induced Fluorescence for the Non-Intrusive Diagnostics of a Fuel Droplet Burning under Microgravity in a Drop Shaft. Meas. Sci. Technol. 1999, 10, 853. [Google Scholar] [CrossRef]

- Mikami, M.; Matsumoto, K.; Yoshida, Y.; Kikuchi, M.; Dietrich, D.L. Space-Based Microgravity Experiments on Flame Spread over Randomly Distributed n-Decane-Droplet Clouds: Anomalous Behavior in Flame Spread. Proc. Combust. Inst. 2021, 38, 3167–3174. [Google Scholar] [CrossRef]

- Nayagam, V.; Dietrich, D.L.; Ferkul, P.V.; Hicks, M.C.; Williams, F.A. Can Cool Flames Support Quasi-Steady Alkane Droplet Burning? Combust. Flame 2012, 159, 3583–3588. [Google Scholar] [CrossRef]

- Moura, W.D.M.; Dos Santos, C.R.; Freitas, M.J.D.S.; Pinto, A.C.; Simões, L.P.; Moraes, A. MicroGravity Explorer Kit (MGX): An Open-Source Platform for Accessible Space Science Experiments. Aerospace 2024, 11, 790. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Z.; Zhang, H.; Zhang, D. Volatile Release and Ignition Behaviors of Single Coal Particles at Different Oxygen Concentrations Under Microgravity. Microgravity Sci. Technol. 2016, 28, 101–108. [Google Scholar] [CrossRef]

- Wang, S.; Hu, J.; Xiao, Y.; Ren, T.; Zhu, F. Opposed-Flow Flame Spread Over Solid Fuels in Microgravity: The Effect of Confined Spaces. Microgravity Sci. Technol. 2015, 27, 329–336. [Google Scholar] [CrossRef]

- Wu, C.; Sun, P.; Wang, X.; Huang, X.; Wang, S. Flame Extinction of Spherical PMMA in Microgravity: Effect of Fuel Diameter and Conduction. Microgravity Sci. Technol. 2020, 32, 1065–1075. [Google Scholar] [CrossRef]

- Sun, P.; Wu, C.; Zhu, F.; Wang, S.; Huang, X. Microgravity Combustion of Polyethylene Droplet in Drop Tower. Combust. Flame 2020, 222, 18–26. [Google Scholar] [CrossRef]

- Zhu, F.; Huang, X.; Wang, S. Flame Spread over Polyethylene Film: Effects of Gravity and Fuel Inclination. Microgravity Sci. Technol. 2022, 34, 26. [Google Scholar] [CrossRef]

- Cai, G.; Liu, L.; He, B.; Ling, G.; Weng, H.; Wang, W. A Review of Research on the Vacuum Plume. Aerospace 2022, 9, 706. [Google Scholar] [CrossRef]

- Dong, W.; Duan, W.; Liu, W.; Zhang, Y. Microgravity Disturbance Analysis on Chinese Space Laboratory. NPJ Microgravity 2019, 5, 18. [Google Scholar] [CrossRef]

- Shen, G.; Zhang, S.; Zhang, X.; Zhang, H.; Yuan, B.; Hou, D.; Wang, C.; Quan, Z.; Yang, Z.; Sun, Y. Using Energy Particle Detection Technology on the Tiangong’s Space Station’s Wentian Laboratory Cabin Module. Aerospace 2023, 10, 373. [Google Scholar] [CrossRef]

- Shi, K.; Yang, H.; Zhang, W.; Chen, W.; Yan, A.; Peng, J. Research on a New Multifunctional Cell Sample Automatic Culture Device for Use in the Chinese Space Station. Aerospace 2025, 12, 90. [Google Scholar] [CrossRef]

- Wang, Y.; Zou, T.; Guo, L.; Zhang, C.; Zhang, L. Design and Implementation of a Generalized Safety Fault Diagnosis System for China Space Station Scientific Experimental Rack. Sensors 2024, 24, 5102. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chen, Y.; Wu, D.; Hu, L.; Ye, Z.; Duan, L.; Zhao, X.; Yin, Y.; Kang, Q. Development and Space Experiment Verification of Annular Liquid Flow Payload for China Space Station. Symmetry 2024, 16, 1530. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Q.; Wang, W. Design and Application Prospect of China’s Tiangong Space Station. Space Sci. Technol. 2023, 3, 0035. [Google Scholar] [CrossRef]

- Wu, W.; Zou, T.; Guo, D.; Zhang, L.; Wang, K.; Li, X. Fault Diagnosis for China Space Station Circulating Pumps: Prototypical Network with Uncertainty Theory. Symmetry 2023, 15, 903. [Google Scholar] [CrossRef]

- Wu, S.; Yan, H.; Zhao, Y.; Chen, Y.; Tang, G. A Framework for Rapidly Predicting the Dynamics of Flexible Solar Arrays in the China Space Station with a Verification Based on On-Orbit Measurement Data. Aerospace 2024, 11, 411. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Y.; Luo, Y. Optimization for Overall Planning of Space-Station on-Orbit Activities and Logistics. Acta Astronaut. 2021, 186, 211–227. [Google Scholar] [CrossRef]

- Zhang, Z.; Kong, W.; Zhang, H. Design of Combustion Science Experimental System for China Space Station. Chin. J. Space Sci. 2020, 40, 72. [Google Scholar] [CrossRef]

- He, L.; Zheng, H.; Wang, X.; Yang, X.; Zhang, X. Ground Experiment Investigation of PIV Unit for Combustion Science Experimental System of China Space Station. Chin. J. Space Sci. 2022, 42, 1152. [Google Scholar] [CrossRef]

- Peng, X.; Zheng, H.; Fang, Y.; Lan, X.; Yang, X.; Zhang, X. Numerical Simulation Study on the Feasibility of Cyclone PIV Tracer Particle Seeder in Microgravity. Energies 2025, 18, 1700. [Google Scholar] [CrossRef]

- Fang, Y.; Zheng, H.; Peng, X.; Zhang, X. Dimensional Homogeneity-Based Motion and Tracking Analysis of Tracer Particles in an Actual Combustion Flow. Appl. Therm. Eng. 2025, 269, 125965. [Google Scholar] [CrossRef]

- Wen, Y.; Li, L.; Li, X.; Luo, L.; Chen, T.; Zhang, W.; Zhou, H.; Chen, S.; Sun, Y.; Shi, J.; et al. Extinction of Microgravity Partially Premixed Flame Aboard the Chinese Space Station. Proc. Combust. Inst. 2024, 40, 105574. [Google Scholar] [CrossRef]

| Indicator | Value | |

|---|---|---|

| Weight | 265.7 kg | |

| Dimension | 944 mm × 752 mm × 1100 mm | |

| Power | 100 V DC | <1200 W |

| 28 V DC | <1200 W | |

| Communication | Ethernet protocol RS422 | ≮600 Mbps 115,200 ± 3% bps |

| Combustion chamber | Volume Pressure | 70 L 0.01~0.30 Mpa |

| Gas supply | Flow rate | 0~2 SLM (O2, Fuel), 0~5 SLM (N2, Ar) |

| Precision | ±(0.4% of reading + 0.2% of range) | |

| Device | Resolution (Pixels) | Frame Rate (fps) | Pixel Size (μm2) | Spectral Range (nm) | Spectrum |

|---|---|---|---|---|---|

| 1, 4, 6 | 1296 × 1024 | 3086 | 11 × 11 | 290~1100 | Color |

| 3, 8 | 1280 × 1024 | 49 | 10 × 10 | 200~900 | Mono |

| 7 | 1296 × 1024 | 3086 | 11 × 11 | 290~1100 | Mono |

| Project | ISS | CSS |

|---|---|---|

| Experimental Conditions | 300 K, 0.02~0.30 MPa | 300 K, 0.02~0.30 MPa |

| Color camera | 640 × 480 (30 fps), Qty 1 | 1296 × 1024 (3086 fps), Qty 3 |

| Mono camera | 1024 × 1024 (30 fps), Qty 1 | 1296 × 1024 (3086 fps), Qty 1 |

| Special camera | Low light level IR camera, Qty 1 Low light level UV camera, Qty 1 | ICCD, Qty 2 |

| Light | 10 mW LED, Qty 1 | 20 W Continuous laser, Qty 1 10 W Collimated light, Qty 1 |

| Optical diagnostics of plugin | Thermal radiometers, Qty 5 Photomultiplier, Qty 3 Monitoring camera | Thermal radiometers, Qty 2 Photomultiplier, Qty 3 Wide-angle camera |

| Other functions of plugin | Replaceable burner Retractable heating wire Thin-filament flame thermometry Electric field generator | Replaceable burner Retractable heating wire Environmental monitoring and alarm Particle protection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Zhang, X.; Fang, Y.; Wu, H.; Yang, X.; Zheng, H. On-Orbit Functional Verification of Combustion Science Experimental System in China Space Station. Aerospace 2025, 12, 448. https://doi.org/10.3390/aerospace12050448

Zhao P, Zhang X, Fang Y, Wu H, Yang X, Zheng H. On-Orbit Functional Verification of Combustion Science Experimental System in China Space Station. Aerospace. 2025; 12(5):448. https://doi.org/10.3390/aerospace12050448

Chicago/Turabian StyleZhao, Pingping, Xiaowu Zhang, Yu Fang, Hailong Wu, Xiaofang Yang, and Huilong Zheng. 2025. "On-Orbit Functional Verification of Combustion Science Experimental System in China Space Station" Aerospace 12, no. 5: 448. https://doi.org/10.3390/aerospace12050448

APA StyleZhao, P., Zhang, X., Fang, Y., Wu, H., Yang, X., & Zheng, H. (2025). On-Orbit Functional Verification of Combustion Science Experimental System in China Space Station. Aerospace, 12(5), 448. https://doi.org/10.3390/aerospace12050448