Damage Detection and Localization Methodology Based on Strain Measurements and Finite Element Analysis: Structural Health Monitoring in the Context of Industry 4.0

Abstract

1. Introduction

2. SHM Context Within the Framework of I4.0

2.1. Modern SHM Applications

2.2. SHM and I4.0 within Industrial Processes

2.3. Sensor Integration and IoT for SHM

2.4. Advanced Analytics for SHM

3. Materials and Methods

3.1. Descriptive Methods

- Recent historical data are crucial for this analysis as it forms the foundation of the model. The model aims to identify trends based on recent behavior or events. If the dataset includes outdated historical data, the model may struggle to accurately simulate and classify current events. Therefore, it is essential to purge older data and retain only recent information that reflects current trends.

- Nonexistence of an objective variable: As previously mentioned, these models focus on understanding the inherent structure of the data rather than making predictions. The model aims to describe phenomena effectively rather than optimizing or predicting a specific numerical value.

3.2. Predictive Methods

- Historical Data: the dataset may include older historical data compared to descriptive methods, while the data describe the same event, and the age of the data—whether from 5 years ago or 20 years ago—does not matter as long as the dataset is labeled with the expected results.

- Existence of an Objective Variable: The model must predict a specific result, which can be numerical or categorical. If categorical, it is typically represented by a binary dummy variable.

- Relation Between Predictive and Result Variables: The dataset needs to be cleaned and analyzed to select variables that have a direct relationship with the objective variable. This requirement distinguishes predictive methods from descriptive methods, which do not need this level of variable selection.

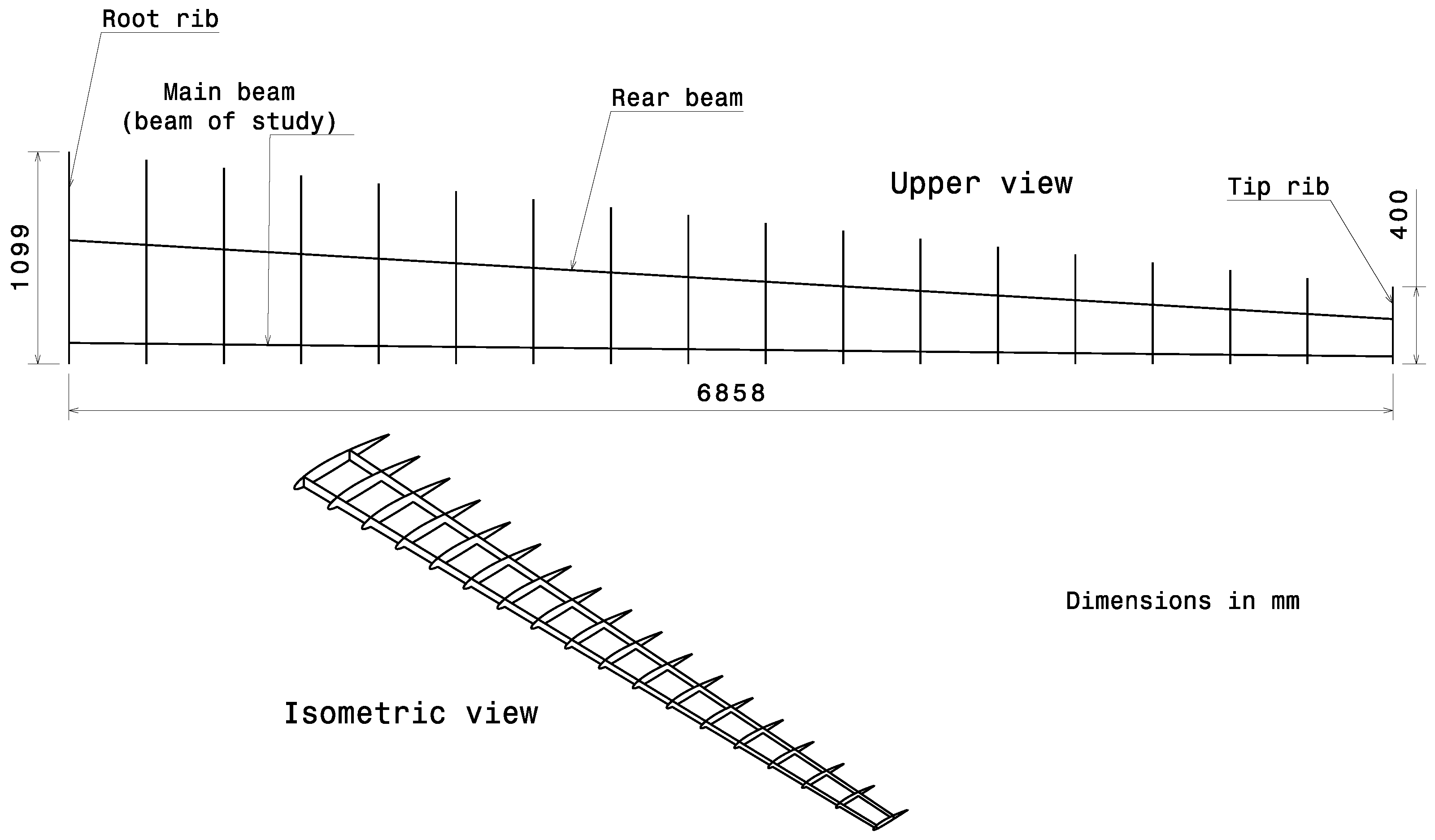

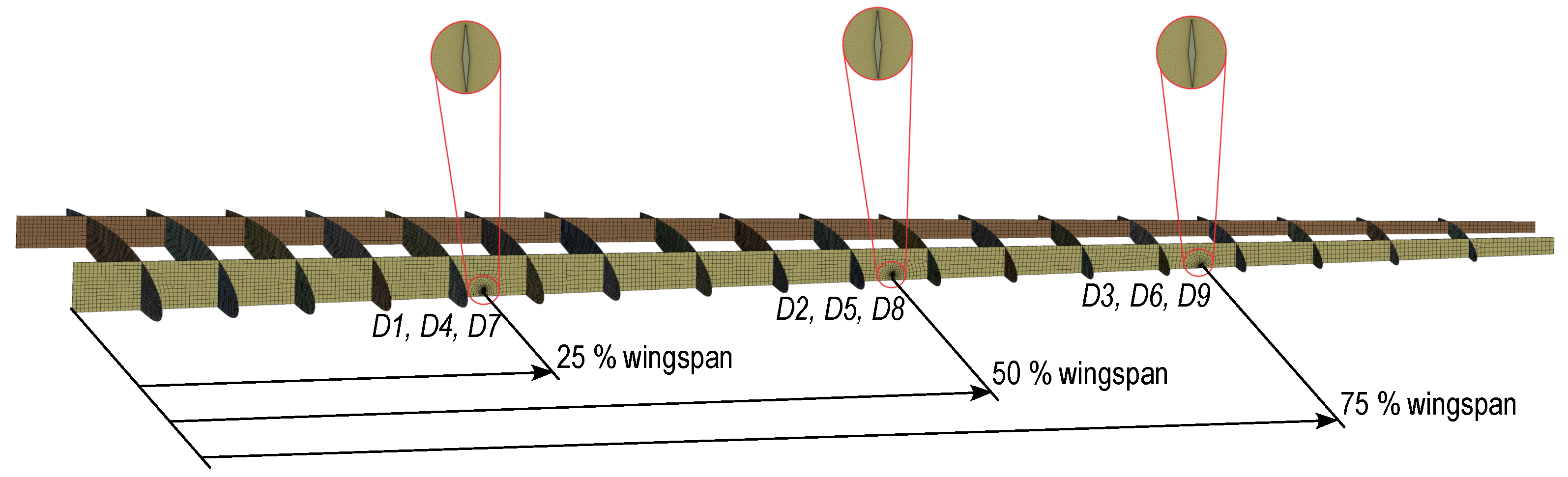

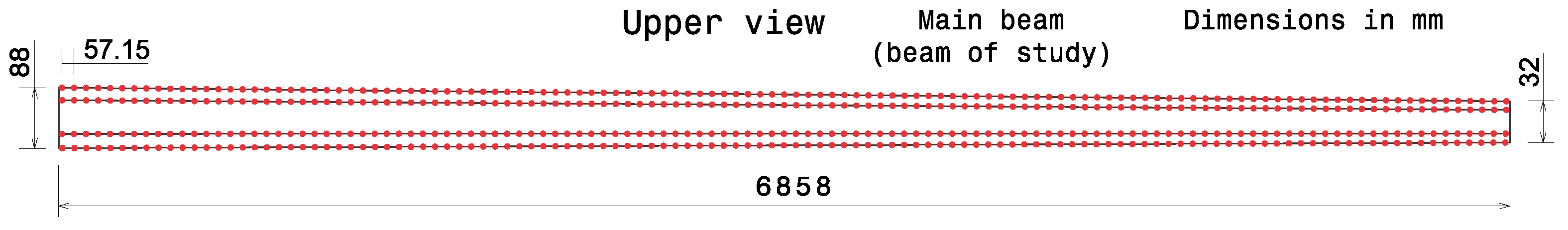

3.3. Virtual Testing Setup

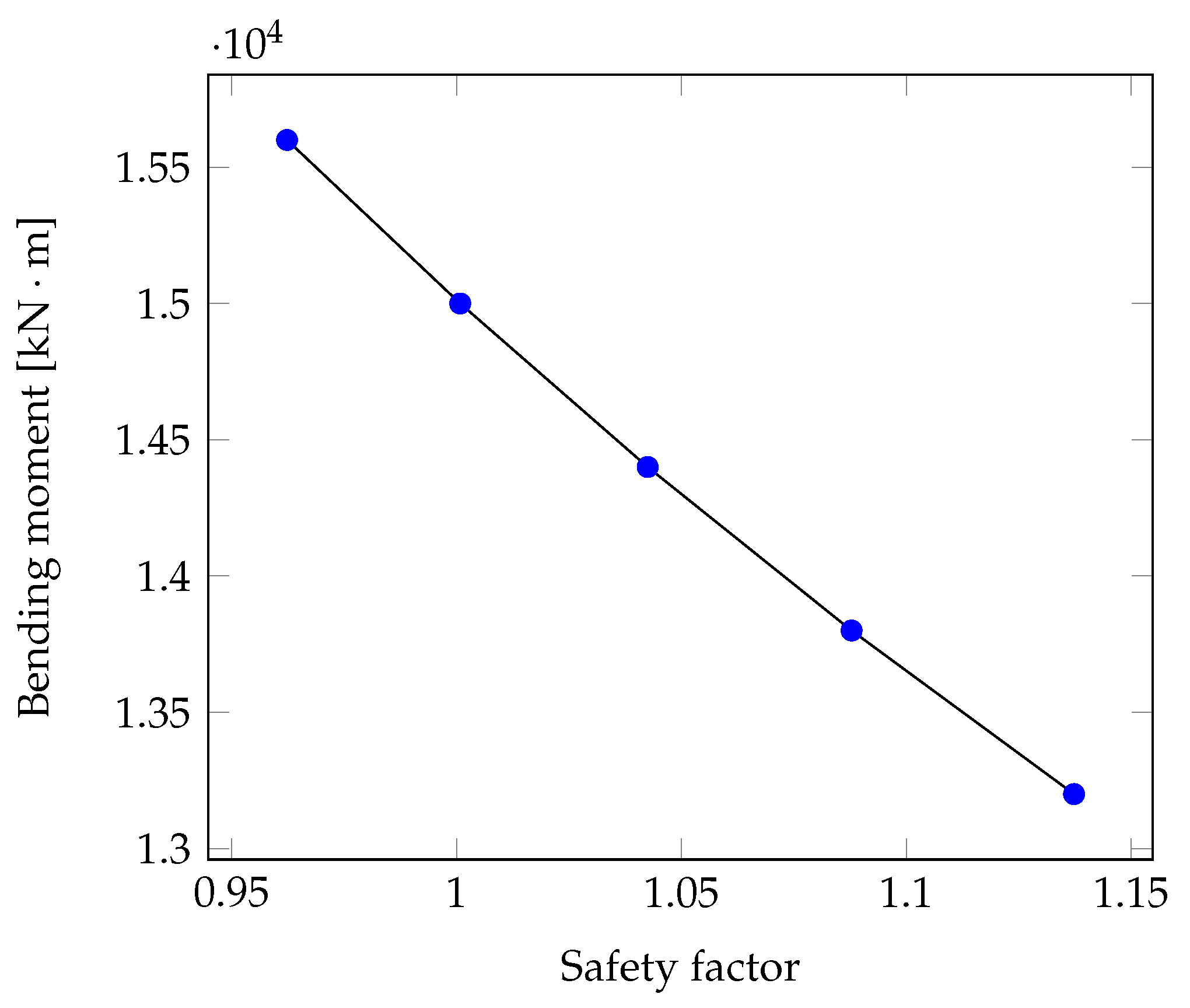

3.4. Validation model

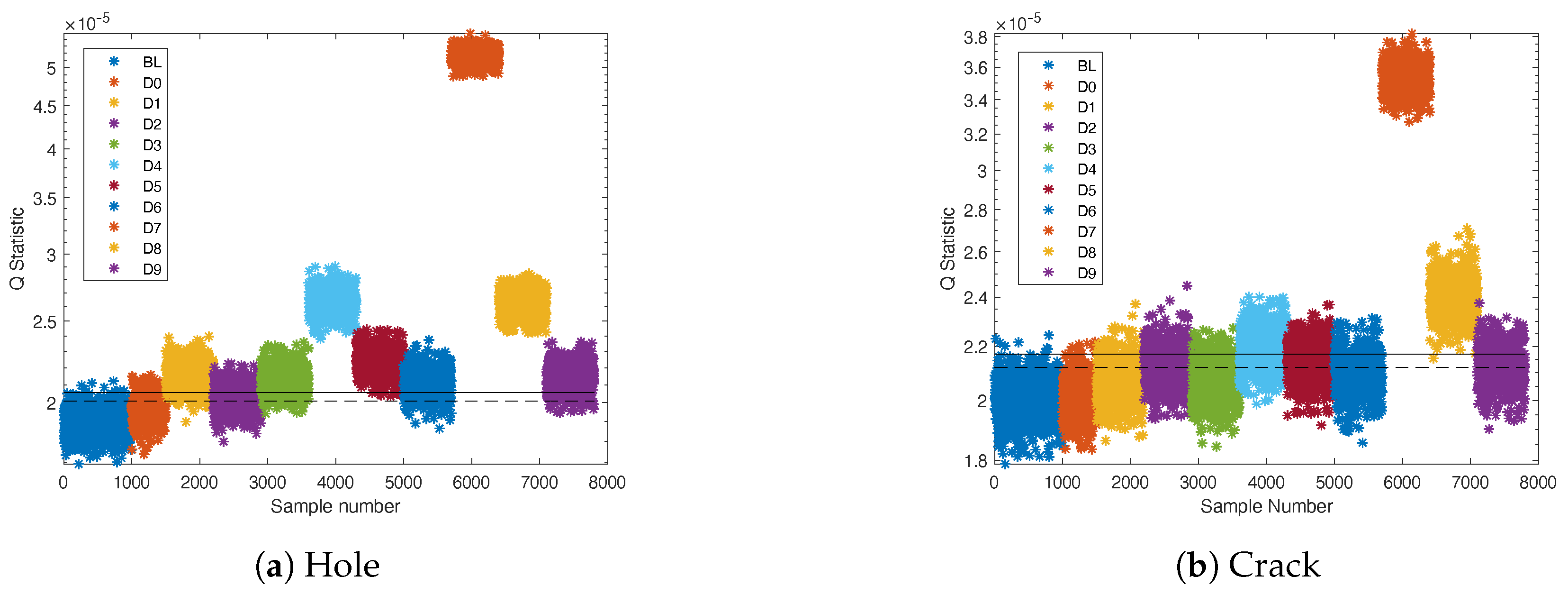

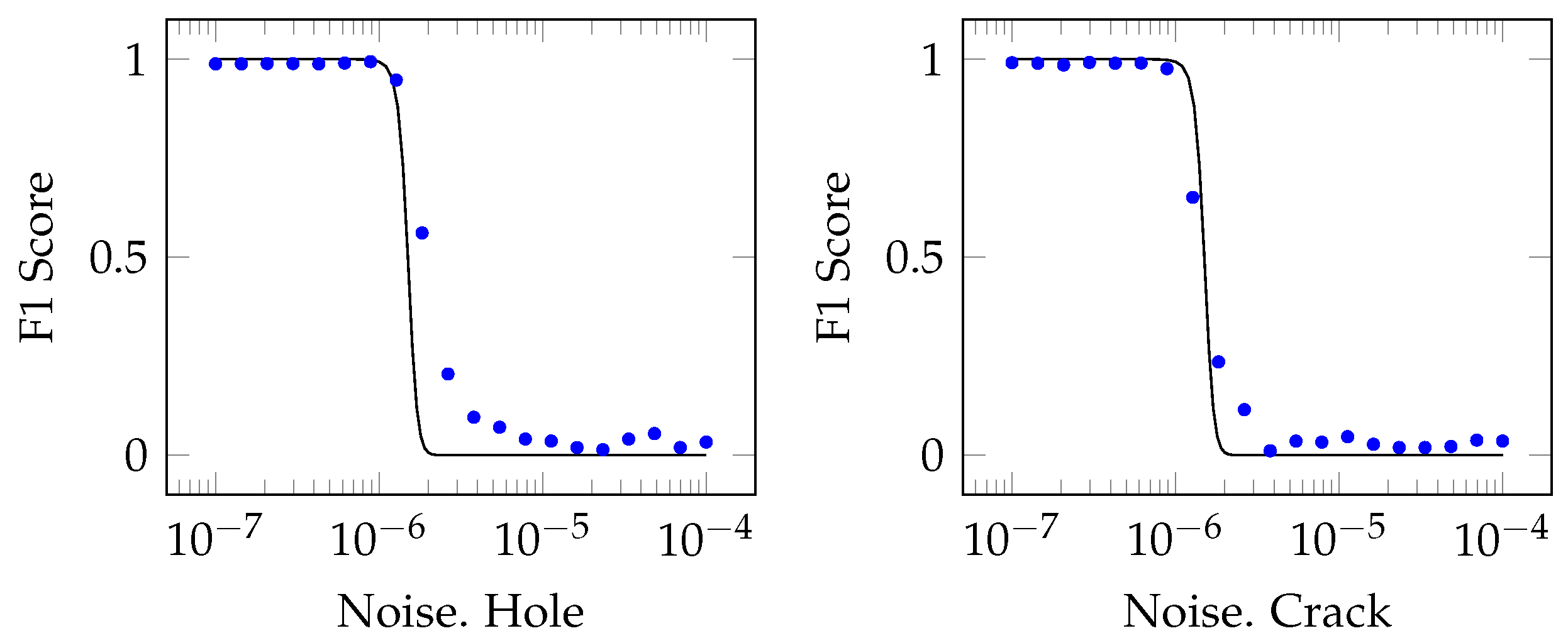

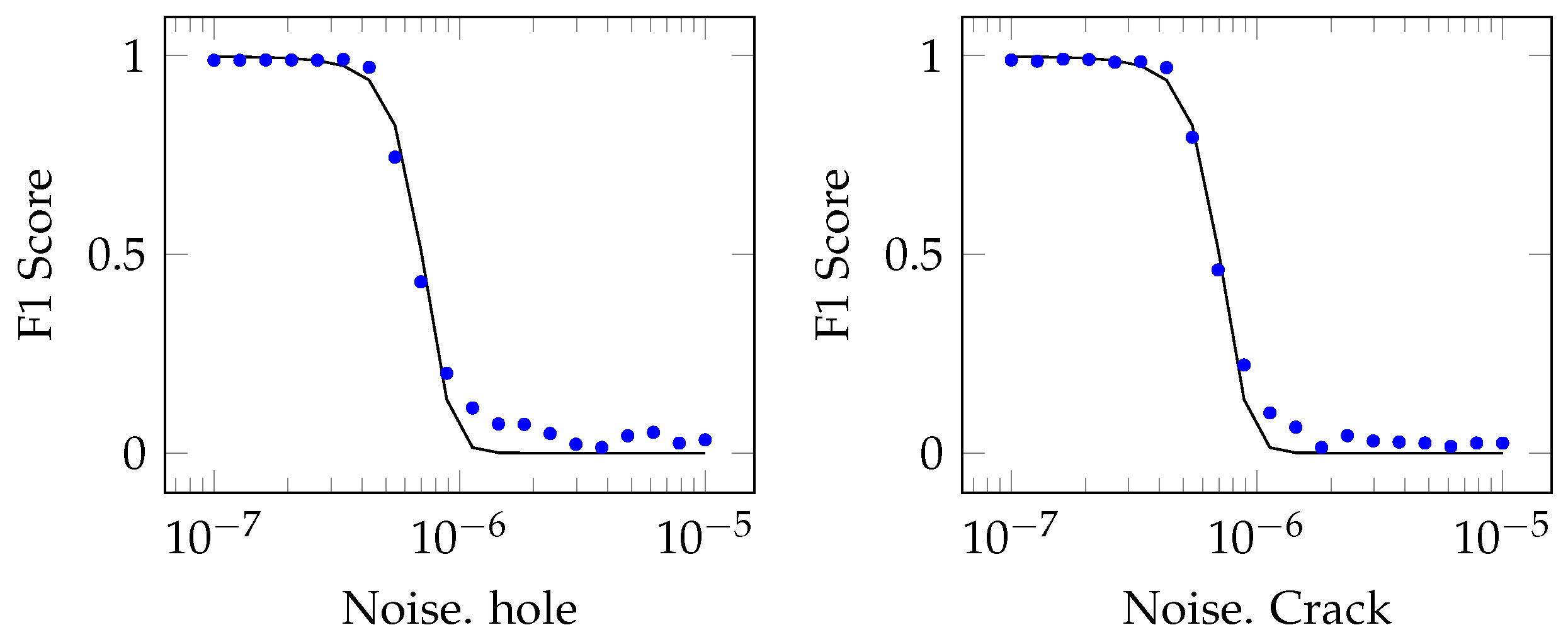

3.5. Damage Detection Methodology

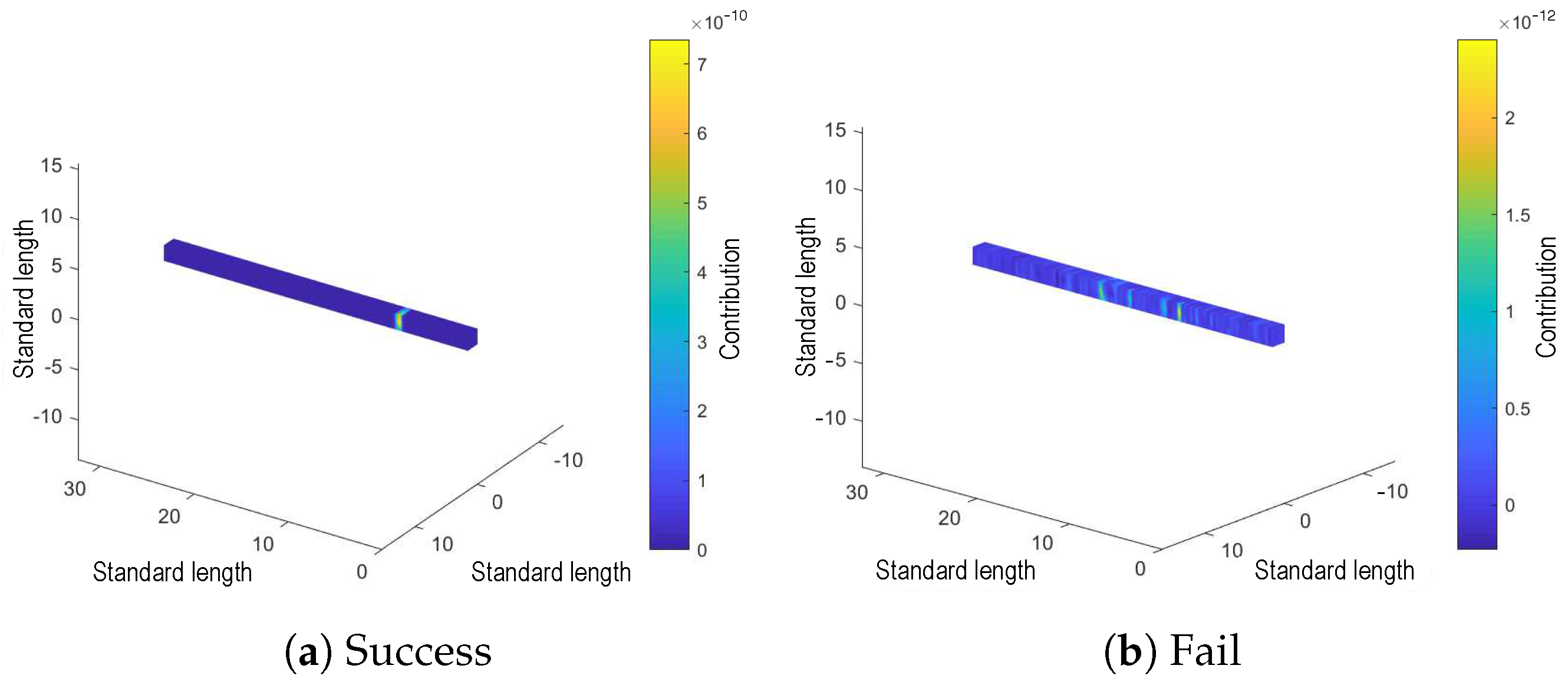

3.6. Damage Localization Methodology

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BL | Baseline |

| DOF | Degrees of Freedom |

| FBG | Fiber Bragg Grating |

| FEA | Finite Element Analysis |

| FOS | Fiber Optic Sensors |

| KNN | K-Nearest Neighbors |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things (IoT) |

| ML | Machine Learning |

| NDT | Non-Destructive Test |

| PCA | Principal Component Analysis |

| ROC | Receiver Operating Characteristic |

| SDG | Sustainable Development Goal |

| SHM | Structural Health Monitoring |

| SVMs | Support Vector Machines |

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2023. Available online: https://sdgs.un.org/2030agenda (accessed on 15 October 2023).

- United Nations. The Sustainable Development Goals Report 2023; Department of Economic and Social Affairs: New York, NY, USA, 2023; Available online: https://unstats.un.org/sdgs/report/2023/ (accessed on 15 December 2023).

- Cárdenas-Robledo, L.A.; Hernández-Uribe, O.; Reta, C.; Cantoral-Ceballos, J.A. Extended reality applications in industry 4.0—A systematic literature review. Telemat. Inform. 2022, 73, 101863. [Google Scholar] [CrossRef]

- Zonta, T.; da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Shaheen, B.W.; Németh, I. Integration of Maintenance Management System Functions with Industry 4.0 Technologies and Features—A Review. Processes 2022, 10, 2173. [Google Scholar] [CrossRef]

- Mishra, M. Machine learning techniques for structural health monitoring of heritage buildings: A state-of-the-art review and case studies. J. Cult. Herit. 2021, 47, 227–245. [Google Scholar] [CrossRef]

- Ahmed, O.; Wang, X.; Tran, M.V.; Ismadi, M.Z. Advancements in fiber-reinforced polymer composite materials damage detection methods: Towards achieving energy-efficient SHM systems. Compos. Part B Eng. 2021, 223, 109136. [Google Scholar] [CrossRef]

- Zaparoli Cunha, B.; Droz, C.; Zine, A.M.; Foulard, S.; Ichchou, M. A review of machine learning methods applied to structural dynamics and vibroacoustic. Mech. Syst. Signal Process. 2023, 200, 110535. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef]

- Abouzeida, E.; Quinones, V.; Gowayed, Y.; Soobramaney, P.; Flowers, G.; Black, R.J.; Costa, J.M.; Faridian, F.; Moslehi, B. Design, manufacture and testing of an FBG-instrumented composite wing. AIP Conf. Proc. 2014, 1581, 1141–1148. [Google Scholar] [CrossRef]

- Han, J. Data Mining, 3rd ed.; Morgan Kaufmann Series in Data Management Systems; Morgan Kaufmann/Elsevier: Waltham, MA, USA, 2012. [Google Scholar]

- Tapeh, A.T.G.; Naser, M.Z. Artificial Intelligence, Machine Learning, and Deep Learning in Structural Engineering: A Scientometrics Review of Trends and Best Practices. Arch. Comput. Methods Eng. 2023, 30, 115–159. [Google Scholar] [CrossRef]

- Khazaee, M.; Derian, P.; Mouraud, A. A comprehensive study on Structural Health Monitoring (SHM) of wind turbine blades by instrumenting tower using machine learning methods. Renew. Energy 2022, 199, 1568–1579. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Glisic, B.; Inaudi, D. Fibre Optic Methods for Structural Health Monitoring; John Wiley & Sons: Chichester, UK, 2007. [Google Scholar]

- Güemes, A.; Fernandez-Lopez, A.; García-Ramírez, J.; Reyes-Perez, M.E.; Zurita, F.C. Simulation Tools for a Fiber-Optic Based Structural Health Monitoring System. Trans. Nanjing Univ. Aeronaut. Astronaut. 2018, 35, 219–225. [Google Scholar] [CrossRef]

- Meindl, B.; Ayala, N.F.; Mendonça, J.; Frank, A.G. The four smarts of Industry 4.0: Evolution of ten years of research and future perspectives. Technol. Forecast. Soc. Chang. 2021, 168, 120784. [Google Scholar] [CrossRef]

- Imoize, A.L.; Adedeji, O.; Tandiya, N.; Shetty, S. 6G Enabled Smart Infrastructure for Sustainable Society: Opportunities, Challenges, and Research Roadmap. Sensors 2021, 21, 1709. [Google Scholar] [CrossRef]

- De Simone, M.C.; Lorusso, A.; Santaniello, D. Predictive maintenance and Structural Health Monitoring via IoT system. In Proceedings of the 2022 IEEE Workshop on Complexity in Engineering (COMPENG), Florence, Italy, 18–20 July 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Huang, C.; Bu, S.; Lee, H.H.; Chan, C.H.; Kong, S.W.; Yung, W.K. Prognostics and health management for predictive maintenance: A review. J. Manuf. Syst. 2024, 75, 78–101. [Google Scholar] [CrossRef]

- Chen, Q.; Cao, J.; Zhu, S. Data-Driven Monitoring and Predictive Maintenance for Engineering Structures: Technologies, Implementation Challenges, and Future Directions. IEEE Internet Things J. 2023, 10, 14527–14551. [Google Scholar] [CrossRef]

- Ventura, R.; Maternini, G.; Barabino, B. Traffic Hazards on Main Road’s Bridges: Real-Time Estimating and Managing the Overload Risk. IEEE Trans. Intell. Transp. Syst. 2024, 15, 12239–12255. [Google Scholar] [CrossRef]

- Yusof, Y.B.; Ping, T.H.; Isa, F.B.M. Strengthening Smart Grids Through Security Measures: A Focus on Real-Time Monitoring, Redundancy, and Cross-Sector Collaboration. Int. J. Intell. Autom. Comput. 2023, 6, 14–36. [Google Scholar]

- Worden, K.; Cross, E. On switching response surface models, with applications to the structural health monitoring of bridges. Mech. Syst. Signal Process. 2018, 98, 139–156. [Google Scholar] [CrossRef]

- An, Y.; Chatzi, E.; Sim, S.; Laflamme, S.; Blachowski, B.; Ou, J. Recent progress and future trends on damage identification methods for bridge structures. Struct. Control Health Monit. 2019, 26, e2416. [Google Scholar] [CrossRef]

- Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R. Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors 2019, 19, 3964. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.; El-Borgi, S.; Patil, D.; Song, G. Inspection and monitoring systems subsea pipelines: A review paper. Struct. Health Monit. 2019, 19, 606–645. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Zagrai, A. Damage Detection in Thin Plates and Aerospace Structures with the Electro-Mechanical Impedance Method. Struct. Health Monit. 2005, 4, 99–118. [Google Scholar] [CrossRef]

- Winklberger, M.; Kralovec, C.; Humer, C.; Heftberger, P.; Schagerl, M. Crack Identification in Necked Double Shear Lugs by Means of the Electro-Mechanical Impedance Method. Sensors 2020, 21, 44. [Google Scholar] [CrossRef]

- Bergmayr, T.; Kralovec, C.; Schagerl, M. Vibration-Based Thermal Health Monitoring for Face Layer Debonding Detection in Aerospace Sandwich Structures. Appl. Sci. 2020, 11, 211. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural Health Monitoring for Advanced Composite Structures: A Review. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Hunt, S.R.; Hebden, I.G. Validation of the Eurofighter Typhoon structural health and usage monitoring system. Smart Mater. Struct. 2001, 10, 497–503. [Google Scholar] [CrossRef]

- Chen, C.; Wu, Q.; Xiong, K.; Zhai, H.; Yoshikawa, N.; Wang, R. Hybrid Temperature and Stress Monitoring of Woven Fabric Thermoplastic Composite Using Fiber Bragg Grating Based Sensing Technique. Sensors 2020, 20, 3081. [Google Scholar] [CrossRef]

- Morozov, O.G. Fiber Bragg Grating-Based Sensors and Systems. Sensors 2021, 21, 8225. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, T.; Lu, J.; Lin, R.; Chen, C.; He, Z.; Cui, S.; Liu, Z.; Wang, X.; Liu, B.; et al. Static and ultrasonic structural health monitoring of full-size aerospace multi-function capsule using FBG strain arrays and PSFBG acoustic emission sensors. Opt. Fiber Technol. 2023, 78, 103316. [Google Scholar] [CrossRef]

- Braunfelds, J.; Senkans, U.; Skels, P.; Janeliukstis, R.; Salgals, T.; Redka, D.; Lyashuk, I.; Porins, J.; Spolitis, S.; Haritonovs, V.; et al. FBG-Based Sensing for Structural Health Monitoring of Road Infrastructure. J. Sens. 2021, 2021, 8850368. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Tseng, M.L.; Thuy-Tran, T.P.; Ha, H.M.; Bui, T.D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2019, 50, 92–111. [Google Scholar] [CrossRef]

- Khan, S.M.; Atamturktur, S.; Chowdhury, M.; Rahman, M. Integration of Structural Health Monitoring and Intelligent Transportation Systems for Bridge Condition Assessment: Current Status and Future Direction. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2107–2122. [Google Scholar] [CrossRef]

- Honghong, S.; Gang, Y.; Haijiang, L.; Tian, Z.; Annan, J. Digital twin enhanced BIM to shape full life cycle digital transformation for bridge engineering. Autom. Constr. 2023, 147, 104736. [Google Scholar] [CrossRef]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Gardner, L. Metal additive manufacturing in structural engineering—Review, advances, opportunities and outlook. Structures 2023, 47, 2178–2193. [Google Scholar] [CrossRef]

- Segura, P.; Lobato-Calleros, O.; Ramírez-Serrano, A.; Soria, I. Human–robot collaborative systems: Structural components for current manufacturing applications. Adv. Ind. Manuf. Eng. 2021, 3, 100060. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Sagoe-Crentsil, K.; Zhang, J.; Duan, W. Intelligent robotic systems for structural health monitoring: Applications and future trends. Autom. Constr. 2022, 139, 104273. [Google Scholar] [CrossRef]

- Gordan, M.; Sabbagh-Yazdi, S.R.; Ismail, Z.; Ghaedi, K.; Carroll, P.; McCrum, D.; Samali, B. State-of-the-art review on advancements of data mining in structural health monitoring. Measurement 2022, 193, 110939. [Google Scholar] [CrossRef]

- Maes, K.; Van Meerbeeck, L.; Reynders, E.; Lombaert, G. Validation of vibration-based structural health monitoring on retrofitted railway bridge KW51. Mech. Syst. Signal Process. 2022, 165, 108380. [Google Scholar] [CrossRef]

- Chadha, M.; Ramancha, M.K.; Vega, M.A.; Conte, J.P.; Todd, M.D. The modeling of risk perception in the use of structural health monitoring information for optimal maintenance decisions. Reliab. Eng. Syst. Saf. 2023, 229, 108845. [Google Scholar] [CrossRef]

- Orcesi, A.D.; Frangopol, D.M. Optimization of bridge maintenance strategies based on structural health monitoring information. Struct. Saf. 2011, 33, 26–41. [Google Scholar] [CrossRef]

- Ndinga Okina, S.; Taillandier, F.; Ahouet, L.; Hoang, Q.A.; Breysse, D.; Louzolo-Kimbembe, P. Using Conceptual Graph modeling and inference to support the assessment and monitoring of bridge structural health. Eng. Appl. Artif. Intell. 2023, 125, 106665. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R.; Al-Ameri, R.; Abawajy, J.; Thwala, W.D. Real-time structural health monitoring for concrete beams: A cost-effective ‘Industry 4.0’ solution using piezo sensors. Int. J. Build. Pathol. Adapt. 2020, 39, 283–311. [Google Scholar] [CrossRef]

- Goyal, D.; Pabla, B.S. The Vibration Monitoring Methods and Signal Processing Techniques for Structural Health Monitoring: A Review. Arch. Comput. Methods Eng. 2015, 23, 585–594. [Google Scholar] [CrossRef]

- Katsikeros, C.; Labeas, G. Development and validation of a strain-based Structural Health Monitoring system. Mech. Syst. Signal Process. 2009, 23, 372–383. [Google Scholar] [CrossRef]

- Dutta, C.; Kumar, J.; Das, T.K.; Sagar, S.P. Recent Advancements in the Development of Sensors for the Structural Health Monitoring (SHM) at High-Temperature Environment: A Review. IEEE Sens. J. 2021, 21, 15904–15916. [Google Scholar] [CrossRef]

- Fu, T.S.; Ghosh, A.; Johnson, E.A.; Krishnamachari, B. Energy-efficient deployment strategies in structural health monitoring using wireless sensor networks. Struct. Control Health Monit. 2012, 20, 971–986. [Google Scholar] [CrossRef]

- Dong, T.; Haftka, R.T.; Kim, N.H. Advantages of Condition-Based Maintenance over Scheduled Maintenance Using Structural Health Monitoring System. In Reliability and Maintenance—An Overview of Cases; IntechOpen: London, UK, 2019; pp. 11–36. [Google Scholar] [CrossRef]

- Gunawan, F.E.; Nhan, T.H.; Asrol, M.; Kanto, Y.; Kamil, I.; Sutikno. A New Damage Index for Structural Health Monitoring: A Comparison of Time and Frequency Domains. Procedia Comput. Sci. 2021, 179, 930–935. [Google Scholar] [CrossRef]

- Sony, S.; Laventure, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control Health Monit. 2019, 26, e2321. [Google Scholar] [CrossRef]

- Dang, H.; Tatipamula, M.; Nguyen, H.X. Cloud-Based Digital Twinning for Structural Health Monitoring Using Deep Learning. IEEE Trans. Ind. Inform. 2022, 18, 3820–3830. [Google Scholar] [CrossRef]

- Sofi, A.; Jane Regita, J.; Rane, B.; Lau, H.H. Structural health monitoring using wireless smart sensor network—An overview. Mech. Syst. Signal Process. 2022, 163, 108113. [Google Scholar] [CrossRef]

- Mishra, M.; Lourenço, P.B.; Ramana, G. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Bao, Y.; Li, H. Machine learning paradigm for structural health monitoring. Struct. Health Monit. 2020, 20, 1353–1372. [Google Scholar] [CrossRef]

- Zinno, R.; Haghshenas, S.S.; Guido, G.; VItale, A. Artificial Intelligence and Structural Health Monitoring of Bridges: A Review of the State-of-the-Art. IEEE Access 2022, 10, 88058–88078. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of Bridge Structural Health Monitoring Aided by Big Data and Artificial Intelligence: From Condition Assessment to Damage Detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Ben Chaabene, W.; Nehdi, M.L. Machine Learning Algorithms in Civil Structural Health Monitoring: A Systematic Review. Arch. Comput. Methods Eng. 2020, 28, 2621–2643. [Google Scholar] [CrossRef]

- Yuan, F.G.; Zargar, S.A.; Chen, Q.; Wang, S. Machine learning for structural health monitoring: Challenges and opportunities. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2020; Zonta, D., Sohn, H., Huang, H., Eds.; SPIE: Bellingham, WA, USA, 2020. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Malekloo, A.; Ozer, E.; AlHamaydeh, M.; Girolami, M. Machine learning and structural health monitoring overview with emerging technology and high-dimensional data source highlights. Struct. Health Monit. 2021, 21, 1906–1955. [Google Scholar] [CrossRef]

- Vagnoli, M.; Remenyte-Prescott, R.; Andrews, J. Railway bridge structural health monitoring and fault detection: State-of-the-art methods and future challenges. Struct. Health Monit. 2017, 17, 971–1007. [Google Scholar] [CrossRef]

- Entezami, A.; Sarmadi, H.; Behkamal, B.; Mariani, S. Big Data Analytics and Structural Health Monitoring: A Statistical Pattern Recognition-Based Approach. Sensors 2020, 20, 2328. [Google Scholar] [CrossRef]

- Bao, Y.; Tang, Z.; Li, H.; Zhang, Y. Computer vision and deep learning–based data anomaly detection method for structural health monitoring. Struct. Health Monit. 2018, 18, 401–421. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Z.; Wei, S.; Xu, Y.; Tang, Z.; Li, H. The State of the Art of Data Science and Engineering in Structural Health Monitoring. Engineering 2019, 5, 234–242. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Wu, Q.; Okabe, Y.; Yu, F. Ultrasonic Structural Health Monitoring Using Fiber Bragg Grating. Sensors 2018, 18, 3395. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.; Yang, Q.; Yang, F.; Huo, Y.; Meng, S. Digital twin for the structural health management of reusable spacecraft: A case study. Eng. Fract. Mech. 2020, 234, 107076. [Google Scholar] [CrossRef]

- Kang, J.S.; Chung, K.; Hong, E.J. Multimedia knowledge-based bridge health monitoring using digital twin. Multimed. Tools Appl. 2021, 80, 34609–34624. [Google Scholar] [CrossRef]

- Matloff, N.S. Statistical Regression and Classification; A Chapman & Hall book; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Burkov, A. The Hundred-PAGE Machine Learning Book; Andriy Burkov: Quebec City, QC, Canada, 2019. [Google Scholar]

- Piernik, M.; Morzy, T. A study on using data clustering for feature extraction to improve the quality of classification. Knowl. Inf. Syst. 2021, 63, 1771–1805. [Google Scholar] [CrossRef]

- Salih-Hasan, B.M.; Abdulazeez, A.M. A Review of Principal Component Analysis Algorithm for Dimensionality Reduction. J. Soft Comput. Data Min. 2021, 2, 20–30. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; da P. Francisco, R.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Makridakis, S.; Spiliotis, E.; Assimakopoulos, V. Statistical and Machine Learning forecasting methods: Concerns and ways forward. PLoS ONE 2018, 13, e0194889. [Google Scholar] [CrossRef]

- Chen, R.C.; Dewi, C.; Huang, S.W.; Caraka, R.E. Selecting critical features for data classification based on machine learning methods. J. Big Data 2020, 7, 52. [Google Scholar] [CrossRef]

- Fernández-Delgado, M.; Sirsat, M.; Cernadas, E.; Alawadi, S.; Barro, S.; Febrero-Bande, M. An extensive experimental survey of regression methods. Neural Netw. 2019, 111, 11–34. [Google Scholar] [CrossRef]

- Wallpapers Vista. General Atomics MQ-1 Predator. 2024. Available online: https://vistapointe.net/general-atomics-mq-1-predator.html (accessed on 15 July 2024).

- Gobbato, M.; Conte, J.P.; Kosmatka, J.B.; Farrar, C.R. A reliability-based framework for fatigue damage prognosis of composite aircraft structures. Probabilistic Eng. Mech. 2012, 29, 176–188. [Google Scholar] [CrossRef]

- Tharwat, A. Classification assessment methods. Appl. Comput. Inform. 2021, 17, 168–192. [Google Scholar] [CrossRef]

- Rezazadeh, N.; Polverino, A.; Perfetto, D.; De Luca, A. Dimensionality Reduction in Structural Health Monitoring: A Case Study on Damaged Wind Turbine Blades. Macromol. Symp. 2024, 413, 2400044. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Torres-Arredondo, M.A.; Alvarez-Montoya, J. Damage detection methodology under variable load conditions based on strain field pattern recognition using FBGs, nonlinear principal component analysis, and clustering techniques. Smart Mater. Struct. 2017, 27, 015002. [Google Scholar] [CrossRef]

- Jolliffe, I. Principal Component Analysis. In International Encyclopedia of Statistical Science; Lovric, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1094–1096. [Google Scholar] [CrossRef]

- Ruiz, M.; Mujica, L.E.; Sierra, J.; Pozo, F.; Rodellar, J. Multiway principal component analysis contributions for structural damage localization. Struct. Health Monit. 2018, 17, 1151–1165. [Google Scholar] [CrossRef]

- Nomikos, P.; MacGregor, J.F. Multivariate SPC charts for monitoring batch processes. Technometrics 1995, 37, 41–59. [Google Scholar] [CrossRef]

- Sierra-Pérez, J.; Güemes, A.; Mujica, L.E. Damage detection by using FBGs and strain field pattern recognition techniques. Smart Mater. Struct. 2012, 22, 025011. [Google Scholar] [CrossRef][Green Version]

- Sierra-Pérez, J.; Güemes, A.; Mujica, L.E.; Ruiz, M. Damage detection in composite materials structures under variable loads conditions by using fiber Bragg gratings and principal component analysis, involving new unfolding and scaling methods. J. Intell. Mater. Syst. Struct. 2015, 26, 1346–1359. [Google Scholar] [CrossRef]

| Position | Size | ||

|---|---|---|---|

| (% of Wingspan) | 2 mm | 10 mm | 20 mm |

| 25% | D1 | D4 | D7 |

| 50% | D2 | D5 | D8 |

| 75% | D3 | D6 | D9 |

| Size | |||

|---|---|---|---|

| Position | 2 mm | 10 mm | 20 mm |

| 25% | 0.6511 | 0.9852 | 0.9852 |

| 50% | 0.0976 | 0.9852 | 0.9852 |

| 75% | 0.2263 | 0.1770 | 0.9737 |

| Size | |||

|---|---|---|---|

| Position | 2 mm | 10 mm | 20 mm |

| 25% | 0.0360 | 0.9936 | 0.9936 |

| 50% | 0.0468 | 0.8939 | 0.9936 |

| 75% | 0.1584 | 0.3850 | 0.6016 |

| Size | |||

|---|---|---|---|

| Position | 2 mm | 10 mm | 20 mm |

| 25% | 321 | 321 | 321 |

| 50% | 347 | 347 | 149 |

| 75% | 364 | 351 | 351 |

| Size | |||

|---|---|---|---|

| Position | 2 mm | 10 mm | 20 mm |

| 25% | 322 | 321 | 321 |

| 50% | 347 | 347 | 148 |

| 75% | 68 | 373 | 373 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herrera, A.R.; Alvarez, J.; Restrepo, J.; Herrera, C.; Rodríguez, S.; Escobar, C.A.; Vásquez, R.E.; Sierra-Pérez, J. Damage Detection and Localization Methodology Based on Strain Measurements and Finite Element Analysis: Structural Health Monitoring in the Context of Industry 4.0. Aerospace 2024, 11, 708. https://doi.org/10.3390/aerospace11090708

Herrera AR, Alvarez J, Restrepo J, Herrera C, Rodríguez S, Escobar CA, Vásquez RE, Sierra-Pérez J. Damage Detection and Localization Methodology Based on Strain Measurements and Finite Element Analysis: Structural Health Monitoring in the Context of Industry 4.0. Aerospace. 2024; 11(9):708. https://doi.org/10.3390/aerospace11090708

Chicago/Turabian StyleHerrera, Andrés R., Joham Alvarez, Jaime Restrepo, Camilo Herrera, Sven Rodríguez, Carlos A. Escobar, Rafael E. Vásquez, and Julián Sierra-Pérez. 2024. "Damage Detection and Localization Methodology Based on Strain Measurements and Finite Element Analysis: Structural Health Monitoring in the Context of Industry 4.0" Aerospace 11, no. 9: 708. https://doi.org/10.3390/aerospace11090708

APA StyleHerrera, A. R., Alvarez, J., Restrepo, J., Herrera, C., Rodríguez, S., Escobar, C. A., Vásquez, R. E., & Sierra-Pérez, J. (2024). Damage Detection and Localization Methodology Based on Strain Measurements and Finite Element Analysis: Structural Health Monitoring in the Context of Industry 4.0. Aerospace, 11(9), 708. https://doi.org/10.3390/aerospace11090708