Vibration Isolation in Stewart Platforms via Phase-Change Low-Melting-Point Alloys for Tunable Stiffness

Abstract

1. Introduction

2. Variable-Stiffness Vibration Isolation and Design Ideas

2.1. Variable-Stiffness Vibration-Damping Foundation

2.2. Temperature-Controlled Phase Transition

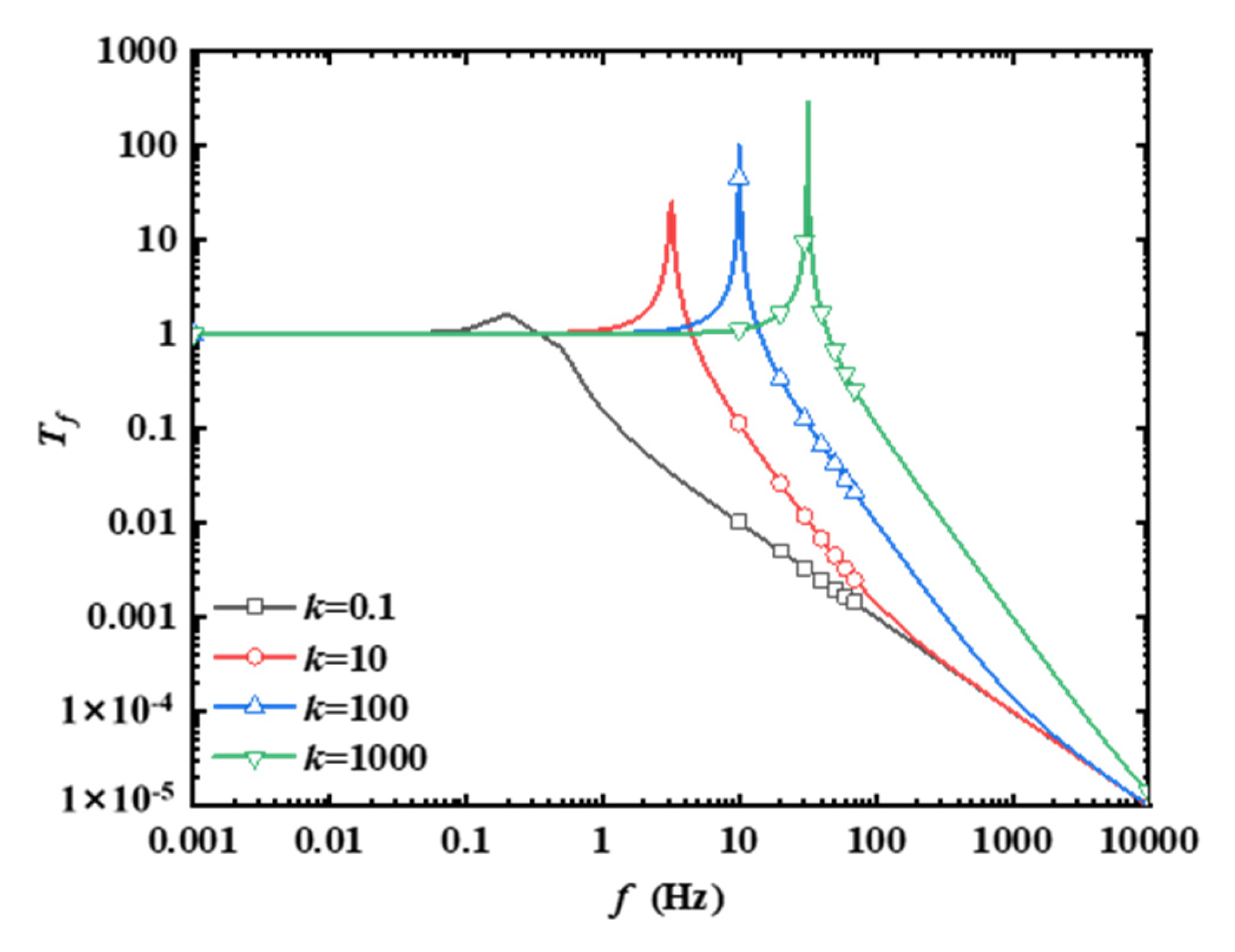

2.3. Variable-Stiffness Vibration Isolation Characteristics of the Stewart Platform

3. Experimental Program of the Samples

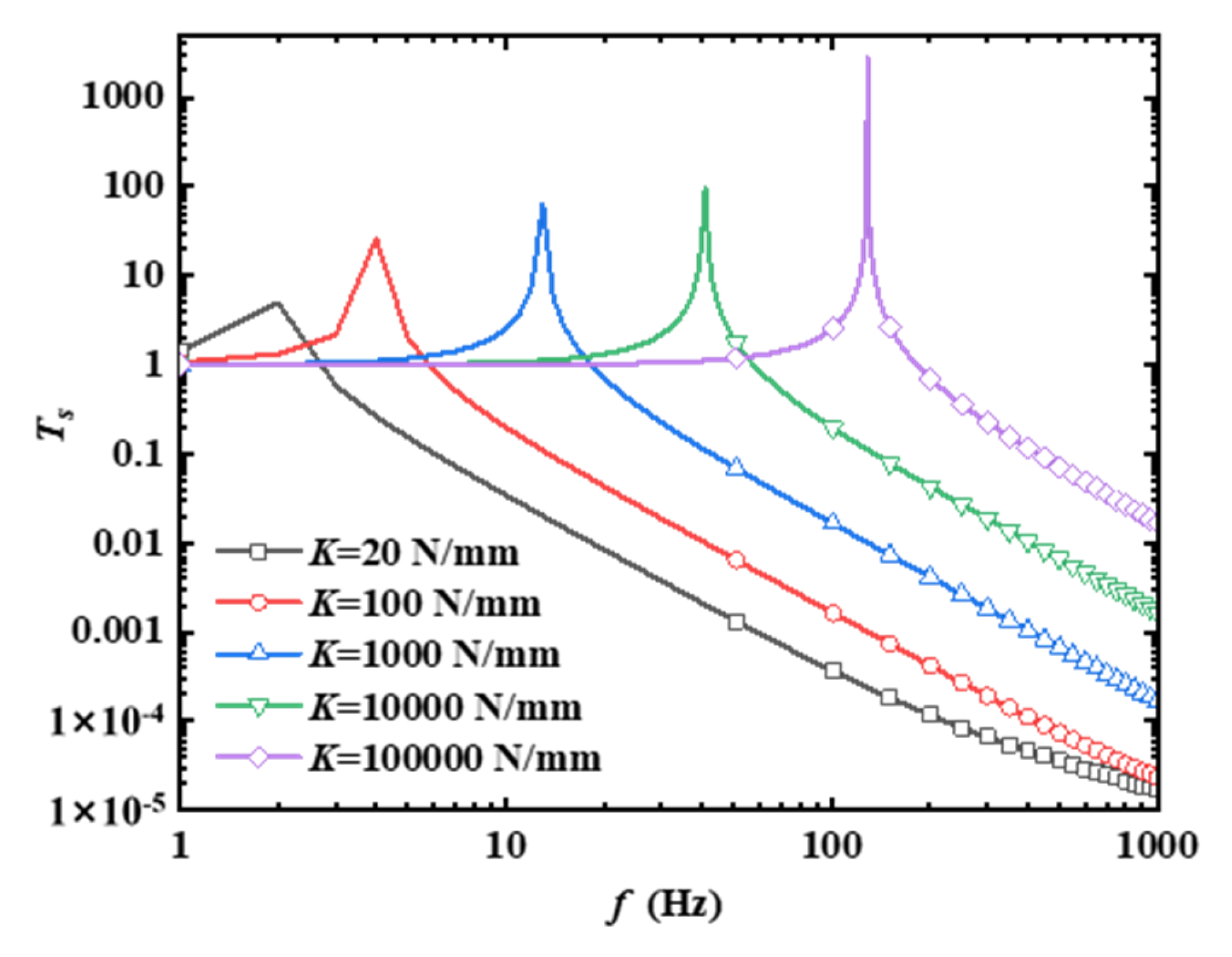

3.1. Preparation Process

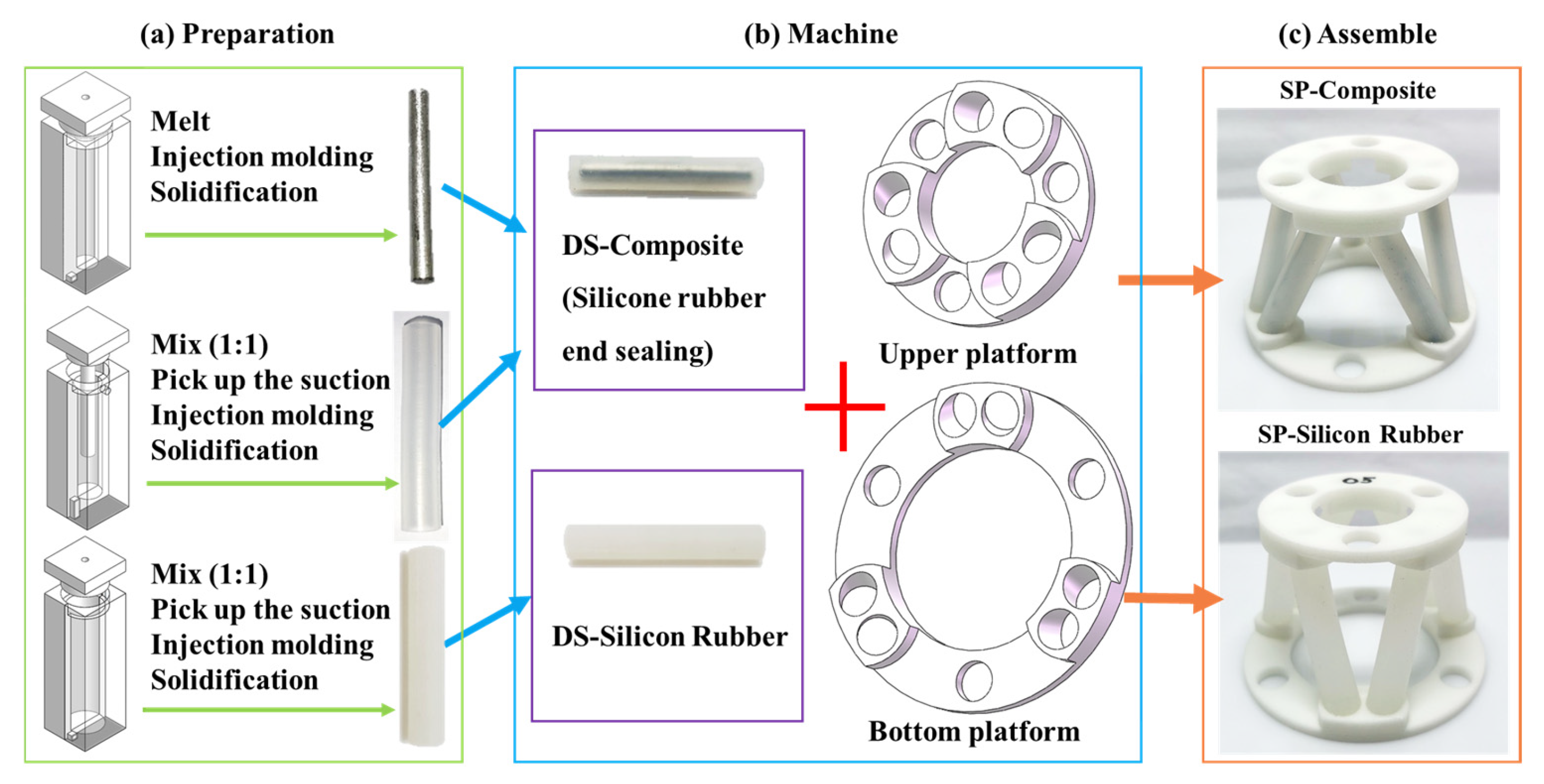

3.2. Parameters of the Driving Column

3.3. Parameters of Stewart Platform Composite Structure

4. Test of the Samples

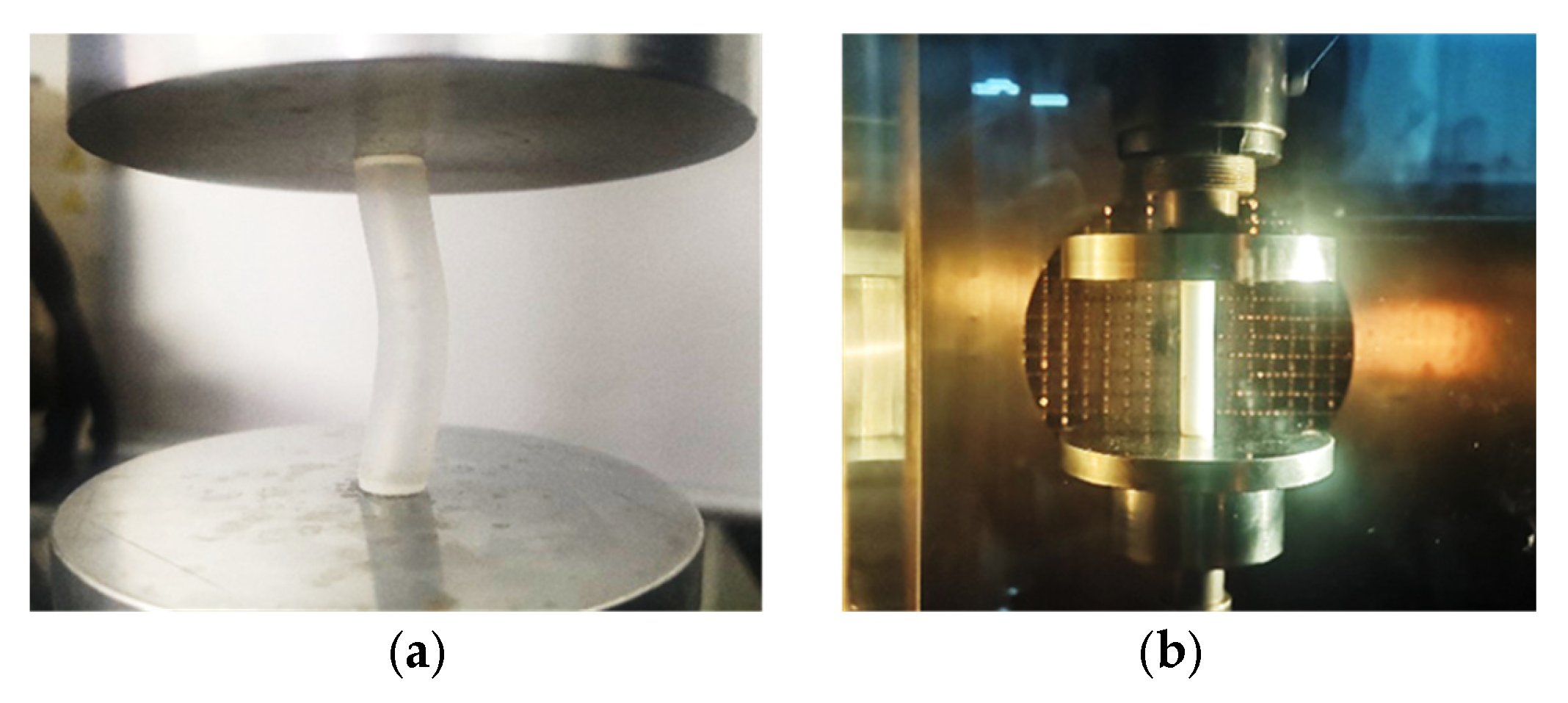

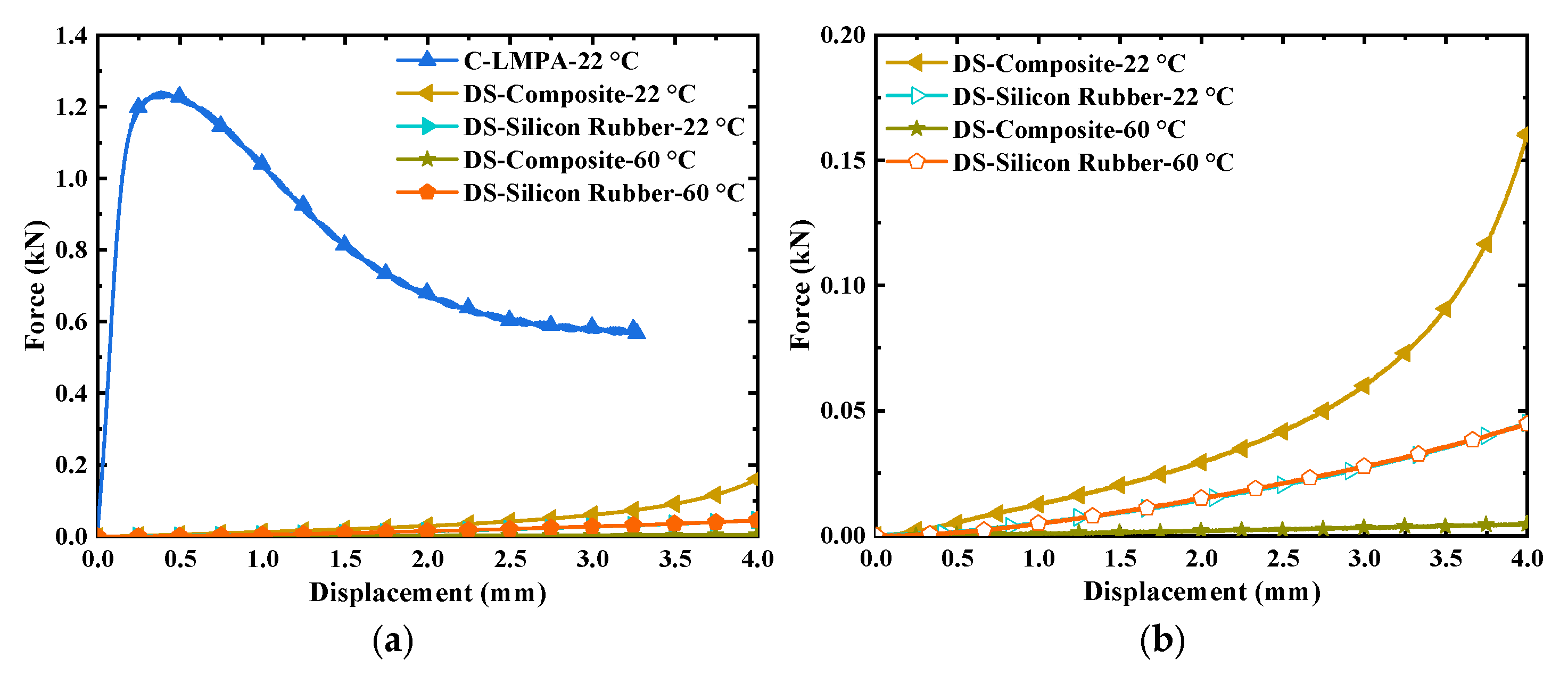

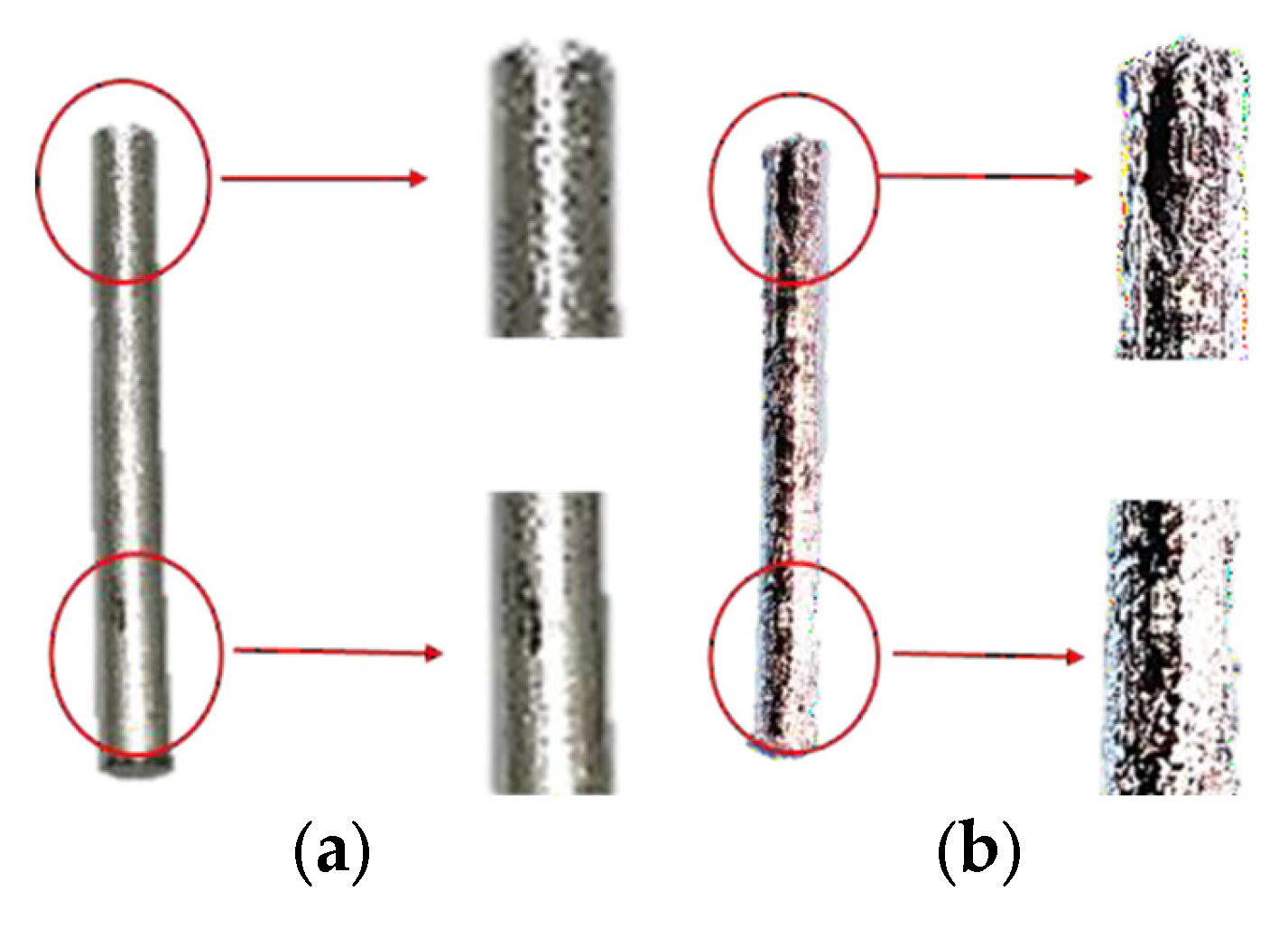

4.1. Compression Test of the Driving Column

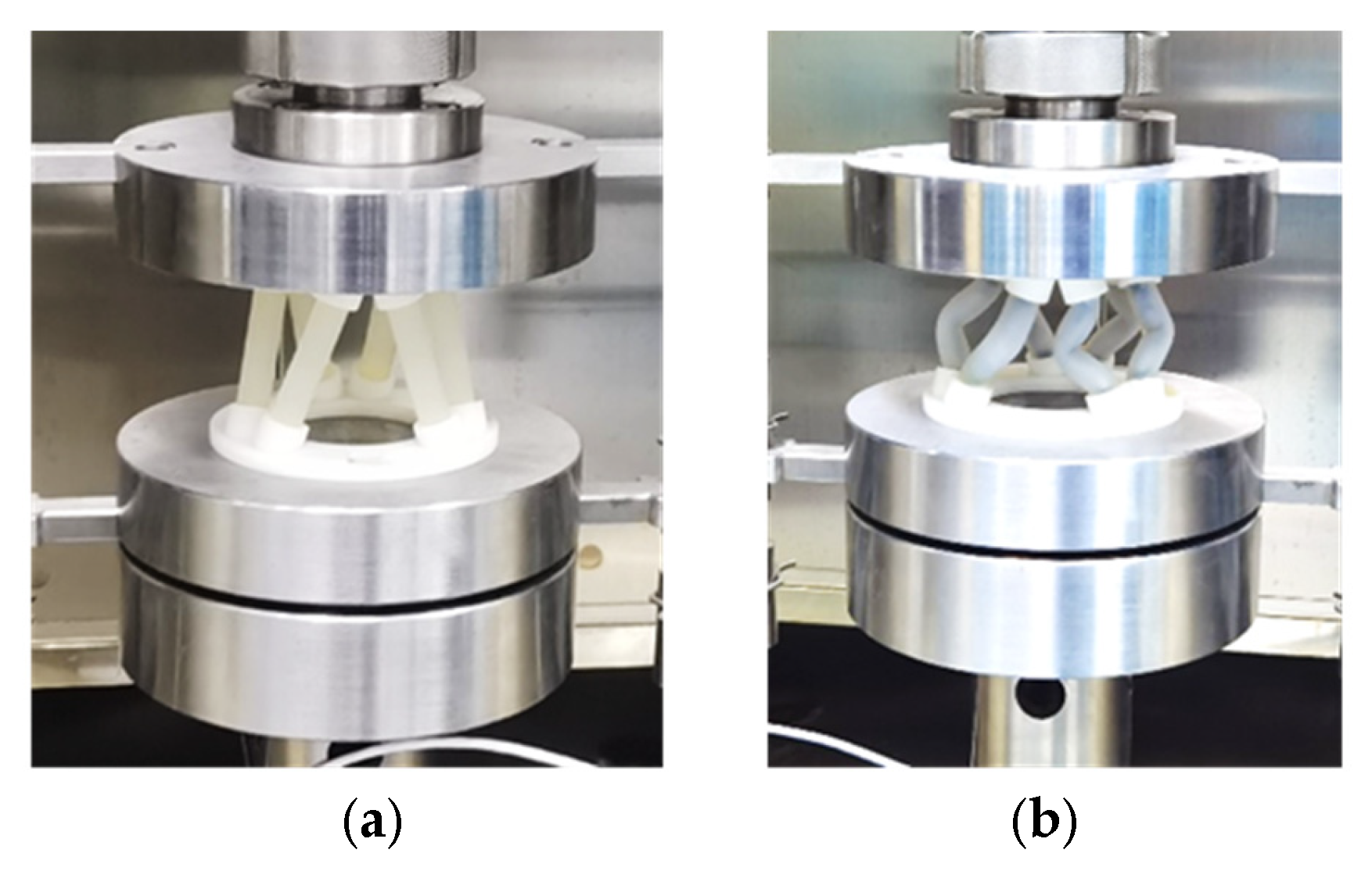

4.2. Compression Testing of the Stewart Platform

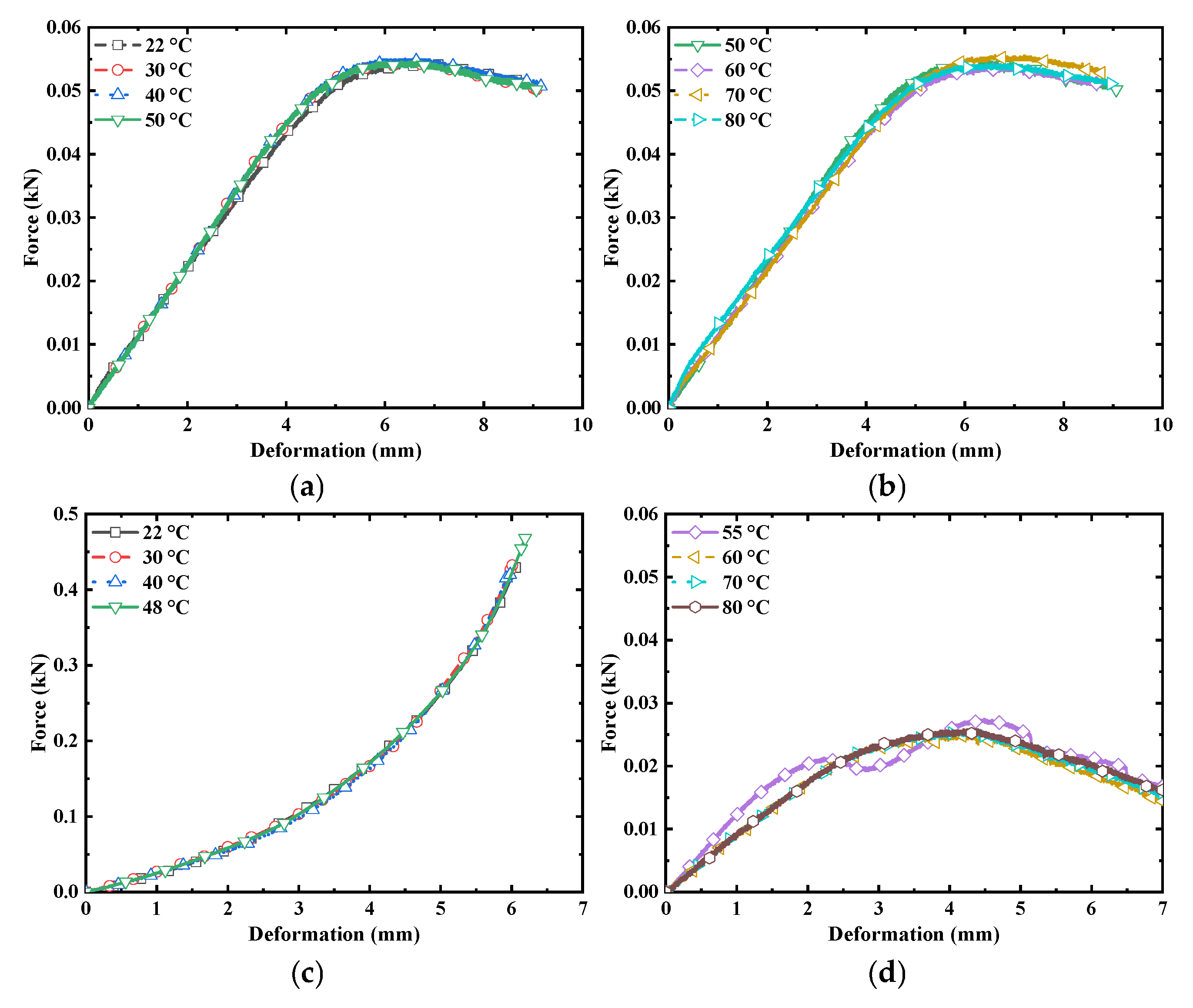

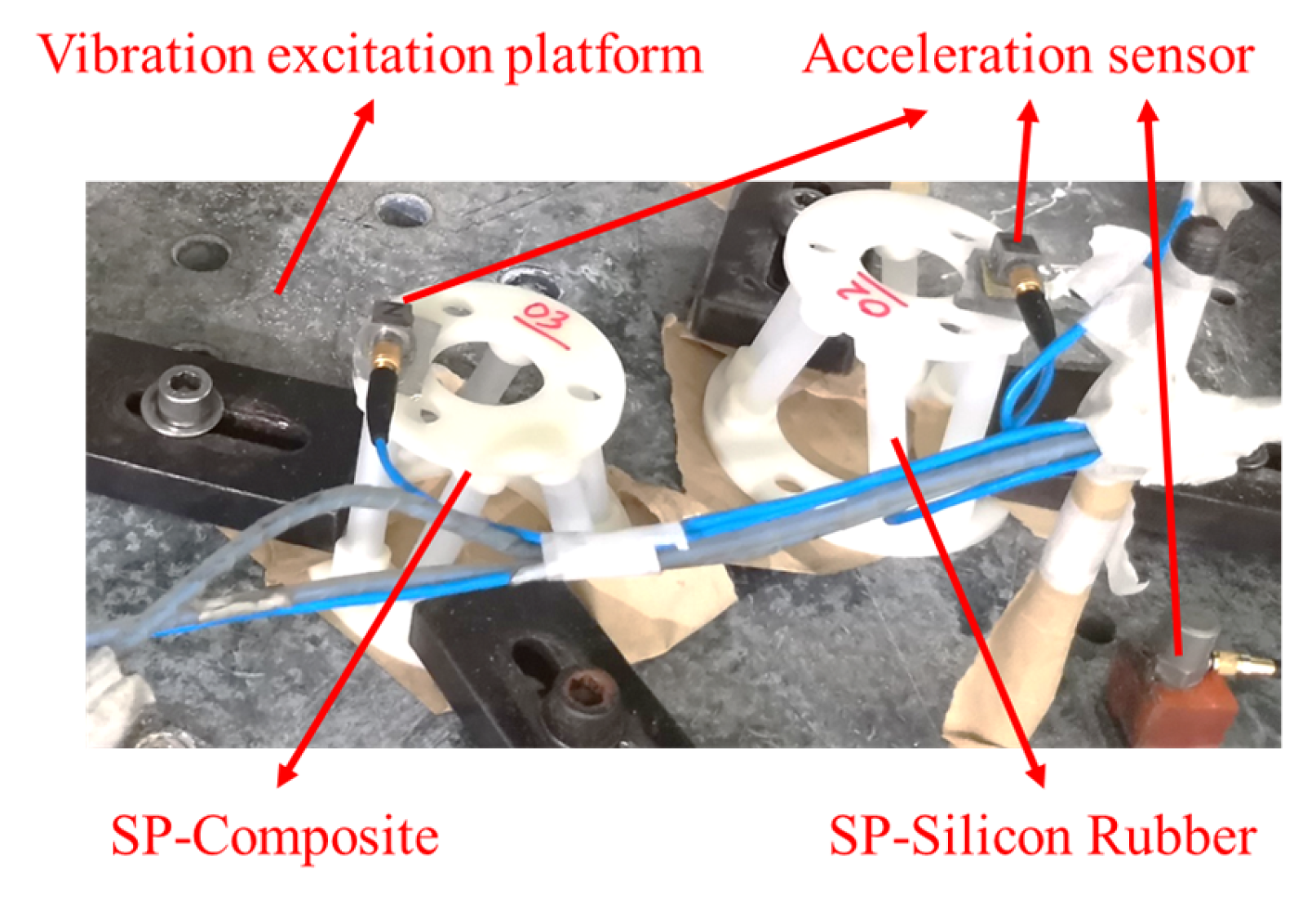

4.3. Vibration Test of the Stewart Platform

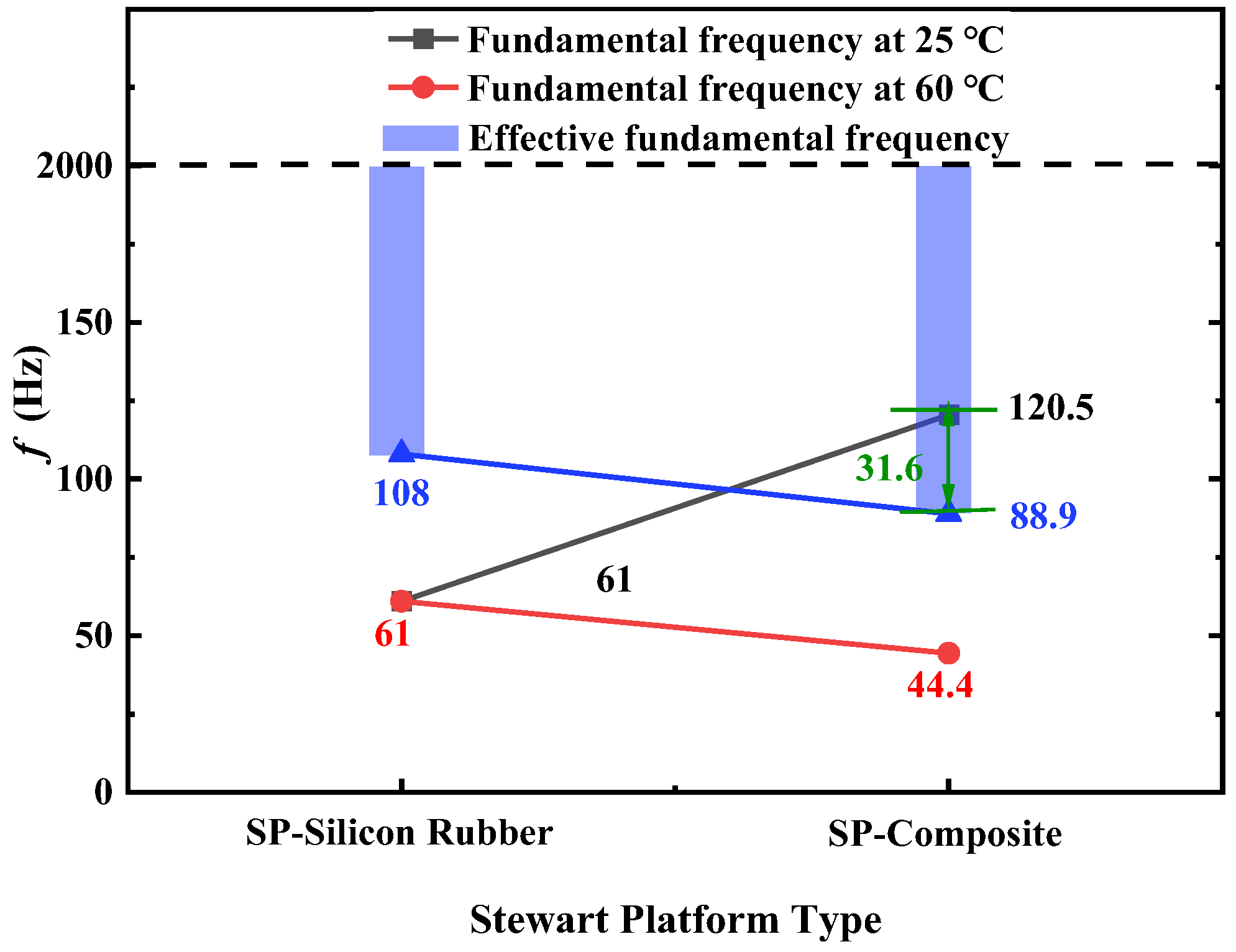

4.4. Results and Discussion

5. Conclusions

- (1)

- A mathematical model for a variable-stiffness Stewart vibration isolation structure was developed, addressing the specific requirements for the isolation of micro-vibrations in spacecraft. We also assessed the impact of the drive column stiffness on the vertical Stewart platform’s axial transmission rate. The study reveals that, as the stiffness coefficient of the drive columns increases, there is a corresponding rise in both the vibration response transmission rate and the resonant frequency of the vertical Stewart platform.

- (2)

- The innovative Stewart damping structure’s stiffness is responsive to changes in temperature. Notably, the stiffness of the SP-Composite at 25 °C can be 5.4 times greater than at 60 °C.

- (3)

- The Stewart platform’s novel composite structure enables the broadening of the effective vibration isolation frequency range with temperature variations. Specifically, the SP-Composite’s effective damping frequency range can be extended by 31.6 Hz, from 88.9 Hz to 120.5 Hz, achieving up to a 10 dB attenuation in vibrations. The expanded effective isolation band (88.9–120.5 Hz) covers 78% of the critical disturbance frequencies from momentum wheels (50–200 Hz), demonstrating significant engineering applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Sun, H.; Hou, L. Event-triggered anti-disturbance attitude and vibration control for T-S fuzzy flexible spacecraft model with multiple disturbances. Aerosp. Sci. Technol. 2021, 117, 106953. [Google Scholar] [CrossRef]

- Liu, Z.; Han, Z.; Zhao, Z.; He, W. Modeling and adaptive control for a spatial flexible spacecraft with unknown actuator failures. Sci. China Inf. Sci. 2021, 64, 152201. [Google Scholar] [CrossRef]

- Zhang, J.; Han, Z.; Liu, Y.; Sun, S. Modal characteristics and manufacturing method of variable stiffness facesheets of sandwich plates made by robotic fiber placement. Compos. Struct. 2021, 270, 114065. [Google Scholar] [CrossRef]

- Yan, G.; Zou, H.X.; Yan, H.; Tan, T.; Wang, S.; Zhang, W.-M.; Peng, Z.-K.; Meng, G. Multi-direction vibration isolator for momentum wheel assemblies. J. Vib. Acoust. 2020, 142, 041007. [Google Scholar] [CrossRef]

- Liu, C.; Jing, X.; Daley, S.; Li, F. Recent advances in micro-vibration isolation. Mech. Syst. Signal Process. 2015, 56, 55–80. [Google Scholar] [CrossRef]

- He, Z.; Feng, X.; Zhu, Y.; Yu, Z.; Li, Z.; Zhang, Y.; Wang, Y.; Wang, P.; Zhao, L. Progress of Stewart vibration platform in aerospace micro–vibration control. Aerospace 2022, 9, 324. [Google Scholar] [CrossRef]

- Li, L.; Wang, L.; Yuan, L.; Zheng, R.; Wu, Y.; Sui, J.; Zhong, J. Micro-vibration suppression methods and key technologies for high-precision space optical instruments. Acta Astronaut. 2021, 180, 417–428. [Google Scholar] [CrossRef]

- Dasgupta, B.; Mruthyunjaya, T.S. The Stewart platform manipulator: A review. Mech. Mach. Theory 2000, 35, 15–40. [Google Scholar] [CrossRef]

- Haynes, L.S. Six Degree of Freedom Active Vibration Damping for Space Applications; NASA: Washington, DC, USA, 1993. [Google Scholar]

- Cheng, J.; Cheng, W.; Li, X. Modeling and simulation of the disturbance torque generated by solar array drive assembly. J. Vib. Shock 2017, 36, 188–194. [Google Scholar]

- Wen, S.; Jing, J.; Cui, D.; Wu, Z.; Liu, W.; Li, F. Vibration isolation of a double-layered Stewart platform with local oscillators. Mech. Adv. Mater. Struct. 2021, 29, 6685–6693. [Google Scholar] [CrossRef]

- Furqan, M.; Suhaib, M.; Ahmad, N. Studies on Stewart platform manipulator: A review. J. Mech. Sci. Technol. 2017, 31, 4459–4470. [Google Scholar] [CrossRef]

- Tsushima, N.; Hayashi, Y.; Yokozeki, T. Dispersion analysis of plane wave propagation in lattice-based mechanical metamaterial for vibration suppression. Aerospace 2024, 11, 637. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, G.; Huang, W. Octo-strut vibration isolation platform and its application to whole spacecraft vibration isolation. J. Sound Vib. 2006, 289, 726–744. [Google Scholar] [CrossRef]

- Boltosi, A.; Chiriac, A.; Nagy, R.; Bereteu, L. Stewart platform: Application of smart fluid dampers in this field. Ann. Univ. Oradea Fascicle Manag. Technol. Eng. 2008, 7, 1–6. [Google Scholar]

- Zheng, Y.; Li, Q.; Yan, B.; Luo, Y.; Zhang, X. A Stewart isolator with high-static-low-dynamic stiffness struts based on negative stiffness magnetic springs. J. Sound Vib. 2018, 422, 390–408. [Google Scholar] [CrossRef]

- Wang, C.; Xie, X.; Chen, Y.; Zhang, Z. Investigation on active vibration isolation of a Stewart platform with piezoelectric actuators. J. Sound Vib. 2016, 383, 1–19. [Google Scholar] [CrossRef]

- Wu, Z.; Jing, X.; Sun, B.; Li, F. A 6-DOF passive vibration isolator using X-shape supporting structures. J. Sound Vib. 2016, 380, 90–111. [Google Scholar] [CrossRef]

- Wang, M.; Hu, Y.; Sun, Y.; Ding, J.; Pu, H.; Yuan, S.; Zhao, J.; Peng, Y.; Xie, S.; Luo, J. An adjustable low-frequency vibration isolation Stewart platform based on electromagnetic negative stiffness. Int. J. Mech. Sci. 2020, 181, 105714. [Google Scholar] [CrossRef]

- Yang, X.; Wu, H.; Chen, B.; Kang, S.; Cheng, S. Dynamic modeling and decoupled control of a flexible Stewart platform for vibration isolation. J. Sound Vib. 2019, 439, 398–412. [Google Scholar] [CrossRef]

- Zhu, D.; Zhan, W. Topology optimization of a 6-DOF spatial compliant mechanism based on Stewart prototype platform. Acta Mech. Sin. 2019, 35, 1044–1059. [Google Scholar] [CrossRef]

- Jiang, M.; Rui, X.; Zhu, W.; Yang, F.; Zhang, Y. Optimal design of 6-DOF vibration isolation platform based on transfer matrix method for multibody systems. Acta Mech. Sin. 2021, 37, 127–137. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, X.; Cai, G.; Liu, X. Active vibration control of a large space telescope truss based on unilateral saturated cable actuators. Acta Mech. Sin. 2022, 38, 522040. [Google Scholar] [CrossRef]

- Seymour, E. Liquid Metals. Nature 1973, 242, 540. [Google Scholar] [CrossRef]

- Buckner, T.; Yuen, M.; Kim, S.; Kramer-Bottiglio, R. Enhanced variable stiffness and variable stretchability enabled by phase-changing particulate additives. Adv. Funct. Mater. 2019, 29, 1903368. [Google Scholar] [CrossRef]

- Piskarev, E.; Shintake, J.; Ramachandran, V.; Baugh, N.; Dickey, M.D.; Floreano, D.; Piskarev, E. Lighter and stronger: Cofabricated electrodes and variable stiffness elements in dielectric actuators. Adv. Intell. Syst. 2020, 2, 2000069. [Google Scholar] [CrossRef]

- Hoang, T.T.; Quek, J.J.S.; Thai, M.T.; Phan, P.T.; Lovell, N.H.; Do, T.N. Soft robotic fabric gripper with gecko adhesion and variable stiffness. Sens. Actuators A Phys. 2021, 323, 112673. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Z.; Luo, X.; Liu, W. Numerical study on convective heat transfer of liquid metal gallium in turbine guide vane. Aerospace 2023, 10, 548. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Yu, Y.; Wang, P. 3D-Printed polymer composites based upon low melting point alloys filled into polylactic acid. J. Phys. Conf. Ser. 2021, 2002, 5. [Google Scholar] [CrossRef]

- Liu, Y.; Matsuhisa, H.; Utsuno, H. Semi-active vibration isolation system with variable stiffness and damping control. J. Sound Vib. 2008, 313, 16–28. [Google Scholar] [CrossRef]

- Dong, X.-J.; Peng, Z.-K.; Zhang, W.-M.; Meng, G.; Chu, F.-L. Parametric characteristic of the random vibration response of nonlinear systems. Acta Mech. Sin. 2013, 29, 267–283. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, W.; Chen, Y.; Oliveira, J.; Zeng, Z.; Li, Y.; Luo, Z.; Ao, S. Wire-based directed energy deposition of NiTiTa shape memory alloys: Microstructure, phase transformation, electrochemistry, X-ray visibility and mechanical properties. Addit. Manuf. 2022, 59, 103115. [Google Scholar] [CrossRef]

- Hao, Y.; Gao, J.; Lv, Y.; Liu, J. Low melting point alloys enabled stiffness tunable advanced materials. Adv. Funct. Mater. 2022, 32, 2201942. [Google Scholar] [CrossRef]

- Marechal, L.; Balland, P.; Lindenroth, L.; Petrou, F.; Kontovounisios, C.; Bello, F. Toward a common framework and database of materials for soft robotics. Soft Robot. 2021, 8, 284–297. [Google Scholar] [CrossRef]

- Segers, J.; Hedayatrasa, S.; Verboven, E.; Poelman, G.; Van Paepegem, W.; Kersemans, M. Efficient automated extraction of local defect resonance parameters in fiber reinforced polymers using data compression and iterative amplitude thresholding. J. Sound Vib. 2019, 463, 114958. [Google Scholar] [CrossRef]

- Jiang, L.; Xiao, S.; Yang, B.; Yang, G.; Zhu, T.; Wang, M. Bimodulus constitutive relation and mesoscopic model of braided composites. Compos. Struct. 2021, 270, 114115. [Google Scholar] [CrossRef]

- Labans, E.; Bisagni, C. Buckling and free vibration study of variable and constant-stiffness cylindrical shells. Compos. Struct. 2019, 210, 446–457. [Google Scholar] [CrossRef]

- Lim, C.; Yaw, Z.; Chen, Z. Periodic and aperiodic 3-D composite metastructures with ultrawide bandgap for vibration and noise control. Compos. Struct. 2022, 287, 115324. [Google Scholar] [CrossRef]

- Kim, H.-G.; Kwon, S.-C.; Koo, K.-R.; Song, S.-C.; Yu, Y.; Song, Y.; Park, Y.-H.; Oh, H.-U. Performance investigation of superplastic shape memory alloy-based vibration isolator for X-band active small SAR satellite of S-STEP under acoustic and random vibration environments. Aerospace 2022, 9, 642. [Google Scholar] [CrossRef]

| Number | Type | Density (kg/m3) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| 01 | LMPA–Solid | 9.5 × 103 | 3000.0~15,000.0 | 0.33 |

| 02 | LMPA–Liquid | 9.5 × 103 | 0.001~0.1 | - |

| 03 | Dragon Skin 30 | 2.68 × 103 | 0.1~1.0 | 0.45 |

| Number | Type | (mm) | (mm) |

|---|---|---|---|

| 01 | C-LMPA | 50.0 | 5.0 |

| 02 | DS-Composite | 50.0 | 10.0 |

| 03 | DS-Silicon Rubber | 50.0 | 10.0 |

| Number | Type | (°C) | (mm) | (mm) |

|---|---|---|---|---|

| 01 | C-LMPA | 22.0 | 10.0 | 5.0 |

| 02 | DS-Silicon Rubber | 22.0 | 12.8 | 10.0 |

| 03 | DS-Silicon Rubber | 60.0 | 10.9 | 9.8 |

| 04 | DS-Composite | 22.0 | 49.5 | 10.0 |

| 05 | DS-Composite | 60.0 | 50.4 | 10.1 |

| Number | Type | (°C) | Modulus (MPa) | Standard Deviations |

|---|---|---|---|---|

| 01 | C-LMPA | 22.0 | 3795.4 | 0.36 |

| 02 | DS-Silicon Rubber | 22.0 | 1.1 | 0.21 |

| 03 | DS-Silicon Rubber | 60.0 | 1.1 | 0.22 |

| 04 | DS-Composite-Soft | 22.0 | 9.4 | 0.18 |

| 05 | DS-Composite-Soft | 60.0 | 0.8 | 0.14 |

| Number | Type | Structural Stiffness at 22 °C (N/m) | Standard Deviations | Structural Stiffness at 60 °C (N/m) | Standard Deviations |

|---|---|---|---|---|---|

| 01 | SP-Silicon Rubber | 10,600 | 0.29 | 10,600 | 0.32 |

| 02 | SP-Composite | 30,400 | 0.36 | 7930 | 0.21 |

| Number | Type | Isolation Range | Resonant Frequency Shift | Structural Stiffness Ratio |

|---|---|---|---|---|

| 01 | SP-Silicon Rubber | - | 61.0 Hz → 61.0 Hz | 1.0 |

| 02 | SP-Composite | 88.9 Hz~120.5 Hz | 44.4 Hz → 120.5 Hz | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Zhu, L.; Liu, Z.; Liu, Z.; Shi, Z. Vibration Isolation in Stewart Platforms via Phase-Change Low-Melting-Point Alloys for Tunable Stiffness. Aerospace 2025, 12, 279. https://doi.org/10.3390/aerospace12040279

He Z, Zhu L, Liu Z, Liu Z, Shi Z. Vibration Isolation in Stewart Platforms via Phase-Change Low-Melting-Point Alloys for Tunable Stiffness. Aerospace. 2025; 12(4):279. https://doi.org/10.3390/aerospace12040279

Chicago/Turabian StyleHe, Zepeng, Lingmin Zhu, Zhenyu Liu, Zongnan Liu, and Zhongjiao Shi. 2025. "Vibration Isolation in Stewart Platforms via Phase-Change Low-Melting-Point Alloys for Tunable Stiffness" Aerospace 12, no. 4: 279. https://doi.org/10.3390/aerospace12040279

APA StyleHe, Z., Zhu, L., Liu, Z., Liu, Z., & Shi, Z. (2025). Vibration Isolation in Stewart Platforms via Phase-Change Low-Melting-Point Alloys for Tunable Stiffness. Aerospace, 12(4), 279. https://doi.org/10.3390/aerospace12040279