Research on the Infrared Radiation Suppression of the High-Temperature Components of the Helicopter with an Integrated Infrared Suppressor

Abstract

1. Introduction

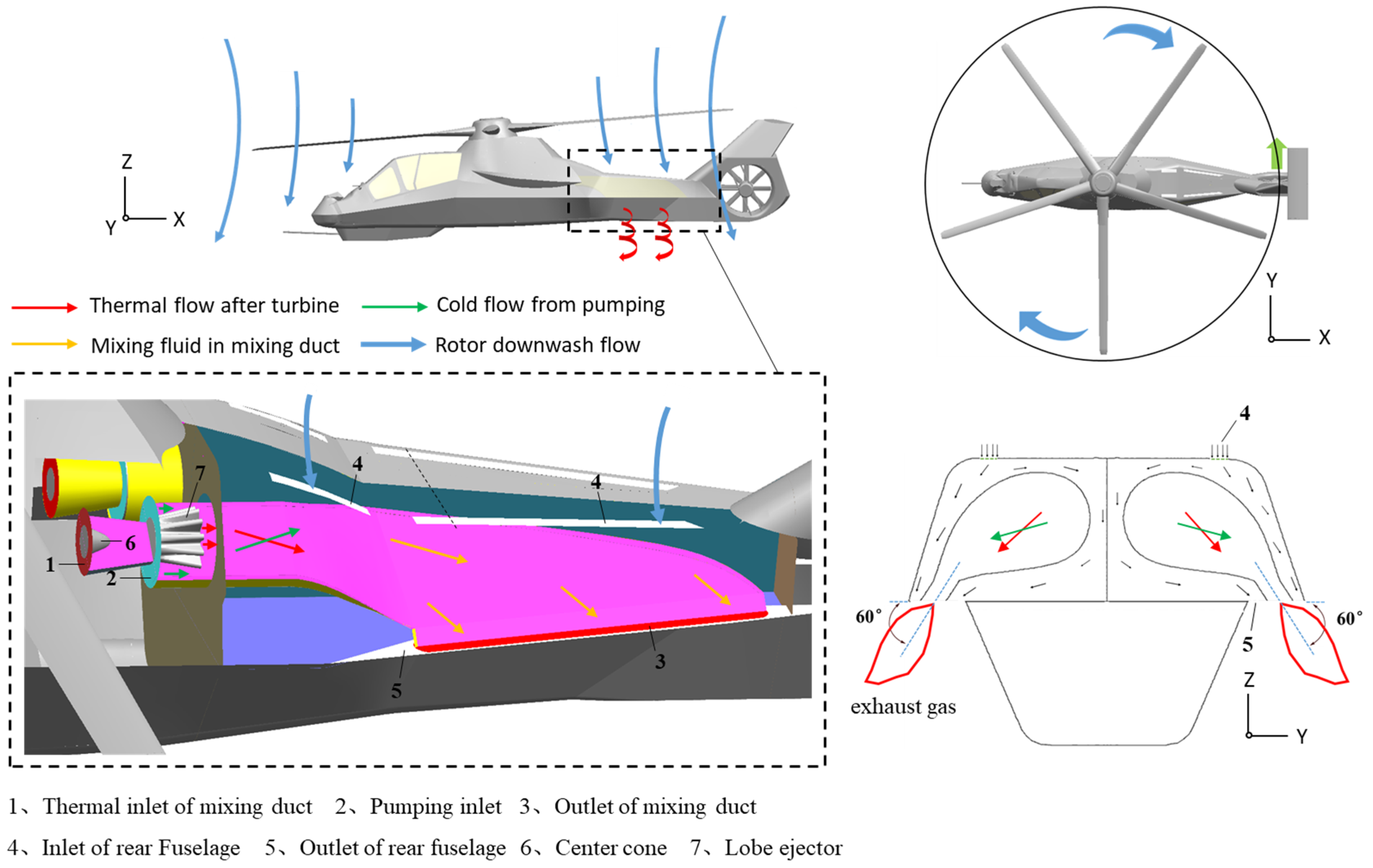

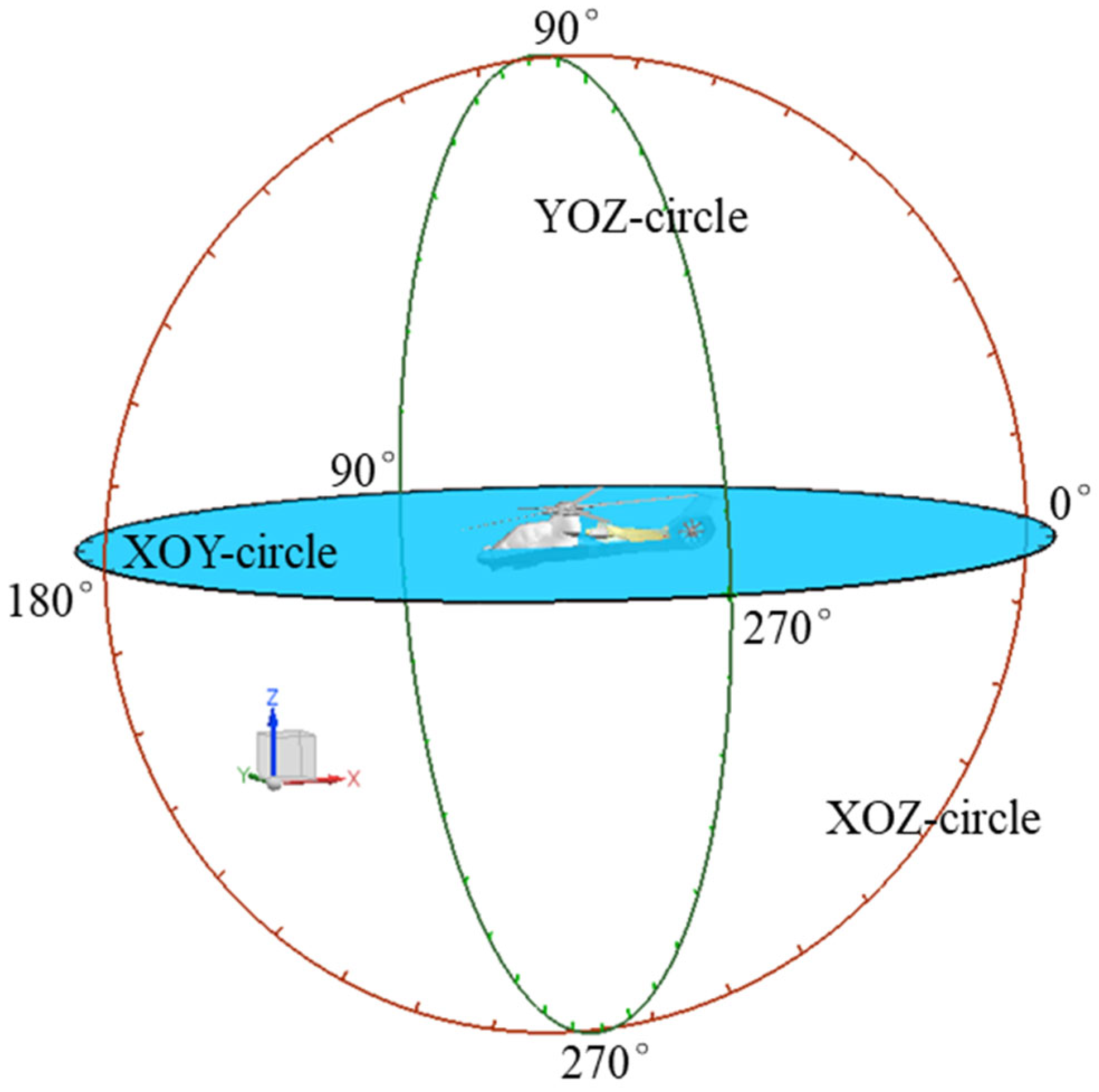

2. Physical and Computational Models

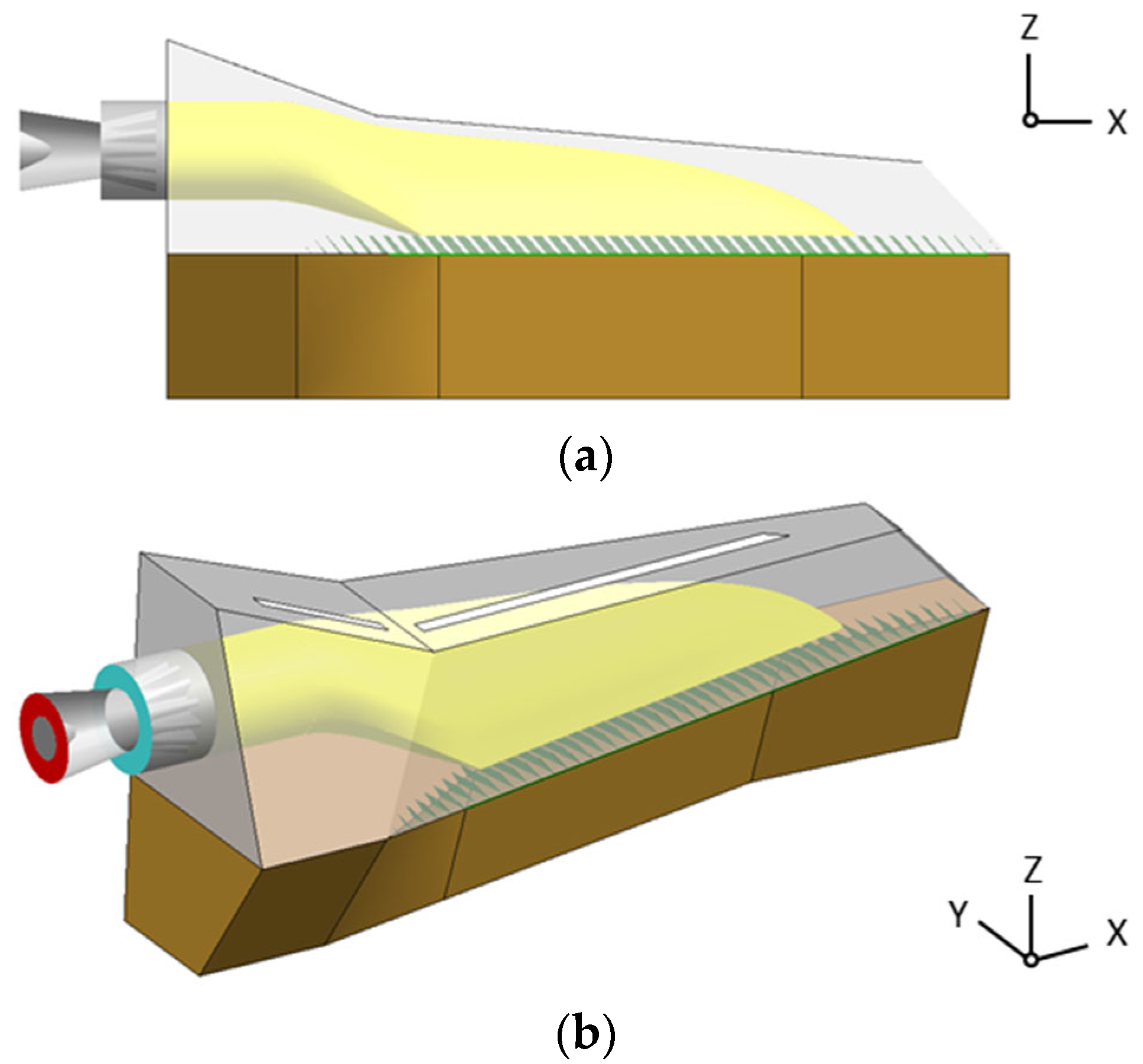

2.1. Physical Model

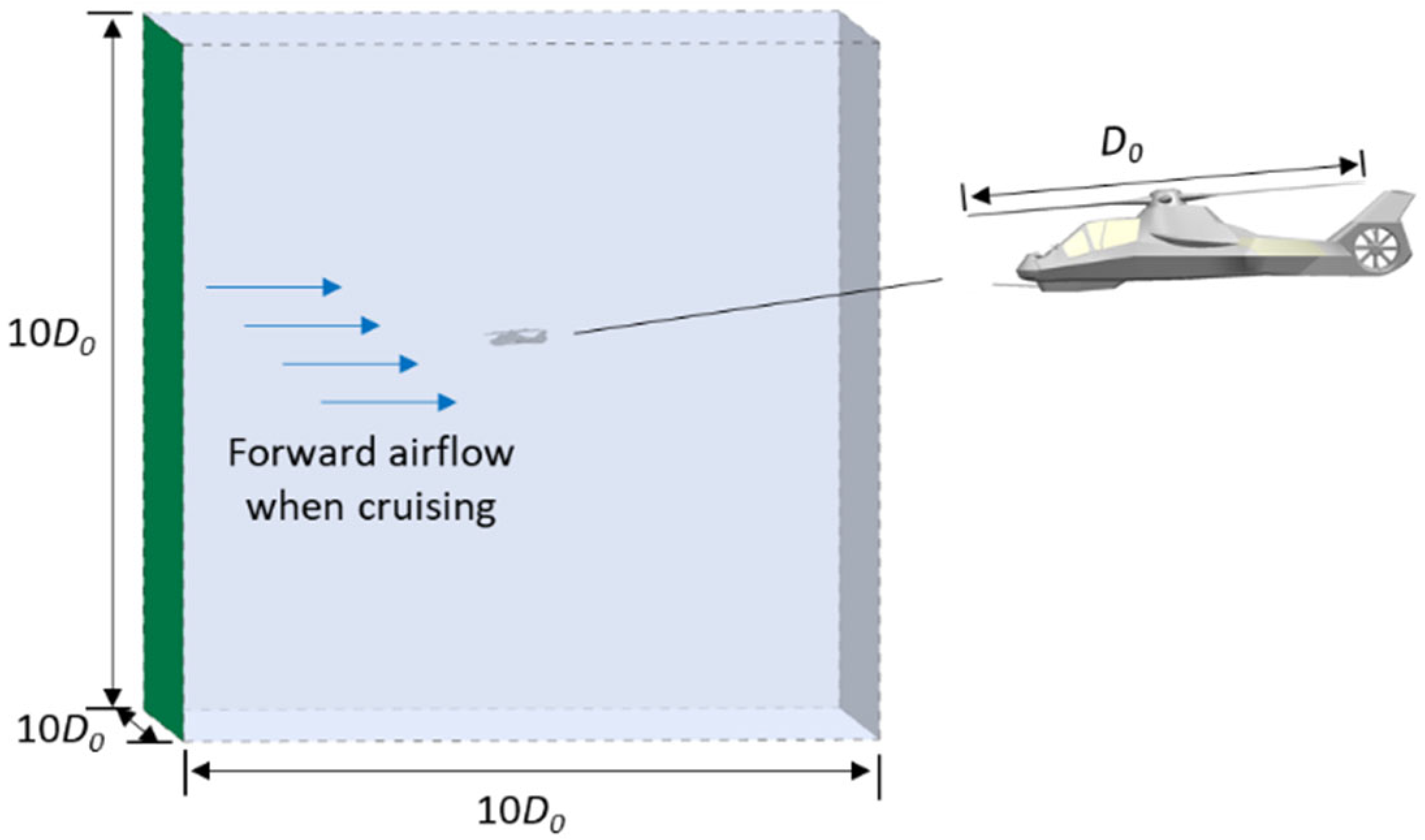

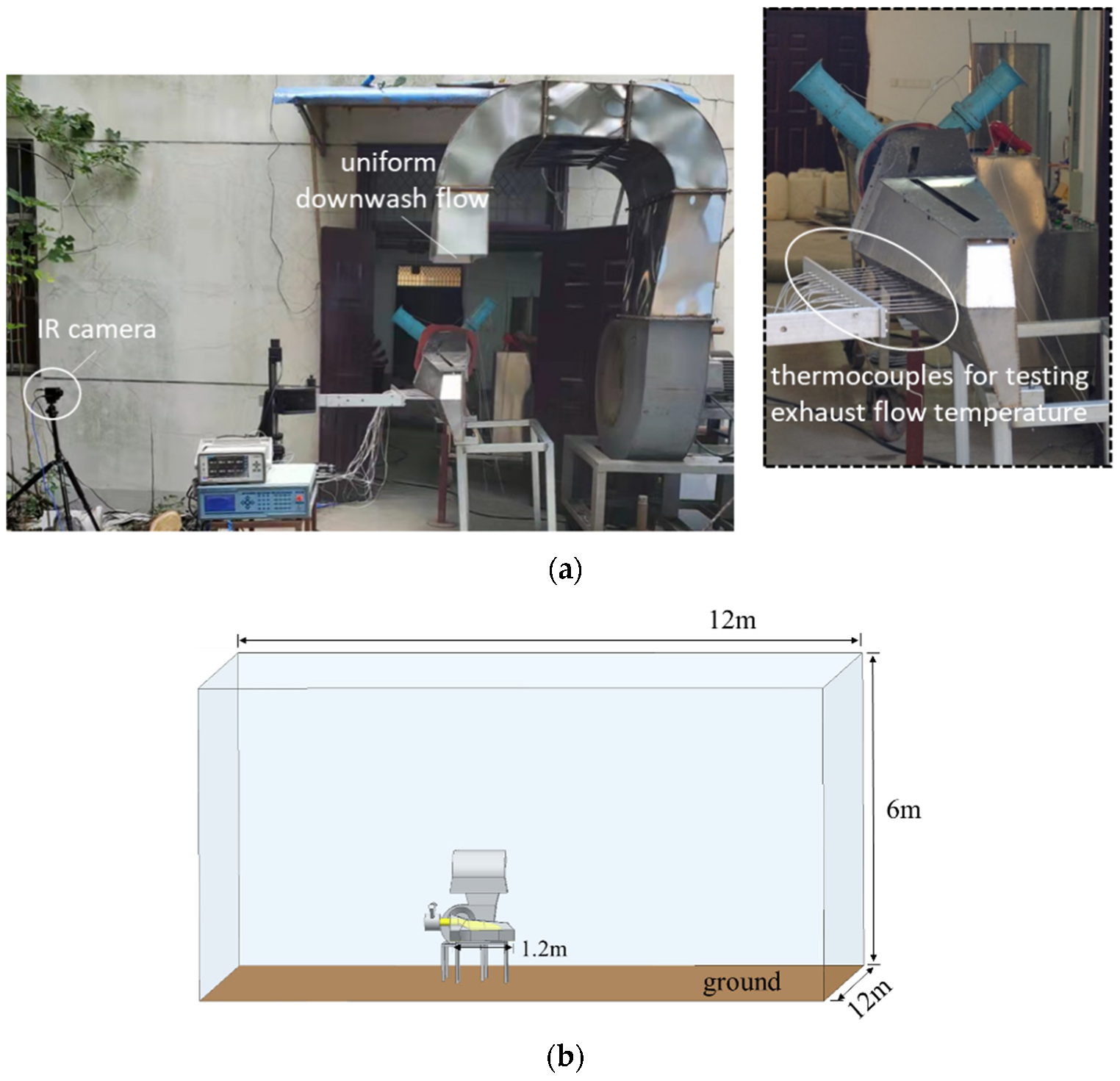

2.2. Computational Model

3. Computational Methodology

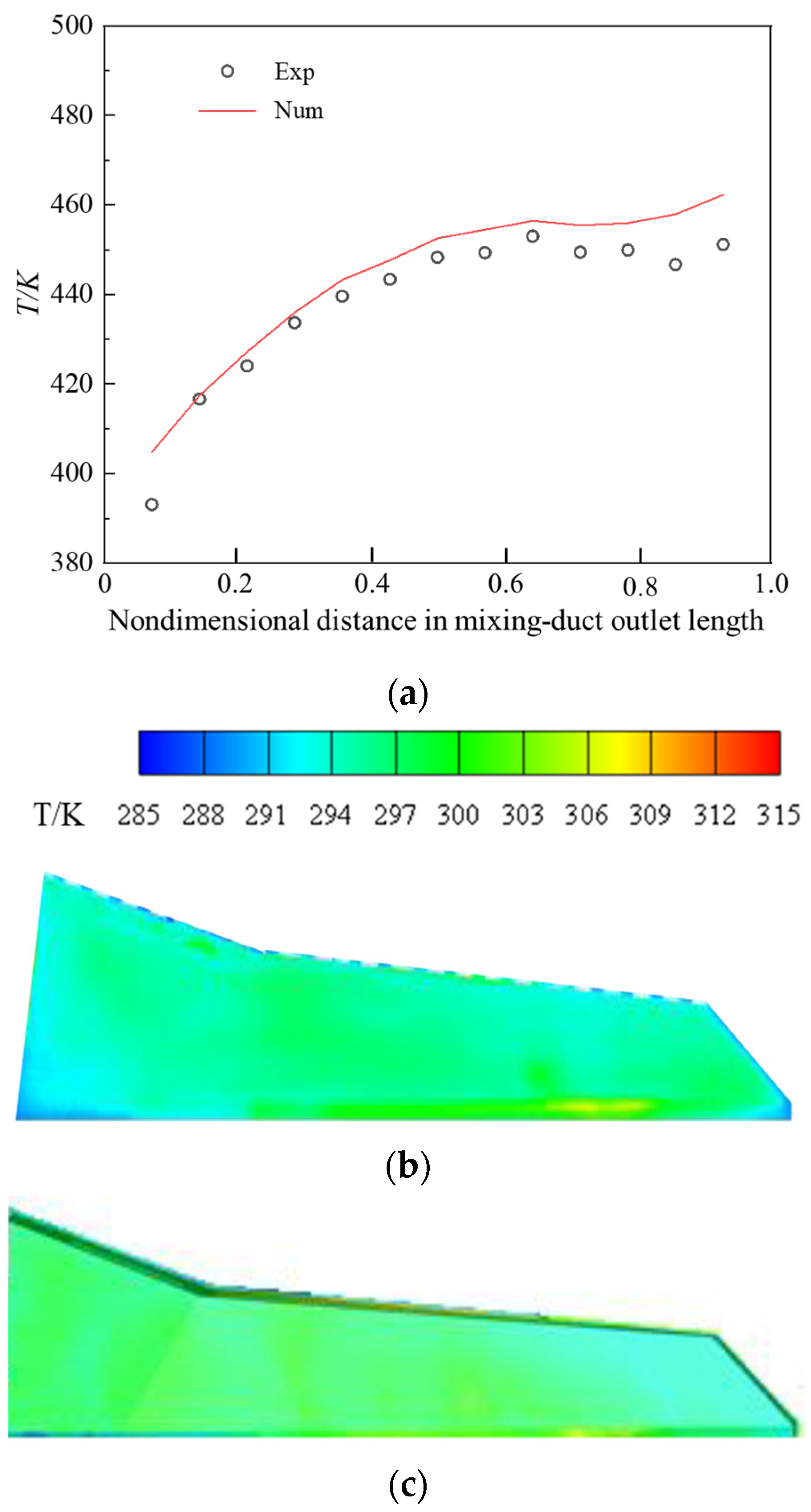

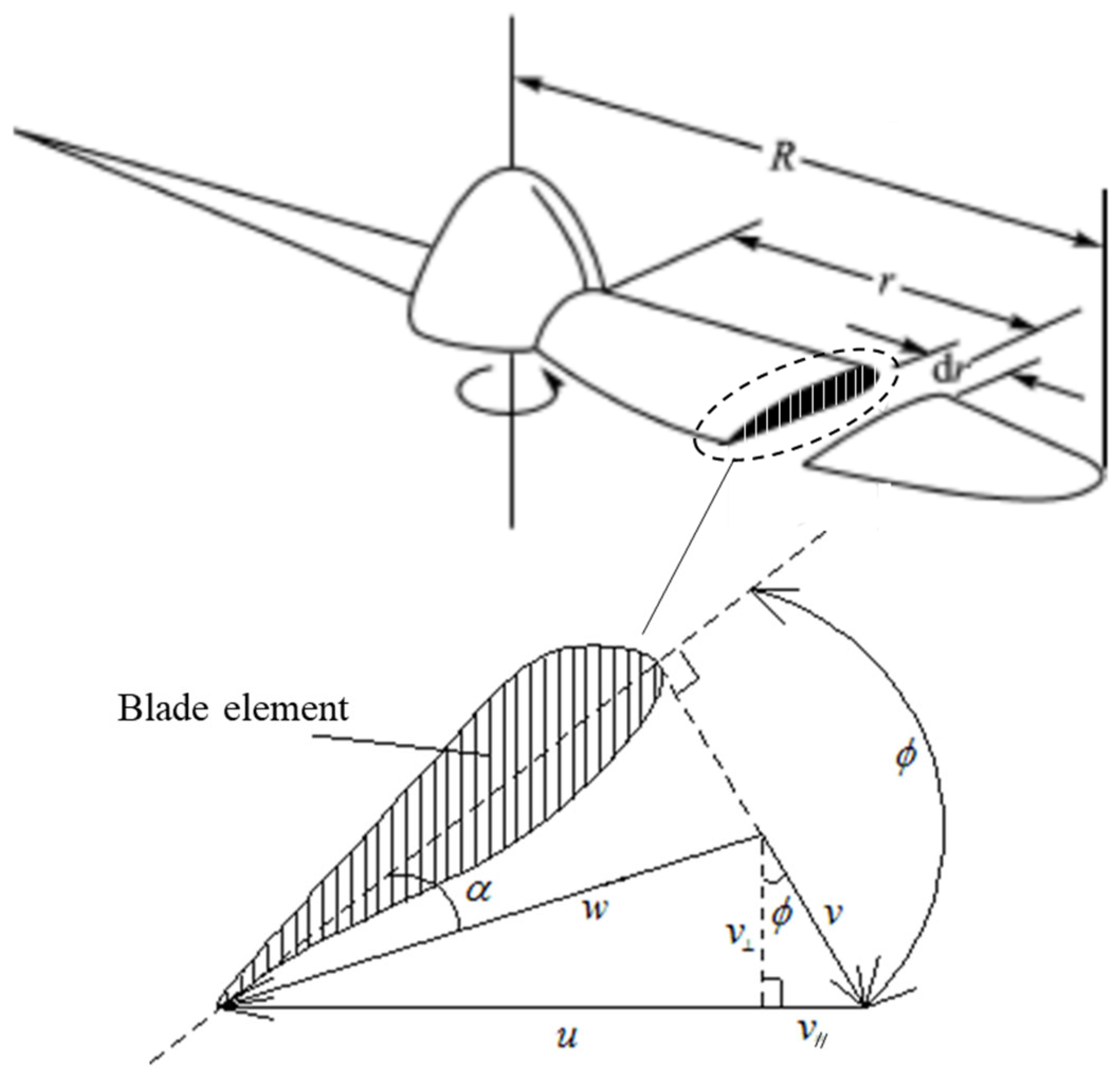

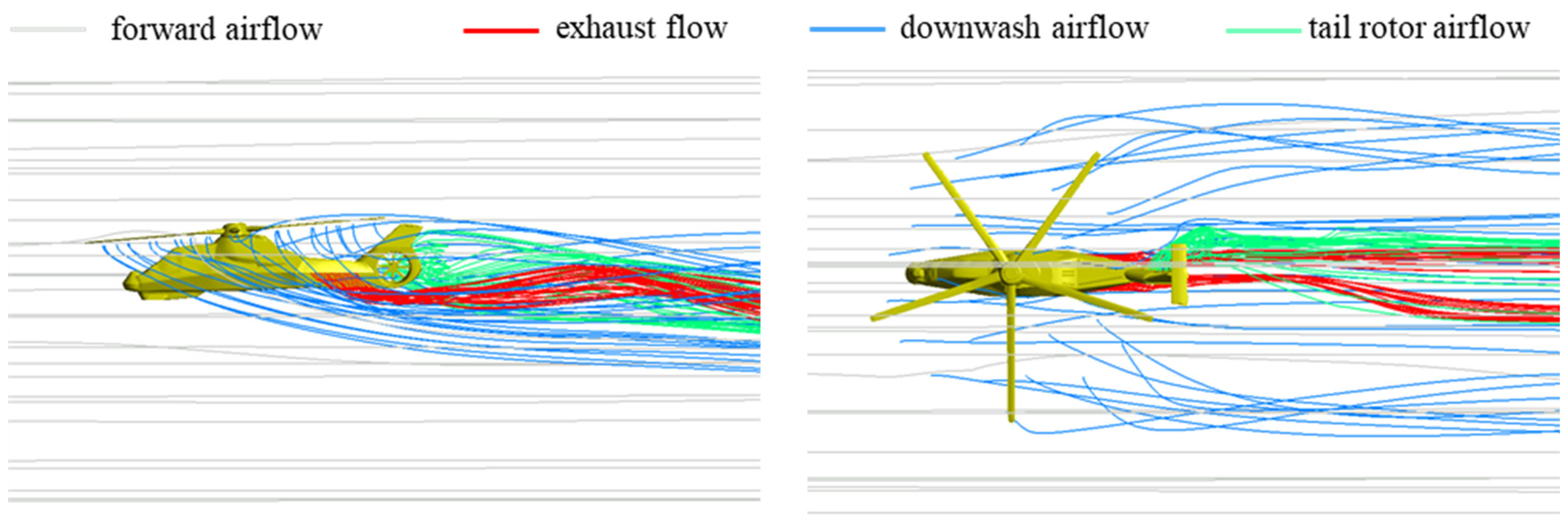

3.1. Flow Field Simulation

3.2. Infrared Radiation Simulation

3.3. Downwash Flow Model

4. Results and Discussion

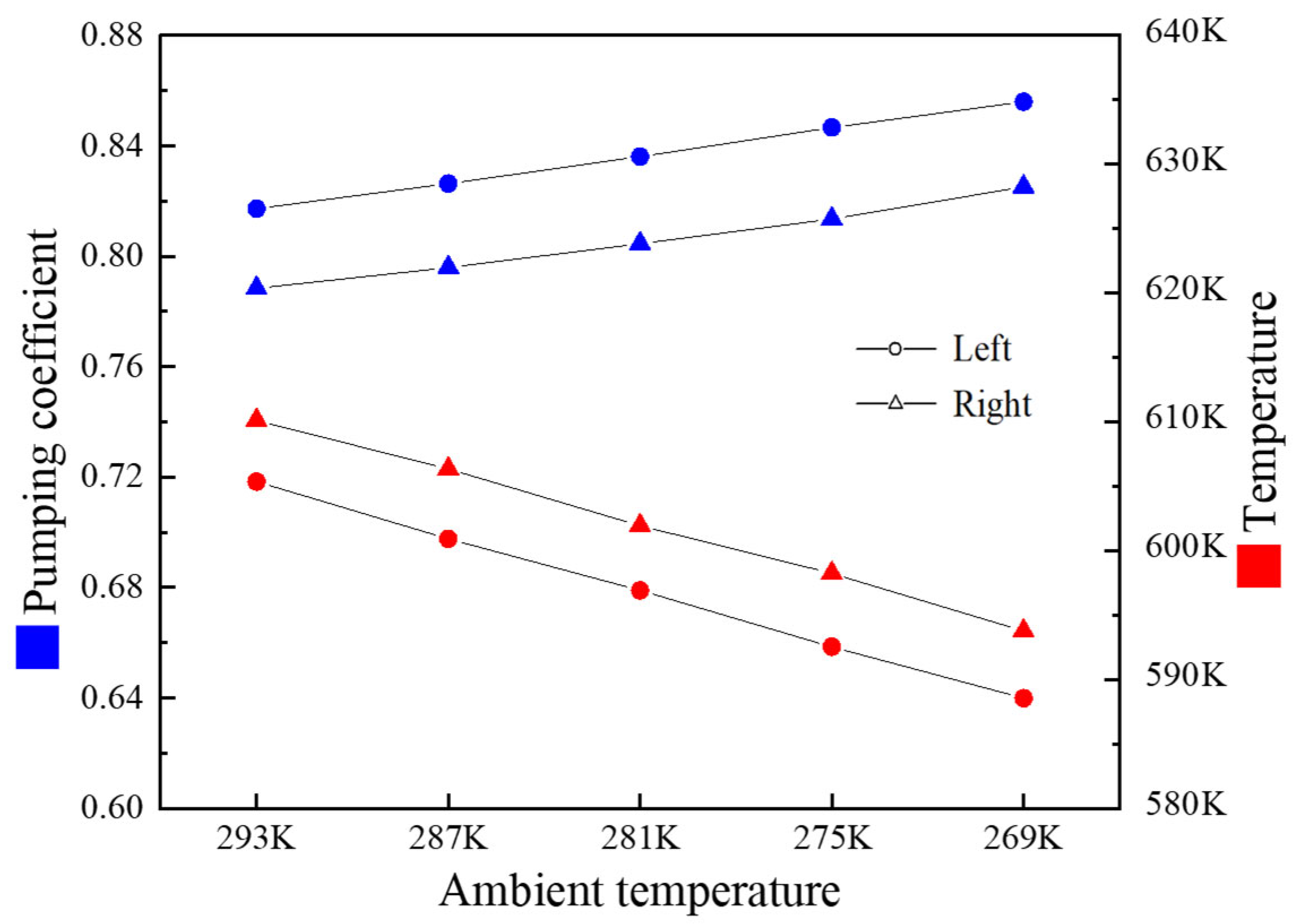

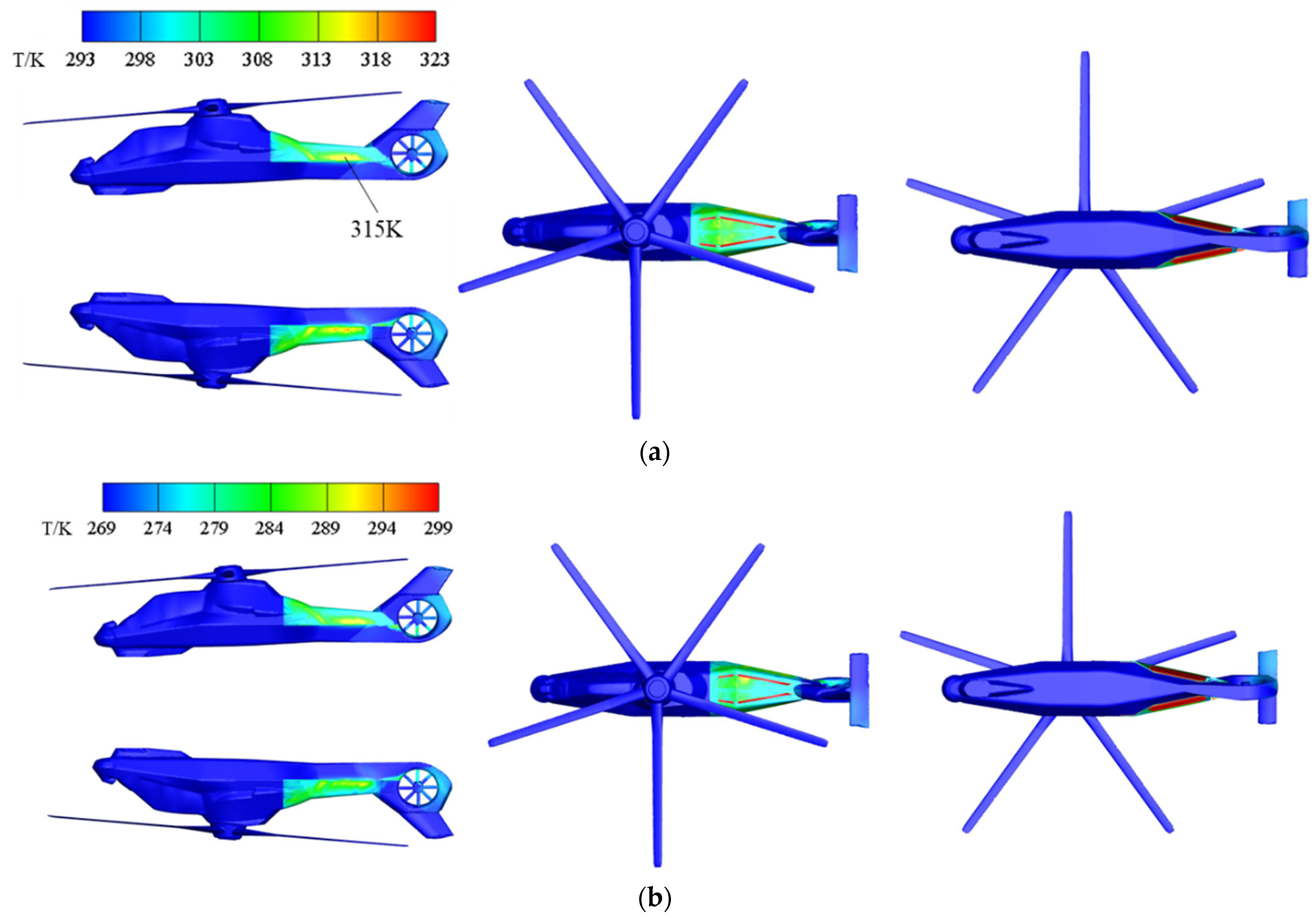

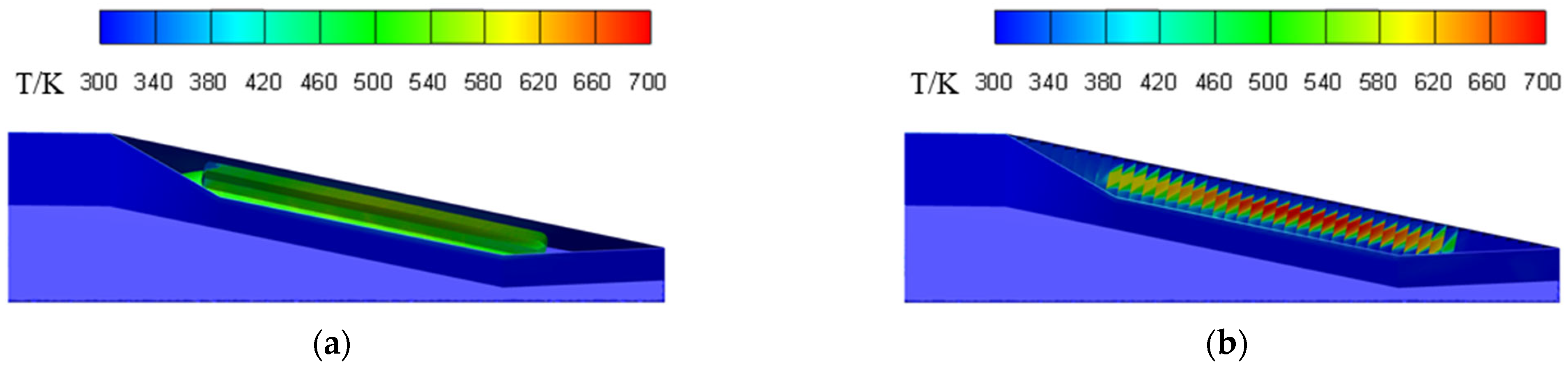

4.1. Flow Field and Thermal Characteristics of the Helicopter

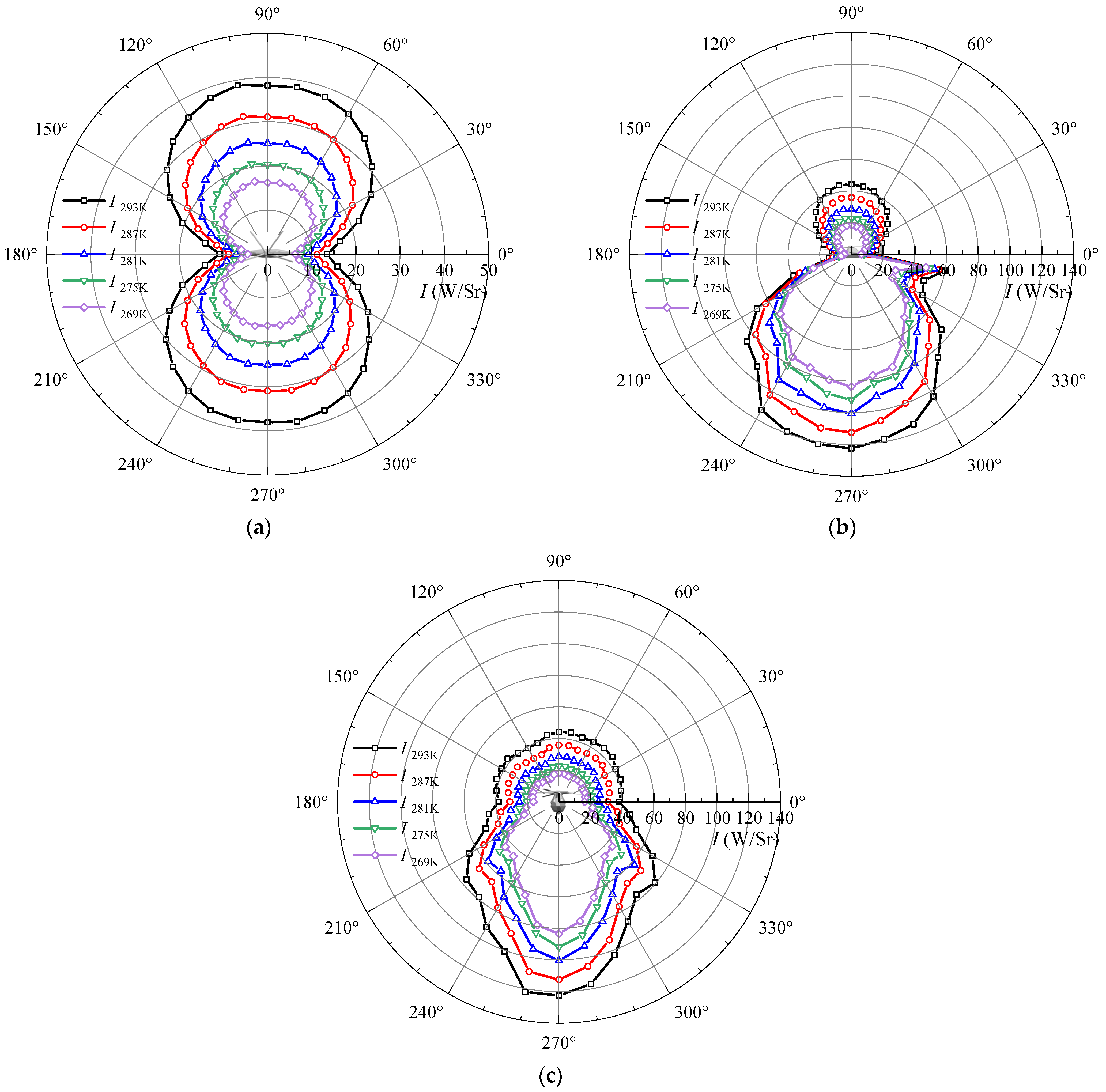

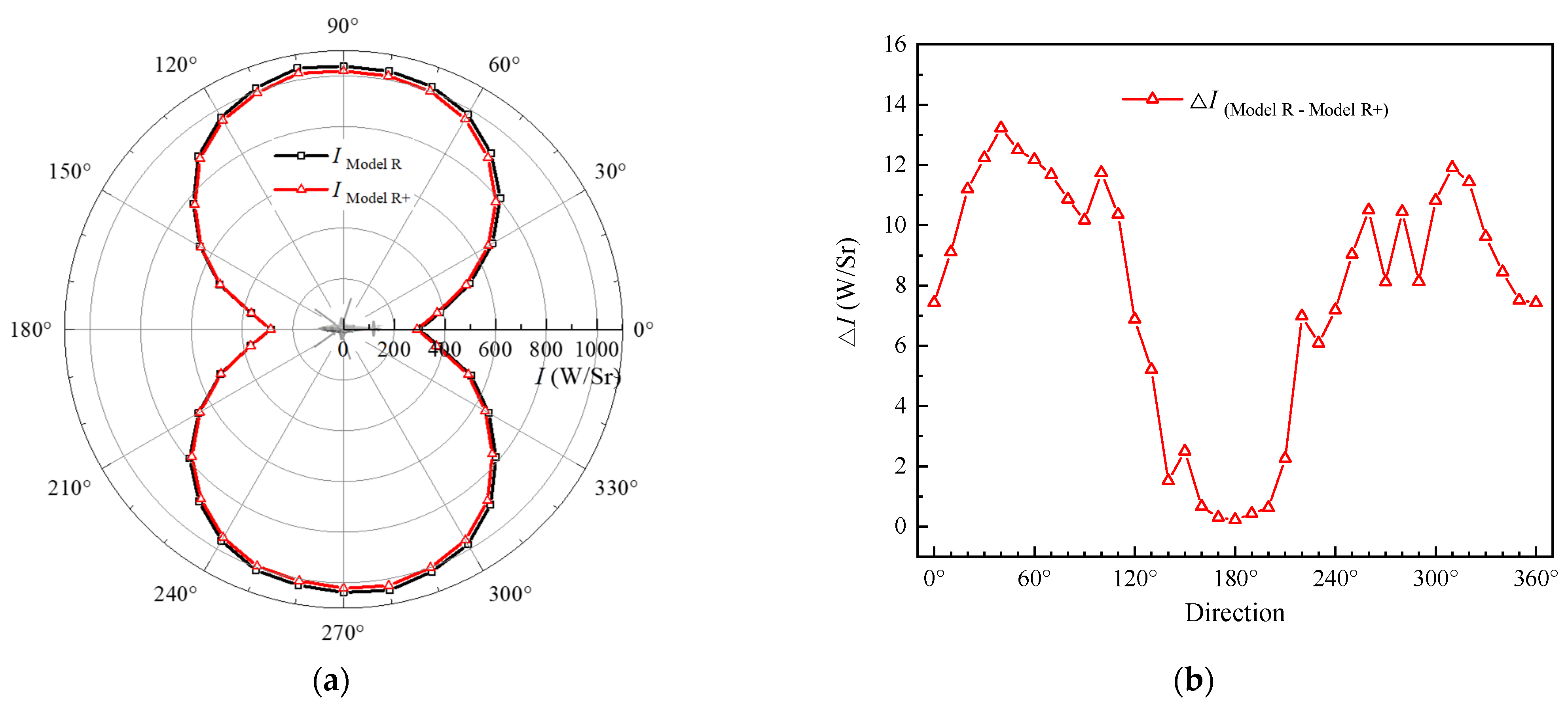

4.2. Infrared Radiation Suppression for the Rear Fuselage

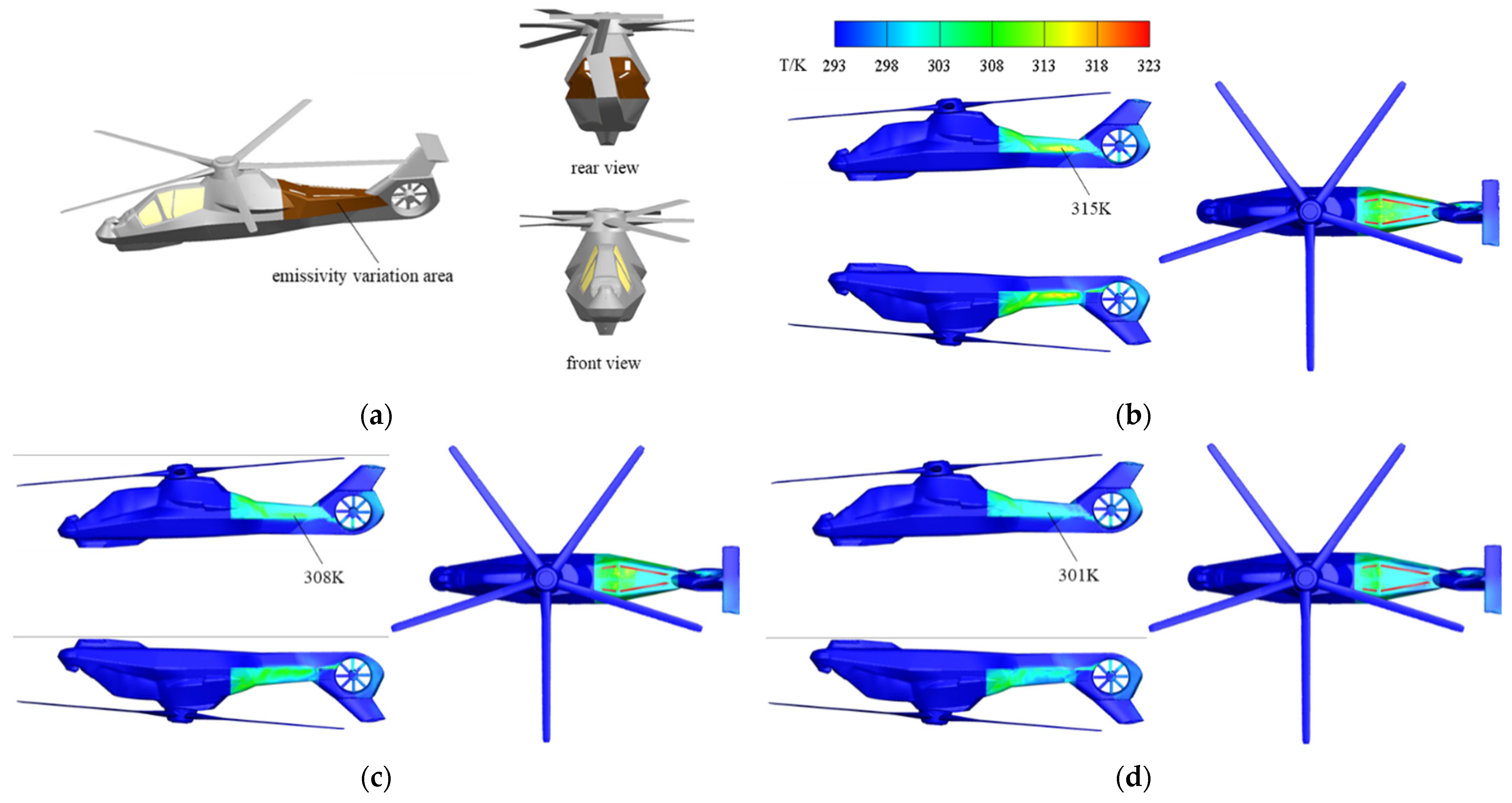

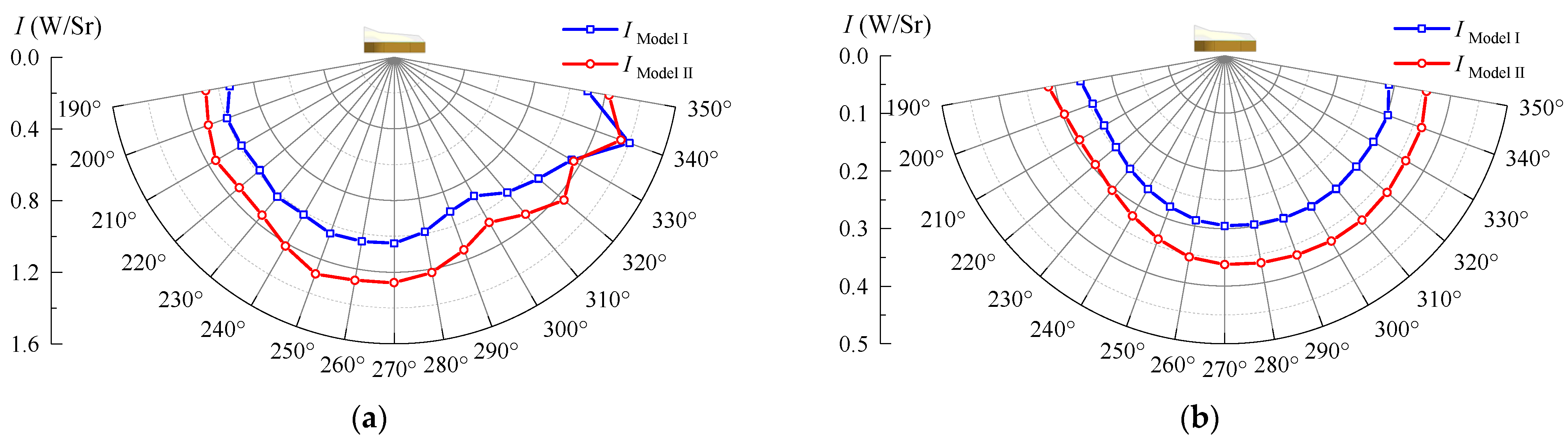

4.2.1. Reducing the Emissivity of the Rear Fuselage Surface

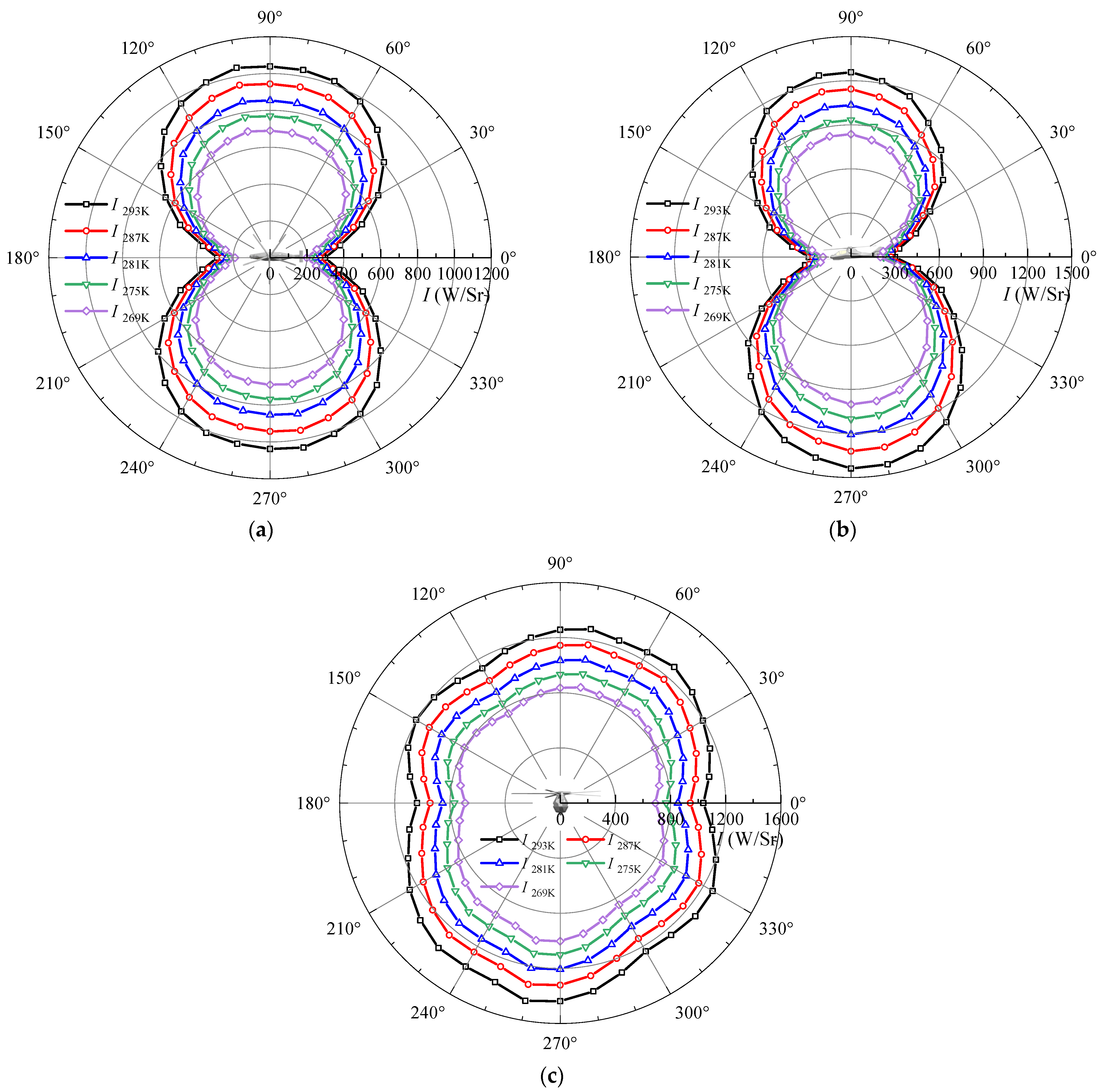

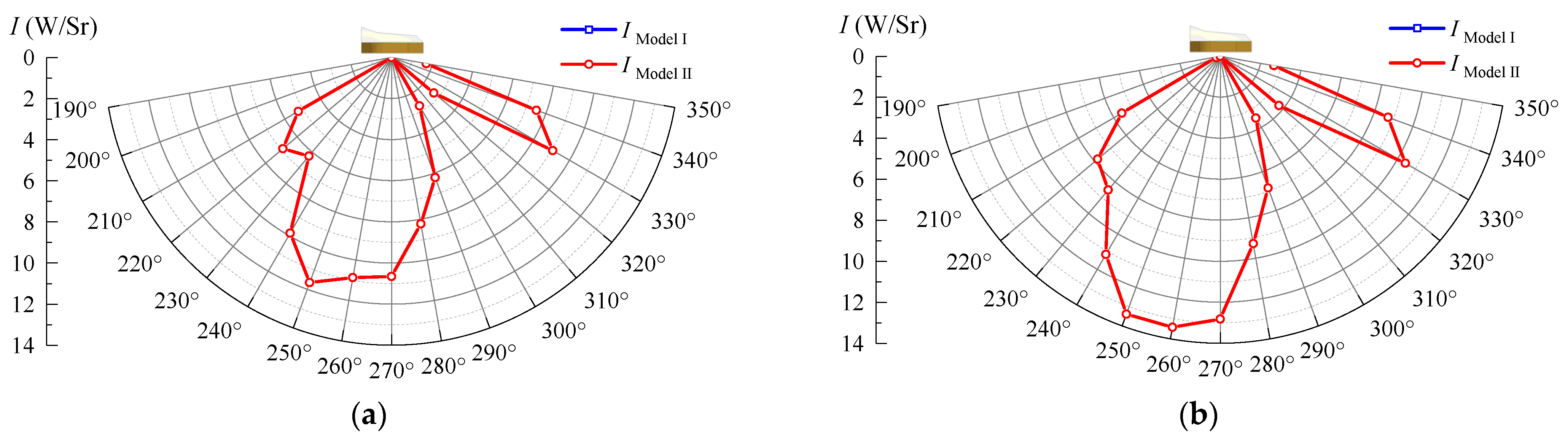

4.2.2. Assembly Shielding Sheath for Mixing Duct

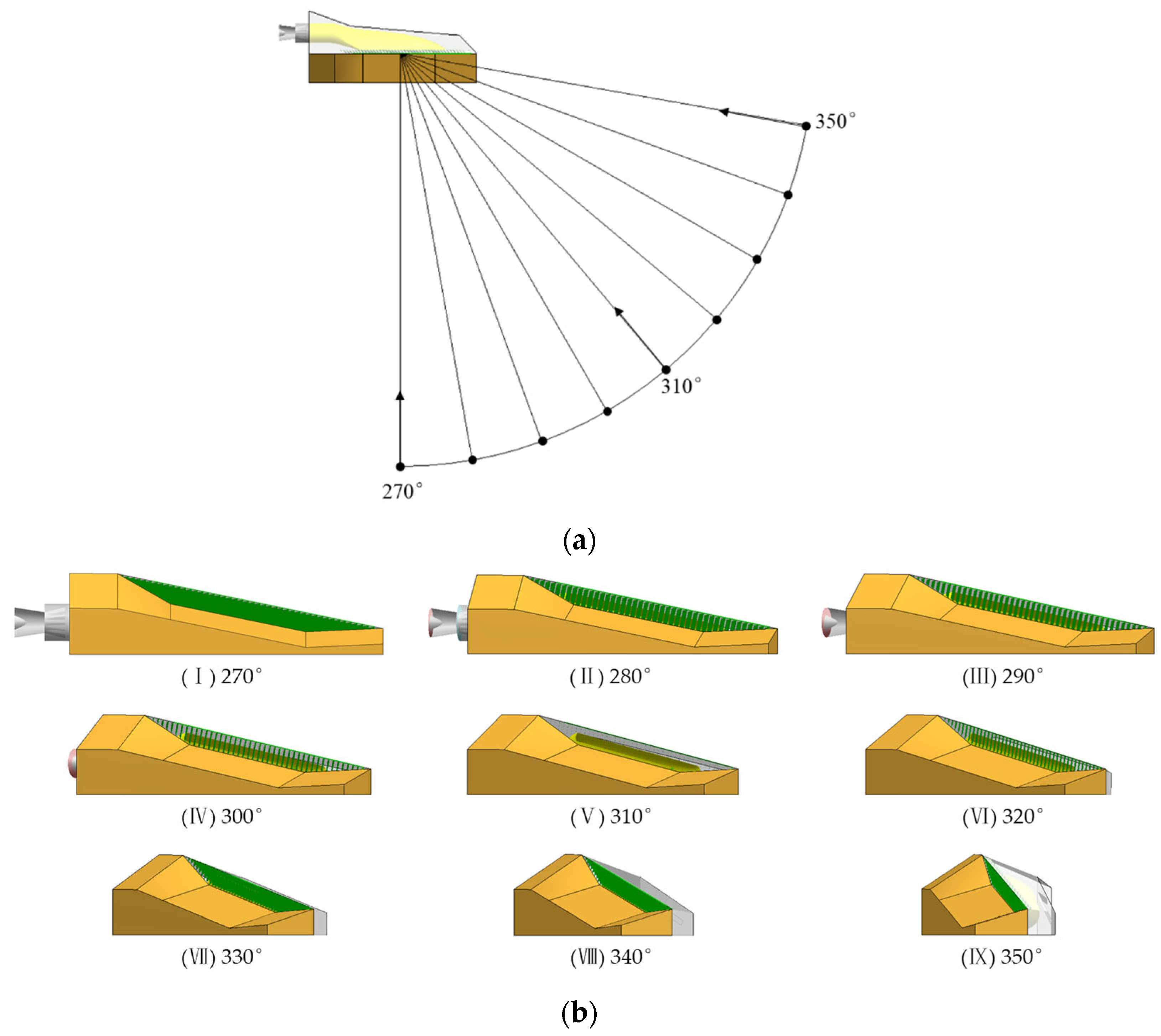

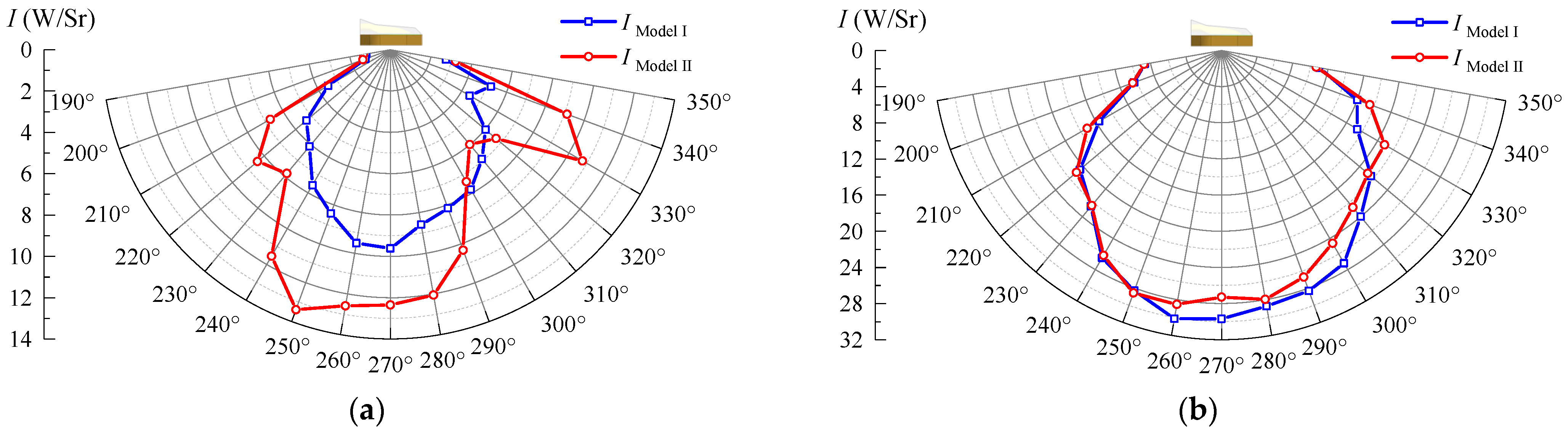

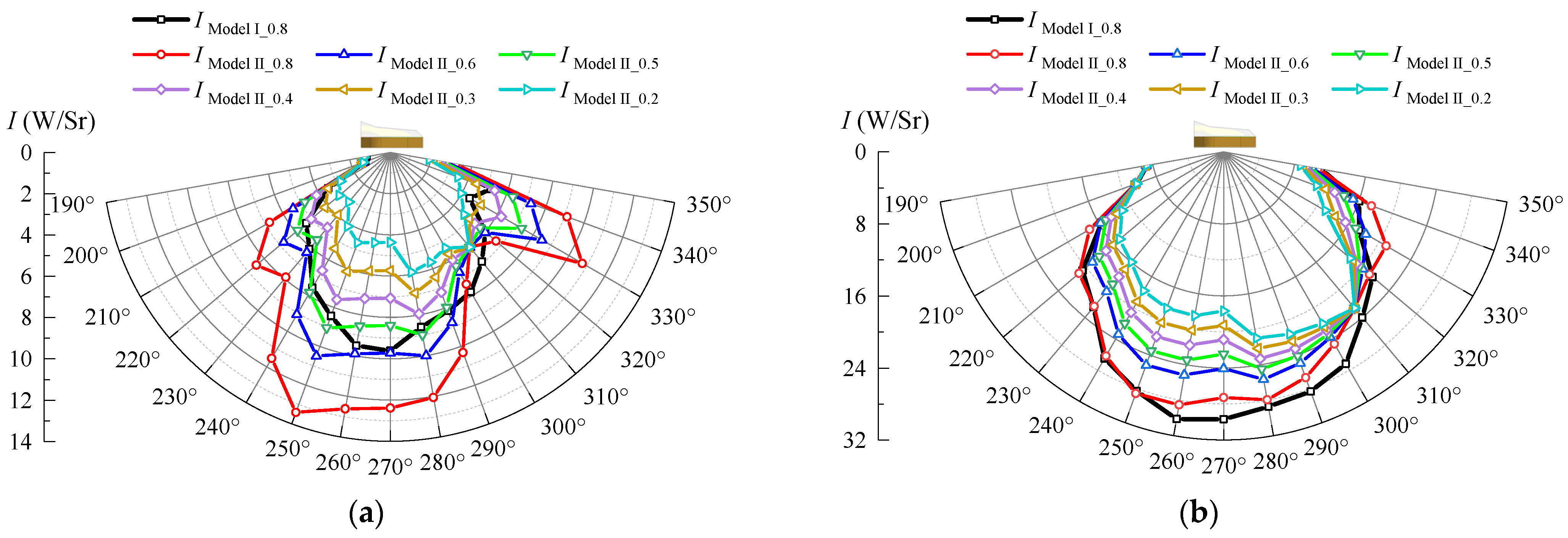

4.3. Infrared Radiation Suppression for the Exhaust Port of Fuselage

5. Conclusions

- (1)

- As the ambient temperature drops, the temperature of the fuselage surface almost drops in an equal proportion. For every 6 K reduction in the ambient temperature, the infrared radiation intensities of the helicopter in the 3–5 μm band and 8–14 μm band decrease by about 20% and 10%, respectively, indicating that the elevation of the flight altitude is beneficial to the infrared stealth of the helicopter.

- (2)

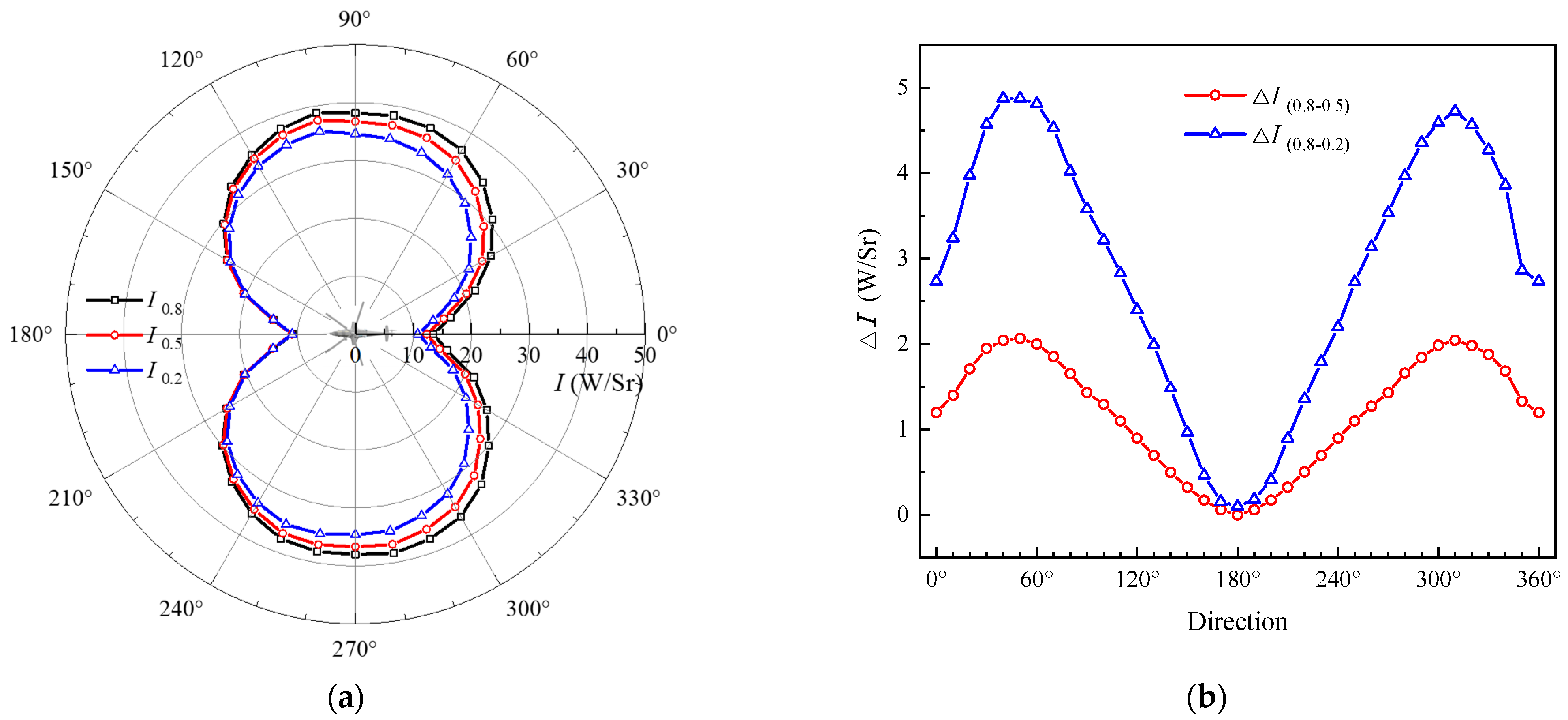

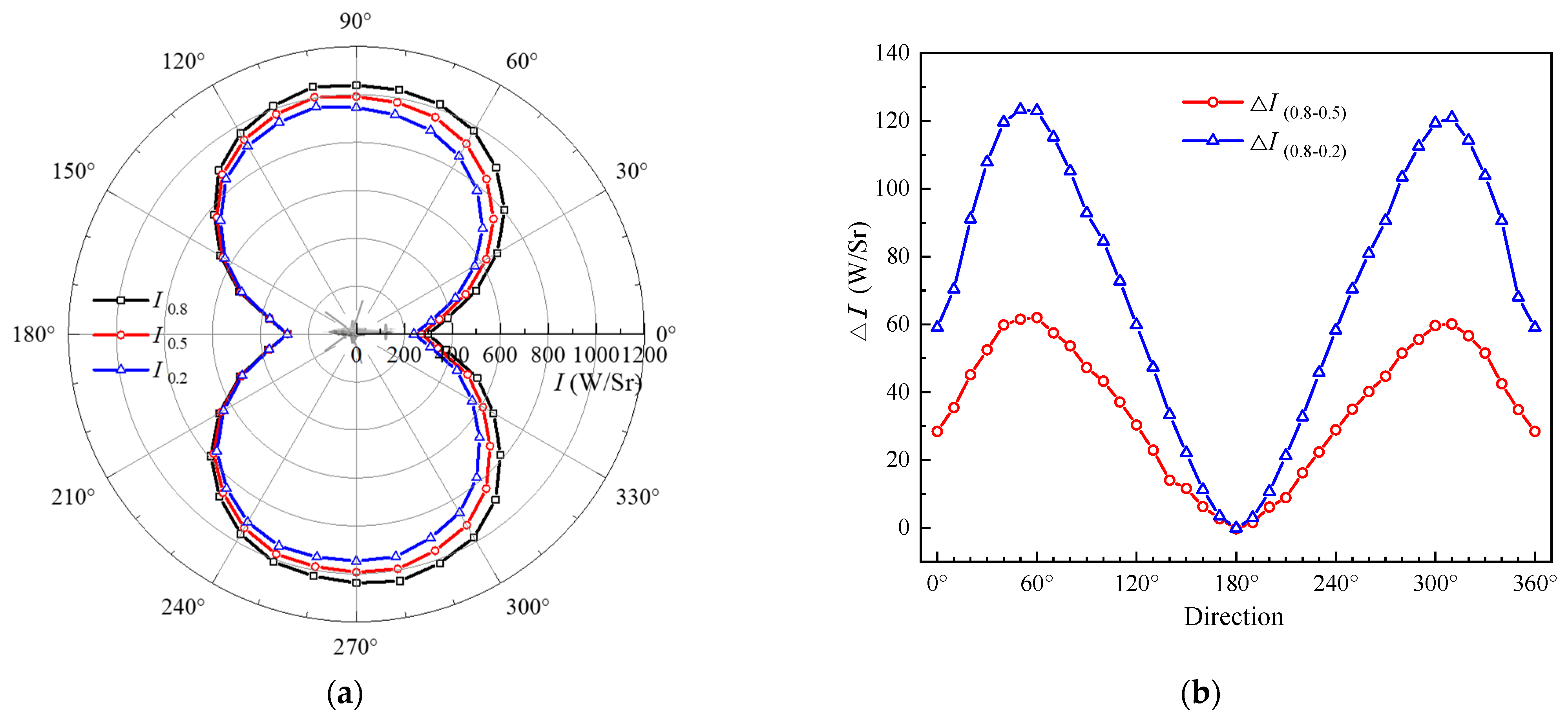

- The rear fuselage of the helicopter is exposed to thermal radiation from the mixing duct, and the temperature of the rear fuselage surface is significantly higher than the ambient temperature. Reducing the emissivity of the rear fuselage will reduce the temperature of the rear fuselage surface slightly. For every 0.3 emissivity reduction, the hot spot temperature of the rear fuselage is reduced by about 7 K. As the emissivity of the rear fuselage surface decreases from 0.8 to 0.5, the maximum infrared radiation intensity of the helicopter decreases by 2.1 W/r in the 3–5 μm band and by 62 W/Sr in the 8–14 μm band. As the emissivity of the rear fuselage surface decreases from 0.8 to 0.2, the maximum infrared radiation intensity of the helicopter decreases by 4.9 W/r in the 3–5 μm band and by 123 W/Sr in the 8–14 μm band. The suppression value of the infrared radiation intensity is directly related to the area of the rear fuselage that is observed at the detection point.

- (3)

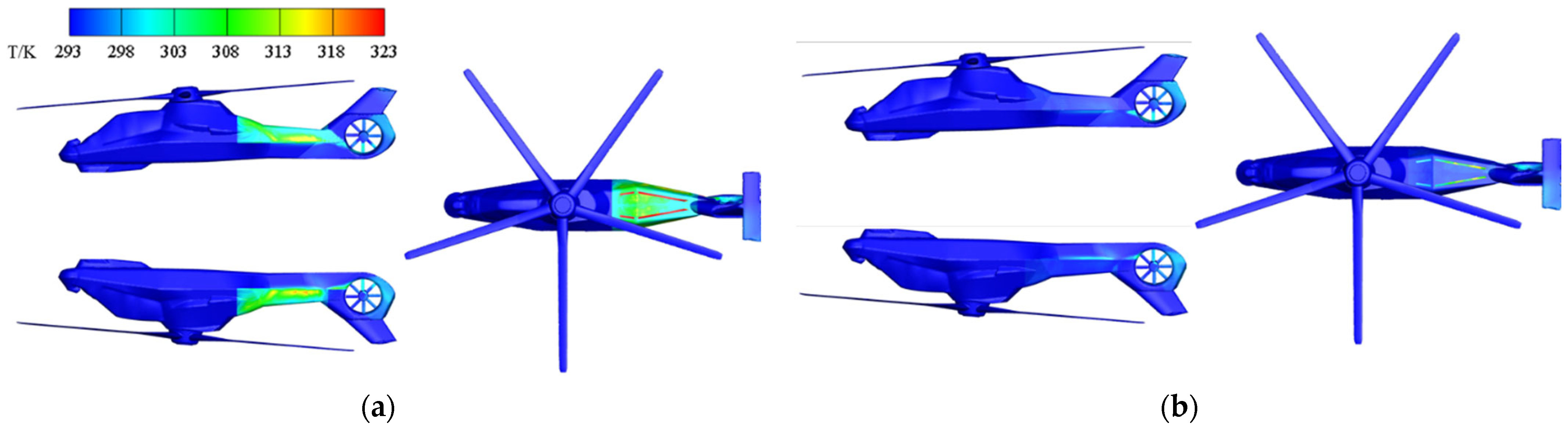

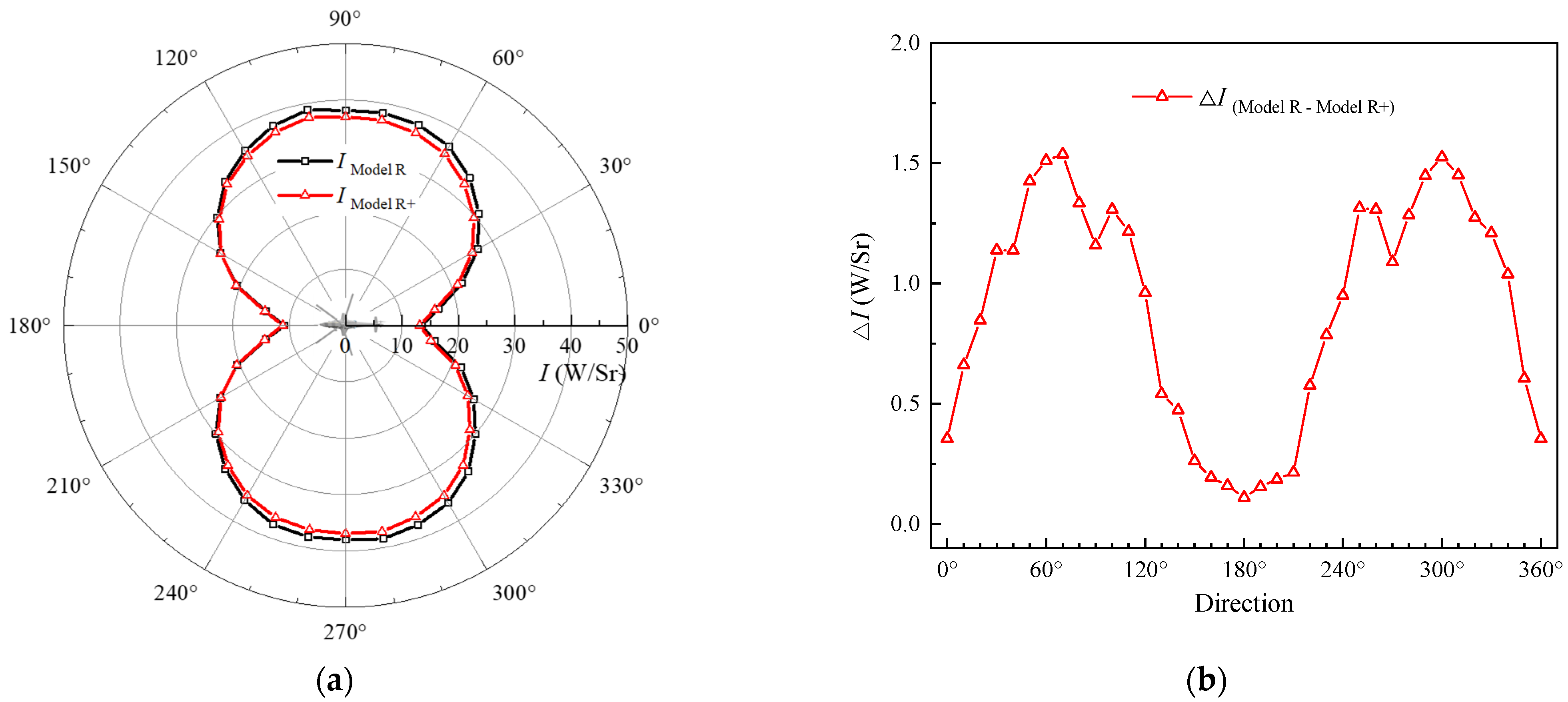

- Installing a shielding sheath for the mixing duct can also effectively restrain the thermal radiation of the high-temperature mixing duct to the rear fuselage, making the temperature of the rear fuselage surface close to the ambient temperature. The maximum reduction in the helicopter’s infrared radiation intensity is 1.5 W/Sr in the 3–5 μm band and 13 W/Sr in the 8–14 μm band. Compared to reducing the emissivity of the rear fuselage surface, installing a shielding sheath for the mixing duct has a better effect on suppressing the temperature of the rear fuselage surface, but not on suppressing the infrared radiation intensity of the helicopter.

- (4)

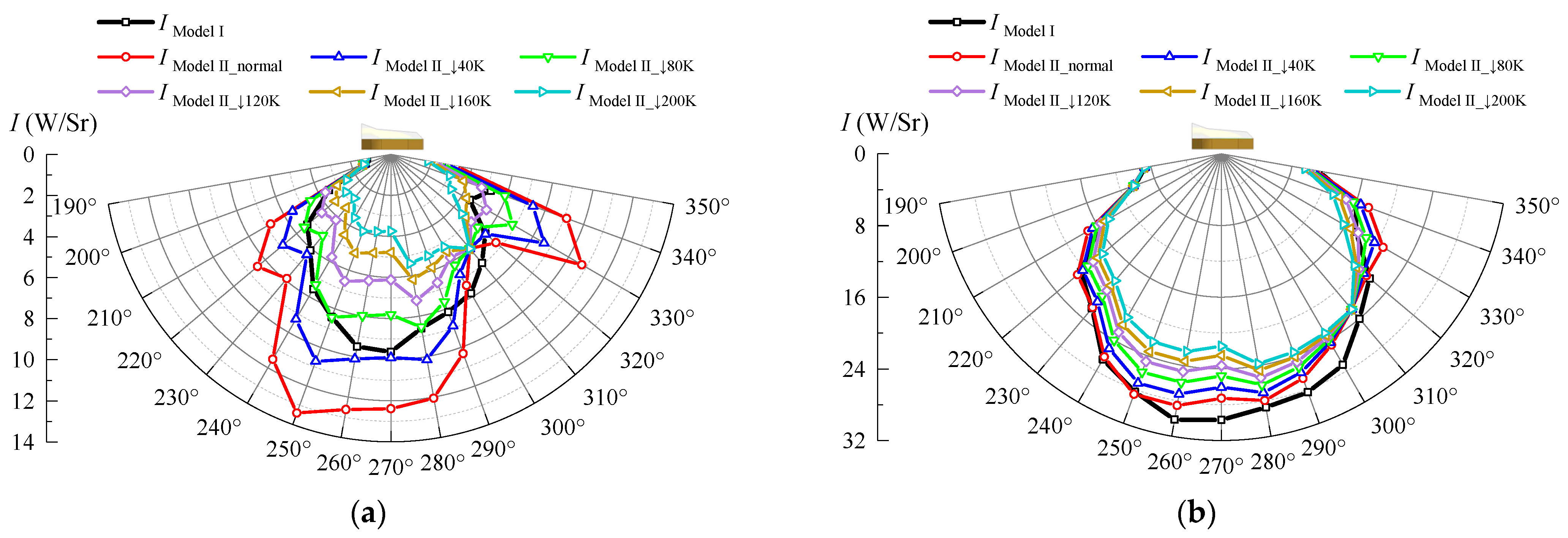

- The temperature of the helicopter’s mixing duct is higher than that of its other parts, so the detected infrared radiation intensity of the rear fuselage is in direct proportion to the detected degree of the mixing duct. The installation of deflectors at the exhaust port can prevent the detection rays from entering the interior of the rear fuselage, thus reducing the infrared radiation that is detected from the mixing duct. However, the deflectors that were heated to a higher temperature by the exhaust plume radiated a strong infrared radiation in the 3–5 μm band, resulting in the 3–5 μm band’s infrared radiation intensity in the bottom direction of Model II being about 40% greater than that of Model I. Further calculations show that, as the emissivity of the deflectors decreases from 0.8 to less than 0.5, or if the deflectors are cooled by more than 80 K, the infrared radiation at the bottom of Model II will begin to be lower than that of Model I. This specific implementation scheme of reducing the temperature of the deflectors can be carried out in a follow-up study.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, D.; Mo, B.; Zhou, J. Boost infrared moving aircraft detection performance by using fast homography estimation and dual input object detection network. Infrared Phys. Technol. 2022, 123, 104182. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, J. Mixed design of radar/infrared stealth for advanced fighter intake and exhaust system. Aerosp. Sci. Technol. 2021, 110, 106490. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, Z.; Zhou, L.; Shi, J.; Sun, X. Infrared signature of serpentine nozzle with engine swirl. Aerosp. Sci. Technol. 2019, 86, 794–804. [Google Scholar] [CrossRef]

- Andersson, K. Modeling the impact of surface emissivity on the military utility of attack aircraft. Aerosp. Sci. Technol. 2017, 65, 133–140. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, Z.; Zhou, L.; Sun, X.; Shi, J. Influences of shield ratio on the infrared signature of serpentine nozzle. Aerosp. Sci. Technol. 2017, 71, 299–311. [Google Scholar] [CrossRef]

- Mahulikar, S.P.; Sonawane, H.R.; Rao, G.A. Infrared signature studies of aerospace vehicles. Prog. Aerosp. Sci. 2007, 43, 218–245. [Google Scholar] [CrossRef]

- Vouros, S.; Goulos, I.; Pachidis, V. Integrated methodology for the prediction of helicopter rotor noise at mission level. Aerosp. Sci. Technol. 2019, 89, 136–149. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, J.; Yi, M. Comprehensive optimization of aerodynamic noise and radar stealth for helicopter rotor based on Pareto solution. Aerosp. Sci. Technol. 2018, 82–83, 607–619. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, J.; Wu, N. Acoustic and radar integrated stealth design for ducted tail rotor based on comprehensive optimization method. Aerosp. Sci. Technol. 2019, 92, 244–257. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, J.; Wang, J. Compound helicopter multi-rotor dynamic radar cross section response analysis. Aerosp. Sci. Technol. 2020, 105, 106047. [Google Scholar] [CrossRef]

- Kanclebo, S.W. Boeing Silorsky findings underscore RAH-66 stealth. Aviat. Week Space Technol. 1993, 139, 22–23. [Google Scholar]

- Sun, Z.H.; Zuo, L.H.; Wang, X.W.; Liu, Q. Research on infrared stealth technology of helicopter. Helicopter Technol. 2006, 2, 19–24. [Google Scholar]

- Tang, Z.F.; Zhang, J.Z.; Shan, Y. Investigation on ejecting and mixing characteristics of lobed nozzle with curved mixing duct and slot exit. J. Aerosp. Power 2005, 20, 978–982. [Google Scholar]

- Tang, Z.F.; Zhang, J.Z.; Wang, X.W.; Liu, Q. Experimental research on infrared suppressor integrating the exhaust system with the tail part of a helicopter. J. Aerosp. Power 2007, 22, 233–237. [Google Scholar]

- Ren, L.; Zhang, J.; Wang, X.; Shan, Y. Analysis of stealth properties on IR radiation suppressor embed inside helicopter rear airframe. Infrared Laser Eng. 2011, 40, 2091–2097. [Google Scholar]

- Pan, C.X.; Zhang, J.Z.; Shan, Y. Effects of exhaust temperature on helicopter infrared signature. Appl. Therm. Eng. 2013, 51, 529–538. [Google Scholar]

- Zhou, Z.; Huang, J.; Wang, J. Radar/infrared integrated stealth optimization design of helicopter engine intake and exhaust system. Aerosp. Sci. Technol. 2019, 95, 105483. [Google Scholar] [CrossRef]

- Jiang, K.H.; Zhang, J.Z.; Shan, Y. Effects of sheltering and outlet shaping on surface-temperature and infrared radiation of rear airframe with an integrating IR suppressor. Acta Aeronaut. Astronaut. Sin. 2020, 41, 152–162. [Google Scholar]

- Sheng, Z.Q.; Liu, J.Y.; Yao, Y.; Xu, Y.H. Mechanisms of lobed jet mixing: About circularly alternating-lobe mixers. Aerosp. Sci. Technol. 2020, 98, 105660. [Google Scholar] [CrossRef]

- Sheng, Z.; Dan, Y.; Zhang, L.; Zhong, B. Jet Mixings of Alternating-Lobe Nozzles under Pumping Air Intake and Stamping Air Intake Conditions. Aerospace 2022, 9, 700. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zhang, J.Z.; Shan, Y. Effects of slot-inlet arrangement at IR-suppressor-integrated rear air-frame on flow organization and infrared radiation characteristics. Acta Aeronaut. Astronaut. Sin. 2021, 42, 135–147. [Google Scholar]

- Yang, Z.; Zhang, J.; Shan, Y. Effects of forward-flight speed on plume flow and infrared radiation of IRS-integrating helicopter. Chin. J. Aeronaut. 2022, 35, 155–168. [Google Scholar]

- Yang, Z.; Zhang, J.; Shan, Y. Research on the influence of integrated infrared suppressor exhaust angle on exhaust plume and helicopter infrared radiation. Aerosp. Sci. Technol. 2021, 118, 107013. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Shan, Y. Research on the suppression of exhaust plume infrared and jet noise of large aspect ratio curved mixing duct. Acta Aeronaut. Astronaut. Sin. 2023, 44, 126848. [Google Scholar]

- Pinto, R.N.; Afzal, A.; D’Souza, L.V.; Ansari, Z.; Mohammed Samee, A. Computational fluid dynamics in turbomachinery: A review of state of the art. Arch. Comput. Methods Eng. 2017, 24, 467–479. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, J.; Yong, S. Modeling and analysis of helicopter thermal and infrared radiation. Chin. J. Aeronaut. 2011, 24, 558–567. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Xuan, Y. The influence of helicopter rotor-fuselage flow interaction on temperature fields in forward flight. Appl. Therm. Eng. 2017, 116, 488–499. [Google Scholar] [CrossRef]

- Liu, P.Q. Theory and Application of Air Propeller; Beijing University of Aeronautics and Astronautics Press: Beijing, China, 2006; pp. 35–36. [Google Scholar]

- Chuiton, F.L. Actuator disc modelling for helicopter rotors. Aerosp. Sci. Technol. 2004, 8, 285–297. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, W.; Qi, L.; Yuan, L.; Huang, G.; Huang, Y.; Weng, X. The High-Temperature Resistance Properties of Polysiloxane/Al Coatings with Low Infrared Emissivity. Coatings 2018, 8, 125. [Google Scholar] [CrossRef]

| Specific Parts | Parameters | Value |

|---|---|---|

| Body | Length | 12.8 (m) |

| Width | 2.10 (m) | |

| Height | 2.90 (m) | |

| Main rotor diameter | 13.9 (m) | |

| Tail diameter | 1.45 (m) | |

| Rear fuselage | Front inlet length | 0.64 (m) |

| Front inlet width | 0.075 (m) | |

| Rear inlet length | 2.10 (m) | |

| Rear inlet width | 0.075 (m) | |

| Outlet length | 2.30 (m) | |

| Outlet width | 0.23 (m) | |

| Lobe ejector | Inlet diameter | 0.27 (m) |

| Outlet diameter | 0.40 (m) | |

| Expansion angle | 24.5° | |

| Number of lobes | 12 | |

| Mixing duct | Length | 3.67 (m) |

| Inlet diameter | 0.048 (m) | |

| Outlet length | 2.1 (m) | |

| Outlet width | 0.11 (m) |

| Node Numbers (106) | Pumping Coefficient | Infrared Radiation Intensity (W/Sr) |

|---|---|---|

| 16.5 | 0.856 | 118.6 |

| 18.3 | 0.823 | 121.6 |

| 21.6 | 0.817 | 122.5 |

| 28.7 | 0.814 | 122.8 |

| Parameter | Model R | Model R+ | |

|---|---|---|---|

| Pumping coefficient | left | 0.82 | 0.83 |

| right | 0.79 | 0.81 | |

| Secondary pumping coefficient | left | 0 | 0.41 |

| right | 0 | 0.39 | |

| Exhaust temperature (K) | left | 596.43 | 594.61 |

| right | 600.09 | 599.26 | |

| Model | I | II |

|---|---|---|

| Pumping coefficient | 0.604 | 0.478 |

| Average exhaust temperature (K) | 632 | 667 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Zhang, J.; Shan, Y. Research on the Infrared Radiation Suppression of the High-Temperature Components of the Helicopter with an Integrated Infrared Suppressor. Aerospace 2023, 10, 351. https://doi.org/10.3390/aerospace10040351

Yang Z, Zhang J, Shan Y. Research on the Infrared Radiation Suppression of the High-Temperature Components of the Helicopter with an Integrated Infrared Suppressor. Aerospace. 2023; 10(4):351. https://doi.org/10.3390/aerospace10040351

Chicago/Turabian StyleYang, Zongyao, Jingzhou Zhang, and Yong Shan. 2023. "Research on the Infrared Radiation Suppression of the High-Temperature Components of the Helicopter with an Integrated Infrared Suppressor" Aerospace 10, no. 4: 351. https://doi.org/10.3390/aerospace10040351

APA StyleYang, Z., Zhang, J., & Shan, Y. (2023). Research on the Infrared Radiation Suppression of the High-Temperature Components of the Helicopter with an Integrated Infrared Suppressor. Aerospace, 10(4), 351. https://doi.org/10.3390/aerospace10040351