Surface-Tailoring and Morphology Control as Strategies for Sustainable Development in Transport Sector

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

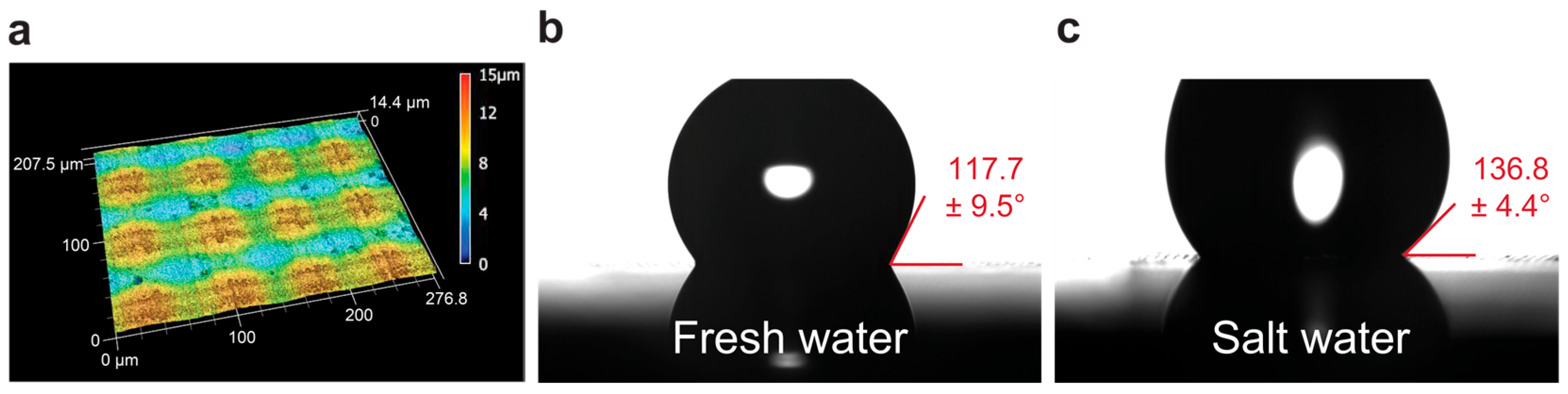

2.2. Saltwater Solution Testing

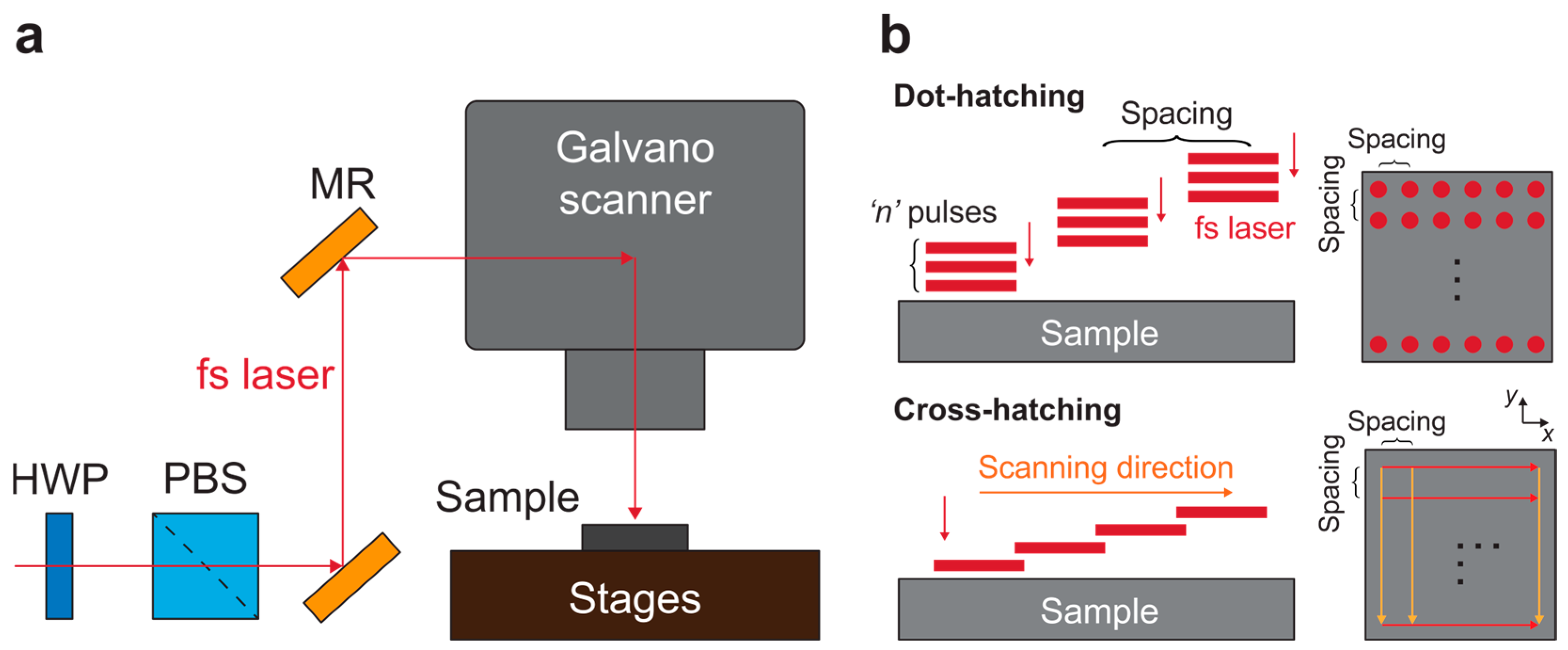

2.3. Ultrafast Fs Laser Processing

2.4. Surface Morphology Characterization

2.5. Water Contact Angle Measurements

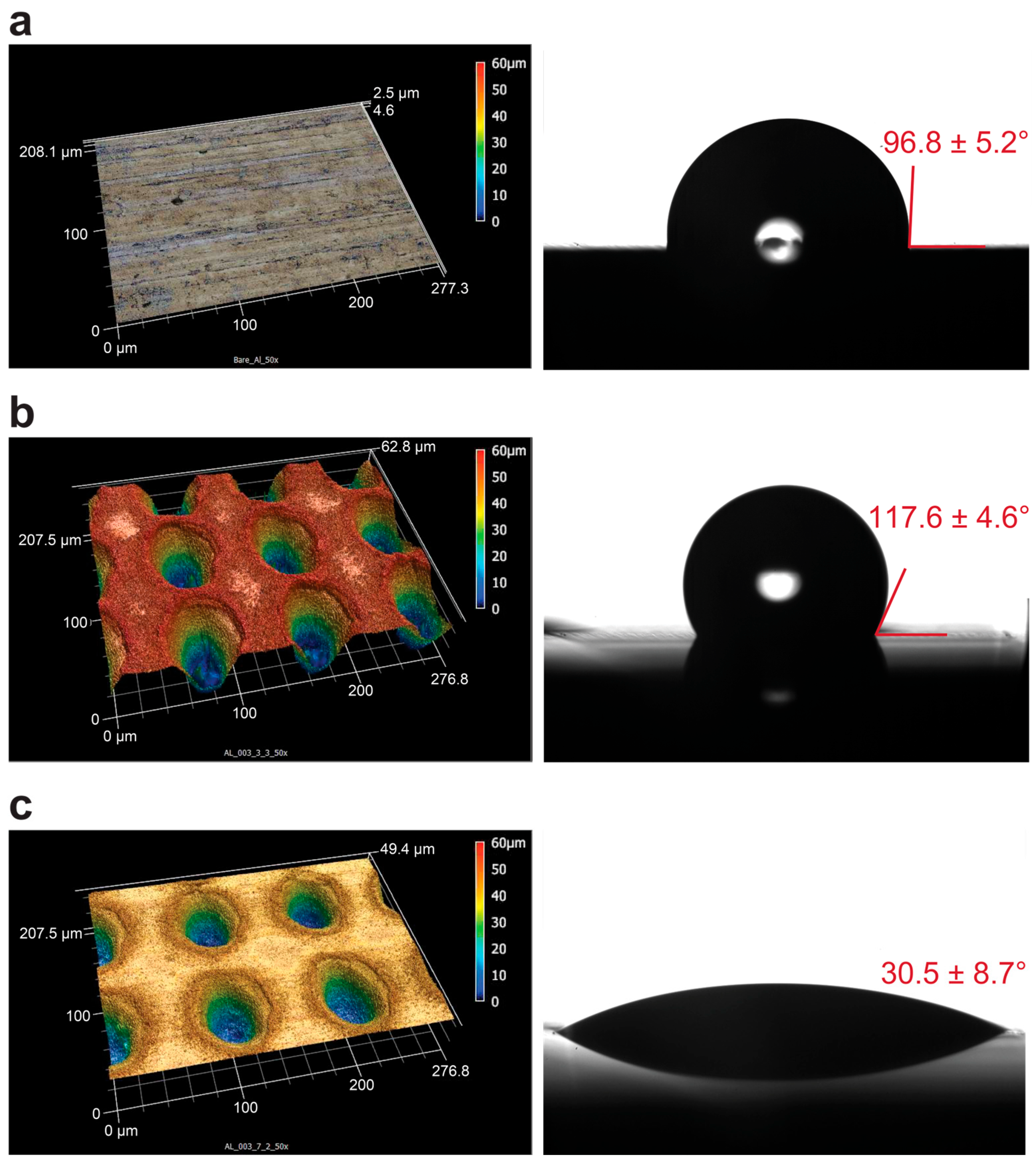

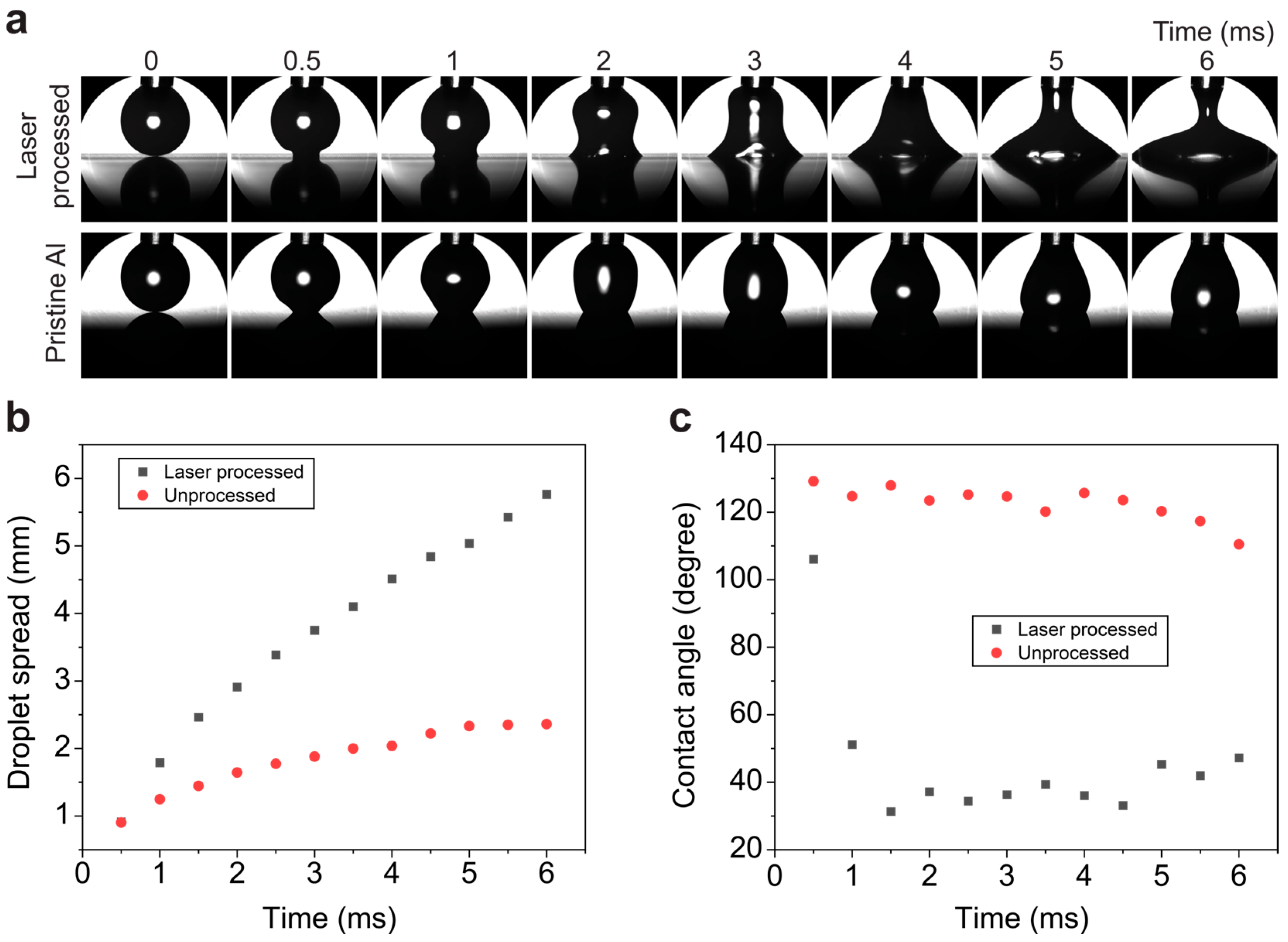

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Al | Aluminum |

| AMG | Aluminum-Magnesium 5000 series alloy |

| HWP | Half wave plate |

| MR | Mirror |

| PBS | Polarizing beam splitter |

| PPL | Pulses per location |

| UV | Ultra-violet |

| WCA | water contact angle |

References

- Yashpall; Jawalkar, C.S.; Kant, S. A Review on Use of Aluminium Alloys in Aircraft Components. I-Manag. J. Mater. Sci. 2015, 3, 33–38. Available online: https://www.proquest.com/scholarly-journals/review-on-use-aluminium-alloys-aircraft/docview/1795918853/se-2 (accessed on 20 March 2025).

- Araujo, J.V.D.S.; Milagre, M.; Costa, I. A Historical, Statistical and Electrochemical Approach on the Effect of Microstructure in the Anodizing of Al Alloys: A Review. Crit. Rev. Solid State Mater. Sci. 2024, 49, 521–581. [Google Scholar] [CrossRef]

- Vourdas, N.; Karanika, A.; Aldanondo, E.; Visser, P.; Van der Geest, M. Effect of Environmentally Friendly Surface Treatments on the Corrosion Behavior of New Al-Cu-Li Alloys. Eng. Fail. Anal. 2024, 163, 108487. [Google Scholar] [CrossRef]

- Wang, C.; Sun, S.; Ling, Y.; Tan, H.; He, C. The Corrosion Resistance of Tartaric-Sulfuric Acid Anodic Films on the 2024 Al Alloy Sealed Using Different Methods. Coatings 2024, 14, 733. [Google Scholar] [CrossRef]

- Del Olmo, R.; Tiringer, U.; Milošev, I.; Visser, P.; Arrabal, R.; Matykina, E.; Mol, J.M.C. Hybrid Sol-Gel Coatings Applied on Anodized AA2024-T3 for Active Corrosion Protection. Surf. Coat. Technol. 2021, 419, 127251. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, H.; Wang, Z.; Liu, Y. Superhydrophobic Aluminum Alloy Surface: Fabrication, Structure, and Corrosion Resistance. Colloids Surf. Physicochem. Eng. Asp. 2014, 441, 319–325. [Google Scholar] [CrossRef]

- Zheng, S.; Li, C.; Fu, Q.; Hu, W.; Xiang, T.; Wang, Q.; Du, M.; Liu, X.; Chen, Z. Development of Stable Superhydrophobic Coatings on Aluminum Surface for Corrosion-Resistant, Self-Cleaning, and Anti-Icing Applications. Mater. Des. 2016, 93, 261–270. [Google Scholar] [CrossRef]

- Bierwagen, G.P.; Tallman, D.E. Choice and Measurement of Crucial Aircraft Coatings System Properties. Prog. Org. Coat. 2001, 41, 201–216. [Google Scholar] [CrossRef]

- Chen, Y.; Sui, Z.; Du, J. Review on Aviation Intelligent Self-Healing Anti-Corrosion Coating. Anti-Corros. Methods Mater. 2025, 72, 170–177. [Google Scholar] [CrossRef]

- Ghaderi, M.; Bi, H.; Dam-Johansen, K. Advanced Materials for Smart Protective Coatings: Unleashing the Potential of Metal/Covalent Organic Frameworks, 2D Nanomaterials and Carbonaceous Structures. Adv. Colloid Interface Sci. 2024, 323, 103055. [Google Scholar] [CrossRef]

- Peltier, F.; Thierry, D. Review of Cr-Free Coatings for the Corrosion Protection of Aluminum Aerospace Alloys. Coatings 2022, 12, 518. [Google Scholar] [CrossRef]

- Trentin, A.; Pakseresht, A.; Duran, A.; Castro, Y.; Galusek, D. Electrochemical Characterization of Polymeric Coatings for Corrosion Protection: A Review of Advances and Perspectives. Polymers 2022, 14, 2306. [Google Scholar] [CrossRef] [PubMed]

- Bouali, A.C.; Serdechnova, M.; Blawert, C.; Tedim, J.; Ferreira, M.G.S.; Zheludkevich, M.L. Layered Double Hydroxides (LDHs) as Functional Materials for the Corrosion Protection of Aluminum Alloys: A Review. Appl. Mater. Today 2020, 21, 100857. [Google Scholar] [CrossRef]

- Bains, N.S.; Vaishya, R.O.; Kant, S.; Gupta, A. Bioinspired Hydrophobic Surfaces: An Overview. Mater. Today Proc. 2022, 64, 1486–1489. [Google Scholar] [CrossRef]

- Rios, P.F.; Dodiuk, H.; Kenig, S.; McCarthy, S.; Dotan, A. Durable Ultra-hydrophobic Surfaces for Self-cleaning Applications. Polym. Adv. Technol. 2008, 19, 1684–1691. [Google Scholar] [CrossRef]

- Dodiuk, H.; Rios, P.F.; Dotan, A.; Kenig, S. Hydrophobic and Self-cleaning Coatings. Polym. Adv. Technol. 2007, 18, 746–750. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Grigoropoulos, C.P. Transport in Laser Microfabrication: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Park, M.; Gu, Y.; Mao, X.; Grigoropoulos, C.P.; Zorba, V. Mechanisms of Ultrafast GHz Burst Fs Laser Ablation. Sci. Adv. 2023, 9, eadf6397. [Google Scholar] [CrossRef]

- Lawrence, J.; Waugh, D.G. (Eds.) Laser Surface Engineering; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Cambridge, UK, 2015; pp. 17–20. [Google Scholar] [CrossRef]

- Kerse, C.; Kalaycıoğlu, H.; Elahi, P.; Çetin, B.; Kesim, D.K.; Akçaalan, Ö.; Yavaş, S.; Aşık, M.D.; Öktem, B.; Hoogland, H.; et al. Ablation-Cooled Material Removal with Ultrafast Bursts of Pulses. Nature 2016, 537, 84–88. [Google Scholar] [CrossRef]

- Park, M.; Jeun, J.; Han, G.; Grigoropoulos, C.P. Time-Resolved Emission and Scattering Imaging of Plume Dynamics and Nanoparticle Ejection in Femtosecond Laser Ablation of Silver Thin Films. Appl. Phys. Lett. 2020, 116, 234105. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, Picosecond and Nanosecond Laser Ablation of Solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Zorba, V.; Stratakis, E.; Barberoglou, M.; Spanakis, E.; Tzanetakis, P.; Anastasiadis, S.H.; Fotakis, C. Biomimetic Artificial Surfaces Quantitatively Reproduce the Water Repellency of a Lotus Leaf. Adv. Mater. 2008, 20, 4049–4054. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Superhydrophobic Surfaces Fabricated by Femtosecond Laser with Tunable Water Adhesion: From Lotus Leaf to Rose Petal. ACS Appl. Mater. Interfaces 2015, 7, 9858–9865. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsov, G.V.; Feoktistov, D.V.; Orlova, E.G.; Zykov, I.Y.; Islamova, A.G. Droplet State and Mechanism of Contact Line Movement on Laser-Textured Aluminum Alloy Surfaces. J. Colloid Interface Sci. 2019, 553, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Angell, D.; Wang, X.; Song, X.; Lei, S. A Study on Surface Texture and Wettability of Femtosecond Laser Treated Aluminum Alloy. In Volume 3: Advanced Manufacturing; American Society of Mechanical Engineers: New Orleans, LA, USA, 2023; p. V003T03A074. [Google Scholar] [CrossRef]

- Xu, S.; Tan, L.; Yao, C.; Miao, X.; Lü, H.; Jiang, X.; Yuan, X. Anti-Reflective and Wetting Properties of Femtosecond Pulsed Laser Textured Al Alloy Surfaces. Optik 2021, 242, 167293. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, D.; Zhang, Y.; Xue, T.; Huang, Y.; Zhang, G. Fabrication and Droplet Impact Performance of Superhydrophobic Ti6Al4V Surface by Laser Induced Plasma Micro-Machining. Appl. Surf. Sci. 2022, 605, 154661. [Google Scholar] [CrossRef]

- Li, B.; Li, H.; Huang, L.; Ren, N.; Kong, X. Femtosecond Pulsed Laser Textured Titanium Surfaces with Stable Superhydrophilicity and Superhydrophobicity. Appl. Surf. Sci. 2016, 389, 585–593. [Google Scholar] [CrossRef]

- Samanta, A.; Wang, Q.; Shaw, S.K.; Ding, H. Roles of Chemistry Modification for Laser Textured Metal Alloys to Achieve Extreme Surface Wetting Behaviors. Mater. Des. 2020, 192, 108744. [Google Scholar] [CrossRef]

- Khajavian, E.; Attar, M.R.; Mohammadi Zahrani, E.; Liu, W.; Davoodi, A.; Hosseinpour, S. Tuning Surface Wettability of Aluminum Surface and Its Correlation with Short and Long Term Corrosion Resistance in Saline Solutions. Surf. Coat. Technol. 2022, 429, 127950. [Google Scholar] [CrossRef]

- Extrand, C.W. Model for Contact Angles and Hysteresis on Rough and Ultraphobic Surfaces. Langmuir 2002, 18, 7991–7999. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1944, 40, 546. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- ISO 9227:2022; Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. ISO: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/81744.html (accessed on 26 November 2024).

- Cazabat, A.M.; Stuart, M.A.C. Dynamics of Wetting: Effects of Surface Roughness. J. Phys. Chem. 1986, 90, 5845–5849. [Google Scholar] [CrossRef]

- Ley, J.R.; Kwon, Y.W.; Park, C.; Menon, S.K. Corrosion of Femtosecond Laser Surface Textured Aluminium Alloy. Corros. Eng. Sci. Technol. 2017, 52, 526–532. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez de Almeida Prado, L.A.; Coskun, S.; Cadène, A.-L.; Antelo Reguengo, R.A.; Carter, J.; Ito, K.; Park, M.; Zorba, V. Surface-Tailoring and Morphology Control as Strategies for Sustainable Development in Transport Sector. Aerospace 2025, 12, 301. https://doi.org/10.3390/aerospace12040301

Sanchez de Almeida Prado LA, Coskun S, Cadène A-L, Antelo Reguengo RA, Carter J, Ito K, Park M, Zorba V. Surface-Tailoring and Morphology Control as Strategies for Sustainable Development in Transport Sector. Aerospace. 2025; 12(4):301. https://doi.org/10.3390/aerospace12040301

Chicago/Turabian StyleSanchez de Almeida Prado, Luis Antonio, Selim Coskun, Anne-Laure Cadène, Ramón Angel Antelo Reguengo, Jake Carter, Kyle Ito, Minok Park, and Vassilia Zorba. 2025. "Surface-Tailoring and Morphology Control as Strategies for Sustainable Development in Transport Sector" Aerospace 12, no. 4: 301. https://doi.org/10.3390/aerospace12040301

APA StyleSanchez de Almeida Prado, L. A., Coskun, S., Cadène, A.-L., Antelo Reguengo, R. A., Carter, J., Ito, K., Park, M., & Zorba, V. (2025). Surface-Tailoring and Morphology Control as Strategies for Sustainable Development in Transport Sector. Aerospace, 12(4), 301. https://doi.org/10.3390/aerospace12040301