Physics-Guided Neural Network Model for Aeroengine Control System Sensor Fault Diagnosis under Dynamic Conditions

Abstract

1. Introduction

- (1)

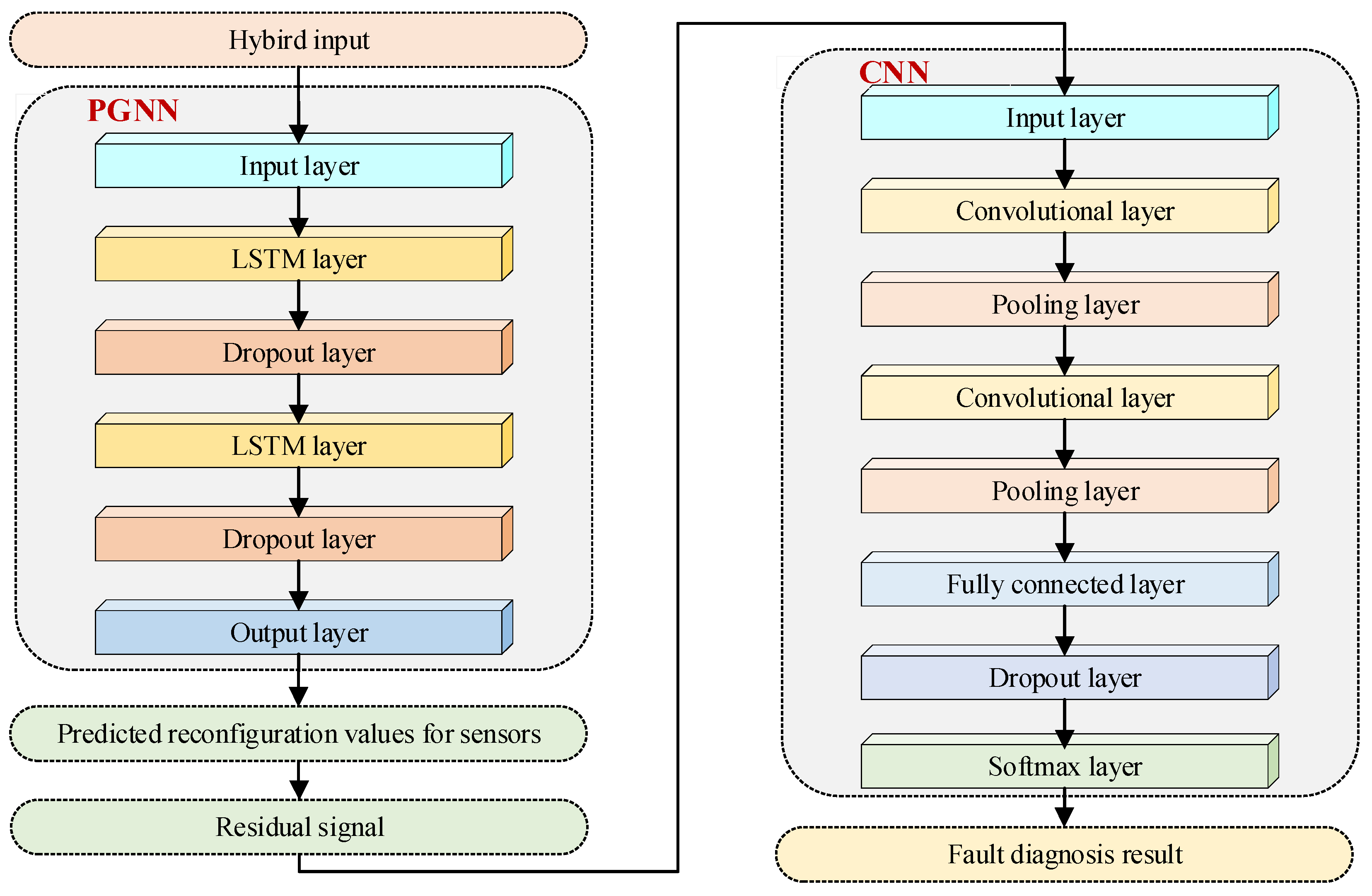

- A PGNN–CNN-based intelligent diagnosis method is provided to solve the fault diagnosis problem of aeroengine control system sensors under dynamic conditions. Firstly, a PGN generates sensor predictions, which are synthesized with the sensor measurements to generate residuals, and then a powerful classification model, the CNN, is used to provide diagnostic results. Through the structure of the prediction–residual–fault classification, the effect of changing the engine flight conditions on the measured engine output is attenuated through residual generation.

- (2)

- A sensor prediction strategy based on a hybrid physics–data model is proposed. By merging the physics-based model and data-driven model for the prediction, data mining and physics principles are effectively combined. The PGNN model fully explores the implicit relationship between the input and output and improves the prediction accuracy.

- (3)

- A new loss function, the physics-guided loss function, is suggested. The physically guided loss function considers physical knowledge by mapping monitoring data and time to a potential variable associated with engine dynamics. Physical inconsistencies in parameters and prediction results are eliminated, thus improving the performance of the PGNN.

2. Physically Guided Neural Network Model

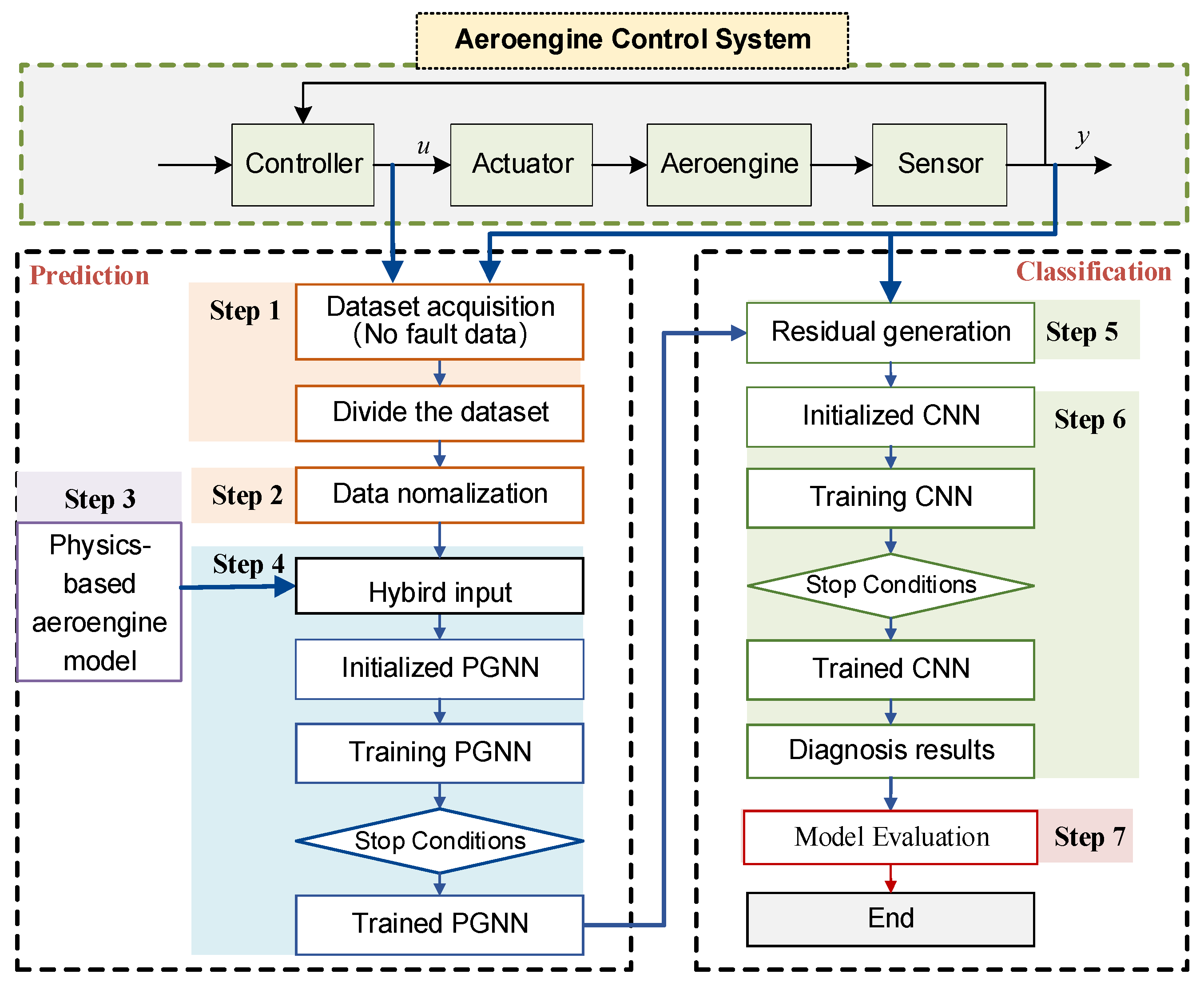

3. The Proposed Method

- (1)

- Data acquisition: The sensor data of the aeroengine control system under dynamic conditions are collected. Then, the data are labeled and the labeled dataset is segmented and grouped into two categories: a training set and a test set.

- (2)

- Data standardization: The signal is normalized and rescaled to the range [0, 1].

- (3)

- Physics-based aeroengine model: Physics-based aeroengine models are built to obtain physics-guided prediction outputs.

- (4)

- PGNN-based prediction: The engine input data and the prediction output of the physics-based aeroengine model engine are sent to the PGNN to obtain the predicted output of the engine.

- (5)

- Residual generation: The actual sensor output of the engine control system is subtracted from the predicted outcome of the PGNN to obtain the residual.

- (6)

- CNN-based fault classification: The residual vector is fed to the CNN-based model to automatically obtain the final diagnosis result.

- (7)

- Model evaluation: The trained model is evaluated to obtain a PGNN–CNN model with a satisfactory performance.

3.1. Data Standardization

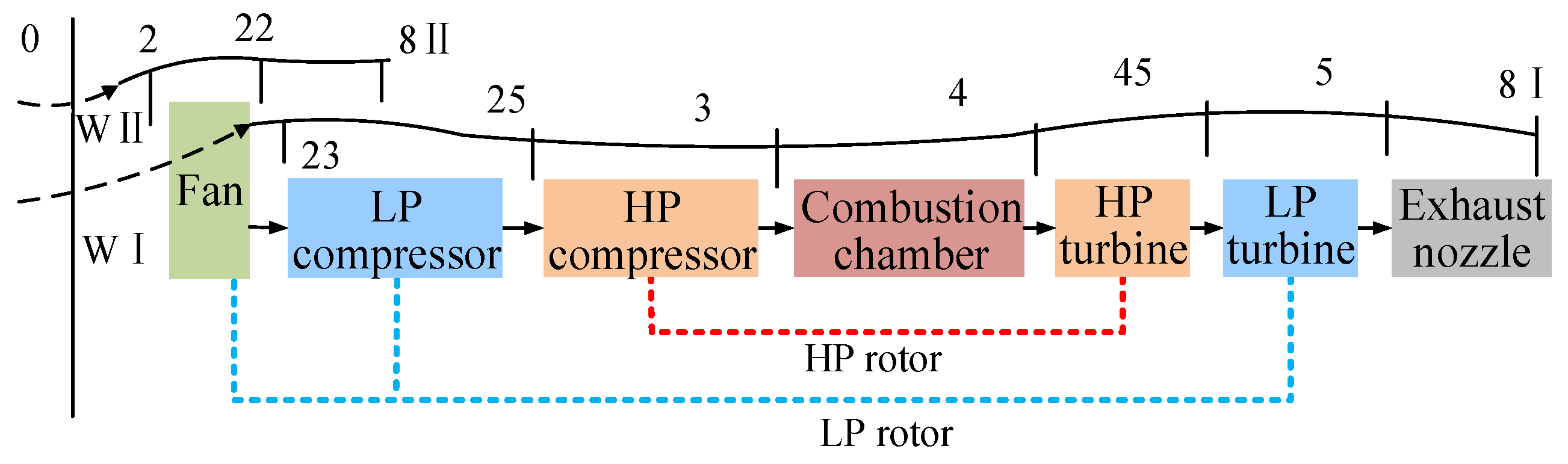

3.2. Physics-Based Aeroengine Model

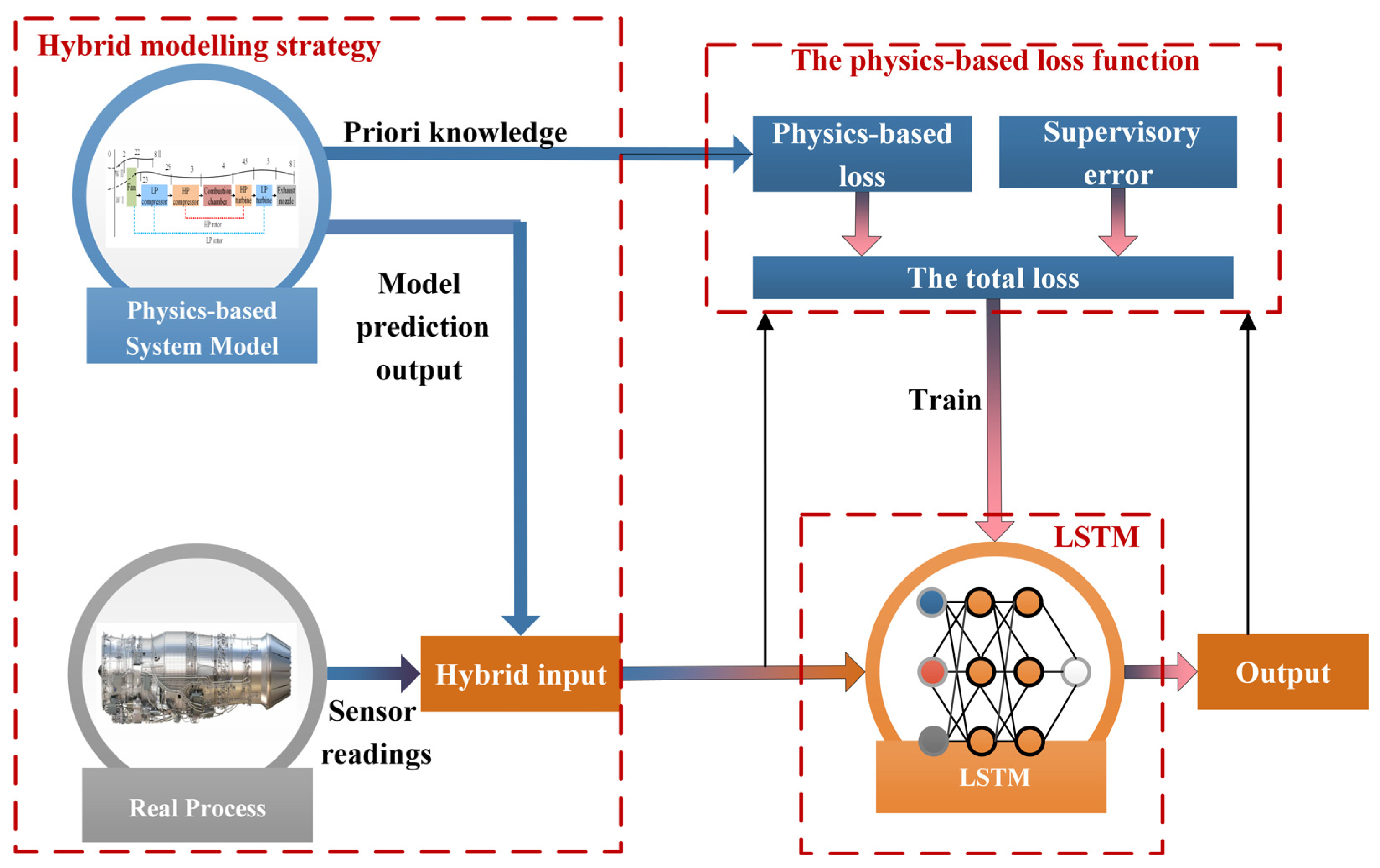

3.3. PGNN-Based Prediction

3.3.1. Hybrid Input

3.3.2. LSTM Model

3.3.3. The Physics-Based Loss Function

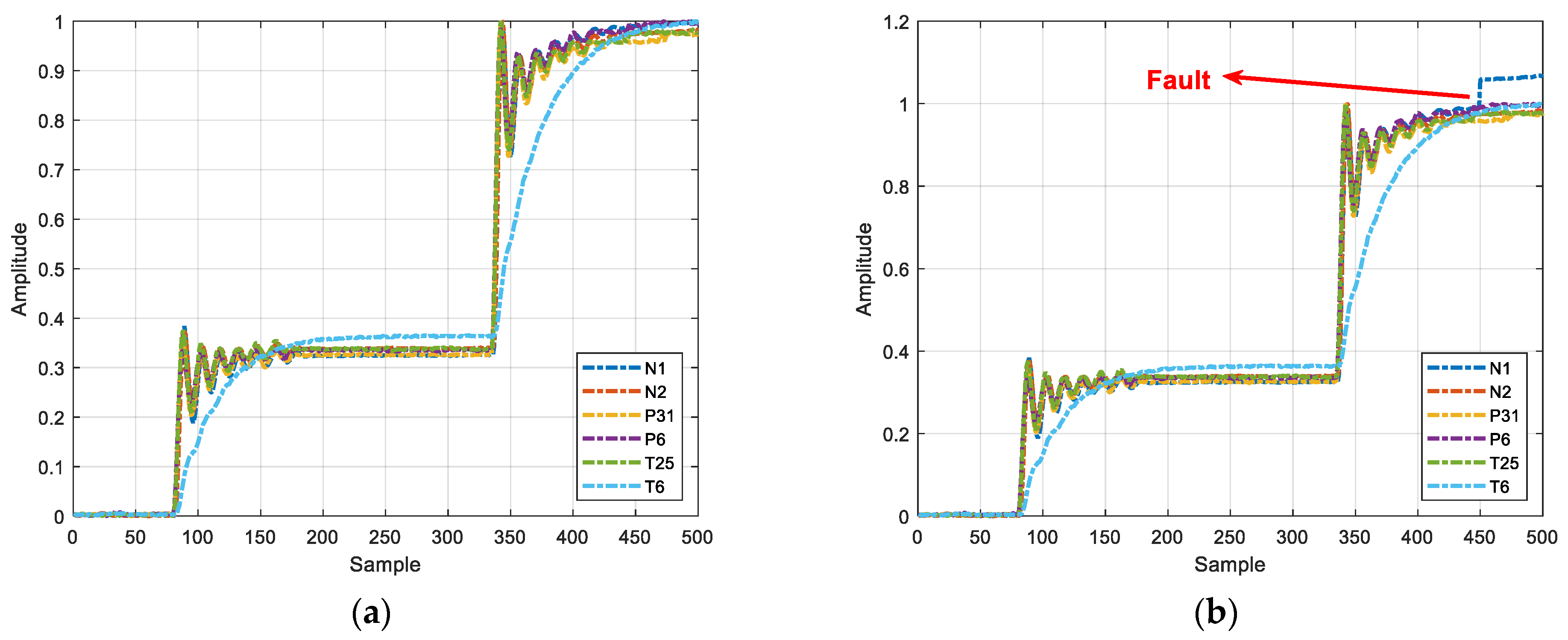

3.4. Residual Generation

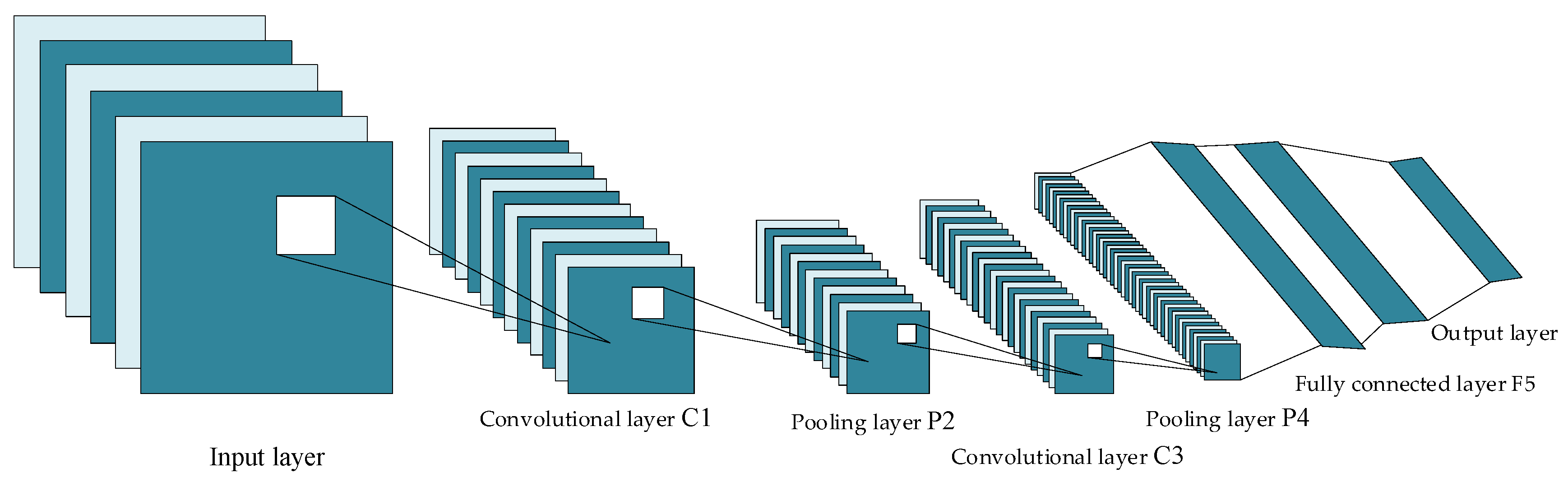

3.5. CNN-Based Fault Classification

3.6. Model Evaluation

4. Experimental Results

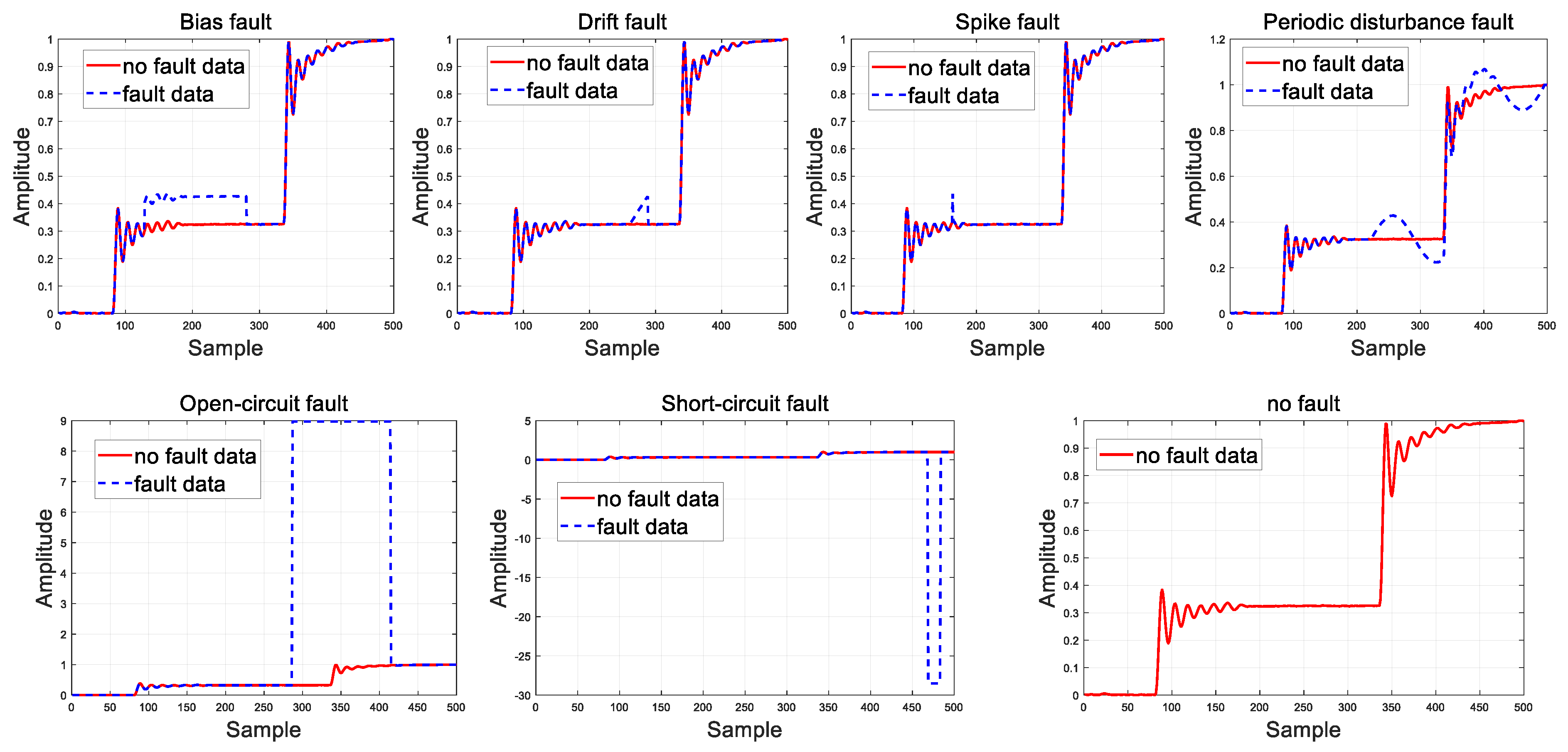

4.1. Experimental Data Collection

4.2. Experimental Parameter Setting

4.3. Experimental Results and Discussion

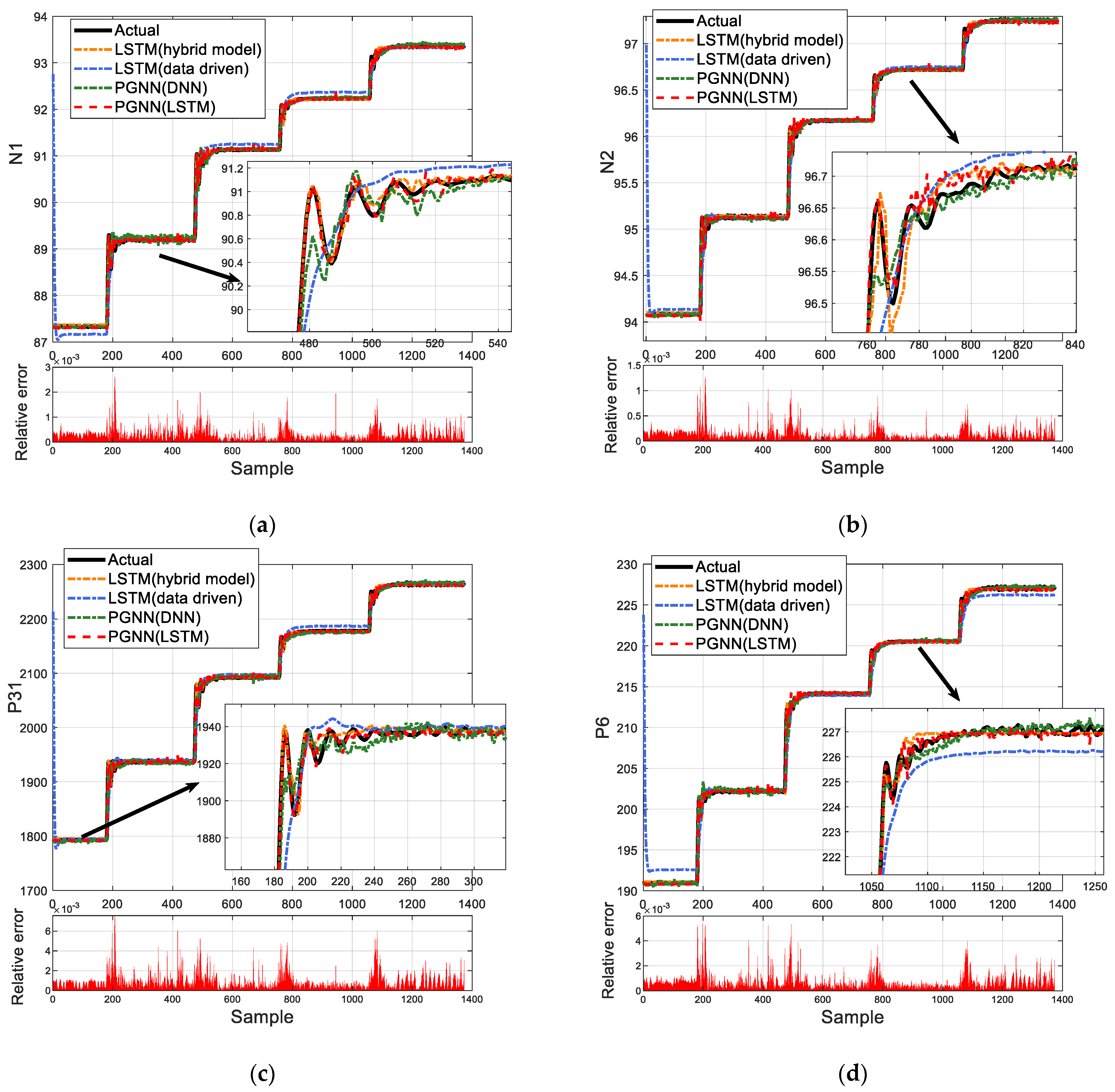

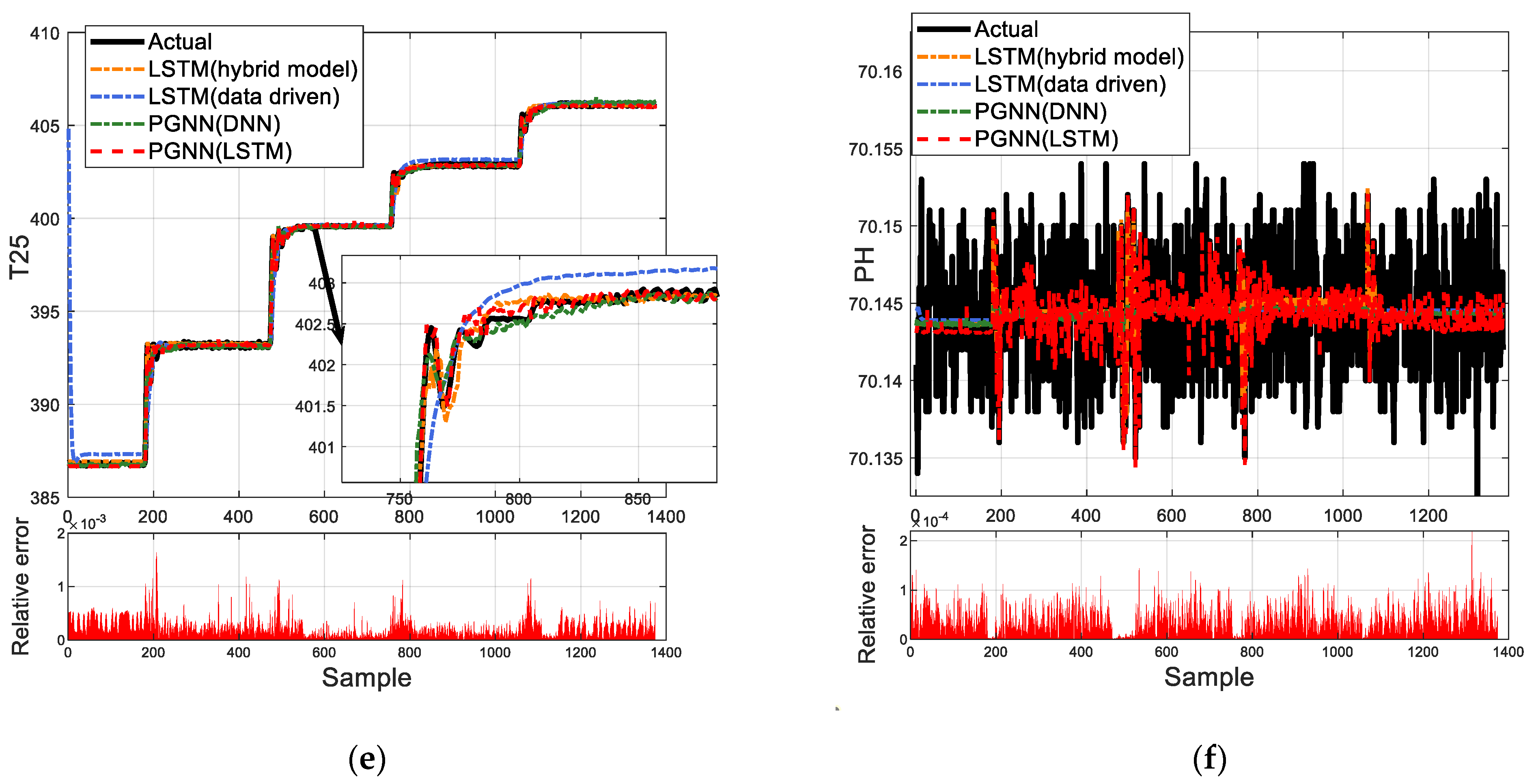

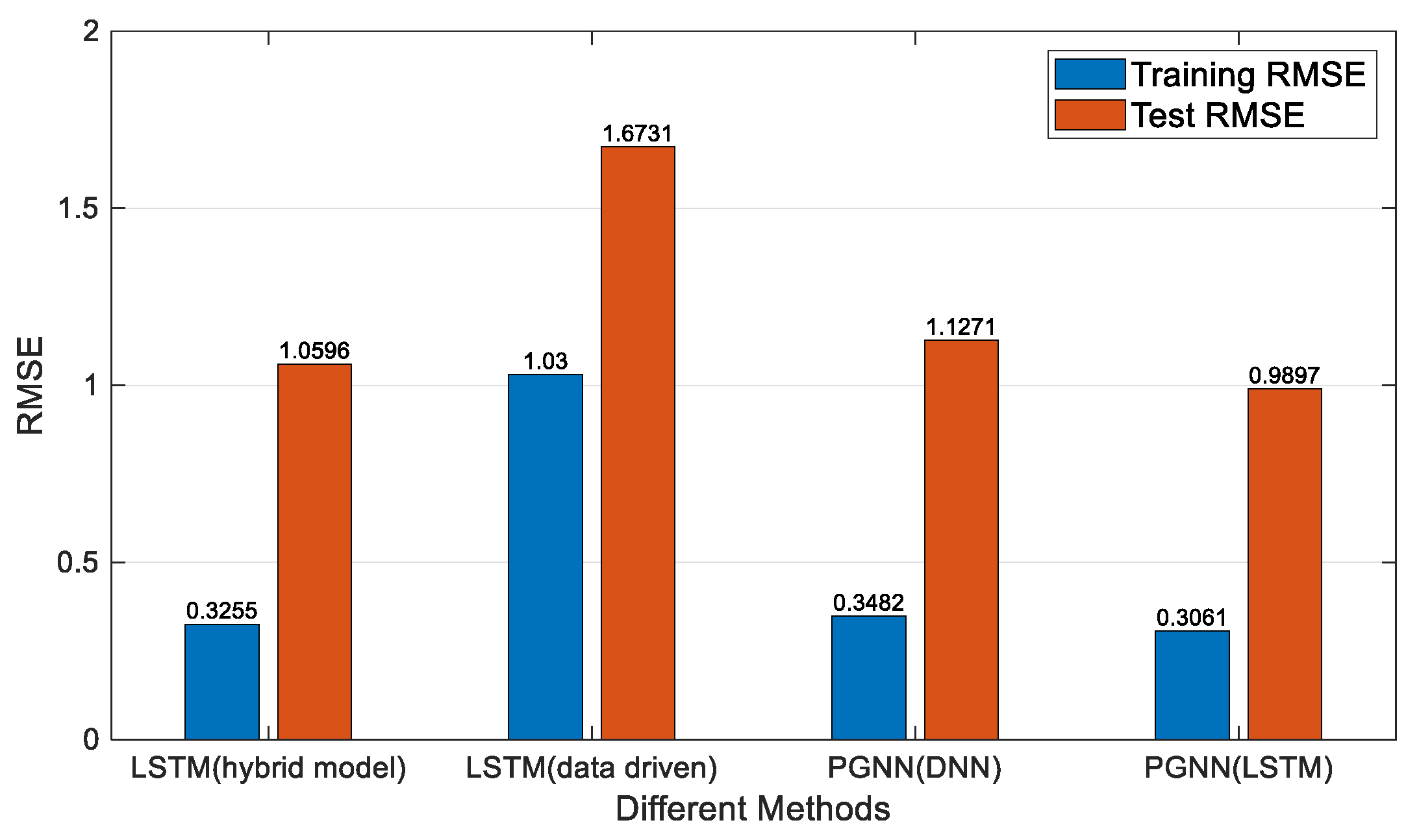

4.3.1. Prediction Results of the PGNN and Discussion

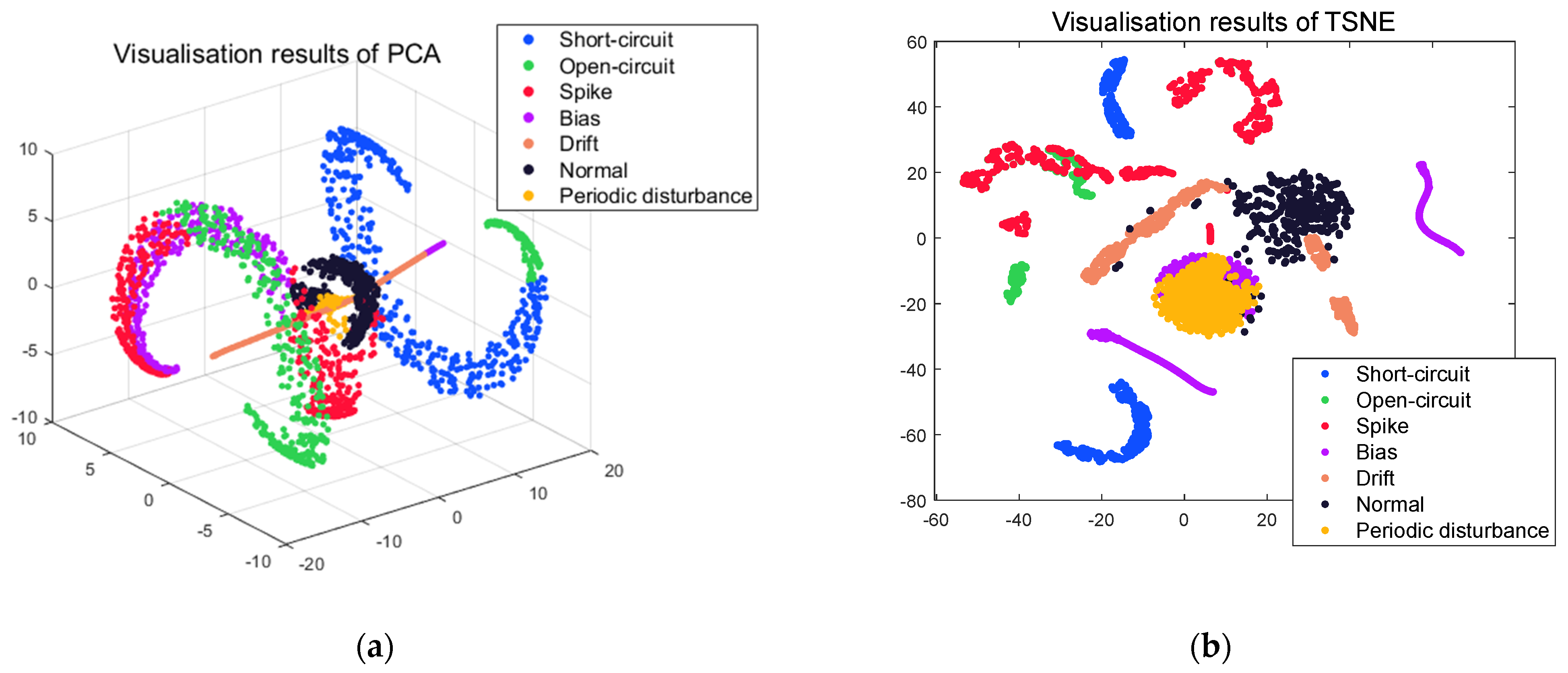

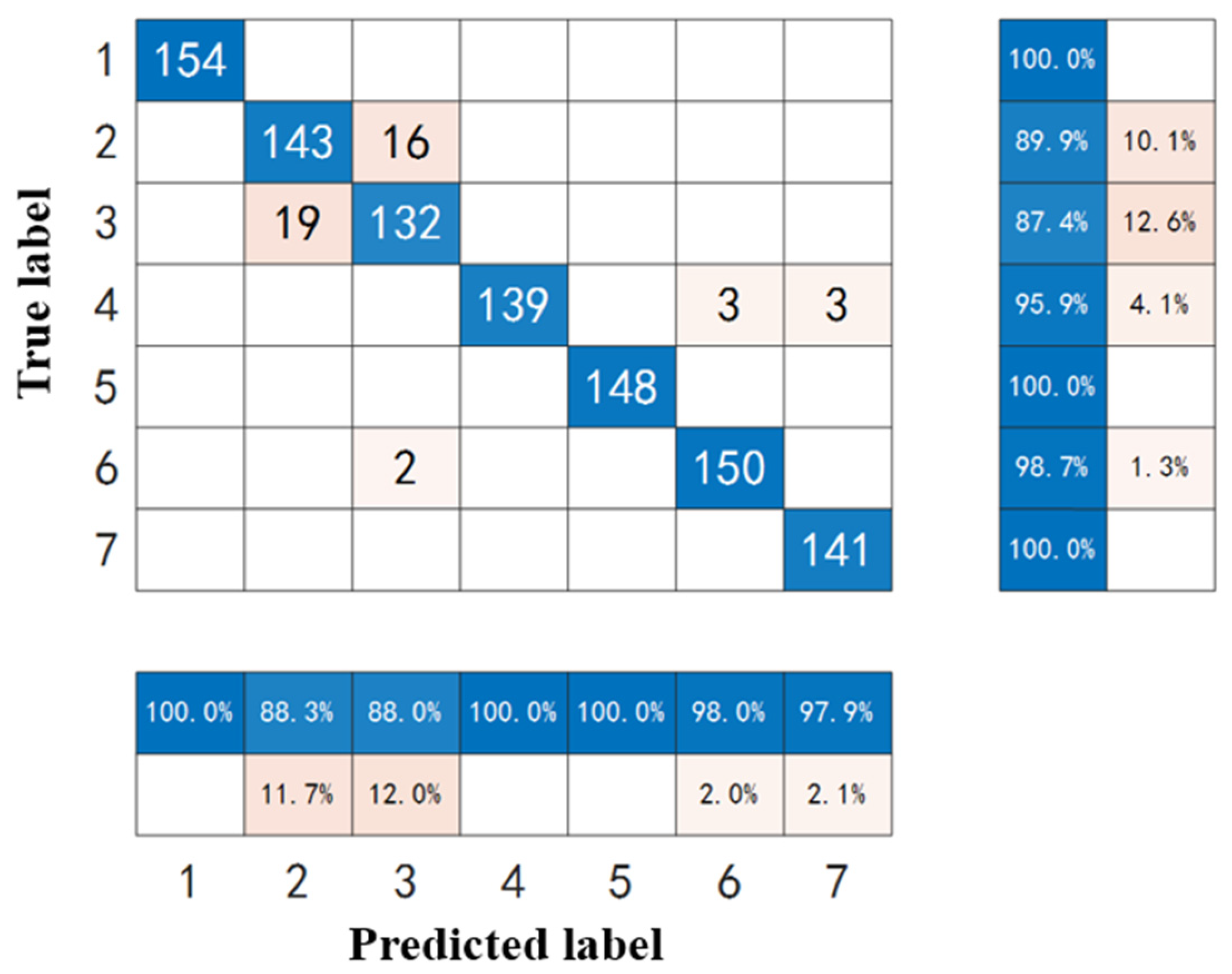

4.3.2. CNN Classification Results and Discussion

4.3.3. Comparison with Other Methods

5. Conclusions

- (1)

- A hybrid physics-data-based input strategy was proposed. After establishing a linear model of the engine based on physical principles, a hybrid information source, consisting of data and a priori knowledge, was formed by combining the physics-based model with historical engine data to fully exploit the implicit relationship between the input and output, improving the accuracy of the prediction.

- (2)

- The customized loss function included not only supervised losses, but also loss functions based on physical information. The physical-information-based loss function took into account known forms of physical relationships between the input and output of the engine. This loss function incorporated the physical knowledge into the PGNN model’s training process to eliminate physical inconsistencies in the parameters and prediction results, thus improving the performance of the PGNN.

- (3)

- An intelligent diagnosis method based on the PGNN–CNN was provided to solve the fault diagnosis problem of engine control systems under dynamic conditions. With a prediction–residual–fault classification structure, the effect of changing the engine flight conditions on the measured engine output was attenuated through residual generation. The proposed PGNN–CNN model was successful in diagnosing engine sensor faults.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yao, H. Aero-Engine Full Authority Digital Electronic Control System; Aviation Industry Press: Beijing, China, 2014. [Google Scholar]

- Liu, Z.; Huang, Y.; Gou, L.; Fan, D. A robust adaptive linear parameter-varying gain-scheduling controller for aeroengines. Aerosp. Sci. Technol. 2023, 138, 108319. [Google Scholar] [CrossRef]

- Lv, C.; Chang, J.; Bao, W.; Yu, D. Recent research progress on airbreathing aero-engine control algorithm. Propuls. Power Res. 2022, 11, 1–57. [Google Scholar] [CrossRef]

- Cao, M.; Huang, J.Q.; Zhou, J.; Chen, X.; Lu, F.; Wei, F. Current status, challenges and opportunities of fault diagnosis and health management for civil aviation engines: Fault diagnosis and prediction of gas path, machinery and FADEC systems. Acta Aeronaut. 2022, 43, 9–41. [Google Scholar]

- Yu, H.; Zhu, J.T.; Sun, Z.S.; Gao, L.J. Sensor fault diagnosis of gas turbine engines using an integrated scheme based on improved least squares support vector regression. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 234, 607–623. [Google Scholar]

- Pourbabaee, B.; Meskin, N.; Khorasani, K. Sensor Fault Detection, Isolation, and Identification Using Multiple-Model-Based Hybrid Kalman Filter for Gas Turbine Engines. IEEE Trans. Control Syst. Technol. 2016, 24, 1184–1200. [Google Scholar] [CrossRef]

- Zhang, M. Data-Driven Aero-Engine Control System Sensor Fault Diagnosis Based on Data; Northwestern Polytechnic University: Fremont, CA, USA, 2023. [Google Scholar]

- Kobayashi, T.; Simon, D.L. Evaluation of an enhanced bank of Kalman filters for in-flight aircraft engine sensor fault diagnostics. J. Eng. Gas Turbines Power-Trans. ASME 2005, 127, 497–504. [Google Scholar] [CrossRef]

- Sun, R.Q.; Han, X.B.; Chen, Y.X.; Gou, L.F. Hyperelliptic Kalman filter-based aeroengine sensor fault FDIA system under multi-source uncertainty. Aerosp. Sci. Technol. 2023, 132, 08058. [Google Scholar] [CrossRef]

- Chen, J.; Patton, R.J.; Zhang, H.Y. Design of unknown input observers and robust fault detection filters. Int. J. Control 1996, 63, 85–105. [Google Scholar] [CrossRef]

- Gou, L.; Shen, Y.W.; Zheng, H.; Zeng, X.Y. Multi-Fault Diagnosis of an Aero-Engine Control System Using Joint Sliding Mode Observers. IEEE Access 2020, 8, 10186–10197. [Google Scholar] [CrossRef]

- Frank, P.M. Fault Diagnosis in Dynamic Systems using Analytical and Knowledge-Based Redundancy—A Survey and Some New Results. Automatica 1990, 26, 459–474. [Google Scholar] [CrossRef]

- Fu, W.J.; Sha, Y.D.; Yao, A.F. Research on aero-engine vibration fault diagnosis using wavelet analysis. J. Shenyang Inst. Aeronautcal Eng. 2008, 91, 11–14. [Google Scholar]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Shen, Y.; Li, L.L.; Wang, Z.H. A Review of Fault Diagnosis and Fault—Tolerant Control Techniques for Spacecraft. J. Astronaut. 2022, 41, 647–656. [Google Scholar]

- Huang, Y.; Tao, J.; Sun, G.; Wu, T.Y.; Yu, L.L.; Zhao, X.B. A novel digital twin approach based on deep multimodal information fusion for aero-engine fault diagnosis. Energy 2023, 270, 126894. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Wang, J.J.; Li, X.Y.; Peng, G.J.; Yang, Z. Extended least squares support vector machine with applications to fault diagnosis of aircraft engine. ISA Trans. 2020, 97, 189–201. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Baptista, M.L.; Prendinger, H. Aircraft Engine Bleed Valve Prognostics Using Multiclass Gated Recurrent Unit. Aerospace 2023, 10, 354. [Google Scholar] [CrossRef]

- Fink, O.; Wang, Q.; Svensén, M.; Dersin, P.; Lee, W.J.; Ducoffe, M. Potential, challenges and future directions for deep learning in prognostics and health management applications. Eng. Appl. Artif. Intell. 2020, 2020, 103678. [Google Scholar] [CrossRef]

- Zhang, Y.; Xin, Y.; Liu, Z.; Ma, G. Health status assessment and remaining useful life prediction of aero-engine based on BiGRU and MMoE. Reliab. Eng. Syst. Saf. 2022, 220, 108263. [Google Scholar] [CrossRef]

- Wen, X.; Xu, Z. Wind turbine fault diagnosis based on ReliefF-PCA and DNN. Expert Syst. Appl. 2021, 178, 115016. [Google Scholar] [CrossRef]

- Yan, B.; Qu, W. Aero-engine sensor fault diagnosis based on stacked denoising autoencoders. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016. [Google Scholar]

- Gou, L.F.; Li, H.H.; Li, H.C.; Pei, X.N. Aeroengine control system sensor fault diagnosis based on CWT and CNN. Math. Probl. Eng. 2020, 2020, 5357146. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, P.F. Failure diagnosis using deep belief learning based health state classification. Reliab. Eng. Syst. Saf. 2016, 17, 1287–1304. [Google Scholar] [CrossRef]

- Willard, J.; Jia, X.; Xu, S.; Steinbach, M.; Kumar, V. Integrating scientific knowledge with machine learning for engineering and environmental systems. arXiv 2022, arXiv:2003.04919. [Google Scholar] [CrossRef]

- Arrieta, A.B.; Díaz-Rodríguez, N.; Del Ser, J.; Bennetot, A.; Tabik, S.; Barbado, A.; Garcia, S.; GilLopez, S.; Molina, D.; Benjamins, R.; et al. Explainable Artificial Intelligence (XAI): Concepts, taxonomies, opportunities and challenges toward responsible AI. Inf. Fusion 2020, 58, 82–115. [Google Scholar] [CrossRef]

- Karniadakis, G.E.; Kevrekidis, I.G.; Lu, L.; Perdikaris, P.; Wang, S.; Yang, L. Physics-informed machine learning. Nat. Rev. Phys. 2021, 3, 422–440. [Google Scholar] [CrossRef]

- Von Rueden, L.; Mayer, S.; Beckh, K.; Georgiev, B.; Giesselbach, S.; Heese, R.; Kirsch, B.; Pfrommer, J.; Pick, A.; Ramamurthy, r.; et al. Informed Machine Learning–A taxonomy and survey of integrating prior knowledge into learning systems. IEEE Trans. Knowl. Data Eng. 2021, 35, 614–633. [Google Scholar] [CrossRef]

- Minh, D.; Wang, H.X.; Li, Y.F.; Nguyen, T.N. Explainable artificial intelligence: A comprehensive review. Artif. Intell. Rev. 2022, 55, 3503–3568. [Google Scholar] [CrossRef]

- Diligenti, M.; Roychowdhury, S.; Gori, M. Integrating prior knowledge into deep learning. In Proceedings of the 2017 16th IEEE International Conference on Machine Learning and Applications (ICMLA), Cancun, Mexico, 18–21 December 2017; pp. 920–923. [Google Scholar]

- Xu, J.; Zhang, Z.; Friedman, T.; Liang, Y.; Van den Broeck, G. A semantic loss function for deep learning with symbolic knowledge. arXiv 2018, arXiv:1711.11157. [Google Scholar]

- Karpatne, A.; Watkins, W.; Read, J.; Kumar, V. Physics-guided neural networks (PGNN): An application in lake temperature modeling. arXiv 2017, arXiv:1710.11431. [Google Scholar]

- Stewart, R.; Ermon, S. Label-free supervision of neural networks with physics and domain knowledge. In Proceedings of the Thirty-First AAAI Conference on Artificial Intelligence, San Francisco, CA, USA, 4–9 February 2017; pp. 2576–2582. [Google Scholar]

- Wang, J.; Li, Y.; Zhao, R.; Gao, R.X. Physics guided neural network for machining tool wear prediction. J. Manuf. Syst. 2020, 57, 298–310. [Google Scholar] [CrossRef]

- Zamzam, A.S.; Sidiropoulos, N.D. Physics-aware neural networks for distribution system state estimation. IEEE Trans. Power Syst. 2020, 35, 4347–4356. [Google Scholar] [CrossRef]

- Chao, M.A.; Kulkarni, C.; Goebel, K.; Fink, O. Fusing physics-based and deep learning models for prognostics. Reliab. Eng. Syst. Saf. 2022, 217, 107961. [Google Scholar] [CrossRef]

- Shen, S.; Lu, H.; Sadoughi, M.; Hu, C.; Nemani, V.; Thelen, A.; Webster, K.; Darr, M.; Sidon, J.; Kenny, S. A physics-informed deep learning approach for bearing fault detection. Eng. Appl. Artif. Intell. 2021, 103, 104295. [Google Scholar] [CrossRef]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Du, X.; Chen, J.; Zhang, H.; Wang, J. Fault detection of aero-engine sensor based on inception-CNN. Aerospace 2022, 9, 236. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, B.Y.; Zhang, D.Y. Research status and prospect of fault diagnosis for gas turbine aeroengine. Acta Aeronaut. Astronaut. Sin. 2022, 43, 626565. [Google Scholar]

- Huang, Y.; Sun, G.; Tao, J.; Hu, Y.; Yuan, L. A modified fusion model-based/data-driven model for sensor fault diagnosis and performance degradation estimation of aeroengine. Meas. Sci. Technol. 2022, 33, 085105. [Google Scholar] [CrossRef]

- Li, H.H.; Gou, L.F.; Chen, Y.X.; Li, H.C. Fault Diagnosis of Aeroengine Control System Sensor Based on Optimized and Fused Multidomain Feature. IEEE Access 2022, 10, 96967–96983. [Google Scholar] [CrossRef]

- Ding, S.; Yuan, Y.; Xue, N.; Liu, X. An onboard aeroengine model-tuning system. J. Aerosp. Eng. 2017, 34, 04017018. [Google Scholar] [CrossRef]

- Gao, W.; Pan, M.; Zhou, W.; Lu, F.; Huang, J.Q. Aero-Engine Modeling and Control Method with Model-Based Deep Reinforcement Learning. Aerospace 2023, 13, 209. [Google Scholar] [CrossRef]

- Jiang, Z.; Yang, S.; Wang, X.; Long, Y. An Onboard Adaptive Model for Aero-Engine Performance Fast Estimation. Aerospace 2022, 9, 845. [Google Scholar] [CrossRef]

- Gou, L.F.; Zeng, X.Y.; Wang, Z.; Han, G.; Lin, C.; Cheng, X. A linearization model of turbofan engine for intelligent analysis towards industrial internet of things. IEEE Access 2019, 7, 145313–145323. [Google Scholar] [CrossRef]

- Tan, M.; Yuan, S.; Li, S.; Su, Y.; Li, H.; He, F. Ultra-short-term industrial power demand forecasting using LSTM based hybrid ensemble learning. IEEE Trans. Power Syst. 2019, 35, 2937–2948. [Google Scholar] [CrossRef]

- Shen, K.; Zhao, D. An EMD-LSTM Deep Learning Method for Aircraft Hydraulic System Fault Diagnosis under Different Environmental Noises. Aerospace 2023, 11, 55. [Google Scholar] [CrossRef]

- Agarap, A.F. Deep learning using rectified linear units (relu). arXiv 2018, arXiv:1803.08375. [Google Scholar]

- Sutskever, I. Training Recurrent Neural Networks; University of Toronto: Toronto, ON, Canada, 2013. [Google Scholar]

- Li, D.; Wang, Y.; Wang, J.X.; Wang, C.; Duan, Y. Recent advances in sensor fault diagnosis: A review. Sens. Actuators A Phys. 2020, 309, 11199. [Google Scholar] [CrossRef]

- Jiao, J.; Zhao, M.; Lin, J.; Liang, K. A comprehensive review on convolutional neural network in machine fault diagnosis. Neurocomputing 2020, 417, 36–63. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, X.; Li, H.; Yang, Z. Intelligent fault diagnosis of rolling bearings based on normalized CNN considering data imbalance and variable working conditions. Knowl. Based Syst. 2020, 199, 105971. [Google Scholar] [CrossRef]

- Li, H.; Gou, L.; Zheng, H.; Li, H.C. Intelligent Fault Diagnosis of Aeroengine Sensors Using Improved Pattern Gradient Spectrum Entropy. Int. J. Aerosp. Eng. 2021, 2021, 1–20. [Google Scholar] [CrossRef]

- Yang, T.L.; Chen, J.J.; Zheng, Q.G. Real Time Verification of Hardware-in-the-Loop for Aeroengine Component Level Model. Aeroengine 2021, 47 (Suppl. 1), 76–84. [Google Scholar]

- Alpaydin, E. Neural Networks and Deep Learning. In Machine Learning: The New AI; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Van der Maaten, L.; Hinton, G. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- Verbanck, M.; Josse, J.; Husson, F. Regularised PCA to denoise and visualise data. Stat. Comput. 2015, 25, 471–486. [Google Scholar] [CrossRef]

| The Input of the PGNN | |

| Number | Name |

| 1 | LM |

| 2 | D8 |

| 3 | A1 |

| 4 | A2 |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| The output of the PGNN | |

| Number | Name |

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| The output of the CNN | |

| Number | Name |

| 1 | Residual |

| The output of the CNN | |

| Number | Name |

| 1 | Fault diagnosis results |

| Fault Type | Cause of Fault | Label |

|---|---|---|

| Short-circuit fault | Pollution caused by the bridge road corrosion line short connection | 1 |

| Open-circuit fault | Broken signal line or an unconnected chip pin | 2 |

| Bias fault | Bias current or bias voltage | 3 |

| Spike fault | Random interference, surge, spark discharge in power and ground, D/A converter burr in the converter, etc. | 4 |

| Drift fault | Temperature drift | 5 |

| Periodic disturbance fault | Power interference or voltage instability | 6 |

| Normal | ---- | 7 |

| Network Layer Type | Parameter Value |

|---|---|

| Input layer | 10 |

| LSTM1 hidden layer | 128 |

| Dropout1 layer | 20% |

| LSTM2 hidden layer | 64 |

| Dropout2 layer | 10% |

| Fully connected layer | 50 |

| Output layer | 6 |

| Maximum number of iterations | 400 |

| Parameter update method | Adam |

| Learning rate | 0.005 |

| Learning rate decline factor | 0.2 |

| Learning rate decrease period | 125 |

| Network Layer | Output |

|---|---|

| Input layer | 1 × 500 × 1 |

| Convolutional layer C1 | 6 filter (size = 5 × 5, slide = 1) |

| Pooling layer P1 | 16 filter (size = 2 × 2, slide = 1) |

| Convolutional layer C2 | 6 filter (size = 5 × 5, slide = 1) |

| Pooling layer P2 | 16 filter (size = 2 × 2, slide = 1) |

| Fully connected layer | 120 |

| Dropout | 0.5 |

| Softmax layer | 1 × 7 |

| Maximum number of iterations | 2000 |

| Learning rate | 0.001 |

| Method | LSTM (Hybrid Model) | LSTM (Data-Driven) | PGNN (DNN) | PGNN (LSTM) |

|---|---|---|---|---|

| Training time (s) | 385 | 381 | 28.15 | 427 |

| Test time (s) | 0.47 | 0.47 | 0.11 | 0.4926 |

| Fault Type | Precision | Recall | F1 Score | Accuracy | Specificity | |

|---|---|---|---|---|---|---|

| 1 | Short-circuit fault | 100% | 100% | 100% | 100% | 100% |

| 2 | Open-circuit fault | 88.3% | 89.9% | 89.1% | 96.7% | 97.9% |

| 3 | Bias fault | 88.0% | 87.4% | 87.7% | 96.5% | 98.0% |

| 4 | Spike fault | 100% | 95.9% | 97.9% | 99.4% | 100% |

| 5 | Drift fault | 100% | 100% | 100% | 100% | 100% |

| 6 | Periodic disturbance fault | 98.0% | 98.7% | 98.4% | 99.5% | 99.7% |

| 7 | Normal | 97.8% | 100% | 98.9% | 99.7% | 99.7% |

| Total accuracy | 95.9% | |||||

| Fault Type | LSTM (Data-Driven)–CNN | PGNN (LSTM)–CNN | PGNN (LSTM)–SVM |

|---|---|---|---|

| Test RMSE | 1.6731 | 0.9897 | 0.9897 |

| Test total accuracy | 77.62% | 95.90% | 85.33% |

| Test total precision | 77.53% | 96.03% | 88.59% |

| Test total recall | 77.40% | 95.99% | 85.44% |

| Test F1 score | 77.40% | 96.00% | 85.64% |

| Train time(s) | 741 | 787 | 431.5 |

| Test time(s) | 1.33 | 1.84 | 3.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Gou, L.; Li, H.; Liu, Z. Physics-Guided Neural Network Model for Aeroengine Control System Sensor Fault Diagnosis under Dynamic Conditions. Aerospace 2023, 10, 644. https://doi.org/10.3390/aerospace10070644

Li H, Gou L, Li H, Liu Z. Physics-Guided Neural Network Model for Aeroengine Control System Sensor Fault Diagnosis under Dynamic Conditions. Aerospace. 2023; 10(7):644. https://doi.org/10.3390/aerospace10070644

Chicago/Turabian StyleLi, Huihui, Linfeng Gou, Huacong Li, and Zhidan Liu. 2023. "Physics-Guided Neural Network Model for Aeroengine Control System Sensor Fault Diagnosis under Dynamic Conditions" Aerospace 10, no. 7: 644. https://doi.org/10.3390/aerospace10070644

APA StyleLi, H., Gou, L., Li, H., & Liu, Z. (2023). Physics-Guided Neural Network Model for Aeroengine Control System Sensor Fault Diagnosis under Dynamic Conditions. Aerospace, 10(7), 644. https://doi.org/10.3390/aerospace10070644