2.2.1. Undamaged Scenario

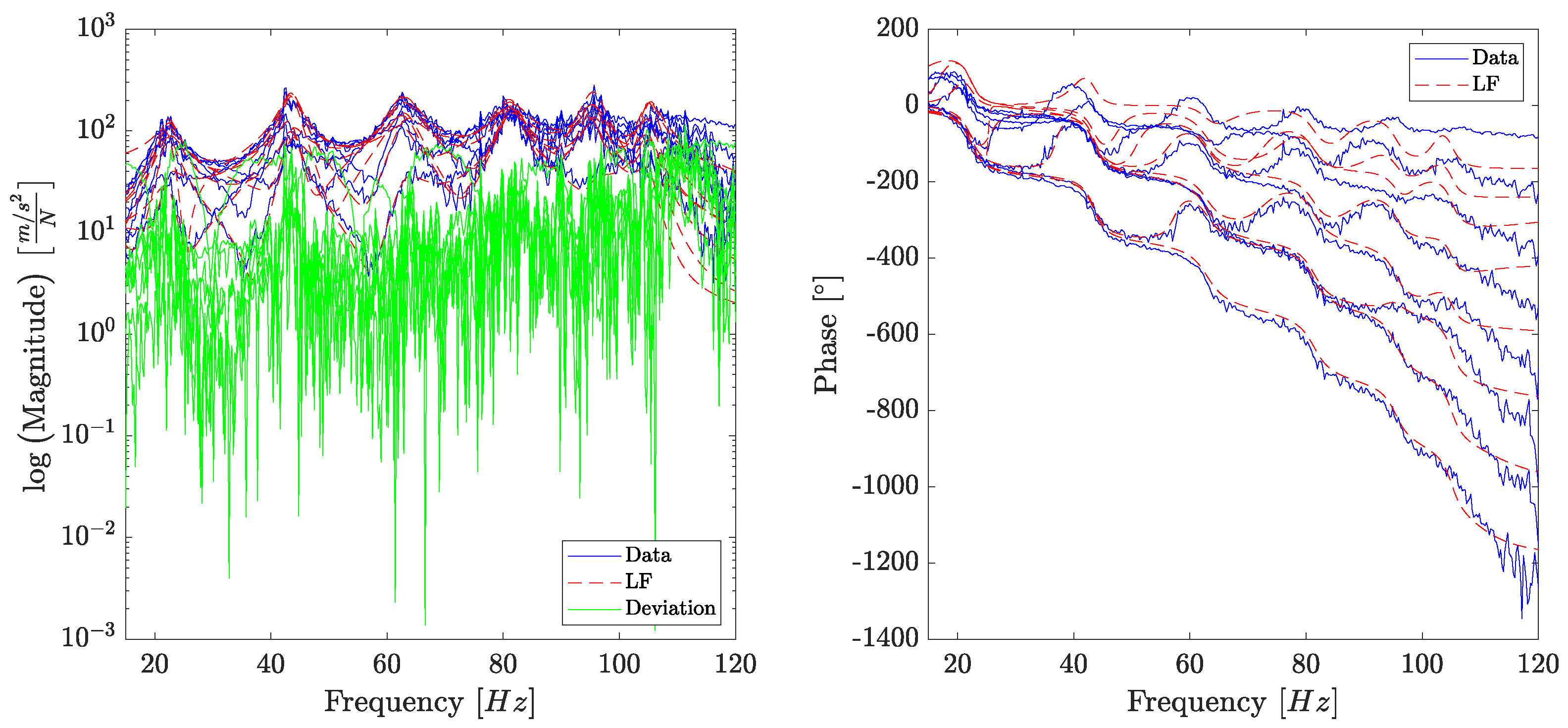

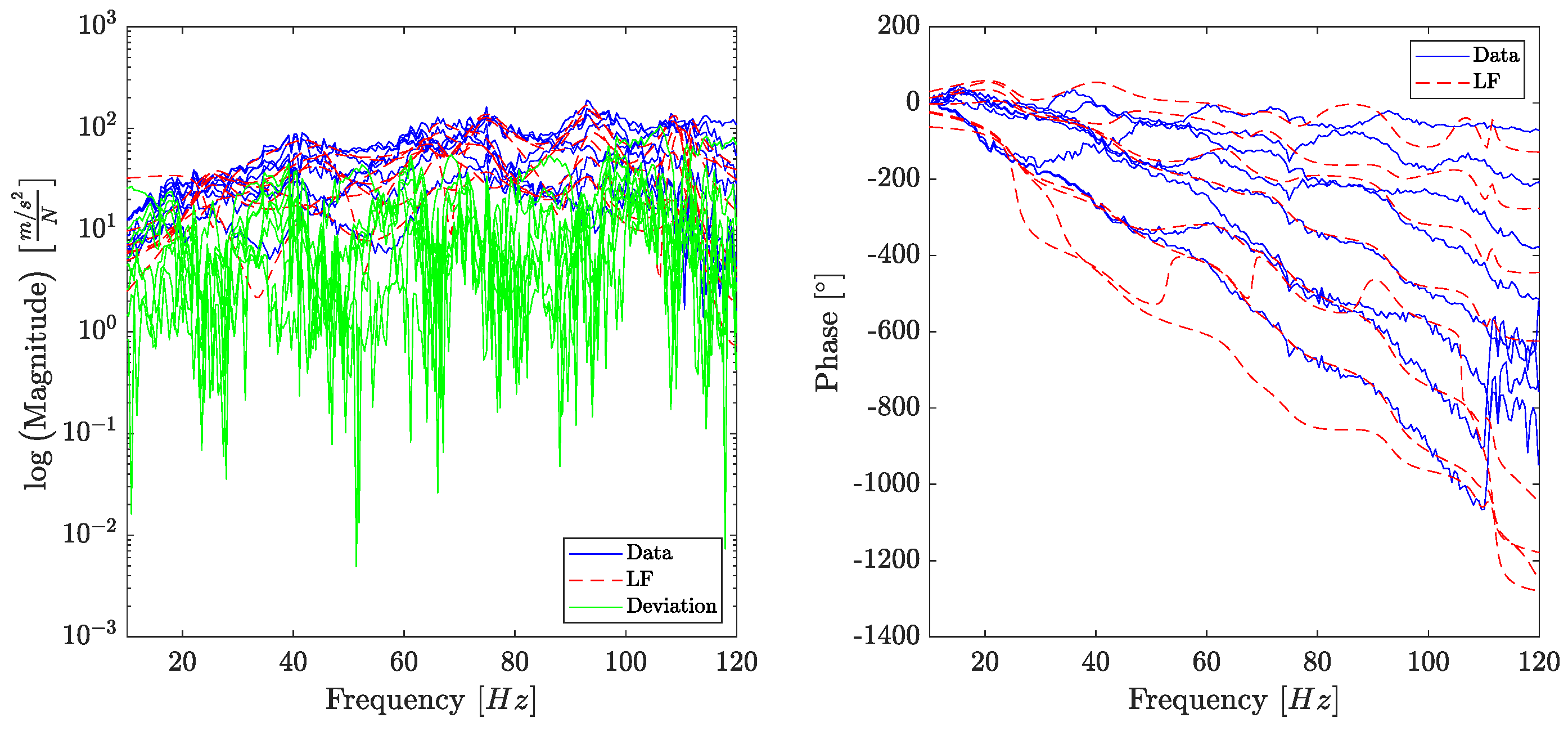

The analysis involved the goodness of fit of the LF, considering all channels in an SIMO fashion, to the computed acceleration FRF.

Figure 8 shows the computed FRF as a solid blue line, the Loewner realisation as a dashed red line and the deviation, defined as the square of the difference’s absolute value at each frequency instance, with a solid green line. The plot on the left shows the absolute gain of the FRF, the LF fit, and the deviation, while the right plot shows the phase angle in degrees. In

Figure 8, the FRF for this case is noisy and, as seen before, this mostly influences the higher frequencies and modes. The absolute gain plot shows, unequivocally, that the deviation trend increases with frequency. This phenomenon returns a coherent fit for the LF, except for the phase angle at higher frequencies, giving an absolute gain deviation between 10

−2 and 10

2. Nevertheless, this deviation magnitude still allows for a coherent identification of parameters by the LF, which is shown in

Table 3,

Table 4 and

Table 5 and

Figure 9. It should be noted that the LF results in

Figure 8 are obtained with the minimum order, in accordance with the literature results, of

k= 12 (since only six modes were extracted in previous literature) and the modal parameters are obtained to the suitable higher-order as prescribed by the poles’ stability.

Table 3 and

Table 4 introduce the raw values of the mean (

) over five iterations, taken for statistical significance, of the identified

, in Hz, and

by the LF and benchmark methods (LSCE and N4SID). Here, a quantitative comparison between N4SID, LSCE, LF, LF from the noiseless numerical system (LF_num), numerical system and benchmark data [

30] is considered by showing, in brackets, their relative difference in percentage to the benchmark values. The

identified within this work tend to be slightly underestimated when compared to the benchmark values. Nevertheless, the identified

deviation from the expected benchmark values never exceeds 6.5%. The identified

are very coherent with the benchmark data. In fact, only

is noticeably underestimated (this is, however, in line with the estimations of the two other methodologies). In addition, LSCE notably overestimates

. The same is valid for LF_num and the numerical system values. They are largely consistent with the N4SID and LF values for

. However, they present large discrepancies for

, since that parameter is assumed to be 3% for all modes in the original model.

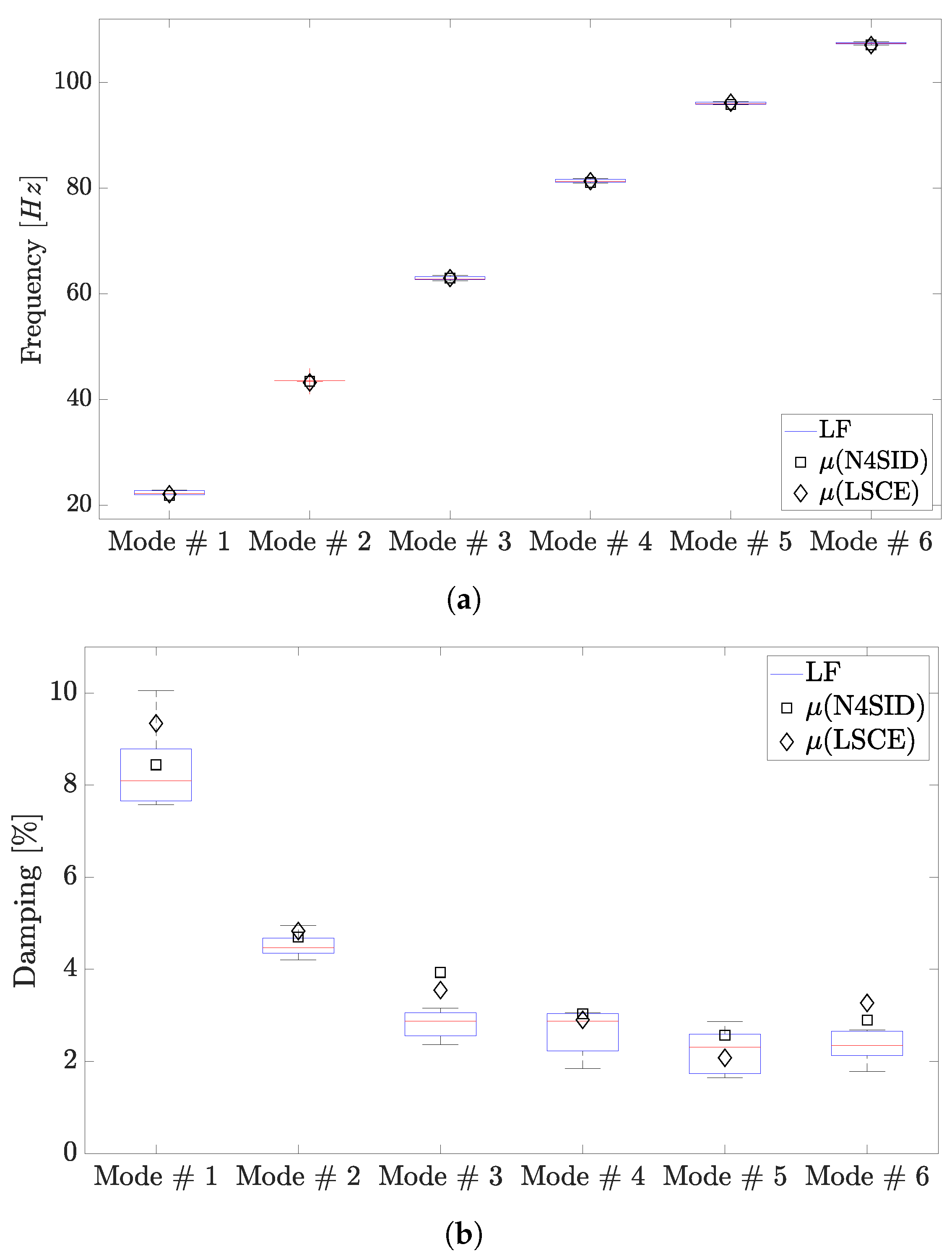

Figure 9 shows the statistical performance of the LF against the mean of the established methods. The choice of presenting the established methods through their mean and not according to the LF is based on the nature of their standard deviation (

), which is of a negligible magnitude if compared with the LF’s own, and to maintain clarity within the plot. Overall,

Figure 9 shows that the LF-identified

and

are in line with the values found through LSCE and N4SID identification.

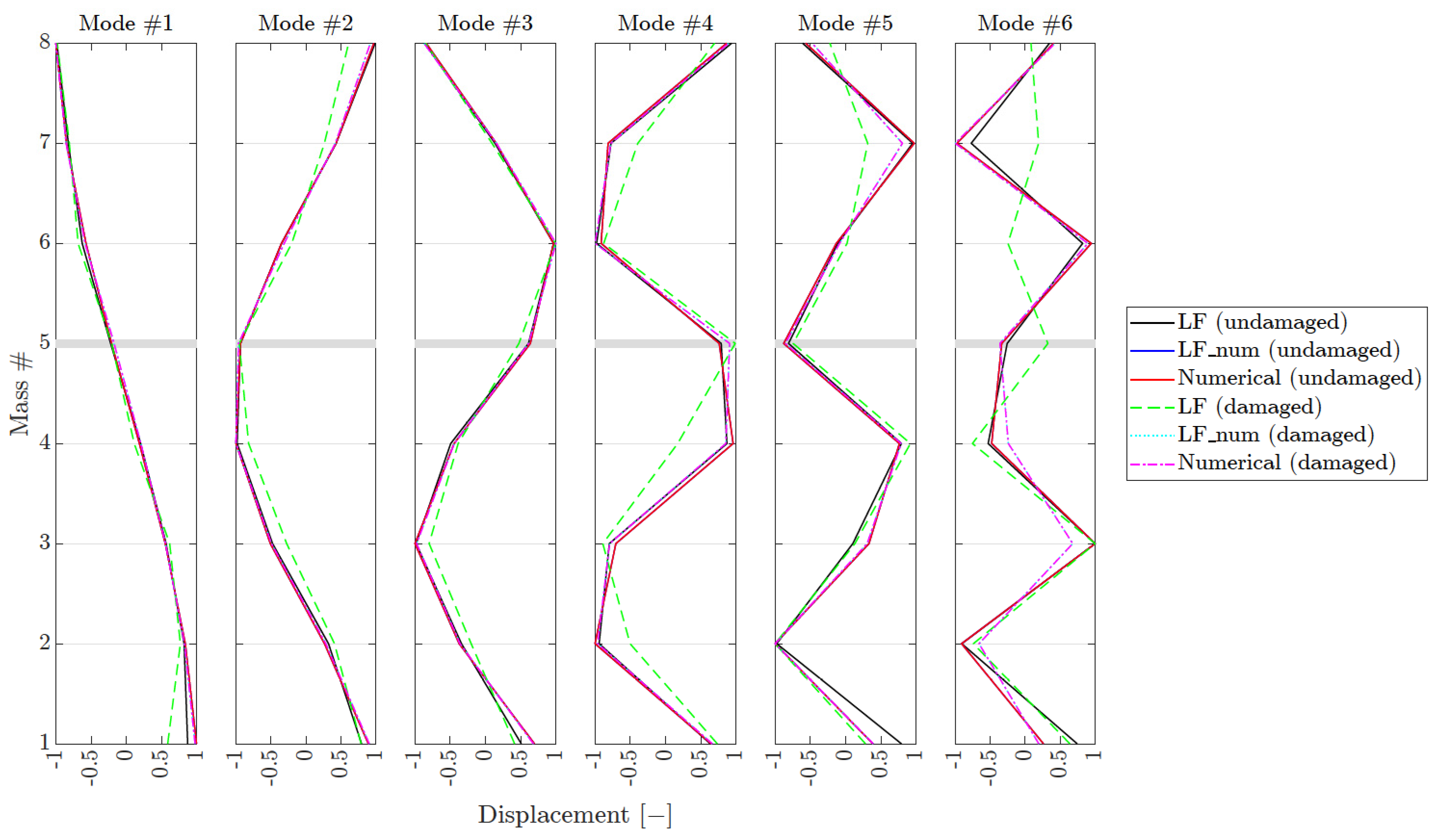

The first six

of the eight DoF system are compared in

Table 5 using the MAC value. The LF slightly underperforms identifying the sixth mode of the undamaged case. Nevertheless, the sixth mode shape is still consistent with the ones identified by LSCE and N4SID. The MAC values between the sixth mode identified by the LF, LSCE, and N4SID are 0.95 and 0.93, respectively. Hence, this is well above what is commonly considered a sufficient correlation by practitioners [

35,

37]. In summary, the first six modes of the eight DoF system are identified by LF accordingly to N4SID and LSCE. The numerical model and LF_num perform well for the first five modes (MAC values are above 0.96); however, they fall short at the sixth mode with an MAC value of 0.80. Notably, this is also the mode for which the quantitative benchmark values are not available [

30].

As well as the accuracy and precision, the efficiency of the method is evaluated. The approach taken here considers the

and

of the time elapsed till identification on the experimental data over several iterations (five in this case), at the order

k. The results are satisfactory when compared with well-established methods. The results are presented in

Table 6, in which LSCE is recognised as the least computationally demanding method and N4SID as the most. The LF lies between them, both in terms of

and

. The values presented in

Table 6 were computed in MATLAB R2022b running on a desktop Microsoft Windows 11 machine with a 6-core AMD Ryzen 5 5600G.

2.2.2. Damaged Scenario

The damaged case is characterised by a 14% reduction in the stiffness of the fifth element. As for the undamaged case, the results obtained from N4SID, LSCE, LF, LF_num and the numerical system are compared to the benchmark values with respect to the identified parameters. The FRF for the damaged system is even noisier than the undamaged, as shown in

Figure 10. The deviation between the acceleration FRF and the Loewner realisation is between 10

−2 and 10

2. Nevertheless, the LF model holds a reasonable approximation for the experimental FRF, particularly for the gain amplitude.

benchmark values are available from [

30], while they are not for

and

. Hence, N4SID-identified values, the mean over five realisations, are used as the baseline for their comparisons.

Table 7 shows the comparison for

.

results are shown in

Table 8 and the

are compared to the N4SID values computing the MAC in

Table 9.

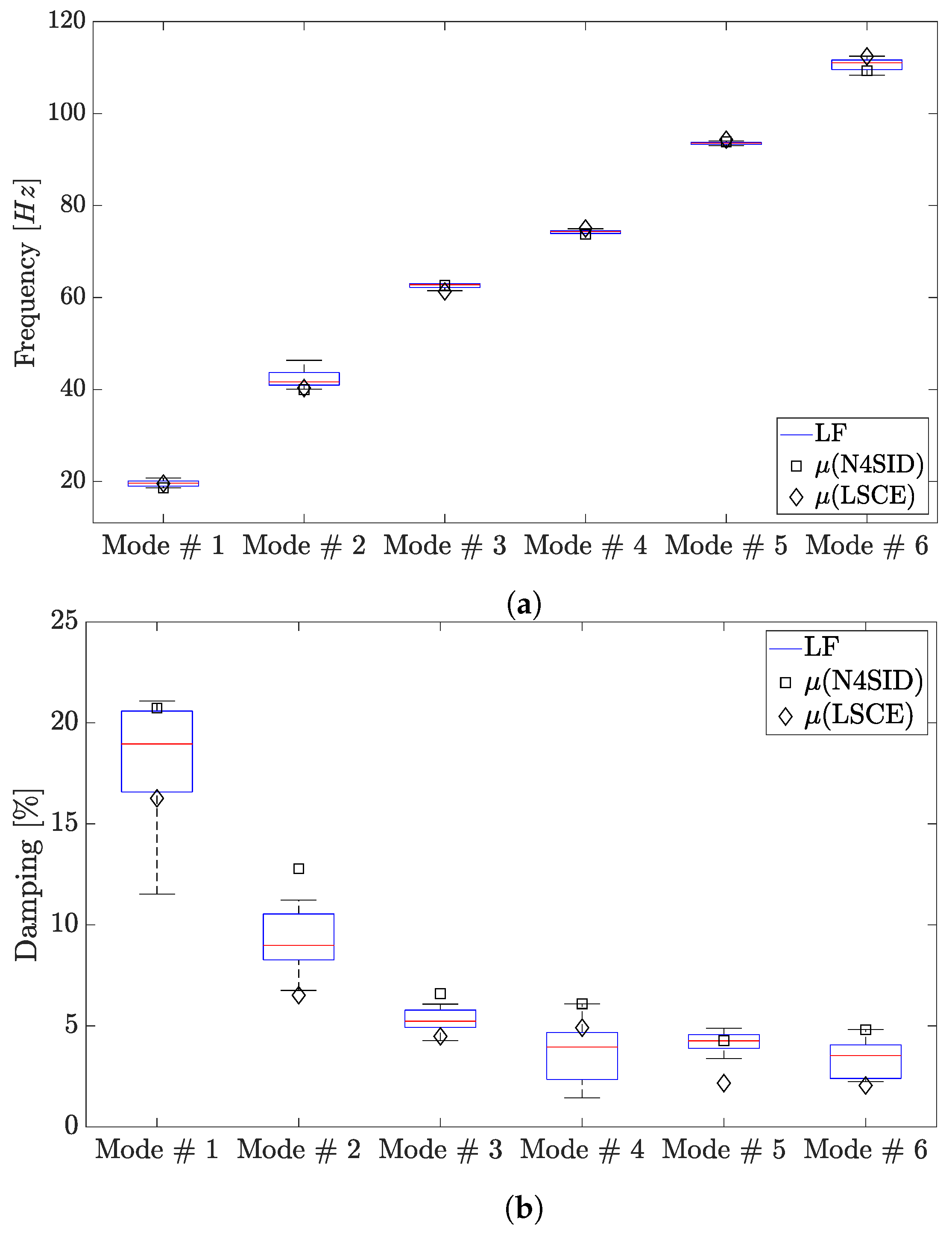

Figure 11 gives a more intuitive representation of the range of

and

identified via LF, LSCE, and N4SID.

In

Table 7, the

identified by N4SID, LSCE, LF and LF_num and those obtained from the numerical system are compared, while in

Figure 11a the identified

via LF over five realisations are compared to the average values from LF and LSCE. When compared to the benchmark values,

seems severely underestimated (over 10 %) by N4SID, LSCE, and LF, while those based on the numerical system performed very well (error close to zero). However, while the input type is mentioned in [

30], the same cannot be said for its amplitude. In fact, it is not clear which, of the three available, is used to obtain the benchmark results (3 V RMS is used in this work). This would be decisive in determining if the discrepancy is an error or a result of the amplitude-dependent non-linearity of the system. This said, the maximum error for the remaining modes never exceeds 9% for N4SID, 8.20% for LSCE, 6.1% for LF and 5.9% for LF_num and the numerical system. Concerning

, the identification becomes more spurious, as expected given the noisy experimental FRF, shown in

Figure 10. Nevertheless, the

are underestimated for all modes by LF and LSCE, when compared to N4SID. However, this is even more true for LSCE, for which the

of all modes are greatly underestimated. LSCE outperforms LF only for the identification of

. Generally, it can be said that LF and, more relevantly, LSCE have slightly underestimated

. These are clearly shown in

Table 8 and

Figure 11b.

With respect to

, benchmark values are not disclosed, as per the undamaged case, in [

30]. Hence, N4SID data are used as a reference for the comparison in

Table 9, where the MAC values are used as a figure of merit. Notably,

identified via LF show a higher correlation to the N4SID

than those identified by LSCE, apart from

. Nevertheless, the LF-identified

MAC values with respect to N4SID are, for all modes, at least 0.93. A correlation is also seenn between the LF_num and numerical modes with LF.

As per the undamaged scenario in

Table 6, the time till identification for the LF, LSCE, and N4SID on the experimental data is investigated for the damaged case as well. In

Table 10, the results in terms of

and

of the time till identification, in seconds, and their order

k are presented. The same picture as per

Table 6 emerged. The only difference is the magnitude of the time till identification, which is higher due to a higher order

k necessary to obtain significant results.

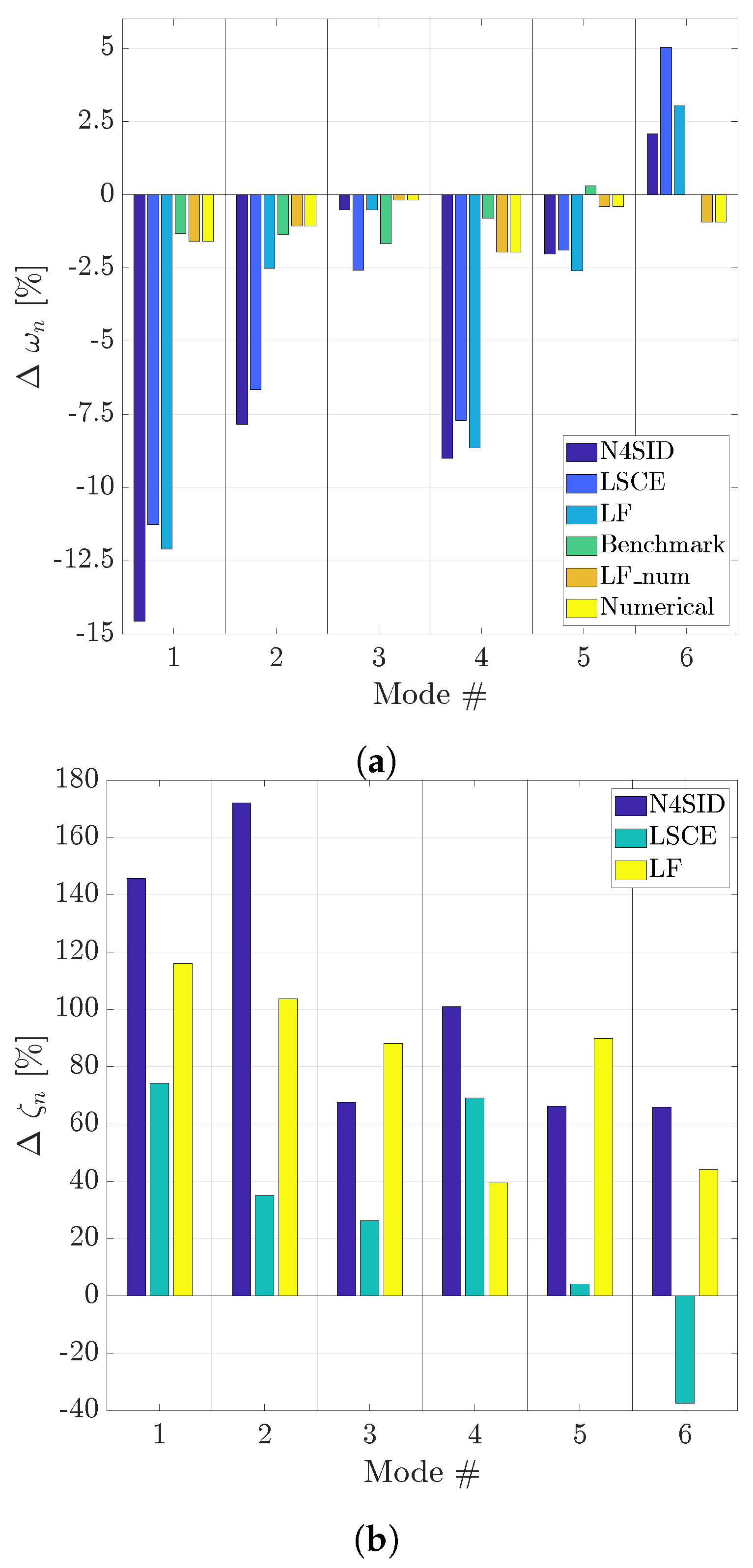

Having established the goodness of the LF identification, when compared to benchmark data and N4SID, it is necessary to carry out a damage assessment on the structure. As is noted in [

25], the expectation for a stiffness reduction is a decrease in

and a change in the

trajectories, particularly at the damaged node. In

Figure 12, the relative difference between the undamaged and damaged cases

(

Figure 12a) and

(

Figure 12b) are presented. The comparison for

includes results from N4SID, LSCE, LF, benchmark, LF_num and the numerical system, while for

only from N4SID, LSCE and LF, since benchmark values are not available for

and it is constant at 3% for the data relative to the numerical system (no change between damaged and undamaged). The undamaged and damaged

identified from the experimental data by LF, LF_numand the numerical system are shown in

Figure 13.

In

Figure 12a, a negative relative difference is found for all methods and modes, apart from

for the benchmark values and

for the methods that use experimental data. This allows the detection of a change in the structural behaviour, thus detecting damage [

25]. It should be noted that the experimental methods see a larger relative difference between damaged and undamaged

than the benchmark and model-based methods. However, uncertainty on the origin of the benchmark data, particularly concerning the input amplitude (as already pointed out) and processing of the data, remains. Nevertheless, LF performs coherently to the other experimental methods, and LF_num results are perfectly correlated to the numerical results. Hence, the difference is not due to the method but the data or system under scrutiny.

On the other hand, for

, an increase is registered for all modes and methods, apart from

for LSCE. An increase in damping is usually seen as a damage indicator [

25]; however, since it is easily influenced by external factors [

17] it is rarely used as such. Notably, the LF increase in

is always closer to N4SID than LSCE, apart for

.

Figure 13 compares the damaged and undamaged

and successfully demonstrates the ability of the LF to detect differences, which is a preparation step for damage localisation [

25]. Notably,

are largely consistent across all methods, proving the goodness of the LF as a modal parameter identification method for SHM.

In essence and given the above-mentioned results, the LF is an effective SI method for SHM in mechanical systems as it was able to detect parameter difference between the damaged and undamaged systems in a similar or improved manner than well-established methods, benchmark values, and numerical models.