Modelling and Transmission Characteristics Analysis of APU Pneumatic Servo System

Abstract

1. Introduction

2. Pneumatic Servo System Working Principle and Modelling

2.1. Working Principle

2.2. Mathematical Model

2.2.1. Mathematical Model of Torque Motor

2.2.2. Mathematical Modelling of Single-Nozzle Baffle Valve

2.2.3. Mathematical Modelling of Actuator Cylinder

2.2.4. Mathematical Modelling of Butterfly Valve

3. Model Parameter Determination and Model Validation

3.1. Analysis of Aerodynamic Torque Characteristics

3.1.1. Introduction of Experimental Equipment and Plan

- (a)

- Energize the solenoid switch valve and the angular displacement sensor;

- (b)

- Open the air supply switch to ventilate the product inlet;

- (c)

- Adjust the regulating valve and feed 335 ± 10 kPa, 188 ± 10 °C high temperature air into the product;

- (d)

- Input control current to torque motor (0~100 mA);

- (e)

- Record the corresponding test data of pressure sensor, displacement sensor and angular displacement sensor.

3.1.2. Analysis of Aerodynamic Torque During Butterfly Valve Closing

3.1.3. Analysis of Aerodynamic Torque of Different Butterfly Valve Openings

3.1.4. Aerodynamic Moment Proxy Model Building Method

3.2. System Model Verification

3.2.1. Torque Motor Mathematical Model Verification

3.2.2. Single-Nozzle Baffle Valve Mathematical Model Verification

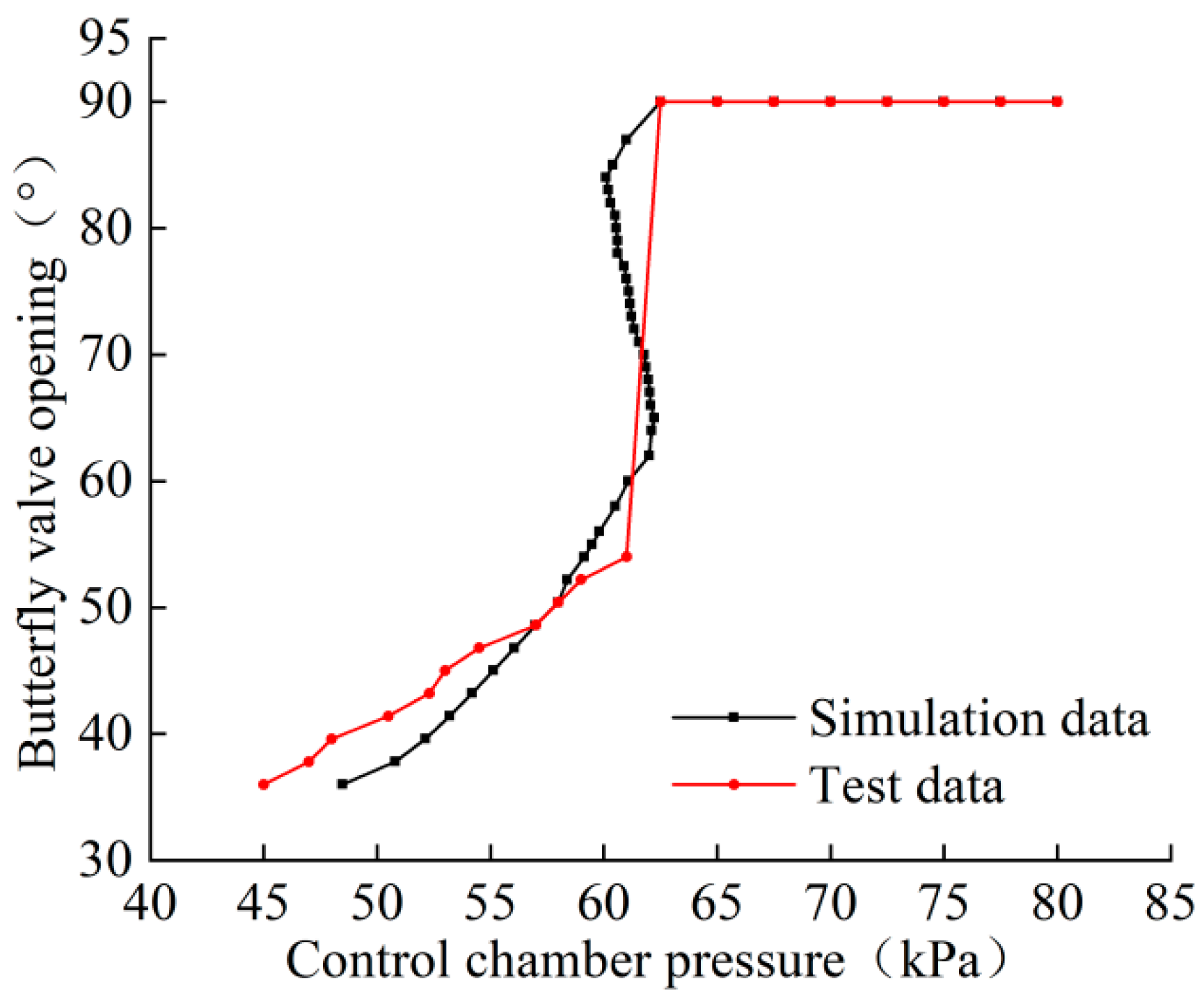

3.2.3. Actuator–Butterfly Valve Mathematical Model Verification

4. Analysis of System Transmission Characteristics

4.1. Analysis of Static Transmission Characteristics of the System

4.2. Analysis of Dynamic Transmission Characteristics of the System

4.2.1. Effect of Fixed Throttle Hole Diameter

4.2.2. Effect of Rodless Chamber Volume of Actuator Cylinder

4.2.3. Effect of Gas Supply Temperature

5. Conclusions

- (1)

- Considering the aerodynamic moment characteristics of butterfly valve assembly during operation, the aerodynamic moment characteristics are analyzed through experiments, and the aerodynamic moment proxy model is proposed and established.

- (2)

- The mathematical model of APU pneumatic servo system is established by combining mechanism analysis and parameter identification. The accuracy of the mathematical model of the system is verified by numerical simulation and comparative analysis of experiments. On this basis, the dynamic and static transmission characteristics of the system are further analyzed.

- (3)

- The throttle area ratio is too small, the difference between the upper and lower limit of the opening pressure of the rodless chamber of the actuator cylinder is large, and the linearity becomes worse. If the throttle area ratio is too large, the controllable range of the load rotating shaft becomes smaller, which affects the control of the flow rate by the servo mechanism. A suitable throttling area ratio can effectively optimize the static transmission characteristics of the pneumatic servo system.

- (4)

- The response speed of the system can be improved by increasing the diameter of the fixed orifice or decreasing the volume of the rodless cavity of the actuator cylinder. The increase of gas supply temperature can only slightly improve the response speed of the system and has little influence on the transmission characteristics of the system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; He, Z.; Xuan, H.; Liu, J.; Guo, X.; Mi, D.; Fang, Z. Study on the Optimal Design Method of the Containment Ring for an Air Turbine Starter. Aerospace 2023, 10, 624. [Google Scholar] [CrossRef]

- Popov, G.; Zubanov, V.; Baturin, O.; Kolmakova, D.; Novikova, Y.; Volkov, A. Optimization of an air turbo starter considering its joint work with an auxiliary power unit. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84089, p. V02CT35A050. [Google Scholar]

- Ramírez, I. Modeling and tracking control of a pneumatic servo positioning system. In Proceedings of the 2013 II International Congress of Engineering Mechatronics and Automation (CIIMA), Bogota, Colombia, 23–25 October 2013; IEEE: New York, NY, USA, 2013; pp. 1–6. [Google Scholar]

- Pascoe, A.G. Start systems for aero gas turbines. Aircr. Eng. Aerosp. Technol. 2005, 77, 448–454. [Google Scholar] [CrossRef]

- Wei, Q.; Jiao, Z.; Wu, S.; Yu, H. Nonlinear Composite Control of Pneumatic Servo Loading System. Chin. J. Mech. Eng. 2017, 53, 217–224. [Google Scholar] [CrossRef]

- Zhang, D.; Gao, L.; Zhou, S.; Ma, Y.; Li, B. Measurement of the mass-flow-rate characterization parameters of high-pressure pneumatic servo slide valves. Sci. Rep. 2022, 12, 3273. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.; Liu, L.; Pu, C.; Meng, D.; Páez, L.M.R. Methods to improve motion servo control accuracy of pneumatic cylinders-review and prospect. Int. J. Hydromechatron. 2023, 6, 274–310. [Google Scholar] [CrossRef]

- Vailati, L.G.; Goldfarb, M. A method for mass flow and displacement estimation in a pneumatic actuation system using valve-based pressure sensing. IEEE/ASME Trans. Mechatron. 2020, 26, 235–245. [Google Scholar] [CrossRef]

- Messina, A.; Giannoccaro, N.I.; Gentile, A. Experimenting and modelling the dynamics of pneumatic actuators controlled by the pulse width modulation (PWM) technique. Mechatronics 2005, 15, 859–881. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.D.; Daw, N.; Wu, Q.H. Identification of pneumatic cylinder friction parameters using genetic algorithms. IEEE/ASME Trans. Mechatron. 2004, 9, 100–107. [Google Scholar] [CrossRef]

- Liu, F.; Wang, L.; Jia, X.; Mi, J. Application of linear/nonlinear active disturbance rejection switching control in variable load pneumatic loading system. J. Mech. Eng. 2018, 54, 225–232. [Google Scholar] [CrossRef]

- Shin, Y.; Moon, S. A Mathematical Model for a Non-Linear Pneumatic Actuation System to Control Dynamic Pressure. Int. J. Precis. Eng. Manuf. 2018, 19, 325–337. [Google Scholar] [CrossRef]

- Valdiero, A.C.; Ritter, C.S.; Rios, C.F.; Rafikov, M. Nonlinear mathematical modeling in pneumatic servo position applications. Math. Probl. Eng. 2011, 2011, 472903. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Okasha, A.; Abdrabbo, S. Online Identification and Artificial Intelligence Control of a Servo Pneumatic System. Sci. J. Oct. 6 Univ. 2018, 4, 60–74. [Google Scholar] [CrossRef]

- Mansour, A.; Kamel, A.M.; Safwat, E. System Identification and Modeling of an Actuation System for Small Aerial Vehicle. In Proceedings of the 2022 13th International Conference on Electrical Engineering (ICEENG), Cairo, Egypt, 29–31 March 2022; IEEE: New York, NY, USA, 2022; pp. 5–8. [Google Scholar]

- Zhu, M.; Chen, S.; Xu, Z.; Dong, X. Design of Two-Degree-of-Freedom Fractional-Order Internal Model Control Algorithm for Pneumatic Control Valves. Actuators 2023, 12, 214. [Google Scholar] [CrossRef]

- Azira, A.R.; Osman, K.; Samsudin, S.I.; Sulaiman, S.F. Predictive functional controller (PFC) with novel observer method for pneumatic positioning system. J. Telecommun. Electron. Comput. Eng. (JTEC) 2018, 10, 119–124. [Google Scholar]

- Abbasi, P.; Nekoui, M.A.; Zareinejad, M.; Abbasi, P.; Azhang, Z. Position and force control of a soft pneumatic actuator. Soft Robot. 2020, 7, 550–563. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, K.; Wang, G.; Liu, J.; Cai, M. Nonlinear model establishment and experimental verification of a pneumatic rotary actuator position servo system. Energies 2019, 12, 1096. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, K.; Cai, M.; Wei, F.; Gong, S.; Li, S.; Lv, B. Establishment and experimental verification of a nonlinear position servo system model for a magnetically coupled rodless cylinder. Actuators 2022, 11, 50. [Google Scholar] [CrossRef]

- Huilcapi, V.; Cajo, R.; Orellana, J.; Cascante, A. Nonlinear identification and position control of a pneumatic system. In Intelligent Technologies: Design and Applications for Society, Proceedings of the 8th International Conference on Science, Technology and Innovation for Society, Guayaquil, Ecuador, 22–24 June 2022; Springer Nature Switzerland: Cham, Switzerland, 2022; pp. 127–138. [Google Scholar]

- Zhang, Y.; Li, K.; Yue, H.; He, S.; Li, D.; Lyu, K.; Wei, F. Experimental Simulation and Verification of Position Servo Control of Mechanical Rodless Cylinder. Mech. Eng. Sci. 2020, 2. [Google Scholar] [CrossRef]

- Wang, T.; Cai, M.; Kawashima, K.; Kagawa, T. Modelling of a nozzle-flapper type pneumatic servo valve including the influence of flow force. Int. J. Fluid Power 2005, 6, 33–43. [Google Scholar] [CrossRef]

- Xi, Z.; Yaobao, Y.; Weida, H. Influence of temperature on null position pressure characteristics of flapper-nozzle servo valve. In Proceedings of the 2010 International Conference on Computer Design and Applications, Qinhuangdao, China, 25–27 June 2010; IEEE: New York, NY, USA, 2010; Volume 3, pp. V3-257–V3-261. [Google Scholar]

- Jiménez, M.; Kurmyshev, E.; Castañeda, C.E. Experimental study of double-acting pneumatic cylinder. Exp. Tech. 2020, 44, 355–367. [Google Scholar] [CrossRef]

- Jin, H.; Jiao, Z.; Li, C.; Zhou, R. Modeling and Characterization of Redundant Direct Drive Servo Actuation System. J. Beijing Univ. Aeronaut. Astronaut. 2006, 32, 1059–1062. [Google Scholar]

- Lü, X.; Peng, J.; Li, S. Dynamic characteristics of the jet force on the flapper of the pilot stage in a flapper nozzle servo valve under the flow-solid interaction. J. Beijing Inst. Technol. 2020, 29, 445–455. [Google Scholar]

- Yang, H.; Wang, W.; Lu, K. Numerical simulations on flow characteristics of a nozzle-flapper servo valve with diamond nozzles. IEEE Access 2019, 7, 28001–28010. [Google Scholar] [CrossRef]

- Kang, J.; Yuan, Z.; Tariq Sadiq, M. Numerical simulation and experimental research on flow force and pressure stability in a nozzle-flapper servo valve. Processes 2020, 8, 1404. [Google Scholar] [CrossRef]

- YYin, Y.; Liang, J.; Yuan, J. Analysis of influencing factors for the characteristics of pneumatic servo mechanisms. J. South China Univ. Technol. (Nat. Sci. Ed.) 2019, 47, 17–24. [Google Scholar] [CrossRef]

- Saravanakumar, D.; Mohan, B.; Muthuramalingam, T. Application of response surface methodology on finding influencing parameters in servo pneumatic system. Measurement 2014, 54, 40–50. [Google Scholar] [CrossRef]

- Nie, M.; Li, J.Y.; Shen, H.K.; Sun, H.M. Study on a Type of Pneumatic Force Servo System. Adv. Mater. Res. 2013, 819, 192–196. [Google Scholar] [CrossRef]

- Beater, P. Pneumatic Drives; Springer-Verlag: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

| Parameter | Mean | Value | ||||

|---|---|---|---|---|---|---|

| A1/mm2 | Pressure acting area of the rodless chamber of the actuator cylinder | 3674.5 | ||||

| A01/mm2 | Pressure acting area in the rod chamber of the actuator cylinder | 3674.5 | ||||

| V/mm | Volume of the rodless chamber of the actuator cylinder | 50 | ||||

| ky/(kN·m−1) | Stiffness of the actuator cylinder spring | 2.08 | ||||

| By (N/(m/s)) | Viscous damping coefficient | 2 | ||||

| (ky·y0)/N | Single acting cylinder spring precompression force | 95.264 | ||||

| l1 (mm) | Length of the connecting rod | 70.6 | ||||

| d1 (mm) | Diameter of the fixed throttle hole | 1 | ||||

| d2 (mm) | Nozzle diamete | 2.8 | ||||

| lc0 (mm) | Gap between the baffle and the nozzle when the current is zero | 0.095 | ||||

| Torque motor Model parameter | Aerodynamic torque proxy model parameters | |||||

| a0 | a1 | 54.9 | a2 | 7.865 | a3 | 0.8748 |

| −2.424 × 10−6 | ||||||

| b0 | b1 | 0.03511 | b2 | 0.0946 | b3 | 0.3466 |

| 0.001166 | ||||||

| c0 | c1 | −0.2753 | c2 | 1.458 | c3 | −1.424 |

| 0.001818 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Wang, M.; Liu, Y.; Guo, Z.; Yue, L. Modelling and Transmission Characteristics Analysis of APU Pneumatic Servo System. Aerospace 2024, 11, 868. https://doi.org/10.3390/aerospace11110868

Yang F, Wang M, Liu Y, Guo Z, Yue L. Modelling and Transmission Characteristics Analysis of APU Pneumatic Servo System. Aerospace. 2024; 11(11):868. https://doi.org/10.3390/aerospace11110868

Chicago/Turabian StyleYang, Fang, Mengqi Wang, Yang Liu, Zipeng Guo, and Lingyun Yue. 2024. "Modelling and Transmission Characteristics Analysis of APU Pneumatic Servo System" Aerospace 11, no. 11: 868. https://doi.org/10.3390/aerospace11110868

APA StyleYang, F., Wang, M., Liu, Y., Guo, Z., & Yue, L. (2024). Modelling and Transmission Characteristics Analysis of APU Pneumatic Servo System. Aerospace, 11(11), 868. https://doi.org/10.3390/aerospace11110868