1. Introduction

Over the past decades, the airline industry and, particularly, commercial aviation has been vastly expanding, rendering flight an indispensable means of transportation around the globe in our modern societies. This trend is expected to carry on in the foreseeable future, as indicated by the latest predictions made by the two main shareholders of commercial aviation, namely, Airbus and Boeing. In particular, in its commercial market outlook [

1], Airbus foresees an 4.3% annual air-traffic growth by means of the Revenue Passenger Kilometer (RPK) index, over the next 20 years. Similarly, Boeing also envisages, via the “Commercial Market Outlook, 2021–2040” [

2], a 4% worldwide RPK growth rate, calculated from years 2019 to 2040. Despite the facilitation of transportation and the associated stimulation of the global economies, the current and forthcoming air-traffic proliferation has severe ramifications and impacts on the environment. The emission of greenhouse gases, mainly in terms of carbon dioxides (CO

2) and nitrogen oxides (NOx), and their corresponding concentrations in the atmosphere is expected to be exacerbated, possibly leading to the constitution and dissemination of severe public-health-related threats. To that end, and as a remedy, the European Commission envisages, through the definition of ACARE FlightPath 2050 [

3] among others, a reduction by 75% in CO

2 emissions and by 90% in NOx, per passenger km, for future commercial transport aircrafts. A key enabler for this effort, allowing for around 20% to 25% reduction in the aforementioned quantities, is the introduction of novel, more efficient airframe designs with improved aerodynamic and structural characteristics. From an aerodynamics point of view, the aerodynamic efficiency of an aircraft is closely related to the aspect ratio of the wings, with higher aspect ratios reducing the induced drag force and increasing the lift-to-drag ratio, which, in turn, enhances fuel efficiency. Therefore, an increasing trend in the aspect ratio of commercial aircraft wings over the past decades is observed [

4], with current efforts endeavoring to further push design envelopes.

The nature and elevated complexity of the aforementioned aircraft design novelties, introduced by the aerodynamics and structures disciplines, pose serious challenges to the scientific community, rendering the design of air vehicles a matter of increasingly extensive research studies. One of the most prominent and challenging phenomenon emanates from the increase in aspect ratio and the accompanied elevated flexibility of the wing which, on one hand, induces a closer coupling between the structure and the surrounding fluid, aggravating static and dynamic aeroelastic phenomena. Additionally, the ever-increasing use of composite materials [

5] complicates the design optimization procedure by vastly increasing the design space via the introduction of new variables such as ply thickness and ply orientation. As a result, the development and embodiment, in a typical aircraft design process, of novel design methodologies and computational tools capable of capturing and predicting the whole spectrum of phenomena inherent to this new generation of structures, as well as producing optimum configurations, is of paramount importance. Furthermore, the aforementioned set of tools should ideally include certain attractive characteristics such as low computational time along with high levels of accuracy, in order to efficiently drive the design process towards optimal configurations. Since this often constitutes a utopian scheme, a vast variety of multi-fidelity tools, each achieving different levels of accuracy, efficiency and ability to capture the physical phenomena present, has emerged and is typically designated at each design stage. Commonly, a three-stage design process spans the development of an aircraft, namely, the conceptual, the preliminary and the detailed [

6]. Over the course of time, multi-fidelity computational tools, with application in a plethora of analysis disciplines, have been designated to a corresponding design stage mainly based on their attributes, as stated earlier. In the early design stages, one enjoys immense design freedom, albeit counterbalanced by little-to-no design knowledge. Low-fidelity computational tools along with statistical models and empirical knowledge are, therefore, preferred due to their fast modeling and turnaround times, even though they typically suffer from limiting accuracy and ability to capture higher order phenomena and nonlinearities. As the design process and knowledge on the current candidate configuration matures, higher fidelity tools which can replicate and resolve the complex phenomena that might be present with greater accuracy come into play in exchange for increased and occasionally prohibitive computational cost. In these stages, the design freedom is highly restricted, and any design alteration could induce severe cost penalties. As a result, and since also historically the majority of the design effort is put into the conceptual and preliminary design phases [

7] and any design change between phases could be costly, the accuracy of low- and medium-fidelity models is usually sought to be to be enhanced and further exploited. In this manner, design-space exploration is reinforced by alleviating the computational burden, steering the design process towards optimality and, in general, towards a better and more reliable decision-making process by providing a wider understanding of a candidate design. Finally, yet importantly, and throughout the design stages, all relevant tools are coupled with optimization algorithms in order to gain further knowledge regarding the design space, as well as to obtain the corresponding optimum solution with respect to the objective functions set.

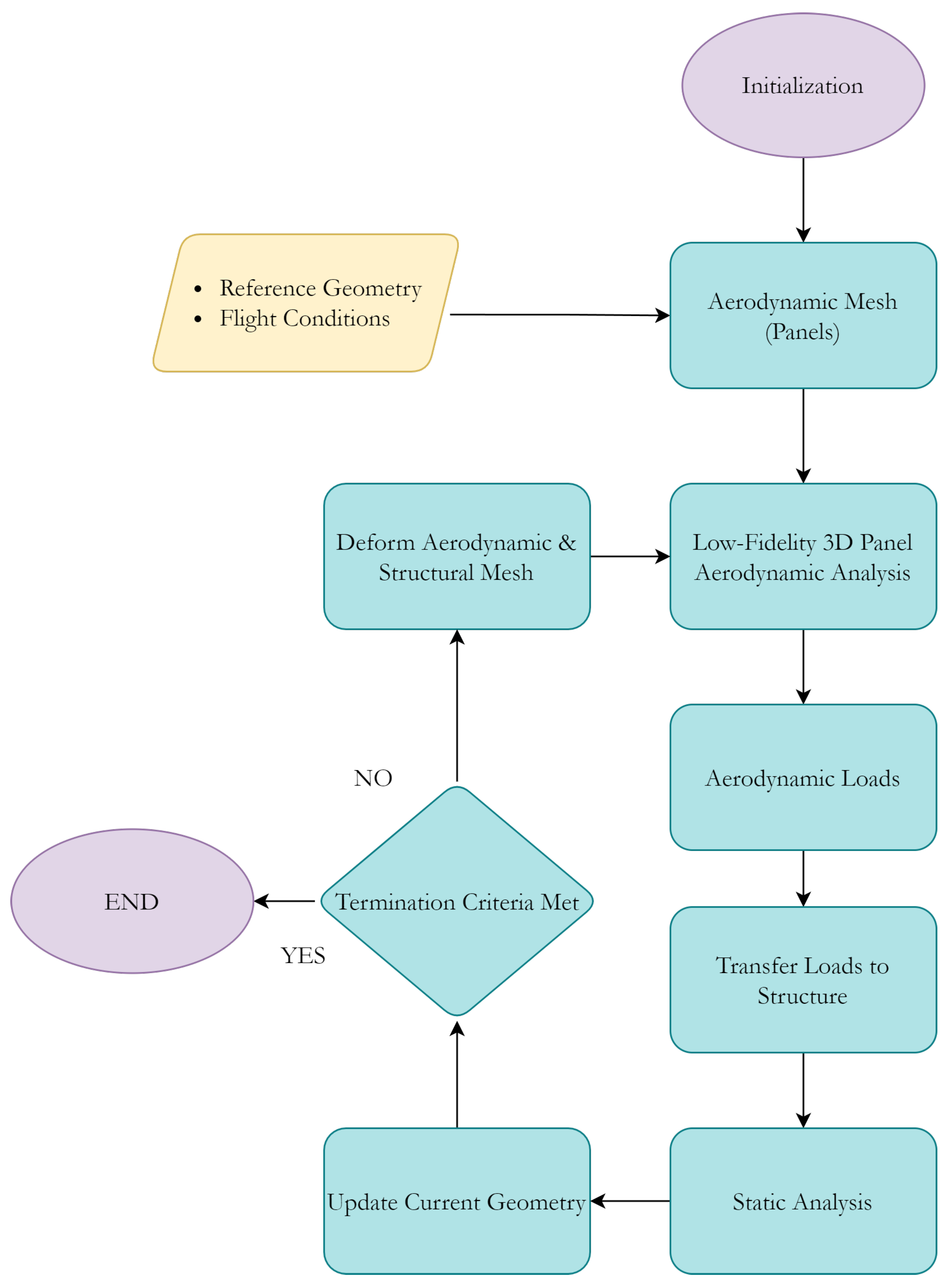

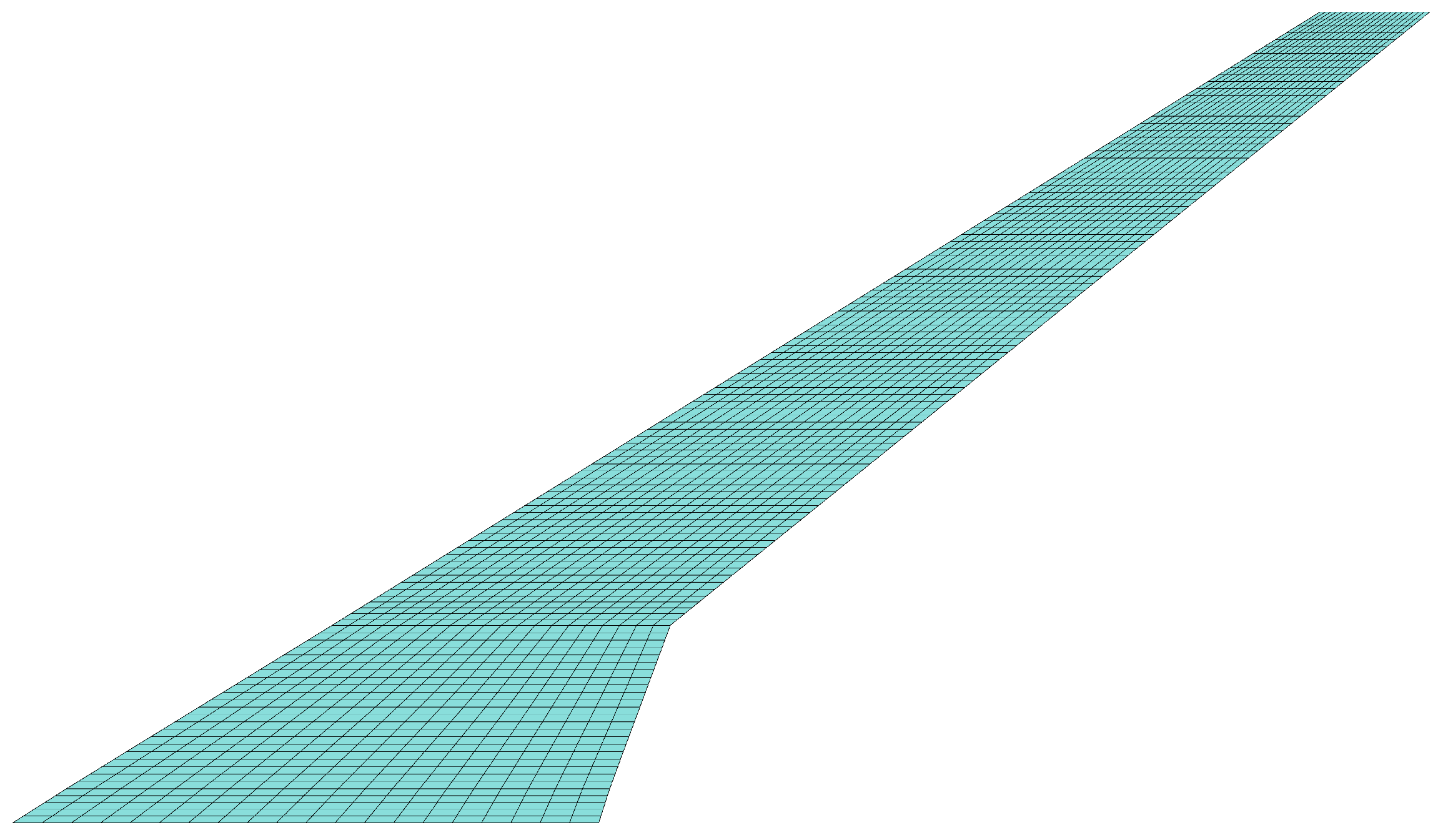

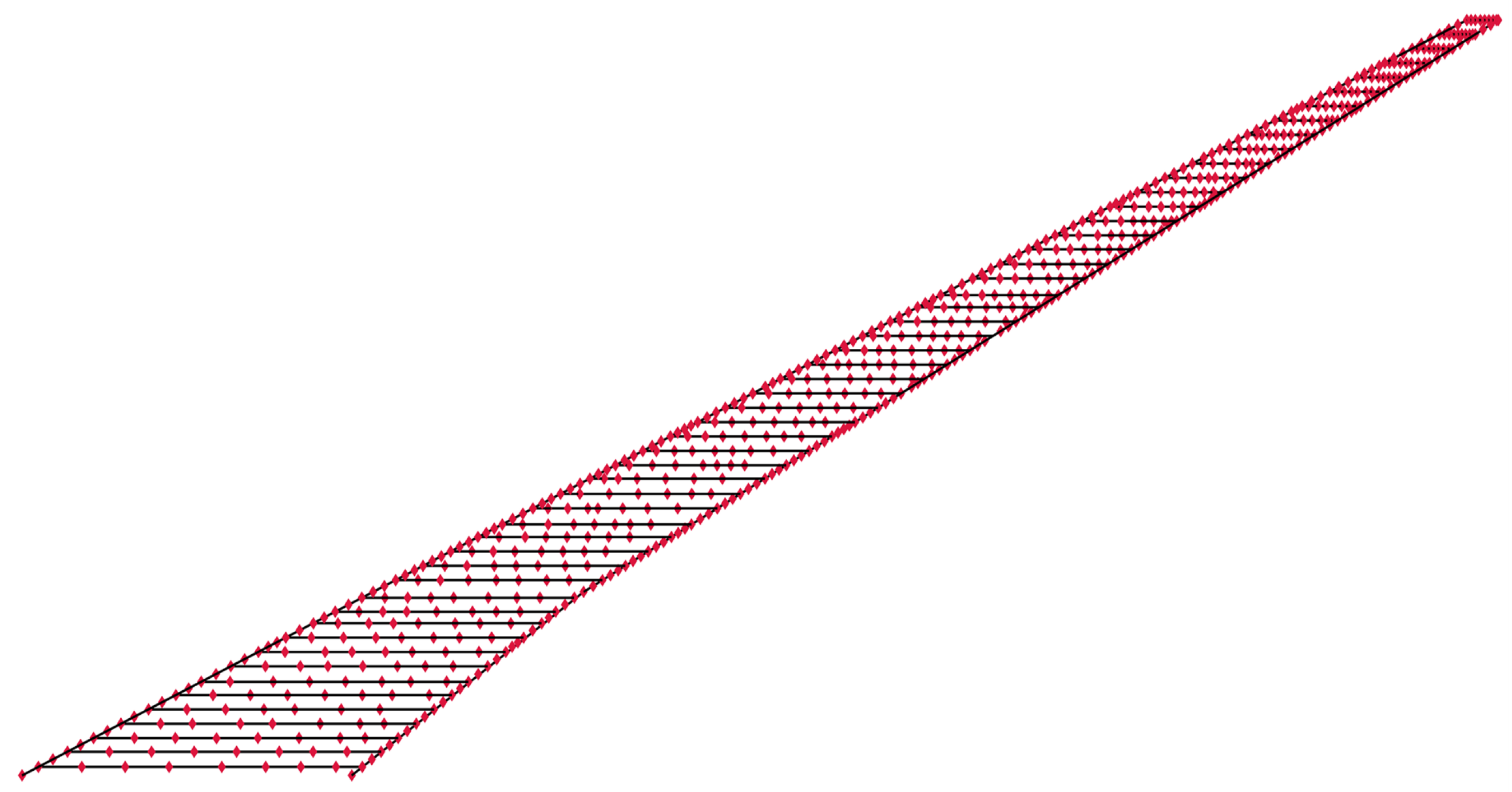

In terms of low-fidelity models, typically planar panel methods such as the vortex lattice method (VLM) and the doublet lattice method (DLM) are introduced for aerodynamics and are coupled with reduced-order or finite element method (FEM) models of the structure [

8,

9,

10,

11]. The inclusion of aeroelastic effects via fluid-structure interaction (FSI) techniques is also conducted at this level of fidelity [

12,

13], but it typically occurs in high-fidelity solvers, employing Euler or Reynolds-averaged Navier–Stokes (RANS) [

14,

15,

16]. Serious challenges arise, nevertheless, from the realization of such algorithms, the main culprits being the possible deterioration of the aerodynamic mesh quality upon structural deformation, an effect which is exacerbated for high-aspect-ratio wings, as well as the elevated computational time. For the latter, inclusion in optimization algorithms constitutes an active research area, due to the complex nature of the problem [

17,

18,

19].

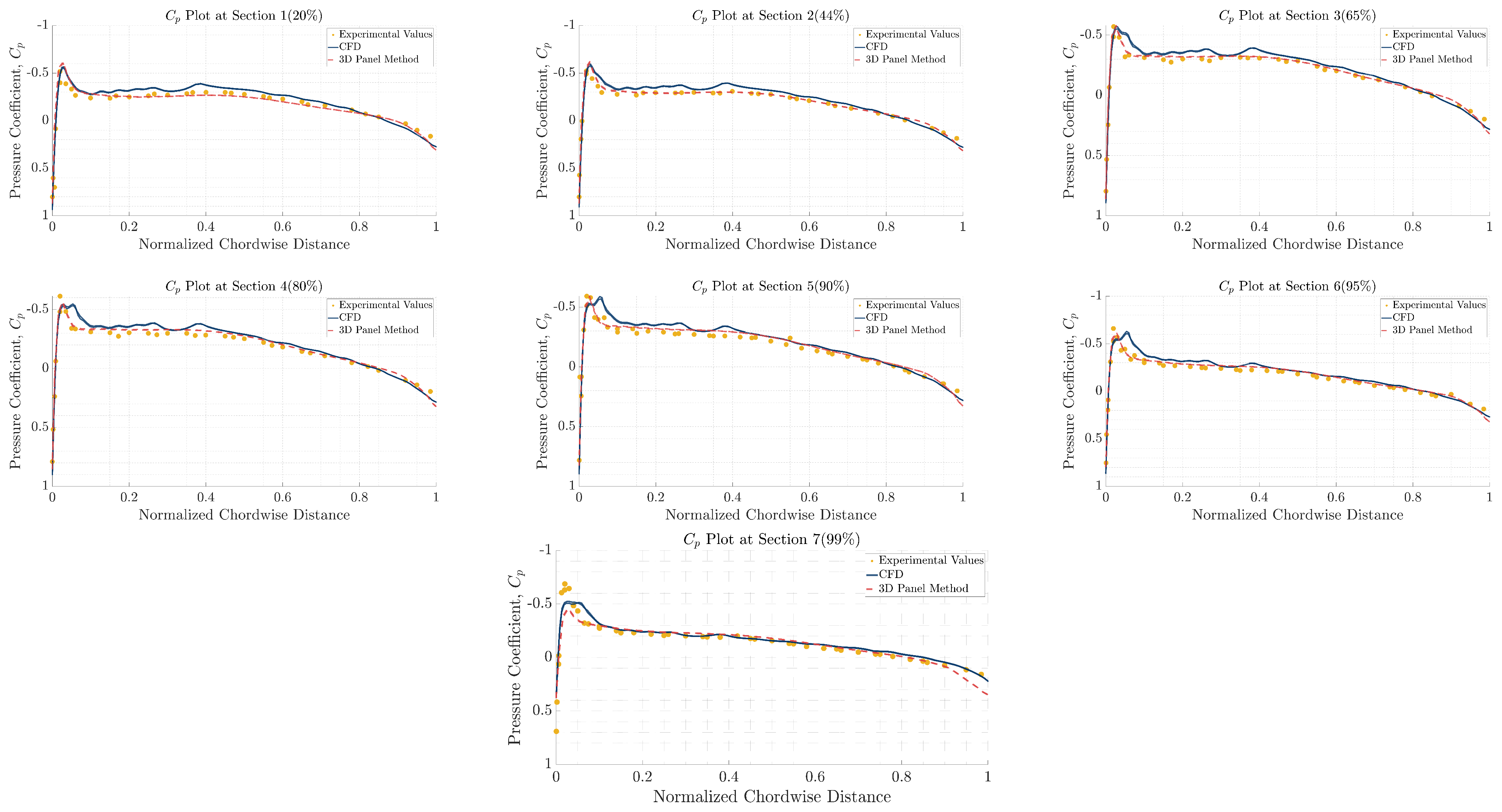

Comparison among the low and high-fidelity models was conducted in terms of aerodynamic loads, flutter and divergence limit speed in [

15,

20]. Despite the inability to accurately capture instabilities that typically occur in the transonic regime, e.g., transonic dip [

21], the steady-state static aeroelastic response of a contemporary airliner wing as predicted by 3D panel methods was in excellent agreement with high-fidelity Euler and RANS solutions, even at the transonic regime [

22]. In [

23], significant changes in the required angle of attack to attain the targeted lift load for a modified CRM wing were obtained by the inclusion of high-fidelity aerodynamics. Nevertheless, for rigid aerodynamics, no significant mass changes were noticed following a single-pass structural optimization stage, implying the correct representation of the lift load.

Even for low-fidelity models, the inclusion of static aeroelastic effects in optimization frameworks, able to reflect on the influence of the design parameters and changes in the final design, often render the numerical optimization tedious in terms of computational cost. The black-box nature of the objective and constraint functions also complicates the evaluation of gradients and, as a result, the use of gradient-based optimization algorithms. Furthermore, gradient-free algorithms may suffer from slow convergence and lack of a true optimum solution, as mentioned in the previous section [

24]. As a result, the optimum is sought via relatively fast mathematical techniques to approximate the underlying objective function, aiming at achieving a good trade off between accuracy and computational speed as well as between the global and local exploration of the design space. To that end, surrogate modeling techniques [

25,

26] have started to draw the attention of the scientific and engineering communities. Such techniques can be used solely for approximations of the underlying functions as well as being cast into surrogate-based optimization (SBO) frameworks, which adopt updated techniques in order to enhance the accuracy of the model and guide the optimization towards the global optimum [

27,

28,

29,

30]. Neural networks, radial basis functions (RBF), Kriging and support vector regression (SVE) constitute typical approaches toward surrogate models.

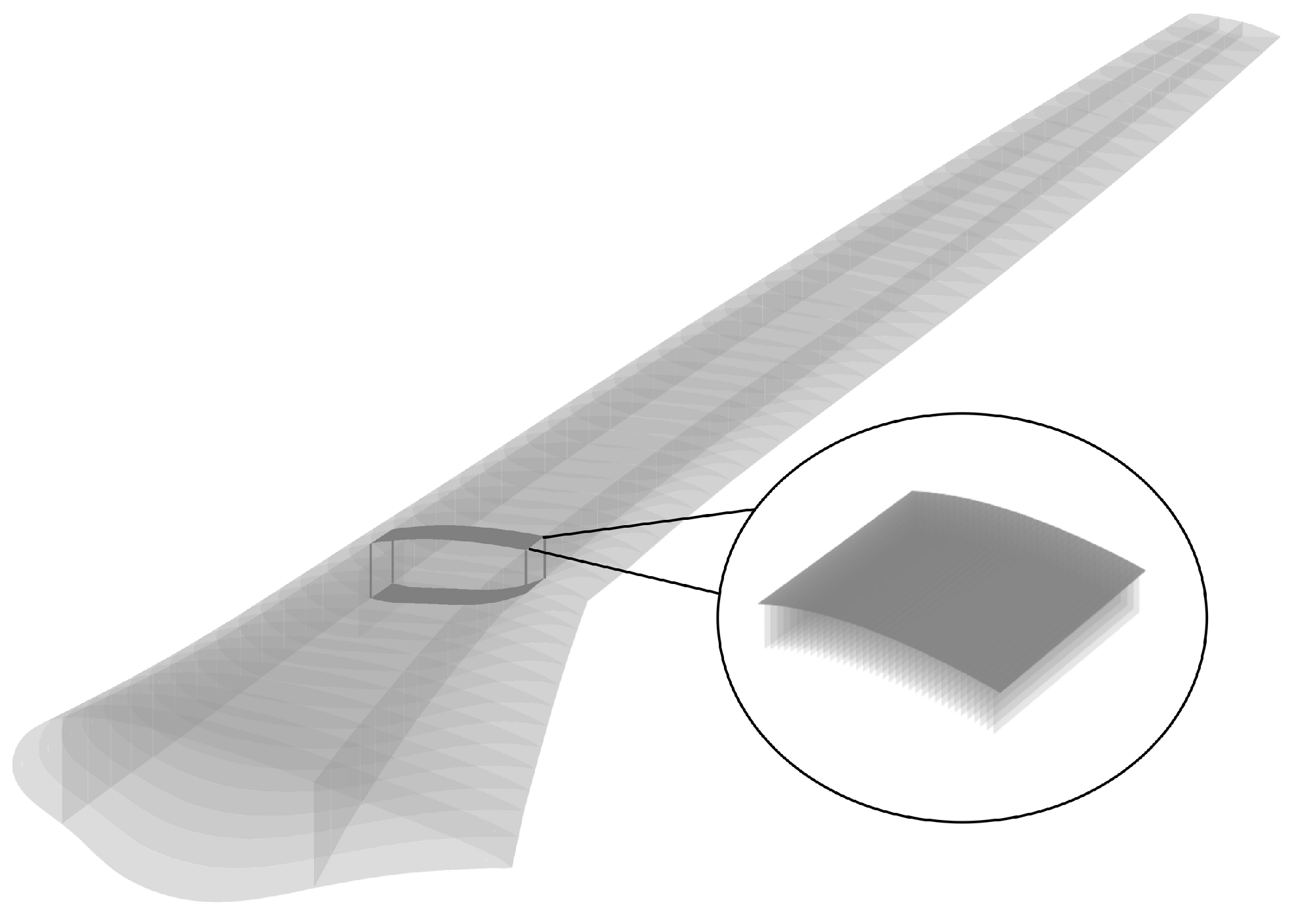

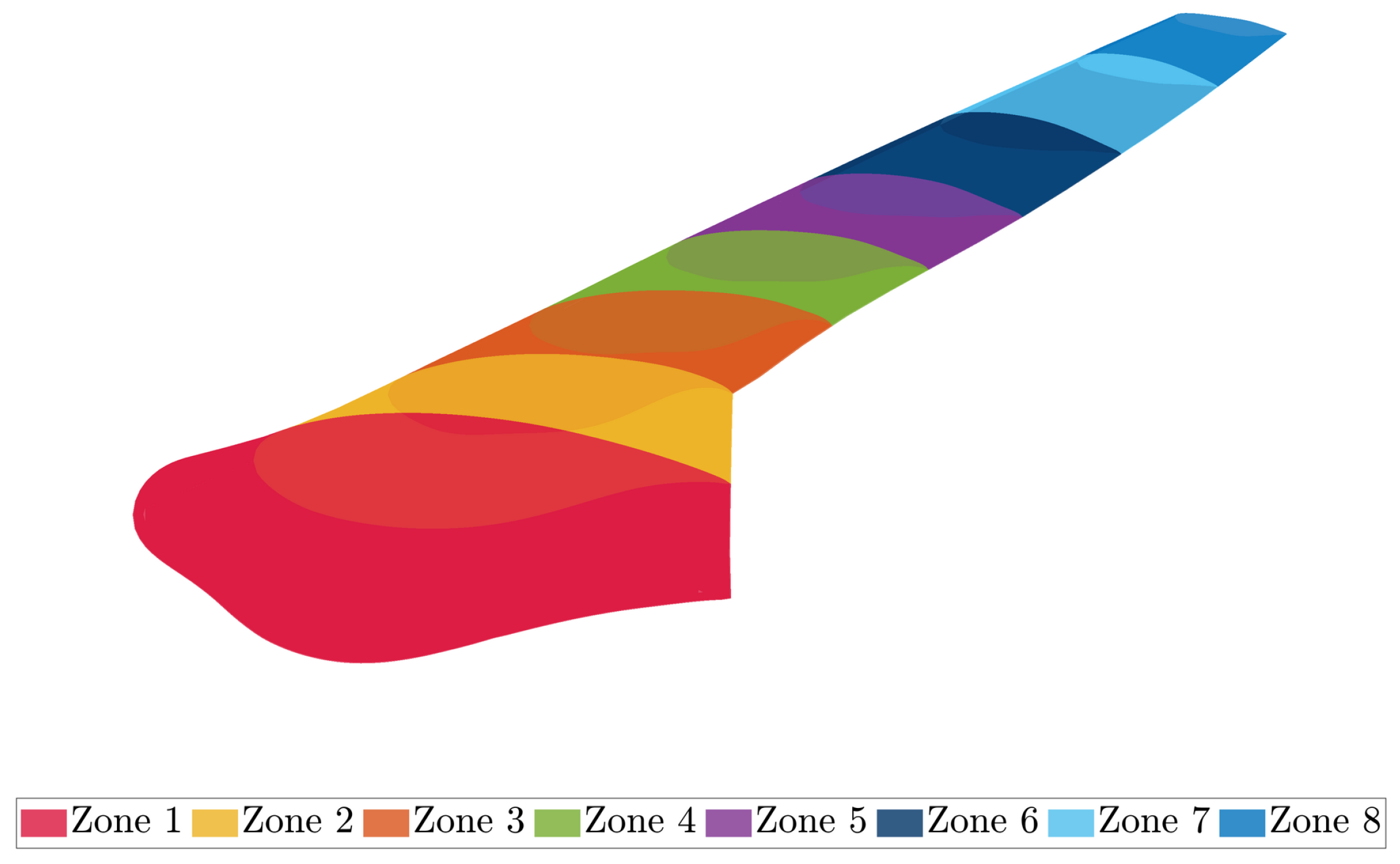

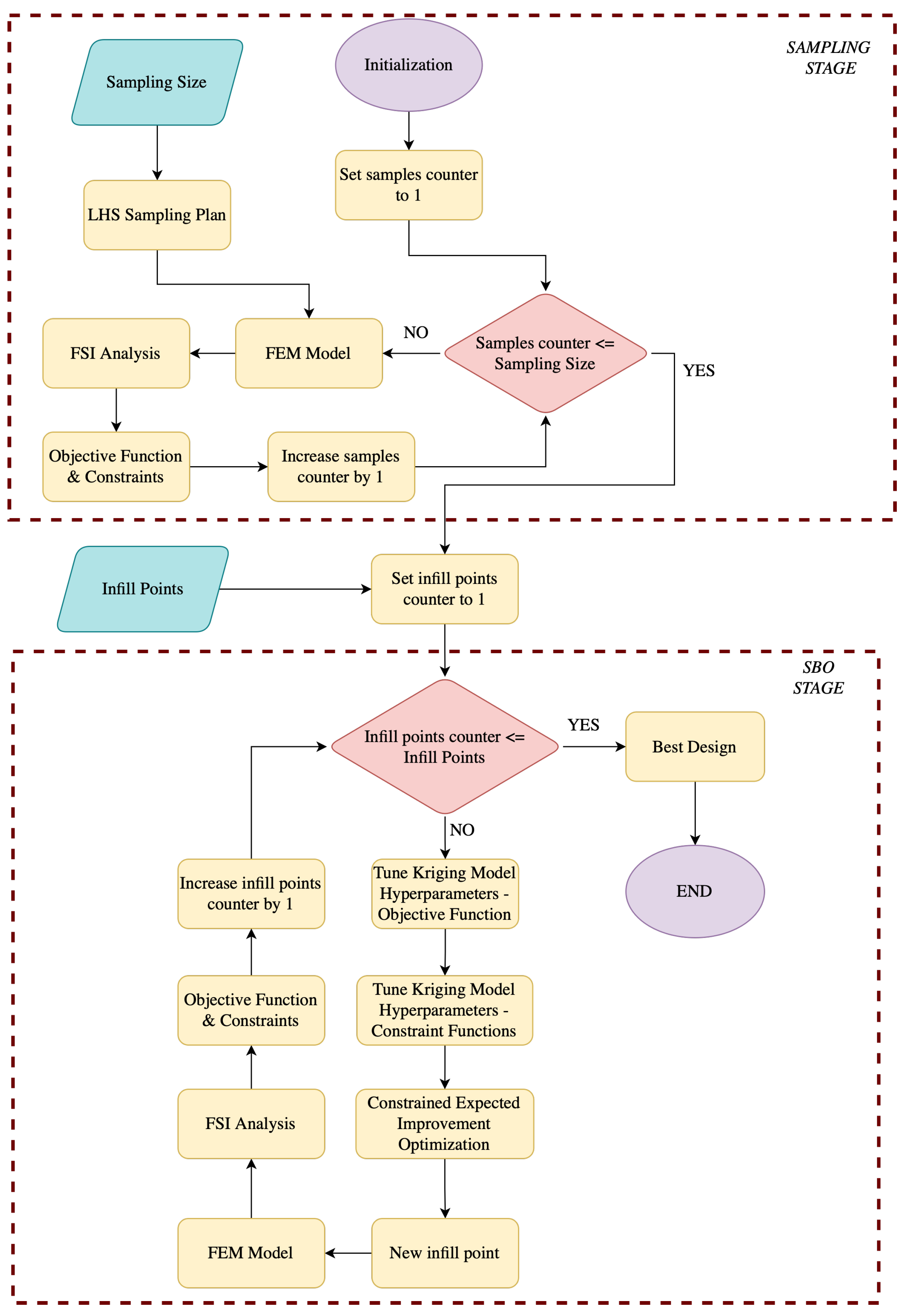

Despite the omnipresence of low-fidelity optimization frameworks, studies of optimization frameworks including static aeroelastic effects for composite-material high-aspect-ratio wings are rarely documented in the literature. This knowledge gap is aggravated when examining embodiment of such tools in SBO frameworks. Aiming to address this issue, this research study provides an efficient structural SBO framework of a high-aspect-ratio composite-materials aircraft wing subject to local panel buckling and strength and flutter constraints. The present study focuses on the development of an in-house SBO optimization technique, encapsulating a low-fidelity steady-state FSI scheme based on a 3D panel method for the sizing of a reference wing. This framework allows, on the one hand, for reductions in terms of computational costs during the optimization process in the preliminary design stages, while, in parallel, accounting for the effect of the elasticity on the structural response, which is of paramount importance to this generation of structures. The structure is parametrized in terms of the thickness of the structural members involved, with the minimization of the structural mass of the wing being set as the objective function. Design-strength, panel-buckling and flutter-instability constraints formulate the optimization problem. Overall, the applicability of the developed SBO framework to novel composite-materials aircraft wings constitutes a step towards more sophisticated and holistic numerical tools for the conceptual and preliminary design stages.

4. Discussion and Conclusions

In the present work, an in-house, steady-state static aeroelastic sizing framework utilizing surrogate modeling techniques was developed for a novel composite high-aspect-ratio wing. The various techniques that were used herein are thoroughly described in the Materials and Methods section.

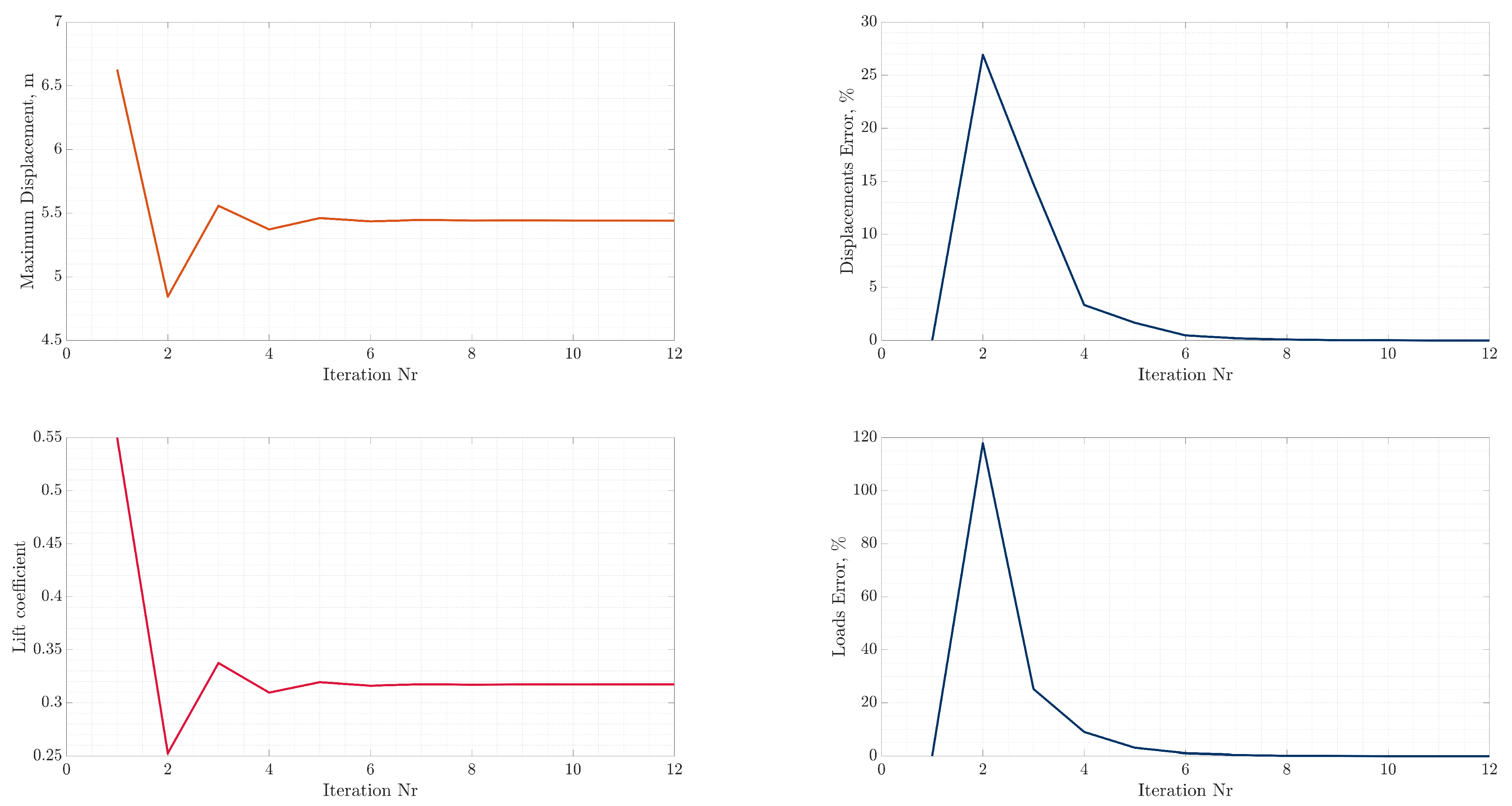

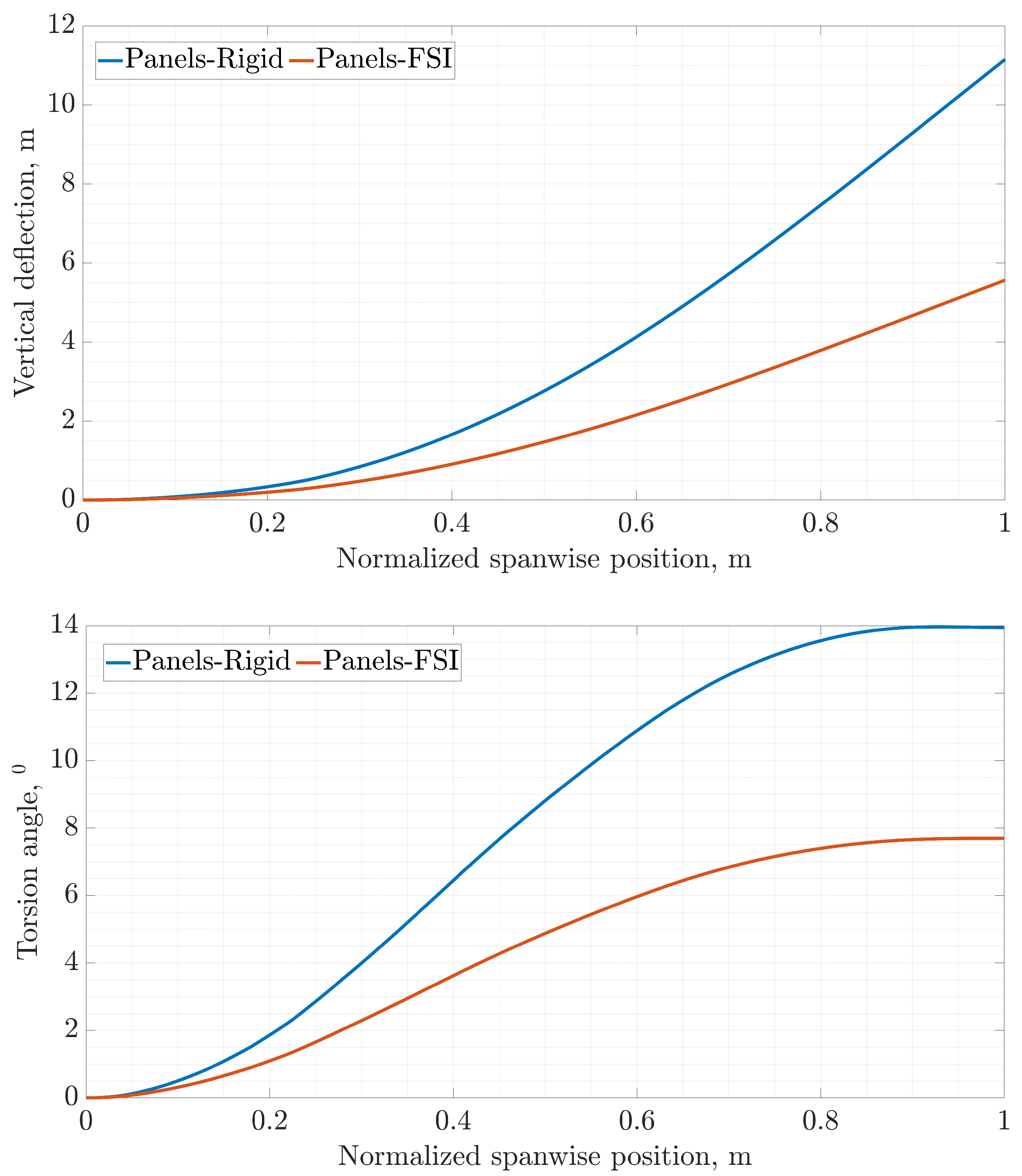

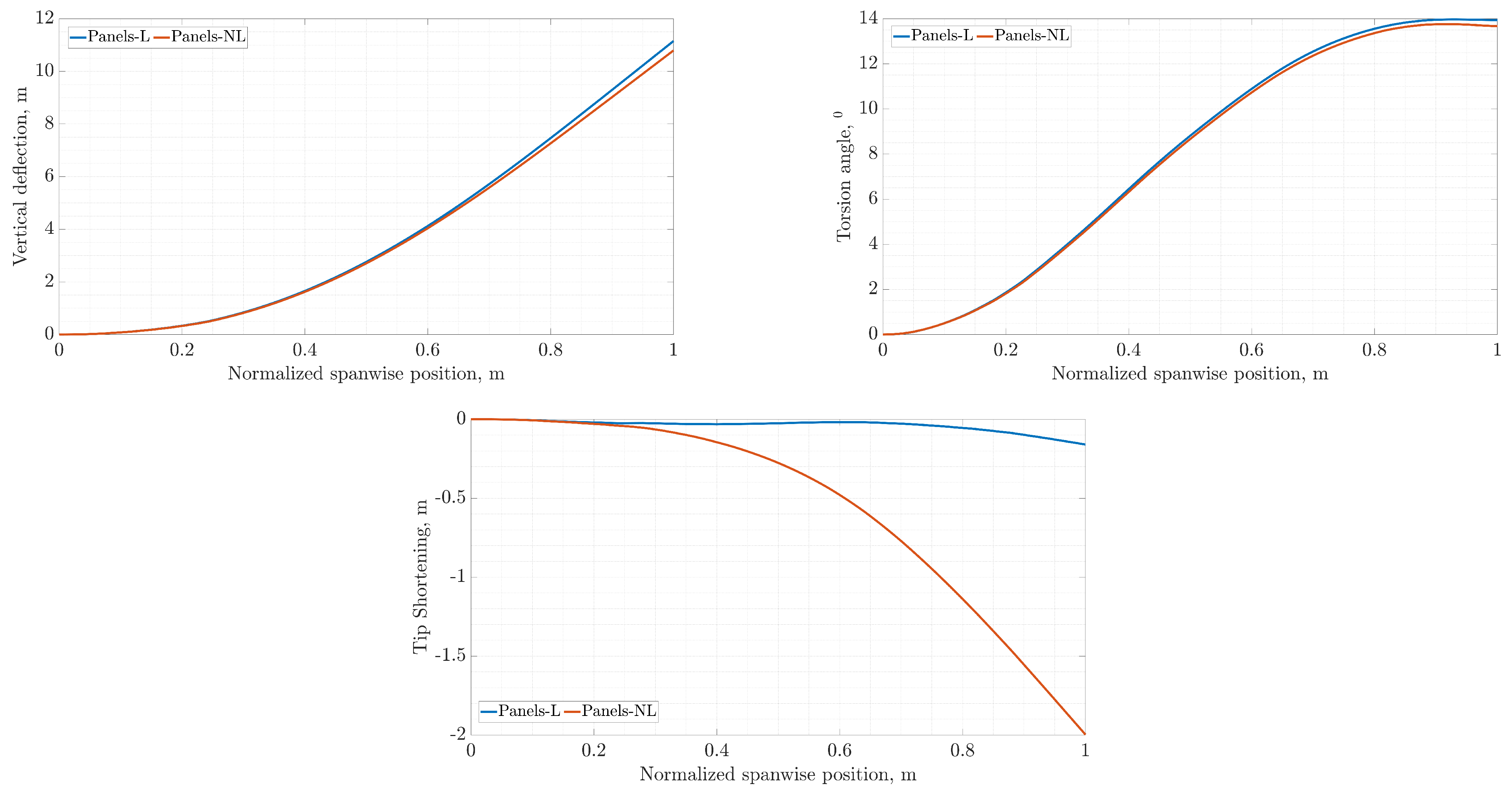

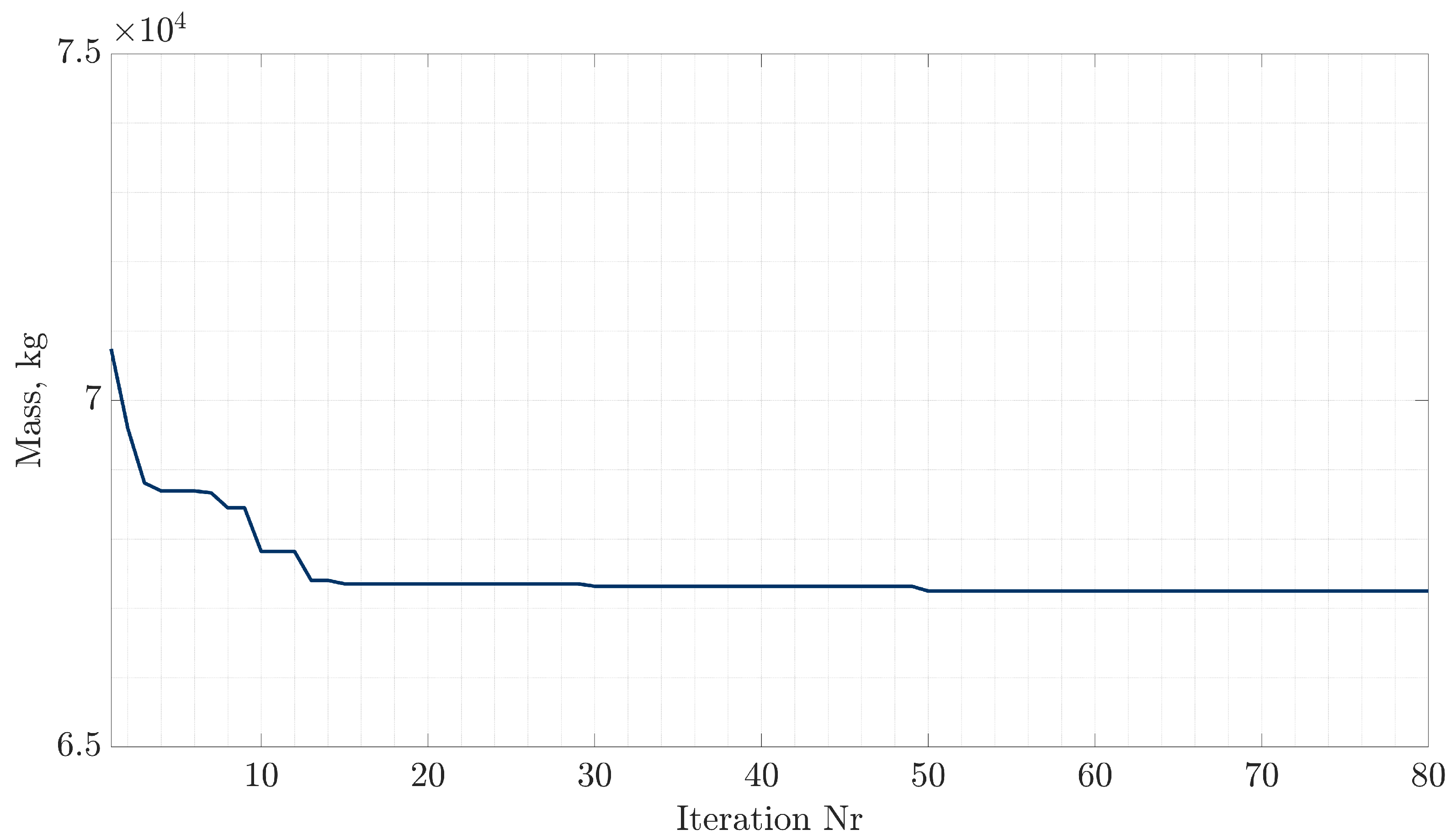

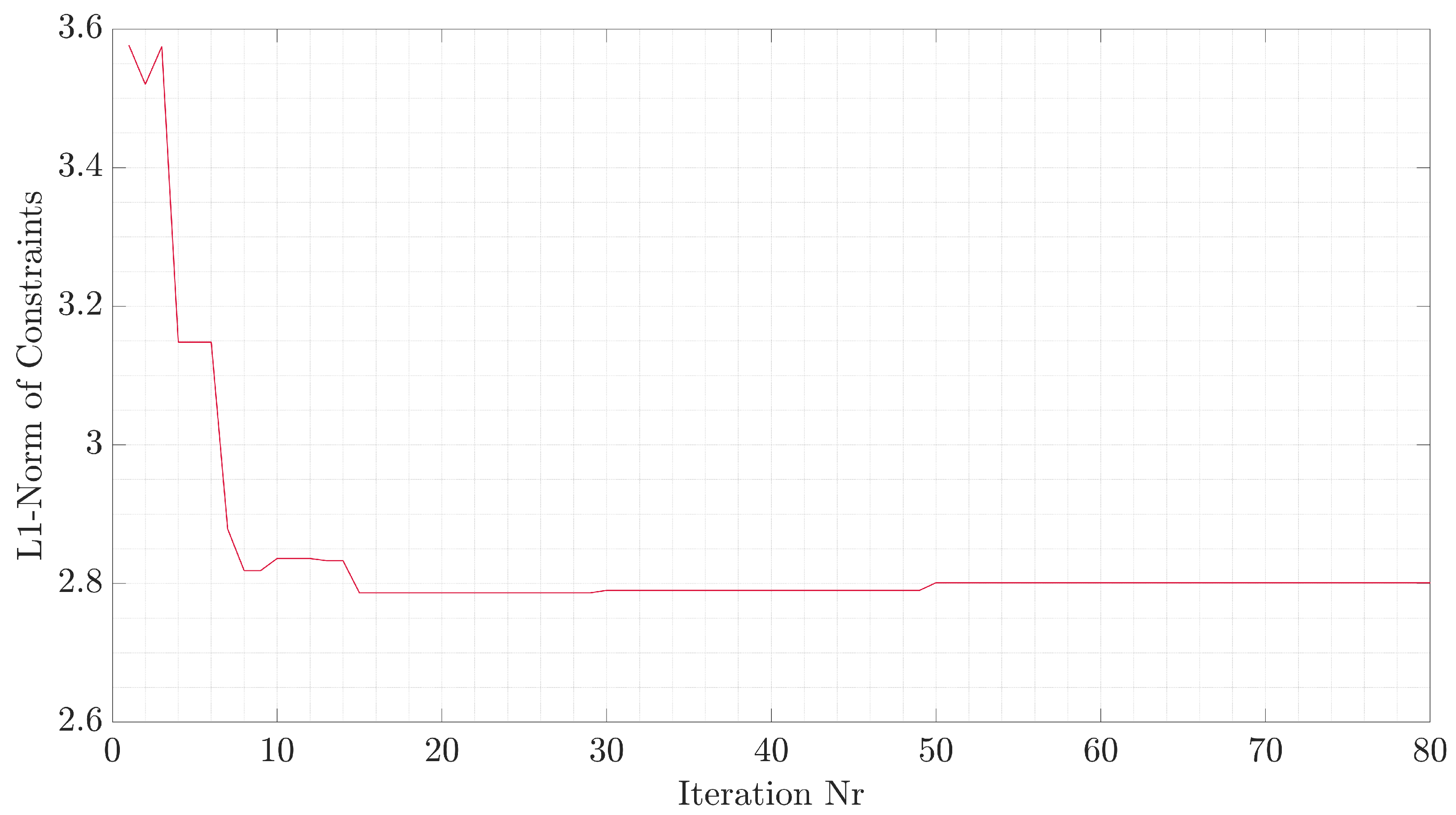

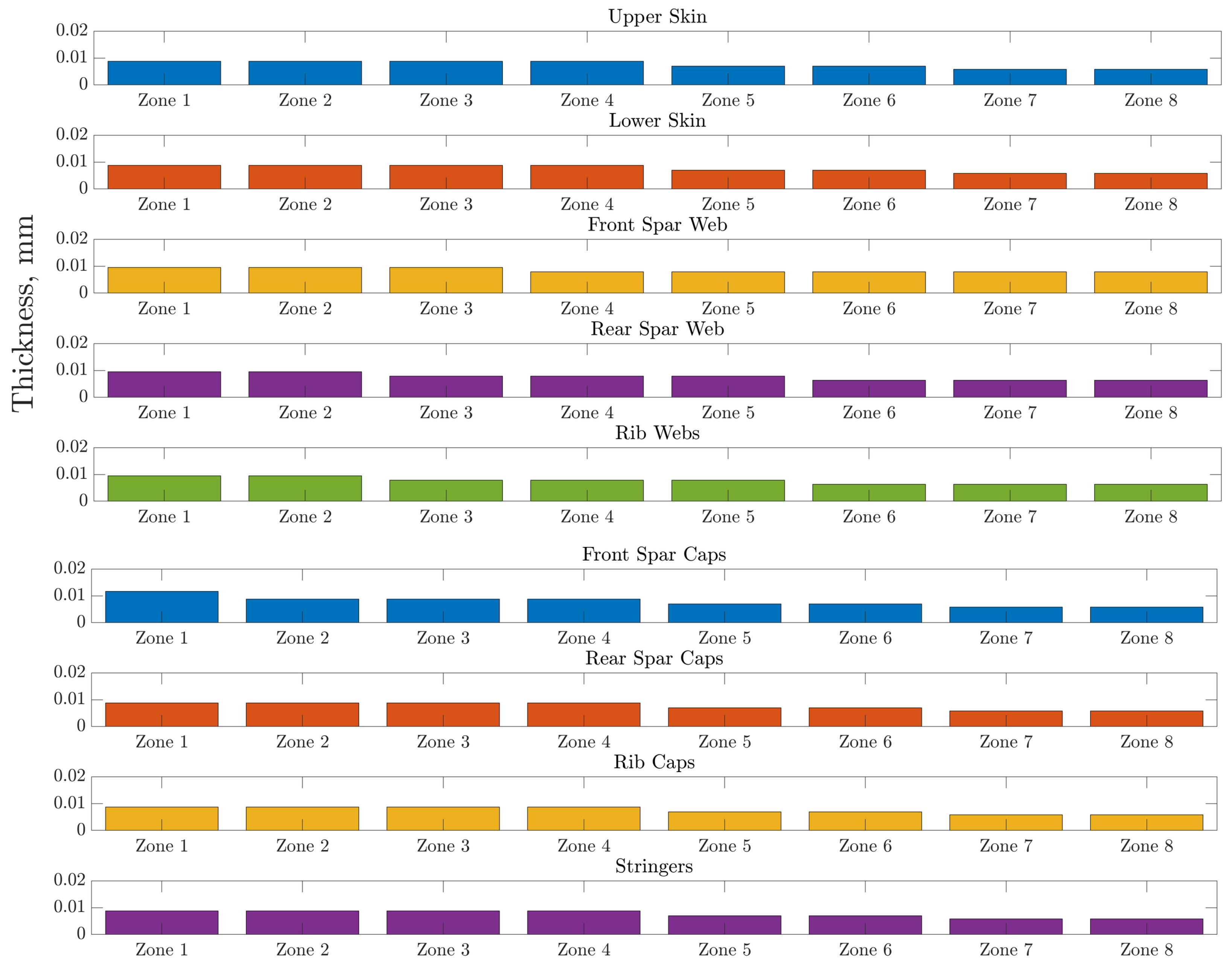

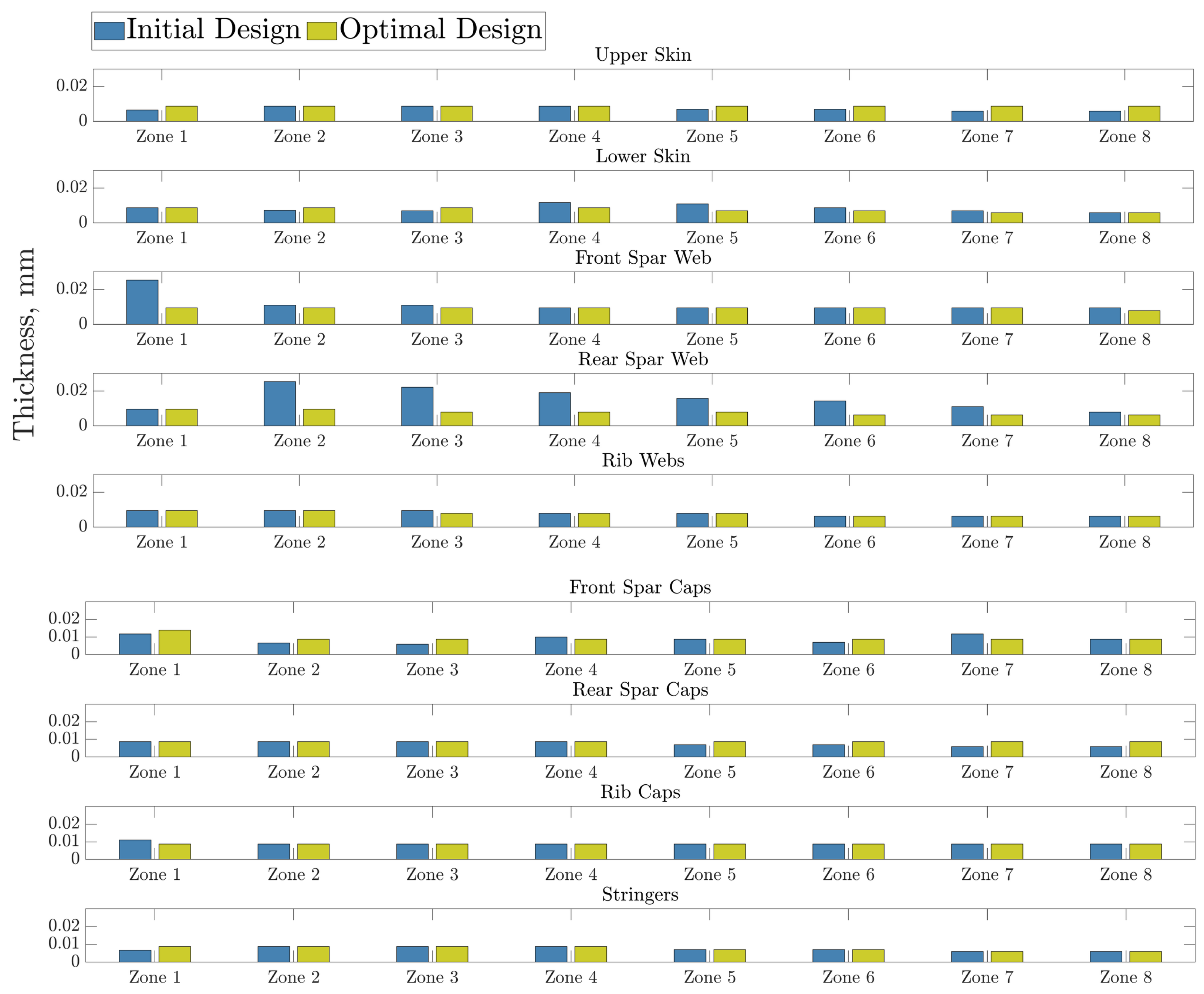

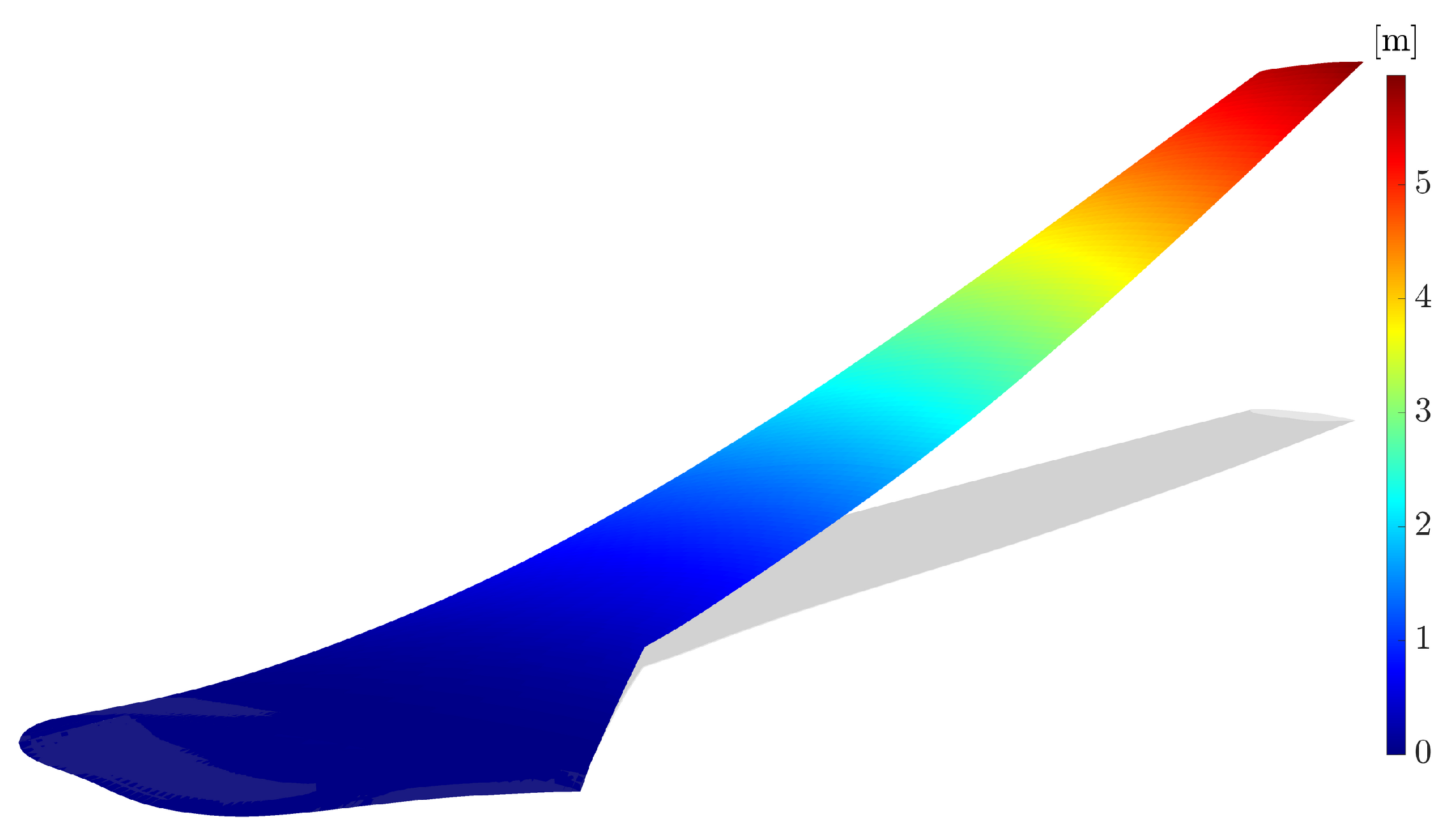

The methodology starts with the main case study and the corresponding 3D FEM model. A sensitivity analysis for the URF value present in the FSI analysis indicated an optimum value of 0.5 for the current case study and critical aerodynamic loading scenario. The bending–torsion coupling allows for a great reduction in the effective AoA, which cascades into lower displacements and overall load reduction, in comparison with rigid aerodynamics. Aiming at providing a step towards the inclusion of the static aeroelastic response early in the design stage at a reduced-as-much-as-possible computational cost, an SBO framework was also provided. In order to increase the efficiency of the framework, the number of design variables was drastically reduced by implementing predefined laminates as well as a thickness distribution for each component of the wing. The SBO framework was then used to drive the mass of the wing to a minimum while satisfying strength, local panel buckling and flutter constraints under the application of the critical aerodynamic loading corresponding to a 2.5 g maneuver. Optimal thickness distributions for each component were obtained. Among the constraints, the buckling critical loads were nearly active at the obtained optimal design, indicating that this type of wing structure might be susceptible to buckling. Strength and flutter constraints were less active in the optimal design. Nevertheless, the NASTRAN flutter solver indicates a dynamic aeroelastic instability, which might need further investigation via higher fidelity methods. Regarding the variables, zones near the yehudi break were accompanied by an increase in thickness. This particular trend was observed for the upper and lower skins and spar caps, since they contribute more to the overall load-carrying capability of the structure.

Several features can be added to the SBO optimization framework presented in this study, in order to obtain more holistic design and optimization methodologies. Both the conceptual and preliminary frameworks could be greatly benefited by the addition of aerodynamic shape optimization procedures. For the composite parts of the wing presented herein, the addition of a library of materials and lay-ups in order could support decision making in manufacturing and cost analysis to a greater extent. A wider variety of global–local analysis techniques, such as the one presented earlier, for the spars buckling, presence of holes and rivets, etc., could enhance cost estimation and manufacturing capabilities, since more light is shed on the detailed design stage.

Last but not least, and as mentioned earlier, the validity and efficiency of the proposed methodology could be enriched by the embodiment of high-fidelity CFD aeroelastic simulations in terms of aerodynamics. Such analyses could be used within a multi-fidelity optimization approach featuring only aeroelastic simulations, since, for at least the current reference wing configuration, great mass and performance gains are expected, as demonstrated.