1. Introduction

The

health condition of a mechanical system determines its performance. Thus, monitoring such condition is essential for various tasks, including control, maintenance, and safety. In particular,

predictive maintenance (also called condition-based maintenance) requires monitoring the system condition for diagnosis [

1,

2,

3,

4] to anticipate when it should be repaired/restored before potentially dangerous breakdown occurs. Thus, predictive maintenance (i) reduces cost [

5] because maintenance tasks are carried out when and where they are truly needed, not just by schedule, and (ii) increases safety by avoiding dangerous events during operation. This type of maintenance has received increased attention in the literature during the last decades [

6,

7,

8], due to its application in a variety of industrial sectors, such as the aerospace [

9,

10], manufacturing [

11], and railway [

12] industries.

Although the methods developed in the paper apply to more general systems, they will be illustrated (and their performance tested) considering a turbofan aeroengine for commercial aviation. This system is representative, in terms of both difficulties and opportunities, of many other complex mechanical systems. The performance of the developed methodology will be tested for synthetic data in cruise conditions, which cover most part of the flight time. Similar results could be obtained considering other flight stages, such as take off and landing.

Concentrating on aeroengines, during the last decade, an increasing interest has arisen in the main industrial companies in the field on developing health monitoring tools to improve their predictive maintenance capability. Many of these tools are either

data-driven or

model-based [

13,

14]; additionally, there are hybrid methods, such as the physics-informed neural networks [

15].

Purely data-driven methods [

16] rely on just data and are usually based on machine learning and statistical algorithms. Their online operation is fairly inexpensive, but constructing these models requires offline training [

17], the computational cost of which is usually enormous. It is performed using former experience in the type of engine that is being analyzed. They lack flexibility, since they do not give good results for other engines (or modified engines) not accounted for in the training stage.

Model-based methods are more flexible and precise than data-driven models because they explicitly take the aeroengine physics into account, using a

nonlinear engine model. Thus, these methods require solving (iteratively) a large set of nonlinear equations, meaning that their online operation is generally more computationally expensive than that of data-driven models. The engine model computes the sensors outputs in terms of several

degradation parameters that depend on the engine condition (health status) and the

operating regime. The operating regime is determined by the flight

altitude and

Mach number, and the

turbine inlet temperature. The latter is very important since it determines the

engine thrust (and affects the engine lifetime) in aircraft aeroengines, as well as the

engine power in related systems, such as naval gas turbines and aeroderivatives. Concerning the aeroengine degradation parameters, Stamatis et al. [

18] proposed

flow capacities and adiabatic efficiencies of several engine components, which are generally acepted nowadays. The main turbofan manufactures have developed their own models for the engines they produce. Unfortunately, these engine models are confidential and not available in the literature. In this paper, we shall use an engine model based on PROOSIS [

19], which is able to simulate different aeroengine types; see [

20] for details of the PROOSIS solver. It must be noted that this (and any other) engine model uses discrete empirical data obtained by actual measurements in the main engine components, and is based on an iterative method. The latter exhibits convergence difficulties when trying to simulate cases that are outside the operating regime where the empirical data have been acquired. A review of model-based methods can be found in our recent work [

20], where a methodology was developed for aeroengine diagnosis. The present paper is a step further in the sense that, while diagnosis was performed in [

20] using a PROOSIS-based engine model, here, we shall construct and use a convenient

reduced order model (ROM), combined with gradient-like condition monitoring tools. In contrast with the engine model, the online operation of this ROM is extremely fast since it only requires to perform a limited set of algebraic computations. This means that the methodology to be developed in this paper shares the advantages of the data-driven and model-based methods, namely

fast online operation and

precise, robust results. In fact, we shall use the experience gained in [

20] to directly select the most convenient gradient-like method, which is an appropriately adapted

global, constrained Newton-based method that gives very good diagnosis results. Full details of this method, omitted here for the sake of brevity, can be found in [

20]. The offline construction of the ROM requires: (i) running a full engine model a very large number of times, to obtain data that are collected in a (high-order) tensor; this may be fairly computationally expensive. Furthermore, (ii) applying a tensor decomposition, which instead is fairly inexpensive. As anticipated, the online operation of the ROM is quite fast, permitting real-time results. The concept of ’real time’ is somewhat ambiguous, since it has several possible meanings, depending of the context. To be precise, two meanings are used in this paper: (a) on the one hand, monitoring data in the aircraft cockpit requires a very small computational time, not larger than, say, 0.5 CPU seconds, which is enough for human eye detection and will be called

continuous real time; (b) on the other hand, since the flight time is at least 30 min, a computational time of up to a few CPU minutes will be called

in-flight real time.

Specifically, the ROM will be constructed by applying a tensor extension of standard

singular value decomposition (SVD), called

higher-order singular value decomposition (HOSVD), combined with

one-dimensional interpolation, to a dataset organized in tensor form. This combination is a higher-dimensional extension of the celebrated, very useful method [

21,

22], which combines proper orthogonal decomposition (or standard SVD) and interpolation. The required data will be obtained using an engine model. In other words, a

surrogate of the engine model will be constructed that gives the sensors outcomes in terms of the engine operating regime and the degradation parameters. Similar ROMs based on HOSVD plus interpolation have been already used in several fields, including generation of aerodynamic databases [

23], continuous real-time control of reciprocating engines [

24], and aircraft conceptual design [

25,

26]. HOSVD-based methods also permit constructing tools for recovering lost data [

27] and filtering large errors [

28] in multidimensional databases, which are relevant in condition monitoring tasks, including:

Recovering sensors data not provided by the engine model, due to convergence difficulties. Furthermore, recovering data at places in the engine not accessible to sensor measurements.

Correcting wrong sensors data due to ill-functioning sensors or engine instrumentation, which may produce large errors.

However, these applications are beyond the scope of this paper and will be considered elsewhere. Here, we shall only consider small errors in the sensors data that somewhat mimic experimental noise, see below.

Using the surrogate engine model, two condition monitoring tools will be developed that compute both the engine degradations and the turbine inlet temperature, , at which the sensors data have been acquired:

The condition monitoring tool 1 is based on a linear approximation, and thus requires small degradations around a baseline state, which are expected in each individual flight. Its online operation is extremely fast; namely, it can operate in continuous real time. It precisely computes the turbine inlet temperature and gives a first approximation of the engine degradation. This tool has been obtained as an unexpected byproduct, when checking the importance of nonlinear effects.

The

condition monitoring tool 2 is the counterpart, using the ROM surrogate, of a very efficient tool developed in [

20] for the full engine model. This tool operates in in-flight real time and is designed for nonsmall degradations (up to ∼2%), for which nonlinear effects must be accounted for. Let us mention here that degradations of 2% are fairly high and usually require performing maintenance tasks on the degraded engine component [

29,

30,

31] to avoid future dangerous events. On the other hand, the very small degradations that are expected during each flight accumulate in subsequent flights. In this sense, if an accumulated degradation becomes larger than 2%, then it must be monitored since it could reach dangerous values as time proceeds. Such monitoring can be performed using the method developed in [

20], which accurately performs diagnosis for very large degradations. In this sense, the tool 2 developed in this paper is complementary to the methodology presented in [

20].

The raw (dimensional) sensors data account for properties such as temperatures, pressures, rotational speeds, and fuel consumption, which take very disparate values. This could cause ill-functioning of condition monitoring tools. Thus, the sensors outcomes need to be appropriately nondimensionalized/scaled.

On the other hand, in practice, the outcomes of actual sensors mounted in the engine are noisy. In order to take this into account, small random noise with zero mean will be added to the engine model outcomes, concluding that the developed tools are robust in connection with noise.

Computations will be performed using standard (uncompiled) MATLAB in a standard PC, with a microprocessor Intel Core I7-6500U at 2.5 GHz, with 16 GB of RAM memory. The CPU times reported along the paper for reference could be significantly reduced using more advanced, customized software and hardware. Quantitative results will be given in the form of tables, which is convenient to facilitate the reader to reproduce results.

Against the above background, the remainder of the paper is organized as follows. The specific aeroengine that will be used to test the performance of the methodology is presented in

Section 2, where the convenient degradation parameters and sensors are described and the output sensors data are appropriately scaled. The required data processing methods, standard SVD and HOSVD, are briefly described in

Section 3, where the detailed construction of the surrogate engine model and the aforementioned condition monitoring tools 1 and 2 are also addressed. Specific condition monitoring results are given in

Section 4 and some concluding remarks are provided in

Section 5.

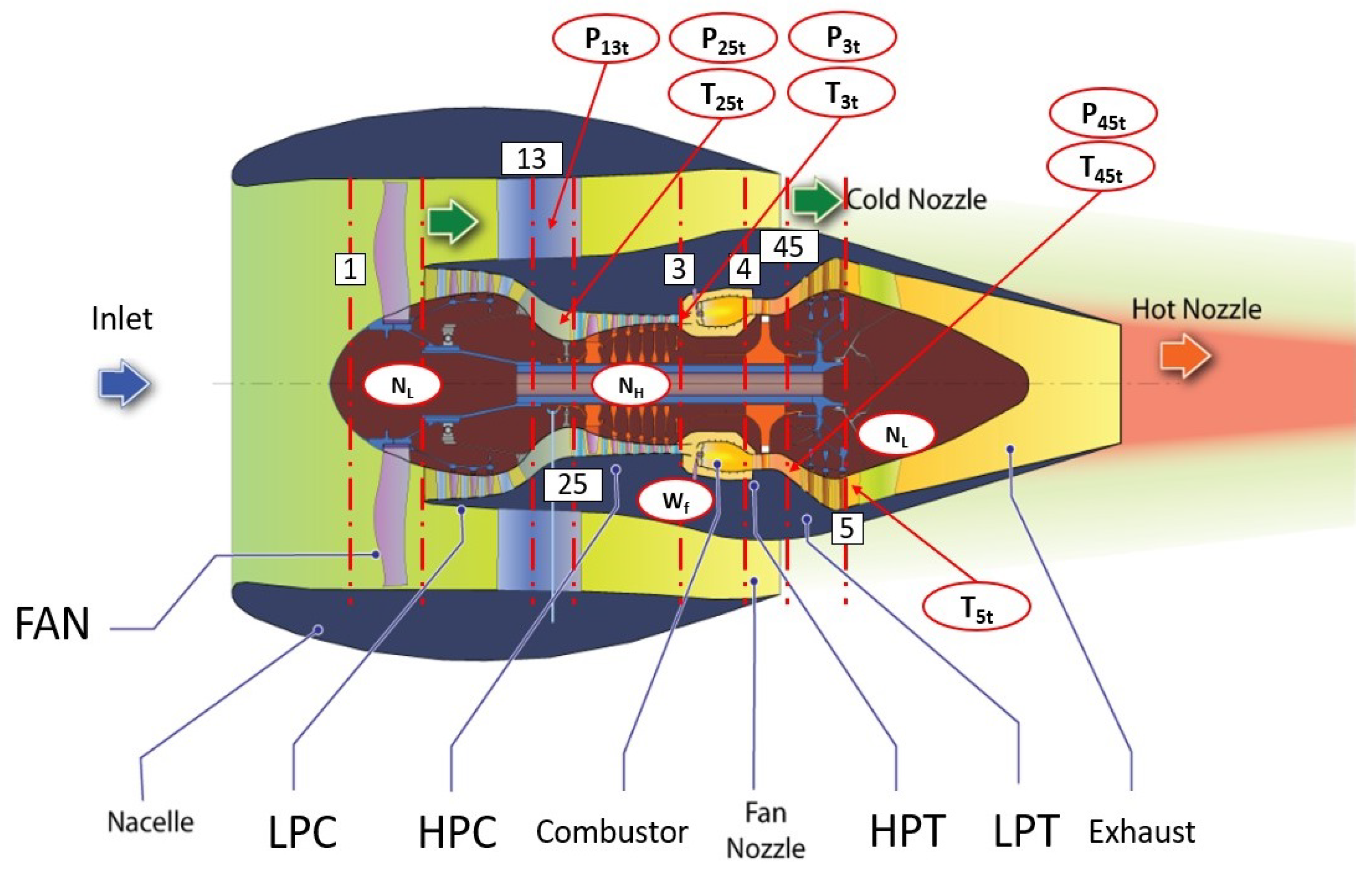

2. Test Case to Evaluate the Performance of the Methodology: The CFM56 Aeroengine

As in [

20], we consider a CFM56 aeroengine, which is representative of those widely used in commercial aviation nowadays [

32]. It is the two-spool turbofan engine sketched in

Figure 1, where the main engine components are indicated, as well as the engine locations where several relevant pressures

P, temperatures

T, rotational speeds,

and

, and the fuel consumption

can be measured. As can be seen, the engine contains both a low-pressure spool and a high-pressure spool, which rotate concentrically at different speeds. The

high-pressure compressor (HPC), the

high-pressure turbine (HPT), and the

combustor constitute the high-pressure part of the engine, also known as the core of the engine. The

fan, the

low-pressure compressor (LPC), also known as the booster, and the

low-pressure turbine (LPT) are mechanically connected and constitute the low-pressure part of the engine. For the various involved technical parameters, see the Appendix in our previous work [

33].

For this engine, condition monitoring will be performed in the following ranges of the flight altitude

h, the Mach number

M, and the turbine inlet temperature

:

which cover typical cruise conditions in commercial aviation.

The engine is characterized by the ten

degradation parameters, whose deviation from their baseline values measure the engine degradation. They are measured in %, which represents an

automatic scaling, and are nonnegative because the engine is degraded, not upgraded. In the present paper, as anticipated, they are allowed to vary in the following range:

The ten degradation parameters give the efficiencies and adiabatic capacities of various engine stations, as displayed in

Table 1.

Our condition monitoring tools will use sensors data to compute the ten degradations and the turbine inlet temperature, which amount to eleven unknowns. After the analysis in [

20], we shall consider the eleven

sensors described in

Table 2, second column, which are conveniently uncorrelated. In fact, the ten sensors 1–3 and 5–11 displayed in the table are representative of those frequently used in diagnosis studies [

3,

33,

35,

36,

37], and are usually mounted in the CFM56 aeroengine instrumentation [

38]. Concerning the 4th sensor, giving

(also included in the CFM56 instrumentation), this was selected in [

20] as one that complements very well the remaining ten sensors.

The average values of the sensors and the associated standard deviations, displayed in the third and fourth columns of the table, have been computed from the outcomes using the full engine model at the 45 combinations of the following three values of the altitude

h, three values Mach number

M, and five values of the turbine inlet temperature

:

Note that these 45 combinations cover well the range defined in (

1) in which the engine is to be inspected, and are necessarily computed because they will be precisely the discrete values of these parameters to construct the ROM. As can be seen in

Table 2, the dimensional values of the sensors outcomes differ among each other by several orders of magnitude; moreover, the standard deviations are dissimilar, since there is a factor of ∼7 between the smallest and the largest. Thus, it is convenient to scale them in such a way that the scaled values are comparable and vary in comparable ranges. As thoroughly explained in [

20], a convenient scaling meeting these requirements is performed as follows. The

(=11 in the present case) scaled sensor outcomes, denoted as

, are calculated as follows:

where, for

,

are the original dimensional sensor outcomes, while

and

are the associated averages and standard deviations displayed in

Table 2. Sensors will always be scaled using (

6) in the paper. This scaling can be computed for any aeroengine, with any value of

and, mutatis mutandis, to the sensor outcomes in other mechanical systems.

5. Concluding Remarks

A methodology has been developed for monitoring aeroengines condition. First, a surrogate engine model was constructed, by applying a tensor decomposition plus interpolation to a multidimensional dataset containing the aeroengine sensor outcomes computed by an engine model. Such a surrogate model can advantageously substitute the full engine model for two main reasons. Firstly, the surrogate model does not give erroneous/spurious sensors outcomes, as the full engine model does due to convergence difficulties. Secondly, once the surrogate engine model has been constructed, it gives results in a computationally inexpensive way, so that it can be installed as digital twin, meaning that the full engine model is no longer needed in the on-board aircraft software. The full engine model needs only be used to update the surrogate engine model after a major maintenance, which seldom occurs during the engine’s lifetime.

Using the surrogate engine model, two gradient-like condition monitoring tools were constructed. The first tool was based on a linear approximation around the baseline state, and able to very precisely compute the turbine inlet temperature, , in continuous real time. Thus, it is able to continuously show, very precisely, the instantaneous value of in a monitor installed in the aircraft cockpit. This represents a considerable added value of the present methodology, since is a very important property for various reasons, including the aeroengine control. However, cannot be precisely computed by the current aeroengine instrumentation in civil aviation. Our tool, instead, computes this temperature very precisely and could well be incorporated to improve the engine instrumentation. On the other hand, even though this tool does not compute degradations accurately, it gives a first approximation of them that permits discerning whether all degradations remain small or whether some of them have abnormally increased. In the latter case, the second engine monitoring tool must be used to precisely compute all degradations.

The second condition monitoring tool, instead, takes nonlinearity into account and precisely computes both the turbine inlet temperature and the degradation parameters. This tool operates in in-flight real time, meaning that it can be used several times in each flight. In other words, this tool can be used to either safely ensure that degradations remain conveniently small, or to identify the in-flight evolution of some nonsmall degradations that must be taken care of before they degrade too much. In the latter case, the tools developed in [

20], which give precise results for very large degradations, can be used. Thus, both dangerous events and costly maintenance are avoided.

It is important that both condition monitoring tools are robust in connection with random noise of realistic size added to the sensors data. For convenience, the present methodology has been tested using synthetic data for a particular aeroengine in cruise conditions, which cover most part of the flight time. However, it can also be applied, with similarly good results, to other aeroengines in other flight stages, such as take off and landing. The resulting monitoring tools would be convenient in the actual application of the methodology, using actual experimental data (instead of synthetic data), which will be considered elsewhere. Moreover, the developed methodology also applies to other complex mechanical systems.