Performance-Seeking Control of Aero-Propulsion System Based on Intelligent Optimization and Active Disturbance Rejection Fusion Controller

Abstract

1. Introduction

2. Materials and Methods

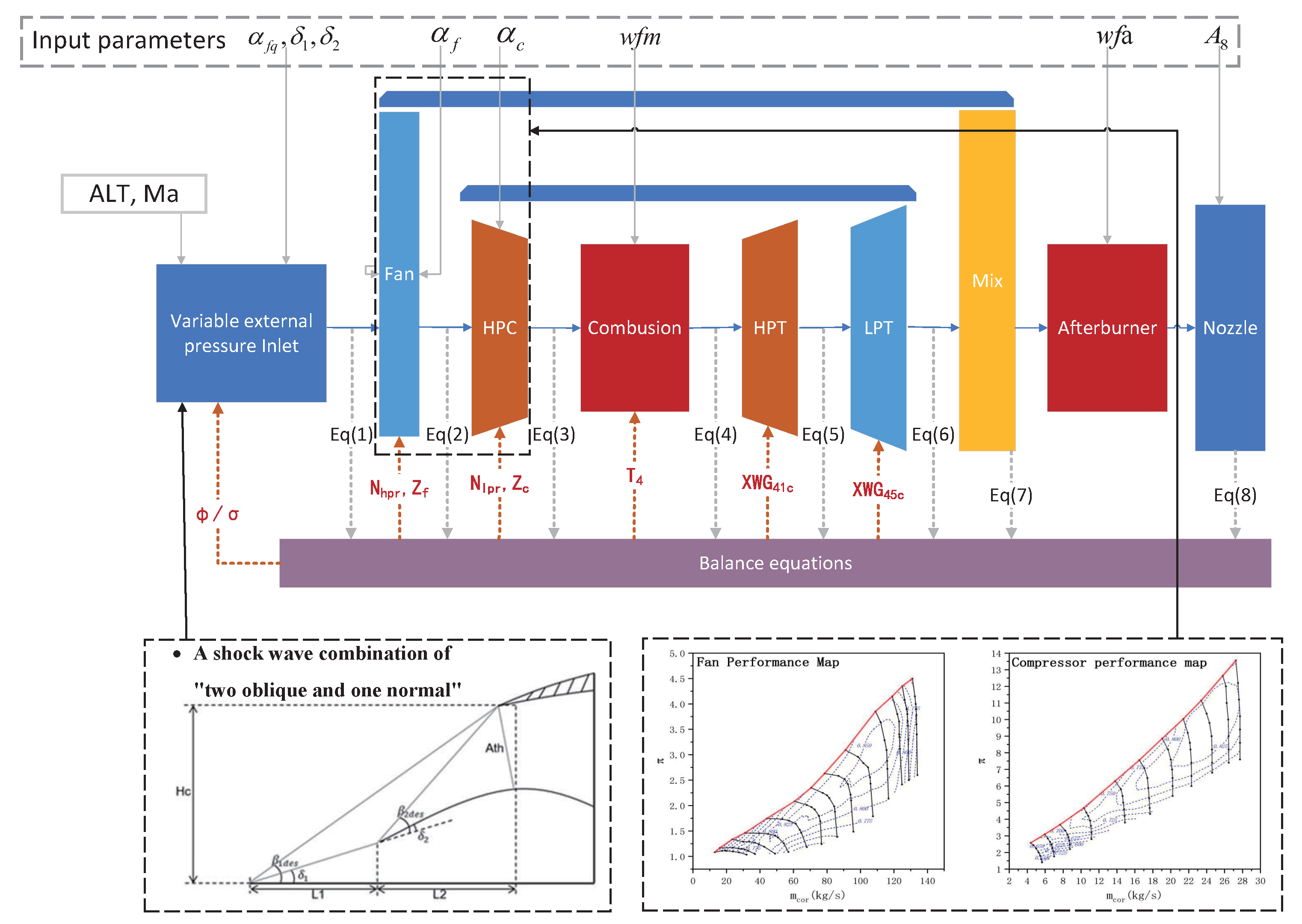

2.1. Supersonic Inlet/Engine Integrated Component-Level Model

2.2. Performance-Seeking Control in Aero-Propulsion System

2.3. The Principle of Improved NSDE-GWO Hybrid Algorithm

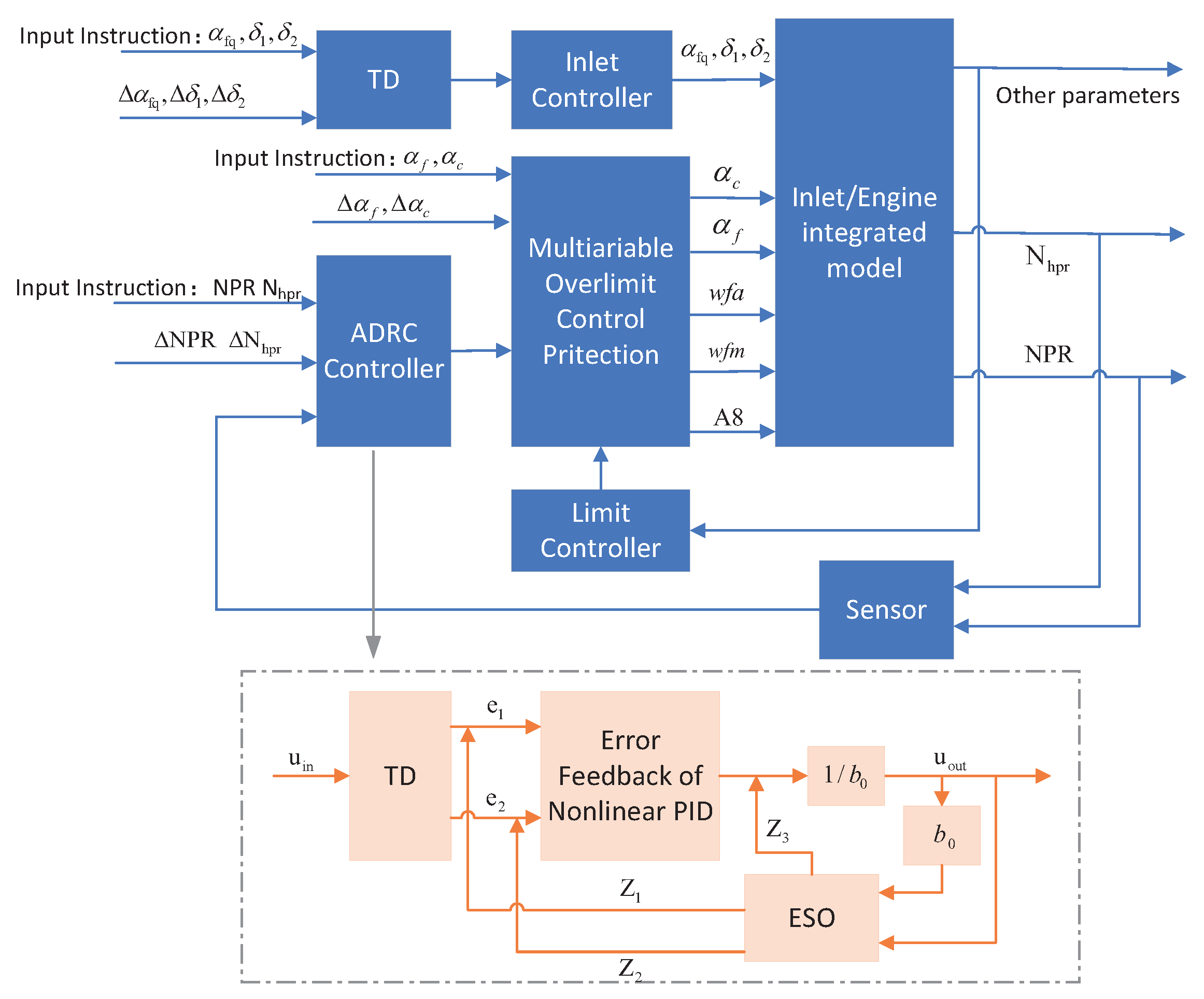

2.4. Design of the ADRC Multivariable Controller

3. Results and Discussion

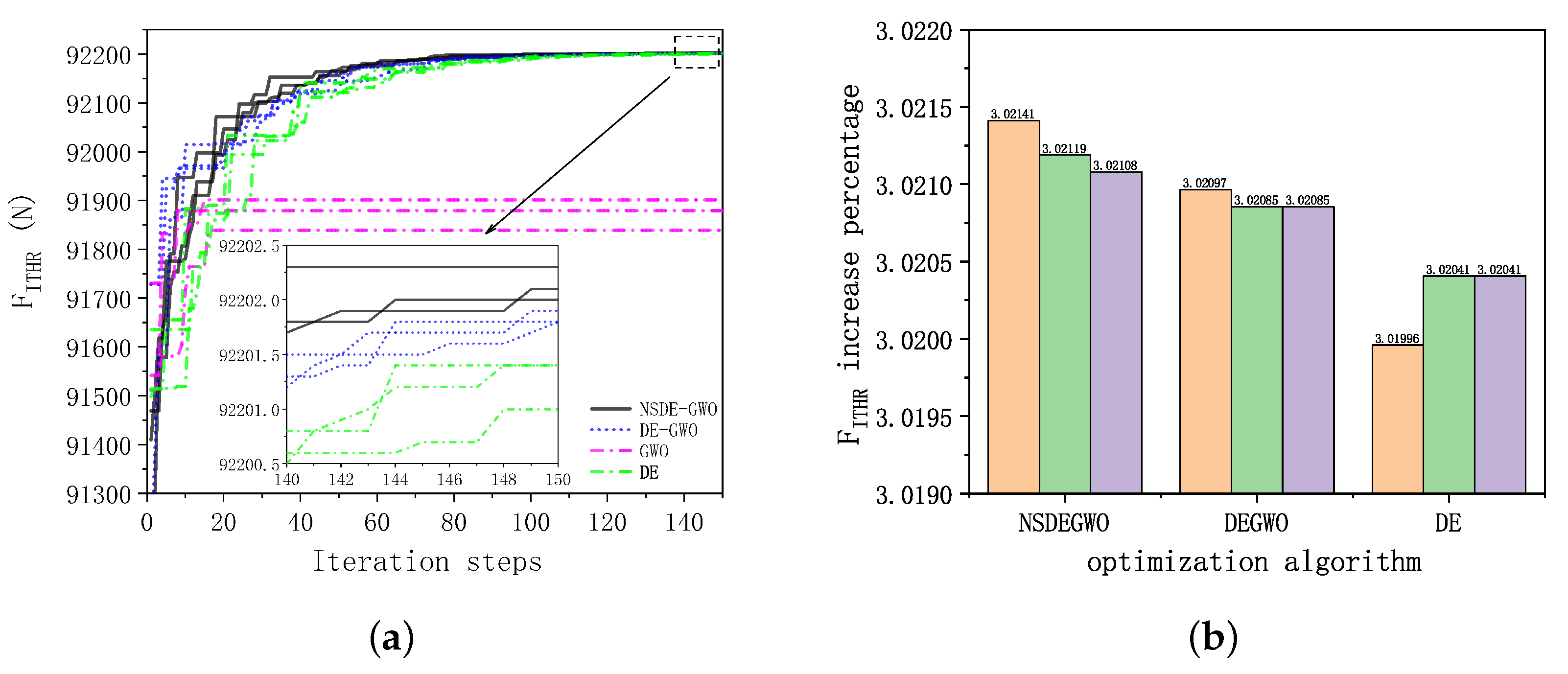

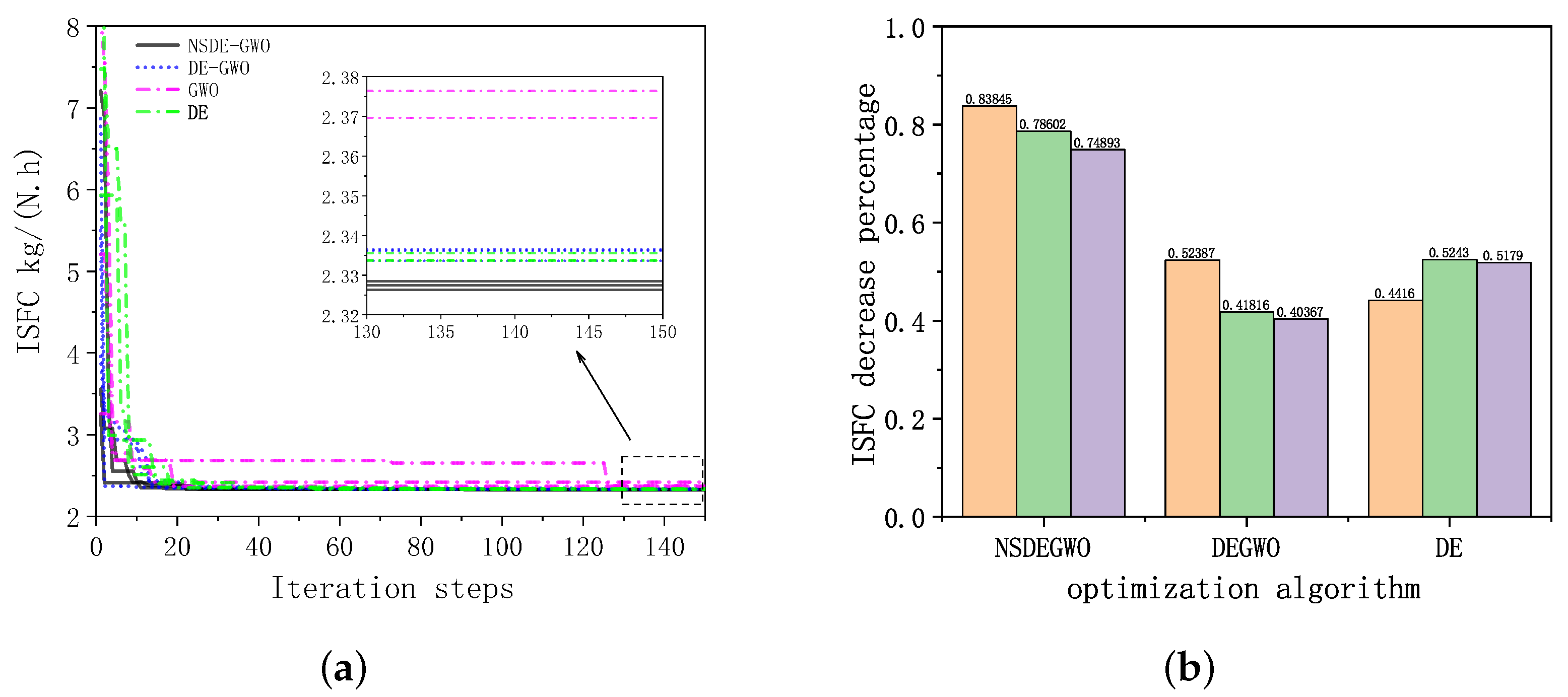

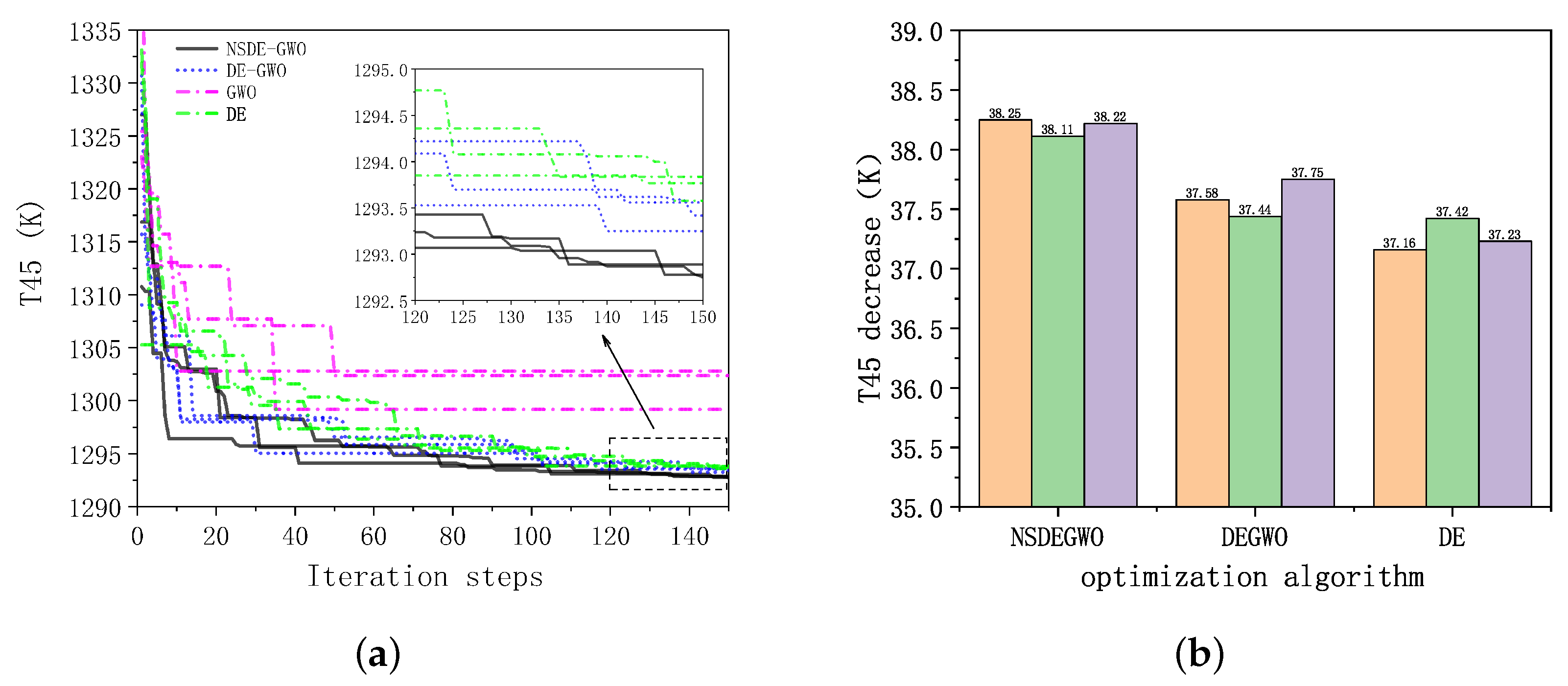

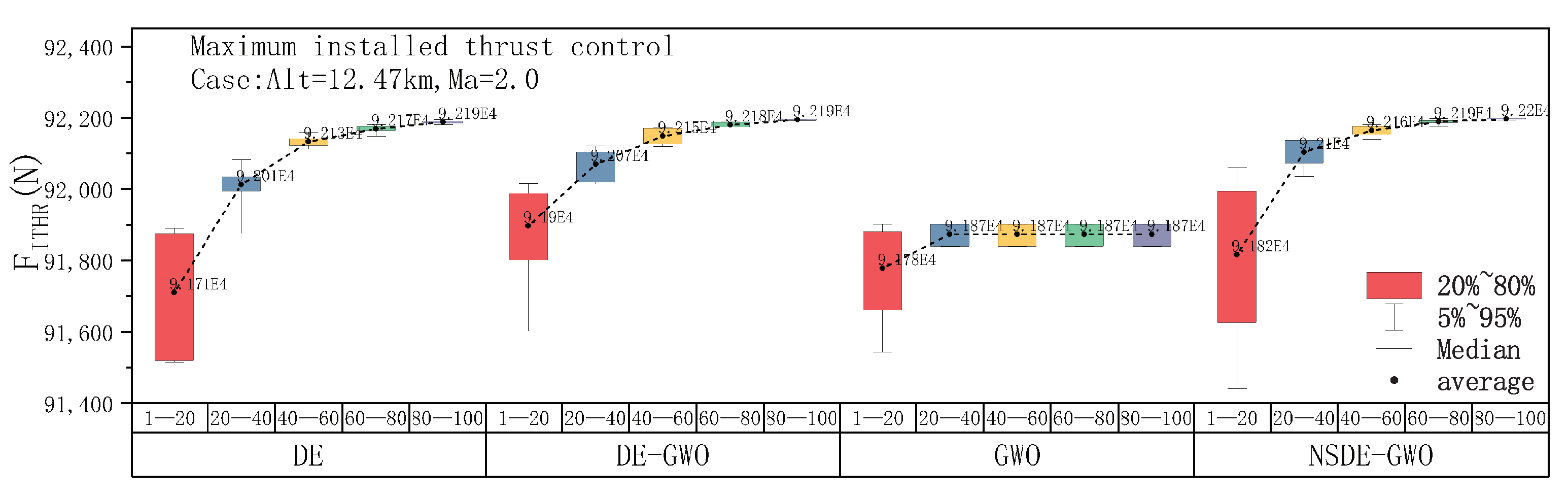

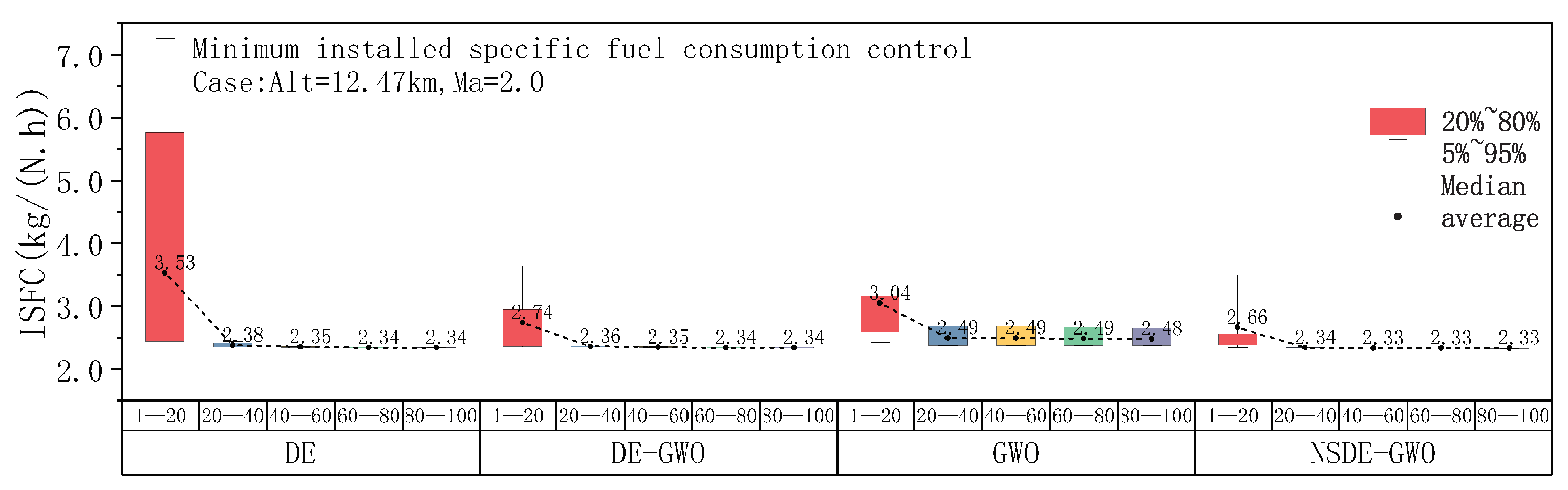

3.1. Comparison of PSC Results of Several Intelligent Algorithms

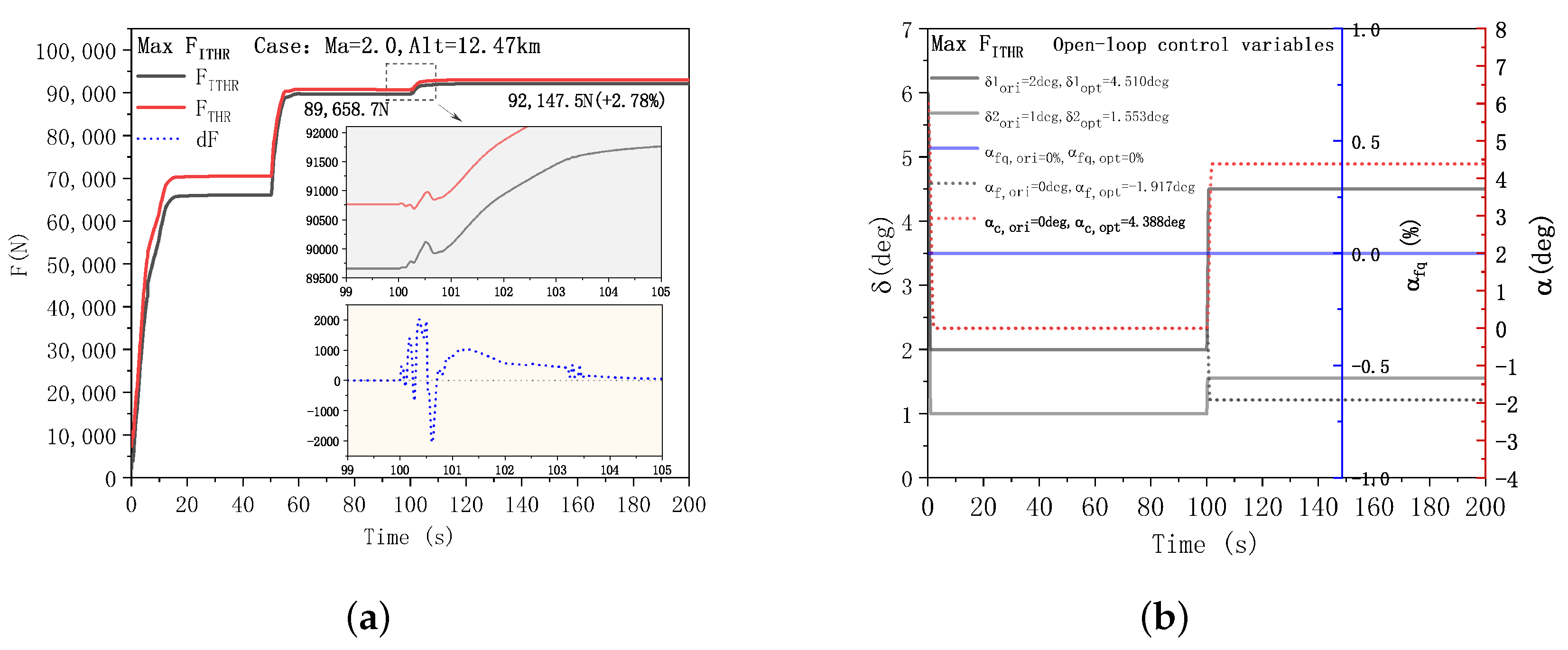

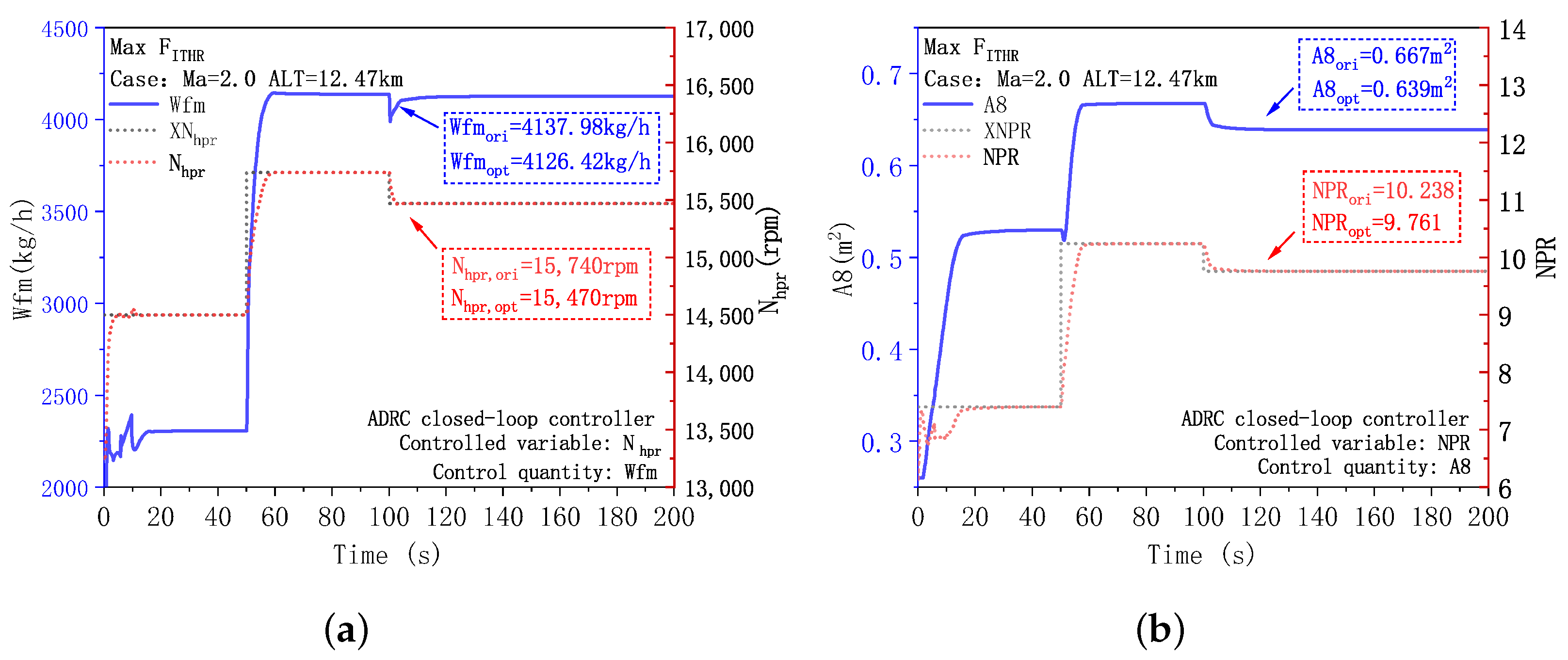

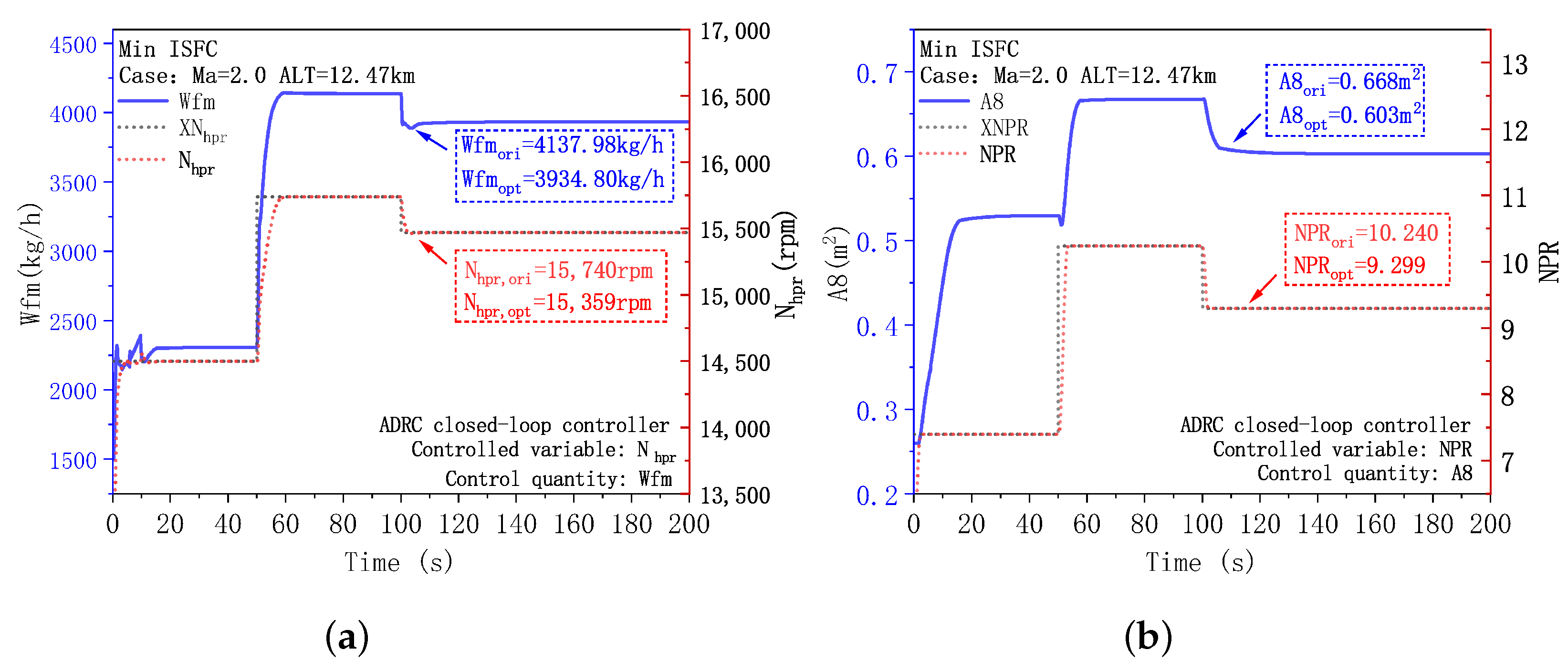

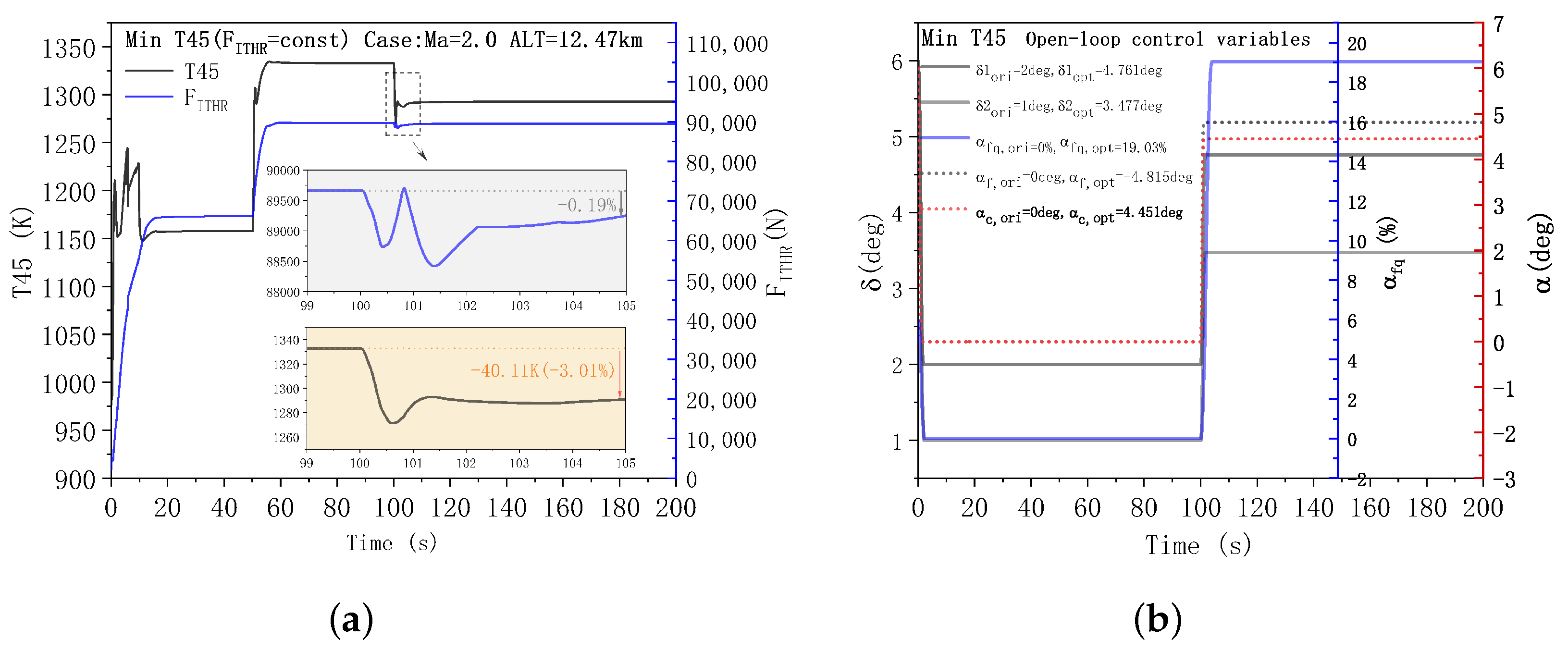

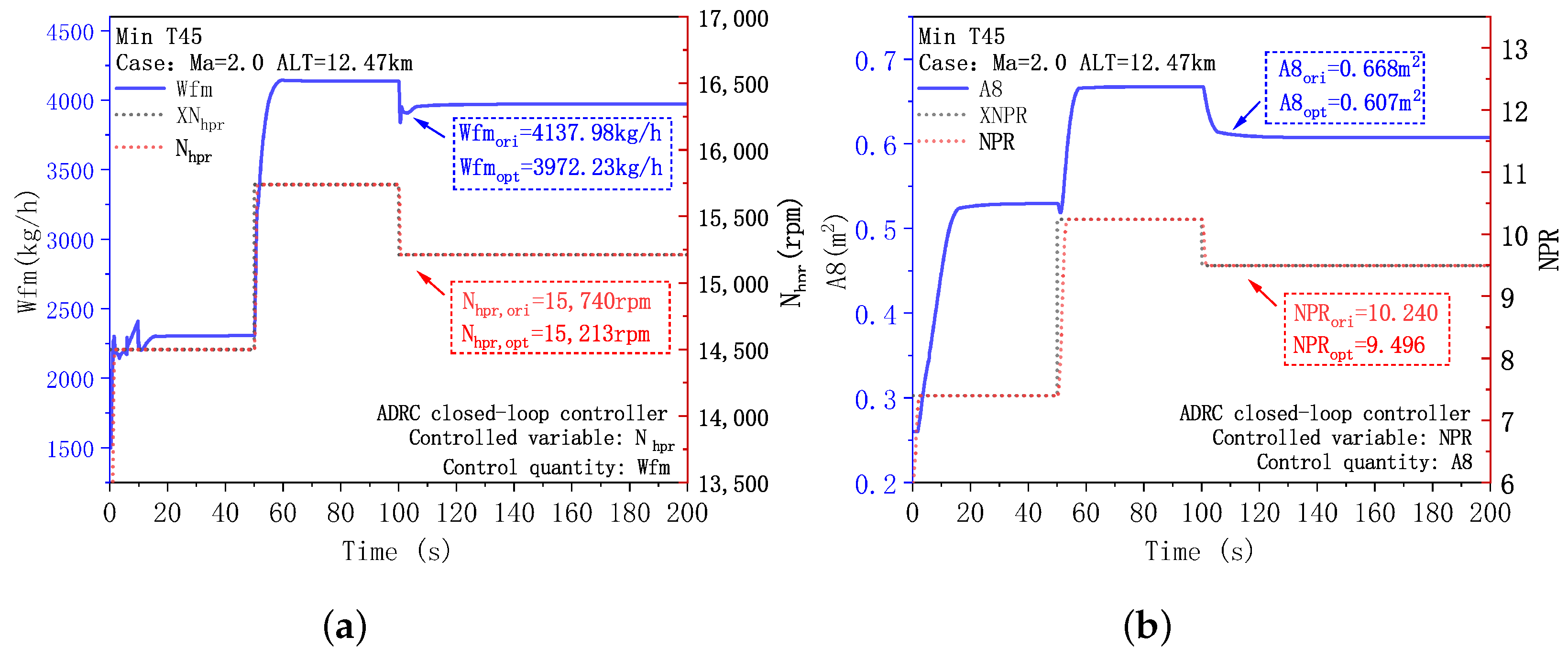

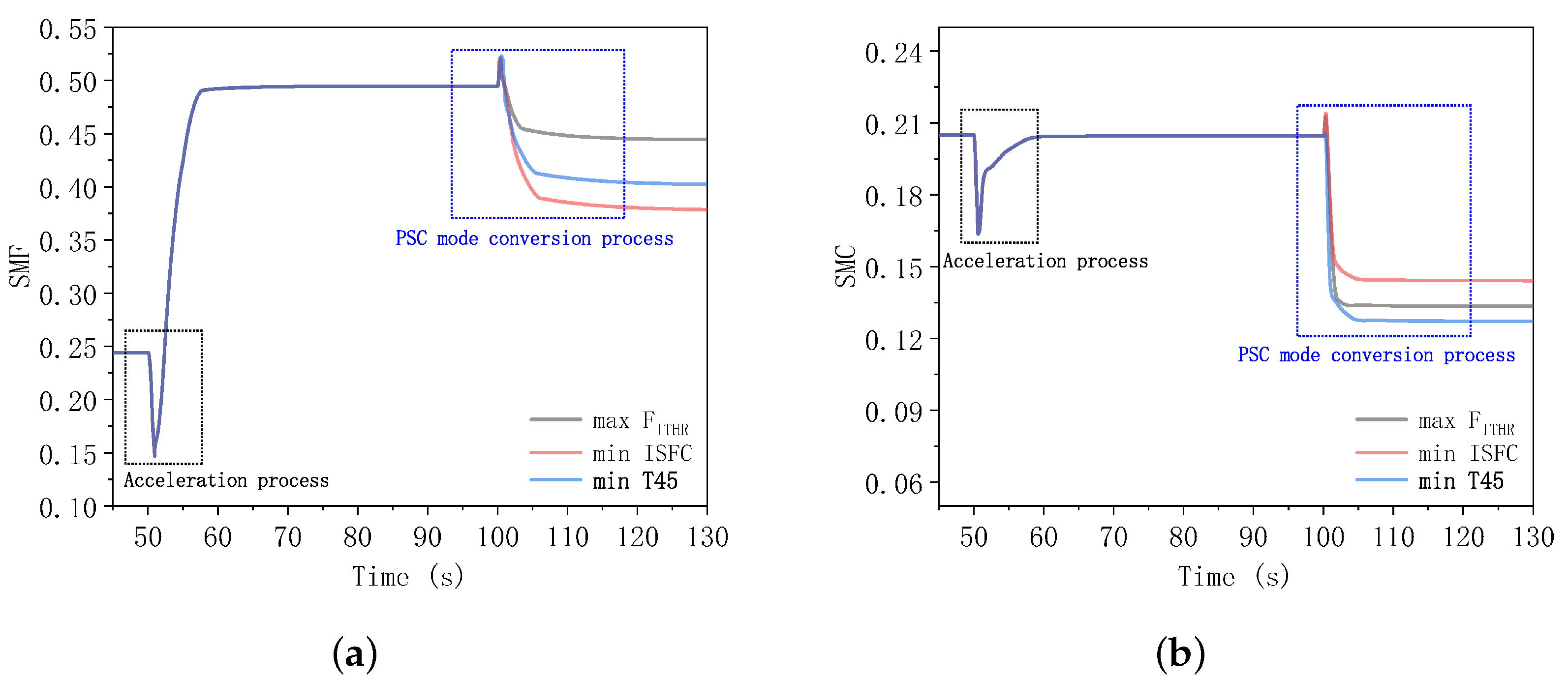

3.2. Analysis of the Performance Mode Transition of the Fusion Controller

4. Conclusions

- Compared to other intelligent algorithms (DE, GWO, and DE-GWO), the NSDE-GWO hybrid algorithm offers larger potential for optimization, the highest iteration efficiency, and the greatest stability. It can obtain better results in three control modes. Under the conditions of Alt = 12.47 km, Ma = 2.0, the installed thrust is increased by 3.02%, the fuel consumption is reduced by 0.84%, and the temperature after high-pressure turbine is reduced by 3.01%.

- The fusion controller can produce a seamless transition of performance modes to guarantee that the engine maintains a stable thrust throughout operation; the dynamic optimization potential is conservative when opposed to ideal steady-state simulation outputs. The maximum thrust mode is capable of achieving no thrust drop and a maximum fluctuation rate within 2000 N/s. In the minimum installed fuel consumption mode, the greatest fluctuation in thrust during the changeover is less than 0.9%, and the minimum turbine temperature mode also has smaller volatility and higher optimization efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PSC | Performance-seeking control |

| ADRC | Active disturbance rejection control |

| ITHR | Installed thrust |

| SFC | Specific fuel consumption |

| ISFC | Installed specific fuel consumption |

| ESO | Extended state observer |

| TD | Tracking differentiator |

| GWO | Grey wolf optimizer |

| DE | Differential evolution |

| NSDE | Neighborhood-based speciation differential evolution |

| NPR | Turbine total pressure ratio |

| HPR | High-pressure rotor |

| LPR | Low-pressure rotor |

| HPC | High-pressure compressor |

| LPT | Low-pressure turbine |

| HPT | High-pressure turbine |

| LP | Linear programming |

| SLP | Sequential linear programming |

| FSQP | Feasible sequential quadratic programming |

| SQCQP | Sequential quadratically constrained quadratic programming |

| GA | Genetic algorithm |

| PSO | Particle swarm optimization |

| EA | Evolutionary algorithm |

| IA | Interval analysis |

References

- Jaw, L.; Mattingly, J. Aircraft Engine Controls; American Institute of Aeronautics and Astronautics: New York, NY, USA, 2009. [Google Scholar]

- Montazeri-Gh, M.; Abyaneh, S.; Kazemnejad, S. Hardware-in-the-loop simulation of two-shaft gas turbine engine electronic control unit. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2016, 230, 512–521. [Google Scholar]

- Wurth, S.; Mahone, T.; Hart, J.; Baxter, J. X-35B integrated flight propulsion control fault tolerance development. In Proceedings of the 2002 Biennial International Powered Lift Conference and Exhibit, Williamsburg, VA, USA, 5–7 November 2002; p. 6019. [Google Scholar]

- Landy, R.; Yonke, W.; Stewart, J. Development of HIDEC adaptive engine control systems. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, Dusseldorf, Germany, 8–12 June 1986; Volume 79290, p. V002T02A015. [Google Scholar]

- Smith, R.H.; Chisholm, J.D.; Stewart, J.F. Optimizing Aircraft Performance With Adaptive, Integrated Flight/Propulsion Control. J. Eng. Gas Turbines Power 1991, 113, 87–94. [Google Scholar] [CrossRef]

- Nobbs, S.; Jacobs, S.; Donahue, D. Development of the full-envelope performance-seeking control algorithm. In Proceedings of the 28th Joint Propulsion Conference and Exhibit, Nashville, TN, USA, 6–8 July 1992. [Google Scholar]

- ORME, J.; GILYARD, G. Preliminary supersonic flight test evaluation of performance seeking control. In Proceedings of the 29th Joint Propulsion Conference and Exhibit, Monterey, CA, USA, 28–30 June 1993; p. 1821. [Google Scholar]

- Nobbs, S.G. PSC algorithm description. In NASA. Dryden Flight Research Center, An Electronic Workshop on the Performance-Seeking Control and Propulsion Controlled Aircraft Results of the F-15 Highly Integrated Digital Electronic Control Flight Research Program; NASA: Washington, DC, USA, 1995; Volume 95, p. 33013. [Google Scholar]

- Ren, X.Y.; Yang, Y.W.; Fan, S.Q. Study on propulsion system overall performance-seeking control algorithm. J. Propuls. Technol. 2010, 31, 62–64. [Google Scholar]

- Wang, J.; Zhang, H.; Sun, J.; Huang, X. Experimental verification of aero-engine performance-seeking control based on the hybrid model and FSQP algorithm. J. Propuls. Technol. 2012, 33, 579–590. [Google Scholar]

- NIE, Y.; LI, Q.; WANG, Y.; GU, S. Variable cycle engine performance-seeking control based on SQCQP algorithm. J. Beijing Univ. Aeronaut. Astronaut. 2017, 43, 2564. [Google Scholar]

- Chen, H.; Zheng, Q.; Gao, Y.; Zhang, H. performance-seeking control of minimum infrared characteristic on double bypass variable cycle engine. Aerosp. Sci. Technol. 2021, 108, 106359. [Google Scholar] [CrossRef]

- Li, J.; Fan, D.; Sreeram, V. Optimization of aero engine acceleration control in combat state based on genetic algorithms. Int. J. Turbo Jet Engines 2012, 29, 29–36. [Google Scholar] [CrossRef]

- Li, Y.; Ghafir, M.; Wang, L.; Singh, R.; Huang, K.; Feng, X. Nonlinear multiple points gas turbine off-design performance adaptation using a genetic algorithm. J. Eng. Gas Turbines Power 2011, 133, 071701. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, H.Q.; Yang, S. Optimization on mistuning blades arrangement of vibration absorption based on genetic particle swarm algorithm in aero-engine. In Proceedings of the Advanced Materials Research. Trans Tech Publ, Xi’an, China, 27–28 July 2013; Volume 655, pp. 481–485. [Google Scholar]

- Sun, F.; Miao, L.; Zhang, H. A Study on the Installed performance-seeking control for Aero-Propulsion under Supersonic State. Int. J. Turbo Jet Engines 2015, 2015, 341–351. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, Y.; Sun, F.; Fang, J.; Zhang, H.; Hu, Z. Research on aero-engine steady model based on an improved compact propulsion system model. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2020, 234, 726–733. [Google Scholar] [CrossRef]

- Zheng, Q.; Fu, D.; Wang, Y.; Chen, H.; Zhang, H. A study on global optimization and deep neural network modeling method in performance-seeking control. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2020, 234, 46–59. [Google Scholar] [CrossRef]

- Frederick, D.K.; Garg, S.; Adibhatla, S. Turbofan engine control design using robust multivariable control technologies. IEEE Trans. Control. Syst. Technol. 2000, 8, 961–970. [Google Scholar] [CrossRef]

- Lehtinen, B.; DeHofft, R.; Hackney, R. Multivariable control altitude demonstration on the FlOO turbofan engine. J. Guid. Control. 1981, 4, 50–58. [Google Scholar] [CrossRef]

- Athans, M.; Kapasouris, P.; Kappos, E.; Spang III, H. Linear-quadratic Gaussian with loop-transfer recovery methodology for the F-100 engine. J. Guid. Control. Dyn. 1986, 9, 45–52. [Google Scholar] [CrossRef]

- Yang, G.; Sun, J.; Yao, H.; Zang, J.; Liu, A.; Yi, X.; Zhang, L. Experimental verification of H/LTR method for aeroengine control systems. Acta Aeronaut. Astronaut.-Sin.-Ser. 2006, 27, 773. [Google Scholar]

- Richter, H. A multi-regulator sliding mode control strategy for output-constrained systems. Automatica 2011, 47, 2251–2259. [Google Scholar] [CrossRef]

- Richter, H. Multiple sliding modes with override logic: Limit management in aircraft engine controls. J. Guid. Control. Dyn. 2012, 35, 1132–1142. [Google Scholar] [CrossRef]

- Han, J.Q. Auto disturbance rejection controller and it’s applications. Control. Decis. 1998, 13, 19–23. [Google Scholar]

- Gao, Z. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the ACC. Citeseer, Borovets, Bulgaria, 10–12 September 2003; pp. 4989–4996. [Google Scholar]

- Miklosovic, R.; Gao, Z. A dynamic decoupling method for controlling high performance turbofan engines. IFAC Proc. Vol. 2005, 38, 532–537. [Google Scholar] [CrossRef]

- Li, S.Q.; Zhang, S.X.; Liu, Y.N.; Zhou, S. Simple design and application of auto disturbance rejection controller for aeroengine. Aeroengine 2012, 38, 46–48. [Google Scholar]

- Zhang, H.B.; Wang, J.K.; Wang, R.X.; Sun, J.G. Design of an active disturbance rejection decoupling multivariable control scheme for aero-engine. J. Propuls. Technol. 2012, 33, 78–83. [Google Scholar]

- Xue, W.; Bai, W.; Yang, S.; Song, K.; Huang, Y.; Xie, H. ADRC with adaptive extended state observer and its application to air–fuel ratio control in gasoline engines. IEEE Trans. Ind. Electron. 2015, 62, 5847–5857. [Google Scholar] [CrossRef]

- Jia, L.Y.; Chen, Y.C.; Xie, J.Q.; Cai, F.C. A Simplified Method to Simulate Supersonic Inlet Installed Performance in Terms of Engine and Inlet Matching. J. Propuls. Technol. 2017, 38, 510–518. [Google Scholar]

- Wang, C.; Sun, X.; Du, X. The Aero-Engine Component-Level Modelling Research Based on NSDE Hybrid Damping Newton Method. Int. J. Aerosp. Eng. 2022, 13, 1–13. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar]

- Wang, C.; Ai, L.; Du, X.; Sun, X. Multivariable Control and Robustness Analysis of Supersonic Aero-Engine Based on ADRC. In Proceedings of the 5th China Aeronautical Science and Technology Conference, Qingdao, China, 24–26 August 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 885–901. [Google Scholar]

- Gao, Z. Active disturbance rejection control: A paradigm shift in feedback control system design. In Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA, 14–16 June 2006; IEEE: Piscataway, NJ, USA, 2006; p. 7. [Google Scholar]

- Zheng, Q.; Xiang, D.; Chen, C.; Zhang, H. Research on aero-engine performance-seeking control based on the NN-PSM on-board model. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2022, 236, 3505–3517. [Google Scholar]

| Optimization Variables | Initial Data | Optimization Range |

|---|---|---|

| Main fuel flow (kg/h) | 4125.6 | [3713, 4126] |

| Afterburner fuel flow (kg/h) | 16,873.2 | [15,187, 16,874] |

| Nozzle area (m2) | 0.6685 | [0.50, 0.67] |

| Fan guide vane angle (deg) | 0 | [−10, 10] |

| Compressor guide vane angle (deg) | 0 | [−10, 10] |

| Relative bleed adjustment (%) | 0 | [−10, 20] |

| First-stage ramp angle (deg) | 2 | [1, 5] |

| Second-stage ramp angle (deg) | 1 | [1, 5] |

| Computational Term | Original Data | Optimized Data | Optimization Percentage (%) |

|---|---|---|---|

| Maximum installed thrust control | |||

| FITHR(N) | 89,658.7 | 92,147.5 | 2.78 |

| SMF | 0.497 | 0.444 | −10.66 |

| SMC | 0.205 | 0.133 | −35.12 |

| Nfan,cor | 0.882 | 0.877 | −0.57 |

| Ncom,cor | 0.973 | 0.957 | −1.64 |

| Minimum installed specific fuel-consumption control | |||

| FITHR(N) | 89,658.7 | 89,410.63 | −0.28 |

| ISFC (kg/N.h) | 2.343 | 2.326 | −0.73 |

| SMF | 0.497 | 0.378 | −23.94 |

| SMC | 0.205 | 0.144 | −29.76 |

| Nfan,cor | 0.882 | 0.863 | −2.15 |

| Ncom,cor | 0.973 | 0.952 | −2.16 |

| Minimum low-pressure turbine inlet temperature control | |||

| FITHR(N) | 89,658.7 | 89,492.21 | −0.19 |

| T45 (K) | 1332.83 | 1292.72 | −3.01 |

| SMF | 0.497 | 0.401 | −19.32 |

| SMC | 0.205 | 0.126 | −38.54 |

| Nfan,cor | 0.882 | 0.824 | −6.58 |

| Ncom,cor | 0.973 | 0.954 | −1.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Du, X.; Sun, X. Performance-Seeking Control of Aero-Propulsion System Based on Intelligent Optimization and Active Disturbance Rejection Fusion Controller. Aerospace 2023, 10, 151. https://doi.org/10.3390/aerospace10020151

Wang C, Du X, Sun X. Performance-Seeking Control of Aero-Propulsion System Based on Intelligent Optimization and Active Disturbance Rejection Fusion Controller. Aerospace. 2023; 10(2):151. https://doi.org/10.3390/aerospace10020151

Chicago/Turabian StyleWang, Chen, Xian Du, and Ximing Sun. 2023. "Performance-Seeking Control of Aero-Propulsion System Based on Intelligent Optimization and Active Disturbance Rejection Fusion Controller" Aerospace 10, no. 2: 151. https://doi.org/10.3390/aerospace10020151

APA StyleWang, C., Du, X., & Sun, X. (2023). Performance-Seeking Control of Aero-Propulsion System Based on Intelligent Optimization and Active Disturbance Rejection Fusion Controller. Aerospace, 10(2), 151. https://doi.org/10.3390/aerospace10020151