Abstract

This paper presents a summary of and introduction to research on high-altitude and subatmospheric combustion concerning turbine and scramjet engines. The investigation includes theoretical analysis, experimental studies, and numerical simulations. The analysis encompasses the flow field structure, fuel atomization, and combustion performance. Subsequently, recent research on the combustion performance of liquid fuels, solid fuels, and gaseous fuels under high-altitude and low-pressure plateau environments is reviewed. This includes an evaluation of flame height, flame temperature, combustion rate, fire spread rate, and heat radiation flux. Additionally, combustion performance prediction models for high-altitude environments based on experimental and theoretical analysis have been introduced. Lastly, issues in subatmospheric combustion in the aerospace and plateau fire fields are presented based on the current research.

1. Introduction

The escalating intensity of aerospace military competition has brought the immense military and societal potential of near space (20–100 km) into the spotlight [1]. With its high boundaries, borderless features, and stable meteorological conditions, near space offers a strategic location for aerospace powers to execute maneuverable defense and enable rapid responses [2]. In response to this demand, significant efforts have been devoted to developing aircraft capable of achieving higher altitudes and greater speeds, with a particular focus on air-breathing hypersonic vehicles [3]. However, the thin atmosphere, low atmospheric pressure, and extremely low temperatures prevalent in near space pose challenges for subatmospheric combustion. The harsh working environment and subpar performance of subatmospheric combustion have hindered the realization of long-endurance and highly efficient aircraft in this domain [4]. This paper explores the potential and limitations of near space for aerospace defense, shedding light on the need for innovative solutions to overcome the hurdles presented by this unique environment.

Subatmospheric combustion not only hinders aerospace development but also plays a crucial role in fire prevention and control in plateau environments [5]. With increasing altitude, environmental pressure and oxygen content are continuously reduced, resulting in plateau regions being situated in a low-pressure and low-oxygen environment [6]. The combustion process, whether controlled for energy utilization or uncontrolled during fires, is subject to external environmental influences [7]. The low-pressure and low-oxygen environment in plateau regions, in particular, exerts a significant impact on combustion performance [8], thereby differing greatly from combustion under normal atmospheric conditions. Hence, the study of ignition and combustion characteristics of different types of fuel under high-altitude and low-pressure environmental conditions forms the foundation for fire prevention [9] and control as well as improving energy utilization efficiency [10] in plateau areas.

Based on the current research on subatmospheric combustion in the aerospace and plateau combustion fields, a concise review paper has been formulated in this study. Firstly, the flow field structure and fuel atomization research inside the combustion chamber under subatmospheric pressure conditions in the aerospace field are elucidated, along with the research progress on subatmospheric combustion performance in different types of engines such as turbo engines, ramjet engines, and rocket engines. Secondly, the early theoretical analysis models of combustion in the field of subatmospheric combustion are introduced, and the research achievements in combustion theories of various types of fuels in plateau environments in recent years are summarized. Finally, the current research status of subatmospheric combustion in both domains is discussed.

2. Subatmospheric Combustion in Aerospace

2.1. Subatmospheric Flow Field and Fuel Atomization

The flow field structure and fuel atomization performance inside the combustion chamber have a significant impact on the overall combustion performance of the aero-engine in an aircraft propulsion system [11,12]. Therefore, it is crucial to summarize the research findings concerning the flow field and fuel atomization performance of the combustion chamber under low-pressure conditions [13]. Subsequently, a comprehensive overview of the research progress on subatmospheric combustion in aero-engines can be presented.

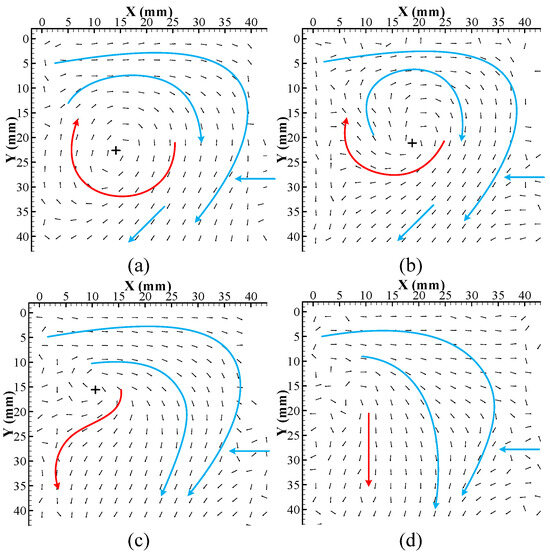

Li and Wang [14] used a hot wire anemometer to investigate the downstream flow field characteristics of a flameholder under low-pressure conditions. The research findings indicate that as the ambient pressure decreases, both the reflux rate and the size of the recirculation zone are reduced. Moreover, the turbulence intensity and Reynolds stress also decrease, resulting in weakened flame stability of the flameholder. Huang et al. [15] investigated the impact of inlet pressure on the flow field structure of a cavity-based flameholder. The results show that, as the pressure decreases, the stable double-vortex structure inside the cavity remains unaffected. However, the vortex structure downstream of the bluff body gradually becomes incomplete with decreasing pressure and disappears when the inlet pressure reaches 0.04 MPa, as shown in Figure 1. Later, Zhang et al. [16] investigated the flow characteristics of a trapped vortex cavity with a radial bluff body under subatmospheric pressure. The study revealed that the fore and rear inlet air jets are entrained into the mainstream, resulting in the absence of a vortex structure inside the cavity at an inlet pressure of 0.04 MPa. As the inlet pressure gradually increases, the vortex structure inside the cavity reappears. These results demonstrate that the decrease in inlet pressure affects the flow field structure downstream of different flameholders.

Figure 1.

The velocity vector maps in the cavity at the center section: (a) Pi = 0.10 MPa, (b) Pi = 0.08 MPa, (c) Pi = 0.06 MPa, (d) Pi = 0.04 MPa [15]. Copyright © 2022, Science Press, License Number 5776540214627.

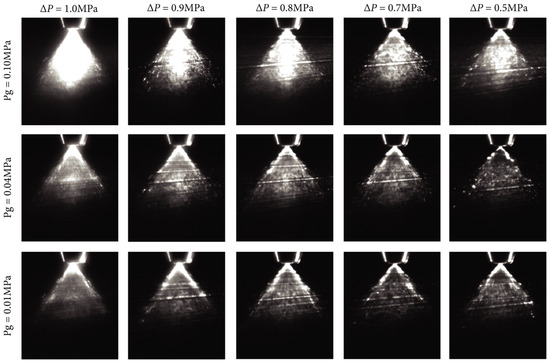

In recent years, numerous researchers have investigated the fuel atomization characteristics of nozzles under low-pressure conditions using optical measurement techniques such as PIV [17], PDPA [18], high-speed cameras [19], and digital holographic microscopy [20]. These studies extensively examined parameters, including penetration depth, breakup process, particle velocity, and size, as well as the spatial distribution of fuel. Xu and Wang [21] used pulsed laser technology to measure the spray field downstream of a direct-spray nozzle under low-pressure conditions while exploring the effects of inlet pressure, fuel pressure, and airflow velocity on fuel atomization. The findings indicated that airflow velocity was the primary determinant of fuel atomization quality. Additionally, a decrease in inlet pressure led to diminished atomization quality. The experimental results of Tang [22] revealed a significant influence of ambient pressure on atomization effects, as increasing ambient pressure visibly increased the average diameter of atomized particles, with a greater impact than atomization pressure itself. Additionally, ambient pressure exhibited a notable effect on the spray angle, whereby an increase in ambient pressure initially caused a decrease in the spray angle followed by an increase. Figure 2 presents the atomization effects under different ambient pressures [23]. The study performed by Zhao et al. [24] aimed to investigate the effects of fuel superheat degree, injection pressure, and nozzle geometry in low-pressure environments on spray characteristics, such as spray form and Sauter mean diameter (SMD). The study involved measurements of the bubble point temperature of kerosene under various ambient pressures, establishing an empirical relationship between ambient pressure and the bubble point temperature.

Figure 2.

Fuel atomization under different environmental pressures [23]. Copyright © 2021 Zhengyan Guo et al.

Additionally, Li et al. [25] established a vacuum environment spray experimental system to investigate the impact of Reynolds number and nozzle diameter on atomization. The research indicated that flashing under low pressure is the primary cause of jet breakup. Liu et al. [26] conducted experimental research on the internal shape and temperature variations of low-pressure flashing fuel droplets, summarizing the influence of ambient pressure and the initial temperature of fuel droplets on the flashing process. Bai [27] employed experimental methods to measure the atomization and evaporation characteristics of fuel within a pressure range of 0.015–1.5 MPa. The results indicated that increased superheat contributes to a reduction in fuel spray droplet size, resulting in a more uniform fuel spray. Moreover, as the ambient pressure decreases from atmospheric to 0.015 MPa, the atomization effect of the fuel spray gradually intensifies. Focusing on the crucial role of bubbles in droplet fragmentation during low-pressure flashing, Chen et al. [28] established a mathematical model and defined the dimensionless number Ch to describe the growth conditions of bubbles. In an environment where the outlet pressure of the plain orifice atomizer is less than 10 Pa, Li et al. [29] undertook experimental research on the effects of injection pressure and nozzle diameter on the vapor volume and turbulent kinetic energy distribution inside the nozzle. The study found that a smaller nozzle diameter promotes intense cavitation flow, thus facilitating atomization.

The research achievements of numerous scholars in subatmospheric flow and fuel atomization provide a theoretical foundation for the analysis and study of the combustion performance of aero-engine combustors under low-pressure inlet conditions.

2.2. Subatmospheric Combustion

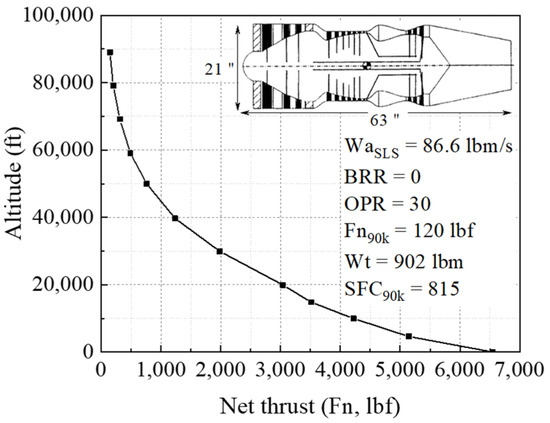

With the expansion of the operating range of ramjet engines to include high-altitude and high-speed conditions, the working pressure within the combustion chamber rapidly decreases, leading to a decline in combustion performance. This limitation significantly impacts the development of aerospace technology. To solve this issue, the National Aeronautics and Space Administration (NASA) of the United States initiated systematic research on the combustion performance of aviation engines under high-altitude conditions in the 1950s. In the initial stages of research, Messing and Black [30] conducted experimental studies on the flameholder system. The research results showed that with an increase in altitude, the maximum temperature at the combustion chamber outlet decreases, resulting in a decrease in combustion efficiency. Specifically, when the altitude exceeds 6 km, the lean and rich blowout limits are very close to each other, resulting in combustion oscillations and harsh noise. With an increase in altitude, the lean blowout fuel–air ratio increases while the rich blowout fuel–air ratio decreases, resulting in a narrower flame stability range [31]. For instance, as the altitude increases from 0.45 km to 6.7 km, the lean blowout fuel–air ratio increases from 0.028 to 0.078. Subsequently, experimental research was conducted by Dugald and Messing [32] on the flameholder system of the rectangular ramjet engine model. The experiments covered a fuel–air ratio range of 0.017 to 0.120, an inlet velocity range of 15 to 38 m/s, and an altitude range of 0.45 to 8.4 km, investigating four different flameholder configurations. The combustion efficiency obtained at a flight altitude of 8.4 km ranged from 28% to 39%. Additionally, research by Bents and Mockler [33] indicated that the thrust of a turbine engine rapidly decreases with increasing altitude. When the altitude exceeds 13.5 km, the thrust of the turbine engine becomes smaller than its weight. Refer to Figure 3 for specific data.

Figure 3.

Relationship between thrust and altitude of a certain type of turbine engine.

Subsequently, NASA and the NACA Lewis Laboratory conducted a series of combustion tests on J-2/J-2s rocket engines [34,35] and 20–28-inch [36,37] ramjet engines under high-altitude operational and simulated conditions [38]. The research results indicate that under low-pressure conditions, the atomization and distribution of fuel become more challenging. Furthermore, the blowout limit and combustion stability are worse under low-pressure conditions. Due to the decrease in pressure, the mixing efficiency of the fuel is reduced, resulting in issues such as local rich-fuel combustion and incomplete combustion [39]. However, NASA has not publicly released relevant literature since 1972. The publicly available literature mainly has a strong engineering focus, with research emphasis on the impact of altitude on combustion performance parameters. In addition, research and development work based on the small liquid ramjet engine (ALVRJ-STM) has been advanced, including the development of power systems for various rocket and ramjet engine combinations. These power systems are applied to high-altitude aircraft with excellent performance, such as the CIM-10 “Bomarc” surface-to-air missile and the Brass Knight RIM-8 ship-to-air missile. Chen [40] compared the ignition limits of five types of aviation kerosene under high-altitude conditions in a preburner. The experimental results showed that under a fuel pressure differential of 0.196 MPa, the ignition limit of the fuel decreased with decreasing environmental pressure. Moreover, at the optimum fuel–air ratio, the ignition limit widened with increasing environment pressure. Wang et al. [41] experimentally and numerically investigated the blowout performance of a swirl combustor under low-pressure conditions. The research results also confirmed that a decrease in pressure leads to an increase in the lean blowout equivalence ratio. Zhang et al. [42] further investigated the pressure fluctuation and heat release pulsation of an evaporative flameholder under low pressure. The study found that an increase in pressure within the range of 0.055 to 0.075 MPa resulted in an increase in heat release fluctuation. However, within the range of 0.075 to 0.085 MPa, an increase in pressure led to a decrease in heat release fluctuation, and the pressure fluctuation did not vary significantly.

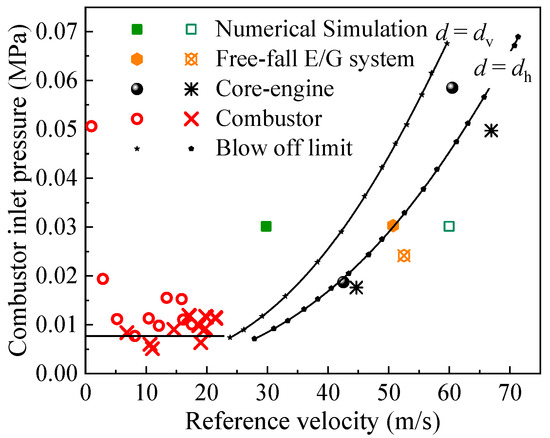

In the 1980s, with the successful deployment of a large number of hypersonic cruise missiles, countries raised higher requirements for the flight altitude, speed, and duration of hypersonic aircraft. Achieving efficient and stable combustion technology under high-altitude and low-pressure conditions has become a primary challenge. However, there is still a lack of theoretical support for subatmospheric combustion in the public literature, which has led researchers to conduct studies on mechanisms such as ignition, flame propagation, and chemical reaction rates under low-pressure conditions. Dung Ngoc Nguyen et al. [43] performed experimental research on the ignition delay characteristics of three gas–liquid biphasic fuels in a constant volume combustor under different pressure and temperature conditions. The experimental results indicate that the ignition delay time is increased when the ambient pressure and temperature decrease. The ignition delay time remains relatively constant in the temperature range above 700 K, while it varies significantly in the temperature range below 700 K. Keiichi Okai et al. [44] investigated the ignition limit under low-pressure conditions in a reversed-flow combustor using gaseous hydrogen as the fuel. Their research similarly demonstrated that low pressure increases the difficulty of ignition. The experimental results show that the minimum pressure for stable combustion of hydrogen fuel is 0.03 MPa. The results also indicate that the inlet pressure and velocity of the combustor have a significant impact on ignition performance, and the flame propagation velocity is limited by the ignition pressure. The ignition pressure limit follows the conclusions of Drell and Belle [45], while the ignition velocity limit conforms to the empirical formula proposed by Fine [46] for laminar flames, . Figure 4 illustrates the low-pressure ignition regime for the present combustor and engines. The graph shows that the reference velocity for ignition decreases rapidly with the combustor inlet pressure.

Figure 4.

Low-pressure ignition regime for the present combustor and engines.

In flameholder studies, Xiao et al. [47] investigated the lean and rich blowout performance of a premixed flameholder under inlet conditions ranging from 41.8 to 76.9 kPa. The research data showed that as the pressure decreased, the lean ignition fuel–air ratio initially increased and then decreased, while the lean blowout fuel–air ratio gradually increased. This reflects the significant influence of fuel atomization on the blowout limit in low-pressure environments. Chen and Zhou [48] found that preheating the fuel by 90 °C before ignition had a significant improvement in high-altitude and low-pressure ignition performance. Zheng et al. [49] compared the combustion performance of five flameholders and the evaporative flameholder applied in Spey-MK-202 under both atmospheric and 0.068 MPa low-pressure conditions. The study found that the evaporative flameholder had a wider lean and rich blowout limit under low-pressure conditions, and its ignition performance and combustion efficiency were improved. The V-gutter flameholder had poorer blowout performance and relatively lower combustion efficiency. Similarly, Han and Wang [50] further improved the ignition and flame stabilization performance under low-pressure conditions by optimizing the dune vortex flameholder into an evaporative dune vortex flameholder.

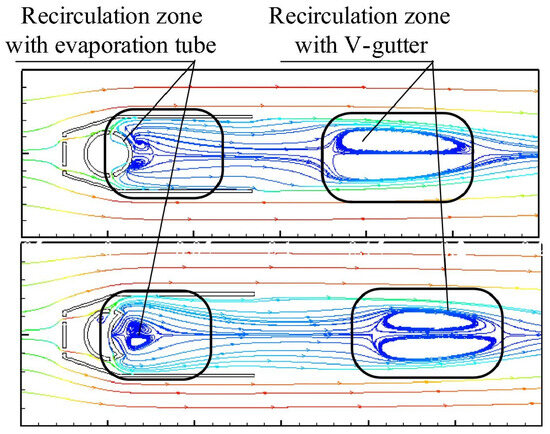

Subsequently, Liu et al. [51] conducted experimental research on the ignition and blowout performance of an evaporative flameholder under pressure conditions of 0.05–0.1 MPa and an inlet velocity of 90 m/s. The research results indicate that as the ambient pressure increases, the lean ignition and blowout equivalence ratio gradually decreases. On the other hand, the rich ignition equivalence ratio first decreases and then increases, while the rich blowout equivalence ratio gradually increases. Figure 5 illustrates the streamlines of the flow field in the evaporative flameholder [52]. In the lean-fuel combustion state, a stable ignition source is established within the recirculation zone inside the flameholder. In contrast, in the rich-fuel combustion state, the ignition source is distributed within the downstream recirculation zone of the flameholder.

Figure 5.

Streamlines of the recirculation zone downstream of the evaporating flameholder [52]. Copyright © 2016 Elsevier Ltd., License Number 5774280298476.

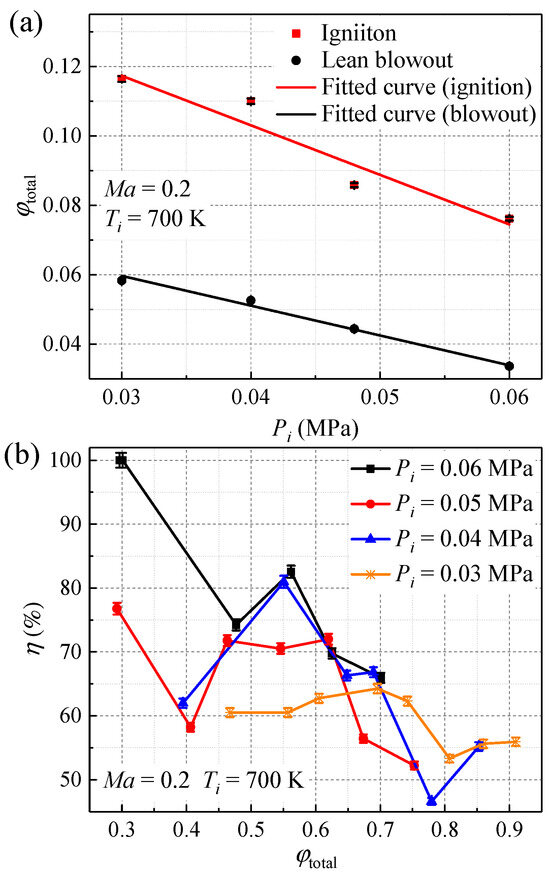

Wang et al. [53] undertook experimental research on the combustion efficiency and total pressure recovery coefficient of an evaporative flameholder under inlet pressures ranging from 67 to 68.6 kPa and temperatures ranging from 755 to 903 K. The experimental results showed that the combustion efficiency of the evaporative flameholder decreases with an increase in the fuel–air ratio and increases with an increment in the inlet temperature. Under the conditions of 68 kPa and 873 K, the total pressure recovery coefficient was consistently in the range of 0.9 to 0.92, with a combustion efficiency exceeding 90%. Niu et al. [54] conducted combustion experiments on a ramjet model in a low-pressure environment (0.094–0.065 MPa). The results showed that the combustion efficiency decreases as the inlet pressure of the combustor decreases. When the ambient pressure is reduced to 0.065 MPa, the combustion performance of the combustor deteriorates sharply, resulting in extremely unstable combustion. Additionally, Li et al. [29] found that when the pressure is below 0.07 MPa, the local combustion efficiency experiences a drastic decline from 75%, and when the pressure drops to 0.03 MPa, combustion cannot be sustained (as seen in Figure 6) [55]. Subsequently, Zhang et al. [56] discovered that the addition of oxygen in a low-pressure environment can effectively improve combustion performance in the rich-fuel state. The research group of Wang [57,58] at the National University of Defense Technology also carried out subatmospheric combustion experiments based on the cavity-scramjet engine combustor. They proposed measures to improve combustion efficiency in response to the issue of reduced combustion efficiency in low-pressure conditions, such as enhancing fuel atomization, increasing the fuel–air ratio, and extending the length of the combustor. Chen and Ling [59] found that the combustion efficiency of an evaporating flameholder under subatmospheric pressure conditions could be improved by increasing the head air quantity and the length of the evaporation tube.

Figure 6.

Flame stability limits and combustion efficiency under subatmospheric pressure [55]. © 2021 Elsevier Ltd., License Number 5776550611665. (a) Pi (Mpa); (b) φtotal.

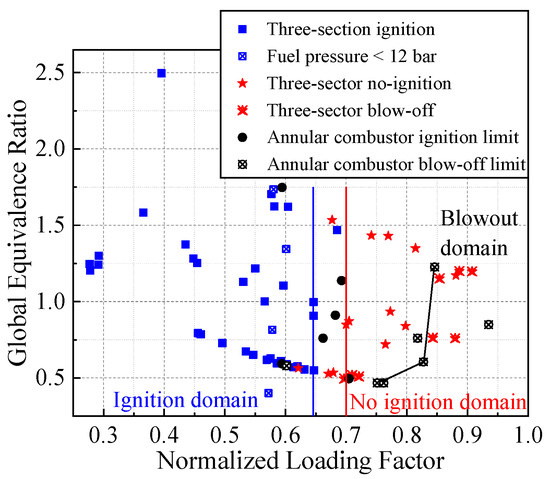

Recently, the development of optical measurement techniques and the maturity of high-speed imaging technology have facilitated the study of flame propagation characteristics. R. W. Read et al. [60] conducted research on high-altitude reignition experiments in a small direct-injection gas turbine combustor. The motion and breakup of the flame were analyzed using an image processing algorithm. The research results showed that when the ambient pressure was 0.04 MPa, the flame kernel disintegrated rapidly under aerodynamic forces, leading to failed reignition. However, when the ambient pressure exceeded 0.04 MPa, the flame kernel expanded downstream and along the fuel injection axis, resulting in a successful reignition. Linassier G et al. [61] studied the ignition process and blowout limit of a three-sector swirl combustor at pressures ranging from 0.06 to 0.09 MPa (as seen in Figure 7). The research found that in the swirl combustor, the ignition limit was mainly influenced by aerodynamics, and the maximal loading factor was similar to that of a stirred reactor. Giusti A et al. [62] used numerical simulations to study the ignition of a single liquid droplet of kerosene in a static low-pressure environment. They studied the relationship between ignition time, droplet diameter, and far-field temperature, emphasizing the necessity of spark-induced mixture formation around the droplet in low-pressure environments.

Figure 7.

Ignition and blow-out limits for three-sector combustor.

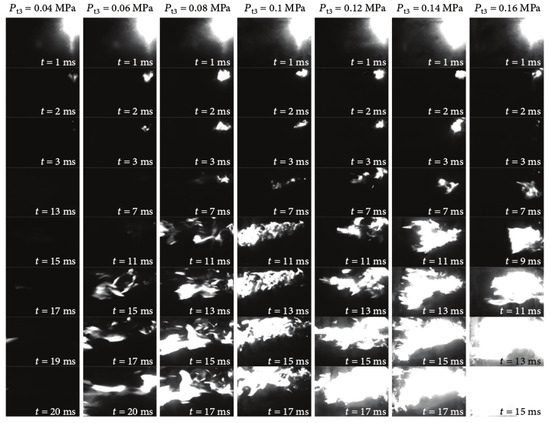

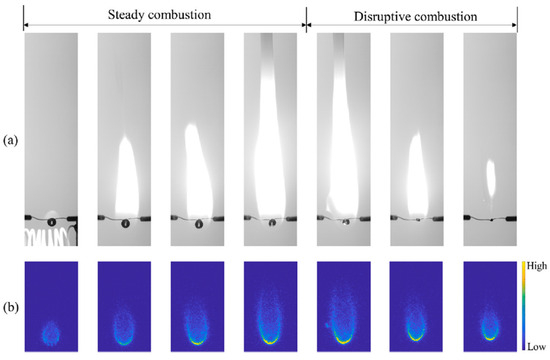

The research of Chen et al. [63] showed that under low-pressure conditions, the flame front contracts toward the nozzle, and the luminous intensity of CH* is decreased. When the simulated flight altitude increases from 2 km to 10 km, the flame color changes from yellow to blue, indicating an enhancement in combustion instability. Chen et al. [64] studied the ignition process and outlet temperature of swirl combustion under pressures ranging from 0.04 to 0.16 MPa. The experimental results showed that as the inlet pressure of the combustor increased, the time of initial flame formation and time of maximum area growth rate of flame decreased. The ignition processes at different pressures are shown in Figure 8. Zhang et al. [65,66] and He et al. [67,68] at Zhejiang University performed studies on RP-3 aviation kerosene, investigating the secondary breakup, ignition delay time, and flame characteristics of single droplets in a static environment (0.02–0.1 MPa), as seen in Figure 9. The research results revealed that the flame propagation time from the burning droplet to the unburned droplet is proportional to the normalized spacing distance between droplets and the ambient pressure. The combustion rate decreases as the pressure decreases. Additionally, as the ambient pressure decreases, the distance between the kerosene and oxygen molecules is increased, resulting in prolonged ignition delay time. Zhu and Huang investigated the ignition and blowout equivalence ratio, the ignition flame propagation process, and the combustion efficiency of the cavity flameholder [55,69] and evaporative flameholder [70] with an inlet pressure ranging from 0.03 to 0.06 MPa. The research results indicate that a decrease in inlet pressure weakens the spreading of flame. Additionally, the results confirmed the significant influence of fuel droplet breakup and penetration depth on combustion performance.

Figure 8.

Ignition process under different inlet pressure [64]. Copyright © 2018 Jian Chen et al.

Figure 9.

Burning sequences at 0.6 bar: (a) images captured by the high-speed camera; (b) images of OH* chemiluminescence emission captured by ICCD equipped with 310 nm filter [67]. Copyright © 2019 The Combustion Institute, License Number 5773651409848.

3. Subatmospheric Combustion in Plateau Fire

The research on plateau fire mainly focuses on analyzing the influence of environmental pressure on the combustion characteristics of different types of fuels [71]. However, early studies were mostly conducted at environmental pressures higher than atmospheric pressure. The purpose was to simulate the characteristics of large-scale fires under normal pressure conditions in laboratory-scale experiments using high-pressure conditions. In 1973, De Ris et al. [72] proposed the pressure model of fires, which is currently the most widely used model for combustion characteristics under variable pressure conditions. Research findings indicate that the use of pressure models as research tools in the study of free-burning and spreading fires demonstrates a high level of accuracy. Subsequently, Alpert [73] validated the applicability of the pressure model in radiation-dominated fires through experiments, showing almost perfect agreement between the simulation results and experimental observations, indicating that the pressure model is also suitable for radiation-dominated fires. Furthermore, to better simulate the thermal radiation feedback of flames to fuel, De Ris et al. [74] introduced a radiation model in large-scale pool fire experiments. Kleinhenz et al. [75] utilized the pressure model to study the vertical flame propagation and combustion rate of solid samples in a low-pressure environment. This indicates that although these combustion models were proposed based on high-pressure experiments, they can also be applied to the study of combustion characteristics in low-pressure environments, laying the theoretical foundation for fire prevention and control in plateau environments. In recent years, research on plateau fire prevention and control has mainly focused on the combustion processes and behaviors of liquid fuels [76], solid fuels [77], and gaseous fuels [78] in low-pressure environments.

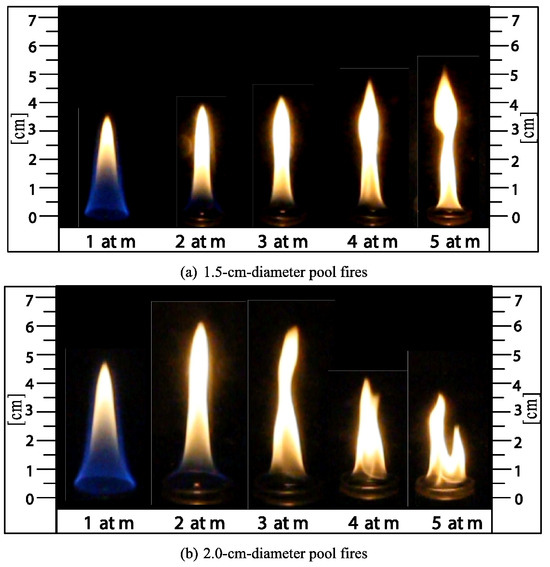

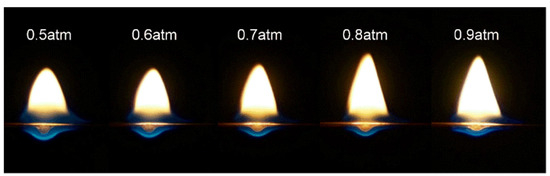

In 1996, Jean-Michel Most et al. [79] investigated the pressure influence on the characteristics of pool-type diffusion flames within the range of 0.03 to 0.3 MPa. The research results showed that when the pressure was below atmospheric pressure, the rich combustion zone in the flame expanded and the flame height increased. In addition, there was a significant decrease in carbon soot generation and radiation heat transfer to the vessel walls. The flame exhibited a blue color. A similar result was obtained in the research of Chen et al. [80], as shown in Figure 10. They also found that as the pressure decreased, the flame structure transitioned from turbulent to laminar. Subsequently, Weiser et al. [81] measured the pool fire burning rate, CO and CO2 concentration changes, and flame temperature in a downsized mobile experimental chamber within the altitude range of 400 m (0.97 bar) to 3000 m (0.71 bar). The study found that as the environmental pressure decreased, fire development slowed down. The experimental data indicated a relationship between the burning rate and pressure. Li [82,83] undertook a study on fire combustion characteristics using two n-heptane cans in two laboratories at different altitudes. Similar to the findings of Weiser, the experimental data indicated that the burning rate, radiative heat flux, and flame temperature were lower in high-altitude regions compared to low-altitude areas.

Figure 10.

Flame images of ethanol pool fires under different pressures [80]. Copyright © 2018 Elsevier Ltd., License Number 5774241275620.

Yan et al. [84] found that the size of the pool has an impact on the characteristics of pool fire combustion under low-pressure conditions. The heat release rate increases with the increase in the size of the pool. Additionally, the mass loss rate is lower than the theoretical value. Zhang et al. [85] investigated the effect of environmental pressure on the flame radiation fraction of pool fires using n-heptane and acetone under cross-flow conditions. They proposed a dimensionless model to describe the variation in the flame radiation fraction. Model analysis revealed that the ratio of flame radiation fraction under cross-flow and no cross-flow conditions is a modified function of the Froude number. Liu et al. [86] studied the entrainment coefficient of small-scale pool fires within the range of 40 to 101 kPa. They found that the entrainment coefficient had a linear relationship with environmental pressure. Subsequently, they determined the influence of pressure and pool diameter on the flame radiation fraction [87]. They further proposed a dimensional scaling theory with the expression . The research findings of Zhao et al. [88] also indicated an exponential decrease in flame radiation fraction with increasing pool diameter. Additionally, they found that with the decrease in environmental pressure, the flame height of n-heptane pool fires increased, and the burning rate decreased. Zhu et al. [89] reached the same conclusion when studying the pool fire combustion characteristics of ethanol–gasoline blended fuel. Moreover, they found that the variation in the ethanol volume fraction led to non-monotonic changes in the burning rate. The flame height and temperature reached a peak when the environmental pressure was 40 kPa and the ethanol volume fraction was 20%. Meng et al. [90] investigated the influence of pressure on spill fires. The study found that the spreading radius of spill fires under atmospheric pressure was smaller than that under low-pressure conditions. Furthermore, the burning rate of spill fires at atmospheric pressure was lower, and the relationship between pressure and the burning rate was expressed as .

Fang et al. [91] conducted pool fire combustion experiments at different altitudes with the same scale, and the study revealed that pool fire flames exhibited stronger periodic oscillations and higher flame puffing frequency under low air pressure. Chen et al. [92] also investigated the influence of pressure on the oscillating behavior of pool fires. The study used the Grashof number to explain the changes in flame structure and oscillation frequency. Furthermore, it was found that the Grashof number could explain the transition of pool fire flame structure from laminar to turbulent. Similarly, Zhao et al. [93] investigated the flame pulsation frequency of ethanol pool fires under low pressure and found that the flame pulsation frequency decreased with an increase in the pool diameter.

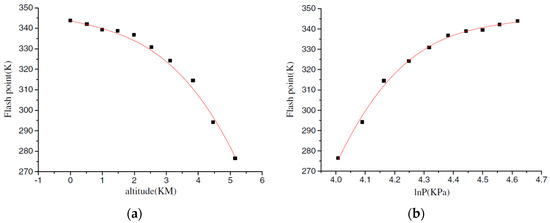

The flash point is an essential physical property of flammable liquids and a primary indicator for evaluating fire hazards. Tang et al. [94] researched the impact of altitude on the flash points of different types of aviation kerosene under pressure conditions ranging from 55 kPa to 101.3 kPa. The results showed that the flash point of the fuel did not decrease linearly with an increase in altitude, as shown in Figure 11. This research finding is beneficial for the safe design of aircraft fuel tanks and fire prevention during the transportation and storage of flammable liquids.

Figure 11.

Variations in flash point of the liquid fuel with (a) altitude and (b) pressure [94]. Copyright © 2012 by John Wiley & Sons, Inc., License Number 5774251017049.

Subsequently, Ding et al. [95,96,97,98] conducted flash point measurements of liquid fuels at different altitudes using a portable flash point meter. Theoretical analysis and experimental results showed that the flash point of liquid fuels exhibited a nonlinear decrease with an increase in altitude, while the reciprocal of the flash point had a linear relationship with altitude. Then, they investigated the variations of the flash point, boiling point, and lean flammability of Jet A and diesel within the pressure range of 35 to 101 kPa. It was observed that the boiling point and flash point decreased with decreasing pressure, while the lean flammability increased with decreasing pressure. Chen [99] established a flash point prediction model considering environmental pressure and obtained results similar to those obtained by Ding. Additionally, they performed oil pan boilover experiments of diesel and aviation kerosene under low-pressure conditions. They proposed predictive models for the occurrence of boilover precursors and boilover times. Wu [100] conducted research on the ignition characteristics and combustion enhancement of −35# diesel fuel under pressure conditions ranging from 0.059 to 0.101 MPa, summarizing the influence mechanisms of low pressure on ignition. The results indicated that the convective heat transfer coefficient reduced with decreasing pressure, promoting the occurrence of ignition.

The combustion process of solid fuels under low-pressure conditions can be divided into several stages, including thermal decomposition, ignition, flame propagation, and flame extinguishment. During the ignition process of solid fuels, they are first heated by the external environment, melting into combustible liquids. Then, they are further heated to evaporate into combustible gases, or they may transform into combustible gases through sublimation and cracking. Then, the combustible gases combine with air to form a flammable mixture and are ignited as the temperature rises [101].

In the field of subatmospheric combustion of solid fuels, a large number of scholars have undertaken relevant research. David Hirsch et al. [102] investigated the oxygen concentration flammability thresholds of different solid materials within the pressure range of 48.2 to 101.3 kPa. They found that pressure had a greater impact on materials with higher thresholds. In 2009, NASA [103] also investigated the combined effects of pressure and oxygen concentration on the ignition delay of different materials under low-pressure conditions. The study revealed that while the oxygen concentration was maintained at 21% and the pressure was reduced, the average ignition time decreased by 17%. Increasing the oxygen concentration at low pressure further reduced the ignition time by an additional 10%. The investigation of Jia et al. [104] also indicated that increasing the oxygen concentration significantly reduced the inhibitory effect of low pressure on solid fuel combustion. The research of Thomsen et al. [105] on PMMA combustion showed that the surface regression rate and the mass burning rate decreased with decreasing pressure, while they increased with decreasing oxygen concentration. Additionally, Thomsen et al. conducted similar studies on two types of fire-resistant fabric [106]. The results indicated that as the pressure decreased, the oxygen concentration required to sustain flame propagation had to increase. Mariusz Zarzecki et al. [107] also performed experimental research on the combustion performance of PMMA under low pressure and varying oxygen concentrations. They developed an analytical model that accounted for the effects of pressure and oxygen on combustion rate. The model exhibited good agreement with measurement results and predicted the impact of pressure and oxygen on the combustion rate.

He et al. [108] investigated the subatmospheric combustion characteristics of PE material. The results showed that the flame height decreased with decreasing pressure, and the flame shape became spherical, as shown in Figure 12. Ding et al. [109] investigated the combustion characteristics of paper stacks within the range of 40 kPa to 101 kPa and measured parameters such as mass loss, heat release rate, and flame temperature. The research revealed a close correlation between the intensity factor of the flame and pressure. In addition, the flame growth rate significantly decreased as the pressure decreased. Feng et al. [110] also measured parameters such as flame temperature and the burning rate of cardboard boxes at different pressures. The study revealed a strong power-law correlation between these parameters and pressure. Ma et al. [111] obtained similar results. Additionally, Zhao et al. [112] found that the flame length had a power-law relationship with the heat release rate through research on PMMA combustion characteristics under low pressure. The power-law exponent was 1.41 when the pressure was below 80 kPa and 1.04 when above 80 kPa. Huang et al. [113] conducted combustion experiments on expanded polystyrene in both sea-level and high-altitude areas. The study found that the flame spread rate decreased with increasing altitude. Wang et al. [114] found that the reduction in reaction rate and heat transfer caused by low pressure was a key factor leading to the decrease in the flame spread rate.

Figure 12.

Flame morphology under low pressure [108]. Copyright WIT Press.

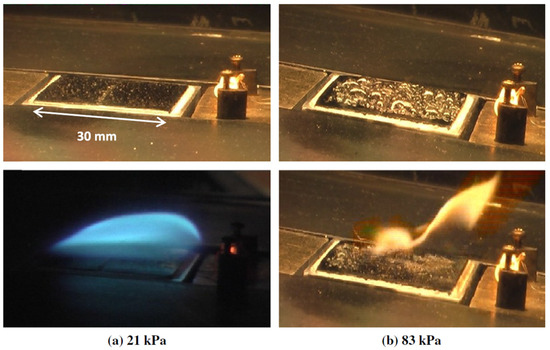

Dai et al. [115,116] undertook experimental and theoretical studies to explore the ignition characteristics of pine wood under different pressures. They developed an extended model considering atmospheric pressure and unsteady gas-phase processes to predict wood pyrolysis. The predicted results of the model are relatively consistent with the experiment. The research results indicated that lower atmospheric pressure led to higher mass loss rates and earlier ignition times. Additionally, Wang et al. [117,118] and his team compared the spontaneous ignition characteristics of wood at two different altitudes. The results are similar to those of Dai. In addition, the influence of surface pressure on ignition temperature is minimal. Sara et al. [119] observed in their research that with decreasing pressure, the ignition delay decreased to a minimum, and then increased until no ignition occurred. They identified different controlling mechanisms for ignition delay in different regimes: the transform regime, where the ignition delay was influenced by convection heat loss and critical mass flux; the chemical kinetic regime, where gas-phase chemical kinetics governed the ignition delay; and the overlap regime, where both transport and chemical effects contributed to the ignition delay. Qie et al. [120] investigated the pyrolysis and ignition characteristics of wood in both horizontal and vertical directions under low-pressure conditions. Compared to the horizontal direction, the ignition time was shorter, the mass loss rate was faster, and the surface temperature was lower in the vertical direction. Research results from NASA [121] indicated that low-pressure environments reduced convective heat loss from the heated material to the surrounding environment, enabling the material to heat up and pyrolyze more rapidly. Consequently, the ignition time decreased. Sonia Fereres et al. [122] validated previous research results through numerical simulations. They found that flames became bluer, had a rounder shape, and were more detached from the solid surface at low pressures compared to standard pressures, as shown in Figure 13. This indicates that pressure affects the heating, pyrolysis, or gasification processes of solids and the characteristics of gases above the solid surface. The research results of Huang et al. [123] showed that in low-pressure environments, pressure had different effects on the ignition time of solid materials at different external radiation temperature ranges. In the temperature range of 500 to 700 °C, the ignition time decreased with decreasing pressure. However, in the range of 800 to 1000 °C, the ignition time under atmospheric pressure approached that under low pressure.

Figure 13.

Visual observations at different pressures (a) 21 kPa and (b) 83 kPa [121]. Copyright © 2010 The Combustion Institute, License Number 5774260876444.

Ren et al. [124] measured the ignition time and surface temperature of wood under pressure conditions ranging from 40 to 100 kPa. The research results indicate that pressure mainly affects the heat loss and pyrolysis reaction of wood. Based on the experiments, the introduction of the pressure parameter allows the wood ignition model to consider the effects of pressure on heat loss and pyrolysis reaction during wood heating. Consequently, the accuracy of the model predictions was improved. Peng [125] established a solid-phase pyrolysis model and then developed a one-dimensional gas–solid pyrolysis model by combining it with the gas-phase ignition model.

Wang et al. [126] discovered that reducing ambient pressure can suppress solid fuel fires by decreasing the mass burning rate and radiative heat flux, thus weakening the combustion of solid fuels and eliminating visible flames. But it cannot eliminate smoldering. Additionally, smoking can lead to the accumulation of smoke containing high levels of carbon particles and flammable gases, increasing the possibility of flashover. Therefore, depressurization fire suppression should consider the combustion characteristics of solid fuels and work with other synergetic fire control measures.

In the research on the combustion of gaseous fuels under low-pressure conditions, Li [127] utilized a cone calorimeter to measure the heat release rate and radiation flux of methane, acetylene, and propane. The study demonstrated that the radiation flux, smoke production, and radiation fraction of jet flames were lower at low pressure. Zeng [128] conducted experimental research on methane jet diffusion flames under buoyancy-dominated and momentum-dominated conditions within the pressure range of 45 kPa to 100 kPa. The study explored the effects of pressure, mass flow rate, and co-flow air on the characteristics of flames under low-pressure conditions. The study found that flame temperature decreased with an increase in pressure. When the pressure was below 70 kPa, the decrease in air density led to a transition from oxygen-rich combustion to fuel-rich combustion, resulting in reduced combustion efficiency. Consequently, the flame temperature was decreased.

4. Conclusions

Currently, significant progress has been made in both the application and fundamental research of subatmospheric combustion. The combustion organization principles of air-breathing near-space propulsion systems have been gradually validated. Many beneficial conclusions have been drawn from research on key technologies and important mechanism issues. Moreover, the development of subatmospheric combustion theory in high-altitude regions has also propelled subatmospheric combustion towards robust development in engineering applications.

In the aerospace field, the development of high-altitude, high-speed aircraft has been driven by the military significance of near space. Numerous scholars have researched the combustion characteristics inside the combustors of aircraft propulsion systems in near-space low-pressure environments. These studies involve theoretical analysis, experimental research, and numerical simulations of the flow field structure, fuel atomization, and combustion performance of turbojet and ramjet engines under subatmospheric conditions. The types of fuels used include aviation kerosene and hydrogen fuel. The main research contents involve combustion efficiency, ignition performance, and flame propagation of combustors.

In the field of plateau fire, current research primarily focuses on the combustion characteristics of liquid fuels, solid fuels, and gaseous fuels under low-pressure conditions. The research content includes flame height, flame temperature, combustion rate, flame propagation speed, and thermal radiation flux. Additionally, many scholars have developed pressure models for combustion, flashpoint prediction models, and uniform models for wood combustion based on experimental and theoretical analyses. These models are significant for predicting combustion performance and preventing fires in plateau environments.

Author Contributions

Conceptualization, G.D., Z.Y. and Y.H.; methodology, Z.Z.; software, Z.Z.; validation, Z.Y. and Y.H.; formal analysis, G.D.; investigation, Z.Z.; resources, Y.H.; data curation, Z.Z.; writing—original draft preparation, G.D.; writing—review and editing, Y.H.; visualization, Z.Z.; supervision, Z.Y. and Y.H.; project administration, Y.H.; funding acquisition, Z.Y. and Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Jiangsu Funding Program for Excellent Postdoctoral Talent (No. 316958), Natural Science Foundation of Jiangsu Province, China (BK20230932), the China Postdoctoral Science Foundation (No. 2023M741697), Fundamental Research Funds for the Central Universities (No. 30923010306), and Major Research Plan of the National Natural Science Foundation of China (No. 92371112).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Choubey, G.; Devarajan, Y.; Huang, W.; Mehar, K.; Tiwari, M.; Pandey, K.M. Recent Advances in Cavity-Based Scramjet Engine—A Brief Review. Int. J. Hydrogen Energy 2019, 44, 13895–13909. [Google Scholar] [CrossRef]

- Li, G.; Ma, D.; Yang, M. Research of near Space Hybrid Power Airship with a Novel Method of Energy Storage. Int. J. Hydrogen Energy 2015, 40, 9555–9562. [Google Scholar] [CrossRef]

- Cecere, D.; Giacomazzi, E.; Ingenito, A. A Review on Hydrogen Industrial Aerospace Applications. Int. J. Hydrogen Energy 2014, 39, 10731–10747. [Google Scholar] [CrossRef]

- Li, Z.; Moradi, R.; Marashi, S.M.; Babazadeh, H.; Choubey, G. Influence of Backward-Facing Step on the Mixing Efficiency of Multi Microjets at Supersonic Flow. Acta Astronaut. 2020, 175, 37–44. [Google Scholar] [CrossRef]

- Hu, X.; He, Y.; Li, Z.; Wang, J. Combustion Characteristics of N-Heptane at High Altitudes. Proc. Combust. Inst. 2011, 33, 2607–2615. [Google Scholar] [CrossRef]

- Krishnan, S.; Swami, R.D. Effect of Catalyst Mixing Procedure on Subatmospheric Combustion Characteristics of Composite Propellants. J. Propuls. Power 1997, 13, 207–212. [Google Scholar] [CrossRef]

- Åkerblom, A.; Passad, M.; Ercole, A.; Zettervall, N.; Nilsson, E.J.K.; Fureby, C. Numerical Modeling of Chemical Kinetics, Spray Dynamics, and Turbulent Combustion towards Sustainable Aviation. Aerospace 2023, 11, 31. [Google Scholar] [CrossRef]

- Jiusheng, Y.; Wei, Y.; Quanyi, L.; Nan, W.; Zhihui, Z.; Yi, W.; Hui, Z. Experimental Study of N-Heptane Pool Fire Behaviors under Dynamic Pressures in an Altitude Chamber. Procedia Eng. 2013, 52, 548–556. [Google Scholar] [CrossRef]

- Yao, W.; Hu, X.; Rong, J.; Wang, J.; Zhang, H. Experimental Study of Large-Scale Fire Behavior under Low Pressure at High Altitude. J. Fire Sci. 2013, 31, 481–494. [Google Scholar] [CrossRef]

- Jiao, Y.; Liu, R.; Zhang, Z.; Yang, C.; Zhou, G.; Dong, S.; Liu, W. Comparison of Combustion and Emission Characteristics of a Diesel Engine Fueled with Diesel and Methanol-Fischer-Tropsch Diesel-Biodiesel-Diesel Blends at Various Altitudes. Fuel 2019, 243, 52–59. [Google Scholar] [CrossRef]

- Sánchez, A.L.; Williams, F.A. Recent Advances in Understanding of Flammability Characteristics of Hydrogen. Prog. Energy Combust. Sci. 2014, 41, 1–55. [Google Scholar] [CrossRef]

- Xing, F.; Kumar, A.; Huang, Y.; Chan, S.; Ruan, C.; Gu, S.; Fan, X. Flameless Combustion with Liquid Fuel: A Review Focusing on Fundamentals and Gas Turbine Application. Appl. Energy 2017, 193, 28–51. [Google Scholar] [CrossRef]

- Zhao, D.; Gutmark, E.; de Goey, P. A Review of Cavity-Based Trapped Vortex, Ultra-Compact, High-g, Inter-Turbine Combustors. Prog. Energy Combust. Sci. 2018, 66, 42–82. [Google Scholar] [CrossRef]

- Li, G.; Wang, J. Experimental Investigation on Flow Characteristics of the Recirculation Zone behind V-Gutter Flameholder. Acta Aeronaut. Astronaut. Sin. 1989, 10, 447–449. [Google Scholar]

- Huang, Y.; Yao, Z.; Zhu, Z.; He, X. Effect of Inlet Pressure on Flow Characteristics in Cavity-Based Flameholder under Subatmospheric Pressure. J. Therm. Sci. 2023, 32, 278–285. [Google Scholar] [CrossRef]

- Zhang, Y.; He, X.; Zhong, S.; Deng, Y.; Wang, J.; Zhang, F. Influence of Incoming Flow Parameters on the Flow Field in a Trapped Vortex Cavity with Radial Bluff-Body. Aerosp. Sci. Technol. 2023, 132, 108050. [Google Scholar] [CrossRef]

- Hill, H.; Ding, C.P.; Baum, E.; Böhm, B.; Dreizler, A.; Peterson, B. An Application of Tomographic PIV to Investigate the Spray-Induced Turbulence in a Direct-Injection Engine. Int. J. Multiph. Flow 2019, 121, 103116. [Google Scholar] [CrossRef]

- Kim, H.; Tongchai, S.; Lim, O. A Study on the Particle Size and Velocity Profile on a Gasoline Port Injector Using a Phase Doppler Particle Analyzers (PDPA). Energy Procedia 2018, 145, 374–380. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, F.; Zhang, Z. Fundamental Spray Characteristics of Air-Assisted Injection System Using Aviation Kerosene. Fuel 2021, 286, 119420. [Google Scholar] [CrossRef]

- Tambe, S.B.; Elshamy, O.M.; Jeng, S.M. Liquid Jets Injected Transversely into a Shear Layer. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cincinnati, OH, USA, 8–11 July 2007; Volume 7, pp. 6765–6774. [Google Scholar]

- Xu, P.; Wang, J. Experimental Study on Atomization Characteristics of Plain Orifice at Subatmospheric Pressure. J. Aerosp. Power 1996, 11, 51–54+109. [Google Scholar]

- Tang, X. Study on the Mechanism of Effervescent Atomization and the Effect of Ambient Pressure on the Spray Characteristics. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2015. [Google Scholar]

- Guo, Z.; Jin, Y.; Zhang, K.; Yao, K.; Wang, Y.; Wu, D.; He, X.; Zheng, M. Effect of Low Ambient Pressure on Spray Cone Angle of Pressure Swirl Atomizer. Int. J. Aerosp. Eng. 2021, 2021, 102104. [Google Scholar] [CrossRef]

- Zhao, L.; Fan, W.; Fan, Z.; Song, H. Experimental Investigation on Spray Characteristics from Superheated Liquid Jets under Low Pressure. J. Propuls. Technol. 2012, 33, 771–778. [Google Scholar]

- Li, L.; Chi, B.; Yang, W.; Hong, L. Experimental Study on Atomization Characteristic of Liquid Jet in Vacuum Environment. J. Rocket Propuls. 2010, 36, 27–30. [Google Scholar]

- Liu, W.; Bi, Q.; Liu, L.; Ji, Y. Study on the Shape and Temperature Variations within Droplet in Low Pressure Environment. J. Eng. Thermophys. 2007, 6, 957–960. [Google Scholar]

- Bai, Y. Characterization of Atomization and Vaporization for Flash-Boiling Sprays in Vacuum Condition. Ph.D. Thesis, Beijing University of Chemical Technology, Beijing, China, 2013. [Google Scholar]

- Chen, P.; Zhou, C.; Xu, Y.; Hong, L. Modelling and Simulation of Bubble Growth Dynamicsin Vacuum Jet. Chin. J. Vac. Sci. Technol. 2016, 36, 753–759. [Google Scholar]

- Li, J.; Li, H.; Sun, Y.; Ba, D. Simulation of Cavitation Flow inside Plain-Orifice Nozzle at Low Outlet Pressure. Chin. J. Vac. Sci. Technol. 2013, 33, 277–283. [Google Scholar]

- Messing, W.E.; Black, D.O. Subsonic Flight Investigation of Rectangular Ram Jet over Range of Altitudes. NASA RM E7H26, 1948. [Google Scholar]

- Tausz, J.; Sohulte, F. Determination of Ignition Points of Liquid Fuels under Pressure. Fiber 1925, 57, 291–297. [Google Scholar]

- Black, D.O.; Messing, W.E. Effect of Three Flame-Holder Configurations on Subsonic Flight Performance of Rectangular Ram Jet over Range of Altitudes. NASA RM E8I01, 1948. [Google Scholar]

- Bents, J.; Mockler, T. Propulsion Subsonic System Unmanned for Very High Aircraft Altitude. NASA TM206636, 1998. [Google Scholar]

- Vetter, N.R.; Franklin, D.E.; Muse, W.W. Altitude Development Testing of the J-2 Rocket Engine in Propulsion Engine Test Cell (J-4). AEDC TR 67-209, 1971. [Google Scholar]

- Mastromonico, C. Altitude Ignition Studies. AFRPL TR 71-70, 1971. [Google Scholar]

- Smolak, G.R.; Wentworth, C.B. Altitude Investigation of Can-Type Flame Holder in 20-Inch-Diameter Ramjet Combustor. NASA RM E54D08, 1954. [Google Scholar]

- Jones, W.C.; Shillito, T.B.; Henzel, J.G. Altitude-Test-Chamber Investigation of Performance of a 28-Inch Ram-Jet Engine Combustion and Operational Performance of Four Combustion-Chamber Configurations. NASA RM E50F16, 1950. [Google Scholar]

- Kerslake, W.R. Combustion of Gaseous Hydrogen at Low Pressures in a 35 Deg Sector of a 28-Inch-Diameter Ramjet Combustor. NASA RM E58A21a, 1958. [Google Scholar]

- Drabble, J.S. Investigation into the Performance of a “REID” Forced Air Blast Ramjet Combustion Chamber on a Low Pressure Combustion. NASA TN G.W.227, 1953. [Google Scholar]

- Chen, N. Investigation of High-Altitude Ignition Performance of Several Chinese Jet Fuels with Different Properties. J. Propuls. Technol. 1987, 6, 44–50+90. [Google Scholar]

- Wang, Y.; Lin, Y.; Li, L.; Xue, X. Experimental Investigation on Ignition Performance of Internally-Staged Combustor. J. Propuls. Technol. 2016, 37, 98–104. [Google Scholar]

- Zhang, X.; Xu, P.; Zhang, Y.; Wang, J. Impact of Low Pressure on Pressure Fluctuations and Heat Release Pulsations of an Afterburner. J. Aerosp. Power 1996, 84–87. [Google Scholar]

- Nguyen, D.N.; Ishida, H.; Shioji, M. Ignition and Combustion Characteristics of Gas-to-Liquid Fuels for Different Ambient Pressures. Energy Fuels 2010, 24, 365–374. [Google Scholar] [CrossRef]

- Okai, K.; Himeno, T.; Watanabe, T.; Kobayashi, H.; Taguchi, H. Investigation of Combustion and Altitude-Ignition Performance of a Small Hydrogen-Fueled Reversed-Flow Turbine Combustor. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MA, USA, 13–17 January 2014; p. 1514. [Google Scholar]

- Drell, I.L.; Belles, F.E. Survey of Hydrogen Combustion Properties. NACA RM E57D24, 1957. [Google Scholar]

- Fine, B. Further Experiments on the Stability of Laminar and Turbulent Hydrogen-Air Flames at Reduced Pressures. NACA TN 3977, 1957. [Google Scholar]

- Xiao, X.; Wang, D.; Wang, H. Experimental Study of Pre-Combustion Flameholder under High Altitude and Low Pressure. Aeroengine 1999, 31, 22–30. [Google Scholar]

- Chen, N.; Zhou, Y. Effect of Advanced Fuel Temperature on the High Altitude Ignition Performance. J. Propuls. Technol. 1996, 17, 69–72. [Google Scholar]

- Zheng, D.; Zhang, H.; Lin, W.; Wang, J. Experimental Investigation on Performance of Vapor Flame Holder at Normal and Low Pressure. J. Harbin Inst. Technol. 2004, 12, 1724–1728. [Google Scholar]

- Han, Q.; Wang, J. Experimental Investigation on Performance of Vapor Barchane Dune Vortex Flameholder at Low Pressure. J. Propuls. Technol. 2001, 22, 40–42+76. [Google Scholar]

- Liu, H.; Wang, F.; Wang, J. Experimental Study on Low Pressure Performance of a Special Vapor Flameholder. J. Chang. Univ. Sci. 2004, 16, 12–14. [Google Scholar]

- Cheng, X.; Fan, Y. Experimental Study of Lean Ignition and Lean Blowout Performance Improvement Using an Evaporation Flameholder. Int. J. Heat Mass Transf. 2016, 103, 319–326. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Su, X. Experimental Investigation of Vaporizing Flameholder at Low Pressure and High Temperature. J. Propuls. Technol. 2006, 27, 208–210. [Google Scholar]

- Niu, Z.; Fei, L.; Feng, S.; He, X. Experiment on Combustion Performance of a Ramjet Prototype Combustor in Low Pressure Condition. J. Propuls. Technol. 2011, 32, 509–511+524. [Google Scholar]

- Zhu, Z.; Huang, Y.; Zhang, H.; He, X. Combustion Performance in a Cavity-Based Combustor under Subatmospheric Pressure. Fuel 2021, 302, 121115. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Y.; Ling, W. Research on Numerical Simulation of Oxygen-Rich Combustion in a Ramjet Combustor. Tactical Missile Technol. 2015, 1, 64–68+101. [Google Scholar]

- Luo, W.; Pan, Y.; Tan, J.; Wang, Z. Experimental Investigation on Combustion Efficiency of the Ramjet Model at Low Pressure. J. Propuls. Technol. 2010, 31, 270–275. [Google Scholar]

- Xi, W. Numerical and Experimental Research on the Ramjet Combustor Based on Cavity. Master’s Thesis, National University of Defense Technology, Changsha, China, 2008. [Google Scholar]

- Chen, L.; Ling, W. Influence of Vaporizing Flame Holder Structure on Combustion Efficiency at Low Pressure. Tactical Missile Technol. 2013, 6, 66–73. [Google Scholar]

- Read, R.W.; Rogerson, J.W.; Hochgreb, S. Relight Imaging at Low Temperature, Low Pressure Conditions. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. [Google Scholar] [CrossRef]

- Linassier, G.; Viguier, C.; Verdier, H.; Lecourt, R.; Heid, G.; Lavergne, G. Experimental Investigations of the Ignition Performances on a Multi-Sector Combustor under High Altitude Conditions. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; pp. 1–9. [Google Scholar] [CrossRef]

- Giusti, A.; Sitte, M.P.; Borghesi, G.; Mastorakos, E. Numerical Investigation of Kerosene Single Droplet Ignition at High-Altitude Relight Conditions. Fuel 2018, 225, 663–670. [Google Scholar] [CrossRef]

- Chen, G.; Wang, X.; Lin, B. Experimental Study on Blowout Characteristics of Aeroengine Combustor under High Altitude Low Pressure and Low Temperature Condition. Phys. Gases 2019, 4, 43–51. [Google Scholar]

- Chen, J.; Li, J.; Yuan, L. Effects of Inlet Pressure on Ignition of Spray Combustion. Int. J. Aerosp. Eng. 2018, 2018, 3847264. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; He, Y.; Xia, J.; Zhang, J.; Zhao, H.; Cen, K. Ignition, Puffing and Sooting Characteristics of Kerosene Droplet Combustion under Sub-Atmospheric Pressure. Fuel 2021, 285, 119182. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; He, Y.; Huang, J.; Cen, K. Interactive Effects in Two-Droplets Combustion of Rp-3 Kerosene under Sub-Atmospheric Pressure. Processes 2021, 9, 1229. [Google Scholar] [CrossRef]

- Chen, B.H.; Liu, J.Z.; Yao, F.; He, Y.; Yang, W.J. Ignition Delay Characteristics of RP-3 under Ultra-Low Pressure (0.01–0.1 MPa). Combust. Flame 2019, 210, 126–133. [Google Scholar] [CrossRef]

- Zhang, J. Study on the Laminar Combustion Characteristics of Domestic Kerosene RP-3 under Atmospheric Pressure. Ph.D Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Huang, Y.; He, X.; Zhu, Z.; Zhu, H. Inlet Pressure Effects on Subatmospheric Flame Stabilization with an Optimum Size of a Cavity-Based Combustor. Int. J. Aerosp. Eng. 2020, 2020, 4126753. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Zhang, H.; Wei, J.; Sng, D.W.M. Spark Ignition and Stability Limits of Spray Kerosene Flames under Subatmospheric Pressure Conditions. Aerosp. Sci. Technol. 2021, 114, 106734. [Google Scholar] [CrossRef]

- Hirst, R.; Sutton, D. The Effect of Reduced Pressure and Airflow on Liquid Surface Diffusion Flames. Combust. Flame 1961, 5, 319–330. [Google Scholar] [CrossRef]

- De Ris, J.; Murty Kanury, A.; Yuen, M.C. Pressure Modeling of Fires. Symp. Combust. 1973, 14, 1033–1044. [Google Scholar] [CrossRef]

- Alpert, R.L. Pressure Modeling of Fires Controlled by Radiation. Symp. Combust. 1977, 16, 1489–1500. [Google Scholar] [CrossRef]

- De Ris, J.L.; Wu, P.K.; Heskestad, G. Radiation Fire Modeling. Proc. Combust. Inst. 2000, 28, 2751–2759. [Google Scholar] [CrossRef]

- Kleinhenz, J.; Feier, I.I.; Hsu, S.Y.; T’ien, J.S.; Ferkul, P.V.; Sacksteder, K.R. Pressure Modeling of Upward Flame Spread and Burning Rates over Solids in Partial Gravity. Combust. Flame 2008, 154, 637–643. [Google Scholar] [CrossRef]

- Jun, F.; Yu, C.Y.; Ran, T.; Qiao, L.F.; Zhang, Y.M.; Wang, J.J. The Influence of Low Atmospheric Pressure on Carbon Monoxide of N-Heptane Pool Fires. J. Hazard. Mater. 2008, 154, 476–483. [Google Scholar] [CrossRef]

- Lastrina, F.A.; Magee, R.S.; McAlevy, R.F. Flame Spread over Fuel Beds: Solid-Phase Energy Considerations. Symp. Combust. 1971, 13, 935–948. [Google Scholar] [CrossRef]

- Gohari Darabkhani, H.; Bassi, J.; Huang, H.W.; Zhang, Y. Fuel Effects on Diffusion Flames at Elevated Pressures. Fuel 2009, 88, 264–271. [Google Scholar] [CrossRef]

- Most, J.M.; Mandin, P.; Chen, J.; Joulain, P.; Durox, D.; Carlos Fernande-Pello, A. Influence of Gravity and Pressure on Pool Fire-Type Diffusion Flames. Symp. Combust. 1996, 26, 1311–1317. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Bi, Y.; Li, C.; Kong, D.; Lu, S. Effect of Initial Pressure on the Burning Behavior of Ethanol Pool Fire in the Closed Pressure Vessel. Process Saf. Environ. Prot. 2021, 153, 159–166. [Google Scholar] [CrossRef]

- Wieser, D.; Jauch, P.; Willi, U. The Influence of High Altitude on Fire Detector Test Fires. Fire Saf. J. 1997, 29, 195–204. [Google Scholar] [CrossRef]

- Li, Z.; He, Y.; Zhang, H.; Wang, J. Combustion Characteristics of N-Heptane and Wood Crib Fires at Different Altitudes. Proc. Combust. Inst. 2009, 32, 2481–2488. [Google Scholar] [CrossRef]

- Li, Z. Research on the Fuel Combustion Characteristics and the Flue Gas Characteristics under the Tibetan Plateau Environment of Hyperpiesia and Hypoxia. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2009. [Google Scholar]

- Yan, Z.G.; Guo, Q.H.; Zhu, H. hua Full-Scale Experiments on Fire Characteristics of Road Tunnel at High Altitude. Tunn. Undergr. Sp. Technol. 2017, 66, 134–146. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, L.; Wu, L.; Kostiuk, L.W. Flame Radiation Emission from Pool Fires under the Influence of Cross Airflow and Ambient Pressure. Combust. Flame 2019, 202, 243–251. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z.; Chen, M. Experimental Investigation on the Effect of Ambient Pressure on Entrainment Coefficient of Pool Fires. Appl. Therm. Eng. 2019, 148, 939–943. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Z. Examination of Radiative Fraction of Small-Scale Pool Fires at Reduced Pressure Environments. Fire Saf. J. 2019, 110, 102894. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, Q.; Zhang, X.; Zhang, J.; Yang, R.; Lu, Y. Experimental Study and Thermal Hazard Analysis of Large-Scale n-Heptane Pool Fires under Sub-Atmospheric Pressure. Process Saf. Environ. Prot. 2022, 166, 279–289. [Google Scholar] [CrossRef]

- Zhu, P.; Tao, Z.X.; Li, C.; Liu, Q.Y.; Shao, Q.; Yang, R.; Zhang, H. Experimental Study on the Burning Rates of Ethanol-Gasoline Blends Pool Fires under Low Ambient Pressure. Fuel 2019, 252, 304–315. [Google Scholar] [CrossRef]

- Meng, D.; Wang, X.; Li, H.; Wang, J. Experimental Study on Spreading and Burning Characteristics of Continuous Spill Fire under Low Pressure. Fire Saf. J. 2022, 134, 103704. [Google Scholar] [CrossRef]

- Fang, J.; Tu, R.; Guan, J.F.; Wang, J.J.; Zhang, Y.M. Influence of Low Air Pressure on Combustion Characteristics and Flame Pulsation Frequency of Pool Fires. Fuel 2011, 90, 2760–2766. [Google Scholar] [CrossRef]

- Chen, J.; Tam, W.C.; Tang, W.; Zhang, C.; Li, C.; Lu, S. Experimental Study of the Effect of Ambient Pressure on Oscillating Behavior of Pool Fires. Energy 2020, 203, 117783. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Q.; Wang, X.; Yang, J.; Zhao, J.; Huang, H. Experimental Study on Burning Characteristics of Ethanol Pool Fire in Plateau. J. Saf. Sci. Technol. 2022, 18, 66–71. [Google Scholar]

- Tang, Y.; Niu, Y.; Yin, L.; Zhou, D.; Wang, J. Experiment Studies on the Effect of Altitude on Jet A’s Flash Point. Fire Mater. 2012, 37, 474–481. [Google Scholar] [CrossRef]

- Ding, C.; Yao, W.; Zhou, D.; Rong, J.; Zhang, Y.; Zhang, W.; Wang, J. Experimental Study and Hazard Analysis on the Flash Point of Flammable Liquids at High Altitudes. J. Fire Sci. 2013, 31, 469–477. [Google Scholar] [CrossRef]

- Ding, C.; Yao, W.; Tang, Y.; Rong, J.; Zhou, D.; Wang, J. Experimental Study of the Flash Point of Flammable Liquids under Different Altitudes in Tibet Plateau. Fire Mater. 2014, 38, 241–246. [Google Scholar] [CrossRef]

- Ding, C.; He, Y.; Yin, J.; Yao, W.; Zhou, D.; Wang, J. Study on the Pressure Dependence of Boiling Point, Flashpoint, and Lower Flammability Limit at Low Ambient Pressure. Ind. Eng. Chem. Res. 2015, 54, 1899–1907. [Google Scholar] [CrossRef]

- Ding, C. Experimental Research on the Flashpoing-Boiling Point of Flammable Liquid and Their Applications under Low Pressure. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2016. [Google Scholar]

- Chen, Q. Experimental and Theoretical Study on the Influence of Water Content on Liquid Fuel Fire Hazard under Normal and Low Pressures. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2018. [Google Scholar]

- Wu, Z. Study of the Ignition and Combustion Intensification of Liquid Fuels in Reduced Pressure at High Altitudes. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2017. [Google Scholar]

- Jia, X.; Ma, J.; Tao, W.; Yang, X. Progress in the Study of Combustion Characteristics of Solid Materials under Low Pressure Environment. Fire Sci. Technol. 2022, 41, 174–179. [Google Scholar]

- Hirsch, D.; Williams, J.; Beeson, H. Pressure Effects on Oxygen Concentration Flammability Thresholds of Polymeric Materials for Aerospace Applications. J. Test. Eval. 2008, 36, 69–72. [Google Scholar] [CrossRef]

- McAllister, S.; Fernandez-Pello, C.; Urban, D.; Ruff, G. Piloted Ignition Delay of PMMA in Space Exploration Atmospheres. Proc. Combust. Inst. 2009, 32, 2453–2459. [Google Scholar] [CrossRef]

- Jia, X.; Ma, J.; Tang, J.; Liu, Q.; Zhu, X.; Zhu, Y.; He, Y. Experimental Study on the Fire Behavior of the Corrugated Cartons under Low-Pressure Environment with Oxygen-Enriched. Int. J. Therm. Sci. 2023, 193, 108450. [Google Scholar] [CrossRef]

- Thomsen, M.; Fernandez-Pello, C.; Olson, S.L.; Ferkul, P.V. Downward Burning of PMMA Cylinders: The Effect of Pressure and Oxygen. Proc. Combust. Inst. 2021, 38, 4837–4844. [Google Scholar] [CrossRef]

- Thomsen, M.; Murphy, D.C.; Fernandez-Pello, C.; Urban, D.L.; Ruff, G.A. Flame Spread Limits (LOC) of Fire Resistant Fabrics. Fire Saf. J. 2017, 91, 259–265. [Google Scholar] [CrossRef]

- Zarzecki, M.; Quintiere, J.G.; Lyon, R.E.; Rossmann, T.; Diez, F.J. The Effect of Pressure and Oxygen Concentration on the Combustion of PMMA. Combust. Flame 2013, 160, 1519–1530. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.X.; Zhao, L.Y.; Liu, J.; Wang, J.J.; Zhang, Y.M. Flame Propagation over Energized Pe-Insulated Wire under Low Pressure. Int. J. Comput. Methods Exp. Meas. 2017, 5, 87–95. [Google Scholar] [CrossRef]

- Ding, C.; Yan, Z.; Li, Y.; He, L.; Ma, S.; Wang, X.; Huang, Q.; Jiao, Y.; Liu, C. Effect of Pressure and Stacking Method on Combustion Characteristics of Paper Stacks. Case Stud. Therm. Eng. 2022, 38, 102375. [Google Scholar] [CrossRef]

- Feng, R.; Tian, R.; Zhang, H.; Zheng, L.; Yang, R. Experimental Study on the Burning Behavior and Combustion Toxicity of Corrugated Cartons under Varying Sub-Atmospheric Pressure. J. Hazard. Mater. 2019, 379, 120785. [Google Scholar] [CrossRef]

- Ma, Q.; Shao, J.; Wan, M.; Liu, Q.; Zhang, H. Experimental Study on the Burning Behavior of Cardboard Box Fire under Low Air Pressure. Fire Mater. 2021, 45, 273–282. [Google Scholar] [CrossRef]

- Zhao, K.; Yang, L.; Tang, W.; Liu, Q.; Ju, X.; Gong, J. Effect of Orientation on the Burning and Flame Characteristics of PMMA Slabs under Different Pressure Environments. Appl. Therm. Eng. 2019, 156, 619–626. [Google Scholar] [CrossRef]

- Huang, X.; Chen, G.; Zhou, Z.; Hu, J.; Wang, C.; Chen, D. Experimental and Numerical Study of Upward Flame Spread and Heat Transfer over Expanded Polystyrene at Different Altitudes. Case Stud. Therm. Eng. 2021, 28, 101623. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J. Experimental Study on Flame Propagation over Horizontal Electrical Wires under Varying Pressure. Int. J. Therm. Sci. 2020, 156, 106492. [Google Scholar] [CrossRef]

- Dai, J.; Yang, L.; Zhou, X.; Wang, Y.; Zhou, Y.; Deng, Z. Experimental and Modeling Study of Atmospheric Pressure Effects on Ignition of Pine Wood at Different Altitudes. Energy Fuels 2010, 24, 609–615. [Google Scholar] [CrossRef]

- Jiakun, D.; Delichatsios, M.A.; Lizhong, Y. Piloted Ignition of Solid Fuels at Low Ambient Pressure and Varying Igniter Location. Proc. Combust. Inst. 2013, 34, 2497–2503. [Google Scholar] [CrossRef]

- Yafei, W.; Lizhong, Y.; Xiaodong, Z.; Jiakun, D.; Yupeng, Z.; Zhihua, D. Experiment Study of the Altitude Effects on Spontaneous Ignition Characteristics of Wood. Fuel 2010, 89, 1029–1034. [Google Scholar] [CrossRef]

- Wang, Y. Research on Influence of Flowing Characteristics of Pyrolysis Gas on Pyrolysis and Ignition Process of Charring Materials. Ph.D Thesis, University of Science and Technology of China, Hefei, China, 2011. [Google Scholar]

- McAllister, S.; Fernandez-Pello, C.; Urban, D.; Ruff, G. The Combined Effect of Pressure and Oxygen Concentration on Piloted Ignition of a Solid Combustible. Combust. Flame 2010, 157, 1753–1759. [Google Scholar] [CrossRef]

- Qie, J.; Yang, L.; Wang, Y.; Dai, J.; Zhou, X. Experimental Study of the Influences of Orientation and Altitude on Pyrolysis and Ignition of Wood. J. Fire Sci. 2011, 29, 243–258. [Google Scholar] [CrossRef]

- Fereres, S.; Lautenberger, C.; Fernandez-Pello, C.; Urban, D.; Ruff, G. Mass Flux at Ignition in Reduced Pressure Environments. Combust. Flame 2011, 158, 1301–1306. [Google Scholar] [CrossRef]

- Fereres, S.; Lautenberger, C.; Fernandez-Pello, A.C.; Urban, D.L.; Ruff, G.A. Understanding Ambient Pressure Effects on Piloted Ignition through Numerical Modeling. Combust. Flame 2012, 159, 3544–3553. [Google Scholar] [CrossRef]

- Huang, S. Study on Combustion Properties of Typical Interior Materials of Aircraft under Low Ambient Pressure. Ph.D. Thesis, Civil Aviation Flight University of China, Deyang, China, 2019. [Google Scholar]

- Ren, B.; Li, Y.; Xu, B.; Tu, R. Study on the Influence of Atmospheric Pressure on the Ignition Model of Wood. In Proceedings of the China National Symposium on Combustion, Heifei, China; 2009; pp. 1–11. [Google Scholar]

- Peng, F. Experimental and Theoretical Study on Effect of Radiation and Covection of Ceiling on Pyrolysis, Ignition and Flame Spread of PMMA. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2016. [Google Scholar]

- Wang, W.; Wang, L.; Yang, R.; Zhang, H.; Ren, C.; Yang, J. Investigation of the Effect of Low Pressure on Fire Hazard in Cargo Compartment. Appl. Therm. Eng. 2019, 158, 113775. [Google Scholar] [CrossRef]

- Li, H. Study on Combustion Characteristics and Flame Morphologies of Gas Jets at Subatmospheric Pressures. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2014. [Google Scholar]

- Zeng, Y. Influence of Sub-Atmospheric Pressure on Jet Diffusion Flame’s Combustion Characteristics and Image Parameters. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).