1. Introduction

The solid rocket motor (SRM) is a simple, low-cost, and highly reliable power unit that is widely used in commercial launch vehicles and various tactical and strategic missiles [

1,

2]. In the process of SRM design, due to its unique mode of operation, it is generally impossible to directly control its thrust magnitude, so it is necessary to design a specific shape of SRM grain to control the thrust according to a specific thrust scheme [

3]. Therefore, the simulation of grain burning surface regression is one of the core problems of SRM design.

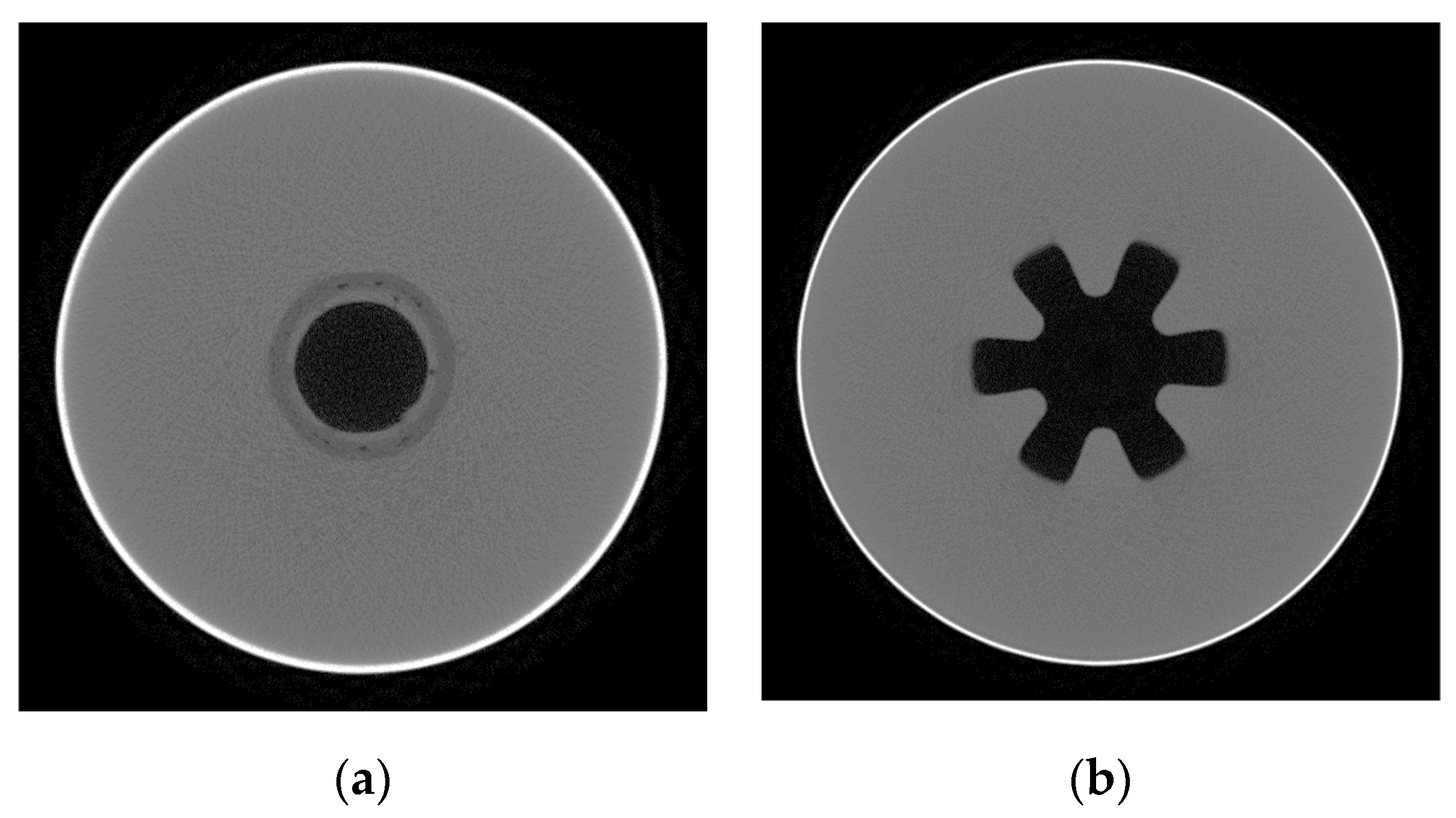

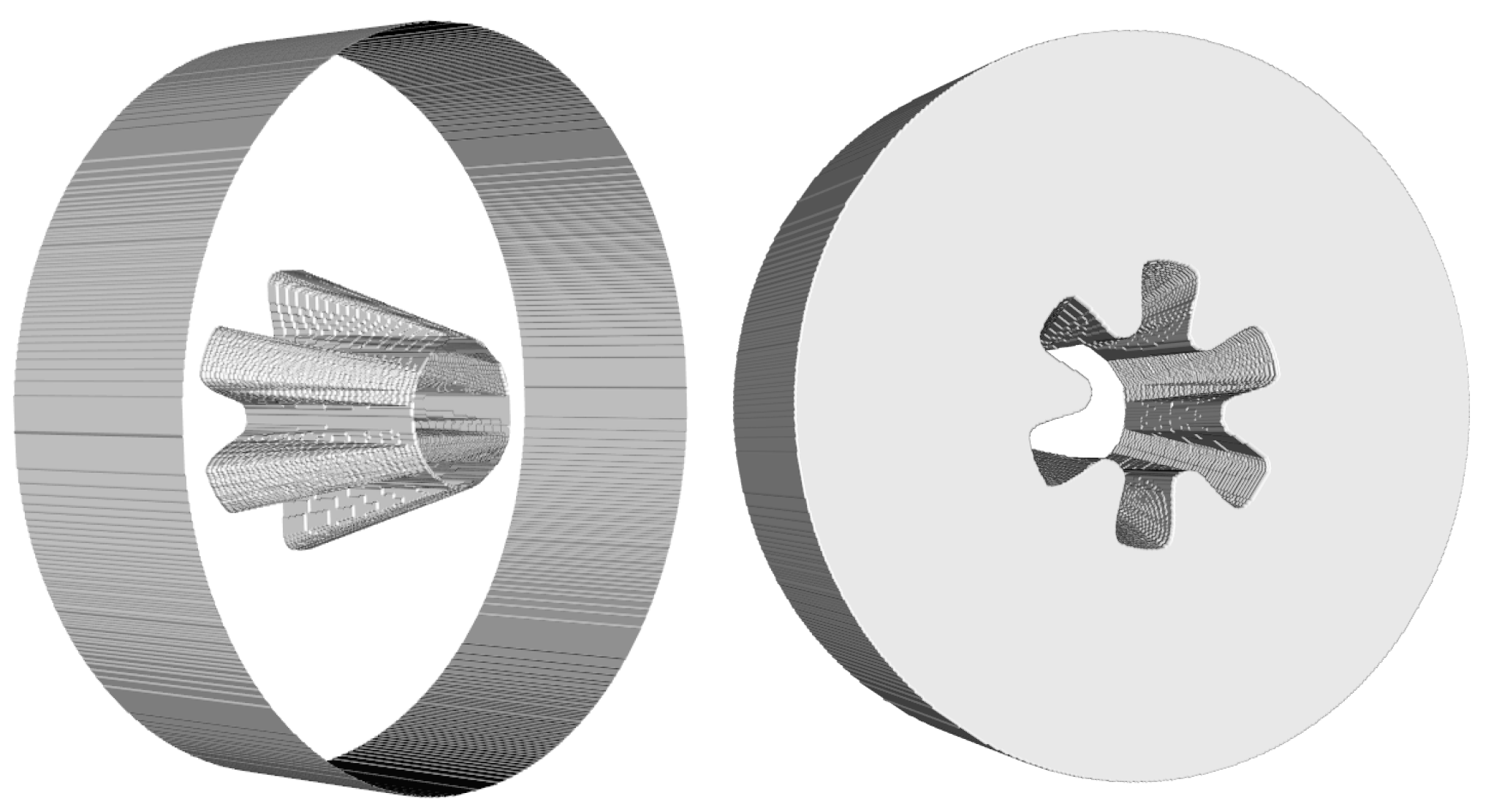

The internal surface of an SRM grain is subject to stress and strain due to manufacturing, storage, internal pressure load and other reasons, and as a result, defects are produced on the internal surface of the grain. In order to build the real internal surface of solid propellant to operate as efficiently as possible, nondestructive testing is required. Computed Tomography (CT) is an advanced technical means of inspecting SRMs, which has the characteristics of visual imaging, is high resolution, and is not limited by the geometry of the workpiece [

4]. CT images can clearly show the internal structure of SRMs. The real grain data is extracted by image processing, and based on this, feature points are found. The initial burning surface is then interpolated to thicken the CT images and reconstructed as a 3D model.

For simple-shaped grains, the burning surface regression under the geometric law of burning can be calculated by the analytical geometry method, while for relatively complex-shaped grains, the burning surface regression algorithm can be used to simulate the burning process [

5]. However, for an accurate prediction of SRM performance, the non-uniform distribution of burning rate in time and space must be considered, so the required burning surface regression algorithm must also support a non-uniform dynamic burning rate, which can also be interpreted as an interface tracking problem [

6].

The numerical methods for solving interface tracking can be divided into two categories: explicit methods and implicit methods [

7]. Explicit methods use a large number of basic elements to approximate the shape of the burning surface, and offset, merge, add and delete elements to simulate the burning surface. These include the general coordinate method [

8,

9], solid modeling method [

10], and dynamic mesh method [

11,

12]. The implicit method is to define an isosurface in the field function on the grid to approximate the shape of the burning surface and to manipulate the values of the field function on the grid to offset the isosurface. Although the implicit methods consume more computational resources, they are more compatible with complex burning surfaces and rate fields, and the implicit methods such as the Level-set (LS) method [

13,

14,

15] and the minimum distance function (MDF) method effectively avoid topology problems [

16,

17]. The commonly used implicit method is the LS method, which represents the real-time burning surface of the grain through the isosurface in the directed distance field, and indirectly moves the isosurface by numerical manipulation of the grid point distance field, which is theoretically applicable to any three-dimensional shape of the grain.

In recent years there have been some studies of LS methods applied to SRM burning surface regression calculations. Yildirim et al. [

18] studied the effect of various factors on internal ballistics using the LS method. Dong-Hui et al. [

19] took advantage of the good generality of the LS method by embedding it into a structural optimization system that can automatically generate a large number of design solutions and perform an automated evaluation. Cavallini et al. [

15] calculated the entire burning process of a solid rocket motor using the quasi-one-dimensional unsteady internal ballistic coupling LS method, which is particularly suitable for calculating the internal ballistics of the motor under erosive burning. There is also a need for research scholars to study the effect of grain defects on internal ballistics using the LS method [

20,

21,

22]. The LS method has been well applied to the simulation of grain burn-back in the above references, but the calculation speed has not been improved and the process of multiple reinitialization has not been solved. Wei et al. [

23] used Boolean operations to extract the burning surface and accelerated the computation of dense regions using GPUs. Oh et al. [

24] proposed a hybrid burning regression analysis method to classify and solve complex grains by selectively using the MDF method and LS method according to different needs. In these references, the speed of the LS method has been continuously improved, but the model it supports is an ideal model. The actual model may have some defects caused by manufacturing and storage, a problem which has not been resolved.

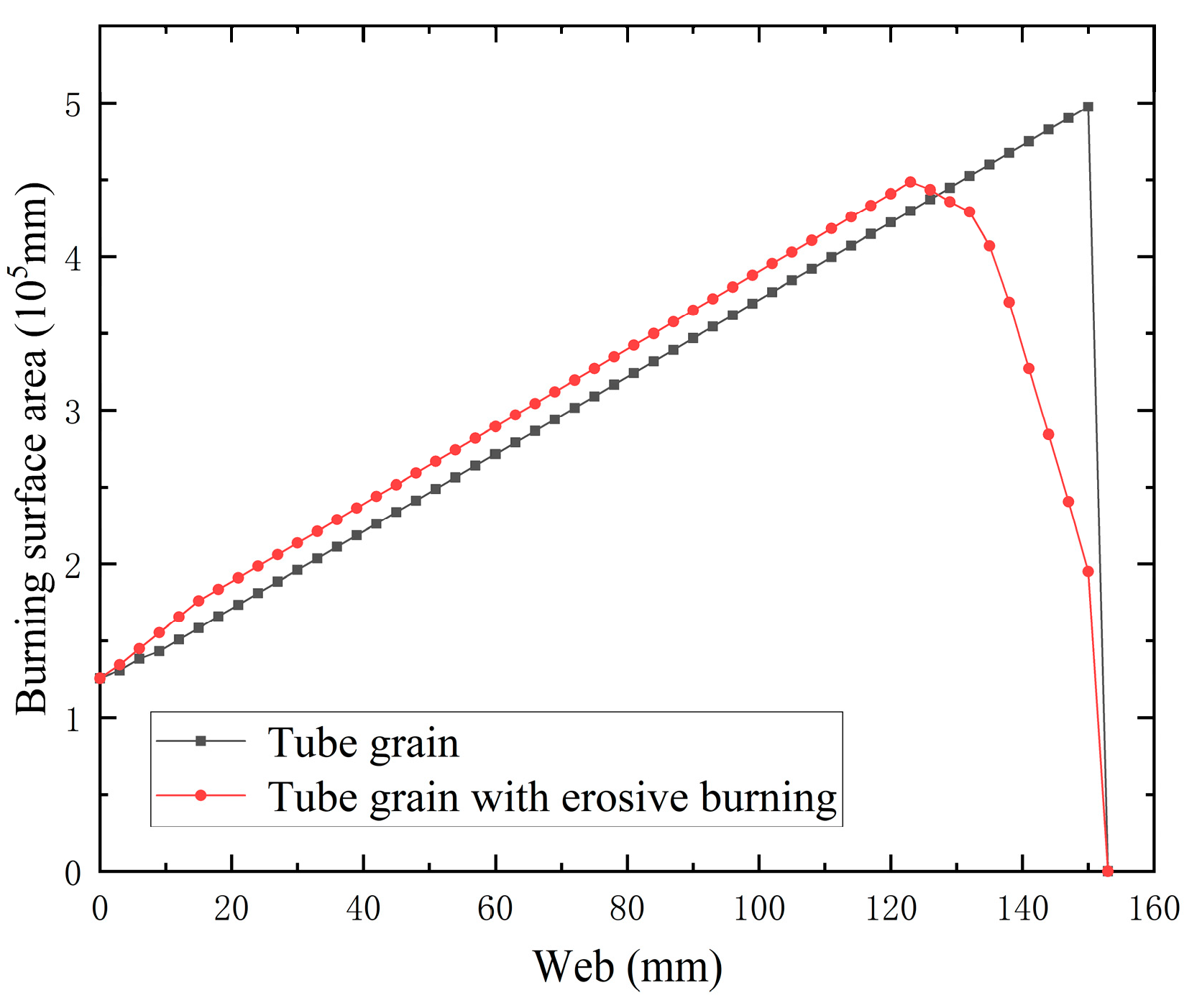

For non-uniform burning rate models, erosive burning effects are the most common important cause of the non-isometric burning surface regression. Erosive burning not only changes the direction of burning surface regression, significantly affecting the internal ballistics and performance of the motor, but also leads to premature exposure of part of the adiabatic layer [

25]. Many researchers have developed erosive burning models from heat transfer mechanisms, among which, the widely used models include the Lenoir–Robillard (LR) model [

26] and the Zeldovich–Novozhilov (ZN) model [

27]. Willcox et al. [

28] improved the LR model, which considers the thermal feedback of the gas to the grain as the pressure and flow rate of the gas. Several studies have successfully applied the LR model to investigate erosive burning effects [

29,

30,

31]. Since the ZN model requires finite element simulation of the heat transfer process in addition to the 1D or 3D solution of the internal flow field calculation, and the high complexity of the model is not conducive to coupling with the burning surface regression algorithm, the LR model is chosen to study the erosive burning effect.

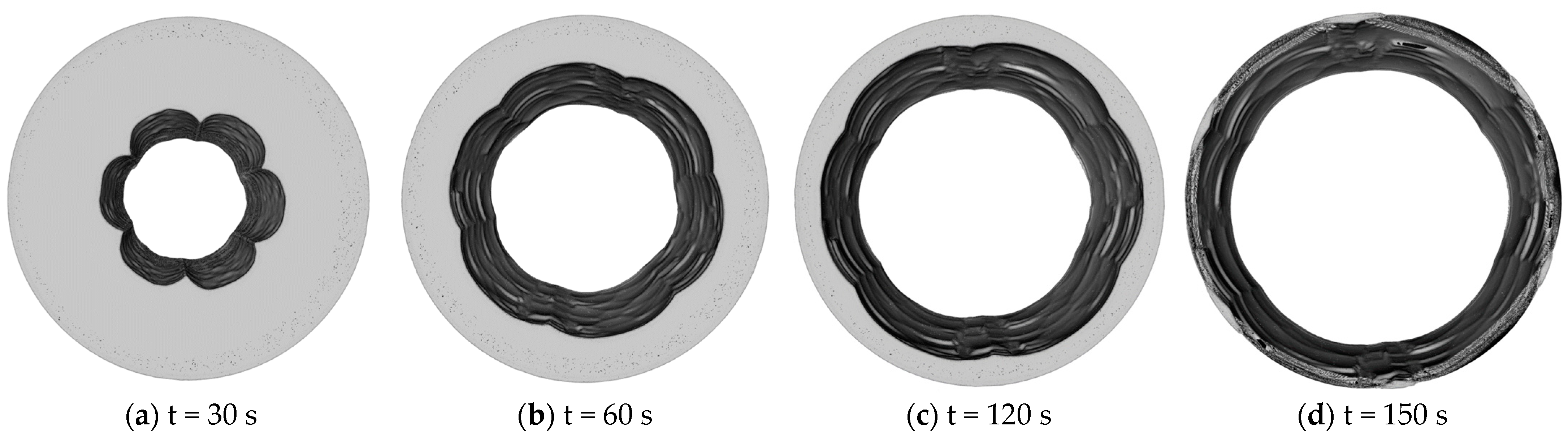

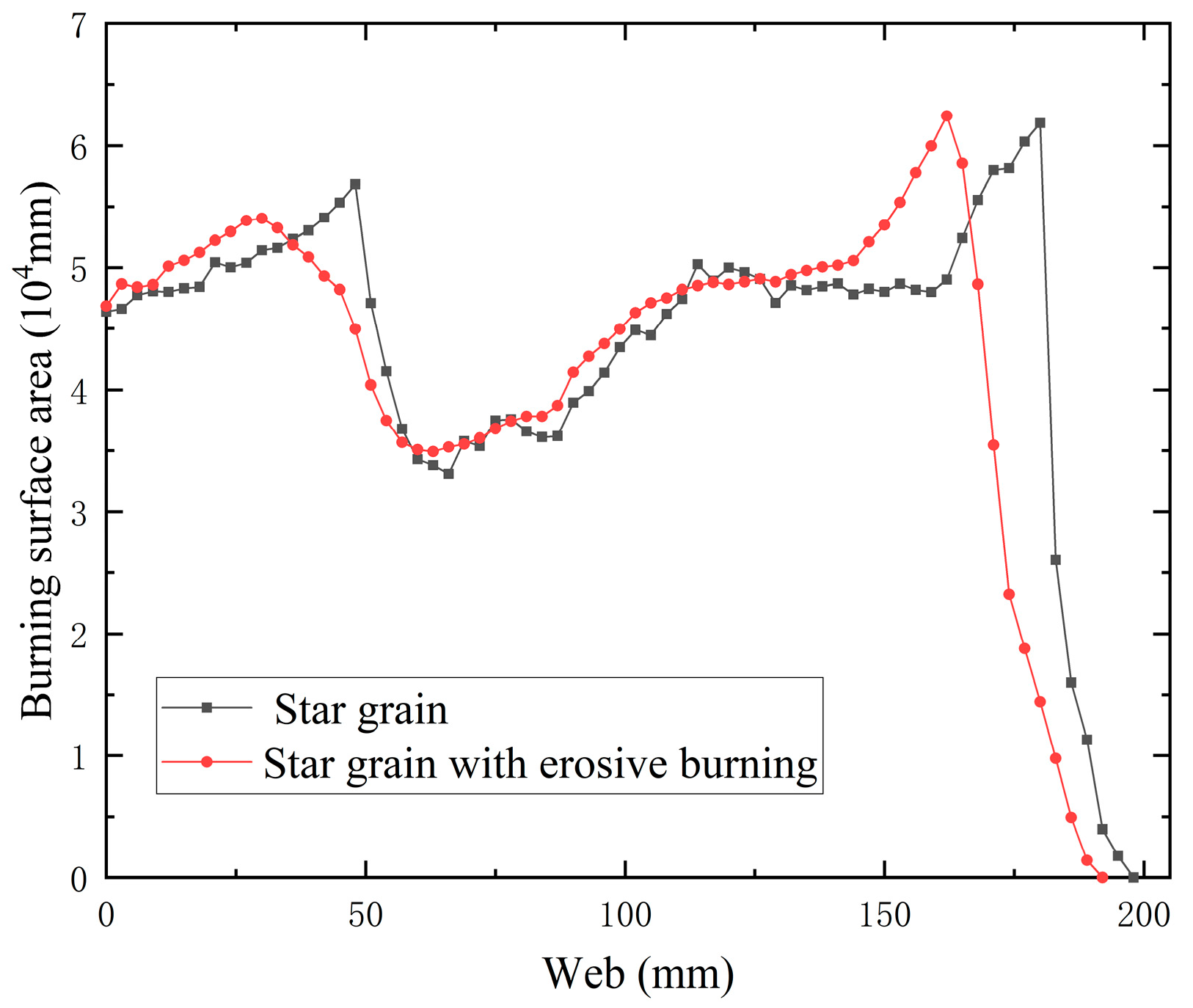

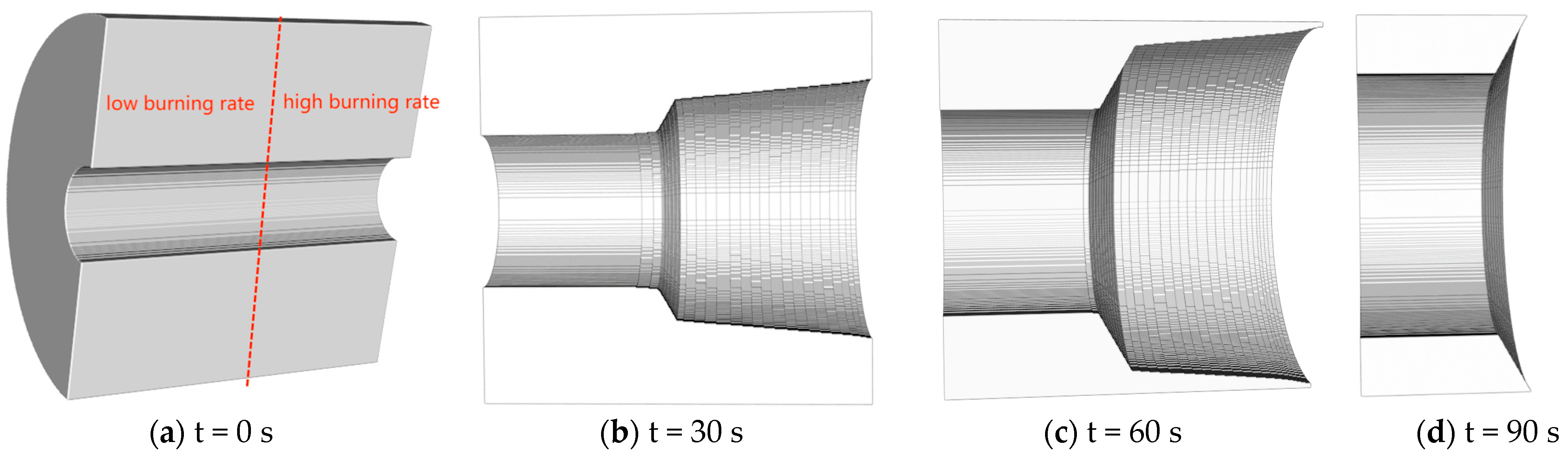

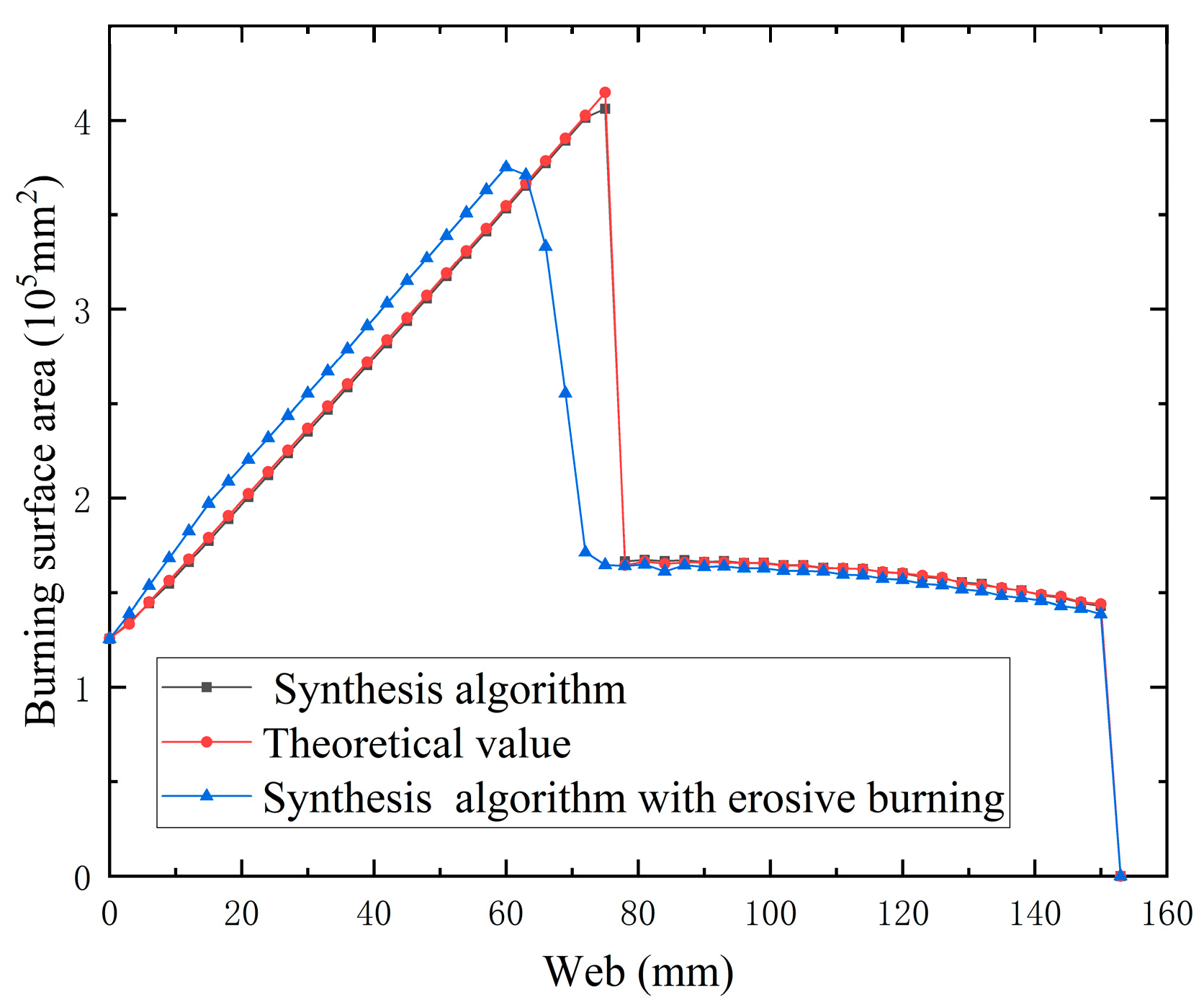

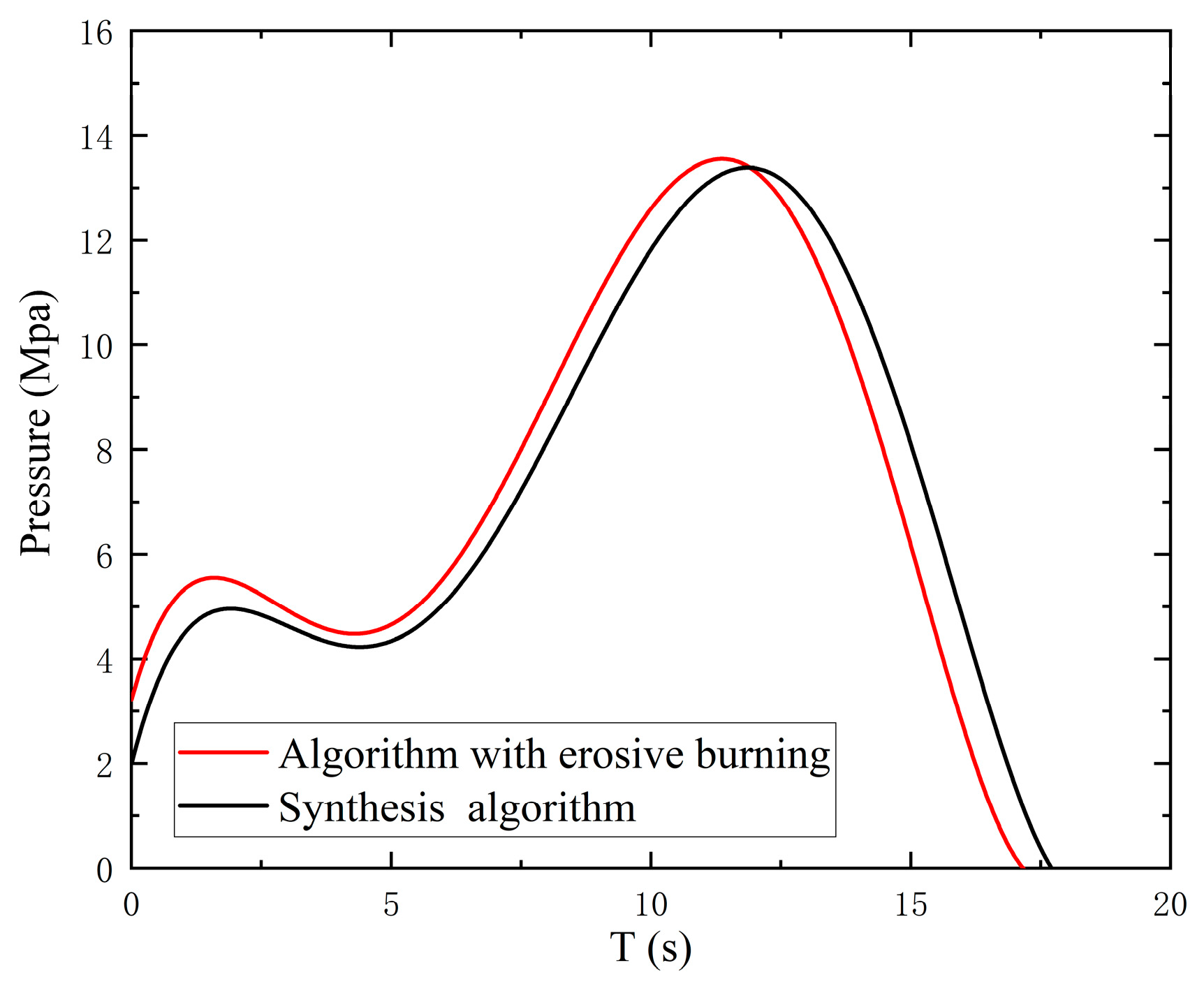

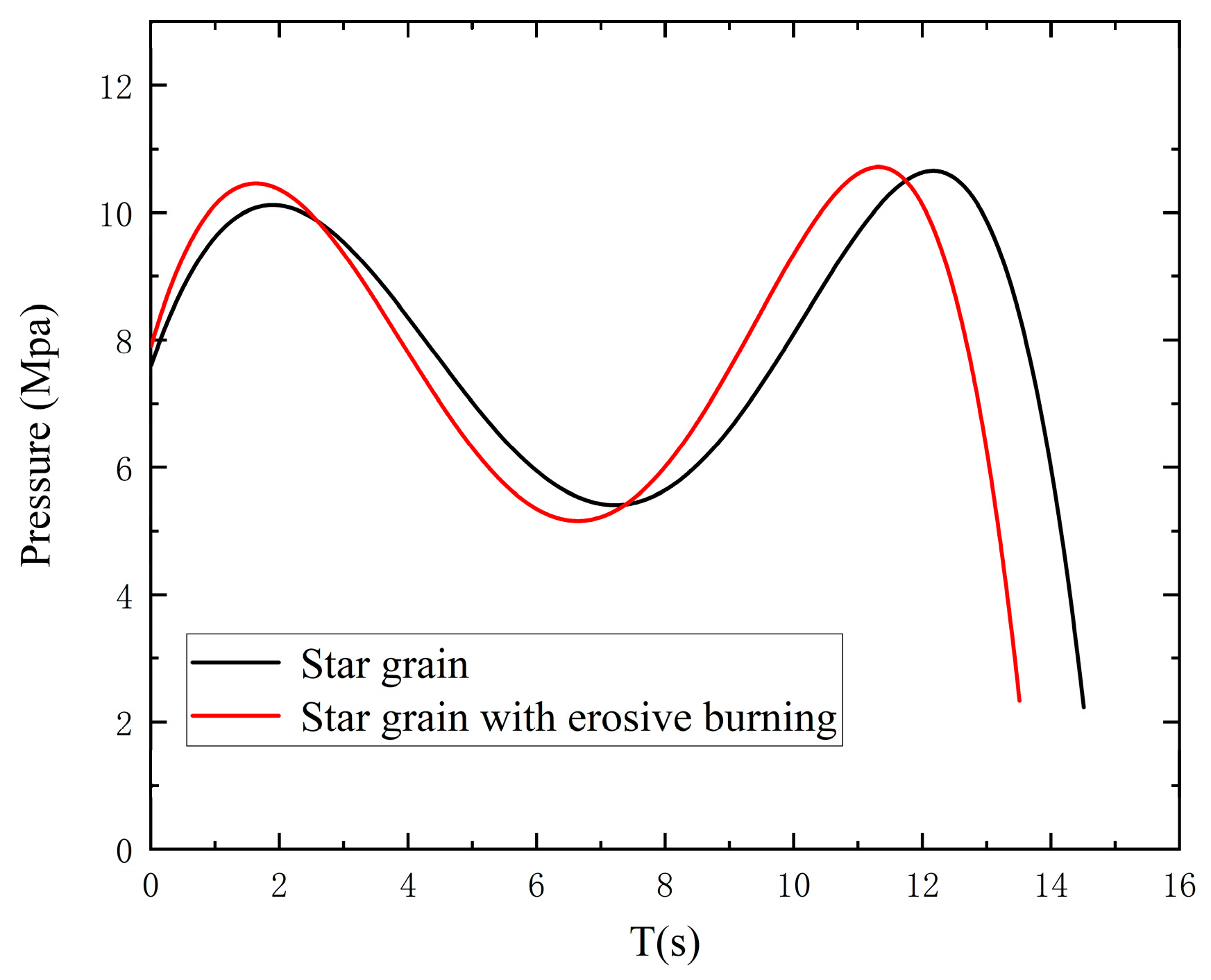

In this study, the 3D model of an SRM grain is reconstructed based on CT images, and the fusion of the LS method and MDF method is proposed to solve the problems of the LS method which requires multiple reinitializations and large computational load. The proposed method is validated in non-uniform and different burning rate grain models. Due to the presence of the erosive burning effect in SRM, the algorithm of this study is used to calculate and simulate an SRM grain with the erosive burning effect based on the LR model to verify the effect of the erosive burning on the motor propellant.

3. Methods

3.1. Level-Set Method

In reality, there are a lot of moving interface problems, also known as Stefan problems [

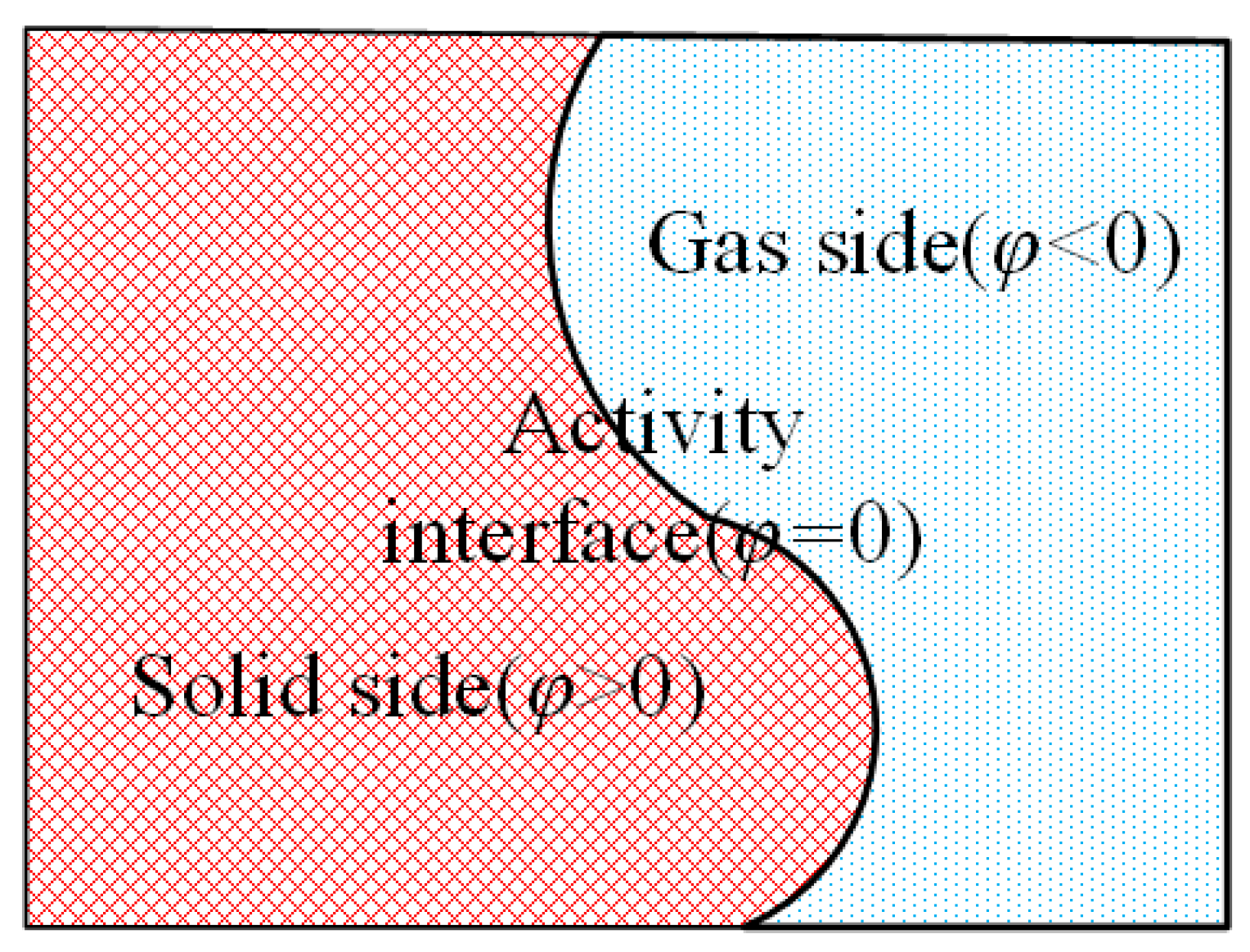

32]. Simulating and tracking the moving interface is the key to solving this problem. The method to solve the moving state of the moving interface can be called the interface tracking algorithm. The burning surface calculation of solid propellant can also be regarded as a kind of interface tracking problem. The LS method adds an additional dimension to the initial interface to describe the interface motion. It uses the implicit functions

to represent the active interface. The isosurface in the directed distance field is used to represent the burning surface of the grain. The numerical value in the directed distance field is operated to move the isosurface indirectly, the implicit function of the higher dimension is adjusted according to the surface motion

, and then the isosurface is calculated to obtain the position of the moving interface (

Figure 3).

The solid area is set as

, the gas area as

, and the interface as

. The function

φ is defined to calculate the conforming distance from any point in the region to the interface, as shown in Equation (5).

Each node in the calculation area changes with the movement of the interface, so the derivative of the coordinates on the interface with respect to

can be expressed as Equation (6).

It is assumed that the curve evolves along the normal direction, according to the interface rate field

. To ensure that the isosurface of the function

φ is the active interface at any moment, it is necessary to satisfy the conservation Equation (7).

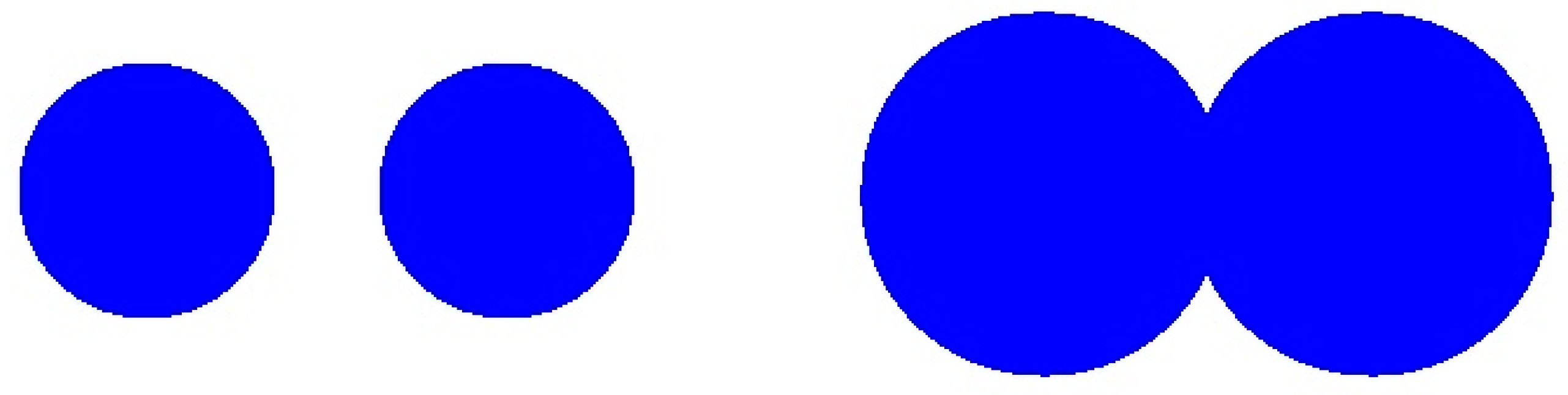

The LS method can easily handle the case of boundary intersections. As in

Figure 4, the two circular interfaces gradually recede into a larger circular interface and intersect and merge.

3.2. Numerical Solution

In order to solve for the partial derivatives of the function

φ, a common first-order method is the Godunov format, where the partial derivatives corresponding to the three axes are combined to calculate the

of the LS method. Since the computational process of the LS method is discretized, it is theoretically impossible to find a completely accurate analytical solution through discrete grid points, and this computational process is estimated from the grid point data for

. In order to maintain the convergence and stability of the solution, the Hamilton–Jacobi equation is chosen for the control equation of the LS method [

33]. The form of the viscosity calculation for this equation satisfying the entropy condition is given in Equation (8):

where

is the central difference equation, as shown in Equations (9) and (10):

where

h is the spatial step size.

and so on.

To improve the accuracy of the time direction, time discretization is also performed using the TVD Runge–Kutta time discretization format [

34,

35]. A one-step Eulerian forward advance is calculated by Equation (11), followed by another advance in the same way.

The results of the two steps are then averaged as in Equation (12).

After obtaining the value at moment

, the Eulerian forward advance can be performed to obtain the value at moment

(see Equation (13)).

Finally, the final desired value of

moments can be obtained by a single averaging operation (see Equation (14)).

3.3. MDF Initialization

Before solving the LS method, the motor model needs to mesh so that the grain and the flow field region are decomposed into small cell bodies, and the composition isosurface is obtained and discretized according to the divided mesh. The minimum distance operation is performed on the whole mesh to obtain the new .

The initial MDF value of each 3D grid node is calculated, and the distance sign of each grid point is discriminated according to whether it is inside the grain or not. Since the initial burning surface and the end surface of the grain column on each slice are closed and non-self-intersecting irregular shapes, the rules for determining the grid point symbols can be assigned by discerning whether they are inside the initial burning surface and the termination surface. The ray method is used to determine that the point is inside the polygon. The main idea of this algorithm is to make a ray in any direction with the target point as the endpoint, usually in the x+ direction. The number of intersection points of this ray with the polygon are counted. If it is technical, the target point is inside the polygon, and if it is even, the target is outside the polygon.

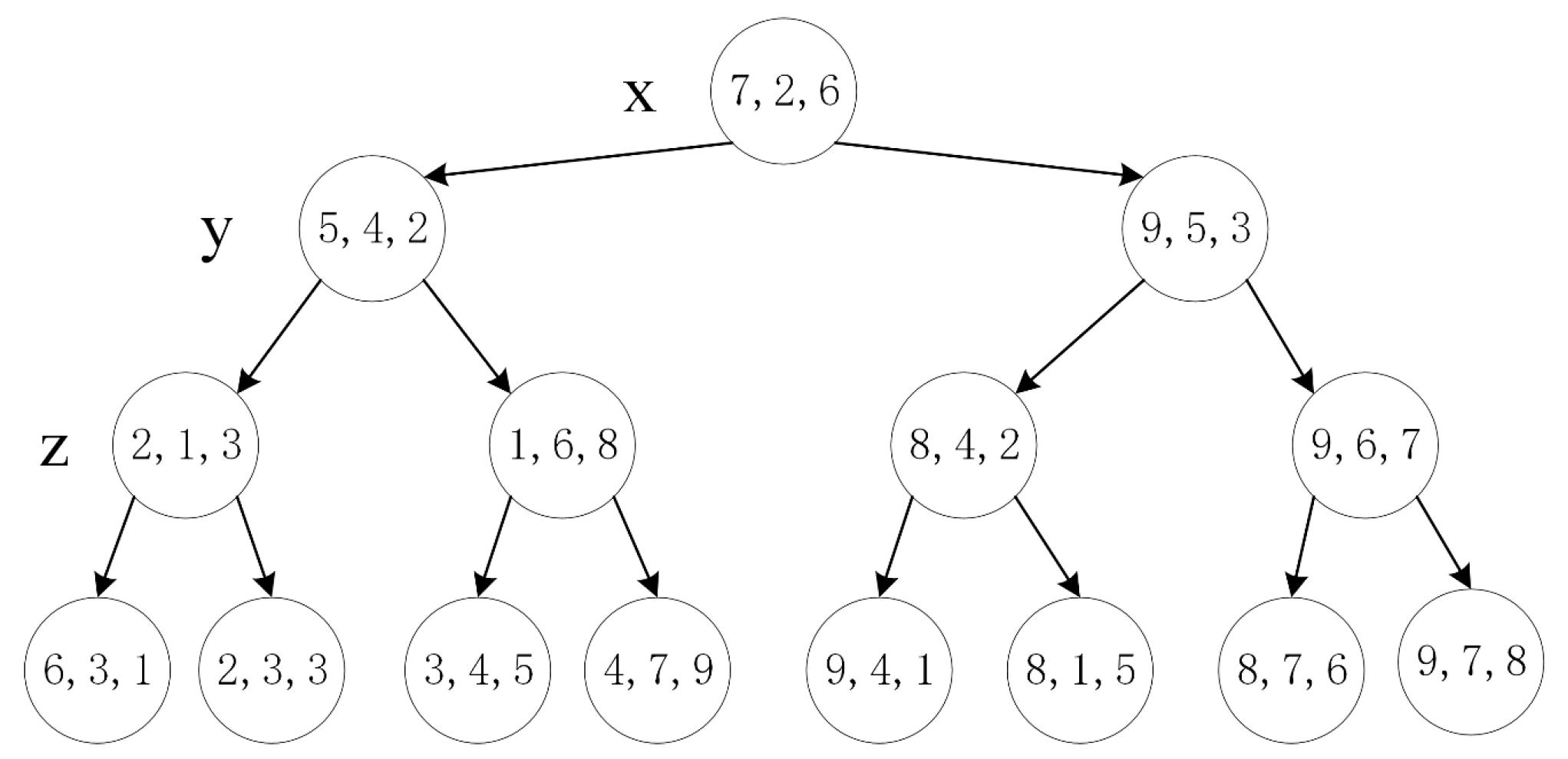

The distance value of each grid point is difficult and computationally intensive, and an efficient data structure is needed to quickly search for the minimum distance from the grid point to be calculated to the burning surface. The nearest neighbor algorithm in machine learning provides a K-d tree, which is a spatial division data structure often used for searching in high-dimensional spaces. The basic idea of the K-d tree is similar to that of the binary tree but differs in that each node represents a sample. The sample is divided into different nodes by selecting a certain dimensional feature in the sample, first sorted by the

x coordinate. The middle

xmid is selected as the root node, and then the points smaller than

xmid are in the left subtree, and those larger than

xmid are in the right subtree. Then the left and right subtrees are sorted by the

y coordinate, and so on (see

Figure 5).

The minimum distance method obtained by directly judging the minimum distance from the grid to the discrete points of the interface does not need to consider complex geometric operations. However, the minimum distance obtained has a certain error with the actual distance, and the error is larger when it is near the burning surface and smaller when it is far from the interface. In order to reduce the calculation error and improve the calculation efficiency at the same time, the distance is discriminated in the form of point-to-surface when the grid point is close to the burning surface (i.e., the distance between the grid point and the burning surface is less than 10 times the space step), and the minimum distance value is obtained directly by the KNN algorithm when the grid point is far from the burning surface. The maximum error of the minimum distance value of the point far from the burning surface should not exceed 1.25%.

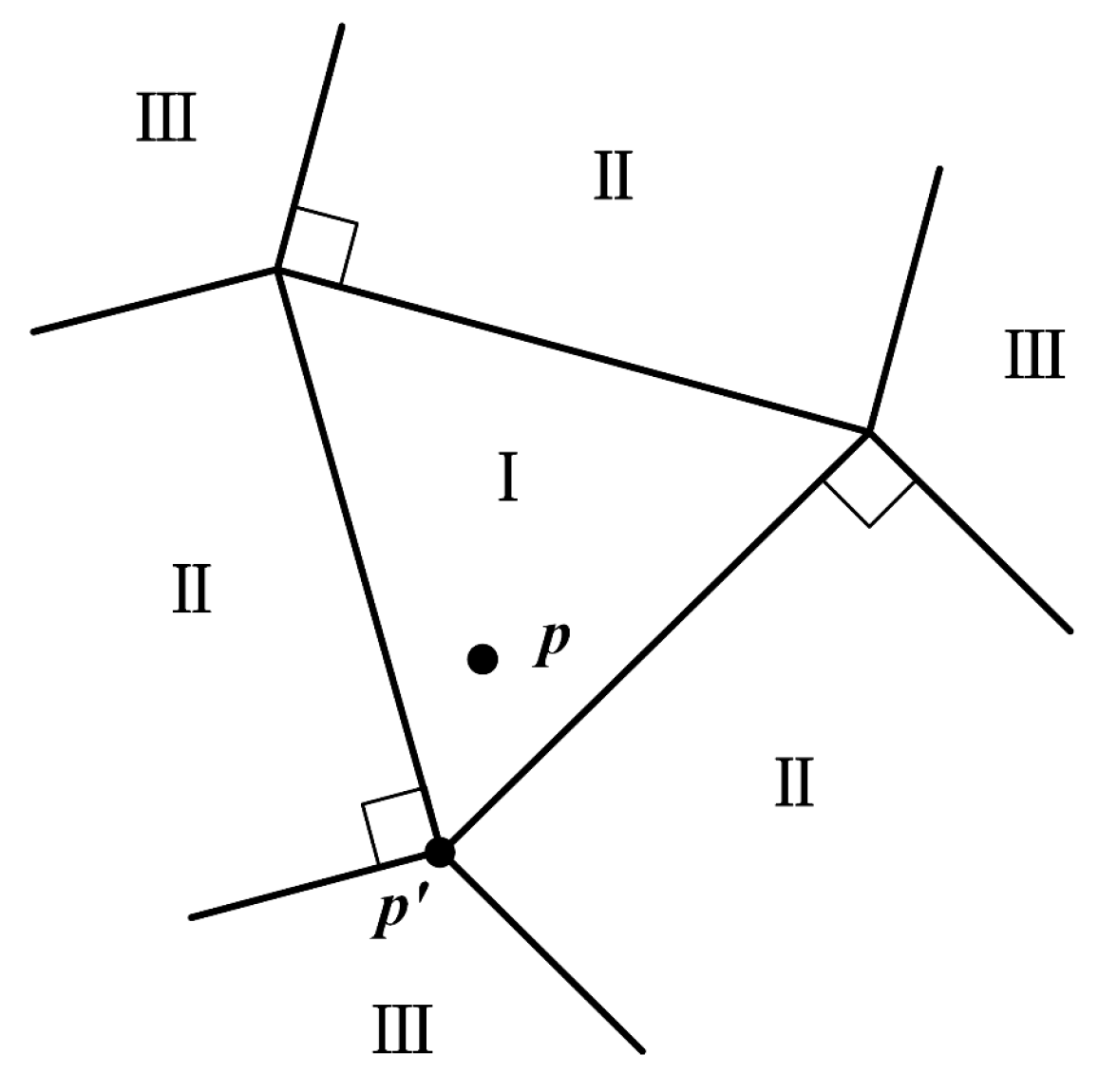

When the grid points are close to the burning surface, the three nearest discrete points are selected to form the surface, as shown in

Figure 6, and can be divided into three cases. The first case: When the point

p is located in region I, this case is the distance from the point to the face. The second case: When the point

p is located in region II, this case is the distance from the point to the line segment. The third case: When point

p is located in region III, this can be approximated as the distance from point

p to the nearest point.

3.4. Reinitialization

The numerical results of the solution should be such that the function

remains as a function of the distance to the interface with compliance. In a rate field with rate

, it is difficult to avoid the deviation of the function

from the sign of the distance to the interface during the calculation, especially in the case where the gradient of

becomes large or small near the isosurface. In order to reduce such errors, a general method needs to be introduced to make the function

keep the distance with the symbol to the isosurface at all times, thus avoiding bias. The commonly used method is to iteratively converge the function

by substituting it into a specific partial differential equation [

36].

The interface

no longer depends on the specific initial value

selected, only that the initial value selected matches

. The reinitialization process is to replace the old function with a new one and both have the same isosurface. However, the characteristics of the new function will be better than the old one to avoid value shifts, and when the new function is obtained it will be used as the initial value to continue the computation until the next reinitialization process is performed [

37]. A better way of solving the Hamilton–Jacobi equation to obtain the new function is described here, and its computational equation is shown in Equation (15) [

37].

The solution of this equation is the optimal symbolic distance after reinitialization, and the computation of grid points near the interface converges very quickly in the actual computation, or the definition shown in Equation (16) can be used.

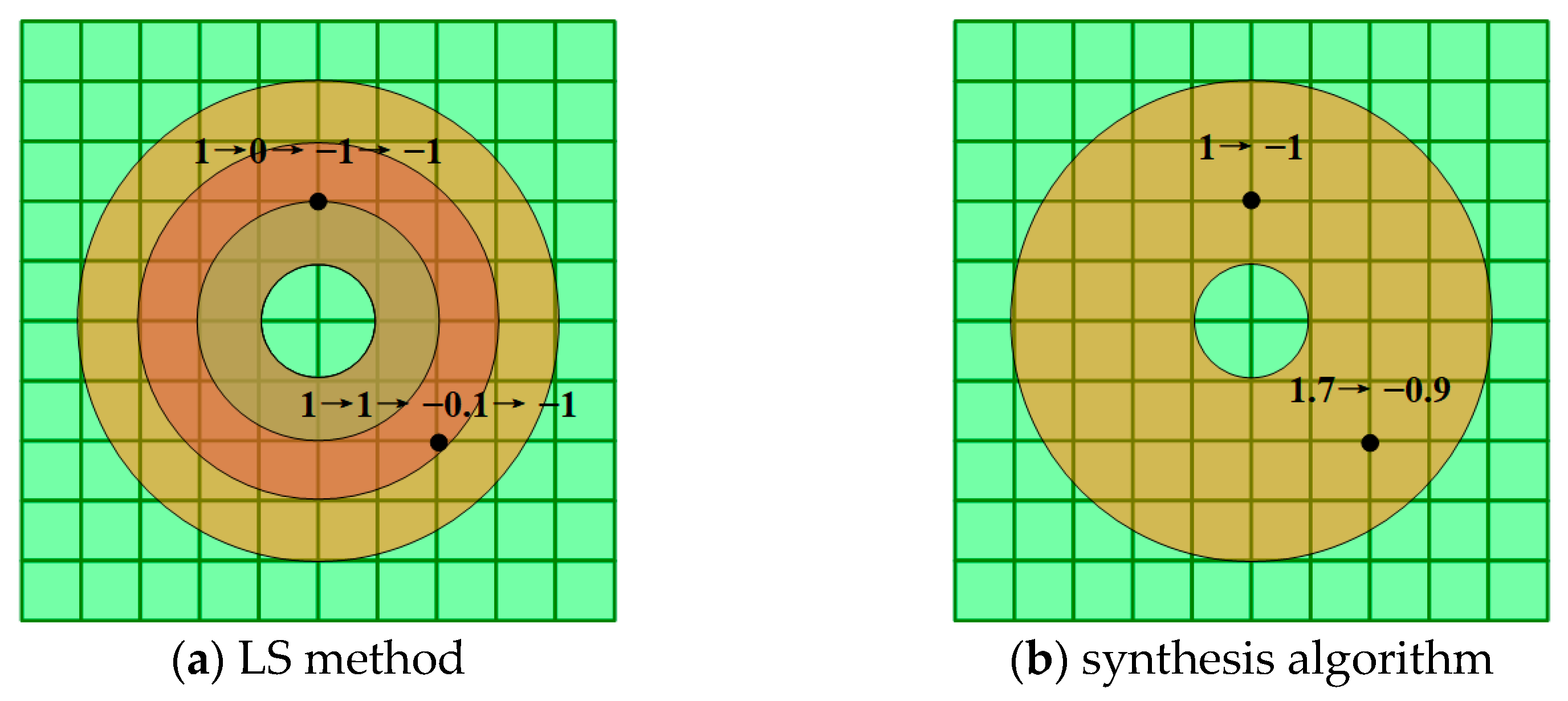

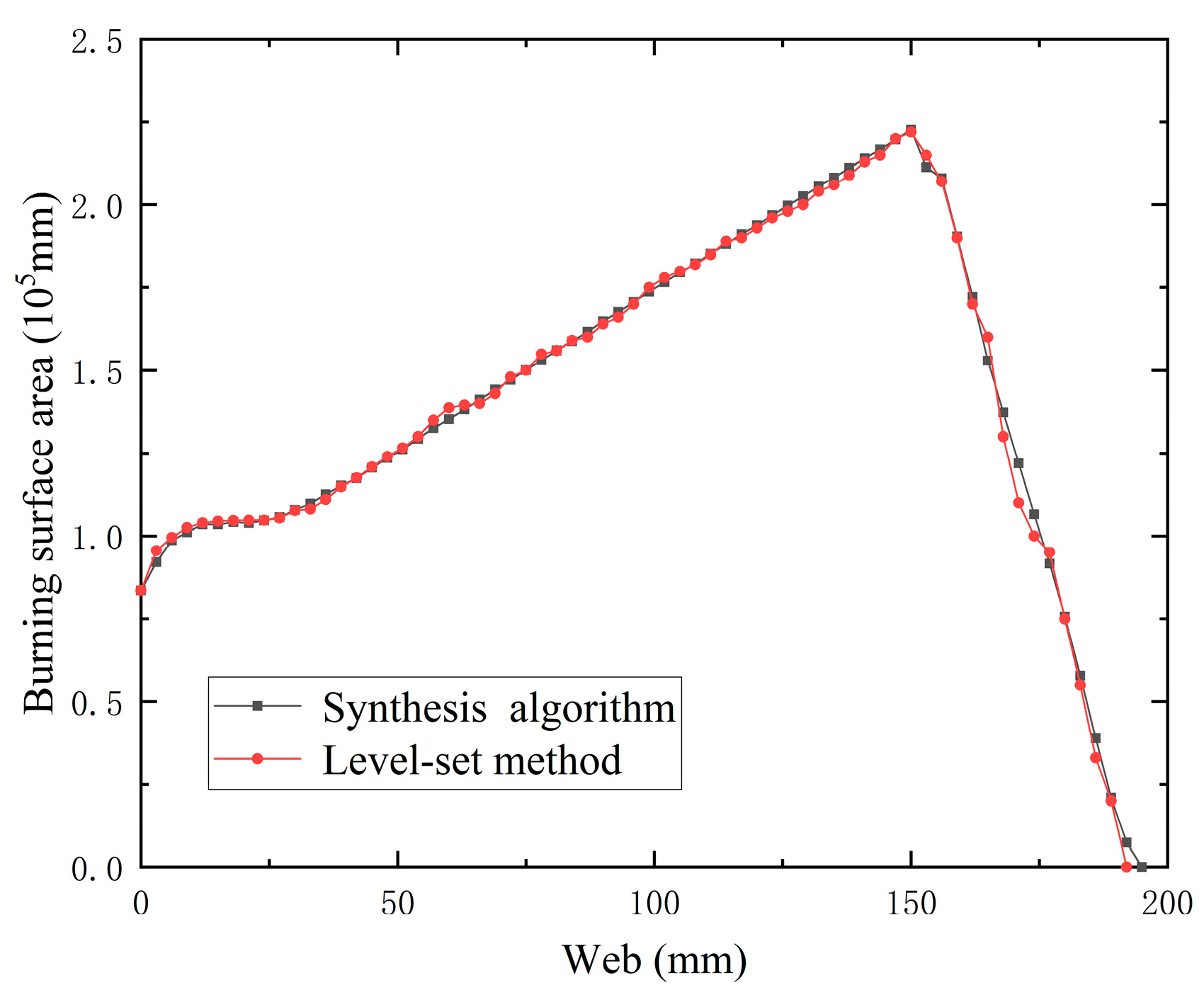

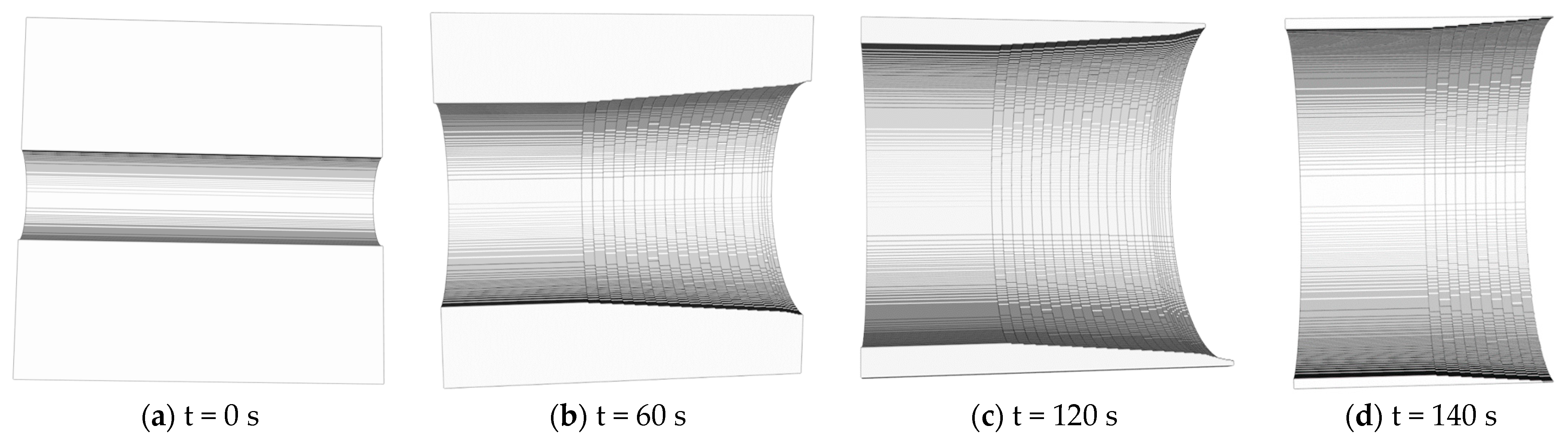

From the accuracy point of view, the synthesis algorithm process does not introduce errors from the gradient estimation process, so the accuracy of this method is no less than that of the general method. In terms of calculation speed, the efficiency of the composite algorithm relative to the horizontal set method depends on whether it takes less time to initialize (rebuild the directed distance field using the geometric method) than it does to reinitialize (until the calculation converges). Obviously, when each step backward makes the directed distance field more distorted, the synthesis algorithm is more efficient. Due to this feature, the synthesis algorithm is more suitable for those pills with more sharp geometric shapes and more discontinuities in the velocity field. The test results show that the synthesis algorithm and the level set method have basically the same compatibility and accuracy. The difference is only that the two methods have different efficiencies for input data with different characteristics.

Figure 7 shows the iterative process of the two algorithms. The LS method is based on narrowband technology, and when a certain step is calculated, points near the

interface need to be reinitialized to either 0 or 1 or −1, then iteration continues. The main errors during this period come from reinitialization errors and the inaccuracy of

updates when there is a gradient that is too large or too small in the iteration. The main error of the synthesis algorithm comes from the error of the first calculation of the distance between the grid points. The difference of the distance between the grid points near

conforms to the curvature of the surface. Therefore, when iterating, the difference distance is passed to other grid points as a ripple. The value on the grid points always maintains its distance from the

interface, and the symbol can be used to determine whether it is on the solid or gaseous side.

5. Conclusions

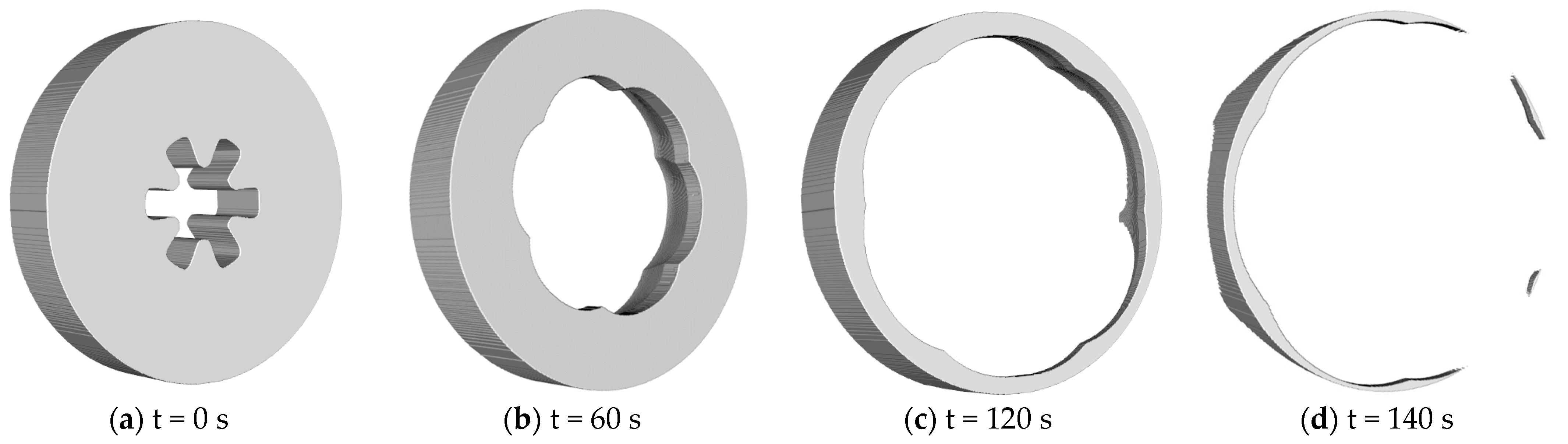

The purpose of this study was to develop a practical 3D grain burning surface regression algorithm based on CT images to reduce the computation time and improve the accuracy of the calculation. A synthesis method was proposed to solve for tracking the moving burning surface using a combination of the LS method and the MDF method. The LS method helps the accuracy of interface tracking, but it is computationally intensive and requires frequent reinitialization of the problem. The MDF method is fast in computation and the problem of frequent reinitialization can be solved by correcting the minimum distance field, which reduces the computational load. The synthesis algorithm effectively exploited the advantages of both methods.

The algorithm developed in this study was validated through the computational simulation of the burning surface regression of the conventional SRM. For the analysis and calculation of irregular and complex three-dimensional grains and grains with different burning rates under the erosive burning effect, the results show that the synthesis algorithm proposed in this study has high applicability and high calculation accuracy. This algorithm could be coupled with internal ballistic calculations in subsequent studies for internal ballistic analysis of solid propulsion systems.

In subsequent research, we will use CT images of SRMs with defects to reconstruct the three-dimensional grain model with defects, including common failure modes such as cavitation, debonding, and cracks. Image processing methods will be used to locate the defects and improve the synthesis algorithm, making it suitable for the simulation of burning surface regression of the grain with defects. The influence of defects on the performance of the grain will be analyzed to simulate the state of the motor when it is working.