Abstract

With the increasing adoption of composite materials in aircraft construction, traditional anti-icing technologies face significant challenges due to the low thermal conductivity and heat resistance of composite resins. These limitations have spurred the development of lightweight, efficient, durable, and cost-effective integrated anti-icing technologies as a critical area of research. This paper begins with an overview of advancements in electrothermal anti-icing and de-icing technologies for aircraft. It then explores the configurations and applications of functional-structural integration technology for anti-icing and de-icing, emphasizing pivotal technologies and current challenges in this field. Finally, the study forecasts the development trends in the multifunctional integration of thermal conductivity/insulation, anti-icing, and electromagnetic wave transparency/wave-absorbing properties. These advancements are driven by the evolution of composite materialization in aircraft and the progression of multi-electrical/all-electrical technologies. The objective is to provide a comprehensive guide for technological development in anti-icing, aiding researchers and relevant departments to further enhance the application of anti-icing technology in composite material aircraft.

1. Introduction

1.1. Background

Icing poses a significant threat to aircraft safety. When an aircraft traverses clouds containing supercooled water droplets, critical components such as the wings, tail, and intakes are susceptible to ice accretion. This phenomenon leads to a reduction in lift, an increase in drag, a marked degradation of aerodynamic characteristics, and a substantial decrease in the stall angle of attack. In severe instances, these adverse effects can culminate in catastrophic outcomes, including aircraft crashes [1,2,3,4].

Composite materials, characterized by their high specific strength and modulus ease of molding, significantly decrease the weight and fuel consumption of structures, thereby mitigating the environmental impact. As a result, composite materials are being increasingly utilized in aerospace applications. For instance, composite materials constitute approximately 50% of the Boeing 787 aircraft and 52% of the Airbus A350 aircraft [5,6,7,8].

However, due to the low thermal conductivity and heat resistance of composite materials, conventional anti-icing techniques encounter technical bottlenecks [9,10,11]. For example, the traditional air-entraining method, commonly employed in hot air anti-icing systems for metallic materials, requires air supply temperatures exceeding 200 °C. This temperature surpasses the tolerance of composite materials, potentially reducing the structural strength of the aircraft and compromising flight safety [12,13,14,15]. Conversely, the conventional electric heating method entails the application of metallic electric heating elements to a protective surface using adhesives, which adversely impacts the aerodynamic profile and is susceptible to issues such as stress, fatigue, and detachment [16,17].

Conventional anti-icing technologies do not adequately match the performance characteristics of composite materials, particularly in terms of temperature resistance and thermal conductivity, which significantly restricts their application in composite aircraft. The development of a lightweight, highly efficient, highly reliable, and cost-effective integrated anti-icing functional structure system for composite aircraft has emerged as a significant research focus [18,19,20].

In recent years, gradual advancements in research on the functional and structural integration of composite aircraft anti-deicing systems have been witnessed. In 2015, Falzon et al. [21] introduced an electrothermal anti-icing/deicing device using conductive carbon-fiber textiles in conjunction with glass-fiber layers to form an insulating layer. The device demonstrated a power density of 0.93 kW/m2 and reached an average temperature of 4.3 °C. Nonetheless, it was characterized by suboptimal thermal conductivity and inefficient deicing performance.

In 2018, Xudan Yao et al. [22], building upon the study by Falzon et al., developed a carbon nanotube (CNT) mesh as a heating element using chemical vapor deposition (CVD) and utilized a woven glass fiber prepreg for support and insulation. Compared with the carbon fiber heating element, this device achieved a 15% reduction in the overall weight and a 10% enhancement in the temperature rise rate. In a deicing test conducted at an ambient temperature of −12 °C, a laminate composed of 40 layers of CNT mesh completed deicing within 15 s under a constant voltage of 16 V and a power density of 4.9 kW/m2.

To enhance the flexibility and reduce the weight of composite anti-icing elements, Park et al. [23] employed a three-roll milling technique to develop a novel heating element by incorporating multi-walled carbon nanotubes (MCNTs) and graphite flakes into the resin matrix. This innovation resulted in a weight reduction of approximately 20% compared to traditional metal heating elements, alongside a significant improvement in the flexibility of the composite element [24].

However, compared to conventional metallic materials, composites generally exhibit lower long-term temperature tolerances, typically not exceeding 90 °C. This limitation is compounded by their susceptibility to uneven heating due to the anisotropic thermal conductivity inherent within the resin components. Such uneven thermal distribution can significantly curtail the operational lifespan of these materials. Furthermore, a notable challenge in integrating composites with metals arises from the mismatch in thermal expansion coefficients and the potential for galvanic corrosion. These interfacial issues necessitate meticulous consideration and strategic mitigation to harness the full potential of composite applications in various engineering domains [25,26,27].

To address the urgent need for lightweight design and improved energy efficiency in the aerospace industry, it is necessary to explore de-icing strategies more suitable for composite material aircraft to ensure safety and performance efficiency in aerospace applications [28,29,30].

The integration of composite materials with anti-icing functions in aircraft structures presents multiple challenges. This integration mandates a cohesive design strategy that harmonizes aerodynamic profiles, structural integrity, and anti-icing efficacy, thus propelling the advancement of essential technologies. Utilizing composite materials for integrating anti-icing functions not only substantially lowers the weight of the aircraft’s anti-icing systems but also elevates their operational efficiency, thereby guaranteeing flight safety across diverse meteorological conditions. This innovative technology finds particular relevance in military and civilian drones, helicopters, and other aircraft designed for operation in high-altitude and frigid environments.

1.2. Aim of the Review

This paper delves into the latest research developments and key technologies in integrated anti-icing function structures within composite material aircraft, analyzes current limitations, and projects future directions in this field to meet the specific anti-icing requirements of composite material aircraft. The first part emphasizes the technical advantages of function-structure integration. The second part details the progress and key technologies of anti-icing function structure integration. Finally, it envisions that with the continuous advancement of composite material technology, future aircraft will incorporate new composite functions such as thermal conduction/insulation, anti-icing, and electromagnetic wave transparency/absorption.

2. Integrated De-Icing and Anti-Icing Heating Layer Structures

2.1. Properties of Heating Layer Structures

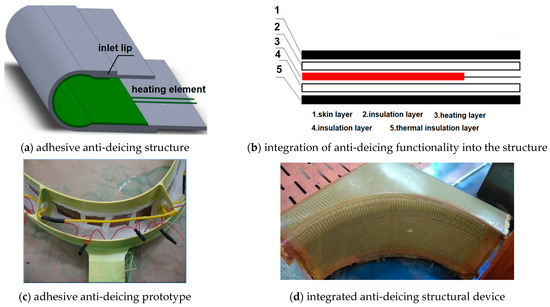

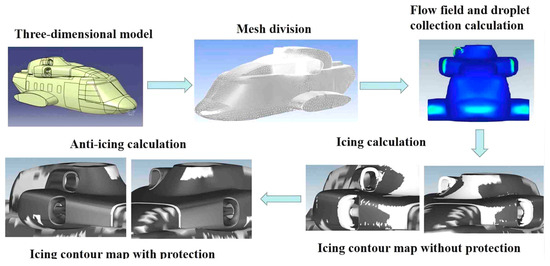

To address technical bottlenecks such as localized overheating, low anti-icing efficiency, and high thermal stress in traditional heating elements, an innovative embedded anti-icing structure based on traditional lamination (separation) techniques has been developed [31,32,33]. This novel design integrates a heating element directly into the composite structure of an aircraft, merging the anti-icing function with the aircraft’s structural framework. This approach not only enhances anti-icing efficiency but also significantly reduces the system’s weight and complexity by minimizing the need for additional components and interfaces [34,35,36]. The embedded design strategically positions the heating elements in specific areas requiring anti-icing, ensuring a uniform heating effect and effectively circumventing the issues of uneven heating and high energy consumption prevalent in conventional electric heating systems. Moreover, the reliability and maintainability of this design have been substantially improved, offering a robust solution for contemporary aircraft anti-icing system designs, as illustrated in Figure 1.

Figure 1.

Configuration of integrated electrothermal anti-deicing function structures in aircraft. (In Figure 1b, red color represents the heating layer, black color represents the outer skin layer, the thermal insulation layer, and white color represents the insulation layer).

Composite anti-icing function structural integration technology represents a groundbreaking approach that offers a lightweight, electrified, and highly efficient anti-icing system. This innovative technology integrates the anti-icing function by embedding an ultrathin, flexible heating film within a composite fiber layer. This strategic placement allows for optimal heat distribution and significantly enhances the overall efficiency and effectiveness of the anti-icing mechanism, making it an ideal solution for modern aircraft operating in diverse and challenging weather conditions [37,38,39]. The specific application scenarios are illustrated in Figure 2.

Figure 2.

Analysis of application scenarios for integrated electrothermal anti-deicing function structures in aircraft.

This innovative electric heating system design embeds the heating elements directly into the aircraft’s composite material structure, effectively merging anti-icing functionality with structural integration. This design offers numerous advantages, including seamless integration, high efficiency, lightweight construction, reduced power consumption, and extended lifespan. Conversely, traditional surface-mounted electric heating systems feature heating elements that are separate from the object being heated and are attached using adhesives. This configuration results in lengthy thermal conduction paths, increased thermal resistance, diminished heating efficiency, and significant thermal stress at the interface. Such stress can lead to the detachment of heating elements after repeated cycles of heating, compromising the system’s overall effectiveness and durability.

2.1.1. Influence on Aerodynamic Profile and Broad Adaptability

This technology caters to the lightweight, high-efficiency, and low-power-consumption anti-deicing requirements of various aircraft, such as fixed-wing aircraft, UAVs, and helicopters. By embedding a heating layer within the composite material, system simplification, and performance optimization were achieved [40].

The application of functional structural integration technology to aircraft anti-deicing systems has gradually proven its significance. In critical components such as wings, tails, and propellers, the integrated design of the electrothermal anti-icing system streamlines the architecture by embedding a heating layer directly within these structures. This approach eliminates the need for complex piping, valves, and additional components, and it does not depend on high-temperature gas from the engine pressurizer. This simplification not only reduces weight and maintenance requirements but also enhances the overall efficiency and safety of the aircraft’s operation in icy conditions [41]. Compared to traditional bleed air systems, this innovative design significantly reduces system weight and decreases power consumption, while enhancing energy efficiency. These improvements align with both environmental and economic requirements, offering a sustainable and cost-effective solution for aircraft anti-icing [42].

Furthermore, this integrated design does not compromise the aerodynamic performance of the aircraft. Traditional anti-icing systems can disrupt the smoothness of the aircraft’s surface due to exposed components, negatively impacting aerodynamic efficiency. In contrast, the seamless integration of the heating layer within the composite structure maintains the aircraft’s smooth exterior, thereby preserving or even enhancing its aerodynamic properties [43]. However, the electrothermal anti-icing system, with its embedded heating layer, maintains low air resistance and optimizes flight performance by having a negligible impact on the aircraft’s surface. This design ensures that the aerodynamic integrity and efficiency of the aircraft are preserved, contributing to enhanced overall flight characteristics.

2.1.2. Influence of Aircraft Energy Consumption and High De-Icing Efficiency

Modern aircraft anti-icing systems are designed to maintain critical areas such as the intake lip, wings, and tail free of ice by embedding heating elements directly onto the aircraft’s surface and coupling them with temperature sensors and power control systems. These systems require high anti-icing efficiency, low power consumption, and rapid heating capabilities, as energy efficiency significantly influences both anti-icing performance and overall operating costs [44]. Efficient energy utilization not only reduces energy consumption and lowers operating expenses but also enhances system response times and reliability, thereby improving flight safety and economic viability. Consequently, energy efficiency is paramount in the design of contemporary aircraft anti-icing systems, affecting operating costs, safety performance, and overall economic benefits.

When designing aircraft anti-icing systems, it is crucial to consider factors such as power requirements, power distribution, and heating conversion efficiency. For instance, traditional surface-mounted electric heating anti-icing systems, though straightforward, typically exhibit lower energy efficiency, approximately 70%, due to heat dissipation into non-icing areas. In contrast, embedded integrated electric heating anti-icing technology significantly enhances anti-icing efficiency, achieving rates of over 95%, by ensuring direct contact between the heating elements and the areas requiring de-icing. This direct contact minimizes energy wastage and targets heat application more effectively, optimizing the system’s overall performance.

In conventional aircraft laminating electric heating technology, heating elements are initially fabricated into heating assemblies, which are subsequently adhered to the structural components of the aircraft requiring protection through the use of adhesives. This method involves attaching the heating elements externally to the critical areas that are susceptible to icing [45]. The primary drawback of this conventional method is the extended heat transfer path, which not only increases the system’s weight but also elevates the total power consumption. Additionally, the use of adhesives introduces thermal resistance at the interface, thereby diminishing the anti-icing efficiency to approximately 70%, as illustrated in Figure 3. This inefficiency arises from the thermal barrier created by the adhesive layer, impeding effective heat transfer to the areas most in need of de-icing.

Figure 3.

Low efficiency of traditional electrothermal anti-deicing technology.

2.1.3. Influence of Design Approach and Enhanced Heating Performance

The design of heating elements crucially influences the speed and uniformity of the de-icing process. Factors such as the materials used, dimensions, shape, and the method of contact with the object being heated all have a direct impact on de-icing performance and efficiency [46]. By optimizing these design parameters, de-icing efficiency can be significantly enhanced, ensuring that operations on critical components like wings, tail surfaces, and intake ducts are conducted safely and effectively. This optimization leads to a more reliable and efficient anti-icing system, essential for maintaining optimal performance in adverse weather conditions.

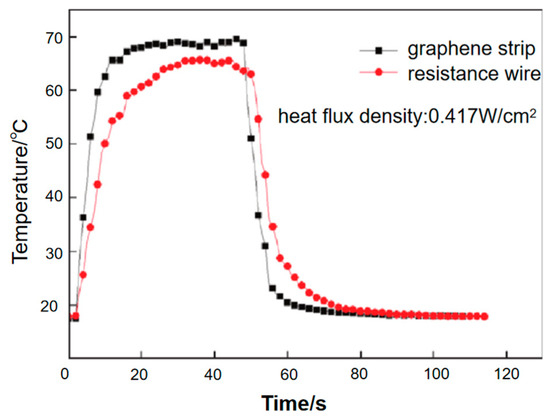

Material Selection: The choice of material for the heating element is pivotal in determining its heating efficiency and operational safety. For example, materials such as graphene are known for their superior thermal conductivity and faster heating capabilities, which can significantly accelerate the de-icing process. Furthermore, the material’s temperature resistance and safety characteristics are essential to ensure that it does not inflict damage on the equipment or present safety hazards during operation. These factors are critical for maintaining both the integrity of the aircraft’s components and the safety of its operations.

The advancement of new heating membrane materials offers substantial benefits for embedded anti-icing structural-functional integration technology. Notably, the utilization of graphene-heated films has emerged as a crucial element in improving the performance of electrothermal deicing systems. These films, due to their exceptional thermal conductivity and efficiency, facilitate rapid heating and uniform heat distribution, thereby enhancing the overall effectiveness and reliability of anti-icing mechanisms in aircraft. In 2021, Tian et al. [47] from Nanjing University of Aeronautics and Astronautics conducted a study on the application of a graphene heating film in an electrothermal deicing system. Their findings revealed that the heating rate of the graphene heating element was significantly faster than that of traditional resistance wire. As illustrated in Figure 4, the temperature rise rate of the graphene element outpaced that of conventional resistance wire within the initial 10 s, reaching approximately 70 °C in just 10 s. This rapid heating capability underscores the efficiency of graphene in electrothermal deicing applications.

Figure 4.

Comparison of heating rates of anti-deicing elements [47].

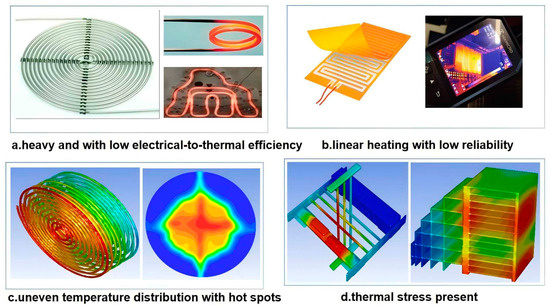

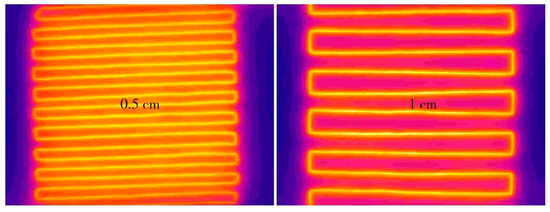

Size and Shape: The size and shape of the heating element are critical in determining the uniformity of its heating coverage. For example, planar heating elements are capable of quickly raising the temperature across a larger area, thereby accelerating the melting of ice and snow. In contrast, linear heating elements may lead to localized overheating, while the areas in between remain at lower temperatures, complicating the effective removal of ice and snow and adversely impacting the overall de-icing performance.

To mitigate icing issues, traditional methods often employ laminated electric heating elements, which predominantly utilize point or line heating. This approach can result in uneven heating, as depicted in Figure 5, often creating concentrated hotspots. These hotspots cause uneven heating effects that can negatively affect the overall efficiency and safety of the system.

Figure 5.

Comparison of uniformity of anti-deicing elements [48].

The comparative analysis depicted in Figure 5 clearly demonstrates that traditional metal heating elements employing strip heating suffer from poor temperature uniformity, exhibiting an overall temperature variance of approximately 8%. In contrast, utilizing a novel nanocomposite material with an integrated functional structure can markedly reduce the temperature disparity to less than 3%. This enhancement not only boosts heating efficiency but also significantly elevates the overall performance and reliability of the anti-deicing system.

To address the issue of uneven heat distribution, researchers have explored the integration of multi-walled carbon nanotubes (MWCNTs) and graphite flakes into resin matrices to develop hybrid nanocomposites [49]. The introduction of these advanced materials significantly enhances the uniformity of in-plane thermal conductivity, owing to the high thermal conductivity properties of the nanocomposites, which facilitate a more uniform distribution of heat within the material. Moreover, by manipulating the direction of heat transfer within the single-layer heating element, the overall temperature distribution can be effectively regulated, achieving a more consistent and uniform heating effect.

2.1.4. Influence of Contact Method

The efficacy of the de-icing process is significantly influenced by the manner in which the heating element interfaces with the object being heated. Optimal contact ensures effective heat transfer and enhances overall heating efficiency. Furthermore, when the heating element is closely fitted to the surface of the object, both the speed and effectiveness of de-icing are notably improved.

Several key factors related to the contact method—namely contact area, contact pressure, contact medium, and contact uniformity—play crucial roles in determining the efficiency of the de-icing process.

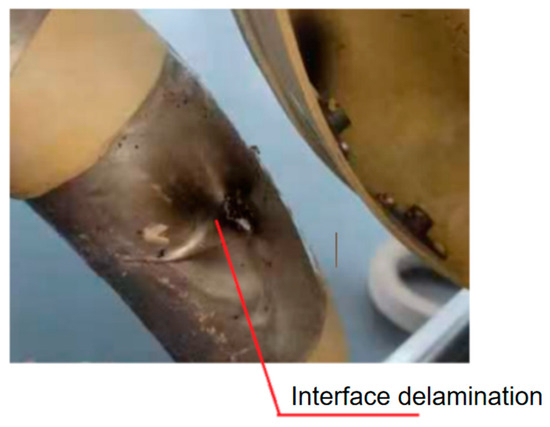

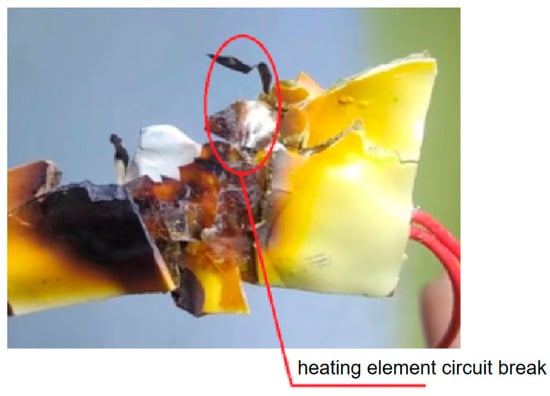

Contact Area: A larger contact area facilitates a more uniform heat transfer across the object, thereby accelerating the ice melting process due to the increased area being heated. Conversely, a smaller contact area may lead to uneven heat distribution, slower ice melting, and potential localized overheating, which can damage the bonding interface between the heating element and the object (such as an aircraft’s surface). This damage can lead to the detachment or disconnection of the heating element, severely compromising reliability, as illustrated in Figure 6 and Figure 7.

Figure 6.

Issue of traditional electric anti-deicing element detachment.

Figure 7.

Issue of traditional electric anti-deicing element circuit breakage.

Contact Pressure: Tight contact, achieved by applying pressure, minimizes heat loss during transfer, thereby increasing heating efficiency. Insufficiently tight contact leads to greater heat dissipation during transfer, reducing heating efficiency and potentially resulting in insufficient heating of the ice, thus impairing the de-icing effect.

Contact Medium: Utilizing a medium with high thermal conductivity, such as thermal adhesive or thermal oil, enhances the efficiency of heat transfer from the heating element to the object, thus accelerating ice melting. If the contact medium has poor thermal conductivity, it impedes heat transfer, leading to ineffective heating and slow ice melting, which can also reduce the efficiency of the heating element.

Contact Uniformity: Uniform contact ensures that heat is evenly distributed across the entire ice layer, preventing localized overheating or unheated areas and promoting faster melting of the entire ice layer. Non-uniform contact can result in uneven heating, causing some areas to melt rapidly while others melt slowly, adversely affecting the overall de-icing effectiveness.

Adjustments to the contact method, such as changing the contact pressure or contact area, can be tailored to specific applications to optimize the heating effect. Adapting the contact configuration of the heating elements to accommodate varying ice thicknesses and shapes can significantly enhance the de-icing performance. In summary, the interaction between the heating elements and the object being heated directly impacts de-icing efficiency. Optimizing the contact area, pressure, and medium to ensure uniform contact can substantially improve de-icing outcomes.

2.1.5. Influence of Material Fatigue Characteristics

Traditional metal anti-deicing heating elements are typically installed on the wing, tail, intake, and leading-edge surfaces of aircraft. These areas are continuously exposed to the atmosphere for extended periods and are subjected to significant environmental impacts. Conventional metallic electric heating elements encounter considerable interfacial thermal stress and material compatibility issues with aircraft structural materials [50,51,52].

More specifically, these metallic elements are susceptible to stress concentration due to mismatched thermal expansion coefficients during repeated heating cycles [52]. The process of prolonged, repeated heating by electrical currents, especially under conditions of high and low environmental temperatures, induces temperature stresses. These stresses contribute to the formation of surface cracks in the metal material, which ultimately lead to stress fatigue fracture failure of the heating element.

To address the interface and fatigue disconnection issues associated with traditional metal heating elements, Zehui Zhao et al. [53] developed a flexible nanocomposite electric heating film utilizing materials such as graphene fabrics and carbon nanotubes (CNTs). This innovative membrane demonstrated the ability to withstand over 100,000 bending cycles with minimal fluctuations in resistance, despite its complex preparation process.

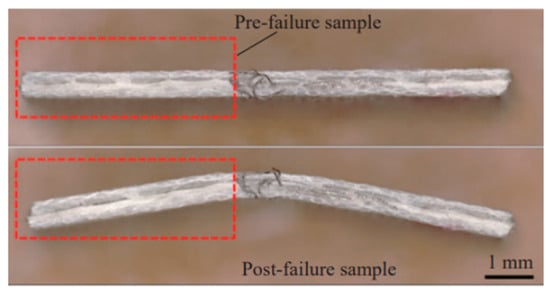

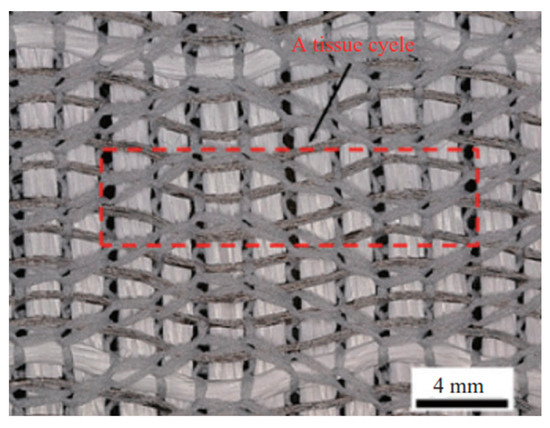

To resolve the susceptibility of metal wires to fatigue breakage, Haijun Dai et al. [54] engineered nickel–copper alloy wire materials using a braiding method in sinusoidal waveforms in 2020. The shear strength values of the three specimens were recorded at 1.61 MPa, 1.08 MPa, and 0.73 MPa, respectively. However, the challenge of low shear strength between layers of electrically heated fabrics persists, as evidenced in Figure 8 and Figure 9.

Figure 8.

Schematic diagram of electrically heated biaxial woven fabric structure [54].

Figure 9.

Physical diagram of electrically heated biaxial woven fabric with shear [54].

2.2. Comparison of Critical Technical Indicators

To further analyze the technical advantages of integrating anti-icing functional structures, a comprehensive review of the progress in electric heating functional structure integration was conducted. Additionally, the technical parameters of traditional laminated electric heating were compared with those of the integrated functional structures in terms of anti-icing efficiency, heating speed, uniformity, anti-icing power density, and weight, as detailed in Table 1.

Table 1.

Comparison between traditional overlay electric heating technology and integrated functional technology.

The structure and composition of aircraft composite materials, specifically the number and sequence of the layers, directly influence ice protection efficiency. The positioning of heating elements within different layers can result in variations in thermal resistance and heat transfer efficiency. Moreover, changes in the sequence of materials and layup angles can significantly affect the mechanical properties and durability of the composite materials, thereby impacting the overall performance and longevity of the anti-icing system. This analysis underscores the importance of strategic material engineering and design in optimizing the effectiveness of anti-icing technologies.

As illustrated in Table 1, the integration technology of anti-icing functional structures significantly outperforms traditional laminated electric heating across several core indicators, including anti-icing efficiency, heating speed, heating uniformity, and weight. Notably, this technology achieves a reduction in anti-icing power consumption by 50% and a decrease in weight by 30%. Given the design flexibility of composite materials and the ongoing advancement of new material technologies, the functional structural integration of anti-icing technology has emerged as a pivotal method for enhancing anti-icing efficiency and reducing power consumption. This approach not only markedly improves anti-icing performance but also facilitates a high degree of customization and optimization in the design and manufacturing processes. The development of these key technologies for integrating anti-icing functions into composite structures holds substantial engineering significance.

3. Progress on Heating Layer Structures

Currently, international helicopters, including models such as the Black Hawk, NH90, EH101, Super Puma, and Mi-171, employ rotor electrothermal anti-icing systems. Specifically, Sikorsky has engineered an electric heat anti-icing system for the Black Hawk helicopter [55].

Presently, the range of anti-ice heating elements encompasses heating tapes, heating pads, heating tubes, and heating films, each tailored for specific de-icing applications on aircraft components such as wings, tail fins, and intake ducts. The materials utilized for these heating elements are varied, predominantly consisting of nickel–chromium alloys, platinum film materials, conductive polymers, and graphite, each offering distinct advantages and limitations depending on the application. The selection of these materials should be strategically aligned with specific operational conditions and requirements.

Nickel–chromium alloys [56] are extensively utilized in the manufacturing of heating wires and tubes due to their exceptional high-temperature performance and stability in resistance. Platinum film materials [57] are integrated into thin-film heaters, providing high precision and uniform heating capabilities. Conductive polymers, like polyaniline [58], are favored for flexible heating applications, whereas graphite is employed in high-temperature furnaces owing to its superior thermal conductivity and stability under high temperatures.

With ongoing advancements in aircraft composite materials and the development of new materials, there is a noticeable shift in anti-ice heating elements from traditional metals to innovative materials such as conductive carbon fibers, carbon nanotubes, and graphene.

The primary structural forms of heating elements include metal sheets, sprayed metal films, metal-woven fabrics, metal-resistant wires embedded in rubber, and metal foils. For instance, the heating element of the Black Hawk helicopter comprises a heating pad woven with resistance wire, a metal heating sheet developed by Goodrich using the etching method, and an ultra-thin semiconductor flexible heating film pioneered by the Austrian company Villinger. This film addresses the issues of heat concentration and damage intolerance in the electric heating system of the Black Hawk helicopter.

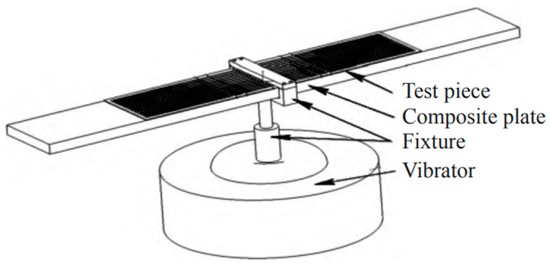

To further assess the fatigue characteristics of the heating element, Meng Lei et al. [59] established a reliability system and utilized a composite flat-plate vibration strain load bonded with a fiberglass cloth to the heating assembly to conduct one million strain cycle tests. This rigorous testing protocol underscores the commitment to enhancing the durability and efficacy of heating elements in demanding operational environments, as illustrated in Figure 10.

Figure 10.

Schematic diagram of experimental system structure [59].

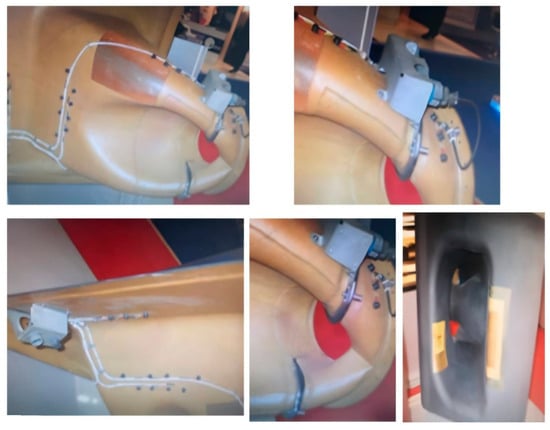

With the advancement of multi-electric helicopters, the application of electric anti-icing systems has expanded significantly. Notably, the European EH101 [60] helicopter employs an embedded metal-alloy belt heating system to prevent ice formation, as illustrated in Figure 11.This heating element within the embedded anti-ice structure is designed to rapidly transfer heat to the targeted area, thereby shortening the heating path and enhancing the anti-icing efficiency. This innovative approach underscores the technological evolution in helicopter design, aiming to improve safety and performance in icy conditions.

Figure 11.

Anti-icing system for EH101 engine inlet lip [60].

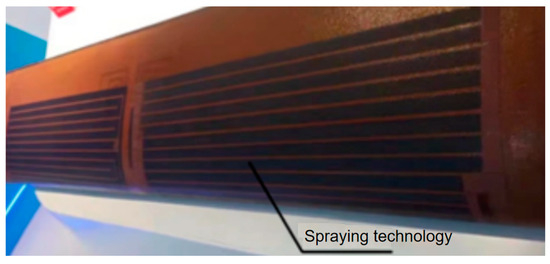

Recently, GKN Aerospace [61], a British company, has developed a composite material heating solution tailored to meet the needs of civil airliners, which increasingly utilize composite materials. This innovative approach employs spray metal layer deposition technology, where liquid metal is sprayed directly onto a glass fiber fabric to create a conductive layer, as illustrated in Figure 12. This technique ensures continuous and uniform heat distribution to the leading edge of the composite wing. However, the metal spraying anti-icing method presents several challenges, including galvanic coupling corrosion, resistance stability, and construction complexities. Compared to the composite embedding process, the technical maturity of this metal spraying method requires further enhancement to meet the rigorous demands of aerospace applications.

Figure 12.

Electric heating scheme for spray coating technology [61].

Currently, small-scale applications have been initiated, but the design and production of functional structure integration electrothermal anti-icing systems have not yet been realized on a large scale. This situation presents several technical challenges that need to be addressed to advance the development and widespread implementation of these systems.

The design of the functional structural integration must adhere to the geometric, structural, power, and thermal constraints of the aircraft’s wing and tail. The dimensions of the different parts of the heating elements, specifically the hot knife zone and cyclic deicing zone, must adequately cover the area impacted by supercooled droplet strikes and provide the requisite heat flow power density. Additionally, the design should incorporate multiple redundant layers to function as a backup in the event of failure.

Extensive testing and studies have been conducted on the temperature, thermal resistance, fatigue characteristics, and mechanical properties of the heating element. A well-considered structural scheme is essential to ensure that the deicing element is structurally compatible with the composite material, highly reliable, boasts a long service life, and, when integrated with the protective part, exerts minimal impact on the overall structural mechanical properties of the composite matrix.

4. Key Technologies for Structural Integration of Anti-Deicing Functions

As aircraft functional requirements escalate, the integration of functional and structural designs has become critically important. This integration must not only consider the structural load-carrying capacity but also incorporate anti-deicing functions to meet the demands for lightweight structures and low power consumption.

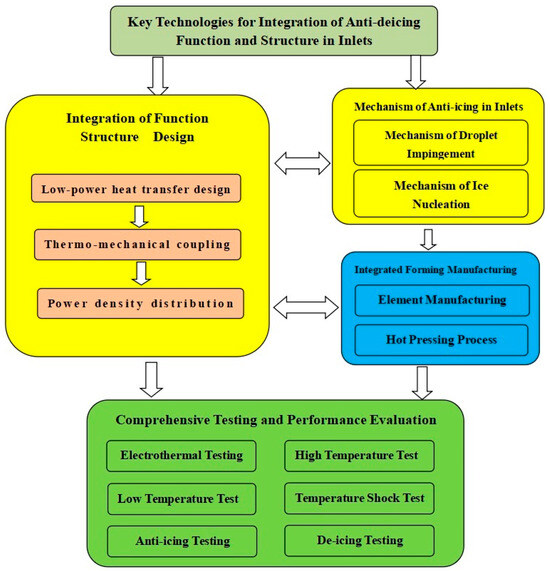

The key technologies for the functional and structural integration of electrothermal anti-deicing in composite aircraft encompass a range of crucial areas. These include the overall design technology for the functional/structural integration of anti-deicing, investigation into the mechanisms of anti-deicing, and the development of molding and fabrication technologies tailored for functional/structural integration. Additionally, comprehensive testing and performance evaluation are essential components of this integration process. The interdependencies among these research areas are illustrated in Figure 13, providing a visual representation of how each component interacts and contributes to the overall efficacy of the anti-deicing system.

Figure 13.

Key technologies for integrated anti-deicing function structures.

4.1. Integrated Design Technology

To achieve the integration of anti-deicing functions within the structural framework of a composite aircraft while adhering to the aerodynamic strength constraints, it is imperative to begin with a comprehensive analysis of the aircraft’s anti-deicing requirements. This involves evaluating heat load calculations, designing the heating structure scheme, and optimizing the anti-icing power distribution. Crucially, this process necessitates the development of a heat transfer model that addresses the anisotropic thermo-solid coupling of composite multilayers, as well as the creation of new, lightweight, and efficient heating elements that are suited for low-power conditions.

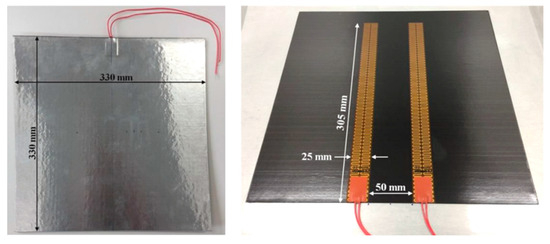

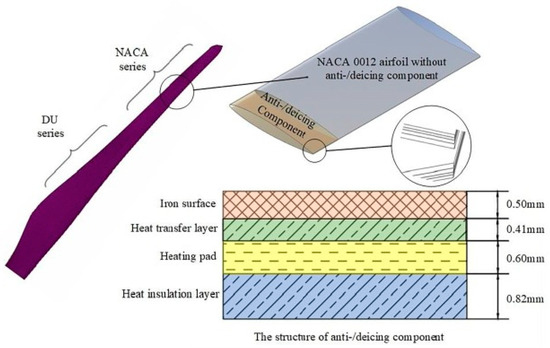

In 2021, Roy et al. [62] innovated a carbon-fiber-reinforced laminate with integrated anti-deicing functionality by embedding an etched metal heating film within the third layer of a carbon-fiber prepreg. The specific details of the layup are documented in Table 2, and the molded prototype is depicted in Figure 14. However, enhancements in the adhesion between the heating element and the epoxy resin are required. One potential improvement method could be the application of plasma surface treatment to enhance the bond strength.

Table 2.

Parameters of composite material layup with electric heating film [62].

Figure 14.

Laminated panel for integrated anti-deicing function structures [62].

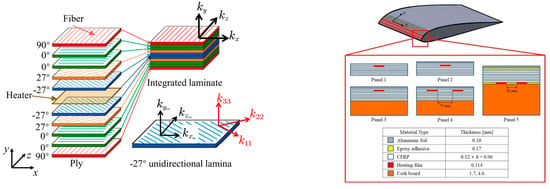

In 2024, Xiaofeng Guo et al. [63] conducted a comprehensive investigation into the anisotropy of mechanical and thermal properties of carbon fiber composites, utilizing T700 and M40 carbon fiber prepregs. Their research meticulously designed the composition and configuration of the system, as illustrated in Figure 15. They explored various factors that influence the thermal response and deicing properties of the composites, including the effects of the layup sequence, the presence of insulation, layup angle, heating area, and the type of prepreg used. This in-depth study provided valuable insights into optimizing the structural and functional integration of anti-icing systems in composite aircraft, enhancing both efficiency and effectiveness.

Figure 15.

Laminated panel for integrated anti-deicing function structures [63].

In multilayer composites, strategic control over temperature distribution can be achieved by manipulating the direction of thermal conductivity in individual layers, utilizing their anisotropic properties. By adjusting the orientation of the unidirectional prepreg within the multilayered structure, the direction of heat flow can be effectively steered to achieve a more uniform temperature distribution across the surface. This method highlights the pivotal role of anisotropic thermal conductivity in shaping the temperature profiles essential for anti-icing applications. Consequently, ensuring a harmonious balance between thermal and mechanical properties within these integrated composite structures is crucial for optimizing performance and enhancing durability.

The heating elements are embedded within the composite material and electrically isolated using prepregs, strategically positioned near the deicing surface to enhance the efficacy of the electrical deicing system while preserving the mechanical stability of the multilayer structure. Although insulation is beneficial for minimizing heat loss during the deicing process, it can substantially increase the system’s thermal inertia, thereby prolonging the response time for deicing. Consequently, it is advisable to minimize or eliminate the thickness of the insulation. An optimal balance between rapid deicing and energy efficiency can be achieved through the implementation of short-term, high-power heating strategies, which provide swift thermal responses without excessive energy consumption.

4.2. Multi-Physics Coupling Calculation

The electrothermal deicing process, which involves the melting of ice, is characterized as a typical Stefan problem [64,65,66,67]. Simulation methods for this process are generally categorized into two types: the tracking method and the fixed grid method.

To advance the understanding of electrothermal anti-icing and deicing in aircraft multilayer materials, a mathematical model was developed. This model facilitated numerical computational research that explored the dynamics of electrothermal anti-icing and deicing, specifically examining the impact of varying incoming flow conditions on the efficiency of the inlet channel’s deicing system. Detailed analyses were conducted on the temperature variations of the icing surface during the electrothermal anti-icing and deicing processes, as illustrated in Figure 16. Additionally, the study investigated the effects of several critical factors, including the arrangement of the heat source, the power of the heat source, the liquid water content, and the temperature of the incoming flow. These factors were scrutinized to determine their influence on the performance of anti-icing and deicing systems, thereby contributing to the optimization of these critical aircraft safety features.

Figure 16.

Schematic diagram of coupled heat transfer for electric anti-deicing [68].

Esmaeilifar et al. [68] developed a thermodynamic phase-change model to assess the power consumption and deicing efficiency of composite laminates that incorporate repetitive S-shaped copper heater elements. This model provides a robust framework for evaluating how these elements can enhance deicing performance while managing energy use effectively.

Meanwhile, Yihua Cao et al. [69] introduced a numerical simulation method for three-dimensional ice accumulation on aircraft wings, grounded in Euler’s two-phase flow theory and extended by Myers’ heat transfer model. This approach allows for a comprehensive analysis of ice formation dynamics under various atmospheric conditions.

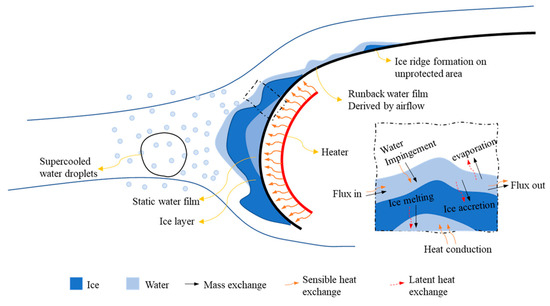

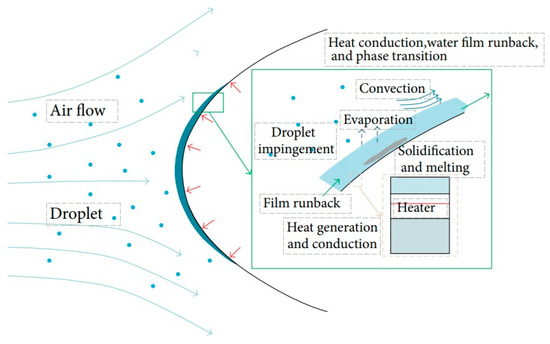

Zuodong Mu et al. [70] employed the conjugate heat transfer (CHT) method to create a multiphysics field framework that integrates different solvers. This framework simulates a range of phenomena, including airflow, droplet impact, phase change, water film dynamics, and heat transfer in the substrate, as well as interactions between the solid and fluid domains. A detailed illustration of this complex interaction is provided in Figure 17. This sophisticated model serves as a critical tool in improving the understanding and management of the thermal and aerodynamic challenges associated with aircraft deicing.

Figure 17.

Electric anti-deicing process in aircraft icing application during flight [70].

The icing of aircraft wings, tails, and intake components represents a multifaceted physical phenomenon involving the two-phase flow of supercooled water droplets in air, alongside processes of heat transfer and phase changes such as solidification, evaporation, and sublimation [71,72,73]. The heat transfer characteristics and the calculation of load power for anti-deicing heating components are crucial for the effectiveness of anti-deicing systems. These components and their operational dynamics are comprehensively analyzed in the simulation workflow depicted in Figure 18. This analytical approach is instrumental in enhancing the understanding and optimization of anti-deicing mechanisms within aviation safety protocols.

Figure 18.

Design of thermal-fluid coupling calculation process for anti-deicing.

Due to the intricate geometric shapes of various airplane components, such as wings, tails, and air intakes, these structures are subjected to a complex external air–water droplet thermosolid coupling heat transfer mechanism [74,75,76]. Despite extensive research in this area, many studies have overlooked the impact of certain parameters on icing characteristics. Notably, factors such as material surface roughness, air intake flow rate, and fuselage shape have often been neglected, depicted in Figure 19. Addressing these overlooked parameters could provide a more comprehensive understanding of icing mechanisms and enhance the effectiveness of deicing strategies.

Figure 19.

Integrated multi-layer functional blade structure [77].

There exists a significant gap in the sensitivity analyses and mechanistic studies concerning the parameters that influence water droplet characteristics and the resultant icing thickness on aircraft surfaces. These parameters encompass variations in flight speeds, angles of attack, air intake conditions, temperatures, and flight durations. There is a pressing need for expanded research on icing mechanisms. Such research is crucial to rapidly pinpoint the critical state points for anti-icing systems, especially under the severe operating conditions frequently encountered in engineering practice. Addressing this gap is essential for enhancing the safety and efficacy of aviation operations in challenging environments.

4.3. Integrated Manufacturing Technology

Advancements in aerospace technology have catalyzed significant progress in structural materials, manufacturing processes, and design technologies. Future aircraft structures are poised to meet stringent design criteria, emphasizing lightweight, high efficiency, and cost-effectiveness.

Presently, the advancement of composite material technology in aircraft applications centers on harnessing automation, digitalization, and other innovative processes and design methodologies to fabricate complex, large-scale composite structures. This approach not only fulfills functional performance requirements but also minimizes the number of components and assembly operations. Consequently, this reduces structural weight and development costs, thereby enhancing the cost-effectiveness of composite structures [78].

The integration of anti-deicing functions into future aircraft fuselage structures is characterized by several key features:

High Proportion of Composite Material Usage: Future aircraft fuselage structures are anticipated to incorporate over 60% composite materials, significantly increasing from current levels [79].

Integration for Significant Weight Reduction: Future designs will likely adopt new types of integral structures, utilizing advanced materials and technologies such as graphene/carbon nanofilm. Coupled with functional design/materials/process integration technologies, these advancements are expected to realize effective weight reductions of 20% to 30% [80].

Economic Affordability: By employing cost-effective materials and process technologies, along with automation technologies like automatic tape-laying, automatic filament-laying, and additive manufacturing, future aircraft can achieve improved production efficiency and quality. These technologies enable economically viable designs that balance structural performance with development costs [81].

Currently, the composite hot-press tank process is utilized to embed flexible heating elements within composite materials. Research has explored the impact of various process parameters on the quality of hot-press molding and has uncovered the extent to which different embedded elements affect the mechanical interlaminar damage state of the composite material.

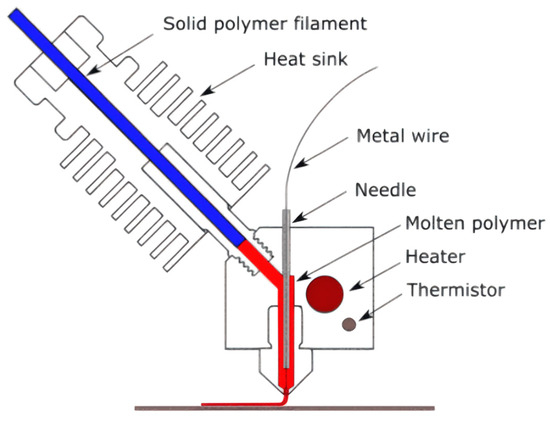

Three-dimensional (3D) additive printing technology [82,83,84] has increasingly been employed for both prototyping and the production of functional systems. This technology is particularly valued for its ability to fabricate complex, precise, and cost-effective parts. The general-purpose 3D printing process, which is pivotal in modern manufacturing workflows, is depicted in Figure 20. This innovative approach not only streamlines production but also enhances the capability to design and implement intricate components that meet rigorous industry standards.

Figure 20.

Three-dimensional printing forming process [85].

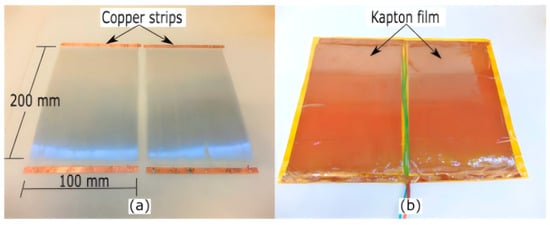

In 2019, Ibrahimet et al. [85] utilized a continuous conductive filler as a heating element to 3D print a composite heater through a fused deposition process, as illustrated in Figure 21.This innovative approach highlights the potential of integrating conductive materials within 3D printed structures to create functional heating elements.

Figure 21.

Three-dimensionally-printed prototype [85]. (a) Two parts of the printed heating element (b) Wire connections and Kapton film layer.

In 2020, Cortés et al. [86] employed a 3D-printed epoxy CNT/GNP conductive ink specifically designed for anti-icing and deicing systems, as illustrated in Figure 22. The efficacy of these systems is heavily influenced by the quality of the 3D-printed circuits, as this quality directly impacts the temperature distribution during Joule heating. Furthermore, the stability of the circuit resistance and its effects on the mechanical properties of the composite materials necessitate additional evaluation to ensure reliability and effectiveness in practical applications.

Figure 22.

Three-dimensionally-printed anti-icing conductive ink [86].

Fabrication methods that leverage the functional integration capabilities of additive manufacturing provide substantial design flexibility [87]. Critical design parameters, including the choice of polymer and wire, as well as the nozzle and wire diameters, and even the length, shape, pattern, and layer count of the heating element, can be finely adjusted during the design process to meet specific application demands [88].

Consequently, the prospective application of 3D printing for structurally and functionally integrated anti-deicing solutions holds significant promise. Such technologies can effectively harness engine heat, diminish structural mass, and enhance safety [89]. Essential aircraft components like the leading edges of wing surfaces and air intake ducts are well-suited for this technology, which offers extensive potential for implementation across civil aircraft, large military aircraft, and unmanned aerial vehicles (UAVs).

4.4. Comprehensive Testing and Performance Evaluation

When heating elements are operational, they experience a rise in temperature, which imposes thermal loads on the electrothermal anti-icing system. Additionally, components such as wings are subjected to lift and drag forces during flight, introducing various mechanical loads [90,91,92,93]. Over several missions, the combined effects of these thermal and mechanical cyclic loads may progressively degrade the structure and performance of the anti-icing system.

To ensure the functional indices meet the engineering application requirements for anti-icing composite structural integration, comprehensive testing is imperative. This includes the characterization of the electrical and thermal performance of the heating components, assessment of anti-icing effects, weather resistance tests, structural mechanics tests, and durability fatigue tests [94,95,96].

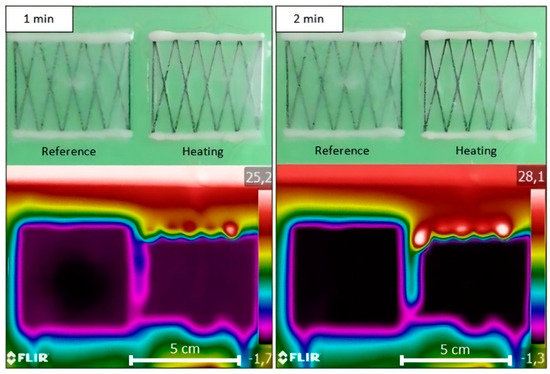

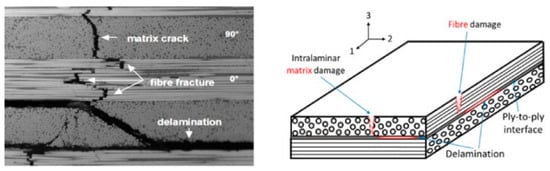

The structurally integrated anti-icing components within aircraft composites are particularly vulnerable to failure due to internal heating. The primary modes of failure include matrix cracking, fiber breakage, and internal delamination [97], as illustrated in Figure 23. These tests are crucial for validating the reliability and longevity of the anti-icing systems under operational stresses.

Figure 23.

Types of damage to integrated functional composite materials [97].

Sinmazçelik et al. [98] developed a methodology to assess the fatigue resistance and damage tolerance of glass fiber reinforcements utilized in the wing structure of the Airbus A380. Müller [99] engineered a thermal cycling device to evaluate the impact of thermal cycling on the properties of GLARE materials, discovering that the interlaminar shear strength increased with the number of cycles. Hagenbeek [100,101] executed long-term thermal cycling and moisture experiments on heated fiber-metal laminates and glass-fiber-epoxy composites to explore their structural durability. Costa [102] further examined the influence of thermal cycling on heated fiber metal laminates under a static load, noting that the addition of a static load significantly altered the interlaminar shear properties post-thermal cycling.

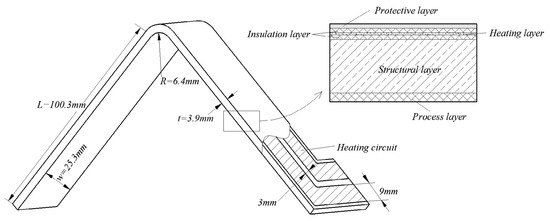

In 2021, Tingyang et al. [103] both experimentally and numerically investigated the effect of internal heating on the delamination performance of deicing composite curved beams subjected to four-point bending, as illustrated in Figure 24. They found that the average damage load of internally heated beams was approximately 36% lower than that in other environments. Additionally, their observations indicated that internal heating significantly influenced the position of delamination.

Figure 24.

Bending test of integrated functional composite materials [103].

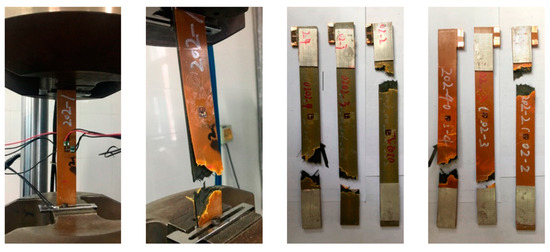

Based on the above studies, Rongjia et al. [104] explored the impact of thermal and mechanical cycling on electrically heated deicing laminates that incorporate a sprayable metal film, as illustrated in Figure 25. Their results revealed that after 1000 cycles between 80 °C and −55 °C, the resistance of the heating element embedded with the sprayable metal film increased by 20% while the heating power decreased by 16.67%. In mechanical cycling tests, it was observed that the heating element succumbed to damage before any structural failure occurred, indicating that the functional fatigue life of the heating element was shorter than the structural fatigue life.

Figure 25.

Mechanical test of integrated functional composite materials [104].

In addressing the functional indices and engineering application requirements of anti-icing composite structural integration, our team conducted a series of comprehensive evaluations. These included electrical and thermal performance characterization, anti-icing effect evaluation, weather resistance tests, structural mechanics tests, and durability fatigue tests of the heating components [105,106]. By employing engineering test methods, the environmental adaptability and stability of the functional/structural integration of composite inlet deicing were thoroughly assessed. This approach aimed to enhance the technology’s maturity and fulfill the specifications of engineering models.

Numerous studies have explored the behavior of composite structures regarding their strength, integrity, and stiffness under various complex thermal and mechanical cycles. However, the electrothermal anti-icing operating environment, structured under the cyclic loading of composite anti-icing components, is influenced by both the mechanical properties of the structure and the characteristics of the heating elements, such as resistance changes and output heating power. Consequently, it is imperative to comprehensively evaluate the reliability of anti-icing systems during these thermal and mechanical cycles to ensure their effectiveness and durability under operational conditions.

5. Development Directions for Integrated Anti-Icing Functions and Structures

5.1. Emerging Research Hot Points in Anti-Deicing Technology

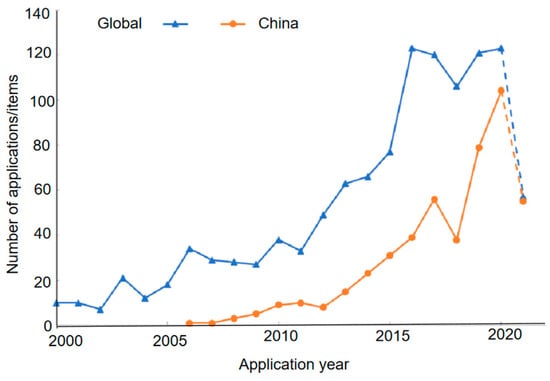

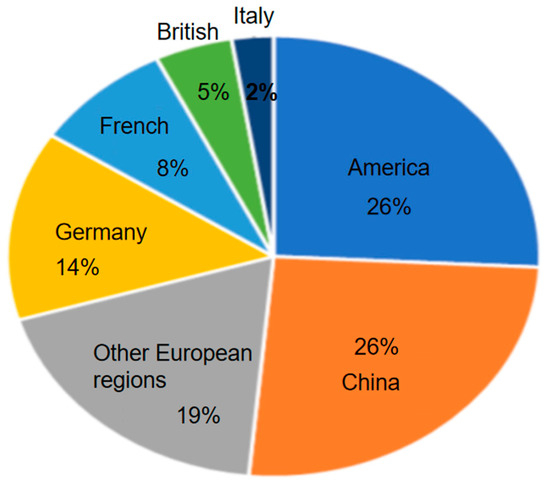

An analysis of global patents related to anti-deicing technology from 2000 to 2020 indicates a significant surge in patent filings during this period. This uptick in patent activity underscores the growing emphasis on innovative solutions to combat ice accumulation across various industries. The majority of these patent applications originated from the United States, China, Germany, France, the United Kingdom, and other European countries, as illustrated in Figure 26 and Figure 27. This geographic distribution highlights the global interest and investment in developing advanced anti-icing technologies, reflecting broader efforts to enhance safety and efficiency in environments susceptible to icing conditions.

Figure 26.

Trend in the number of global anti-deicing patents.

Figure 27.

Geographic distribution of global anti-deicing patents.

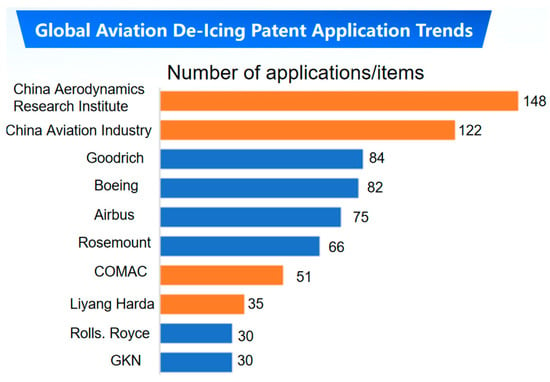

Applications for anti-deicing patents predominantly originate from prominent organizations such as the China Aerodynamic Research Institute, Aerospace Industry, Goodrich, Boeing, Airbus, and others. This trend is clearly depicted in Figure 28. These entities are at the forefront of addressing the challenges associated with ice accumulation, driving innovation in anti-deicing technology through their sustained research and development efforts. The involvement of such leading institutions underscores the critical importance and high stakes of advancing anti-icing solutions in industries where safety and efficiency are paramount.

Figure 28.

Major owners of global anti-deicing patents.

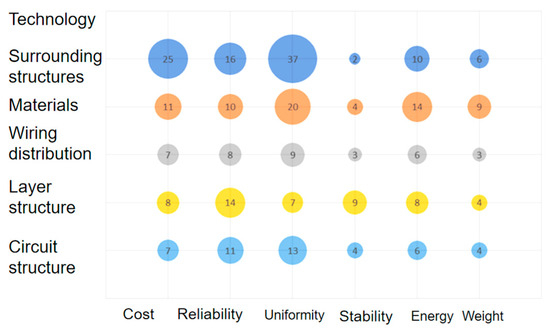

Patents were meticulously analyzed across various dimensions, including cost, reliability, uniformity, stability, energy consumption, and weight [107,108]. Notably, the largest category of patents pertains to the surrounding structures and materials, illustrating a pronounced focus within the aircraft anti-deicing sector on these components [109,110]. This trend underscores the critical importance placed on optimizing structural and material elements to enhance anti-icing efficacy.

Moreover, functional structure-integrated anti-deicing technology has emerged as a novel research direction and a current hotspot in the field. Detailed insights into this emerging trend are illustrated in Figure 29, highlighting its growing significance and the innovative strides being made in integrating anti-icing functionalities directly into structural components.

Figure 29.

Analysis of technical hotspots in anti-deicing patents.

5.2. New Development Direction of Anti-Deicing

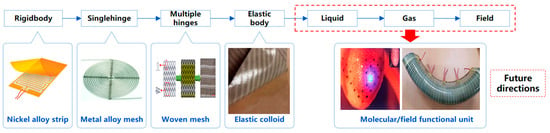

According to prevailing trends in existing anti-deicing systems, the development trajectory is increasingly focusing on the flexibility, dynamization, and micronization of heating components [111,112]. This evolution path underscores a shift towards more adaptable, responsive, and finely controlled anti-icing technologies. The detailed progression of these technological advancements in anti-deicing is systematically depicted in Figure 30, illustrating the strategic development routes that are set to define the future landscape of anti-icing solutions.

Figure 30.

Development roadmap of anti-deicing technologies.

As the demand for anti-fatigue and lightweight attributes in electric heating elements continues to rise, research focused on developing low-power-consumption, anti-fatigue, lightweight, and flexible electric heating elements has emerged as a central area of interest within the domain of electric heating anti-icing technology [113,114]. Looking forward, it is imperative for future composite aircraft anti-deicing electric heating systems to innovate a new type of electric heating element characterized by its lightweight nature, high efficiency, strong adaptability to varied shapes, and resilience to environmental factors [115].

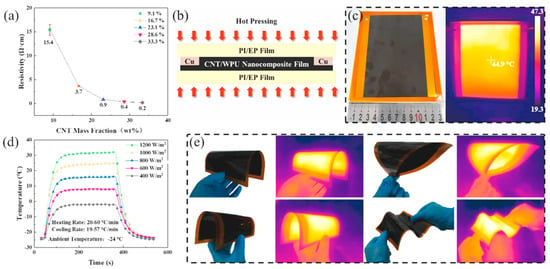

Key Characteristics of the New Heating Element, as illustrated in Figure 31.

Figure 31.

Heating effect of new-type heating elements [116]. (a) The resistivity of the fflms with the content of MWCNTs. (b) The schematic illustration of the structure and corresponding hot pressing of the CNT/WPU electrothermal fflm. (c) The photograph and an IR thermal image of the CNT/WPU electrothermal fflm. (d) The heating and cooling curves at the power densities in the range of 400–1200 W/m2. (e) The digital and IR thermal images of the CNT/WPU electrothermal films.

Light Weight: The density of the new heating element is approximately 10% lighter than that of conventional metals.

High Efficiency: The new element features excellent surface heating uniformity, superior heating interface combination, and a heat utilization rate exceeding 90%.

Excellent Shape Adaptability: Demonstrating remarkable compatibility with composite resins, the new heating element is easily deformable and apt for integration into complex and variably shaped aircraft structures. Future heating materials should be corrosion-resistant and possess a porous structure to ensure seamless amalgamation with the resin, thereby eliminating interface issues.

New materials like carbon fibers, carbon nanotubes (CNTs), and graphene, frequently employed as heating elements, must maintain stable resistances. However, the conductive networks of these materials exhibit significant resistance changes after repeated heating cycles. Despite the high strength of materials such as carbon fibers [117], CNTs [118], and graphene [119], their limited toughness predisposes them to linting and fracture during the manufacturing process, posing substantial challenges in the development of new heating pads [120]. Consequently, the use of carbon fibers, CNTs, and graphene as deicing elements remains largely confined to laboratory prototypes and has not yet achieved broad engineering application [121].

In the future, the integration of structural functions in aircraft composites is expected to advance further with the development of new materials and functionalities such as graphene and CNTs. Future enhancements may include the integration of properties such as thermal conductivity, anti-icing capabilities, electromagnetic shielding, lightning protection, and electromagnetic transparency [122]. This represents a significant step toward multifunctional composites that can enhance aircraft performance and safety across a range of operating conditions.

6. Limitations and Main Problems of Heating Layer Structures

To summarize, there has been notable progress in the functional and structural integration of aircraft deicing technologies both domestically and internationally. This advancement has catalyzed the development of composite deicing technologies within the aviation sector. However, the broad application of these technologies in aerospace encounters several challenges [123].

Stable Control of Quality Consistency: The technology for lightweight, efficient anti-deicing functional components is still in its nascent stages and faces various issues. These include high costs, significant fluctuations in quality stability, the absence of industry-wide quality inspection standards, and limited production scale. These factors critically impact the performance stability of anti-deicing functional integrated composite components, especially those prepared by embedding and hot pressing.

Production Technology for Large-Scale Application: Anti-icing components, composed of diverse materials, present more complex assembly challenges compared to traditional composites and involve multiple functional materials. Traditional composite preparation processes may result in uneven resin dispersion, poor fluidity, and compromised mechanical and electrothermal performance. Hence, developing a production process suitable for integrating multiple functions/materials remains crucial for preparing functional/structurally integrated composites for anti-icing applications.

Construction of an Integrated Evaluation Method: New heating elements, while conferring anti-icing functions to composite materials, may compromise mechanical strength. The need for efficient electrothermal network channels and robust fiber–resin interfacial bonding often requires a trade-off between mechanical and electrothermal properties. Establishing a comprehensive evaluation method and a mechanical model that assesses tensile strength, compression, interlaminar shear, and impact within the composite material is essential.

Demand for New Methods of Low-Cost Manufacturing: Contemporary research and application trends indicate that advanced composites with integrated anti-deicing structures and functions represent a future development direction. The challenge lies in achieving a blend of superior mechanical and electrical properties within the composite materials.

Early Monitoring and In-Depth Study of Damage Assessment Technology: The integrated functional structure of anti-icing parts will be subjected to dual cyclic loads-compressive shear and thermal—during actual service. This necessitates early monitoring of delamination and cracks within composite materials and further in-depth research on damage assessment technology.

In conclusion, while theoretical and experimental strides have been made in integrating the anti-deicing function with structural elements, numerous technical challenges persist in practical applications. Addressing these challenges will require collaborative efforts and continuous technological innovation both within and beyond the industry.

7. Conclusions and Outlook

This paper provides a comprehensive overview of the current state and future prospects of technology for the integration of aircraft anti-icing functional structures. Initially, it presents an exploration of the development and application of anti-icing configurations and functional structure integration technology for aircraft, both domestically and internationally. Subsequently, it delves into the key technologies and primary challenges associated with the integration of anti-icing functional structures.

While research into the functional-structural integration of anti-icing agents in composite airplanes has advanced, scaling these applications remains challenging. The introduction of new materials such as carbon nanotubes (CNTs) and graphene has the potential to enhance the thermal conductivity, electrical resistivity, and electromagnetic shielding capabilities of traditional composite materials. Investigating these materials for applications in electromagnetic shielding and lightning strike protection offers innovative design possibilities.

By optimizing material and structural design and refining the preparation process, it is possible to develop functional-structurally integrated composites that possess multifunctional properties. These properties include thermal conductivity, heat insulation, anti-icing, electromagnetic shielding, electromagnetic wave transparency, and electromagnetic wave-absorbing, combined with characteristics such as light weight and high strength. Such composites hold extensive application potential across various sectors, including aerospace, weaponry, electronics, and transportation.

Author Contributions

Conceptualization, Y.C. and W.C.; methodology, Y.C. and W.C.; validation, C.H.; formal analysis, N.D.; investigation, Y.C. and C.H.; resources, W.C. and N.D.; data curation, Y.C. and C.H.; writing—original draft preparation, Y.C. and C.H.; writing—review and editing, W.C. and N.D.; visualization, Y.C.; supervision, W.C. and N.D.; project administration, W.C. and N.D.; funding acquisition, W.C. and N.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (Grant No. 52275255).

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank their organizations and institutions for supporting this activity.

Conflicts of Interest

Yanchao Cui was employed by the Tianjin Aerospace Electro-Mechanical Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Qiu, X.G.; Han, F.H. Aircraft Anti-Icing System; Compilation and Examination Group of Aero Specialized Teaching Materials: Beijing, China, 1985; pp. 1–17. [Google Scholar]

- Cao, Y.; Tan, W.; Wu, Z. Aircraft Icing: An Ongoing Threat to Aviation Safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Farzaneh, M.; Ryerson, C.C. Anti-Icing and Deicing Techniques. Cold Reg. Sci. Technol. 2011, 65, 1–4. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Z.; Su, Y.; Xu, Z. Aircraft Flight Characteristics in Icing Conditions. Prog. Aerosp. Sci. 2015, 74, 62–80. [Google Scholar] [CrossRef]

- Jin, W. Numerical Investigation of Icing Effects on Dynamic Inlet Distortion. Int. J. Aeronaut. Space Sci. 2018, 19, 354–362. [Google Scholar] [CrossRef]

- Zhu, L. Development of General Aviation Aircraft Design Technology Abroad. Aircr. Des. Ref. Mater. 2012, 2, 29–34. [Google Scholar]

- Lynch, F.T.; Khodadoust, A. Effects of Ice Accretions on Aircraft Aerodynamics. Prog. Aerosp. Sci. 2001, 37, 669–767. [Google Scholar] [CrossRef]

- Jung, S.K.; Shin, S.; Myong, R.S.; Cho, T.H. An Efficient CFD-Based Method for Aircraft Icing Simulation Using a Reduced Order Model. J. Mech. Sci. Technol. 2011, 25, 703–711. [Google Scholar] [CrossRef]

- De Rosa, F.; Esposito, A. Electrically heated composite leading edges for aircraft anti-icing applications. Fluid Dyn. Mater. Process. 2012, 8, 107–128. [Google Scholar] [CrossRef]

- He, Q.; Li, K.; Xu, Z.; Wang, J.; Wang, X.; Li, A. Research Progress on Construction Strategy and Technical Evaluation of Aircraft Icing Accretion Protection System. Chin. J. Aeronaut. 2023, 36, 1–23. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, Development, Outcomes, and Application Versatility of Carbon Fiber-Based Polymer Composites: A Review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Kang, Y.S.; Park, S.W.; Roh, J.S.; Myong, R.S. Computational Investigation of Effects of Expanded Metal Foils on the Lightning Protection Performance of a Composite Rotor Blade. Int. J. Aeronaut. Space Sci. 2021, 22, 203–221. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, Y.; Zhao, Z.Q. Applications and key challenges of polymer composites in civil aero-engines: State-of-art review. Acta Aeronaut. Astronaut. Sin. 2024, 45, 028556. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, H. Inflatable Wing Design Parameter Optimization Using Orthogonal Testing and Support Vector Machines. Chin. J. Aeronaut. 2012, 25, 887–895. [Google Scholar] [CrossRef]

- Wang, H.; Sun, X.Y.; Zhang, J.G. Research progress on the structure-function integration on of graphene/carbon fiber hybrid composites. J. Solid Rocket. Technol. 2021, 44, 737–746. [Google Scholar]

- Cao, Y.; Farha, F.I.; Ge, D.; Liu, X.; Liu, W.; Li, G.; Zhang, T.; Xu, F. Highly Effective E-Heating Performance of Nickel Coated Carbon Fiber and Its Composites for deicing Application. Compos. Struct. 2019, 229, 111397. [Google Scholar] [CrossRef]

- Zhou, Y.J. Summary and exploration of aircraft anti-icing and deicing methods. Mod. Trade Ind. 2019, 1, 195–196. (In Chinese) [Google Scholar]

- Wang, Y.; Yuan, X.; Zhang, F. The development of the wing ice protection system. Henan Sci. 2012, 30, 1246–1250. [Google Scholar]

- Al-Khalil, K. Thermo-mechanical expulsion deicing system—TMEDS. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8 January–11 January 2007. [Google Scholar]

- Chen, S.J. Civil Research and Development of Advanced Composite Materials. Mater. Rev. 2010, 11, 22–25. [Google Scholar]

- Falzon, B.G.; Robinson, P.; Frenz, S.; Gilbert, B. Development and Evaluation of a Novel Integrated Anti-Icing/de-Icing Technology for Carbon Fibre Composite Aerostructures Using an Electro-Conductive Textile. Compos. Part A Appl. Sci. Manuf. 2015, 68, 323–335. [Google Scholar] [CrossRef]

- Yao, X.; Hawkins, S.C.; Falzon, B.G. An advanced anti-icing/deicing system utilizing highly aligned carbon nanotube webs. Carbon 2018, 136, 130–138. [Google Scholar] [CrossRef]

- Park, H.K.; Kim, S.M.; Lee, J.S.; Park, J.H.; Hong, Y.K.; Hong, C.H.; Kim, K.K. Flexible plane heater: Graphite and carbon nanotube hybrid nanocomposite. Synth. Met. 2015, 203, 127–134. [Google Scholar] [CrossRef]

- Wei, J.; Li, H.; Zhang, Y.; Gu, Z.; Hu, Y.; Jiang, W.; Zhou, J. Research Progress of Graphene Composites in the Field of Electrothermal Anti-Icing /Deicing. Mater. China 2022, 41, 487–496. [Google Scholar]

- Li, W.B.; Hao, Y.Q.; Wang, J.T. Influence of helicopter rotor icing and anti-/deicing methods: A review. J. Aerosp. Power 2023, 38, 258–260. [Google Scholar]

- Yang, C.W.; Hu, H.P.; Ma, Y.L. A new idea on anti-icing and deicing of helicopter rotor blade. Helicopter Tech. 2009, 3, 47–51. [Google Scholar]

- Lin, G.; Bu, X.; Shen, X. Aircraft Icing and Anti-Icing Method; Beihang University: Beijing, China, 2016. [Google Scholar]

- Dehaghani, S.T.; Dolatabadi, A.; McDonald, A. Thermally Sprayed Metal Matrix Composite Coatings as Heating Systems. Appl. Therm. Eng. 2021, 196, 117321. [Google Scholar] [CrossRef]

- Yan, W.; An, Y.; Zhou, Z.; Xiong, H.; Wu, Z. Study on Thermal Energy of Three-Dimensional Propeller Anti-Icing Electrothermal System. In Proceedings of the 2023 17th Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Chengdu, China, 10–12 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Bourgault, Y.; Habashi, W.G.; Dompierre, J.; Baruzzi, G.S. A Finite Element Method Study of Eulerian Droplets Impingement Models. Int. J. Numer. Methods Fluids 1999, 29, 429–449. [Google Scholar] [CrossRef]

- Lian, W.; Xuan, Y. Experimental Investigation on a Novel Aero-Engine Nose Cone Anti-Icing System. Appl. Therm. Eng. 2017, 121, 1011–1021. [Google Scholar] [CrossRef]

- Cao, Y.; Li, G.; Song, D. Numerical Simulation of Melting of Ice Accreted on an Airfoil. Aerosp. Sci. Technol. 2021, 119, 107223. [Google Scholar] [CrossRef]

- Kang, H.; Kaiqiang, W.; Chunyu, G.; Chao, W.; Liyu, Y.; Zeping, W. Mechanism Analysis of Propeller-Ice Contact and Rapid Prediction of Ice Loads. Cold Reg. Sci. Technol. 2023, 216, 103987. [Google Scholar] [CrossRef]

- Yao, X.; Falzon, B.; Hawkins, S.; Tsantzalis, S. Aligned Carbon Nanotube Webs Embedded in a Composite Laminate: A Route towards a Highly Tunable Electro-Thermal System. Carbon 2018, 129, 486–494. [Google Scholar] [CrossRef]

- Zanjani, J.S.; Okan, B.S.; Pappas, P.N.; Galiotis, C.; Menceloglu, Y.Z.; Yildiz, M. Tailoring Viscoelastic Response, Self-Heating and Deicing Properties of Carbon-Fiber Reinforced Epoxy Composites by Graphene Modification. Compos. Part A Appl. Sci. Manuf. 2018, 106, 1–10. [Google Scholar] [CrossRef]

- Baigang, M. A CFD–CSD Coupling Method for Simulating the Dynamic Impact and Expulsion of Fragile Foreign Objects from the “Inlet–Bypass Duct” Junction of a Turboprop Aircraft. Eng. Appl. Comput. Fluid Mech. 2022, 16, 73–94. [Google Scholar] [CrossRef]

- Kim, Y.; Jo, J.; Kim, D.; Lee, H.; Myong, R. Effects of Lightning on UAM Aircraft: Complex Zoning and Direct Effects on Composite Prop-Rotor Blade. Aerosp. Sci. Technol. 2022, 124, 107560. [Google Scholar] [CrossRef]

- Lee, J.S.; Jo, H.; Choe, H.S.; Lee, D.S.; Jeong, H.; Lee, H.R.; Kweon, J.H.; Lee, H.; Myong, R.S.; Nam, Y. Electro-Thermal Heating Element with a Nickel-Plated Carbon Fabric for the Leading Edge of a Wing-Shaped Composite Application. Compos. Struct. 2022, 289, 115510. [Google Scholar] [CrossRef]

- Ji, Z.; Huang, X.; Sheng, H.; Wang, X.; Hu, W.; Liu, H. Neuron-like Thermal Silica Bridge between Boron Nitride Nanosheets with Hard-Soft Composite Structure to Enhance Thermal Conductivity and Anti-Icing Properties on CFRP. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107806. [Google Scholar] [CrossRef]

- Affonso, W.; da Silva, R.G.A.; da Silva, F.S.; Thomas, G.; Kessler, S.; Domingos, R.H. Carbon Nanotube (CNT) Based Ice Protection System Applied to a Small Aircraft. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and deicing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Lopera-Valle, A.; McDonald, A. Flame-Sprayed Coatings as deicing Elements for Fiber-Reinforced Polymer Composite Structures: Modeling and Experimentation. Int. J. Heat Mass Transf. 2016, 97, 56–65. [Google Scholar] [CrossRef]

- Jianzhen, G.U.; Huimin, Q.I.; Jiaxin, Y.U.; Yafeng, Z.H.; Xingshi, G.U. Investigation on Anti/Deicing Performance of an Innovative Electrothermal Structure. Trans. Nanjing Univ. Aeronaut. Astronaut. 2016, 40, 97–104. [Google Scholar]

- Yuan, L.; Linwei, Z.; Zhiqiang, H.; Dejun, W.; Hui, H.; Zhiyong, L. Deicing System of Wind Turbine Blades Based on Polymorphic Intelligent Network. In Proceedings of the International Conference on Ubiquitous Communication (Ucom), Xi’an, China, 7–9 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 432–437. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ming, Y.; Duan, Y.; Zhang, S.; Zhu, Y.; Wang, B. Self-Heating 3D Printed Continuous Carbon Fiber/Epoxy Mesh and Its Application in Wind Turbine Deicing. Polym. Test. 2020, 82, 106309. [Google Scholar] [CrossRef]

- Tian, T.; Wang, Y.; Tao, M. Experimental study on electro-thermal deicing of graphene composites. Sci. Technol. Eng. 2019, 19, 390–395. [Google Scholar]

- Zou, L.; Wang, X.; Li, Y. Research progress of flexible electric heating fabrics. Mater. Sci. Technol. 2021, 29, 74–88. [Google Scholar]

- Zhang, C.; Ling, Y.; Zhang, X.; Liang, M.; Zou, H. Ultra-Thin Carbon Fiber Reinforced Carbon Nanotubes Modified Epoxy Composites with Superior Mechanical and Electrical Properties for the Aerospace Field. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107197. [Google Scholar] [CrossRef]

- Yao, L.; Zhang, S.; Cao, X.; Gu, Z.; Wang, C.; He, W. Tensile Mechanical Behavior and Failure Mechanisms of Fiber Metal Laminates under Various Temperature Environments. Compos. Struct. 2022, 284, 115142. [Google Scholar] [CrossRef]

- Süsler, S.; Bora, M.; Uçan, C.; Türkmen, H.S. The Effect of Surface Treatments on the Interlaminar Shear Failure of GLARE Laminates Subjected to Pre-cyclic Thermal Loads. Polym. Compos. 2022, 43, 9040–9053. [Google Scholar] [CrossRef]

- Fan, W.; Dang, W.; Liu, T.; Li, J.; Xue, L.; Yuan, L.; Dong, J. Fatigue Behavior of the 3D Orthogonal Carbon/Glass Fibers Hybrid Composite under Three-Point Bending Load. Mater. Des. 2019, 183, 108112. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, Y.; Wang, Z.; Zhang, Y.; Zhang, K.; Chen, J.; Liu, X.; Chen, H. A Biaxial Stretchable, Flexible Electric Heating Composite Film for deicing. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107124. [Google Scholar] [CrossRef]

- Dai, H.; Li, J.; Sun, Y.; Liu, L.; Chen, L. Electrothermal and interlayer shear properties of warp-knitted biaxial fabric/epoxy electrically heated composite materials. Acta Mater. Compos. Sin. 2020, 37, 1997–2004. [Google Scholar]

- Hong, H.; Liu, W.; Ai, J. Anti-deicing system for helicopters. Helicopter Technol. 2010, 1, 52–56. [Google Scholar]

- Rauch, P.; Quillien, C. Advanced technologies for high performance NH90 blades. Annu. Forum Am. Helicopter Soc. 2003, 59, 554–565. [Google Scholar]

- Yang, C.W.; Zhang, G.H.; Sun, T. Development Black Hwak Helicopter Rotor Blade Anti-/Deicing System. Helicopter Tech. 2011, 1, 37–44. [Google Scholar]

- Wang, L.G.; Zhou, L.; Zhang, S.; Wu, Y.; Li, P.; Chen, J. Research Progress in Anti-icing and Deicing Technology for Helicopter rotors. Acta Aeronaut. Astronaut. Sin. 2023, 44, 729458. [Google Scholar]

- Meng, L.; Chen, P.; Gu, Y. Reliability Experiment and Structural Optimized of Helicopter Rotor Blade Heating Materials Assemble. Fail. Anal. Prev. 2022, 17, 379–384. [Google Scholar]

- Chen, G.C.; Ji, S.Y.; Zhao, W.M.; Yi, X. Experimental study on heating pad of helicopter rotor deicing system. Adv. Aeronaut. Sci. Eng. 2019, 10, 201–205. [Google Scholar]