Evaluation of Ozonation Technique for Pesticide Residue Removal in Okra and Green Chili Using GC-ECD and LC-MS/MS

Abstract

1. Introduction

2. Results

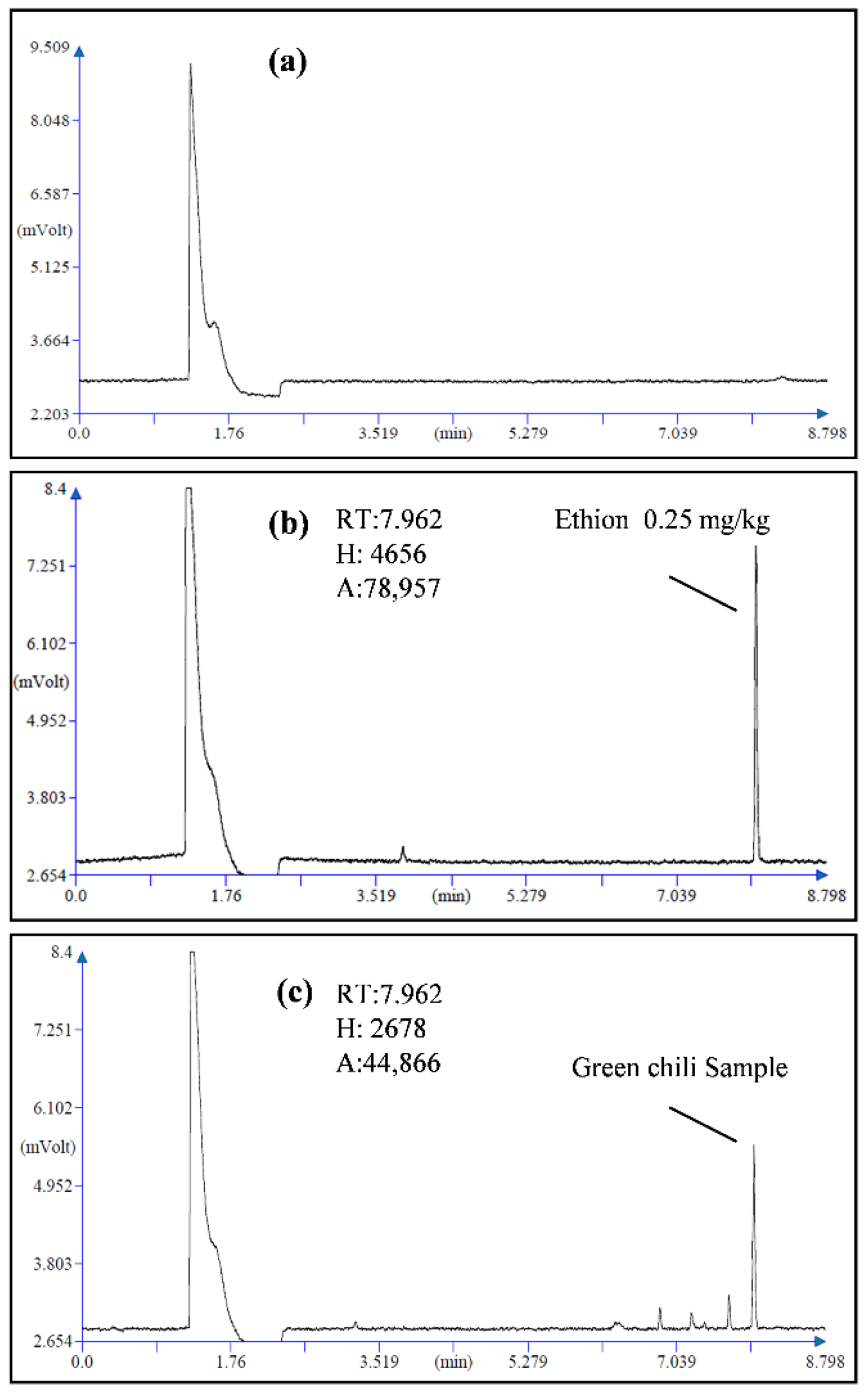

2.1. Verification of Method Performance for Insecticide Extraction

2.2. Pesticide Removal Efficiency

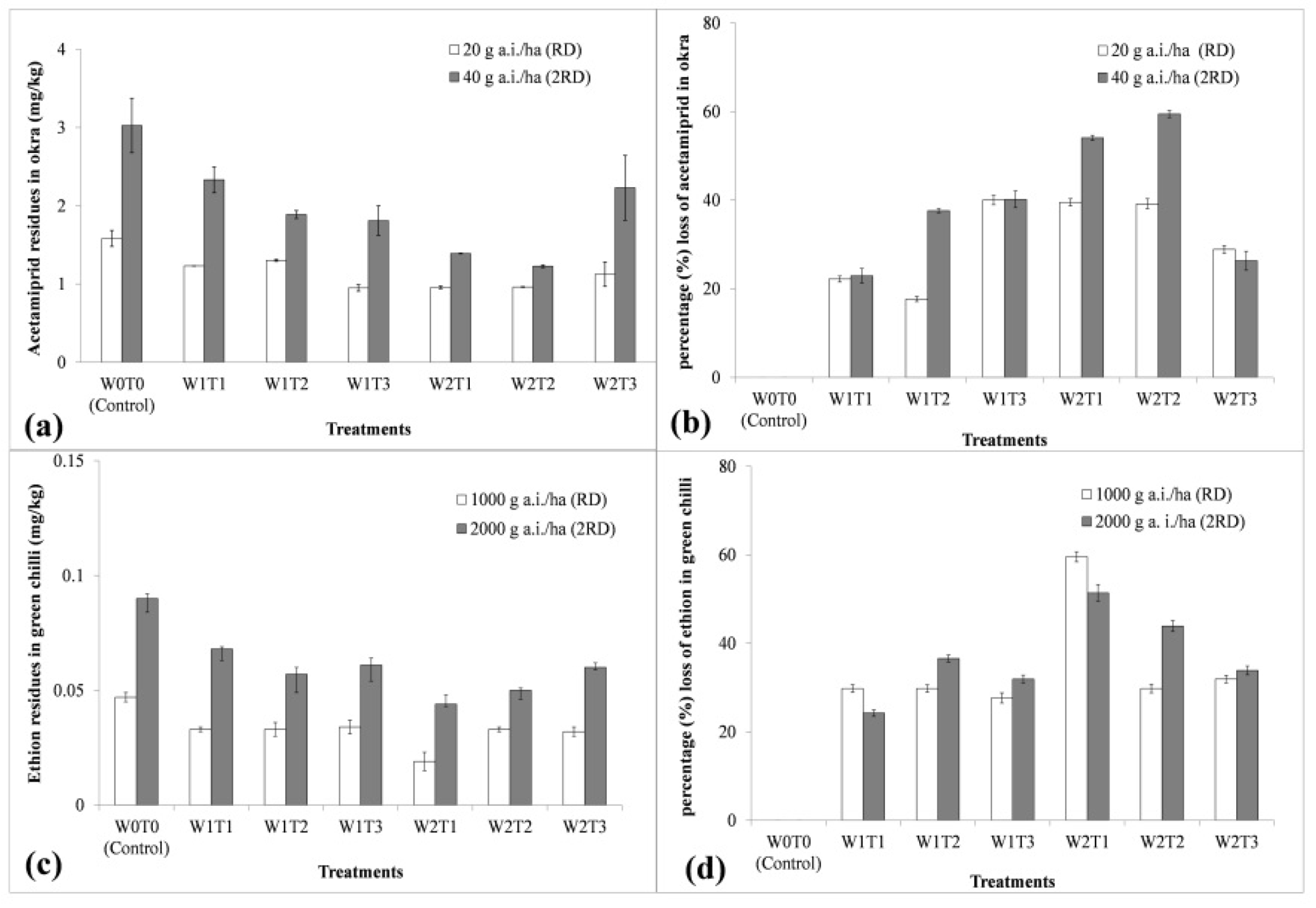

2.2.1. Acetamiprid in Okra

2.2.2. Ethion in Green Chili

2.3. Dietary Risk Assessment

3. Discussion

4. Materials and Methods

4.1. Field Experiment

4.2. Sample Collection and Ozonation Treatment

4.3. Sample Extraction and Cleanup

4.4. Verification of Method Performance for Insecticide Extraction

4.5. Acetamiprid Detection in Okra by LC-MS/MS Analysis

4.6. Ethion Detection in Green Chilli by GC-ECD

4.7. Dietary Risk Assessment

4.8. Data Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Craddock, H.A.; Huang, D.; Turner, P.C.; Quirós-Alcalá, L.; Payne-Sturges, D.C. Trends in neonicotinoid pesticide residues in food and water in the United States, 1999–2015. Environ. Health 2019, 18, 7. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). The EPA Children’s Environmental Health Yearbook; U.S. Environmental Protection Agency, Office of Children’s Health Protection: Washington, DC, USA, 1998.

- Kim, K.H.; Kabir, E.; Jahan, S.A. Exposure to pesticides and the associated human health effects. Sci. Total Environ. 2017, 575, 525–535. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Alcalde, A.; Sans, C.; Esplugas, S. Priority pesticide dichlorvos removal from water by ozonation process: Reactivity, transformation products and associated toxicity. Sep. Purif. Technol. 2018, 192, 123–129. [Google Scholar] [CrossRef]

- Phogat, A.; Singh, J.; Kumar, V.; Malik, V. Toxicity of the acetamiprid insecticide for mammals: A review. Environ. Chem. Lett. 2022, 20, 1453–1478. [Google Scholar] [CrossRef]

- Bonmatin, J.M.; Giorio, C.; Girolami, V.; Goulson, D.; Kreutzweiser, D.P.; Krupke, C.; Liess, M.; Long, E.; Marzaro, M.; Mitchell, E.A.; et al. Environmental fate and exposure; neonicotinoids and fipronil. Environ. Sci. Pollut. Res. Int. 2015, 22, 35–67. [Google Scholar] [CrossRef] [PubMed]

- Mali, H.; Shah, C.; Raghunandan, B.H.; Prajapati, A.S.; Patel, D.H.; Trivedi, U.V.; Subramanian, R.B. Organophosphate pesticides an emerging environmental contaminant: Pollution, toxicity, bioremediation progress, and remaining challenges. J. Environ. Sci. 2023, 127, 234–250. [Google Scholar] [CrossRef]

- Subhadra, A.; Mishra, H.P.; Dash, D. Efficacy of insecticides against okra jassid, Amrasca biguttula biguttula Ishida. Ann. Plant Sci. 2002, 10, 230–232. [Google Scholar]

- Dewan, A.; Patel, A.B.; Pal, R.R.; Jani, U.J.; Singel, V.C.; Panchal, M.D. Mass ethion poisoning with high mortality. Clin. Toxicol. 2008, 46, 85–88. [Google Scholar] [CrossRef]

- MPRNL (Monitoring of Pesticide Residues at National Level) Annual Progress Report 2013–2014. Available online: http://agricoop.nic.in/PPfinal2732015.pdf (accessed on 24 May 2017).

- Anonymous. Horticulture Statistics at a Glance 2018; Ministry of Agriculture and Farmer Welfare, Government of India: New Delhi, India, 2018. [Google Scholar]

- Arya, R.L.; Arya, S.; Arya, R.; Kumar, J. Fundamentals of Agriculture; Scientific Publishers: Stevenson Ranch, CA, USA, 2015; p. 470. [Google Scholar]

- APEDA (Agricultural and Processed Food Products Export Development Authority). 2015. Available online: https://apeda.gov.in/apedawebsite/menupages/Export_Regulations.htm (accessed on 15 March 2015).

- Wang, S.; Wang, J.; Wang, T.; Li, C.; Wu, Z. Effects of ozone treatment on pesticide residues in food: A review. Int. J. Food Sci. Technol. 2019, 54, 301–312. [Google Scholar] [CrossRef]

- Bajwa, U.; Sandhu, K. Effect of handling and processing on pesticide residues in food-a review. J. Food Sci. Technol. 2014, 51, 201–220. [Google Scholar] [CrossRef]

- Sukarminah, E.; Djali, M.; Andoyo, R.; Mardawati, E.; Rialita, T.; Cahyana, Y.; Setiasih, I.S. Ozonization technology and its effects on the characteristics and shelf-life of some fresh foods. KnE Life Sci. 2017, 2, 459–470. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Sunoj, S.; Manikantan, M.R.; Kothakota, A.; Hebbar, K.B. Application and kinetics of ozone in food preservation. Ozone Sci. Eng. 2017, 39, 115–126. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Kaavya, R.; Jayanath, Y.; Veenuttranon, K.; Lueprasitsakul, P.; Divya, V.; Ramesh, S.V. Ozone as a novel emerging technology for the dissipation of pesticide residues in foods–a review. Trends Food Sci. Technol. 2020, 97, 38–54. [Google Scholar] [CrossRef]

- Sujayasree, O.J.; Chaitanya, A.K.; Bhoite, R.; Pandiselvam, R.; Kothakota, A.; Gavahian, M.; Mousavi Khaneghah, A. Ozone: An advanced oxidation technology to enhance sustainable food consumption through mycotoxin degradation. Ozone Sci. Eng. 2022, 44, 17–37. [Google Scholar] [CrossRef]

- Chuwa, C.; Vaidya, D.; Kathuria, D.; Gautam, S.; Sharma, S.; Sharma, B. Ozone (O3): An Emerging Technology in the Food Industry. Food Nutr. J. 2020, 5, 224. [Google Scholar] [CrossRef]

- Vijay Rakesh Reddy, S.; Sudhakar Rao, D.V.; Sharma, R.R.; Preethi, P.; Pandiselvam, R. Role of Ozone in Post-Harvest Disinfection and Processing of Horticultural Crops: A Review. Ozone Sci. Eng. 2022, 44, 127–146. [Google Scholar] [CrossRef]

- Lozowicka, B.; Jankowska, M.; Hrynko, I.; Kaczynski, P. Removal of 16 pesticide residues from strawberries by washing with tap and ozone water, ultrasonic cleaning and boiling. Environ. Monit. Assess. 2016, 188, 1–19. [Google Scholar] [CrossRef]

- Wu, Y.; An, Q.; Li, D.; Wu, J.; Pan, C. Comparison of Different Home/Commercial Washing Strategies for Ten Typical Pesticide Residue Removal Effects in Kumquat, Spinach and Cucumber. Int. J. Environ. Res. Public Health 2019, 16, 472. [Google Scholar] [CrossRef]

- Chen, J.Y.; Lin, Y.J.; Kuo, W.C. Pesticide residue removal from vegetables by ozonation. J. Food Eng. 2013, 114, 404–411. [Google Scholar] [CrossRef]

- Rekhate, C.V.; Srivastava, J.K. Recent advances in ozone-based advanced oxidation processes for treatment of wastewater—A review. Chem. Eng. J. Adv. 2020, 3, 100031. [Google Scholar] [CrossRef]

- SANTE. Guidance Document on Analytical Quality Control and Method Validation Procedures for Pesticide Residues Analysis in Food and Feed; 2017, SANTE/11813/2017; SANTE: Osaka, Japan, 2017. [Google Scholar]

- CODEX ALIMENTARIUS International Food Standards: Online. Available online: https://www.fao.org/fao-who-codexalimentarius/codex-texts/dbs/pestres/pesticides/en (accessed on 3 October 2020).

- Amjad, A.; Muhammad, R.A.; Saeed, A.; Muhammad, R. Assessment of Imidacloprid and Acetamiprid Residues in Okra and Eggplant Grown in Peri-Urban Areas and their Dietary Intake in Humans. J. Chem. Soc. Pak. 2018, 40, 225–232. [Google Scholar]

- Paramasivam, M. Dissipation kinetics, dietary and ecological risk assessment of chlorantraniliprole residue in/on tomato and soil using GC-MS. J. Food Sci. Technol. 2021, 58, 604–611. [Google Scholar] [CrossRef] [PubMed]

- Horvitz, S.; Cantalejo, M.J. Application of ozone for the postharvest treatment of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2014, 54, 312–339. [Google Scholar] [CrossRef] [PubMed]

- Ong, K.C.; Cash, J.N.; Zabik, M.J.; Siddiq, M.; Jones, A.L. Chlorine and ozone washes for pesticide removal from apples and processed apple sauce. Food Chem. 1996, 55, 153–160. [Google Scholar] [CrossRef]

- Kim, S.D.; Kim, I.D.; Park, M.Z.; Lee, Y.G. Effect of ozone water on pesticide-residual contents of soybean sprouts during cultivation. Korean J. Food Sci. Technol. 2000, 32, 277–283. [Google Scholar]

- Khadre, M.A.; Yousef, A.E.; Kim, J.G. Microbial aspects of ozone applications in food: A review. J. Food Sci. 2001, 66, 1242–1252. [Google Scholar] [CrossRef]

- Gabler, F.M.; Smilanick, J.L.; Mansour, M.F. Influence of fumigation with high concentrations of ozone gas on postharvest gray mold and fungicide residues on table grapes. Postharvest Biol. Technol. 2010, 55, 85–90. [Google Scholar] [CrossRef]

- Anbarasan, R.; Jaspin, S.; Bhavadharini, B.; Pare, A.; Pandiselvam, R.; Mahendran, R. Chlorpyrifos pesticide reduction in soybean using cold plasma and ozone treatments. LWT-Food Sci. Technol. 2022, 159, 113–193. [Google Scholar] [CrossRef]

- Takahashi, M.; Kawamura, T.; Yamamoto, Y.; Ohnari, H.; Himuro, S.; Shakutsui, H. Effect of shrinking microbubble on gas hydrate formation. J. Phys. Chem. A 2003, 107, 2171–2173. [Google Scholar] [CrossRef]

- Sumikura, M.; Hidaka, M.; Murakami, H.; Nobutomo, Y.; Murakami, T. Ozone micro-bubble disinfection method for wastewater reuses system. Water Sci. Technol. 2007, 56, 53–61. [Google Scholar] [CrossRef]

- Pesticide Properties DataBase (PPDB): Online. Available online: https://sitem.herts.ac.uk/aeru/ppdb/en/Reports/11.htm (accessed on 15 March 2015).

- Patil, G.S. Prediction of aqueous solubility and octanol-water partition coefficient for pesticides based on their molecular structure. J. Hazard. Mater. 1994, 36, 34–43. [Google Scholar] [CrossRef]

- Parsons, E.P.; Popopvsky, S.; Lohreya, G.T.; Alkalai-Tuvia, S.; Perzelan, Y.; Bosland, P.; Jenks, M.A. Fruit cuticle lipid composition and water loss in a diverse collection of pepper (Capsicum). Physiol. Plant. 2013, 149, 160–174. [Google Scholar] [CrossRef]

- Edwards, C.A. Factors that affect the persistence of pesticides in plants and soils. Pure Appl. Chem. 1975, 42, 39–56. [Google Scholar] [CrossRef]

- CIBRC (Central Insecticide Board and Registration committee). Approved Uses of Registered Insecticides cleaning and boiling. Environ. Monit. Assess. 2017, 188, 51. [Google Scholar]

- Sharma, K.K. Pesticide Residues Analysis Manual; IARI: New Delhi, India, 2013; pp. 92–94. [Google Scholar]

- Patil, V.M.; Singh, S.; Patel, K.G.; Patel, Z.P. Effect of sun drying and grinding on the residues of six insecticides in chillifruits. Pestic. Res. J. 2018, 30, 140–146. [Google Scholar] [CrossRef]

- Adou, K.; Bontoyan, W.R.; Sweeney, P.J. Multi residue method for the analysis of pesticide residues in fruits and vegetables by accelerated solvent extraction and capillary gas chromatography. J. Agric. Food Chem. 2001, 49, 4153–4160. [Google Scholar] [CrossRef]

- Anonymous. Dietary Guidelines for Indian—A Manual; National Institute of Nutrition, ICMR Publication: Hyderabad, India, 2011; pp. 1–139. [Google Scholar]

- World Health Organization (WHO). WHO Specifications and Evaluations for Public Health Pesticides: L-Cyhalothrin and Acetamiprid; WHO: Geneva, Switzerland, 2012; pp. 3–92.

- Sanchez-Bayo, F.; Baskaran, S.; Kennedy, I.R. Ecological relative risk (EcoRR): Another approach for risk assessment of pesticides in agriculture. Agric. Ecosyst. Environ. 2002, 91, 37–57. [Google Scholar] [CrossRef]

- Panse, V.G.; Sukhatme, P.V. Statistical Analysis for Agricultural Workers; ICAR: New Delhi, India, 1985; pp. 50–65. [Google Scholar]

| Parameters | Particular | Acetamiprid | Ethion | ||

|---|---|---|---|---|---|

| Linearity (n = 5) | Calibration concentration range | 0.001–0.1 mg/kg | 0.005–1.0 mg/kg | ||

| Regression equation | y = 83501x + 10105 | y = 16.372x + 34.75 | |||

| R2 [R2 ≥ 0.99] | 0.999 | 0.999 | |||

| Sensitivity (n = 5) | LOD (mg/kg) | 0.002 | 0.006 | ||

| LOQ (mg/kg) | 0.007 | 0.018 | |||

| Accuracy (n = 7) | Percentage Recovery [70–120%] | Fortified level (mg/kg) | (%) | Fortified level (mg/kg) | (%) |

| 0.025 | 95.80 ± 4.44 | 0.100 | 85.82 ± 6.16 | ||

| 0.050 | 89.13 ± 6.78 | 0.250 | 88.47 ± 7.89 | ||

| 0.100 | 104.05 ± 6.26 | 0.500 | 86.52 ± 7.96 | ||

| Precision (n = 7) | RSD [≤ 20%] | Fortified level (mg/kg) | (%) | Fortified level (mg/kg) | (%) |

| 0.025 | 15.99 | 0.100 | 16.53 | ||

| 0.050 | 16.65 | 0.250 | 11.94 | ||

| 0.100 | 13.41 | 0.500 | 16.57 | ||

| Group | Particulars with Age | Food Consumption (g/day) | Body Weight (kg) | Dietary Risk Assessment | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Acetamiprid @20 g a.i./ha (RD) | ||||||||||

| RQ a | RQ b | RQ c | RQ d | RQ e | RQ f | RQ g | ||||

| Children | 1–3 years | 50 | 12.90 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 4–6 years | 100 | 18.00 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| 7–9 years | 100 | 25.10 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Boys | 10–12 years | 200 | 34.30 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Girls | 10–12 years | 200 | 35.00 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Boys | 13–15 years | 200 | 47.60 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Girls | 13–15 years | 200 | 46.60 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Boys | 16–18 years | 200 | 55.40 | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 |

| Girls | 16–18 years | 200 | 52.10 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Man | Sedentary work | 200 | 60.00 | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 |

| Moderate work | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 | |||

| Heavy work | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 | |||

| Woman | Sedentary work | 200 | 55.00 | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 |

| Moderate work | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 | |||

| Heavy work | 0.1 | 0.1 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 | |||

| Group | Particulars with Age | Food Consumption (g/day) | Body Weight (kg) | Dietary Risk Assessment | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ethion @1000 g a.i./ha (RD) | ||||||||||

| RQ a | RQ b | RQ c | RQ d | RQ e | RQ f | RQ g | ||||

| Children | 1–3 years | 50 | 12.90 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 4–6 years | 100 | 18.00 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| 7–9 years | 100 | 25.10 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |

| Boys | 10–12 years | 200 | 34.30 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Girls | 10–12 years | 200 | 35.00 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Boys | 13–15 years | 200 | 47.60 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Girls | 13–15 years | 200 | 46.60 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Boys | 16–18 years | 200 | 55.40 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Girls | 16–18 years | 200 | 52.10 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Man | Sedentary work | 200 | 60.00 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Moderate work | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |||

| Heavy work | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |||

| Woman | Sedentary work | 200 | 55.00 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Moderate work | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |||

| Heavy work | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, S.; Solanki, V.; Bardhan, K.; Kansara, R.; Vyas, T.K.; Gandhi, K.; Dhakan, D.; Ali, H.M.; Siddiqui, M.H. Evaluation of Ozonation Technique for Pesticide Residue Removal in Okra and Green Chili Using GC-ECD and LC-MS/MS. Plants 2022, 11, 3202. https://doi.org/10.3390/plants11233202

Singh S, Solanki V, Bardhan K, Kansara R, Vyas TK, Gandhi K, Dhakan D, Ali HM, Siddiqui MH. Evaluation of Ozonation Technique for Pesticide Residue Removal in Okra and Green Chili Using GC-ECD and LC-MS/MS. Plants. 2022; 11(23):3202. https://doi.org/10.3390/plants11233202

Chicago/Turabian StyleSingh, Susheel, Vanrajsinh Solanki, Kirti Bardhan, Rohan Kansara, Trupti K. Vyas, Kelvin Gandhi, Darshan Dhakan, Hayssam M. Ali, and Manzer H. Siddiqui. 2022. "Evaluation of Ozonation Technique for Pesticide Residue Removal in Okra and Green Chili Using GC-ECD and LC-MS/MS" Plants 11, no. 23: 3202. https://doi.org/10.3390/plants11233202

APA StyleSingh, S., Solanki, V., Bardhan, K., Kansara, R., Vyas, T. K., Gandhi, K., Dhakan, D., Ali, H. M., & Siddiqui, M. H. (2022). Evaluation of Ozonation Technique for Pesticide Residue Removal in Okra and Green Chili Using GC-ECD and LC-MS/MS. Plants, 11(23), 3202. https://doi.org/10.3390/plants11233202