Recent Developments in the Aerodynamic Heat Transfer and Cooling Technology of Gas Turbines Endwalls

Abstract

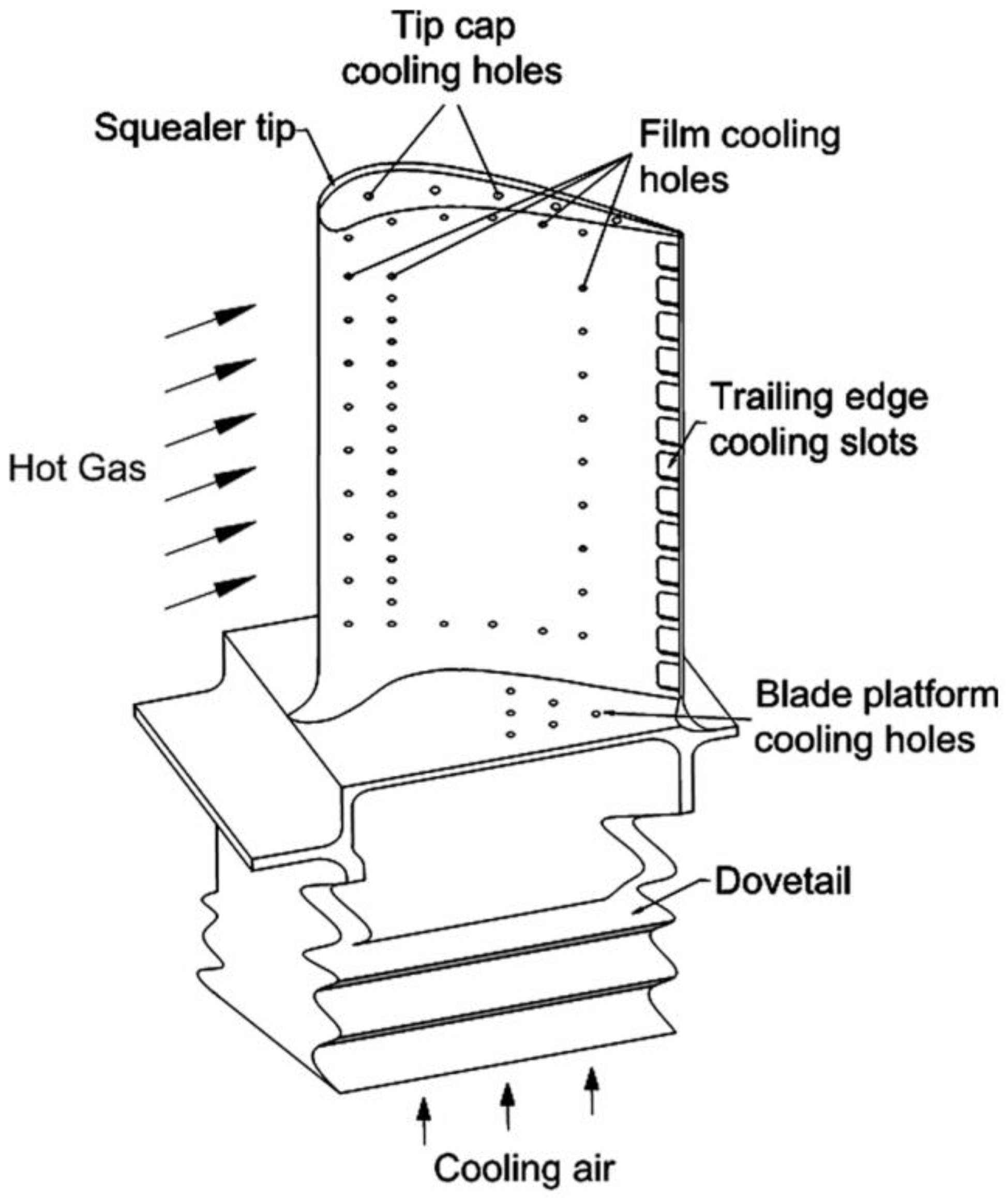

:1. Introduction

2. Geometrical Design of Cooling Structures

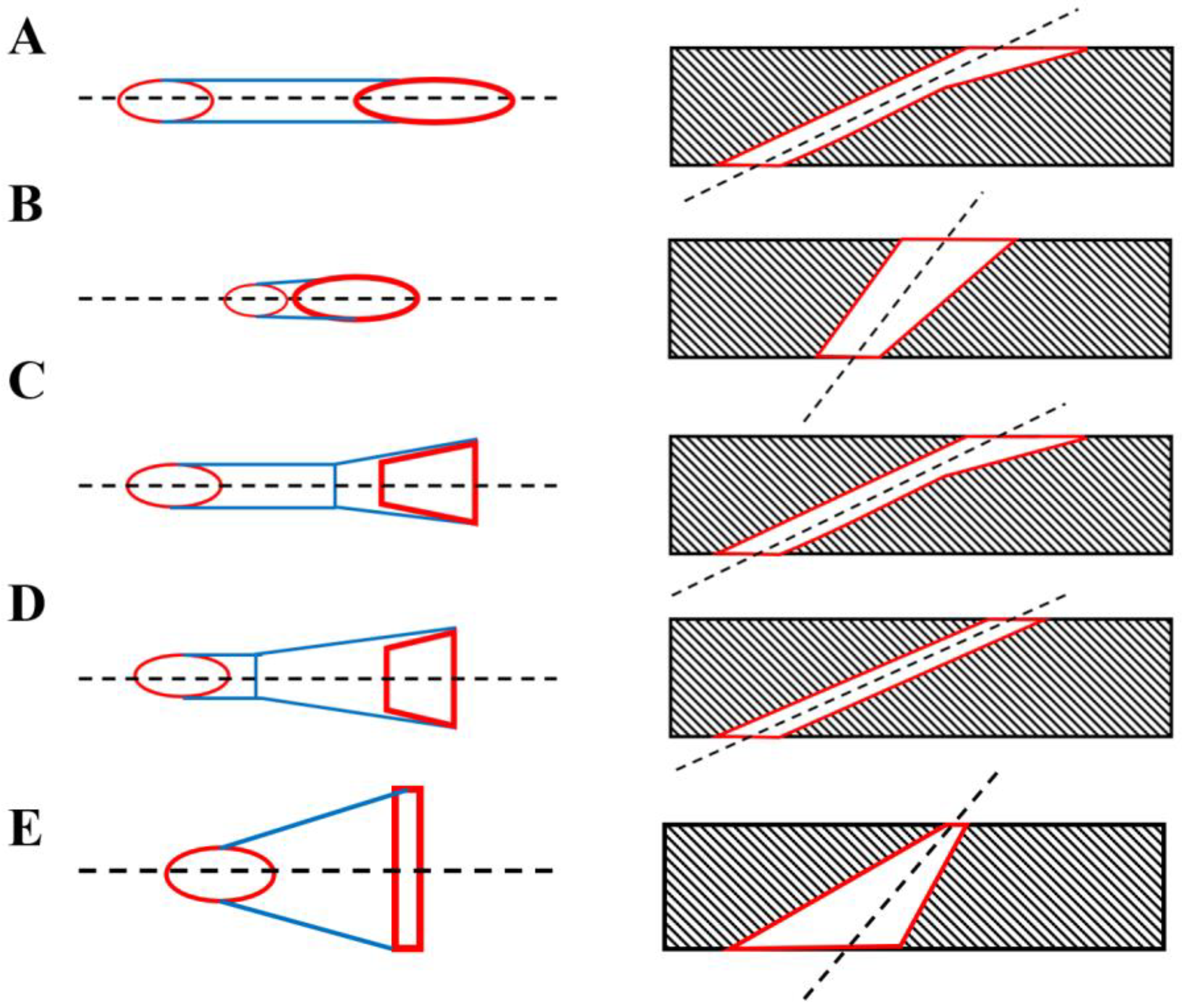

2.1. Design of Cooling Holes

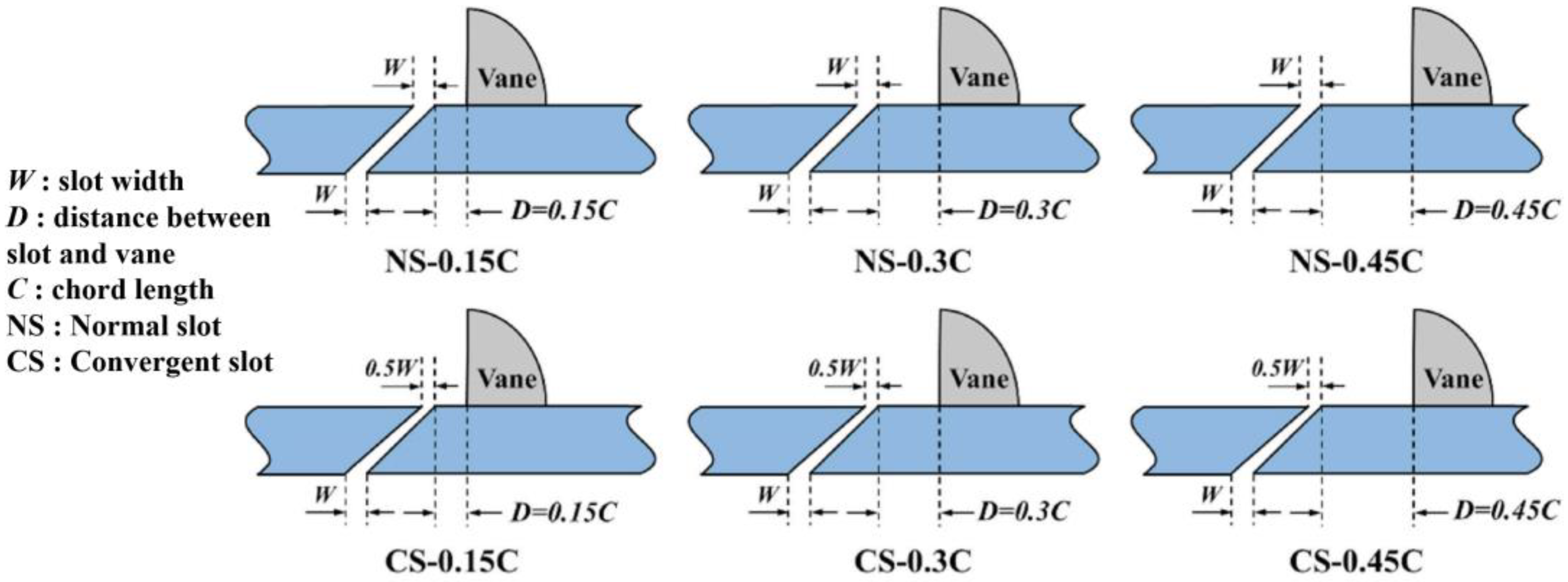

2.2. Upstream Slot Injection Cooling

2.3. Passage Gap Injection Cooling

2.4. Endwall Profile

2.5. Optimization Design

3. Influence of Flow Conditions

3.1. Turbulence Intensity

3.2. Mass Flow Ratio

3.3. Blowing Ratio

3.4. Density Ratio

3.5. Injection Angle

3.6. Transverse Pressure Gradient

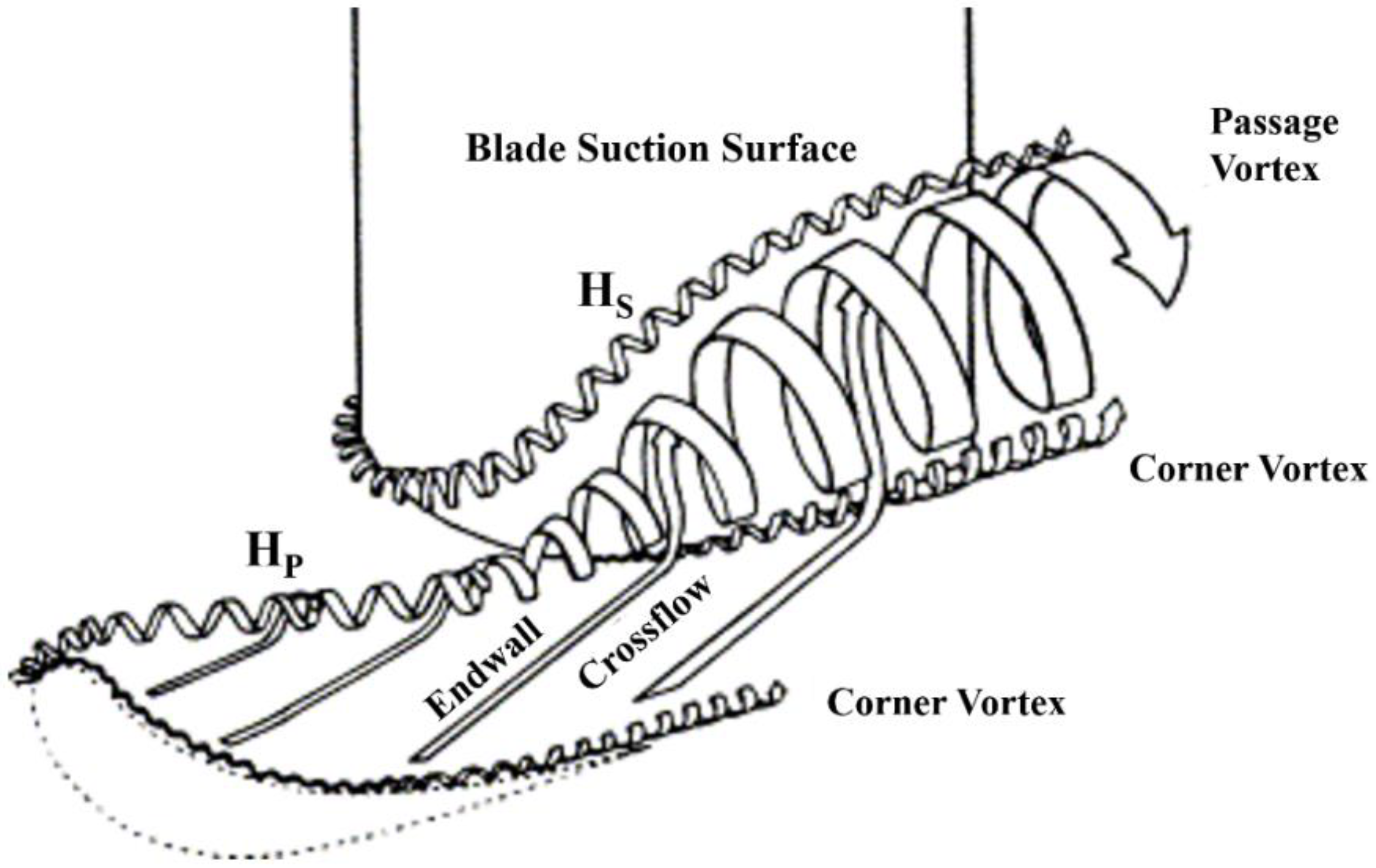

3.7. Secondary Flow

3.8. Mach Number

4. Experimental Method

4.1. Flow Field Measurements

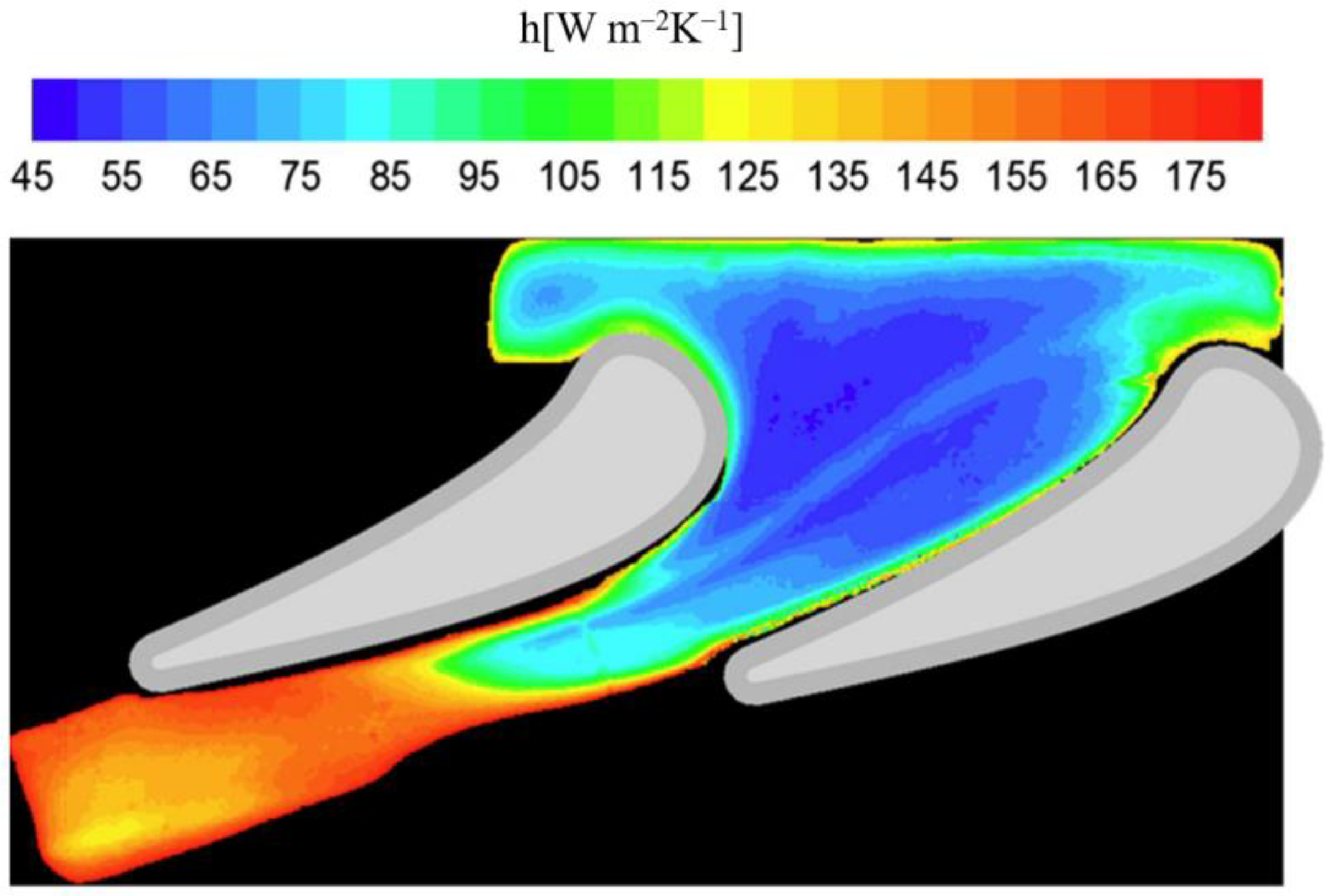

4.2. Temperature Field Measurement

5. Other Research Directions

5.1. Surface Deposit

5.2. Phantom Cooling

6. Developments and Challenges

- (1)

- It is highly significant to develop new and efficient designs for film holes to enhance the cooling efficiency and aerodynamic performance of the film. These film holes can generate specific vortex structures that considerably improve endwall cooling efficiency. Future research should focus on paired novel film holes.

- (2)

- Most studies on endwall cooling focus on specific cooling structures; however, in practice, a variety of cooling structures are employed on cascade endwalls to ensure their safe operation. Future studies should examine the interaction between cooling jets in slots and film holes, as well as the gaps between channels. Additionally, the influence of different cooling structures on endwall cooling efficiency and aerodynamic loss should be considered.

- (3)

- Research on the cooling characteristics of new cooling mechanisms primarily focuses on planar endwalls, neglecting the impact of the complex vortex system on the passage endwalls. Future work should investigate the interaction mechanism between the cooling jet and the complex vortex system in the vicinity of the endwall within a realistic cascade environment. This will enhance the practicality of the new cooling structure.

- (4)

- The rapid development of artificial intelligence has significantly advanced numerous fields. In the research field of endwall film cooling, it is crucial to embrace traditional approaches while actively exploring novel methods, such as deep learning, artificial intelligence and interdisciplinary integration with big data research.

- (5)

- As a coolant, steam is much more efficient than air when the conditions are under the same parameters because of steam’s higher thermal capability and higher Prandtl number. On the other hand, a high efficiency is achievable by merging preheating fuel, recuperation and injection of steam. Adding cooling system to a powerplant increases the overall thermal efficiency by more than 1% [112]. Therefore, research into coolants should be a future focus.

- (6)

- New cooling structures, such as micro-scale cooling and laminate cooling, should be explored. Three-dimensional printing will allow the construction of complex cooling structures. In addition, the cooling characteristics of these new structures will need to be studied [113].

Author Contributions

Funding

Conflicts of Interest

References

- Han, J.C.; Dutta, S.; Ekkad, S. Gas Turbine Heat Transfer and Cooling Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Simon, T.W.; Piggush, J.D. Turbine endwall aerodynamics and heat transfer. J. Propuls. Power 2006, 22, 301–312. [Google Scholar] [CrossRef]

- Li, H.W.; Lin, G.W.; Xu, Q.; Fang, X.J.; Xian, S.X. Overall Heat Transfer Coefficient Evaluation Method for Uncracked Hydrocarbon Fuel in a Regeneratively-Cooled Heat Exchanger of a Scramjet. Appl. Sci. 2022, 12, 6590. [Google Scholar]

- Han, J.C. Recent Studies in Turbine Blade Cooling. Int. J. Rotating Mach. 2004, 10, 443–457. [Google Scholar]

- Yang, X.; Zhao, Q.; Liu, Z.; Liu, Z.; Feng, Z. Film Cooling Patterns over an Aircraft Engine Turbine Endwall with Slot Leakage and Discrete Hole Injection. Int. J. Heat Mass Transf. 2021, 165, 120565. [Google Scholar]

- Wang, H.P.; Olson, S.J.; Goldstein, R.J.; Eckert, E.R.G. Flow Visualization in a Linear Turbine Cascade of High Performance Turbine Blades. J. Turbomach. 1997, 119, 1–8. [Google Scholar]

- Moon, Y.J.; Koh, S.R. Counter-rotating streamwise vortex formation in the turbine cascade with endwall fence. Comput. Fluids 2001, 30, 473–490. [Google Scholar]

- Holley, B.M.; Becz, S.; Langston, L.S. Measurement and Calculation of Turbine Cascade Endwall Pressure and Shear Stress. J. Turbomach. 2006, 128, 232–239. [Google Scholar]

- Bai, B.; Li, Z.; Li, J.; Mao, S.; Ng, W.F. Effects of Upstream Step Geometries on Endwall Film Cooling and Phantom Cooling Performances of a Transonic Turbine Vane. J. Therm. Sci. Eng. Appl. 2022, 14, 121005. [Google Scholar]

- Zhang, Y.; Yuan, X. Experimental Investigation of Turbine Phantom with Combustor-Turbine Leakage Gap Flow and Endwall Film Cooling. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Du, K.; Li, Z.; Li, J. Effects of Trenched Film Hole Configurations on the Endwall Film Cooling and Suction Side Phantom Cooling. J. Therm. Sci. 2019, 28, 905–914. [Google Scholar]

- Bai, B.; Li, Z.; Li, J.; Mao, S.; Ng, W.F. Turbine Vane Endwall Film Cooling and Pressure Side Phantom Cooling Performances with Upstream Coolant Flow at Various Injection Angles. J. Therm. Sci. Eng. Appl. 2022, 14, 111014. [Google Scholar]

- Du, K.; Song, L.; Li, J.; Sunden, B. Effects of the layout of film holes near the vane leading edge on the endwall cooling and phantom cooling of the vane suction side surface. Numer. Heat Transf. Part A Appl. 2017, 71, 910–927. [Google Scholar]

- Sundaram, N.; Thole, K.A. Effects of Surface Deposition, Hole Blockage, and Thermal Barrier Coating Spallation on Vane Endwall Film Cooling. J. Turbomach. 2007, 129, 599–607. [Google Scholar]

- Sundaram, N.; Barringer, M.D.; Thole, K.A. Effects of deposits on film cooling of a vane endwall along the pressure side. In Proceedings of the ASME Turbo Expo 2007, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- Mensch, A.; Thole, K. Simulations of Multiphase Particle Deposition on a Gas Turbine Endwall with Impingement and Film Cooling. J. Turbomach. 2015, 137, 111002. [Google Scholar]

- Lawson, S.A.; Lynch, S.P.; Thole, K.A. Simulations of Multiphase Particle Deposition on a Nonaxisymmetric Contoured Endwall with Film-Cooling. J. Turbomach. 2013, 135, 031032. [Google Scholar]

- Bunker, R.S. A Review of Shaped Hole Turbine Film-Cooling Technology. J. Heat Transf. 2005, 127, 441–453. [Google Scholar]

- Colban, W.; Thole, K. Influence of hole shape on the performance of a turbine vane endwall film-cooling scheme. Int. J. Heat Fluid Flow 2007, 28, 341–356. [Google Scholar]

- Barigozzi, G.; Franchini, G.; Perdichizzi, A.; Ravelli, S. Film cooling of a contoured endwall nozzle vane through fan-shaped holes. Int. J. Heat Fluid Flow 2010, 31, 576–585. [Google Scholar]

- Zhang, L.; Yin, J.; Liu, K.; Hee-Koo, M. Effect of Hole Diameter on Nozzle Endwall Film Cooling and Associated Phantom Cooling. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Zhou, J.; Wang, X.; Li, J.; Lu, H. CFD analysis of mist/air film cooling on a flat plate with different hole types. Numer. Heat Transf. Part A Appl. 2017, 71, 1123–1140. [Google Scholar]

- Yu, Z.; Liu, J.; Li, C.; An, B.; Xu, G. Experimental Investigation of Film Cooling Performance on Blade Endwall with Diffusion Slot Holes and Stator-Rotor Purge Flow. J. Turbomach. 2021, 143, 051009. [Google Scholar]

- Noughabi, A.K.; Sammak, S. Detailed Design and Aerodynamic Performance Analysis of a Radial-Inflow Turbine. Appl. Sci. 2018, 8, 2207. [Google Scholar]

- Huyssen, B.B.; Shote, A.S.; Mahmood, G.I. Upstream Endwall Film-Cooing in a Vane Cascade with Cylindrical Shape Holes. J. Thermophys. Heat Transf. 2023, 37, 676–689. [Google Scholar]

- Kunze, M.; Vogeler, K.; Crawford, M.; Brown, G. Single and Multiple Row Endwall Film-Cooling of a Highly Loaded First Turbine Vane with Variation of Loading. J. Turbomach. 2014, 136, 061012. [Google Scholar]

- Satta, F.; Tanda, G. Effect of discrete-hole arrangement on film-cooling effectiveness for the endwall of a turbine blade cascade. Appl. Therm. Eng. 2015, 91, 507–514. [Google Scholar]

- Li, X.; Ren, J.; Jiang, H. Multi-row film cooling characteristics on a vane endwall. Int. J. Heat Mass Transf. 2016, 92, 23–33. [Google Scholar]

- Zhou, Y.; Zhang, Y.; Su, X.; Yuan, X. Effect of inlet rotating swirl on endwall film cooling for two representative hole arrangements. Chin. J. Aeronaut. 2018, 31, 1095–1108. [Google Scholar]

- Liu, J.H.; Liu, Y.B.; Liu, L. Film cooling modeling of a turbine vane with multiple configurations of holes. Case Stud. Therm. Eng. 2018, 11, 71–80. [Google Scholar]

- Fu, J.; Hossain, J.; Kapat, J. Aero-Thermal Performance of A Rotor Blade Cascade with Film Cooling in Passage Endwall. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Cheng, S.C.; Izzet, S.; Nian, W.; Chin, H.J.; Hongzhou, X.; Michael, F. Turbine Vane Endwall Film Cooling Comparison From Five Film-Hole Design Patterns and Three Upstream Injection Angles. J. Therm. Sci. Eng. Appl. 2019, 11, 031012. [Google Scholar]

- Liu, J.; Du, W.; Hussain, S.; Xie, G.; Bengt, S. Endwall film cooling holes design upstream of the leading edge of a turbine vane. Numer. Heat Transf. Part A Appl. 2020, 79, 222–245. [Google Scholar]

- Liu, J.; Xu, M.; Xi, W. Effects of Gas Thermophysical Properties on the Full-Range Endwall Film Cooling of a Turbine Vane. Aerospace 2023, 10, 592. [Google Scholar]

- Day, C.R.; Oldfield, M.L.; Lock, G.D.; Dancer, S.N. Efficiency Measurements of an Annular Nozzle Guide Vane Cascade with Different Film Cooling Geometries. In Proceedings of the ASME International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2 June 1998. [Google Scholar]

- Ganzert, W.; Hildebrandt, T.; Fottner, L. Systematic experimental and numerical investigations on the aerothermodynamics of a film cooled turbine cascade with variation of the cooling hole shape: Part I—Experimental approach. In Proceedings of the ASME Turbo Expo: Power for Land, Sea, and Air, Munich, Germany, 8 May 2000. [Google Scholar]

- Zhang, L.J.; Jaiswal, R.S. Turbine nozzle endwall film cooling study using pressure-sensitive paint. J. Turbomach. 2001, 123, 730–738. [Google Scholar]

- Hada, S.; Thole, K.A. Computational study of a midpassage gap and upstream slot on vane endwall film-cooling. In Proceedings of the ASME Turbo Expo 2006, Barcelona, Spain, 6–11 May 2006. [Google Scholar]

- Xu, Q.; Du, Q.; Wang, P.; Zhu, J. Computational study of film cooling and flowfields on a stepped vane endwall with a row of cylindrical hole and interrupted slot injections. Int. J. Heat Mass Transf. 2019, 134, 796–806. [Google Scholar]

- Gunther, M.; Christian, L.; Martin, B.; Robert, K. Turbine Vane Endwall Film Cooling Effectiveness of Different Purge Slot Configurations in a Linear Cascade. J. Turbomach. 2020, 142, 031008. [Google Scholar]

- Du, K.; Li, J. Numerical study on the effects of slot injection configuration and endwall alignment mode on the film cooling performance of vane endwall. Int. J. Heat Mass Transf. 2016, 98, 768–777. [Google Scholar]

- Yang, X.; Liu, Z.; Liu, Z.; Feng, Z.; Simon, T.W. Combustor Wall Coolant Discharge Effects on Turbine Vane Endwall Curtain Cooling. J. Thermophys. Heat Transf. 2018, 32, 933–945. [Google Scholar]

- Yao, Y.; Zhu, P.; Tao, Z.; Song, L.; Li, J. Experimental Study on the Effects of Slot Jet on Film Cooling Performance in the Cascade Endwall with Purge Flow. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Tao, Z.; Yao, Y.; Zhu, P.; Song, L.; Li, J. Experimental and numerical study on film cooling effectiveness of an annular cascade endwall with different slot configuration. Int. J. Therm. Sci. 2020, 158, 106517. [Google Scholar]

- Xiao, X.; Wang, P.; Du, Q.; Xu, Q.; Liu, J.; Zhu, J. Numerical Investigations of Film Cooling Characteristics of Interrupted Slot and Trench Holes on a Vane Endwall. J. Therm. Sci. 2021, 30, 1010–1024. [Google Scholar]

- Knost, D.G.; Thole, K.A. Adiabatic Effectiveness Measurements of Endwall Film-Cooling for a First-Stage Vane. J. Turbomach. 2005, 127, 297–305. [Google Scholar]

- Hada, S.; Thole, K.A. Computational Study of a Midpassage Gap and Upstream Slot on Vane Endwall Film-Cooling. J. Turbomach. 2011, 133, 011024. [Google Scholar]

- Chowdhury, N.H.K.; Shiau, C.; Han, J.C.; Zhang, L.; Moon, H. Turbine Vane Endwall Film Cooling with Slashface Leakage and Discrete Hole Configuration. J. Turbomach. 2017, 139, 061003. [Google Scholar]

- Chen, P.; Gao, H.; Li, X.; Ren, J.; Jiang, H. Effects of Endwall 3D Contouring on Film Cooling Effectiveness of Cylindrical Hole Injections at Different Locations on Vane Endwall. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Thrift, A.A.; Thole, K.A.; Hada, S. Effects of an Axisymmetric Contoured Endwall on a Nozzle Guide Vane: Adiabatic Effectiveness Measurements. J. Turbomach. 2011, 133, 041007. [Google Scholar]

- Takeishi, K.; Oda, Y.; Seguchi, J.; Kozono, S. Effect of Endwall Film Cooling Upstream of An Airfoil/Endwall Junction to Suppress the Formation of Horseshoe Vortex in A Symmetric Airfoil. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Bai, B.; Li, Z.; Li, J.; Mao, S.; Ng, W.F. The Effects of Axisymmetric Convergent Contouring and Blowing Ratio on Endwall Film Cooling and Vane Pressure Side Surface Phantom Cooling Performance. J. Eng. Gas Turbines Power 2022, 144, 021020. [Google Scholar]

- Wang, Z.; Hu, G.; Zhang, D.; Kim, B.; Xu, F.; Xiao, Y. Aerodynamic Characteristics of a Square Cylinder with Vertical-Axis Wind Turbines at Corners. Appl. Sci. 2022, 12, 3515. [Google Scholar]

- Mahmood, G.I.; Gustafson, R.; Acharya, S. Flow Dynamics and Film Cooling Effectiveness on A Non-Axisymmetric Contour Endwall in A Two Dimensional Cascade Passage. In Proceedings of the ASME Turbo Expo 2009, Orlando, FL, USA, 8–12 June 2009. [Google Scholar]

- Lynch, S.P.; Thole, K.A.; Kohli, A.; Lehane, C. Computational Predictions of Heat Transfer and Film-Cooling for a Turbine Blade with Non-Axisymmetric Endwall Contouring. In Proceedings of the ASME Turbo Expo 2010, Glasgow, Scotland, 3–7 June 2013. [Google Scholar]

- Lynch, S.P.; Thole, K.A.; Kohli, A.; Lehane, C. Computational Predictions of Heat Transfer and Film-Cooling for a Turbine Blade with Nonaxisymmetric Endwall Contouring. J. Turbomach. 2011, 133, 041003. [Google Scholar]

- Taremi, F.; Sjolander, S.A.; Praisner, T.J. Application of Endwall Contouring to Transonic Turbine Cascades: Experimental Measurements at Design Conditions. J. Turbomach. 2013, 135, 011031. [Google Scholar]

- Rezasoltani, M.; Schobeiri, M.T.; Han, J.C. Experimental Investigation of the Effect of Purge Flow on Film Cooling Effectiveness on a Rotating Turbine with Nonaxisymmetric End Wall Contouring. J. Turbomach. 2014, 136, 091009. [Google Scholar]

- Mensch, A.; Thole, K.A. Overall Effectiveness and Flowfield Measurements for an Endwall with Nonaxisymmetric Contouring. J. Turbomach. 2016, 138, 031007. [Google Scholar]

- Panchal, K.V.; Abraham, S.; Roy, A.; Ekkad, S.V.; Ng, W.; Lohaus, A.S.; Crawford, M.E. Effect of Endwall Contouring on a Transonic Turbine Blade Passage: Heat Transfer Performance. J. Turbomach. 2017, 139, 011009. [Google Scholar]

- Li, J.; Yan, X.; He, K. Effect of Non-Axisymmetric Endwall Profiling on Heat Transfer and Film Cooling Effectiveness of a Transonic Rotor Blade. J. Turbomach. 2020, 142, 051006. [Google Scholar]

- Chen, P.; Wang, L.; Li, X.; Ren, J.; Jiang, H. Effect of axial turbine non-axisymmetric endwall contouring on film cooling at different locations. Int. J. Heat Mass Transf. 2020, 147, 118995. [Google Scholar]

- Tao, Z.; Yu, B.; Li, Y.; Song, L.; Li, J. Effects of non-axisymmetric endwall contouring on aerothermal performance of a gas turbine blade endwall with a purge flow. Int. J. Therm. Sci. 2021, 164, 106921. [Google Scholar]

- Faqih, M.; Omar, M.B.; Ibrahim, R.; Omar, B.A.A. Dry-Low Emission Gas Turbine Technology: Recent Trends and Challenges. Appl. Sci. 2022, 12, 10922. [Google Scholar]

- Yao, Y.J.; Tao, Z.; Wang, J.; Song, L.M.; Li, J. The effects of swirling purge leakage on aerothermal performance of flat and non-axisymmetric endwalls. Int. Commun. Heat Mass Transf. 2023, 142, 106669. [Google Scholar]

- Du, K.; Jia, Y.H.; Song, H.; Chen, L.; Zhang, Q.; Cui, T.T.; Liu, C.L. Effect of Slot Jet Flow on Non-Axisymmetric Endwall Cooling Performance of High-Load Turbines. Machines 2023, 11, 134. [Google Scholar]

- Friedrichs, S.; Hodson, H.P.; Dawes, W.N. Distribution of film-cooling effectiveness on a turbine endwall measured using the ammonia and diazo technique. J. Turbomach. 1996, 118, 613–621. [Google Scholar]

- Liu, J.; Xu, M.; Xi, W.; Song, J.; Luo, S.; Sunden, B.A. Numerical investigations of endwall film cooling design of a turbine vane using four-holes pattern. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 2177–2197. [Google Scholar]

- Thole, K.A.; Radomsky, R.W.; Kang, M.B.; Kohli, A. Elevated freestream turbulence effects on heat transfer for a gas turbine vane. Int. J. Heat Fluid Flow 2002, 23, 137–147. [Google Scholar]

- Radomsky, R.W.; Thole, K.A. Detailed boundary layer measurements on a turbine stator vane at elevated freestream turbulence levels. J. Turbomach. 2002, 124, 107–118. [Google Scholar]

- Ames, F.E.; Barbot, P.A.; Wang, C. Effects of aeroderivative combustor turbulence on endwall heat transfer distributions acquired in a linear vane cascade. J. Turbomach. 2003, 125, 210–220. [Google Scholar]

- Lee, S.W.; Jun, S.B.; Park, B.K.; Lee, J.S. Effects of combustor-level high inlet turbulence on the endwall flow and heat/mass transfer of a high-turning turbine rotor cascade. KSME Int. J. 2004, 18, 1435–1450. [Google Scholar]

- Choi, W.; Jung, K.J.; Park, J.S. Characteristics of heat transfer on a turbine blade endwall under various inlet flow conditions. Exp. Heat Transf. 2021, 34, 678–694. [Google Scholar]

- Yang, X.; Zhang, K.; Wu, J.M.; Lei, J.; Su, P.F.; Fang, Y. Numerical analysis of vane endwall film cooling and heat transfer with different mainstream turbulence intensities and blowing ratios. Int. J. Therm. Sci. 2022, 175, 107482. [Google Scholar]

- Li, X.Y.; Ren, J.; Jiang, H.D. Experimental Investigation of Endwall Heat Transfer with Film and Impingement Cooling. J. Eng. Gas Turbines Power 2017, 139, 101901. [Google Scholar]

- Salinas, D.A.; Ullah, I.; Wright, L.M.; Han, J.-C.; McClintic, J.W.; Crites, D.C.; Riahi, A. Upstream Film Cooling on the Contoured Endwall of a Transonic Turbine Vane in an Annular Cascade. J. Turbomach. 2021, 143, 061012. [Google Scholar]

- Gustafson, R.; Mahmood, G.I.; Acharya, S. Flowfield in a film-cooled three-dimensional contoured endwall passage: Aerodynamic measurements. In Proceedings of the ASME Turbo Expo 2007, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- He, K.; Li, J.; Yan, X. Numerical investigations into heat transfer and film cooling effect on a transonic blade endwall. Appl. Therm. Eng. 2018, 129, 934–952. [Google Scholar]

- Yang, X.; Liu, Z.; Liu, Z.S.; Simon, T.; Feng, Z.P. Endwall Film Cooling Performance for a First-Stage Guide Vane with Upstream Combustor Walls and Inlet Injection. J. Therm. Sci. Eng. Appl. 2019, 11, 011008. [Google Scholar]

- Zhang, W.X.; Li, F.; Xie, Y.H.; Ding, Y.Q.; Liu, Z.; Feng, Z.P. Experimental and numerical investigations of discrete film holes cooling performance on a blade endwall with mid-passage gap leakage. Int. J. Heat Mass Transf. 2023, 201, 123550. [Google Scholar]

- Zhang, Y.; Yuan, X. Turbine endwall film cooling with combustor-turbine interface gap leakage flow: Effect of incidence angle. J. Therm. Sci. 2013, 22, 135–144. [Google Scholar]

- Johnson, B.; Tian, W.; Zhang, K.; Hu, H. An experimental study of density ratio effects on the film cooling injection from discrete holes by using PIV and PSP techniques. Int. J. Heat Mass Transf. 2014, 76, 337–349. [Google Scholar]

- Li, X.; Ren, J.; Jiang, H. Influence of different film cooling arrangements on endwall cooling. Int. J. Heat Mass Transf. 2016, 102, 348–359. [Google Scholar]

- Liu, X.; Zhou, X.; Wang, S.; Feng, G. Impact of Different Cooling Air Injection Angle at Endwall on the Aerodynamic Performance of Heavy Duty Gas Turbine Cascade. In Proceedings of the International Conference on Software Engineering and Multimedia Communication (SEMC 2011), Qingdao, China, 9–10 July 2011. [Google Scholar]

- Zhang, L.; Yin, J.; Moon, H.K. The Effects of Vane Showerhead Injection Angle and Film Compound Angle on Nozzle Endwall Cooling (Phantom Cooling). J. Turbomach. 2015, 137, 021003. [Google Scholar]

- Zhang, H.; Wang, Q.; Chen, Z.; Su, X.; Yuan, X. Effects of compound angle on film cooling effectiveness considering endwall lateral pressure gradient. Aerosp. Sci. Technol. 2020, 103, 105923. [Google Scholar]

- Zhang, H.; Gou, J.L.; Yin, P.; Su, X.R.; Yuan, X. Film-cooling hole optimization and experimental validation considering the lateral pressure gradient. Front. Mech. Eng. 2023, 8, 973293. [Google Scholar]

- Friedrichs, S.; Hodson, H.P.; Dawes, W.N. Aerodynamic Aspects of Endwall Film-Cooling. J. Turbomach. 1997, 119, 786–793. [Google Scholar]

- Ornano, F.; Povey, T. Experimental and Computational Study of the Effect of Momentum-Flux Ratio on High-Pressure Nozzle Guide Vane Endwall Cooling Systems. J. Turbomach. 2017, 139, 121002. [Google Scholar]

- Alqefl, M.H.; Nawathe, K.P.; Chen, P.; Zhu, R.; Kim, Y.W.; Simon, T.W. Aero-Thermal Aspects of Film Cooled Nozzle Guide Vane Endwall Part 1: Aerodynamics. J. Turbomach. 2021, 143, 121009. [Google Scholar]

- Hermanson, K.S.; Thole, K.A. Effect of Mach number on secondary flow characteristics. Int. J. Turbo Jet-Engines 2000, 17, 179–196. [Google Scholar]

- Giel, P.W.; Thurman, D.R.; Van Fossen, G.J.; Hippensteele, S.A.; Boyle, R.J. Endwall Heat Transfer Measurements in a Transonic Turbine Cascade. J. Turbomach. 1998, 120, 305–313. [Google Scholar]

- Sveningsson, A.; Davidson, L. Computations of flow field and heat transfer in a stator vane passage using the (v)over-bar(2)-f turbulence model. J. Turbomach. 2005, 127, 627–634. [Google Scholar]

- Mahi, M.Y.; Chukwuemeka, E.; Donovan, S.; Ames, F.; Kanani, Y.; Acharya, S. The Influence of Turbulence and Reynolds Number on Endwall Heat Transfer in a Vane Cascade. J. Turbomach. 2023, 145, 071012. [Google Scholar]

- Yang, X.; Zhang, K.; Yao, J.X.; Wu, J.M.; Lei, J.; Su, P.E.; Fang, Y. Experimental and numerical investigations of vane endwall film cooling with different density ratios. Int. Commun. Heat Mass Transf. 2023, 144, 106778. [Google Scholar]

- Denton, J.D. The 1993 IGTI Scholar Lecture: Loss Mechanisms in Turbomachines. J. Turbomach. 1993, 115, 621–656. [Google Scholar]

- Blair, M.F. An Experimental Study of Heat Transfer and Film Cooling on Large-Scale Turbine Endwalls. J. Heat Transf. 1974, 96, 524–529. [Google Scholar]

- Giovanna, B.; Giuseppe, F.; Antonio, P.; Marco, Q. Endwall Film Cooling Effects on Secondary Flows in a Contoured Endwall Nozzle Vane. J. Turbomach. 2010, 132, 041005. [Google Scholar]

- Kang, M.B.; Thole, K.A. Flowfield measurements in the endwall region of a stator vane. J. Turbomach. 2000, 122, 458–466. [Google Scholar]

- Yang, X.; Zhao, Q.; Feng, Z. Turbine Vane Endwall Film Cooling Considering Flow Nonuniformities And Coolant Injection From Upstream Combustors. Heat Transf. Res. 2021, 52, 11–31. [Google Scholar]

- Cheng, F.; Zhang, J.; Tian, X.; Zhang, J.; Zhang, Y. Turbine vane endwall partition film cooling based on the passage vortex core line. Int. J. Heat Mass Transf. 2020, 162, 120354. [Google Scholar]

- Wang, Q.S.; Su, X.R.; Xin, Y. Large-Eddy Simulation of Shaped Hole Film Cooling with the Influence of Cross Flow. Int. J. Turbo Jet-Engines 2022, 39, 575–588. [Google Scholar]

- Lin, X.C.; Liu, J.J.; An, B.T. Calculation of film-cooling effectiveness and aerodynamic losses using DES/SAS and RANS methods and compared with experimental results. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13 June 2016. [Google Scholar]

- Nicklas, M. Film-cooled turbine endwall in a transonic flow field: Part II—Heat transfer and film-cooling effectiveness. J. Turbomach. 2001, 123, 720–729. [Google Scholar]

- Ostrowski, T.; Schiffer, H.P. High-resolution heat transfer measurements on a rotating turbine endwall with infrared thermography. Meas. Sci. Technol. 2021, 32, 125207. [Google Scholar]

- Li, X.; Li, M.; Ren, J.; Jiang, H. Heat Transfer Measurements of Vane Endwall with Film Cooling and Impingement Cooling. In Proceedings of the ASME Turbo Expo: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Chowdhury, N.H.K.; Shiau, C.C.; Han, J.C.; Xu, H.; Fox, M. Film Cooling Effectiveness Comparison on Turbine Vane Endwall with Cluster Configurations Using PSP Measurement Technique. In Proceedings of the International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Shiau, C.C.; Sahin, I.; Ullah, I.; Han, J.C.; Mirzamoghadam, A.V.; Riahi, A.; Stimpson, C. Transonic Turbine Vane Endwall Film Cooling Using the Pressure-Sensitive Paint Measurement Technique. J. Turbomach. 2020, 142, 081004. [Google Scholar]

- Qenawy, M.; Liu, Y.; Zhou, W. On the unsteady behaviours of the adiabatic endwall film cooling effectiveness. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1172, 012031. [Google Scholar]

- Kunze, M.; Vogeler, K.; Brown, G.; Prakash, C.; Landis, K. Aerodynamic and Endwall Film-Cooling Investigations of a Gas Turbine Nozzle Guide Vane Applying Temperature-Sensitive Paint. J. Turbomach. 2011, 133, 031027. [Google Scholar]

- Satta, F.; Tanda, G. Measurement of local heat transfer coefficient on the endwall of a turbine blade cascade by liquid crystal thermography. Exp. Therm. Fluid Sci. 2014, 58, 209–215. [Google Scholar]

- Chowdhury, T.S.; Mohsin, F.T.; Tonni, M.M.; Mita, M.N.H.; Ehsan, M.M. A Critical Review on Gas Turbine Cooling Performance and Failure Analysis of Turbine Blades. Int. J. Therm. 2023, 18, 100329. [Google Scholar]

- Unnikrishnan, U.; Yang, V.J.P. A review of cooling technologies for high temperature rotating components in gas turbine. Propuls. Power Res. 2022, 11, 293–310. [Google Scholar]

| Ref. | Numerical Method | Measurement Method | Related Parameter | |

|---|---|---|---|---|

| [69] | Turbulence intensity | / | Laser Doppler velocimeter | Re = 400,000~600,000 |

| [70] | / | Re = 115,000~230,000 | ||

| [71] | / | Steady-state liquid crystal technique | Re = 500,000~2,000,000; T = 37 °C | |

| [72] | / | Naphthalene sublimation technique | Re = 278,000; T = 26 °C | |

| [73] | SST | Hot-wire anemometer | Re = 100,000; T = 25 °C | |

| [74] | k-ε, SST | PSP | Blowing ratio (M) = 0.5~2.0; turbulence intensities (Tu) = 5~25% | |

| [75] | Mass flow ratio | / | PSP, TSP | Mass flow ratios (MFRs) = 0.5~0.8%; T = 313~350 K, density ratio (DR) = 1.1 |

| [76] | / | PSP | MFR = 0.75~1.25%; DR = 1.0~2.0; Ma = 0.7~0.9 | |

| [22] | Blow ratio | k-ε, SST | / | M = 0.6~1.4; T = 328 K; Tu = 3.47% |

| [29] | / | PSP | M = 0.2~1.3; V = 24.3 m/s; T = 276.5 K, 298 K, 308 K | |

| [77] | / | PSP | M = 1.0~2.0 | |

| [78] | RANS, k-ω, SST | / | M = 0.3~0.5; P = 35.6 kPa; T = 350 K | |

| [79] | RANS, k-ω, SST | / | M = 1.3~2.8; P = 179 kPa; T = 295 K; DR = 1.75; Re = 410,000 | |

| [80] | / | PSP | M = 0.5~3; Ma = 0.12 | |

| [81] | / | PSP | M = 0.7~1.3; T = 298~308 K; V = 35 m/s | |

| [12] | Density ratio | RANS | / | DR = 1.2~2.5; Re = 1.7 × 106; Ma = 0.85; M = 2.5 |

| [76] | / | PSP | DR = 1.0~2.0; MFR = 0.75~1.25%; Ma = 0.7~0.9 | |

| [82] | / | PSP, PIV | DR = 0.97~1.53; Re = 2.2 × 105; V = 30 m/s; T = 23~32.6 °C; M = 0.5 | |

| [83] | / | PSP | DR = 1.0~1.51; MFR = 0.5~1.5%; V = 23 m/s; Ma = 0.065; Re = 1.78 × 105 | |

| [32] | Injection Angle | / | PSP | Injection angles = 30~50°; Ma = 0.5; Re = 380,000; DR = 1.5; MFR = 1.0% |

| [84] | Spalart–Allmaras | / | Injection angles = 15°–50°; MFR = 1.3%; | |

| [85] | / | PSP | Injection angles = 30°; Showerhead angles = 30~45°; MFR = 1.5~4% | |

| [86] | Side pressure gradient | LES, k-ω, SST | PSP | M = 1~3; Compound angles = −30~40° |

| [87] | / | PSP | M = 2; Tu = 5% | |

| [88] | Secondary flow | / | PSP | M = 0.8~2.4; Re = 8.6 × 105 |

| [89] | / | Infrared camera system | Re = 6.6 × 105; DR = 1.1; M = 0.05~0.15; MFR = 1.1~13.4% | |

| [90] | / | Thermochromic liquid crystal | Tu = 11%; Re = 3.93 × 105; M = 1.95; MFR = 2%; Ma = 0.19 | |

| [91] | Mach number | RANS, k-ω | / | Ma = 0.012~0.9; Re = 1.2 × 106 |

| [92] | / | Steady-state liquid crystal technique | Ma = 1.0~1.3; Re = 1.0 × 106; Injection angles = 41.54~63.6° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Liu, P.; Zhang, X.; Xi, W.; Liu, J. Recent Developments in the Aerodynamic Heat Transfer and Cooling Technology of Gas Turbines Endwalls. Aerospace 2023, 10, 702. https://doi.org/10.3390/aerospace10080702

Zhang R, Liu P, Zhang X, Xi W, Liu J. Recent Developments in the Aerodynamic Heat Transfer and Cooling Technology of Gas Turbines Endwalls. Aerospace. 2023; 10(8):702. https://doi.org/10.3390/aerospace10080702

Chicago/Turabian StyleZhang, Rongdi, Pengchao Liu, Xirui Zhang, Wenxiong Xi, and Jian Liu. 2023. "Recent Developments in the Aerodynamic Heat Transfer and Cooling Technology of Gas Turbines Endwalls" Aerospace 10, no. 8: 702. https://doi.org/10.3390/aerospace10080702

APA StyleZhang, R., Liu, P., Zhang, X., Xi, W., & Liu, J. (2023). Recent Developments in the Aerodynamic Heat Transfer and Cooling Technology of Gas Turbines Endwalls. Aerospace, 10(8), 702. https://doi.org/10.3390/aerospace10080702