The objective of this section is to present, compare and discuss the outcomes coming from the implementation of the three different architectures together with the mission profile.

4.2. Baseline Analysis

In this section, the entire propulsive system is evaluated for the fixed characteristics resulted from the sensitivity analysis, to allow for the comparison between architectures. The same power hybridization factor of 10% is considered for the series and parallel hybrid configurations. It is relevant to mention that this constant value of the hybridization factor results in different propulsion system masses. Thus, the payload will be different for each architecture and care should be taken, which will be considered in the multi-objective optimization problem. In this subsection, the focus is to compare how the power required, heat dissipation, fuel flow and emissions differ for each considered powertrain.

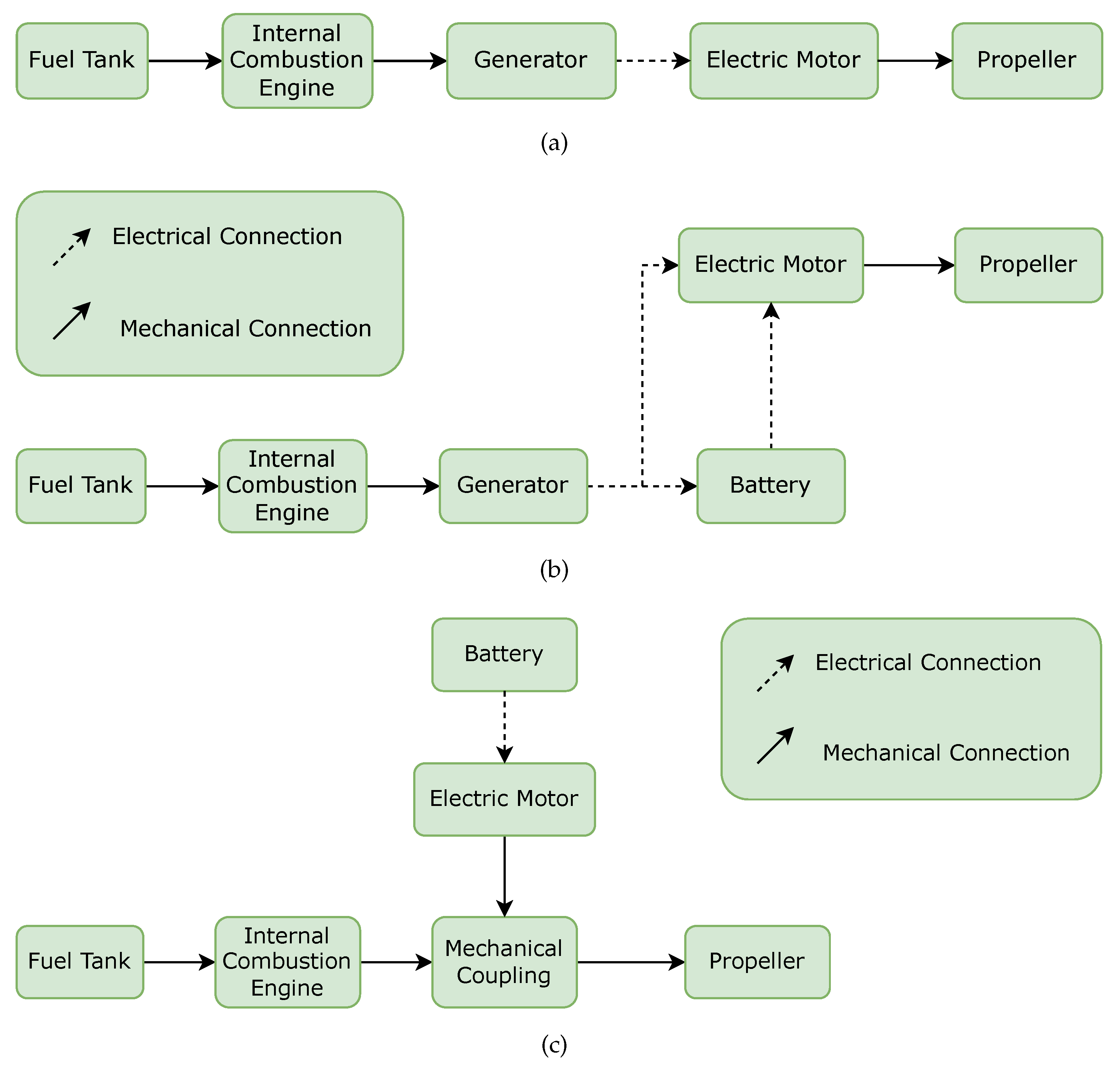

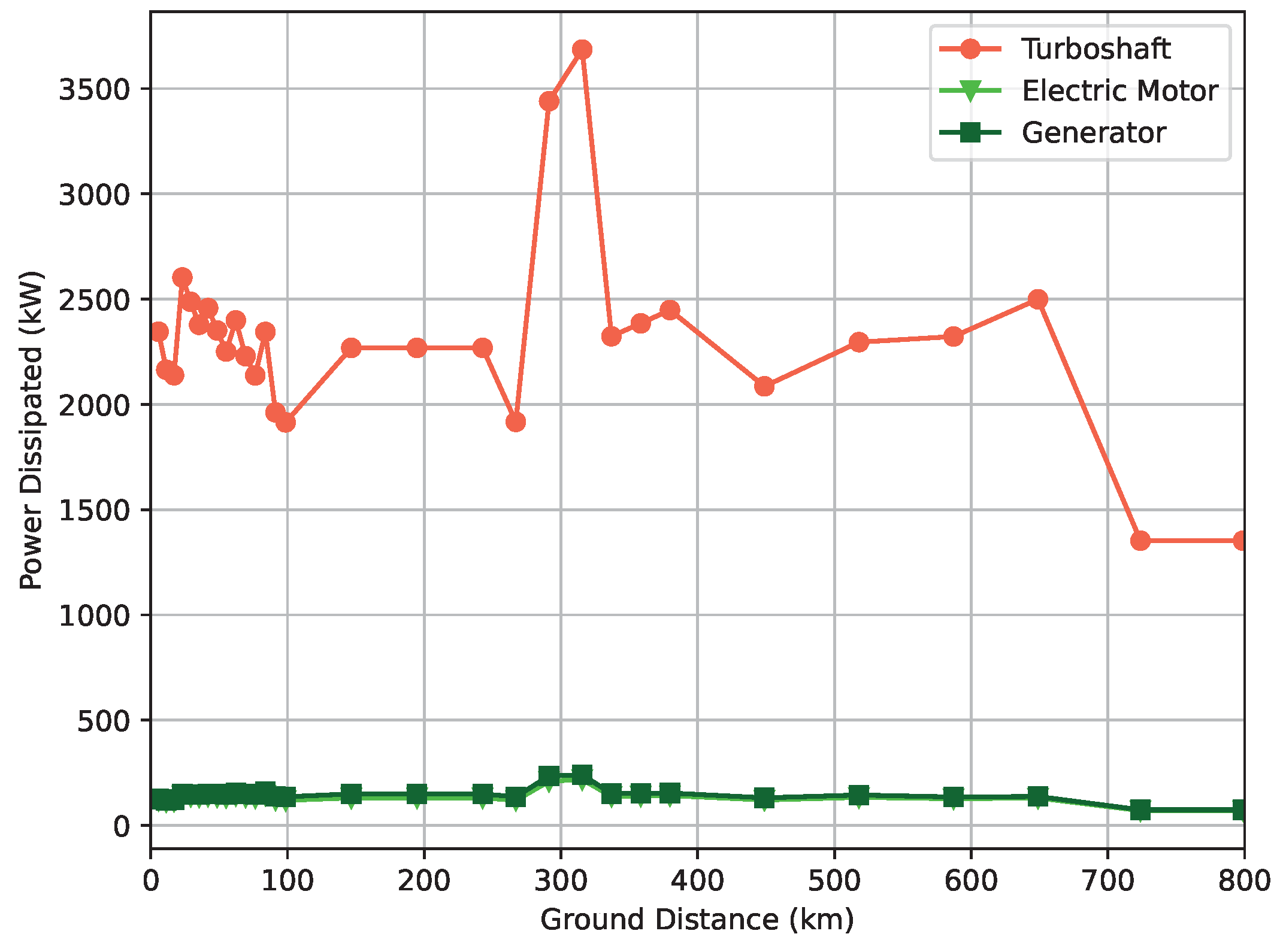

4.2.1. Turboelectric

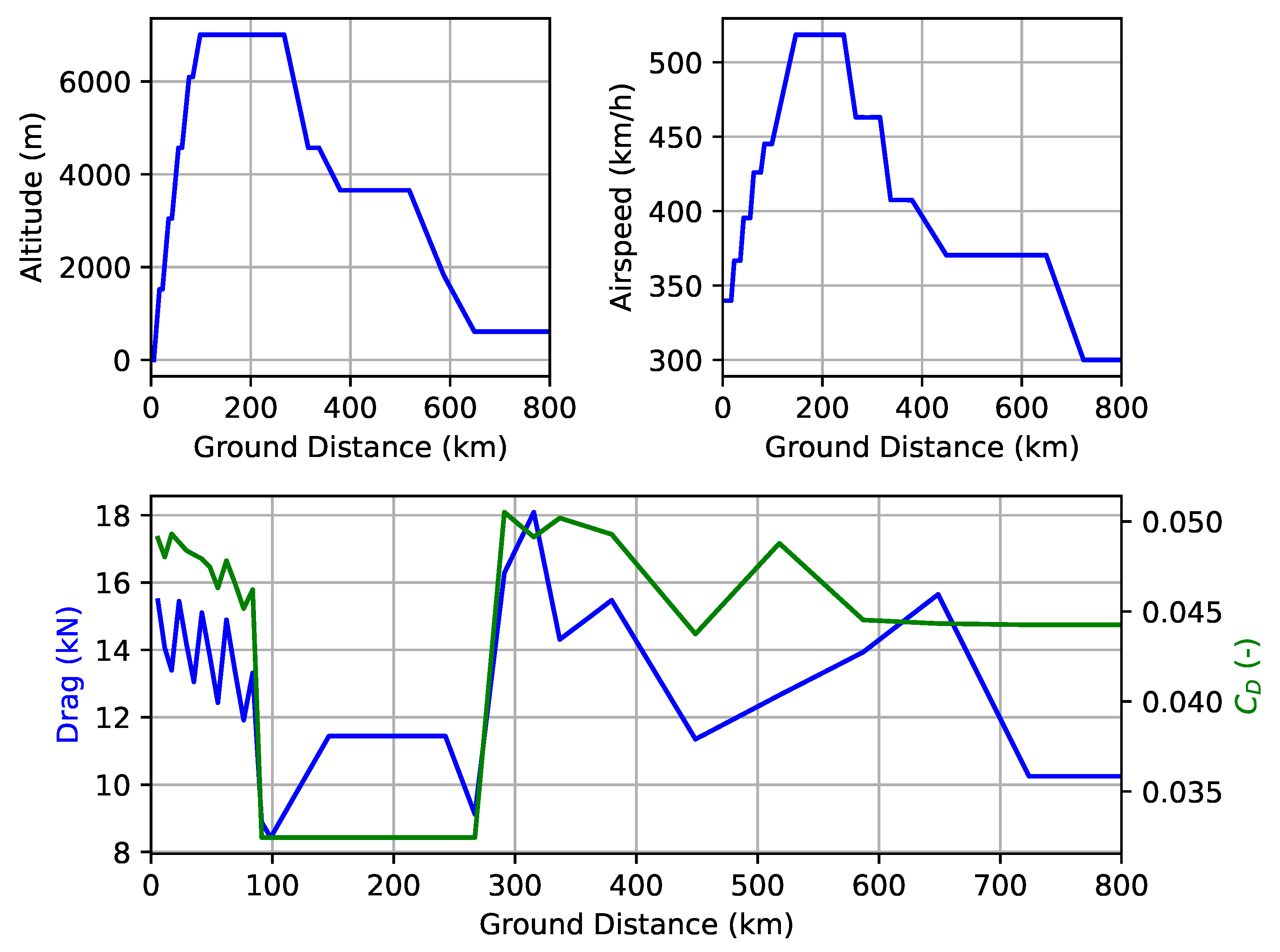

Figure 8 and

Figure 9 show the power required and dissipated by the turboelectric powertrain, respectively. Overall, the results are consistent with the drag profile displayed in

Figure 2, and the power output of the ICE (Internal Combustion Engine) is comparable to the engines of the ATR42-600 [

21,

57]. The total propulsion system of the ATR42-600 generates between 2 and 4 MW of power, and when converting to a turboelectric propulsion system, the number of components required to generate this power will increase, namely the generator and the electric motor. This can improve the propulsive efficiency, but it will also be heavier and generate more heat, which will of course impact the TMS.

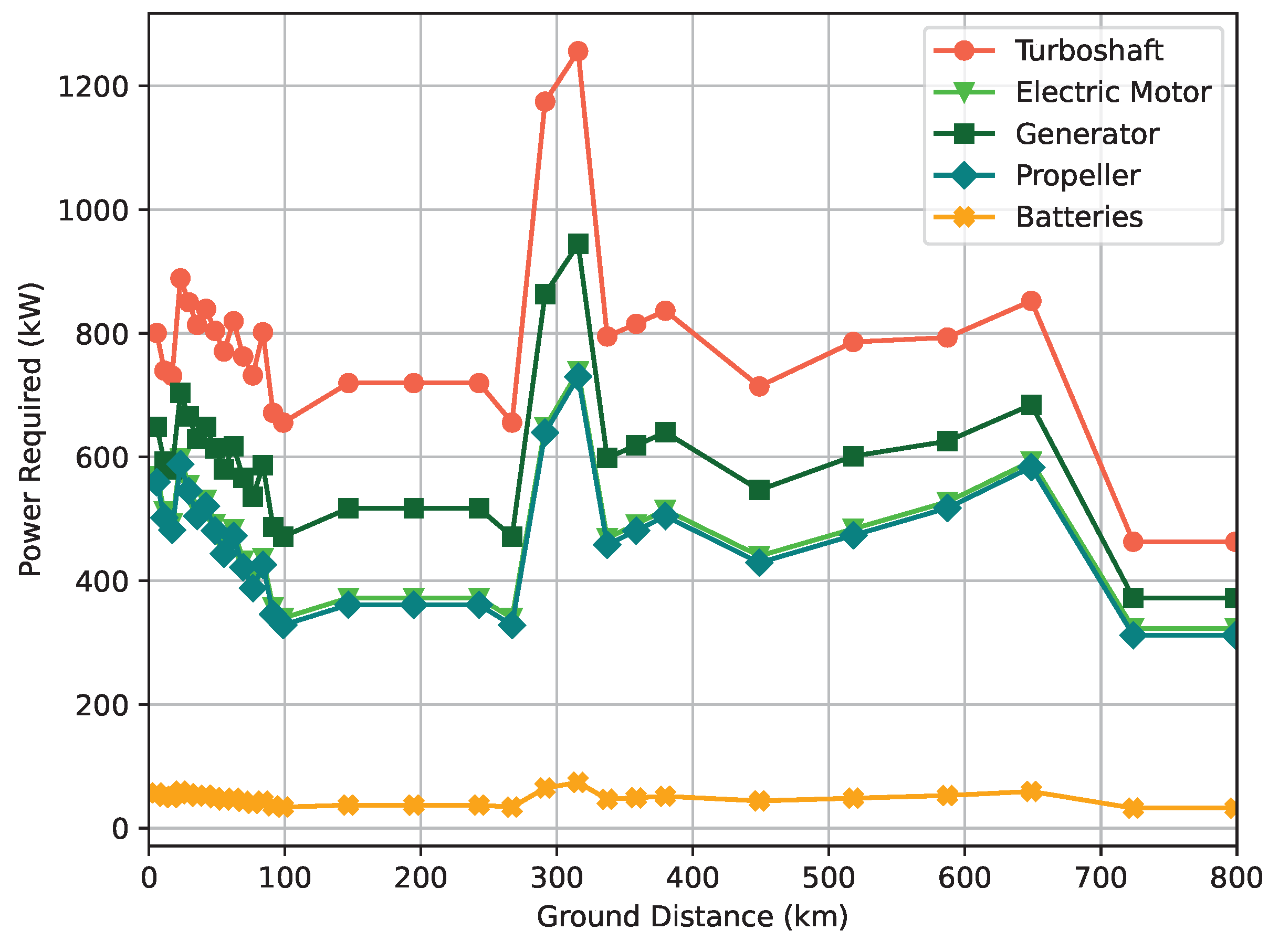

4.2.2. Series Hybrid-Electric

Figure 10 depicts the power required for the series hybrid-electric propulsive system. The turboshaft remains less efficient than the electrical components. As seen by this mission, it is common to observe peaks in the power demand owing to acceleration or sustained flying at the same altitude. After that, the standard landing operation begins, and the power demand is rather minimal.

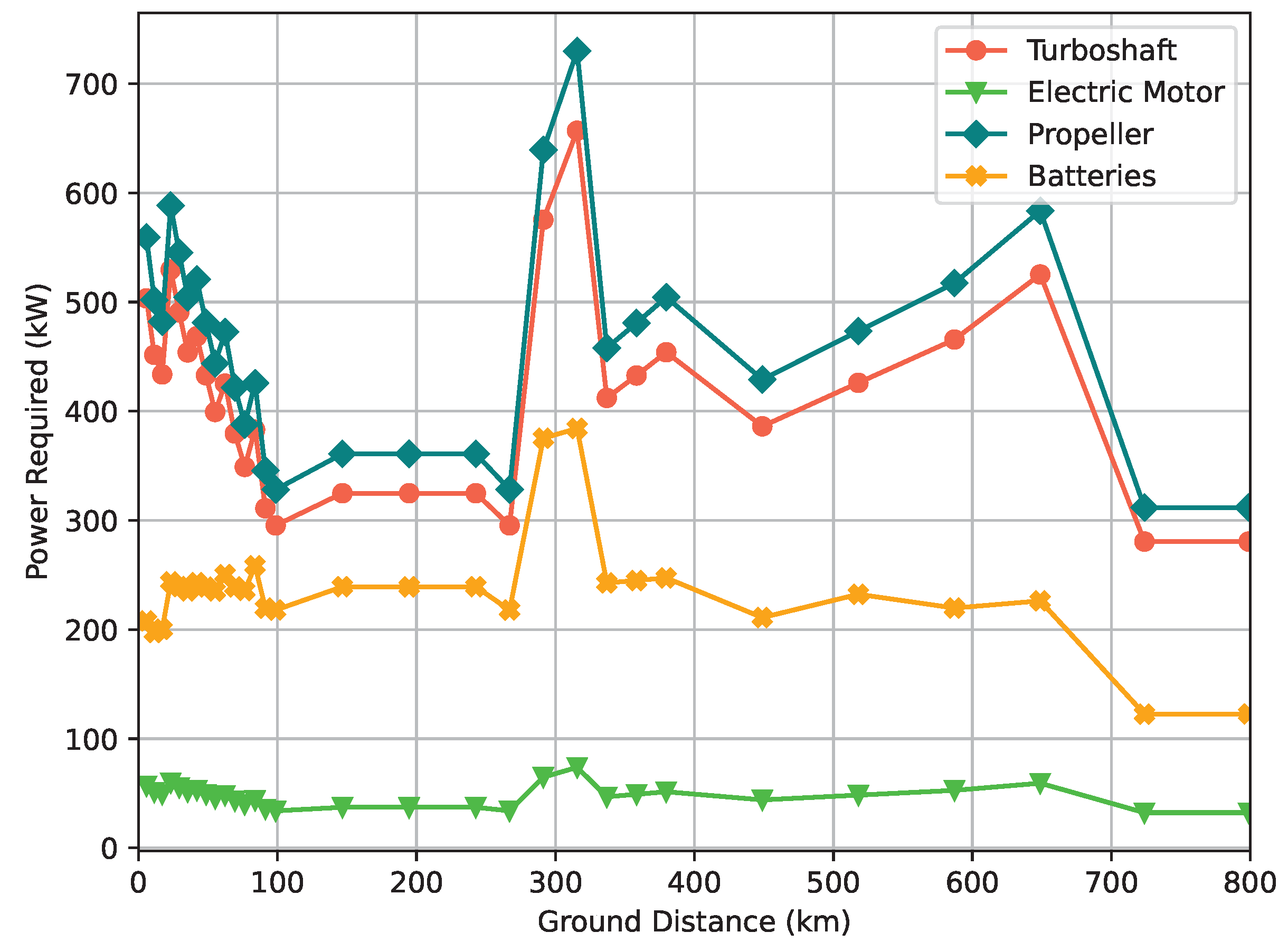

4.2.3. Parallel Hybrid-Electric

Figure 11 represents the power required by the different components of the parallel hybrid-electric configuration. Given that the turboshaft and the propeller only have a gearbox between them, the power needed for these two components is now closer. The consequence of this is a reduction in power lost by the internal combustion engine. It is worth mentioning that the power required for the propeller is higher than the one required for the turboshaft in the parallel configuration since the hybridization factor considered (10%) is higher than the power loss in the gearbox.

Compared to the series hybrid-electric setup, this architecture may appear favorable because it has one less component and results in the same reduction in power loss for the same hybridization factor. However, once again care should be taken when comparing with the series architecture as will be seen in

Section 4.3.

The inefficiency of the internal combustion engine relative to other components is underlined once more.

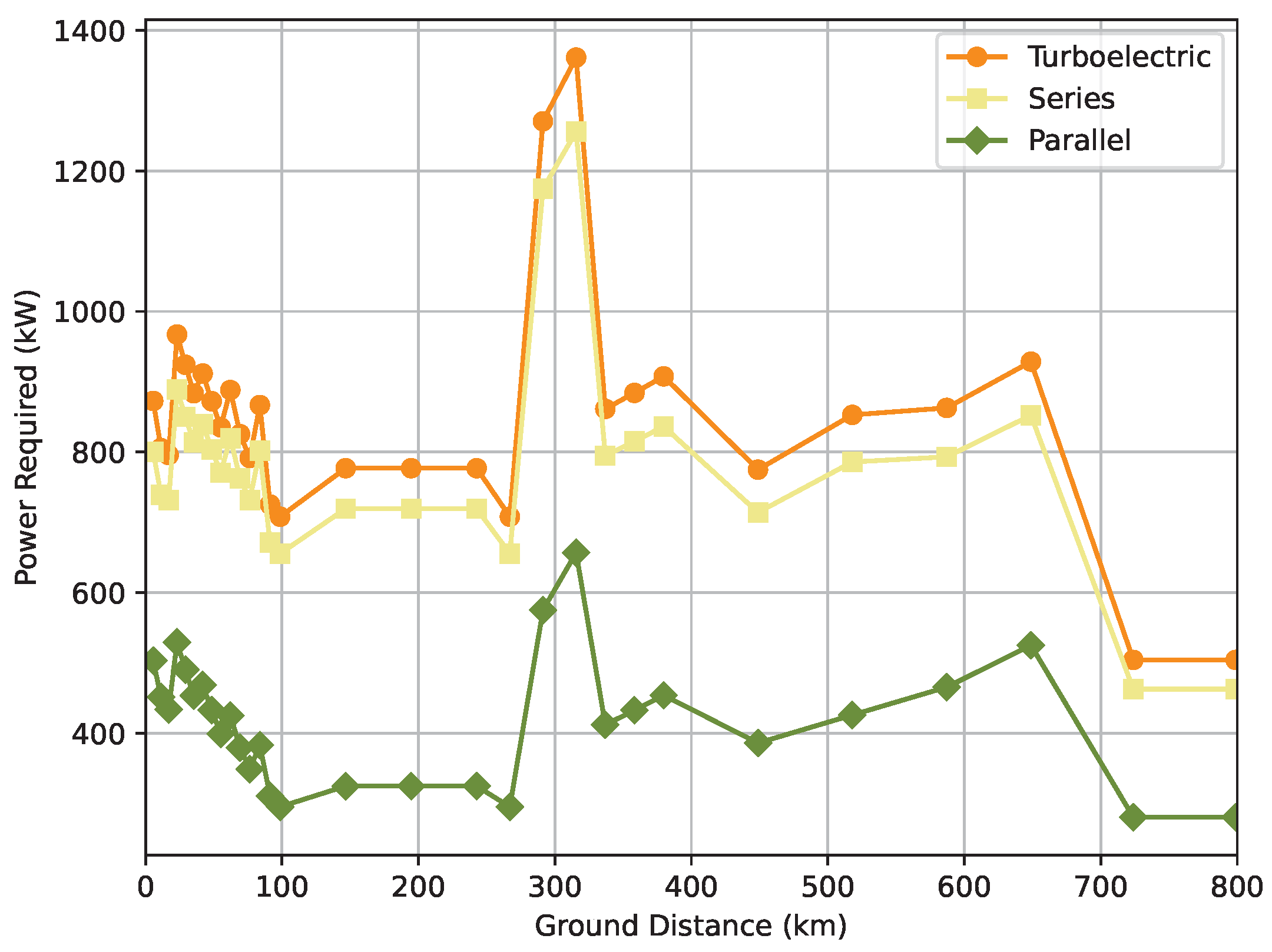

4.2.4. Comparison

As projected, the series hybrid architecture requires less power from the internal combustion engine than the turboelectric one. Moreover, the parallel hybrid-electric configuration demands less power from the turboshaft, as portrayed in

Figure 12, due to the number of components in the powertrain of this architecture and the way they are linked, as mentioned previously in

Section 3.3.

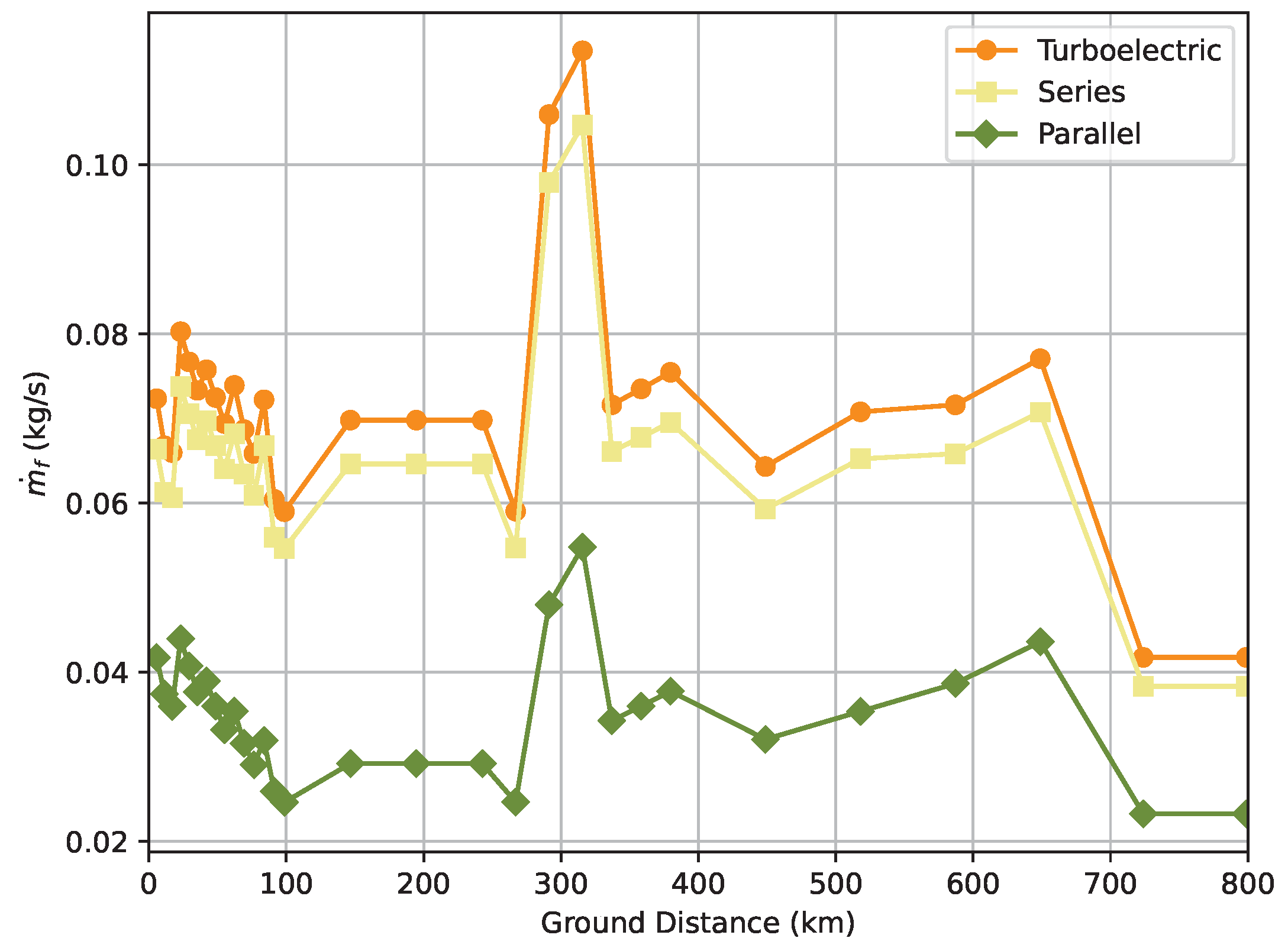

A linear correlation was noted between the power required for the turboshaft and fuel consumption, and given that, the same comments made for power can be made for the fuel flow, as seen in

Figure 13: although the series hybrid-electric system is more efficient than the turboelectric one, it is less efficient than the parallel hybrid system, assuming the same hybridization factor and disregarding the usable payload.

Even though the same combustion engine model, tuned for the validation test case, was used for all the propulsion systems, different power requirements are noticeable for the 3 propulsive architectures. Thus, different engine models could boost the efficiency of the turboshaft and consequently the entire powertrain.

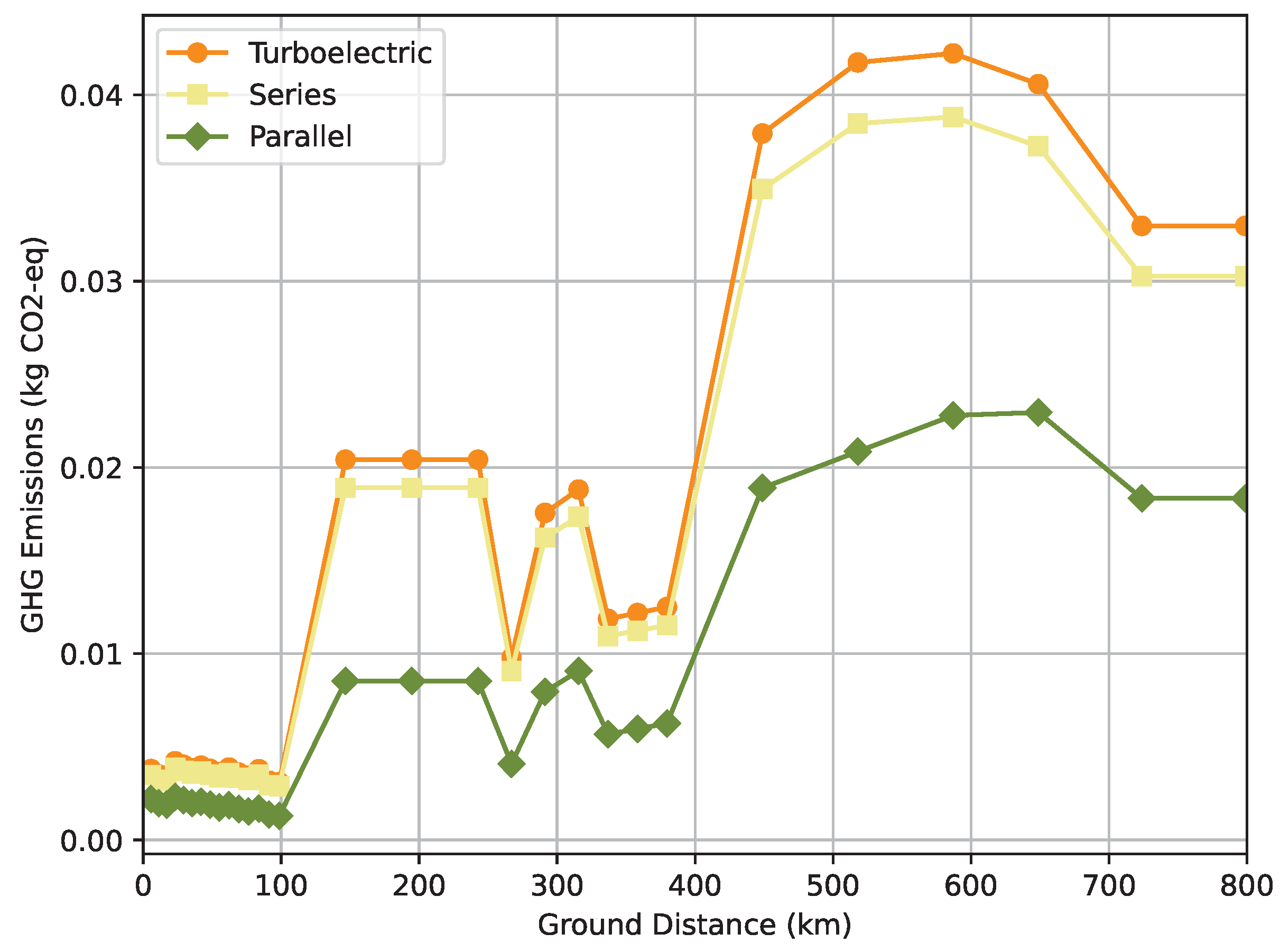

Regarding flight emissions, from

Figure 14 one can conclude that the majority of pollutants are emitted throughout the last segments after cruise, corresponding to descent, alternate, hold, and landing segments. Even though this result might seem counter-intuitive, it is the combined outcome of lower air speeds, a longer ground distance to cover, and a lower aerodynamic efficiency as denoted in the drag profile earlier depicted in

Figure 2.

As previously stated, batteries do not yet possess a high enough energy density for their implementation to not significantly raise the weight of the propulsion system.

For the considered conditions the mass of the turboelectric propulsion system–including the fuel mass–for this mission is 2323.2 kg, the one of the series hybrid-electric configuration is 4098.2 kg and the one of the parallel hybrid-electric architecture is approximately 10,505 kg. For comparison purposes a reference value of 5611 kg considering the ATR42-600 aircraft is used. This value corresponds to around 31% of the MTOW and includes the fuel mass, engines and propellers (data from aircraft, engine and propeller manufacturers), which are also accounted for the developed model. Considering the MTOW of the FutPrInt50–18,100 kg, 500 kg lighter than this aircraft, the propulsion system will occupy 12.8% of the turboelectric architecture, 22.6% of the series architecture, and 58% of the parallel architecture, considering 10% of power hybridization factor in these last two configurations. The mass of the parallel hybrid system is rather larger than the ATR42-600 reference mass for the propulsion system (including fuel) and will result in an infeasible design, as will be observed in

Section 4.3.

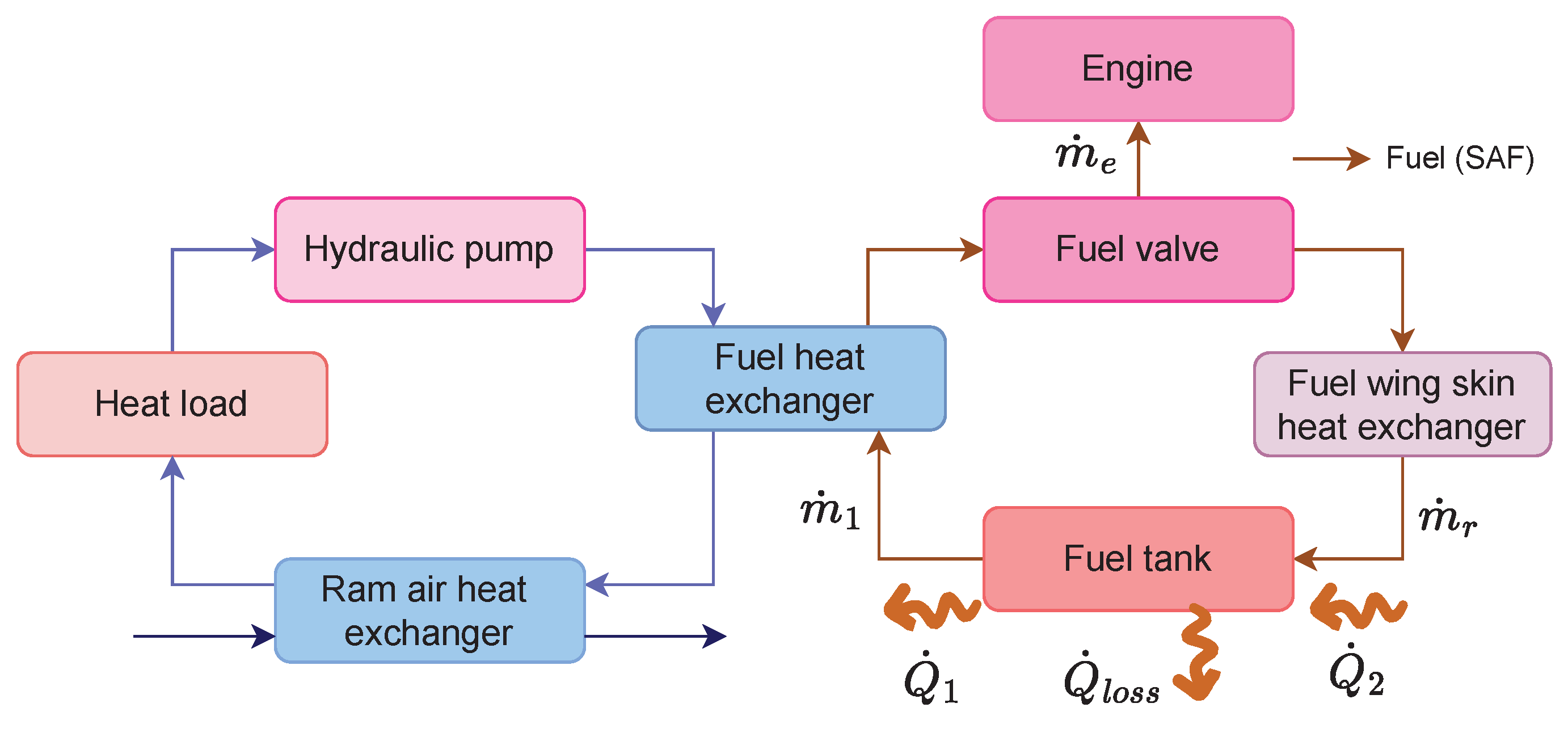

As far as TMS is concerned, most of the heat is dissipated at the RHX. This can be visualized in

Figure 15 where one can note that the heat transfer rate at the RHX follows the heat load directly associated with the power generated and drag profile. As expected from the power required graph (

Figure 12), the turboelectric and series hybrid architectures require a larger heat load to be rejected by the TMS which is done at the RHX. If the heat dissipated by the turboshaft would be considered for the TMS, i.e., assuming that the turbine is installed internally rather than externally, the amount of heat needed to be rejected from the aircraft increases by an order of magnitude due to the low efficiency of the thermodynamic cycle. This consideration significantly impacts the mass of the TMS as can be seen in

Section 4.3. Given the lower capacity to dissipate heat from the aircraft, dependent on the amount of fuel, the FHX contribution to this aspect is consequently lower than the RHX one. This expected outcome can be noticed by comparing

Figure 15 with

Figure 16.

The heat transfer rate at the FHX initially decreases since the ambient air temperature is higher than the fuel temperature. Then, it increases with the raise of both altitude and airspeed, i.e., conditions favorable to the capacity of the fuel-wing skin heat exchanger to dissipate the heat load. From the peak of power onwards, the heat transfer rate reduces with the decrease in airspeed and altitude.

4.3. Multi-Objective Optimization

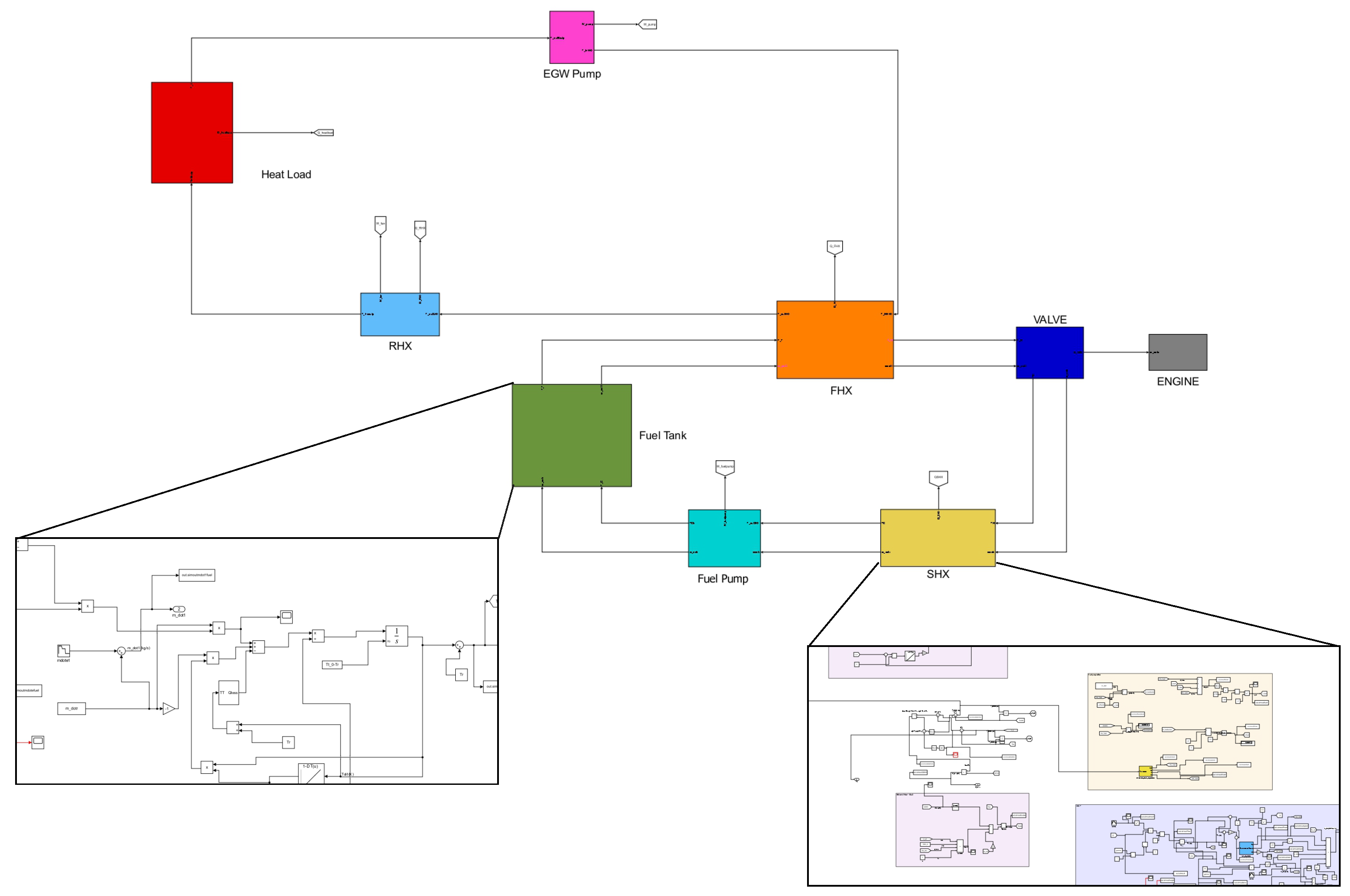

In this examination, the previously described TMS architecture was coupled with the propulsive models, and several optimization experiments were carried out.

The optimization model ran for both series and parallel architectures and it employs the power hybridization factor as a design variable.

Since the behavior from generation to generation was not substantially different and the Pareto front converges after a small number of generations, due to the computational cost, the algorithm ran only for one, with a population of 50. All the designs were of rank 1. This behavior is attributable to the usage of a single design variable, which drastically decreases the available design space.

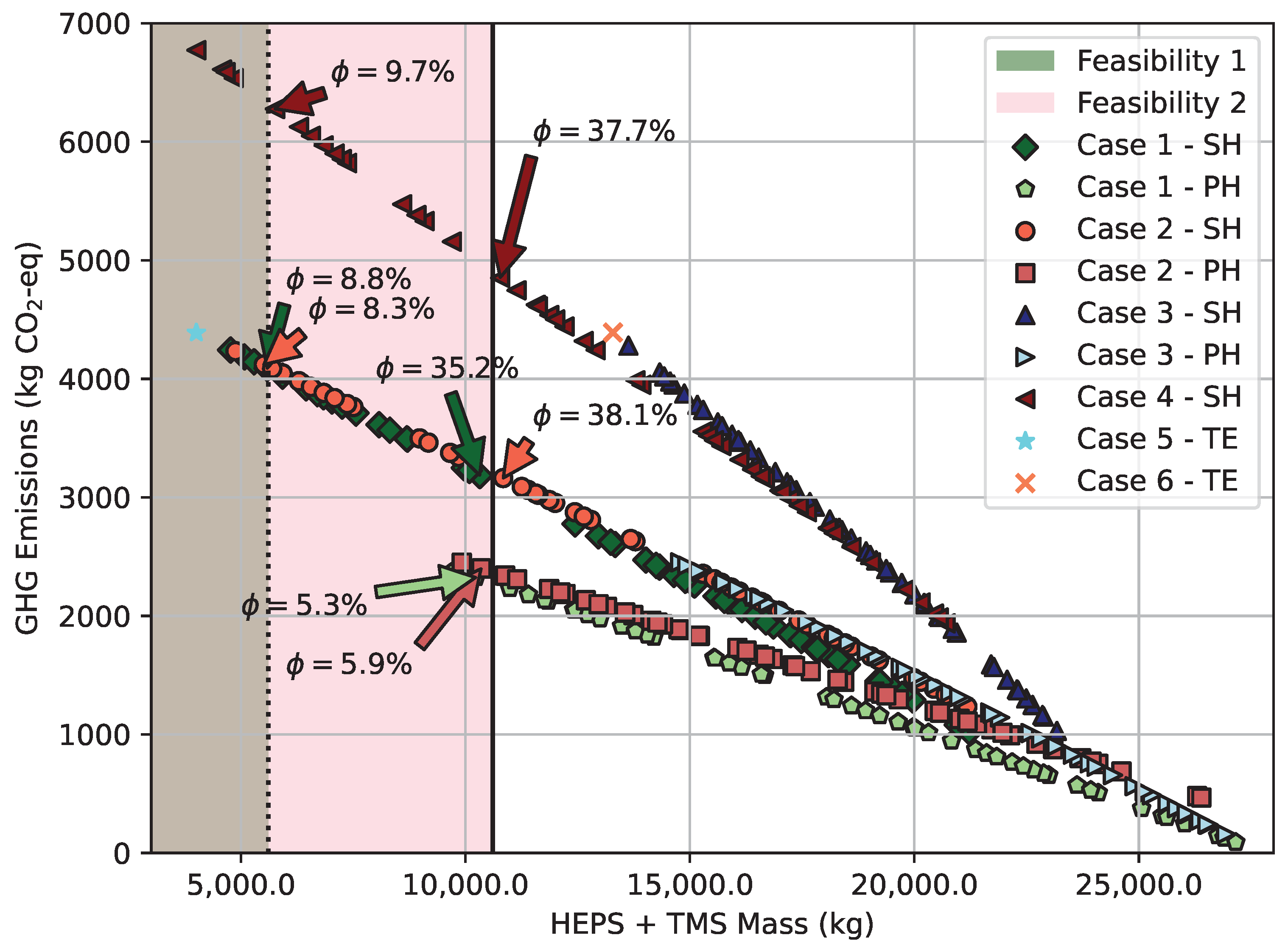

More distinct scenarios are examined, with optimistic values for consumption, production, recharging of battery, fuel and cooling liquid, and the corresponding pessimistic cases: (i) case 1: optimization of the total HEPS (Hybrid-Electric Propulsive System) and TMS mass and CO emissions using SAF in an optimistic scenario, with the TMS controlling the heat generated by the battery, electric motor, generator and gearbox; (ii) case 2: optimization of the combined masses of HEPS and TMS and CO emissions considering SAF in the aforementioned pessimistic scenario, with the TMS in charge of controlling the heat generated by the battery, electric motor, generator and gearbox; (iii) case 3: minimization of the combined mass (HEPS and TMS) and CO emissions using SAF in an optimistic scenario, considering turboshaft dissipated in the TMS besides the heat produced by the battery, electric motor, generator, gearbox; (iv) case 4: identical to case 2, but considering the Jet-A instead of a SAF. Additionally, two cases are depicted as benchmarks for both total mass and emissions: turboelectric configurations without (case 5) and with (case 6) considering the heat dissipated by the ICE.

The resulting approximated Pareto-optimal solutions are shown in

Figure 17, where the expected trade-off in optimal layouts is evident.

Overall, the batteries have the greatest impact on the mass of the total system (which are substantial for high hybridization factor values), whereas the fuel required by the turboshaft has the greatest influence in terms of flight emissions. The power required to the battery will increase as the hybridization factor increases, by definition. Consequently, a higher mass penalty will appear when the flight emissions are lower.

The projected outcome is reached by comparing the optimistic and pessimistic scenarios. For the pessimistic scenario, a rise in emissions is recorded for the same mass of propulsion and thermal systems. Due to the larger dependence on fossil fuels for battery recharging, this rise is greater for hybridization factors that are higher.

The typical efficiency of a thermodynamics cycle is low: specifically, in this case, it is of around 30%. Thus, for all the cases that include the heat dissipated of the ICE, this low efficiency translates into a TMS that has significantly more heat that must be managed. Consequently, the impact on emissions and mass will also be substantially higher in these cases (3 and 6) than in cases 1, 2, 4 or 5. When the hybridization factor is reduced, the propulsion system generates additional waste heat - due to the lower efficiency of the turboshaft compared to the higher efficiency assumed for the battery - that must be eliminated. With greater heat that must be handled for a lower hybridization factor, the TMS mass and the CO-eq emissions associated to liquid cooler production are increased.

As expected, the use of Jet-A has a larger impact on the environment than SAF as can be observed by comparing cases 2 and 4.

Considering again the same reference fraction of 31% of the overall mass for the propulsion module, a vertical line has also been added to the graph to represent a realistic mass limit. The zone on the right side of the reference line provides ambitious pollutant emissions by increasing the power required by the battery and also unrealistic maximum propulsive mass values. This feasible range is between 0 and 9% for the series-hybrid architecture.

By analyzing the different propulsive architectures, important remarks can be taken. The parallel powertrain is preferable when compared to the series case in terms of emissions as can be noticed from the curve slope in

Figure 17, even though it has a higher mass penalty. Consequently, the parallel architecture results in a lower usable payload and larger CO

-eq emissions per kilogram of payload carried, as can be seen in

Table 8. This, again, can be justified by the battery impact. According to the electrical branch chain, the power required by the battery pack is higher in the parallel case. This way, the system will be heavier for all the hybridization factors and the turboshaft will be downsized, leading to fewer emissions. When comparing the turboelectric case and the lowest hybridization factor series case, it can be seen that the CO

emissions and the overall mass are identical. This is because the series case for a hybridization factor of 0% corresponds to the turboelectric architecture, where no battery is included in the powertrain. In the optimization simulation, the random design space ended up not including a hybridization factor of 0%. Otherwise, the corresponding series result would coincide with the turboelectric result.

Another mass reference added - the continous line - denotes a new feasible zone for the mass of the whole system if the passengers and their respective payload were removed (5000 kg). In this scenario, both configurations (series and parallel hybrid-electric) are acceptable for some range of hybridization factors, until hybridization factors of 37% and 6%, respectively.