1. Introduction

Recently, the space industry has been focusing on the mass-production system technology of small satellites with a relatively low risk of mission failure owing to the advantages of low cost, short-term development and operation compared with the existing small production systems of medium and large satellites with high performance and capabilities under the New Space paradigm [

1]. As a result, missions that are difficult to achieve with conventional medium and large satellite operations, such as quasi-real-time Earth observations and the establishment of a global Internet service network, are being conducted using constellations of small satellites [

2]. Based on the development of space technology and previously researched technology for developing small satellites, the missions utilizing them are being advanced and diversified, and the application of high-performance large-scale antennas is essential for performing advanced missions such as synthetic aperture radar (SAR), high-speed communication, and signal intelligence (SIGINT) missions. However, because of the limited weight and internal volume requirements of launch vehicles, large-scale antennas must be designed based on the concept of deployable structures [

3]. Consequently, large-scale deployable mesh antenna technology is in the spotlight with advantages such as high gain, ultralight weight, and high packaging efficiency.

Deployable antennas are stowed to satisfy volume requirements and ensure structural safety under launch conditions; subsequently, they are deployed to perform on-orbit space missions. The deployment mechanism of mesh reflector antennas is particularly important because of the characteristics of the mesh that constitutes the reflecting surface. The mesh applied to the antennas utilizes wires fabricated from metallic materials, such as molybdenum and tungsten, to maintain the precision of the reflecting surface during orbital operation. These materials have low elongation and high strength compared with general textile materials [

4,

5]. However, despite the application of metallic wires, the mesh has a low stiffness and deforms easily, causing problems such as variations in the mesh opening per inch (OPI), surface curvature distortion, and tearing of the mesh when excessive deformation occurs during orbital deployment. Because physical changes in the reflecting surface directly affect the antenna performance, the deployment mechanism should be designed considering mesh characteristics.

As representative large-scale deployable mesh antennas, parabolic reflectors have been used in space applications, and several studies have been conducted. Hasanzade et al. [

6] proposed a compact and spatially deployable hinged-rib umbrella antenna. Each rib of the proposed antenna contains five beams and two connectors, and a total of six ribs are deployed as one actuator to achieve lightness of the mechanism and high storage efficiency. Lopatin et al. [

7] proposed a deployment mechanism for a mesh antenna that utilizes the elastic strain energy of a composite tube generated in a folded rim in its stowed configuration. The rim was designed as a composite thin-walled toroidal shell with cut-outs. By applying three elastic hinges between each spoke and attaching them directly to the spoke, a lower resistance moment can be obtained compared with the deployment method utilizing a cable network. A 4 m antenna consisting of 16 carbon fiber-reinforced polymer (CFRP) spokes was designed to validate the proposed mechanism. The design parameters with minimum rim mass were derived using mathematical calculations and deployment simulations, and the design validity was demonstrated by showing that the deployment moment was twice the resistance moment. Chahat et al. [

8] proposed a Ka-band mesh antenna that can be stowed in a 1.5 U size for application on a 6 U CubeSat. A deployable mesh reflector was constructed using 30 ribs to achieve the target radiofrequency (RF) performance. The deployment mechanism utilizes the strain energy of springs. The selected spring produces 290 N of force when fully deployed and over 1000 N of force when stowed. Each hinge has a deployment limiter to minimize surface error, which can degrade the antenna RF performance. Urata et al. [

9] proposed a wrapped-rib type deployable parabolic mesh antenna for application in small SAR satellites in the 150 kg class. A total of 24 ribs, which are parabolic strips cut from a spring steel plate, are stowed around a central hub and then deployed based on the resilience of the ribs themselves. In mesh antennas, the shape of the reflection surface should be maintained as it is stowed and deployed to ensure the desired performance. As suggested in previous studies, research on various deployment mechanisms aimed at achieving antenna design objectives and considering the mesh characteristics is being actively conducted.

To achieve the various design objectives of the deployment mechanism, such as implementing reflector curvature, being lightweight, and simplifying mechanical systems, we focused on the superelastic effect of a shape memory alloy (SMA). SMAs have unique characteristics that depend on the phase-transformation temperature. The superelastic effect occurs when the operating environment temperature of an SMA exceeds the austenite finish temperature. Owing to the superelastic effect, they recover to their original shape without residual stress when the mechanical load is removed. Therefore, they exhibit much higher plastic deformation resistance than general metallic materials. In addition, they experience different loading paths that dissipate strain energy during loading and unloading, leading to high damping and fatigue durability [

10,

11,

12]. Superelastic SMA materials, with their attractive features, have been widely utilized in space applications such as gear wheels to enhance the micro-jitter isolation capability, launch vibration isolation systems, and solar array yokes designed to ensure high damping performance [

13,

14,

15,

16]. To date, regarding the deployable mesh antennas, only the study of Lim et al. [

17] has been presented implementing a 2 m diameter deployable mesh reflector antenna that utilizes the superelastic SMA and the hysteresis effect of a composite tape spring hinge. It has 24 primary reflector ribs, each fabricated from an SMA in the form of a rod. It is a hingeless passive-deployment mechanism that deploys with resilience owing to the superelastic effect, thus gaining advantages in terms of reliability and light weight. The secondary reflector is a two-stage deployment type with a tape spring hinge to maximize the storage efficiency and achieve an energy-dissipation capacity owing to the hysteresis characteristic when deployed. In the deployment test of the primary reflector deployment mechanism, an aluminum rib of the same size was plastically deformed, but the SMA rib recovered to its original shape. In addition, the free-vibration response of the SMA rib rapidly decreased owing to the high damping performance of the superelastic SMA after deployment. The above results shows that the application of a superelastic SMA in a deployable mesh antenna effectively ensures stable deployment. However, since the entire rib is a hingeless type composed of SMA rods, it can only be stowed in the range within the allowable maximum strain of SMA material, limiting the ability to reduce the packaging volume when the antenna size increases.

Nevertheless, the superelasticity of the SMA is a unique characteristic that makes it highly attractive for use in spaceborne antenna mechanisms, as mentioned above. Therefore, to implement larger-sized antenna mechanisms based on the superelasticity of the SMA material, a novel design strategy for the antenna deployment mechanism is essential, utilizing a different stowage and deployment concept for the primary reflector within the allowable strain of the SMA. This is a starting point of this study. In this paper, a superelastic SMA-based antenna mechanism is proposed for application to a 6 m deployable mesh reflector antenna. The stowage and deployment concept of the mesh antenna is established based on the specified condition that a single small satellite with the stowed antenna is loaded and launched by a small-class launch vehicle. This antenna mainly consists of deployable primary reflector with a superelastic SMA-based hinge mechanism and a fixed-type secondary reflector mast, where the rotary-type holding and release mechanism (HRM) is placed to release all ribs simultaneously by rotating in the in-plane direction when deployment initiates. In addition, rotary dampers are installed to control the deployment speed by connecting each rib to a wire. The SMA is applied to the hinge mechanism of each primary reflector rib and the rotary-type HRM as the deployment mechanism. The main feature of these mechanisms is utilization of the plate shape superelastic SMA. The shape of the SMA plate has the advantages of manufacturability, which make it easy to change the deployment torque created by the bent plate in stowed state by simply modifying the length, width, and thickness of the plate. Additionally, the hinge mechanism is simplified than the antennas using conventional hinges as it functions as a mechanical guide along the deployment direction of ribs owing to the high in-plane stiffness implemented by the shape of the SMA plate. This type of hinge mechanism made by SMA plate is firstly developed for the antenna mechanism in this study. In addition, considering the allowable maximum strain of the SMA material, feasible stowage and deployment angles for the rib segments were determined. Our strategy to accomplish this involves designing the secondary reflector mast to be fixed, and find the best height from the antenna base. The fixed-type secondary reflector mast makes it easier to secure dimensional accuracy compared to a deployable-type mast and is more reliable because no additional mechanism is required to release and deploy the reflector mast. Furthermore, by applying a superelastic SMA wire to the antenna in the circumferential direction, the curvature of the primary reflector is maintained without plastic deformation, even for large deformations, owing to the stowed and deployed configurations. We performed a repeated deployment test on a specimen of the superelastic SMA-based hinge mechanism to verify its feasibility. The effectiveness of the proposed mechanism design was verified through a repeated deployment test of the antenna system and a comparison of the reflection surface root mean square (RMS) error measurements before and after these tests. In addition, the space mission applicability of the antenna with the proposed mechanism was evaluated by calculating the expected antenna gain using the surface RMS error data obtained from repeated deployment tests.

3. Specimen-Level Deployment Test of the Superelastic SMA-Based Hinge Mechanism

To verify the feasibility of the proposed superelastic SMA-based hinge mechanism, we performed a repeated deployment test was performed at room temperature.

Figure 10 shows the setup of the repeated deployment test. The test setup consisted of a specimen of the superelastic SMA-based hinge mechanism, an acceleration sensor, and a laser displacement sensor. To facilitate a laboratory testing environment, we simplified the setup using a second rib shorter than the first rib. The primary focus of the deployment test, the hinge mechanism, was created from materials identical to those used in actual applications, including Al-6061, Delrin, and SMA. The rib was manufactured as a dummy capable of simulating mechanical characteristics by applying a generic plastic material instead of CFRP. An acceleration sensor was attached to the tip of the rib to measure the latch shock when deployed. The laser displacement sensor measured the change in position resulting from repeated deployments based on the deployment configuration of the rib. The data were used to determine whether the SMA plates underwent plastic deformation. Each deployment test was configured for deployment under the same stowage conditions using a pin fixation method. In the test setup, which excluded the 0 g device and hinge pin connecting each hinge component, the rotating part experienced torsion owing to its own weight. Consequently, the test was performed in the worst-case scenario, resulting in high friction compared with actual antenna applications. In addition, the maximum deflection of the rib specimen due to torsion was measured at 1.8 mm, which was used to establish the initial position requirements for the SMA plate at the point of complete deployment during the tests.

Three SMA plate specimens with thicknesses of 0.8 mm (Case 1), 1.2 mm (Case 2), and 1.6 mm (Case 3) were manufactured, and deployment tests were performed for each specimen. The number of repetitions for each case was selected as 30 based on the rules of the European Cooperation for Space Standardization (ECSS) [

23].

Figure 11 shows the latch shock measurement results for Cases 1 and 3. As the thickness of the SMA plate specimens increased, a higher resilience was exerted, resulting in latch shock of 15.69 g for Case 1, 18.04 g for Case 2, and 23.79 g for Case 3. However, the damping ratios calculated for each case based on the acquired acceleration responses were 0.12, 0.202, and 0.209, respectively, demonstrating that the damping ratio increased with the specimen thickness. This represents the damping characteristics obtained owing to the energy dissipation by the superelastic effect that occurs as the SMA plate recovers to its original shape under unloading at displacements exceeding the critical stress point. This is considered effective in reducing residual vibrations immediately after deployment.

Figure 12 shows the results of the repeated deployment tests. In Cases 2 and 3, the plastic deformation of the specimens occurred during the fourteenth and seventh deployment tests, respectively, as the initial displacement exceeded 1.8 mm. However, in Case 1, the specimen recovered to its original shape without plastic deformation after 30 repeated tests. The visual inspection results were consistent with the initial displacement measurement results: Case 1 exhibited no plastic deformation, whereas Cases 2 and 3 experienced deformations of approximately 5° and 10°, respectively. This indicated that an increase in the thickness of the specimens leads to a higher stress on the plate under the same deformation, which was considered to have caused the plastic deformation in Cases 2 and 3. The repeated deployment test results verified that the proposed mechanism had a relatively low latch shock, and its feasibility was secured when applying Case 1, which satisfied the requirements of repeated deployment.

A deployment analysis was performed to evaluate the reduction performance of the latch shock based on the energy dissipation caused by the hysteresis characteristics of the proposed hinge mechanism.

Table 3 lists the results of the deployment analysis with and without hysteresis. The analytical model was implemented under the same conditions as the test setup for Case 1 and was validated through repeated deployment testing. The area inside the hysteresis curve, represented on the strain (

)–stress (

) plot derived from the analysis applying the mechanical properties of the superelastic SMA, was calculated using Equation (4). This area signifies the energy dissipation (

) during the deployment process, which was calculated to be 8.7 J/m

3.

The results of the deployment analysis indicated that a latch shock of 15.7 g was generated when the hysteresis characteristic was applied, which was similar to the test results. In contrast, a higher latch shock (52.4 g) was observed when the hysteresis characteristics were not applied, which was an increase of 3.3 times. The analysis conclusively demonstrated that the proposed mechanism can achieve high damping characteristics that are unattainable with conventional metallic materials. Consequently, the superelastic SMA-based mechanism effectively reduces latch shock and contributes to the development of smaller and lighter components.

5. System-Level Deployment Test of the Antenna Development Model

To verify the design effectiveness of the antenna mechanisms at the system level, we performed repeated deployment tests and surface error measurement on the antenna development model in a room-temperature environment under 1 g conditions.

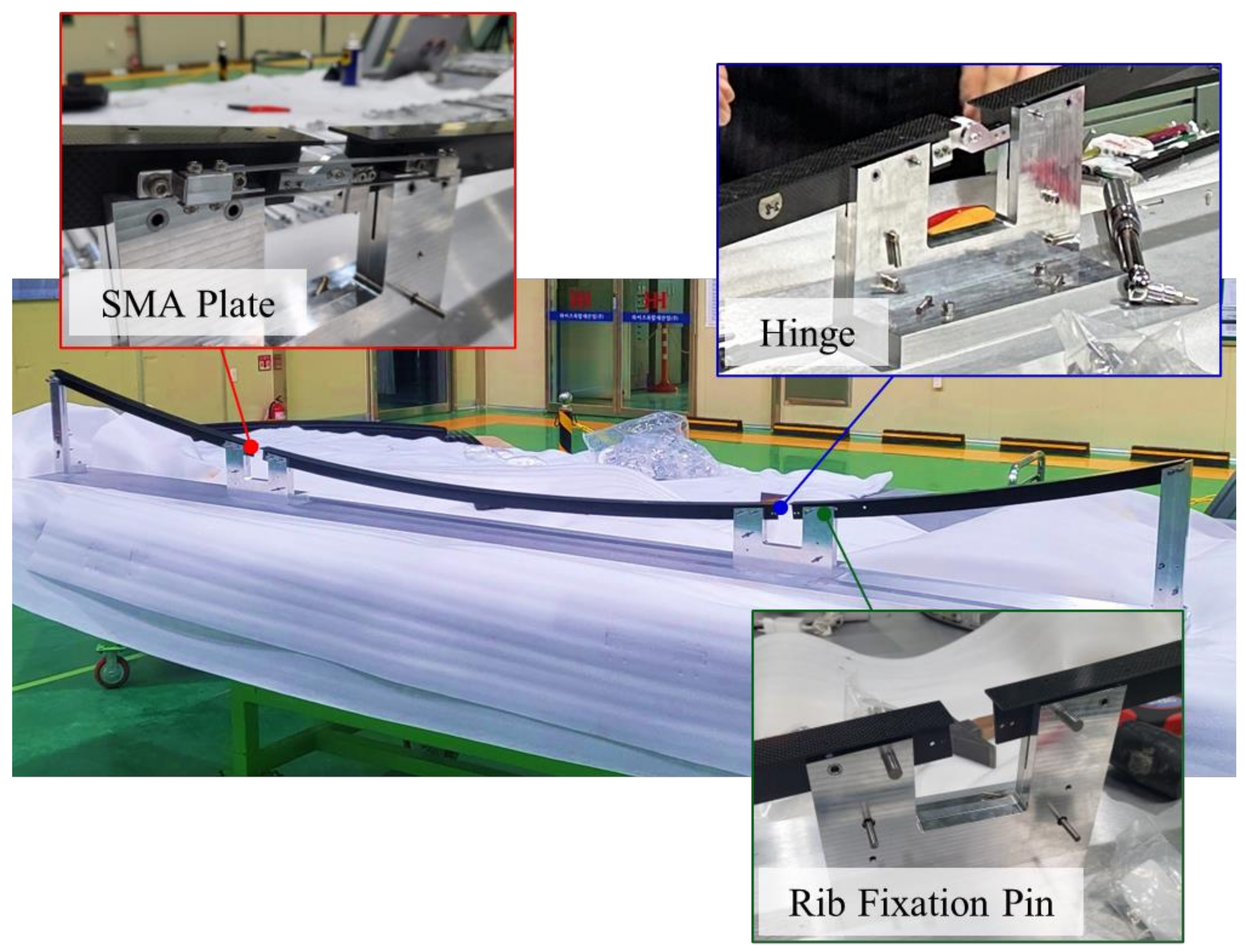

Figure 17 shows the repeated deployment test setup of the antenna development model system. During the entire deployment process, excluding the release of the launch lock device, the sequence proceeded with the release of the rotary-type HRM, simultaneous deployment of the first and second ribs, speed control of the deployment using the rotary damper, and deployment completion. For the rotary-type HRM, the pin-puller mechanism was simulated using a hot-wire cutting method to sever the nylon wire.

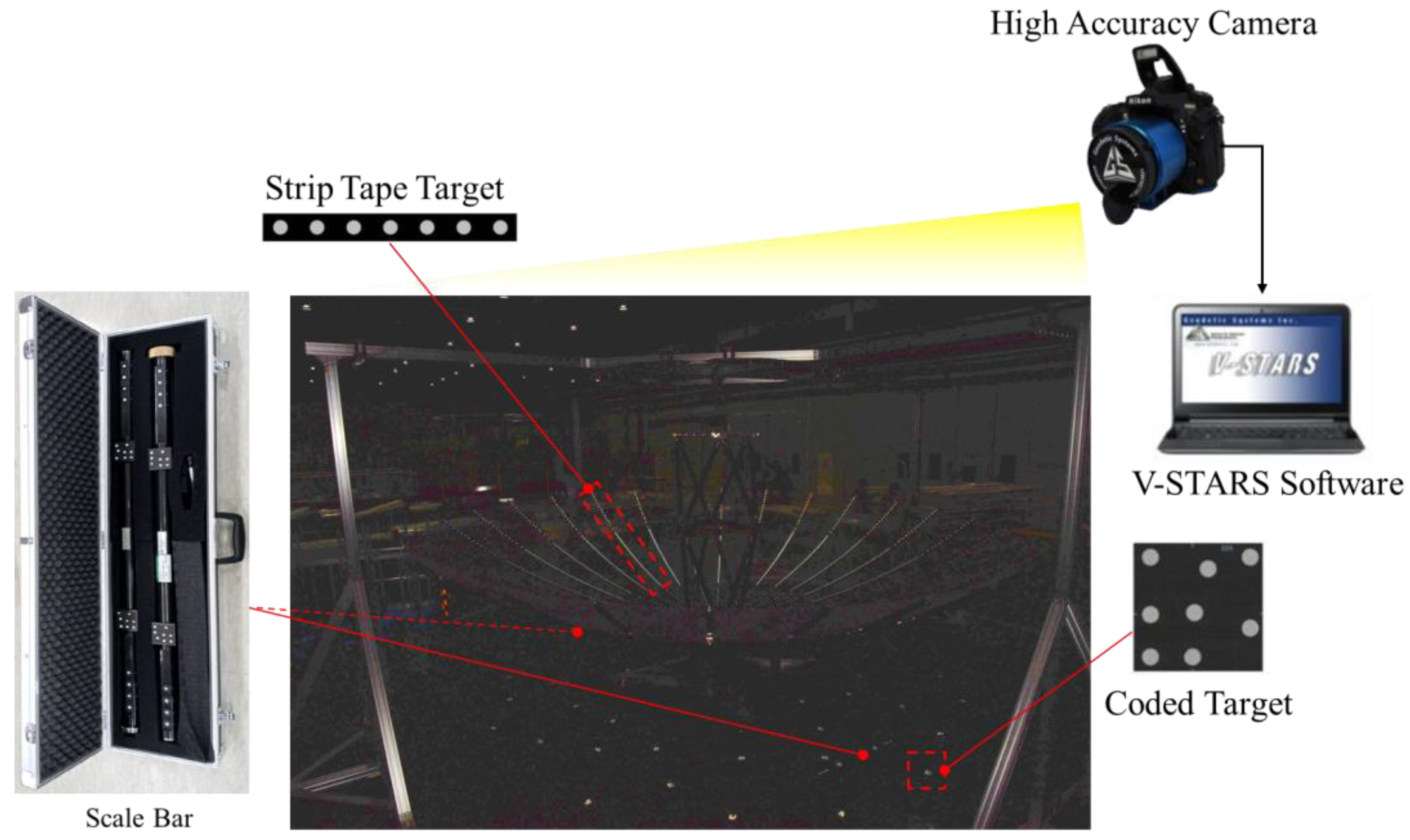

Figure 18 shows the surface RMS error measurement process of the primary reflector. To scan the reflection surface, a digital photogrammetry technique was used, with 78 tape targets for each rib, for a total of 2184 tape targets, which were attached to the surface of the primary reflector ribs. Two scale bars and 45 coded targets were placed on the floor of the test facility to determine the position and angle of the camera in 3D space. Finally, 30 photographs per deployment test from various angles were taken with a high accuracy digital camera, and surface RMS error measurement results for the ideal design surface was obtained through V-STARS software from Geodetic Systems, Inc [

24]. The surface RMS error requirement for repeated deployments was set to within 1 mm, based on the wavelength of the S-band.

Figure 19 shows the deployment sequence of the mesh antenna during the deployment tests, with three repetitions performed to verify the functionality. During the test, we confirmed that the rotary-type HRM functioned properly as the second ribs were released immediately after the nylon wire was cut. Visual inspection was performed to assess any damage to the components of the antenna mechanisms before and after the repeated deployment tests. We verified that deployment occurred without any performance degradation or plastic deformation.

Figure 20 shows the RMS error analysis results obtained after the repeated deployment tests. The RMS error of the surface was measured for an ideal curved surface with a focal length of 2100 mm. The surface RMS error after the assembly was 11.42 mm, and the maximum difference of surface RMS errors before and after the test under repeated deployment were 10.51 mm. The tendency for high surface RMS errors compared with the designed surface was caused by the application of readily available commercial components to realize the mechanical shape of the antenna development model, except for the superelastic SMA based mechanism, contributed to the high manufacturing and assembly errors. The application of commercial rotary dampers with a wide error margin of ±26% resulted in excessive damping torques relative to the designed deployment torque and the dummy mesh made of silver nano-coated Teflon with a 16% elongation, which is easily deformed. The use of commercial composites with lower stiffness and strength compared to space-grade materials for the primary and secondary reflector structures increased manufacturing and cumulative assembly errors. In addition, the absence of mechanical ground support equipment such as a test platform, which can be leveled depending on the flatness of the test facility and jigs that can maintain alignment during antenna system assembly contributed to the increase in surface error. Despite the high numerical surface error compared with the ideal design surface owing to the aforementioned factors, the surface error distribution on the primary reflector exhibited a consistent pattern following repeated deployments. The difference in surface RMS error before and after testing was a maximum of 0.91 mm, corresponding to an error rate of 8.3%, which satisfied the testing requirements and thus confirmed the effectiveness of the antenna mechanisms.

Table 4 lists antenna gain calculated results based on measured surface RMS error. The gain was calculated by substituting the surface RMS error data obtained from the repeated deployment test using Microwave Studio, an antenna simulation software from Dassault Systèmes [

25]. The minimum gain was calculated to be 42.8 dBi, and it was confirmed that the 6 m mesh reflector antenna with the proposed mechanism can be utilized as an S-band antenna, which is mainly applied in satellite communication systems. However, the allowable temperature range of superelastic SMA is −20~80 °C [

18]. It is believed that the space application of the proposed mechanisms is possible if the operating temperature requirements are set at the design stage and thermal design is applied.

6. Conclusions

In this study, we designed and experimentally verified the mechanisms for a 6 m parabolic deployable mesh reflector antenna based on a superelastic SMA. The SMA was applied to the hinge mechanism of each primary reflector rib and a rotary-type HRM as a deployment mechanism. Additionally, by applying an SMA wire to the outside of the antenna, the curvature of the primary reflector was maintained without plastic deformation, even for large deformations owing to the stowed and deployed configurations. When fastening the mesh, a clamping-type mesh fastening technique was presented using a thin plate and push-button rivets. This technique is effective in preventing tearing of the mesh, maintaining the curvature, and easing the fastening process compared with the commonly applied stitching method.

Repeated deployment tests were performed on the superelastic SMA-based hinge mechanism specimen to verify the feasibility of the proposed mechanism. The results of the test demonstrated that deployment without plastic deformation was possible even after 30 repeated deployments when applying a plate with a thickness of 0.8 mm, as per the design concept. Furthermore, an increase in the thickness of the specimens resulted in enhanced damping characteristics, which can be attributed to the superelastic effect of the SMA. This tendency is expected to effectively reduce the residual vibrations of the reflection surface after deployment.

Finally, a development model of the 6 m deployable mesh reflector antenna with the proposed antenna mechanisms was manufactured, and repeated deployment tests were performed on the antenna development model to verify the design effectiveness of the antenna mechanisms at the system level. A total of three repetitions were performed to verify the functionality, and the surface precision was verified through an RMS error analysis. The results of the deployment test showed that the primary reflector satisfied the testing requirements, confirming the effectiveness of the antenna mechanism. In addition, the surface RMS error data obtained from repeated deployment tests were substituted to calculate the expected antenna gain. From the results, it is believed that the space application of the proposed antenna mechanism is feasible if the operating temperature requirements and thermal design for the allowable temperature range of the superelastic SMA are established.