2.1. Model Reduction Based on POD-SVD

Proper Orthogonal Decomposition (POD) obtains multiple sets of low-dimensional optimal bases from a large set of experimental or simulation data. POD combines these optimal bases to approximate the original complex system, achieving dimension reduction [

4,

33,

34]. For unsteady flow fields, the physical field characteristics at a given moment can be recorded as a snapshot, and snapshots from different times are then assembled to form the physical field dataset

U(

m,

N), as shown in Equation (1):

where

m represents the number of sampling points,

N denotes the number of snapshots, and

is referred to as the snapshot matrix of the original physical field.

According to POD theory [

35], the snapshot matrix is decomposed into the sum of the mean matrix

and the fluctuating matrix

, as shown in Equation (2):

The mean matrix

is calculated as follows:

Using the method of separation of variables, the fluctuation matrix

can be decomposed into POD basis vectors and modal coefficients, as shown in Equation (4):

where

represents the POD basis vectors and

denotes the modal coefficients.

By extracting the key features of the system’s evolution and using a small number of optimal modes to reconstruct complex physical processes, typically, only the first

A modes are used for flow field approximation. Therefore, Equation (4) is rewritten as Equation (5):

where

represents the approximate deviation matrix of the fluctuation matrix.

Therefore, the problem of using POD to describe flow field modal variations becomes one of determining the

A-order modes

and modal coefficients

. To ensure the accuracy of the mode truncation process, an error expression is constructed. The error between the truncated orthogonal modes and the fluctuation matrix can be expressed as Equation (6):

Utilizing the orthogonality between the proper orthogonal modes, Equation (7) can be obtained:

The truncation error can be rewritten as shown in Equation (8):

Let

, where

R is a real symmetric matrix. The truncation error can be expressed as:

Thus, the problem of finding the optimal set of modes can be transformed into minimizing the truncation error while ensuring the orthogonality of the mode set. Using the Lagrange multiplier method, we introduce the Lagrange multiplier

and construct the Lagrangian function as follows:

To find the extrema, set

, which yields:

From Equation (11), it can be seen that the Lagrange multiplier

represents the eigenvalues of the real symmetric matrix

and

represents the eigenvectors of the real symmetric matrix

. Using the properties of real symmetric matrices, all eigenvalues of the matrix

are real numbers, and the eigenvectors are mutually orthogonal. Thus, the truncation error can be expressed as:

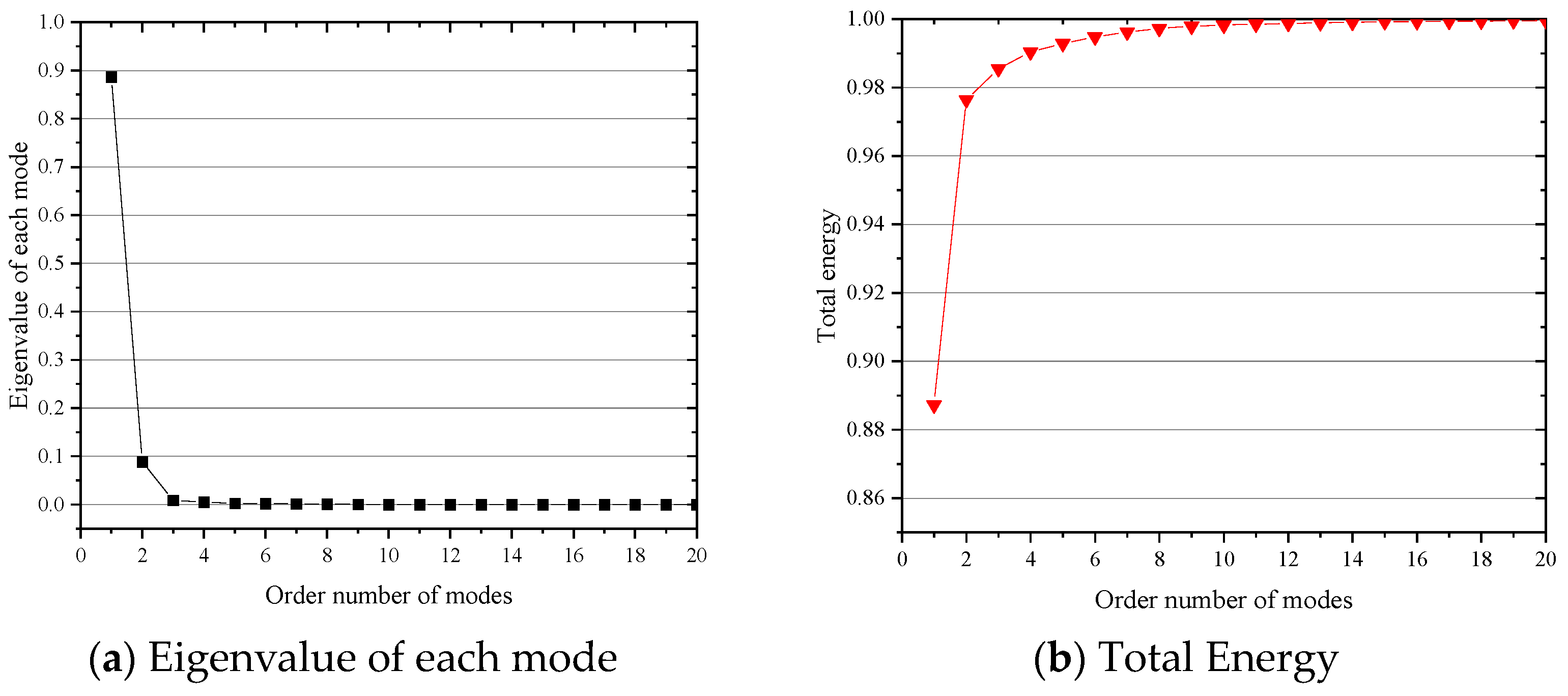

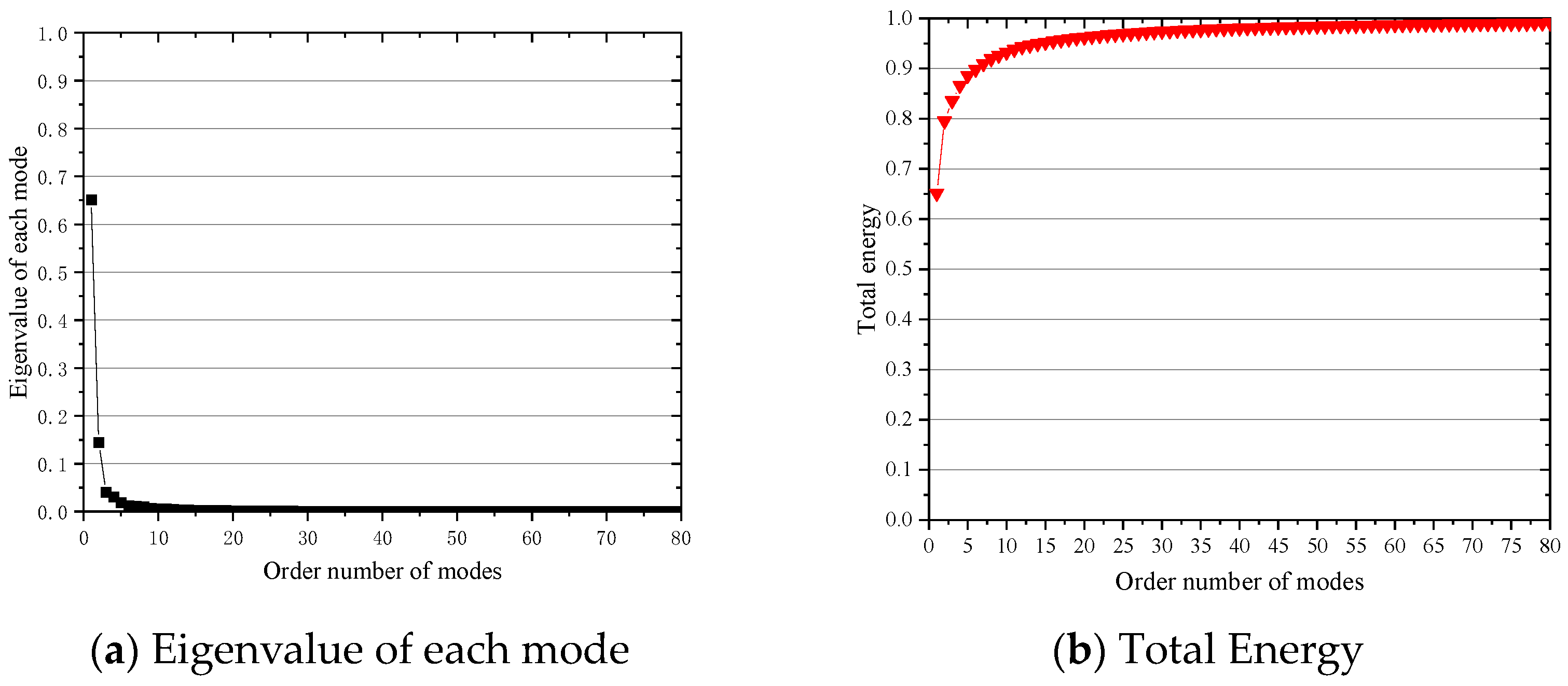

To minimize the truncation error, the eigenvalues

are arranged in descending order, and the top

N largest eigenvalues are selected. The eigenvectors corresponding to these eigenvalues constitute the optimal orthogonal mode set for POD. The selection rule is as follows:

where

represents the proportion of energy retained in the original mode set by the orthogonal mode set after truncation.

Based on the orthogonality of eigenvectors, the Singular Value Decomposition (SVD) [

36] method can simplify the solution process. By applying SVD, the matrix in Equation (2) is decomposed into three distinct matrices, namely:

where

,

,

,

B is the matrix containing the standard orthogonal eigenvectors of

, and is therefore referred to as the mode construction matrix.

S is a diagonal matrix consisting of singular values arranged in descending order, and

V represents the spatial modes.

The POD basis vectors

are solved according to Equation (15):

the modal coefficients

are solved according to Equation (16):

the energy of each mode, represented by the eigenvalues

of the characteristic matrix R, is solved according to Equation (17):

for a given snapshot matrix U, the POD basis vectors

extracted through POD decomposition are constants. In a nonlinear flow field, the modal coefficients

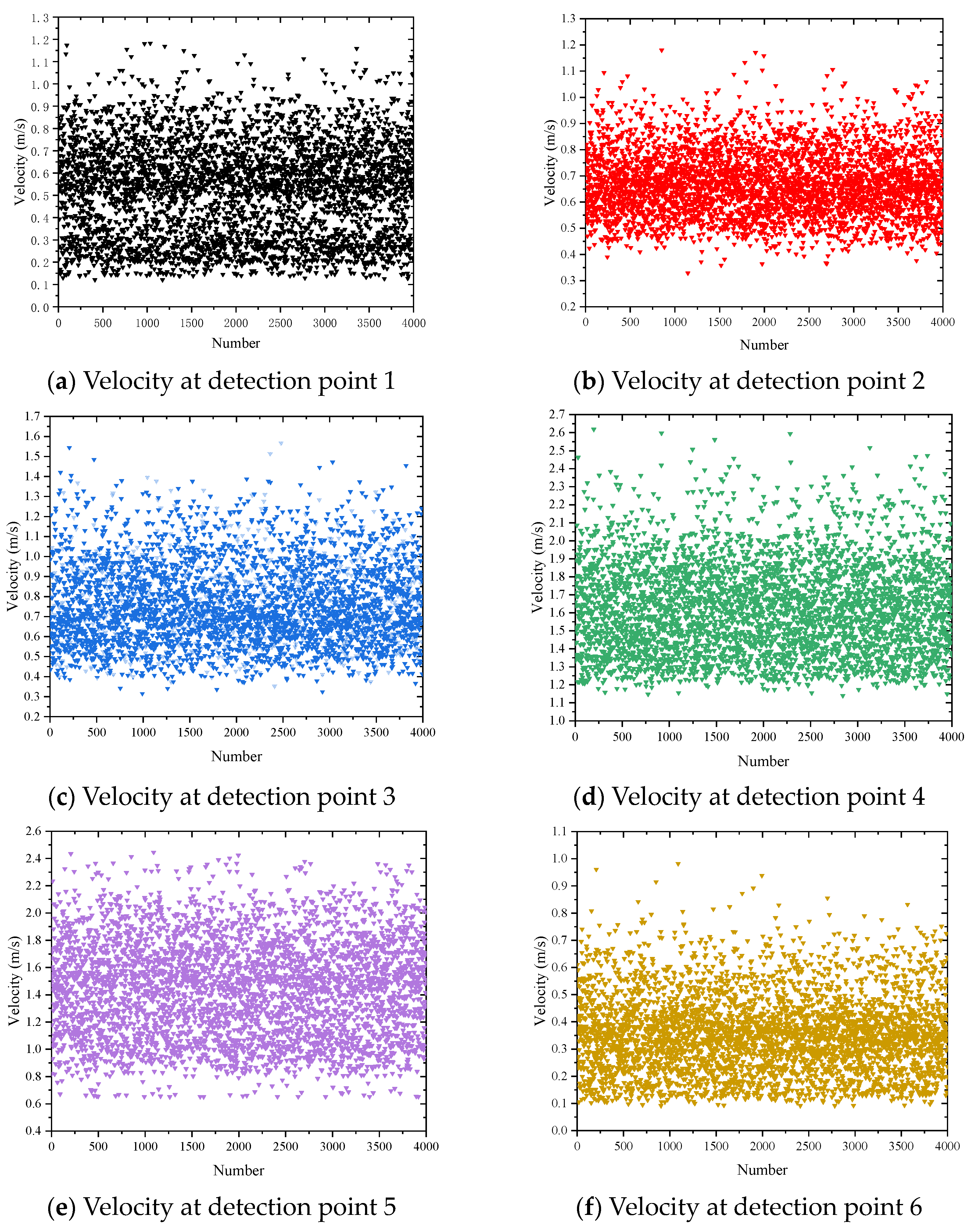

can be considered to have some implicit relationship with the local measurement points.

2.2. CSSA Improve BP

By utilizing neural network algorithms, a nonlinear transfer model between modal coefficients

and detection point features was established. The Backpropagation Neural Network (BPNN) provides high versatility and adaptability and its objective function is:

where

represents the number of training samples,

P denotes the number of neurons in the input layer,

Q is the dimension of the input variable

y,

is the predicted value, and

is the actual value.

The relationship between the input and output of a neuron can be represented by an activation function

:

where

represents the output of the

th neuron in the hidden layer,

represents the input to the

th neuron,

denotes the weight coefficient,

is the bias value of the neuron, and

represents the number of neurons in the previous layer.

In order to determine the network structure and address issues such as the algorithm easily getting trapped in local optima and slow convergence speed, the Chaotic Sparrow Search Algorithm (CSSA) was employed for optimization. In SSA, a matrix was used to represent the position coordinates of virtual sparrows during the food search process:

where

represents the position of the sparrow in space. The sparrow’s foraging process was abstracted into a producer–joiner model, where the producer updated its position using the following equation:

where

represents the current iteration count,

is the maximum number of iterations,

is a uniform random number between [0, 1],

is a random number following a normal distribution,

is a matrix of size

with all elements equal to 1, and

and

represent the warning and safety values, respectively. When

, it indicates that the population has not detected the presence of predators or other dangers, guiding the population to achieve higher fitness. Conversely, when

, the scouting sparrow detects a predator and immediately releases a danger signal, prompting the population to adjust its search strategy and move towards a safer area.

Sparrows other than the producers, acting as joiners, updated their positions using the following equation:

where

represents the worst position of the sparrow in the

d-dimensional space during the

t-th iteration of the population;

represents the best position of the sparrow in the

d-dimensional space during the

-th iteration; when

, it indicates that an

i-th joiner did not obtain food, resulting in low fitness, and needs to search for food elsewhere; when

, the

i-th joiner randomly searches for food near the current optimal position

.

The position of the scouting sparrow is updated according to the following equation:

where

represents the step size control parameter, which follows a normal distribution with a mean of 0 and a variance of 1;

is the step size control parameter;

;

is a very small constant;

is the fitness value of an individual;

and

represent the best and worst fitness values in the population, respectively.

To prevent the SSA from getting trapped in local optima and to increase population diversity, Tent chaotic perturbation was introduced, which carries the chaotic variables into the solution space:

where

and

represent the maximum and minimum values of the

-dimensional variable

.

The individual chaotic disturbance was applied according to the following equation:

where

represents the individual requiring chaotic disturbance,

is the generated chaotic disturbance, and

is the individual after chaotic disturbance.

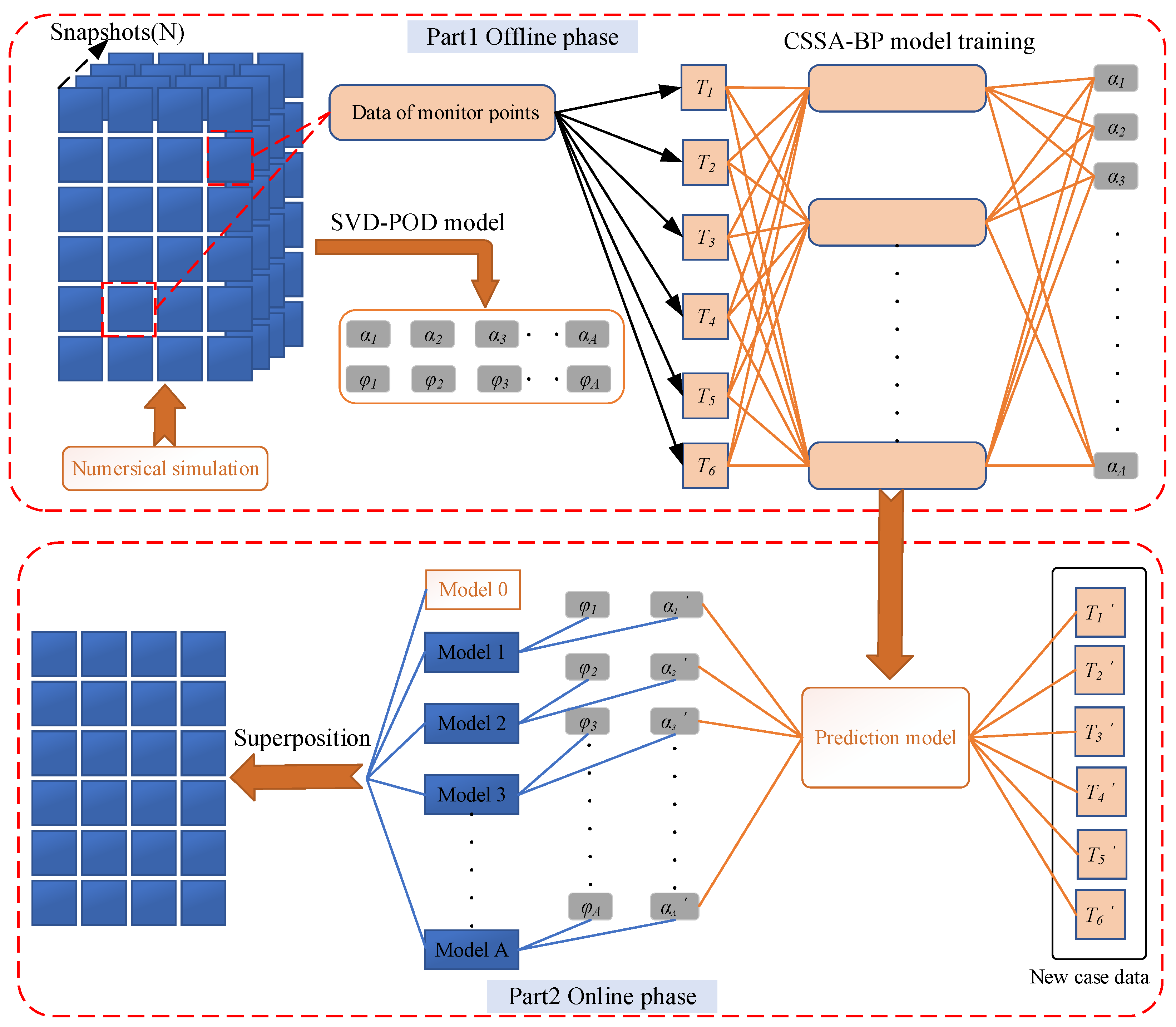

2.3. Flow Field Rapid Reconstruction Model Based on Limited Detection Point Information

Based on the SVD-POD method introduced in

Section 2.1 and the CSSA-BP method introduced in

Section 2.2, a data-driven deep learning model can be established for the rapid reconstruction of flow field states, as shown in

Figure 1.

The model can be divided into two parts:

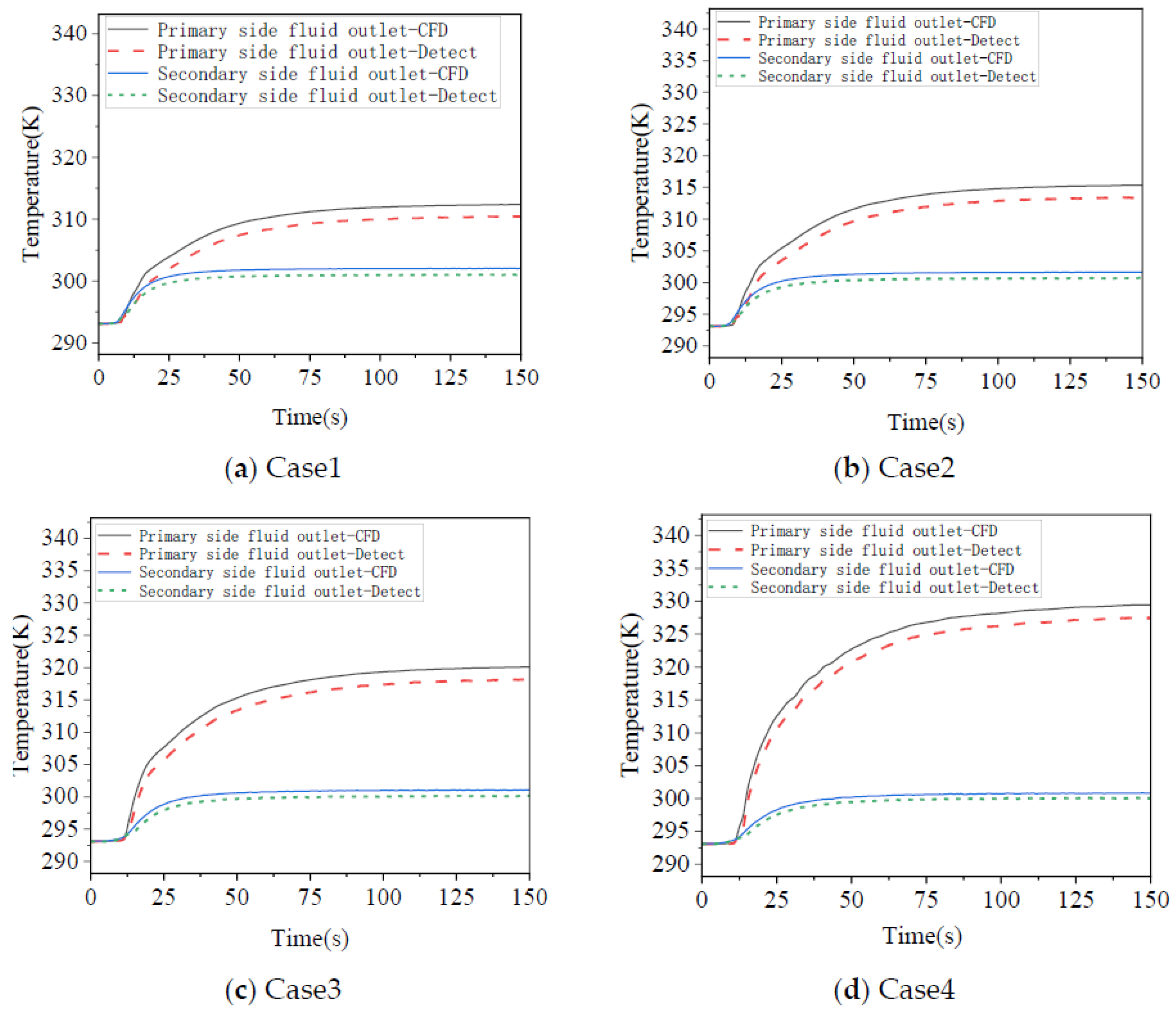

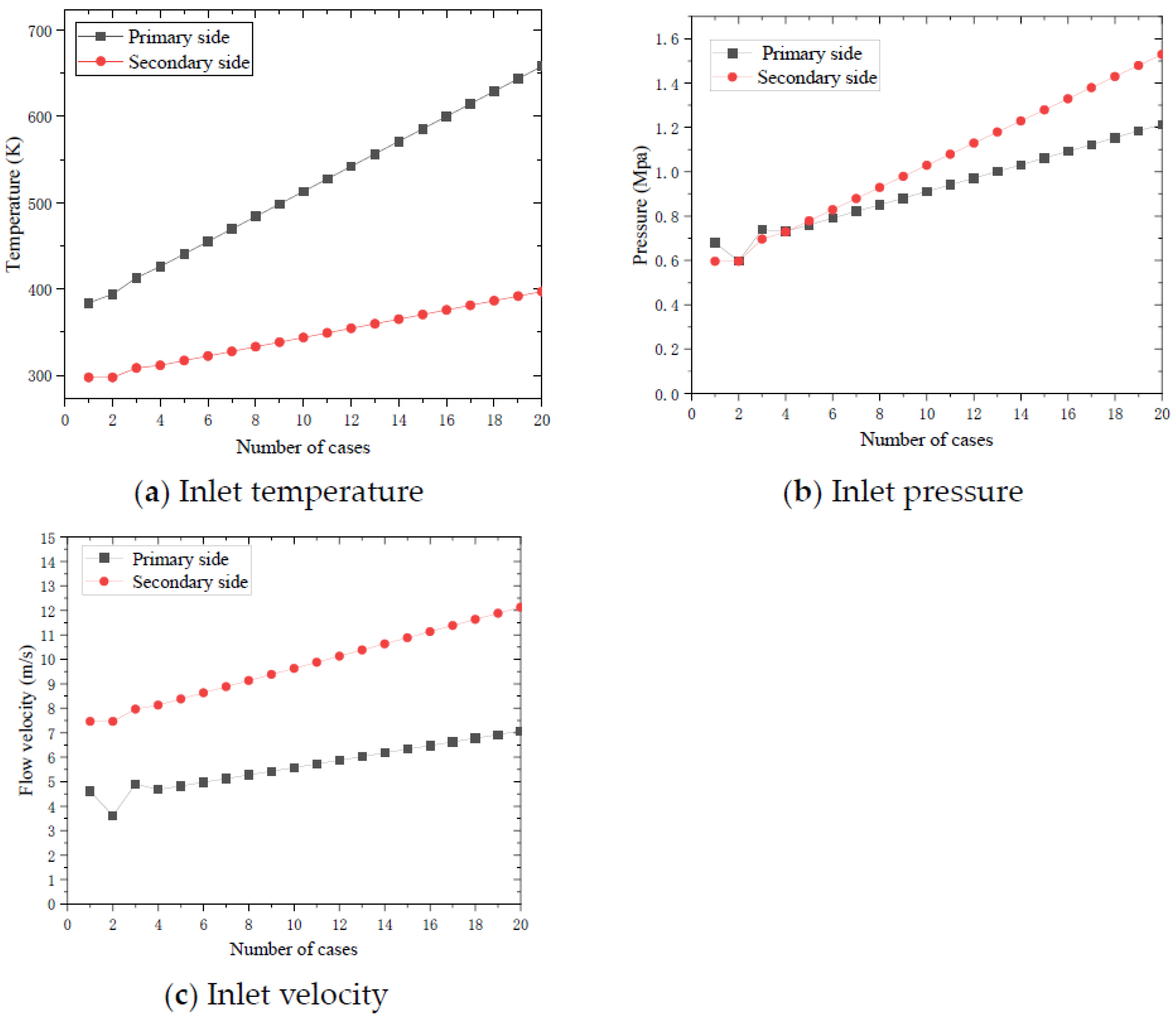

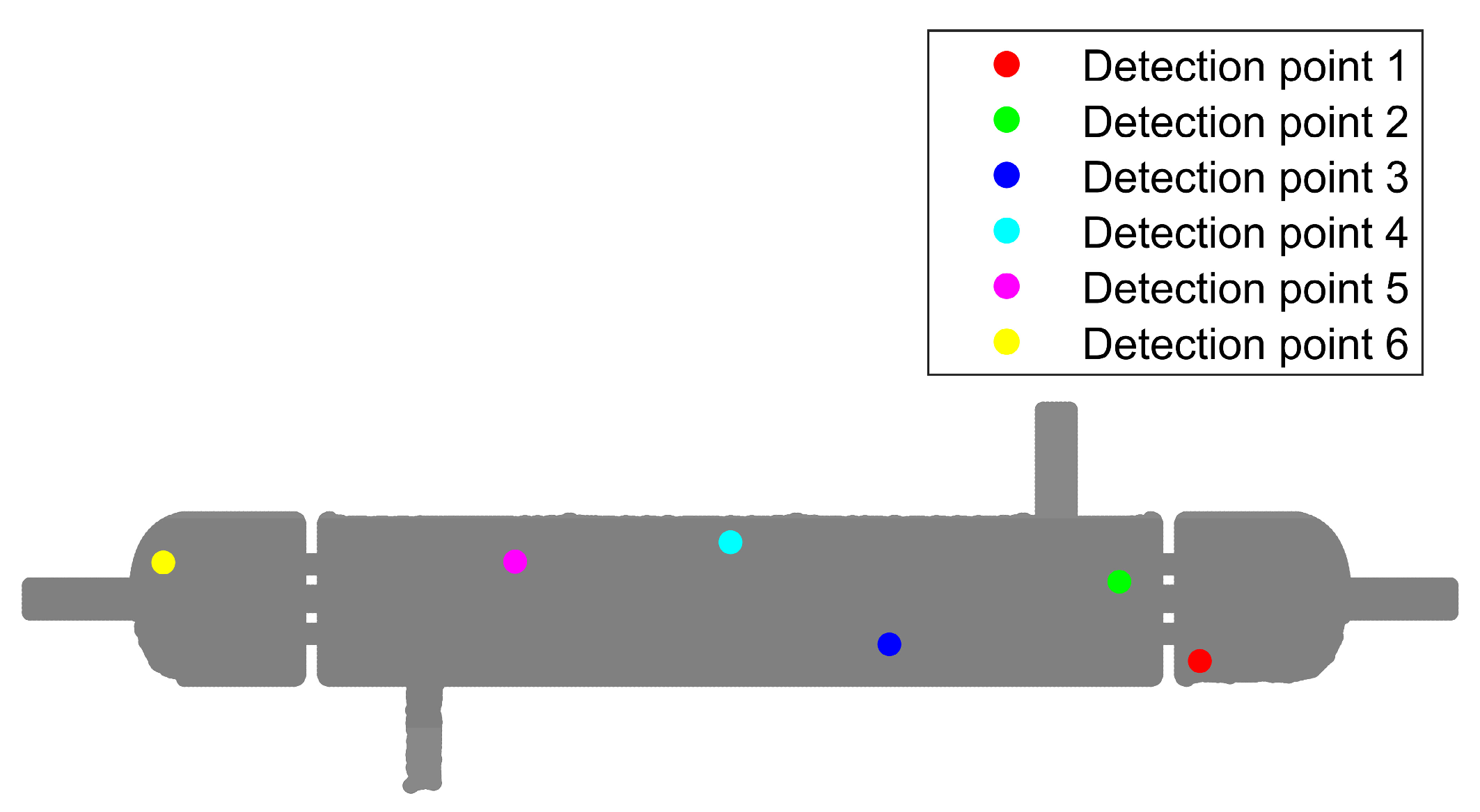

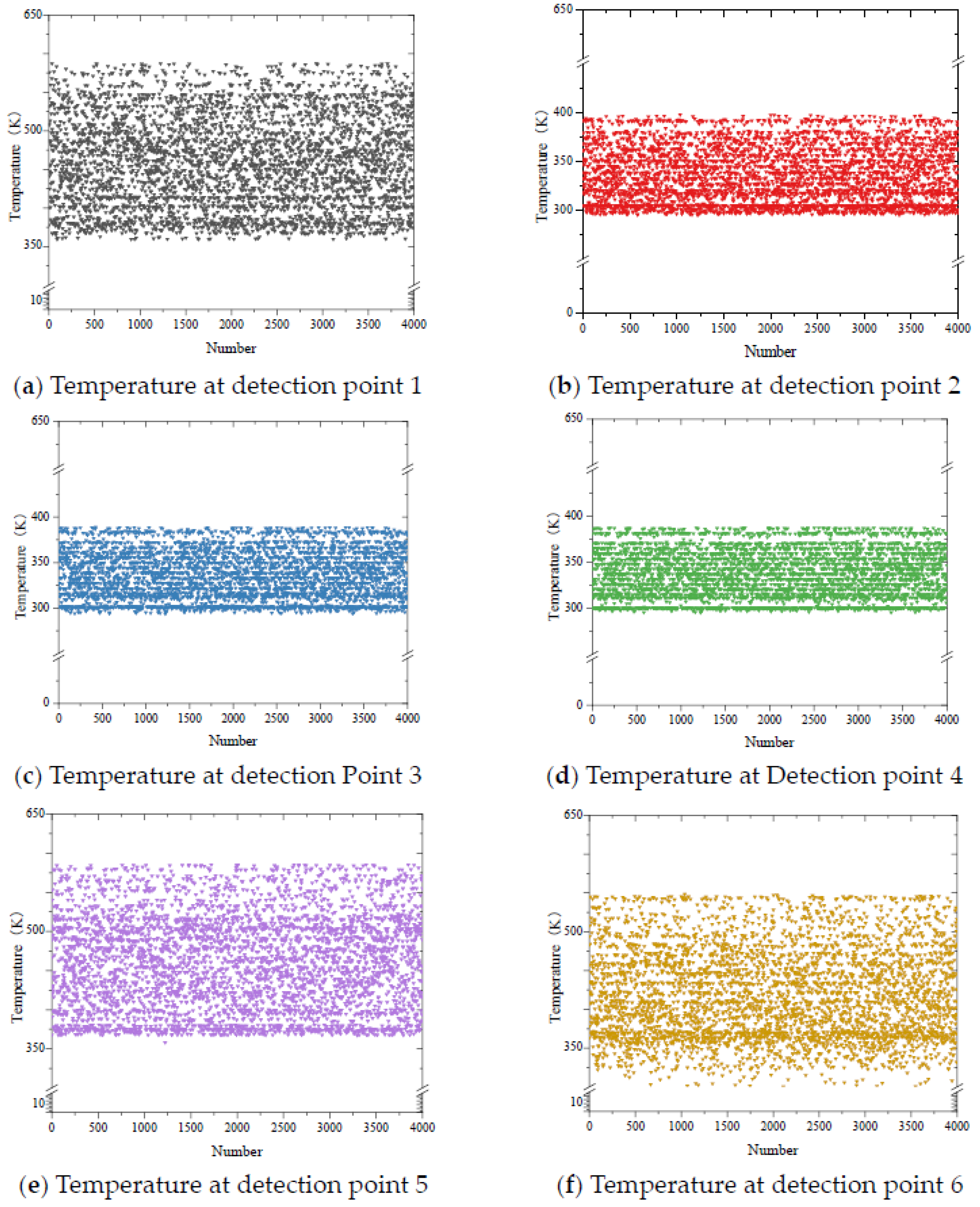

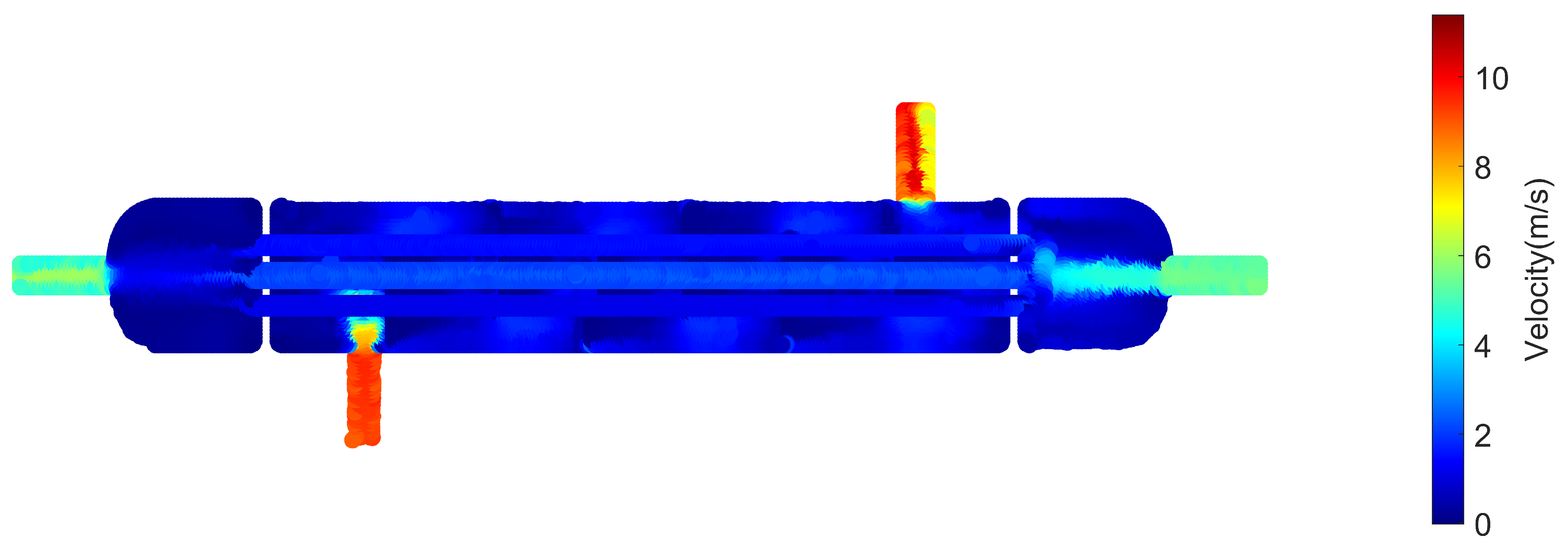

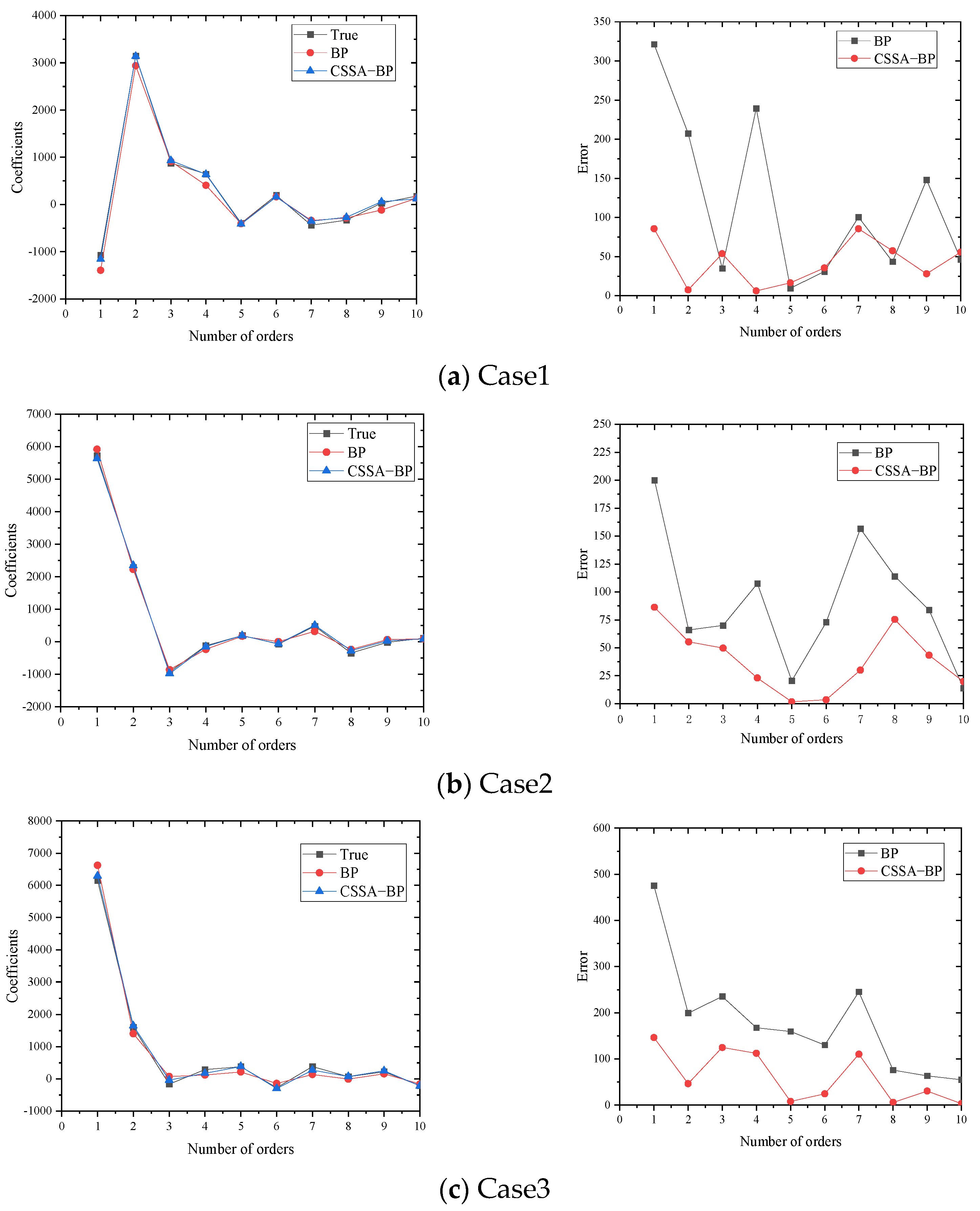

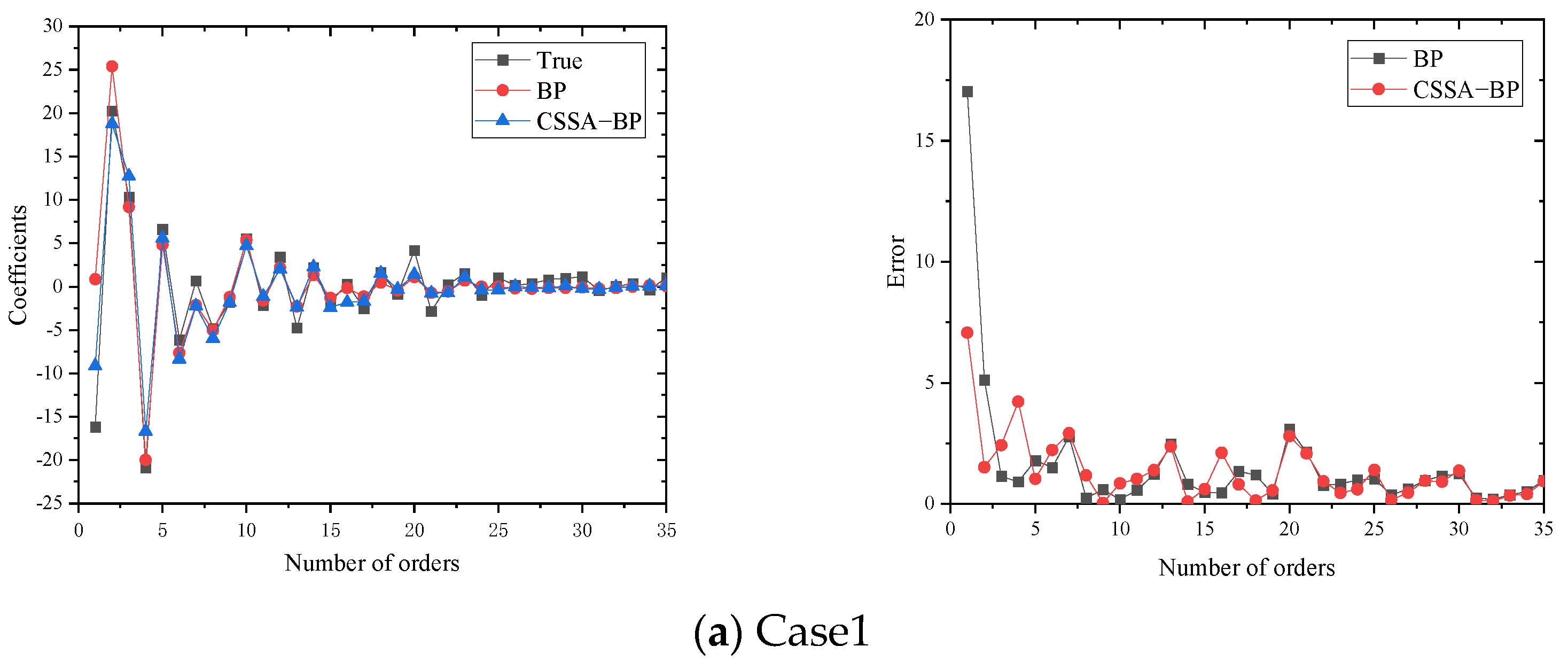

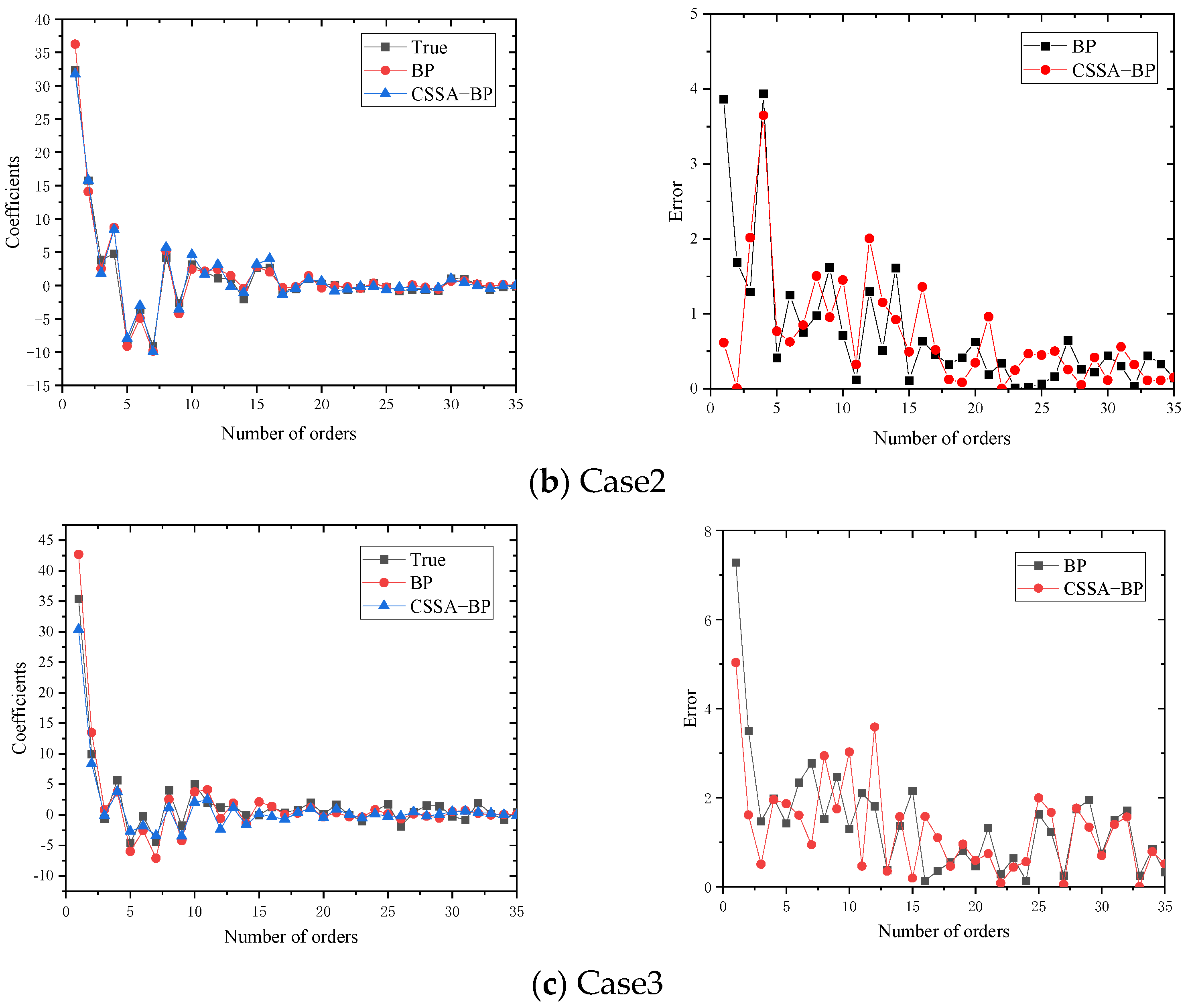

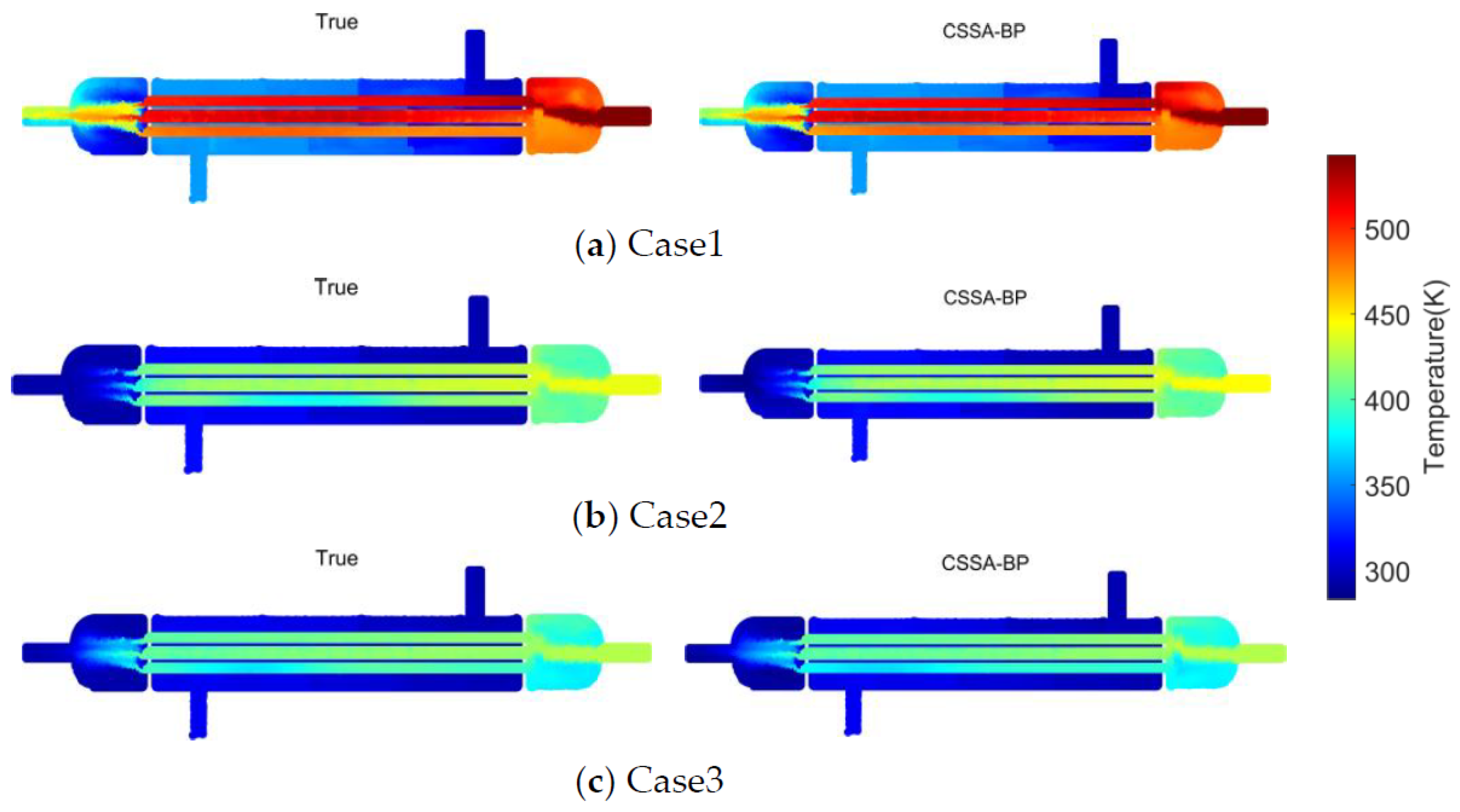

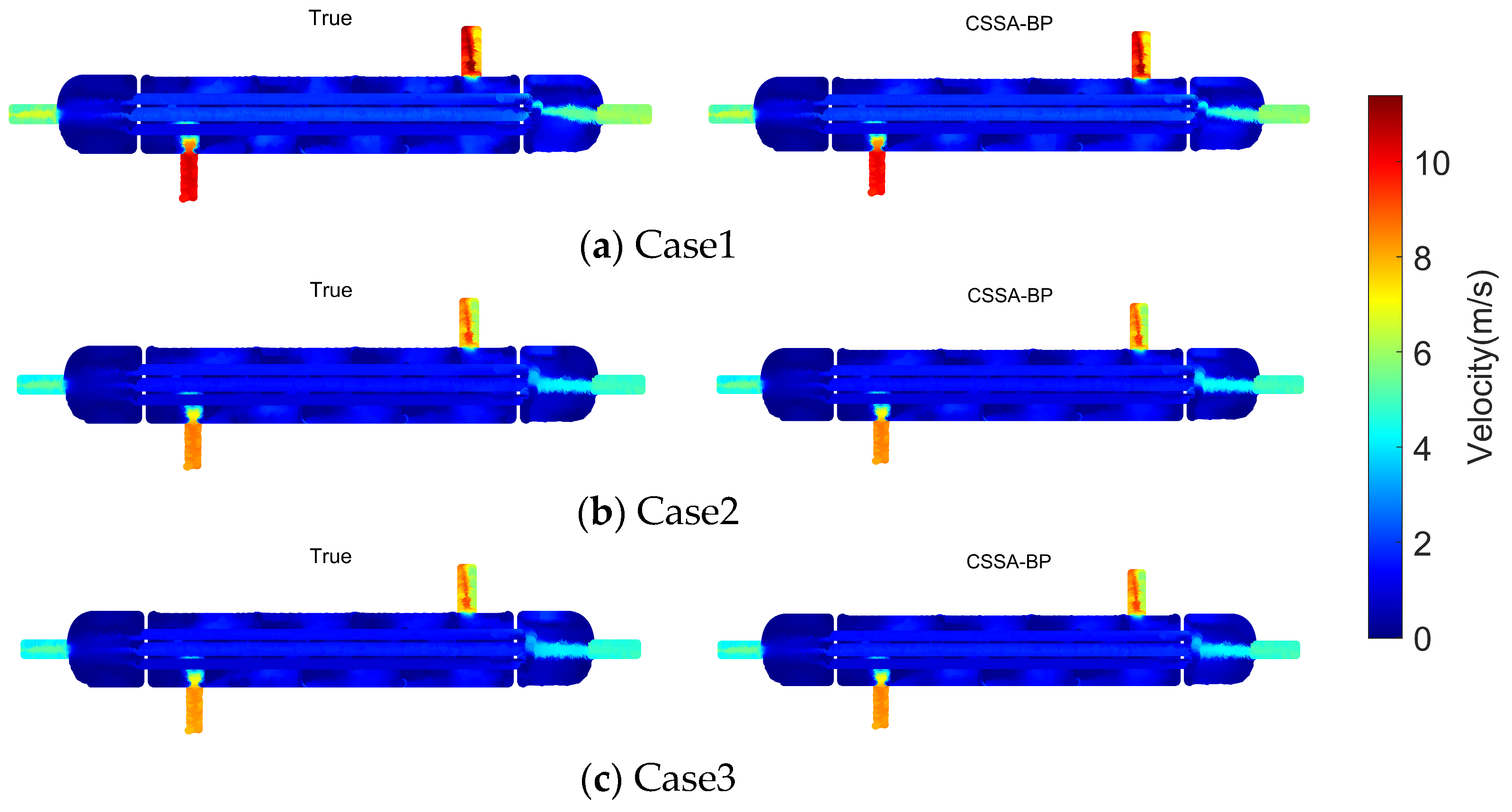

Offline phase: Based on different operating conditions of the equipment, a series of numerical simulations of the flow field were conducted. Representative planes were extracted from the CFD simulation results to construct snapshot data. The SVD-POD method was then used to perform modal decomposition on the snapshot matrix, resulting in POD modes and corresponding feature coefficients. The average mode of the flow field was extracted, and the top A modes were selected based on the truncated modal energy ratio requirement to approximate the dynamic characteristics of the physical system. Detection point data were extracted and combined with the top A-order POD modal coefficients to train a CSSA-BP model, which established a surrogate relationship between the detection point data and the global flow field state.

Online Phase: When the equipment operates under new working conditions, information from the detection points is obtained and input into the trained neural network. This allows for the rapid acquisition of flow field modal coefficients under the new conditions. The deterministic POD modes obtained during the offline phase are linearly combined with the characteristic coefficients predicted by the CSSA-BP model and then superimposed with the average flow field mode to quickly reconstruct the flow field.

Through these steps, the dimensionality of the flow field system is reduced, enabling the rapid reconstruction of the physical field inside the pressure vessel. This provides a foundation for the online monitoring of pressure vessel equipment and the development of digital twins.