Low-Complexity Ultrasonic Flowmeter Signal Processor Using Peak Detector-Based Envelope Detection

Abstract

1. Introduction

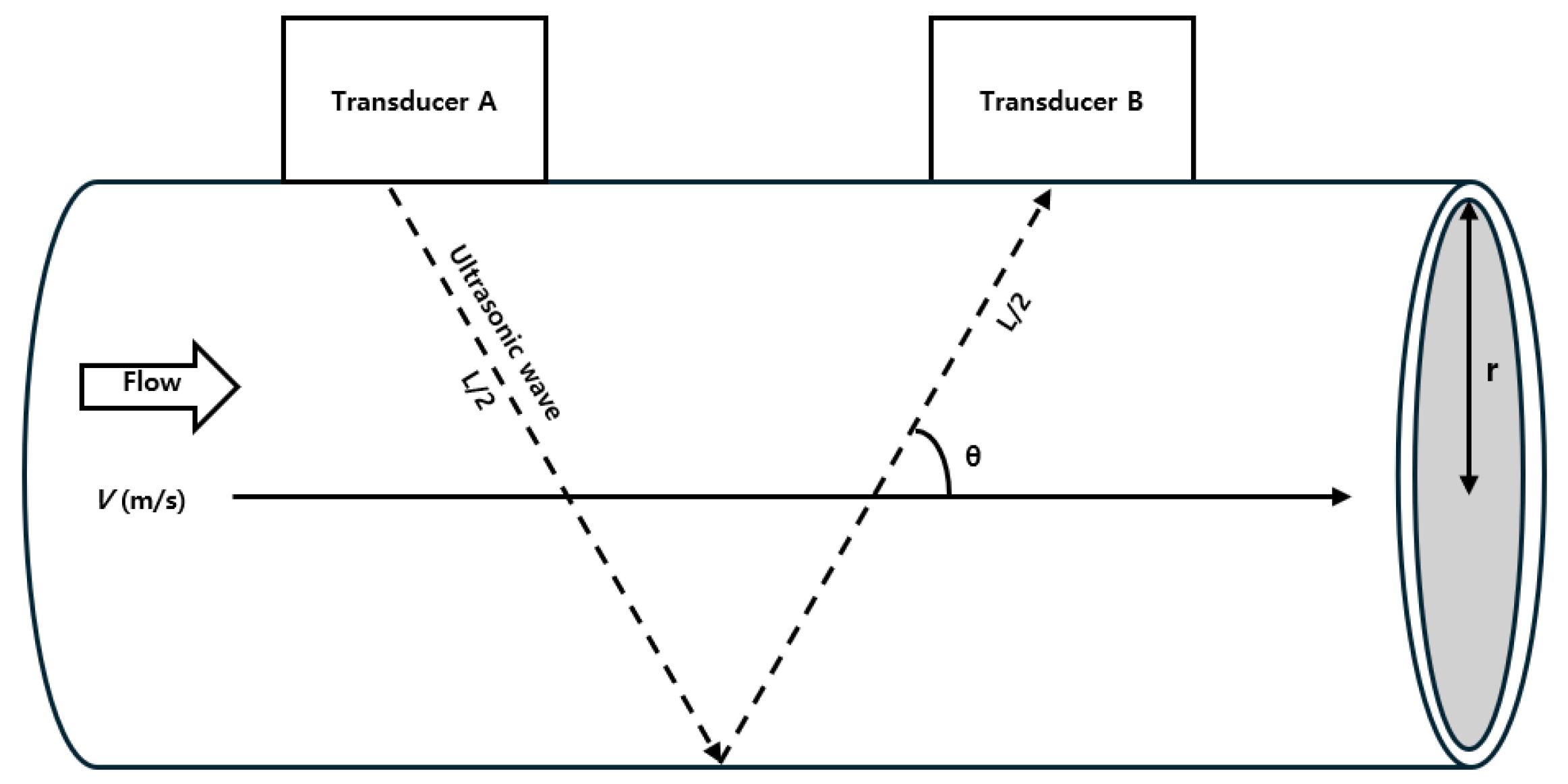

2. Principles and Measurement Model

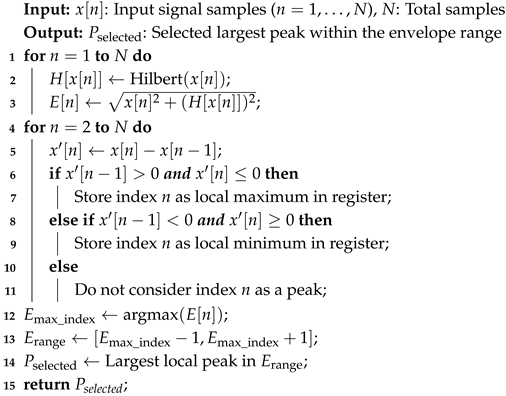

3. Proposed Algorithm

| Algorithm 1: Parallel Peak Detector-Based Envelope Detection |

|

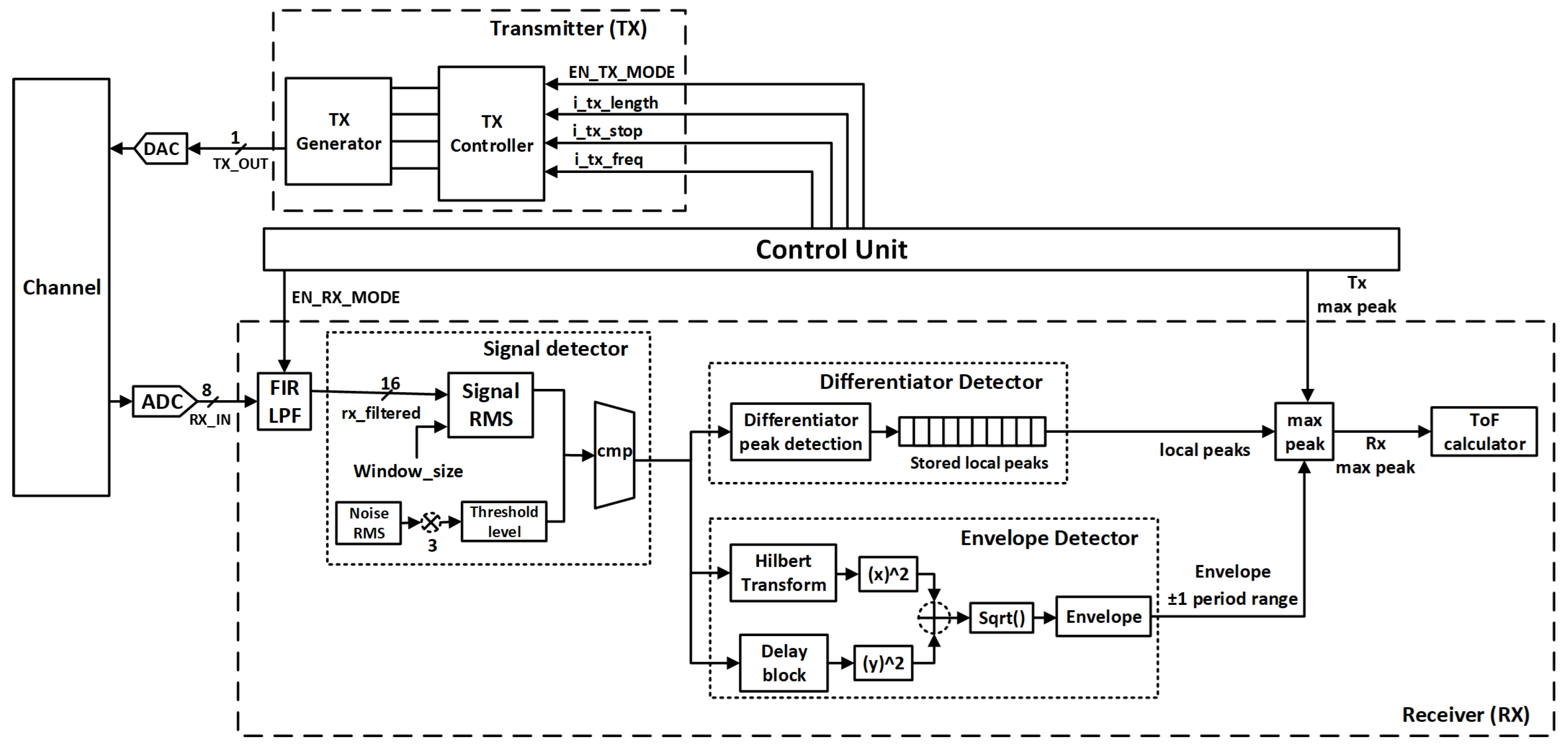

4. System Architecture

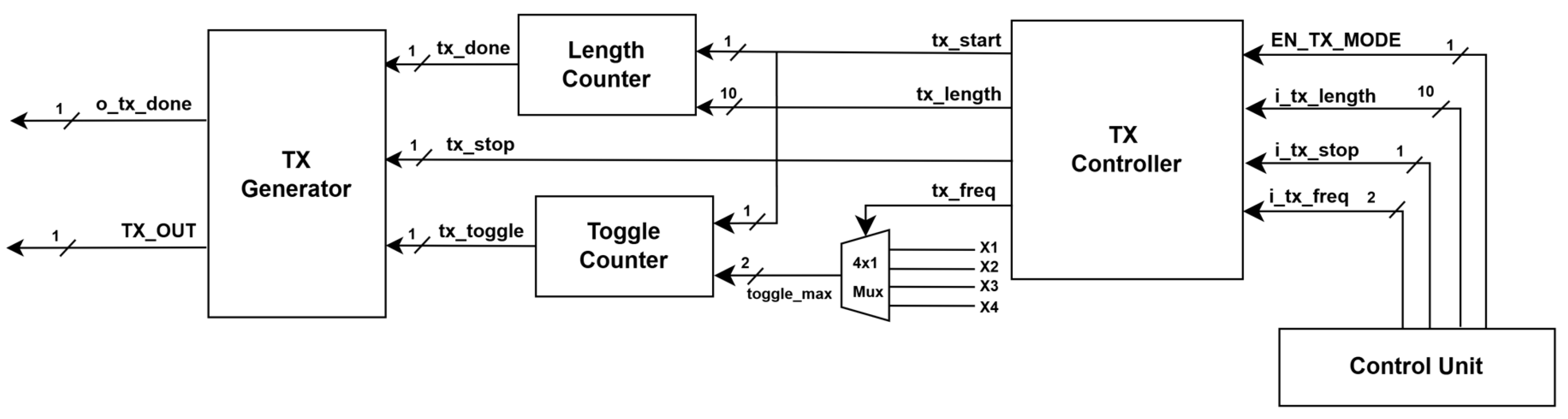

4.1. Transmitter

4.2. Receiver

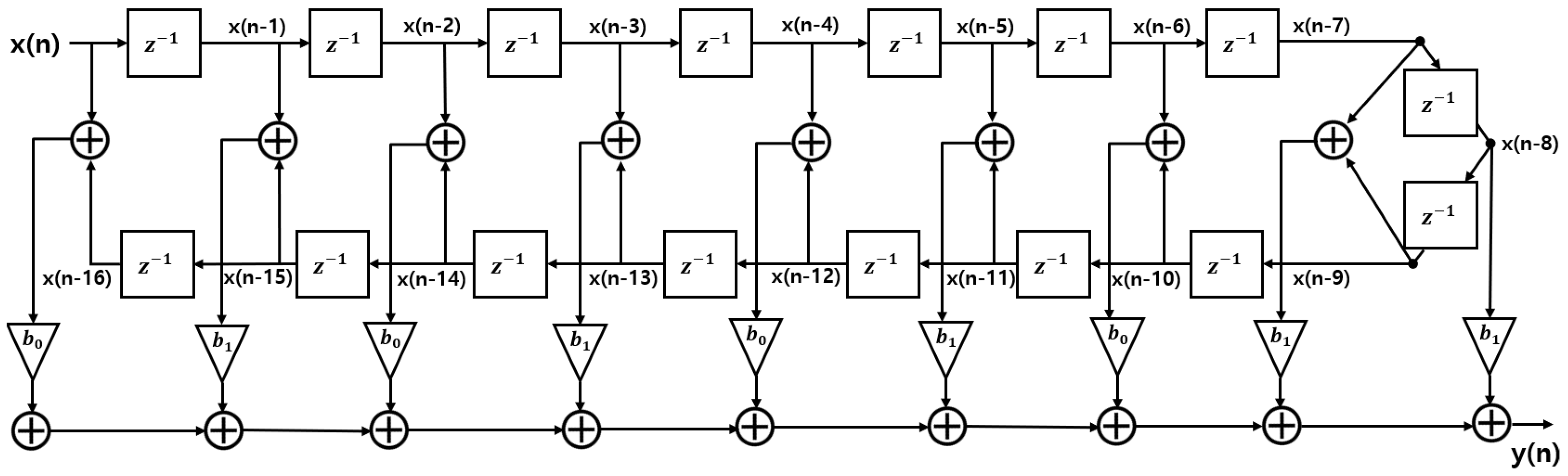

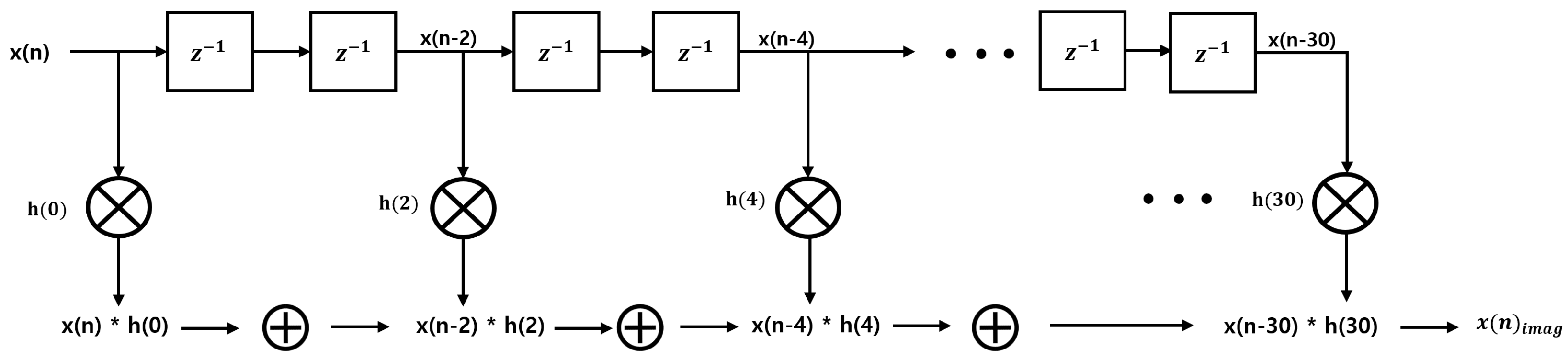

4.2.1. Pre-Processing

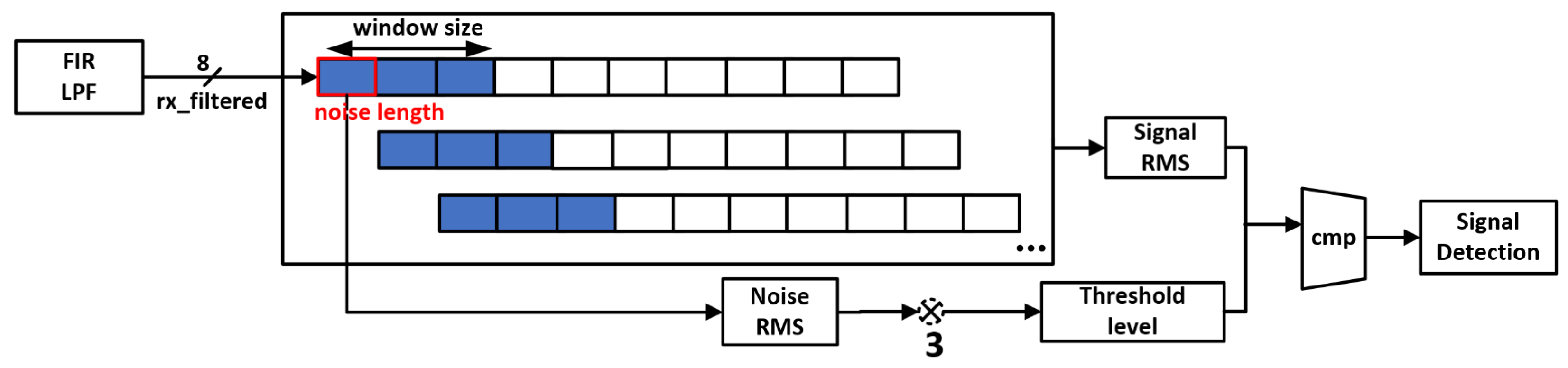

4.2.2. Power Detection Based on Windowing Method

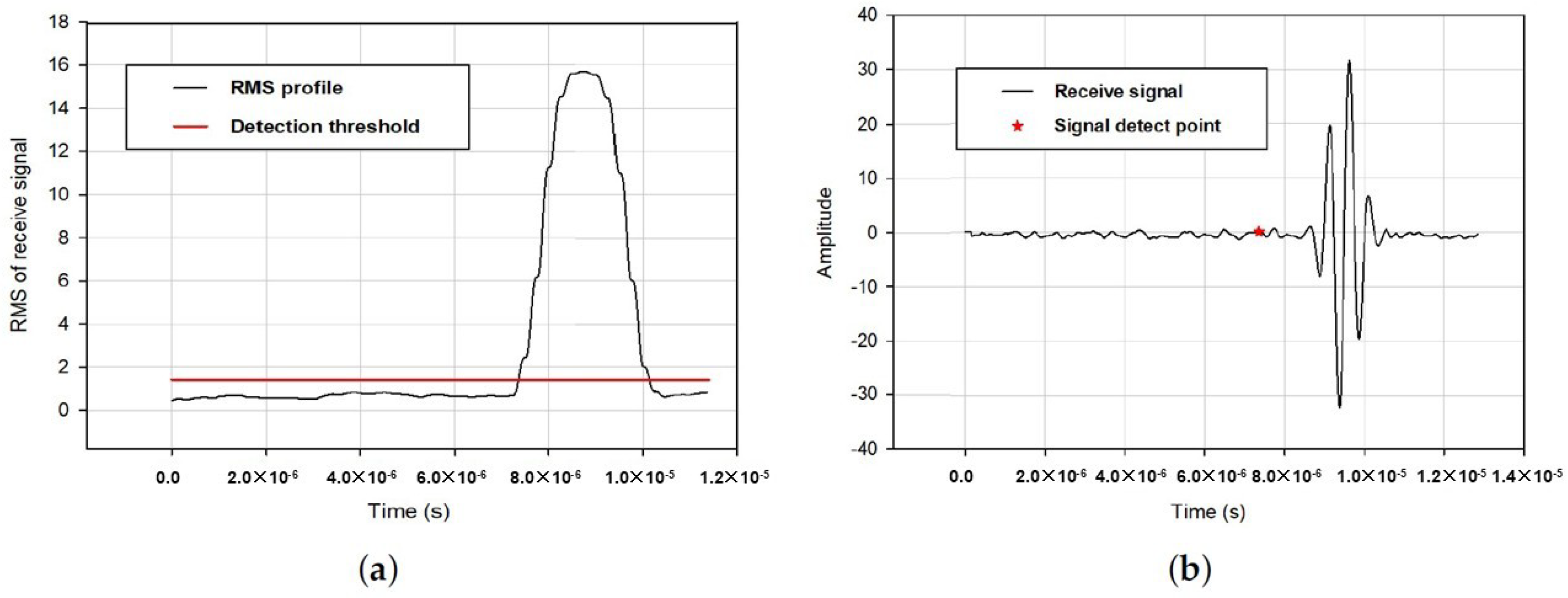

4.2.3. Proposed Architecture

5. Results and Discussion

5.1. Simulation Experiment Setup

5.2. Performance of the Proposed Method

5.3. Comparison of Performance and Hardware Complexity with Other Methods

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Priyadarshi, R. Energy-efficient routing in wireless sensor networks: A meta-heuristic and artificial intelligence-based approach: A comprehensive review. Arch. Comput. Methods Eng. 2024, 31, 2109–2137. [Google Scholar] [CrossRef]

- Karthick Raghunath, K.; Koti, M.S.; Sivakami, R.; Vinoth Kumar, V.; NagaJyothi, G.; Muthukumaran, V. Utilization of IoT-assisted computational strategies in wireless sensor networks for smart infrastructure management. Int. J. Syst. Assur. Eng. Manag. 2024, 15, 28–34. [Google Scholar] [CrossRef]

- Sivakumar, S.; Logeshwaran, J.; Kannadasan, R.; Faheem, M.; Ravikumar, D. A novel energy optimization framework to enhance the performance of sensor nodes in Industry 4.0. Energy Sci. Eng. 2024, 12, 835–859. [Google Scholar] [CrossRef]

- Khernane, S.; Bouam, S.; Arar, C. Renewable Energy Harvesting for Wireless Sensor Networks in Precision Agriculture. Int. J. Networked Distrib. Comput. 2024, 12, 8–16. [Google Scholar] [CrossRef]

- Mitra, S.; Chakraborty, B.; Mitra, P. Smart meter data analytics applications for secure, reliable and robust grid system: Survey and future directions. Energy 2024, 289, 129920. [Google Scholar] [CrossRef]

- Ferrigno, L.A.; Morello, R.; Paciello, V.; Pietrosanto, A. Remote metering in public networks. Metrol. Meas. Syst. 2013, 20, 705–714. [Google Scholar] [CrossRef]

- Matani, A.G. Internet of things (IoT) in renewable energy utilities towards enhanced energy optimization. In Deregulated Electricity Structures and Smart Grids; CRC Press: Boca Raton, FL, USA, 2022; pp. 113–123. [Google Scholar]

- Lozano, D.; Mateos, L. Field evaluation of ultrasonic flowmeters for measuring water discharge in irrigation canals. Irrig. Drain. 2009, 58, 189–198. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Wu, J. Realization of a multipath ultrasonic gas flowmeter based on transit-time technique. Ultrasonics 2014, 54, 285–290. [Google Scholar] [CrossRef] [PubMed]

- Kaga, Y.; Johguchi, K. A 180 nm CMOS smart ultrasonic water flow meter circuit for IoT smart society. Jpn. J. Appl. Phys. 2021, 60, SBBL05. [Google Scholar] [CrossRef]

- Rajita, G.; Mandal, N. Review on transit time ultrasonic flowmeter. In Proceedings of the 2016 2nd International Conference on Control, Instrumentation, Energy & Communication (CIEC), Kolkata, India, 28–30 January 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 88–92. [Google Scholar]

- Munasinghe, N.; Paul, G. Ultrasonic-based sensor fusion approach to measure flow rate in partially filled pipes. IEEE Sens. J. 2020, 20, 6083–6090. [Google Scholar] [CrossRef]

- Bourke, P. Cross Correlation. Cross Correlation”, Auto Correlation—2D Pattern Identification. 1996. Available online: https://paulbourke.net/miscellaneous/correlate/ (accessed on 28 December 2024).

- Hsue, S.Z.; Soliman, S.S. Automatic modulation classification using zero crossing. IEE Proc. F Radar Signal Process. 1990, 137, 459–464. [Google Scholar] [CrossRef]

- Law, T. Elementary signal detection and threshold theory. In Stevens’ Handbook of Experimental Psychology and Cognitive Neuroscience, Methodology; Wiley: Hoboken, NJ, USA, 2018; Volume 5, p. 161. [Google Scholar]

- Han, J.; Liu, H.; Zhou, Y.; Zhang, R.; Li, C. Studies on the transducers of clamp-on transit-time ultrasonic flow meter. In Proceedings of the 2014 4th IEEE International Conference on Information Science and Technology, Shenzhen, China, 26–28 April 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 180–183. [Google Scholar]

- Afandi, A.; Khasani; Deendarlianto; Catrawedarma, I.G.N.B.; Wijayanta, S. The development of the ultrasonic flowmeter sensors for mass flow rate measurement: A comprehensive review. Flow Meas. Instrum. 2024, 97, 102614. [Google Scholar] [CrossRef]

- Iooss, B.; Lhuillier, C.; Jeanneau, H. Numerical simulation of transit-time ultrasonic flowmeters: Uncertainties due to flow profile and fluid turbulence. Ultrasonics 2002, 40, 1009–1015. [Google Scholar] [CrossRef] [PubMed]

- Ulrich, T. Envelope Calculation from the Hilbert Transform; Technical Report; Los Alamos National Laboratory: Los Alamos, NM, USA, 2006. [Google Scholar]

- Kaur, A.; Kumar, S.; Agarwal, A.; Agarwal, R. An efficient R-peak detection using Riesz fractional-order digital differentiator. Circuits Syst. Signal Process. 2020, 39, 1965–1987. [Google Scholar] [CrossRef]

- Bose, S.; De, A.; Chakrabarti, I. Area-delay-power efficient VLSI architecture of FIR filter for processing seismic signal. IEEE Trans. Circuits Syst. II Express Briefs 2021, 68, 3451–3455. [Google Scholar] [CrossRef]

- Prabhu, K.M. Window Functions and Their Applications in Signal Processing; Taylor & Francis: Abingdon, UK, 2014. [Google Scholar]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE). Geosci. Model Dev. Discuss. 2014, 7, 1525–1534. [Google Scholar]

- Barshan, B. Fast processing techniques for accurate ultrasonic range measurements. Meas. Sci. Technol. 2000, 11, 45. [Google Scholar] [CrossRef]

- Jordanov, V.T.; Hall, D.L. Digital peak detector with noise threshold. In Proceedings of the 2002 IEEE Nuclear Science Symposium Conference Record, Norfolk, VA, USA, 10–16 November 2002; IEEE: Piscataway, NJ, USA, 2002; Volume 1, pp. 140–142. [Google Scholar]

- Smits, A.J.; McKeon, B.J.; Marusic, I. High–Reynolds number wall turbulence. Annu. Rev. Fluid Mech. 2011, 43, 353–375. [Google Scholar] [CrossRef]

- Joshi, S.; Zaitsev, B.; Kuznetsova, I. Miniature high efficiency transducers for use in ultrasonic flow meters. J. Appl. Phys. 2009, 105, 034501. [Google Scholar] [CrossRef]

- Ren, R.; Wang, H.; Sun, X.; Quan, H. Design and implementation of an ultrasonic flowmeter based on the cross-correlation method. Sensors 2022, 22, 7470. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Su, R.; Hu, L.; Fu, X. A simple and easy-implemented time-of-flight determination method for liquid ultrasonic flow meters based on ultrasonic signal onset detection and multiple-zero-crossing technique. Measurement 2021, 168, 108398. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, P.; Wang, R.; Niu, Z.; Zhang, K. Signal processing method of ultrasonic gas flowmeter based on transit-time mathematical characteristics. Measurement 2025, 239, 115485. [Google Scholar] [CrossRef]

| Fluid Velocity (m/s) | Reynolds Number (Re) | Flow Regime |

|---|---|---|

| 0.10 | 1979 | Laminar |

| 0.30 | 5937 | Turbulent |

| 0.50 | 9895 | Turbulent |

| 0.70 | 13,853 | Turbulent |

| 0.90 | 17,811 | Turbulent |

| 1.10 | 21,768 | Turbulent |

| 1.30 | 25,726 | Turbulent |

| 1.50 | 29,684 | Turbulent |

| 1.70 | 33,642 | Turbulent |

| Velocity Point (m/s) | Detected Velocities (m/s) | Relative Deviation (%) | Reynolds Number (Re) | Flow Type |

|---|---|---|---|---|

| 0.10 | 0.0850 | −15.00 | 1979 | Laminar |

| 0.30 | 0.2750 | −8.33 | 5937 | Turbulent |

| 0.50 | 0.4758 | −4.83 | 9895 | Turbulent |

| 0.70 | 0.6738 | −3.75 | 13,853 | Turbulent |

| 0.90 | 0.8740 | −2.89 | 17,811 | Turbulent |

| 1.10 | 1.0740 | −2.36 | 21,768 | Turbulent |

| 1.30 | 1.2750 | −1.92 | 25,726 | Turbulent |

| 1.50 | 1.4770 | −1.53 | 29,684 | Turbulent |

| 1.70 | 1.6750 | −1.47 | 33,642 | Turbulent |

| Method | Signal Processing | Complexity | Mean Relative Deviation (%) | |

|---|---|---|---|---|

| Mul | Add | |||

| Proposed | Signal Detector | 75 | 74 | 5.07 |

| 17-tap FIR LPF | 9 | 17 | ||

| 31-tap FIR Hilbert | 16 | 15 | ||

| Differentiator Peak Detector | 0 | 0 | ||

| Total | 305 | 309 | ||

| FFT-based correlator [28] | Total | 1445 | 1319 | 3.47 |

| Multiple zero-crossing detection [29] | DC Removal | 0 | 251 | 11.67 |

| Zero-Crossing | 0 | 0 | ||

| Energy Calculation | 212 | 106 | ||

| Frequency Normalization | 106 | 106 | ||

| Energy Normalization | 106 | 106 | ||

| Probability Calculation | 106 | 0 | ||

| Total | 530 | 569 | ||

| Dynamic weighted average filter [30] | Weighted Recursive Filter | 882 | 756 | 3.12 |

| Dynamic Threshold | 0 | 126 | ||

| Total | 882 | 882 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.-G.; Kim, D.-S. Low-Complexity Ultrasonic Flowmeter Signal Processor Using Peak Detector-Based Envelope Detection. J. Sens. Actuator Netw. 2025, 14, 12. https://doi.org/10.3390/jsan14010012

Yu M-G, Kim D-S. Low-Complexity Ultrasonic Flowmeter Signal Processor Using Peak Detector-Based Envelope Detection. Journal of Sensor and Actuator Networks. 2025; 14(1):12. https://doi.org/10.3390/jsan14010012

Chicago/Turabian StyleYu, Myeong-Geon, and Dong-Sun Kim. 2025. "Low-Complexity Ultrasonic Flowmeter Signal Processor Using Peak Detector-Based Envelope Detection" Journal of Sensor and Actuator Networks 14, no. 1: 12. https://doi.org/10.3390/jsan14010012

APA StyleYu, M.-G., & Kim, D.-S. (2025). Low-Complexity Ultrasonic Flowmeter Signal Processor Using Peak Detector-Based Envelope Detection. Journal of Sensor and Actuator Networks, 14(1), 12. https://doi.org/10.3390/jsan14010012