A Smart Wing Model: From Design to Testing in a Wind Tunnel with a Turbulence Generator

Abstract

1. Introduction

1.1. Directions for Aircraft Wing Vibrations Attenuation and Flight Envelope Expansion

1.2. Motivation of the Research

- Airlines frequently report turbulence during flights, with or without injuries to passengers, cabin crew, or damage to aircraft.

- Costs of maintenance, fuel, infrastructure, cancellation, and rerouting of the flight increase as turbulence often occurs.

- The complex problem of turbulence remains an unresolved issue and still brings challenges in the field of scientific research [39].

- Lack of method for identifying CAT leads to the development of ways to combat the effects induced by turbulence by controlling and reducing vibrations.

- The desire of the aeronautical companies is to make long-distance flights in the shortest possible time, which can be achieved by increasing the flight envelope inclusively through vibration control.

- In general, the design of aviation wind tunnels was based on the outdated idea that aircraft usually fly at altitudes of kilometers where the degree of turbulence is very low, which is true only if the phenomenon of CAT is ignored.

- The goal assumed in the project was to apply simple and efficient solutions, both in terms of hardware and software.

1.3. Contributions

- Elaboration of a complex procedure for active vibration control of an elastic model of the wing with aileron in the presence of turbulence generated in the wind tunnel, based on a methodology of simple experimental identification of the open loop system in the frequency domain

- Designing an elastic physical wing model displaying a given set of basic natural (modal) frequencies

- Designing an electric servo actuator consisting of a moving coil linear actuator and a crank-type mechanism

- Developing an algorithm for tuning the PD internal feedback loop of a servo actuator to increase the bandwidth

- Designing a passive turbulence generator in the wind tunnel, with the important property that the achieved degree of turbulence does not depend on the value of the air speed V upstream of the generator

- Developing a procedure for system mathematical model identification

- Reaching a vibration reduction of about 18 dB on the basic 5 Hz modal frequency for both control laws LQG and , meaning a competitive performance with other achievements described in the literature of the field.

2. Smart Wing System with Active Control

3. Tests on the Smart Wing in Subsonic WT for Mathematical Model Identification

- (a)

- A chirp signal (Figure 4) is applied to the actuator; the signal has constant amplitude (corresponding to an expected angular aileron displacement, for example, 2 degrees, 4 degrees, etc.) and a linearly variable frequency in time in the band [0 Hz; 60 Hz], which sufficiently covers the interest field of the first two modal frequencies of the wing.

- (b)

- The signal (Figure 4), corresponding to wing displacement in the normal direction on the wing, and provided by the accelerometer, is recorded by integrating the acceleration twice; the accelerometer is mounted on the wing (Figure 2) so as to react simultaneously to the bending and torsional movements corresponding to the first two modes of vibration.

- (c)

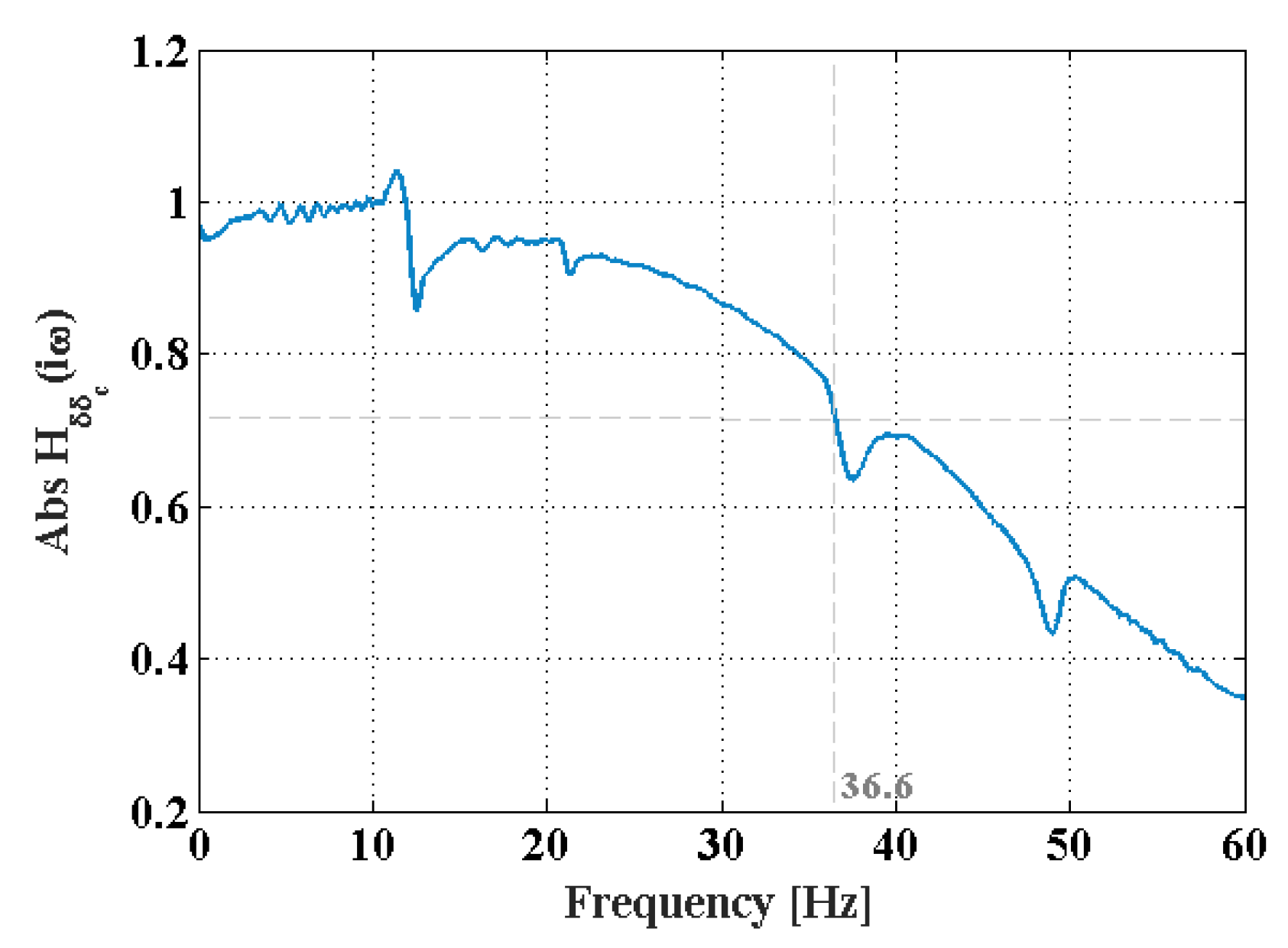

- The experimental frequency response, defined by the − phase- − attenuation-frequency characteristics, and frequency characteristics, , associated with the transfer function is estimated; the latter is obtained by comparing (dividing) the Fast Fourier Transform (FFT) of the two experimental time signals and ; therefore consists of a sequence of complex numbers, of length M, indexed with values of the circular frequencies .

- (d)

- A convenient approximation of this response by rational transfer functions is sought (i.e., a ratio of two polynomials in the complex variable ), ; for this purpose, functions from the MATLAB System Identification Toolbox are available. For the air speed in WT of 25 m/s, the experimental and identified transfer functions are represented in the graphs in Figure 9. is obtained with an accuracy of estimation of 81.58% (see Figure 10) and is given analytically below as a rational expression of two polynomials, with two zeros and two pairs of complex-conjugated poles (, see Figure 4). The estimation accuracy of over 80% of the transfer function.

- (e)

- The identification of the frequency domain is followed by converting the transfer function (19) into the state space system ; for this purpose, the MATLAB function tf2ss is used

4. Brief Presentation of Active Control Laws

4.1. Standard LQG Control Synthesis

4.2. Synthesis

- (i)

- The pairs , are stabilizable, respectively, detectable.

- (ii)

- The pairs , are stabilizable, respectively, detectable.

- (iii)

- .

5. Results of Active Control Tests

6. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Environment Agency; European Union Aviation Safety Agency. European Aviation Environmental Report; TO-01-18-673-EN-N; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Williams, P.D.; Joshi, M. Clear-Air Turbulence in a Changing Climate. In Aviation Turbulence. Processes, Detection, Prediction; Sharman, R., Lane, T., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 465–480. [Google Scholar]

- Coffel, E.; Horton, R. Climate change and the impact of extreme temperatures on aviation. Weather Clim. Soc. 2015, 7, 94–102. [Google Scholar] [CrossRef]

- Williams, P.D. Increased light, moderate, and severe Clear-Air Turbulence in response to climate change. Adv. Atmos. Sci. 2017, 34, 576–586. [Google Scholar] [CrossRef]

- Ellrod, G.P.; Knox, J.A.; Lester, P.F.; Ehernberger, L.J. Clear Air Turbulence. In Encyclopedia of Atmospheric Sciences; North, G.R., Pyle, J., Zhang, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; Volume 1, pp. 177–186. [Google Scholar]

- Pao, Y.-H.; Goldburg, A. (Eds.) Clear Air Turbulence and Its Detection; Springer Science + Business Media: New York, NY, USA, 1969. [Google Scholar]

- Available online: https://www.spacescience.ro/projects/contur/index_en.html (accessed on 14 May 2024).

- Hauchecorne, A.; Cot, C.; Dalaudier, F.; Porteneuve, J.; Gaudo, T.; Wilson, R.; Cénac, C.; Laqui, C.; Keckhut, P.; Perrin, J.-M.; et al. Tentative detection of clear-air turbulence using a ground-based Rayleigh lidar. Appl. Opt. 2016, 55, 3420–3428. [Google Scholar] [CrossRef] [PubMed]

- Belson, B.L. An Automated Method of Predicting Clear-Air Turbulence. Master’s Thesis, Air Force Institute of Technology, Wright-Patterson Air Force Base, Dayton, OH, USA, 2004. [Google Scholar]

- Available online: https://www.nasa.gov/aeronautics/nasa-microphone-detects-turbulence-hundreds-of-miles-away/ (accessed on 17 June 2024).

- Available online: https://tc.canada.ca/en/aviation/publications/transport-canada-aeronautical-information-manual-tc-aim-tp-14371 (accessed on 14 May 2024).

- Ursu, I.; Giurgiutiu, V.; Toader, A. Towards spacecraft applications of structural health monitoring. INCAS Bull. 2012, 4, 111–124. [Google Scholar]

- Available online: https://en.wikipedia.org/wiki/1919_Verona_Caproni_Ca.48_crash (accessed on 14 May 2024).

- Kehoe, M.W. A Historical Overview of Flight Flutter Testing; NASA-TM-4720; Dryden Flight Research Center: Edwards, CA, USA, 1995.

- Garrick, I.E.; Reed, W.H., III. Historical development of aircraft flutter. J. Aircr. 1981, 18, 897–912. [Google Scholar] [CrossRef]

- Ursu, I. The kinematics of the rigid feedback linkage, the impedance of the hydraulic servomechanism and the flutter occurrence. INCAS Bull. 2012, 4, 63–70. [Google Scholar]

- Ursu, I.; Vladimirescu, M.; Ursu, F. About aeroservoelasticity criteria of the electrohydraulic servomechanisms synthesis. In Proceedings of the 20th Congress of the International Council of the Aeronautical Sciences, ICAS 96, Sorrento, Napoli, Italy, 8–13 September 1996; Volume 2, pp. 2335–2344. [Google Scholar]

- Ursu, I.; Ursu, F. Active and Semiactive Control; Publishing House of the Romanian Academy: Bucharest, Romania, 2002. (In Romanian) [Google Scholar]

- Zhang, R.J.; Zhigang, W.; Chao, Y. Dynamic stiffness testing-based flutter analysis of a fin with an actuator. Chin. J. Aeronaut. 2015, 28, 1400–1407. [Google Scholar] [CrossRef]

- Available online: https://en.wikipedia.org/wiki/IAR-93_Vultur (accessed on 14 May 2024).

- Ursu, I. Study of the Stability and Compatibility of the Hydraulic Servomechanisms from the Primary Flight Controls; Report No. 34125; IMFCA: Bucharest, Romania, 1974. (In Romanian) [Google Scholar]

- Available online: https://en.wikipedia.org/wiki/Dowty_Group (accessed on 14 May 2024).

- Ursu, I. The Determination of the Static Characteristics of the Hydraulic Spool Valve and the Analysis of the Dynamic Stability of the SMHR Hydraulic Servomechanism Correlated with the Results of the Experiments Carried Out within the Qualification Testing in Laboratory; Report code N-5303; INCAS (INCREST): Bucharest, Romania, 1984. [Google Scholar]

- Ardelean, E.V.; McEver, M.A.; Cole, D.G.; Clark, R.L. Active flutter control with V-stack piezoelectric flap actuator. J. Aircr. 2006, 43, 482–486. [Google Scholar] [CrossRef]

- Jiffri, S.; Fichera, S.; Mottershead, J.E.; Da Ronch, A. Experimental nonlinear control for flutter suppression in a nonlinear aeroelastic system. J. Guid. Control Dyn. 2017, 40, 1925–1938. [Google Scholar] [CrossRef]

- Papatheou, E.; Tantaroudas, N.D.; Da Ronch, A.; Cooper, J.E.; Mottershead, J.E. Active control for flutter suppression: An experimental investigation. In Proceedings of the International Forum on Aeroservoelasticity and Structural Dynamics (IFASD), Bristol, UK, 24–26 June 2013. [Google Scholar]

- Da Ronch, A.; Tantaroudas, N.D.; Jiffri, S.; Mottershead, J.E. A nonlinear controller for flutter suppression: From simulation to wind tunnel testing. In Proceedings of the AIAA-2014-0345 Science and Technology Forum and Exposition, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- Livne, E. Aircraft active flutter suppession: State of the art and technology maturation needs. J. Aircr. 2018, 55, 410–450. [Google Scholar] [CrossRef]

- Aridogan, U.; Basdogan, I. A review of active vibration and noise suppresion of plate-like structures with piezoelectric transducers. J. Intell. Mater. Syst. Struct. 2015, 26, 1455–1476. [Google Scholar] [CrossRef]

- Toader, A.; Ursu, I. Pilot modelling based on time delay synthesis. Proc. Inst. Mech. Eng. Part G 2014, 228, 740–754. [Google Scholar] [CrossRef]

- Available online: https://www.incas.ro/subsonic-wind-tunnel/ (accessed on 14 May 2024).

- Munteanu, F.; Oprean, C.; Stoica, C. INCAS Subsonic Wind Tunnel. INCAS Bull. 2009, 1, 12–14. [Google Scholar]

- Varadan, V.K. Handbook of Smart Systems and Materials; IOP Publishing: London, UK, 2005. [Google Scholar]

- Ursu, I.; Ursu, F. An intelligent ABD control based on fuzzy logic. In Proceedings of the ICTAMI 2003, International Conference on Theory and Applications of Mathematics and Informatics, Alba Iulia, Romania, 24–25 October 2003; pp. 355–368. [Google Scholar]

- Ursu, I.; Tecuceanu, G.; Toader, A.; Calinoiu, C. Switching neuro-fuzzy control with antisaturating logic. Experimental results for hydrostatic servoactuators. Proc. Rom. Acad. Ser. A 2011, 12, 231–238. [Google Scholar]

- Goh, C.J.; Caughey, T.K. On the stability problem caused by finite actuator dynamics in the control of large space structures. Int. J. Control 1985, 41, 787–802. [Google Scholar] [CrossRef]

- Raja, S.; Upadhya, A. Active control of wing flutter using piezoactuated surface. J. Aircr. 2007, 44, 2007. [Google Scholar] [CrossRef]

- Menter, F.R. Best Practice: Scale-Resolving Simulations in ANSYS CFD; ANSYS Germany GmbH: Darmstadt, Germany, 2015. [Google Scholar]

- Feynman, R.P.; Leighton, R.B.; Sands, M.L. The Relation of Physics to Other Sciences. In The Feynman Lectures on Physics; Addison-Wesley: Reading, MA, USA, 1965; Volume I, Chapter 3; Available online: https://www.feynmanlectures.caltech.edu/ (accessed on 17 June 2024).

- Ursu, I.; Ion Guta, D.D.; Enciu, D.; Toader, A.; Dan, M.; Donciu, C.; Turcan, V. Mathematical modelling of a V-stack piezoelectric aileron actuation. INCAS Bull. 2016, 8, 141–155. [Google Scholar]

- Ursu, I.; Ion Guta, D.D.; Enciu, D.; Tecuceanu, G.; Radu, A.A. Flight envelope expansion based on active mitigation of flutter via a V-stack piezoelectric actuator. IOP Conf. Ser. J. Phys. 2018, 1106, 012033. [Google Scholar] [CrossRef]

- Halanay, A.; Ursu, I. Stability of equilibria of some switched nonlinear systems with applications to control synthesis for elecrohydraulic servomechanisms. IMA J. Appl. Math. 2009, 74, 361–373. [Google Scholar] [CrossRef]

- Ko, J.; Strganac, T.W.; Junkins, J.L.; Akella, M.R.; Kurdila, A.J. Structured model reference adaptive control for a wing section with structural nonlinearity. J. Vib. Control 2002, 8, 553–573. [Google Scholar] [CrossRef]

- Available online: https://www.cfd-online.com/Wiki/Turbulence_intensity (accessed on 14 May 2024).

- Comte-Bellot, G.; Corssin, S. Simple Eulerian time correlation of full and narrow-band velocity signals in grid-generated “isotropic” turbulence. J. Fluid Mech. 2006, 48, 273–337. [Google Scholar] [CrossRef]

- Ursu, I.; Ursu, F.; Popescu, F. Backstepping design for controlling electrohydraulic servos. J. Frank. Inst. 2006, 343, 94–110. [Google Scholar] [CrossRef]

- Ursu, I. Dealing with mathematical modeling in applied control. INCAS Bull. 2011, 3, 87–93. [Google Scholar]

- Xu, B.; Zhang, W.; Ma, J. Stability and Hopf bifurcation of two-dimensional supersonic airfoil with a time-delayed feedback control surface. Nonlinear Dyn. 2014, 77, 819–837. [Google Scholar] [CrossRef]

- Ursu, I.; Iorga, L.; Toader, A.; Tecuceanu, G. Active robust control of a smart plate. In Proceedings of the ICINCO 2011 8th International Conference on Informatics in Control, Automation and Robotics, Noordwijkerhout, The Netherlands, 28–31 July 2011. [Google Scholar]

- Birnir, B. The Kolmogorov-Obukhov Thepry of Turbulence. A Mathematical Theory of Turbulence; Springer: New York, NY, USA, 2013. [Google Scholar]

- Kalman, R.E. Contributions to the theory of optimal control. Bol. Soc. Mat. Mex. 1960, 5, 102–109. [Google Scholar]

- Kalman, R.E. A new approach to linear filtering and prediction problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Kwakernaak, H.; Sivan, R. Linear Optimal Control Systems; Wiley Interscience: New York, NY, USA, 1972. [Google Scholar]

- Ursu, I.; Tecuceanu, G.; Ursu, F.; Vladimirescu, M.; Sireteanu, T. From robust control to antiwindup compensation of electrohydraulic servoactuators. Aircr. Eng. Aerosp. Technol. 1998, 70, 259–264. [Google Scholar] [CrossRef]

- Zhou, K.; Doyle, J.C.; Glover, K. Robust and Optimal Control; Prentice Hall: Hoboken, NJ, USA, 1996. [Google Scholar]

- Zames, G. Nonlinear Operators for Systems Analysis. Ph.D. Thesis, MIT, Cambridge, MA, USA, 1960. RLE Technical Report 370. [Google Scholar]

- Zames, G. Feedback and optimal sensitivity: Model reference transformations, multiplicative seminorms, and approximate inverses. IEEE Trans. Automat. Contr. 1981, 26, 301–320. [Google Scholar] [CrossRef]

- Iorga, L.; Baruh, H.; Ursu, I. H∞ control with μ-analysis of a piezoelectric actuated plate. J. Vib. Control 2009, 15, 1143–1171. [Google Scholar] [CrossRef]

- Zhou, K.; Doyle, J.C. Essentials of Robust Control; Prentice Hall: Hoboken, NJ, USA, 1999. [Google Scholar]

- Pusch, M. Aeroelastic mode control using—Optimal blends for inputs and outputs. In Proceedings of the AIAA 2018 Guidance, Navigation, and Control Conference, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Kruger, W.R.; Dillinger, J.; Meddaikar, M.Y.; Lübker, J.; Tang, M.; Meier, T.; Böswald, M.; Soal, K.T.; Manuel, P.; Kier, T. Design and wind tunnel test of an actively controlled flexible wing. In Proceedings of the International Forum on Aeroelasticity and Structural Dynamics IFASD 2019, Savannah, GA, USA, 10–13 June 2019. [Google Scholar]

- Munteanu, E.; Ursu, I. Piezo smart composite wing with LQG/LTR control. In Proceedings of the IEEE International Symposium on Industrial Electronics ISIE 2008, Cambridge, UK, 30 June–2 July 2008; pp. 1160–1165. [Google Scholar]

- Tahk, M.; Speyer, J.L. Modelling of parameter variations and asymptotic LQG synthesis. IEEE Trans. Automat. Contr. 1987, 32, 793–801. [Google Scholar] [CrossRef]

- Byun, K.W.; Wie, B.; Geller, D.; Sunkel, J. Robustified H∞ control design for the space station with structured parameter uncertainty. J. Guid. Control Dyn. 1991, 14, 1115–1120. [Google Scholar] [CrossRef]

- Wie, B.; Qiang, L.; Byun, K.W. Robust control synthesis method and its application to benchmark problems. J. Guid. Control Dyn. 1992, 15, 1140–1148. [Google Scholar] [CrossRef]

- Iorga, L.; Baruh, H.; Ursu, I. A review of robust control of piezoelectric smart structures. Trans. ASME Appl. Mech. Rev. 2008, 61, 17–31. [Google Scholar] [CrossRef]

| Mode Number | Longeron Frequency [Hz] CATIA Model | Wing Frequency [Hz] CATIA Model | Wing Frequency [Hz] Experimental Tests |

|---|---|---|---|

| 1 | 13.59 | 6.23 | 5.93 |

| 2 | 43.42 | 10.21 | 11.70 |

| 3 | 44.12 | 20.83 | 22.73 |

| 4 | 59.14 | 26.32 | - |

| 5 | 78.91 | 29.83 | - |

| X (m) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 |

|---|---|---|---|---|---|---|---|---|---|

| I | 0.0338 | 0.019 | 0.0142 | 0.0116 | 0.01 | 0.0089 | 0.008 | 0.0073 | 0.0068 |

| Control Law | # | UC | AC | Attenuation |

|---|---|---|---|---|

| Normal (−37.04%) | 1 | 0.096 | 0.052 | −45.83% |

| 2 | 0.085 | 0.061 | −28.24% | |

| LQG (−41.49%) | 1 | 0.061 | 0.045 | −26.23% |

| 2 | 0.085 | 0.044 | −48.24% | |

| 3 | 0.080 | 0.040 | −50.00% |

| Control Law | # | UC | AC | Attenuation |

|---|---|---|---|---|

| Strong (−24.61%) | 1 | 0.642 | 0.537 | −16.36% |

| 2 | 0.746 | 0.524 | −29.76% | |

| 3 | 0.722 | 0.522 | −27.70% | |

| super-strong (−36.04%) | 1 | 0.815 | 0.447 | −45.15% |

| 2 | 0.749 | 0.498 | −33.51% | |

| 3 | 0.662 | 0.467 | −29.46% | |

| LQG (−26.75%) | 1 | 0.784 | 0.558 | −28.83% |

| 2 | 0.635 | 0.529 | −16.69% | |

| 3 | 0.726 | 0.447 | −34.71% |

| Control Law | V = 25 m/s | V = 33 m/s |

|---|---|---|

| robust | −37.04% | −30.16% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ursu, I.; Tecuceanu, G.; Enciu, D.; Toader, A.; Nastase, I.; Arghir, M.; Calcea, M. A Smart Wing Model: From Design to Testing in a Wind Tunnel with a Turbulence Generator. Aerospace 2024, 11, 493. https://doi.org/10.3390/aerospace11060493

Ursu I, Tecuceanu G, Enciu D, Toader A, Nastase I, Arghir M, Calcea M. A Smart Wing Model: From Design to Testing in a Wind Tunnel with a Turbulence Generator. Aerospace. 2024; 11(6):493. https://doi.org/10.3390/aerospace11060493

Chicago/Turabian StyleUrsu, Ioan, George Tecuceanu, Daniela Enciu, Adrian Toader, Ilinca Nastase, Minodor Arghir, and Manuela Calcea. 2024. "A Smart Wing Model: From Design to Testing in a Wind Tunnel with a Turbulence Generator" Aerospace 11, no. 6: 493. https://doi.org/10.3390/aerospace11060493

APA StyleUrsu, I., Tecuceanu, G., Enciu, D., Toader, A., Nastase, I., Arghir, M., & Calcea, M. (2024). A Smart Wing Model: From Design to Testing in a Wind Tunnel with a Turbulence Generator. Aerospace, 11(6), 493. https://doi.org/10.3390/aerospace11060493