Mining Geomatics

Abstract

1. Introduction

2. Materials and Methods Used in Research

2.1. Comparative Analysis of GIS and GMP Technologies

2.2. Analysis of Concepts Related to Spatial Data Processing in Mining

2.2.1. Attempts to Modify the Nomenclature of GIS Technology for Mining Applications

- The first step is to outline the scope that the name is intended to cover in the existing reality. In this case, we are defining that all spatial data, no matter how acquired and processed, relating to mining fall within the scope of consideration of the new concept.

- The new name must encapsulate the approach to the definition using the name of any particular information system, not singling out a particular computer system or geospatial technology.

- The name of the study area should not be an acronym and, in particular, should not include the name of the GIS technology or its derived acronyms.

2.2.2. Identification of Concept Meaning Spatial Data Processing

2.2.3. Analysis of the Applicability of the Concept of Geomatics in the Context of Mining

3. Results

3.1. Results of Technological Change over Time and Naming Analyses

3.2. Proposed Definition of the Term Mining Geomatics

4. Preliminary Proposal for the Scope of the Body of Knowledge for Mining Geomatics

4.1. Single Geodetic Coordinate System at the Mine Site

4.2. Management of Spatial Data Acquisition

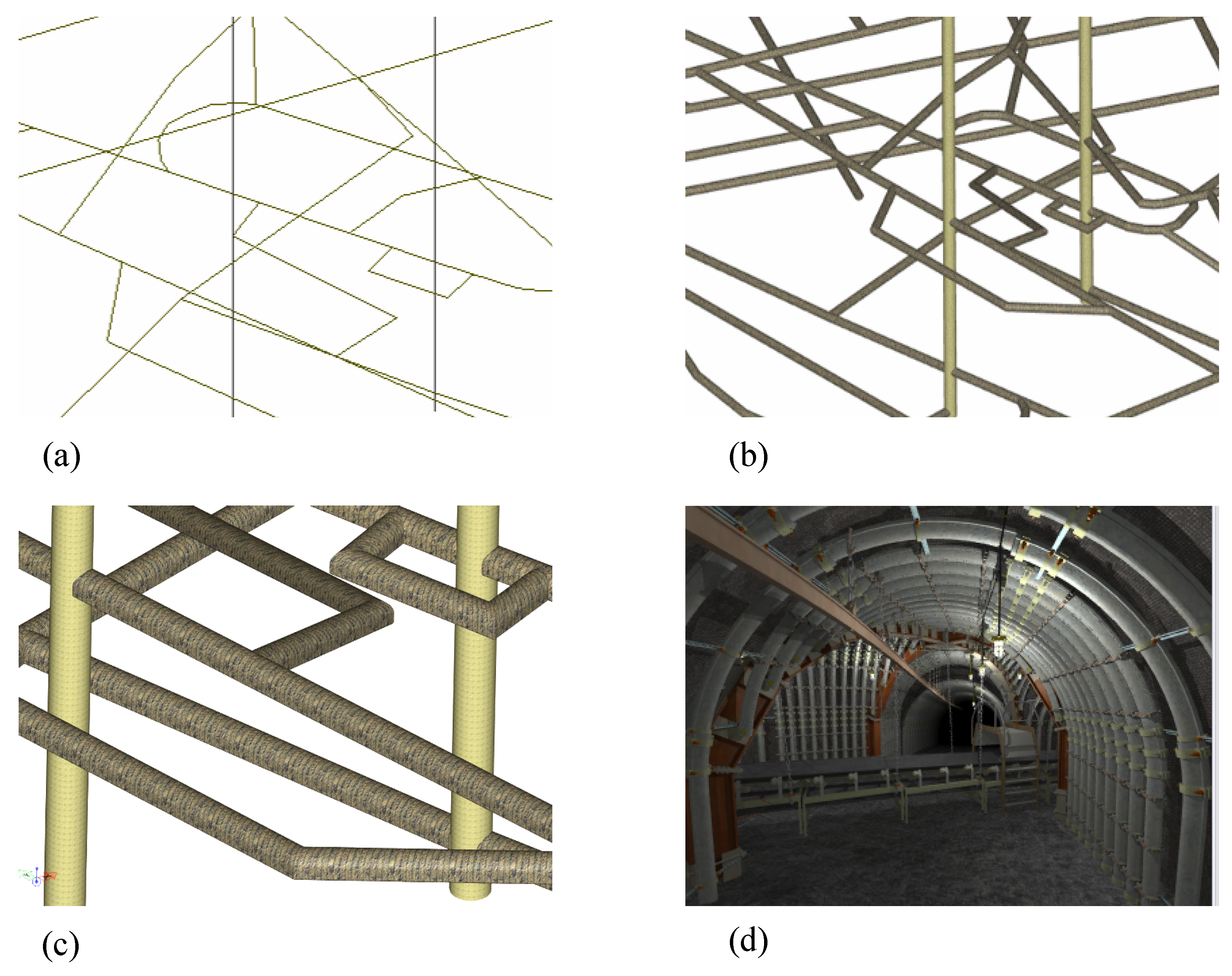

4.3. Three-Dimensional Modelling of Mining Data

- Visualisation of the deposit model with the completed, planned and projected exploitation;

- Location, identification and visualisation of mine workings infrastructure equipment linked to systems supporting material and equipment management of the mine plant;

- Locating, identifying and visualising the process of mining, haulage, extraction, enrichment, storage and sale of exploited raw material links to systems that monitor the output of each stage of its life cycle;

- Visualisation of the fourth dimension—time;

- The construction of the digital twin of the underground part of the mining plant.

4.4. Management of Data Processing Systems

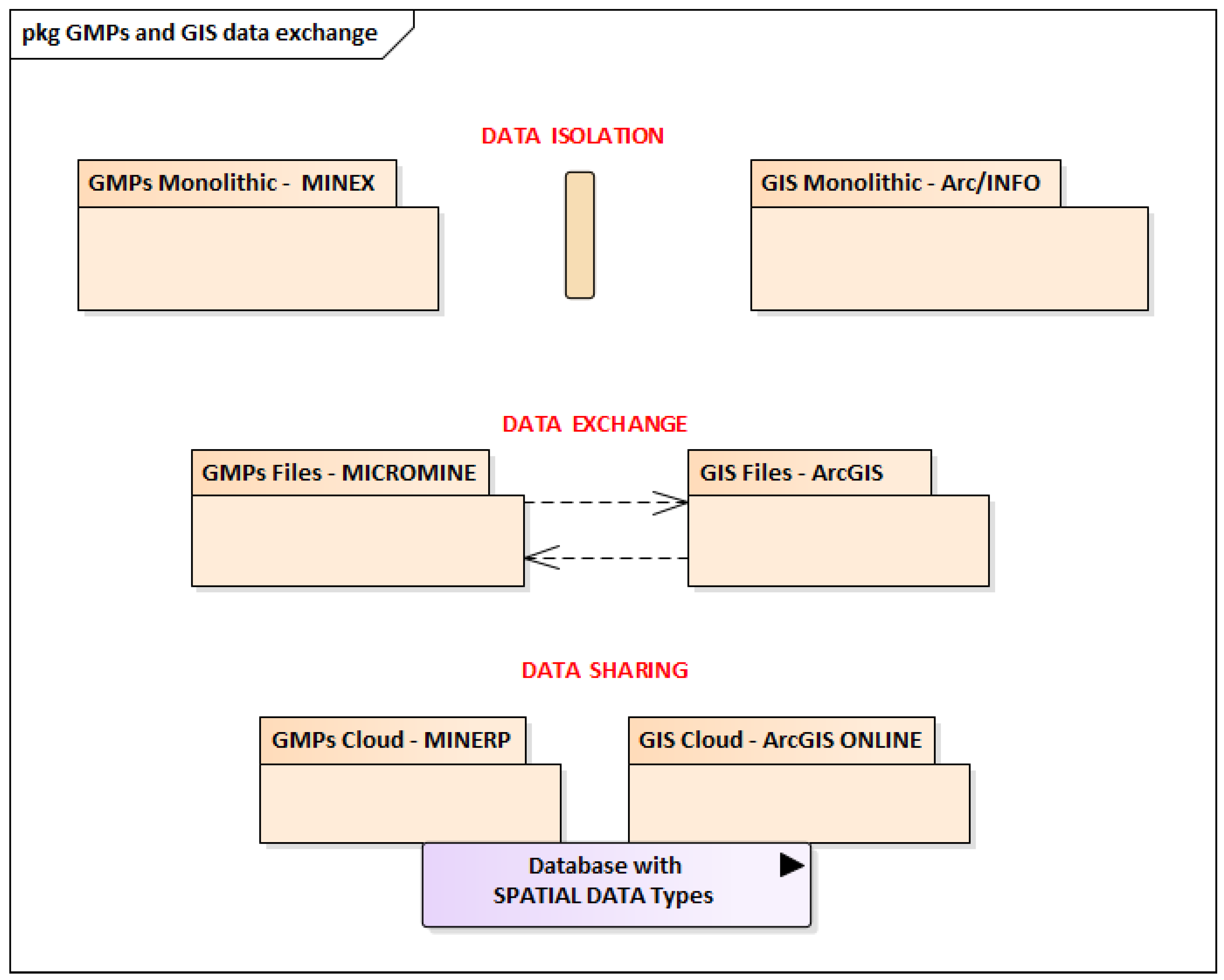

4.4.1. Methods of Integrating Spatial Data

- The expansion of existing databases with a spatial data processing component or installation of such databases dedicated to spatial data management at the scale of the mining company.

- The use of extraction, transformation and load (ETL) servers to transform features (i.e., geometric objects) between different specialised mining data processing systems. One of the more popular ETL servers on the market is Safe Software’s Feature Manipulation Engine (FME).

- The use of spatial data service technologies, such as Web Feature Service (WFS) or Web Map Service (WMS), as defined by the Open Geospatial Consortium (OGC), or using commercial solutions, such as WebGIS.

4.4.2. Separation of Spatial Data from Their Processing Systems

4.4.3. Standardisation of Spatial Data in Mining

4.5. Big Data in Mining

4.6. Augmented Reality and Virtual Reality

4.7. Data Exchange and Collaboration with the Social, Administrative and Economic Environment and in the Mine Life Cycle

4.8. Mining Geomatics Engineer as a New Profession

5. Discussion

6. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Apollo, M.; Jakubiak, M.; Nistor, S.; Lewinska, P.; Krawczyk, A.; Borowski, L.; Specht, M.; Krzykowska-Piotrowska, K.; Marchel, L.; Pęska-Siwik, A.; et al. Geodata in science—A review of selected scientific fields. Acta Sci. Pol. Form. Circumiectus 2023, 22, 1–30. [Google Scholar]

- Kajzar, V.; KukuStsch, R.; Heroldova, N. Verifying the possibilities of using a 3D laser scanner in the mining underground. Acta Geodyn. Geomater. 2015, 12, 51–58. [Google Scholar] [CrossRef]

- Lipecki, T.; Jaśkowski, W. Application of laser scanners to determine the shape of mine excavations for safety assessment, using the example of the cross-cut mina in the Salt Mine Wieliczka. Rep. Geod. 2009, 2/87, 239–250. [Google Scholar]

- Chen, S.; Walske, M.L.; Davies, I.J. Rapid mapping and analysing rock mass discontinuities with 3D terrestrial laser scanning in the underground excavation. Int. J. Rock Mech. Min. Sci. 2018, 110, 28–35. [Google Scholar] [CrossRef]

- Nghia, N.V.; Long, N.Q.; Cuc, N.T.; Bui, X.N. Applied Terrestrial Laser Scanning for coal mine high definition mapping. World Min.-Surf. Undergr. 2019, 71, 237–242. [Google Scholar]

- Lipecki, T.; Jaskowski, W.; Gruszczynski, W.; Matwij, K.; Matwij, W.; Ulmaniec, P. Inventory of the geometric condition of inanimate nature reserve Crystal Caves in “Wieliczka” Salt Mine. Acta Geod. Geophys. 2016, 51, 257–272. [Google Scholar] [CrossRef]

- Singh, S.K.; Banerjee, B.P.; Raval, S. Three-Dimensional Unique-Identifier-Based Automated Georeferencing and Coregistration of Point Clouds in Underground Mines. Remote Sens. 2021, 13, 3145. [Google Scholar] [CrossRef]

- Jabłoński, M.; Jaśkowski, W. The usage of telemetry measurements methods in order to determine shaft tube. Bud. Archit. 2016, 15, 63–74. [Google Scholar] [CrossRef]

- Jones, E. Mobile LiDAR for underground geomechanics: Learnings from the teens and directions for the twenties. In Proceedings of the Second International Conference on Underground Mining Technology; Wesseloo, J., Ed.; Australian Centre for Geomechanics: Crawley, Australia, 2020; pp. 3–26. [Google Scholar] [CrossRef]

- Palamara, D.R.; Nicholson, M.; Flentje, P.; Baafi, P.; Brassington, G.M. An evaluation of airborne laser scan data for coalmine subsidence mapping. Int. J. Remote Sens. 2007, 28, 3181–3203. [Google Scholar] [CrossRef]

- Lewińska, P.; Dyczko, A. Thermal digital terrain model of a coal spoil tip—A way of improving monitoring and early diagnostics of potential spontaneous combustion areas. J. Ecol. Eng. 2016, 17, 170–179. [Google Scholar] [CrossRef]

- Gocał, J.; Bałut, A.; Kocierz, R.; Kuras, P.; Ortyl, L.; Owerko, T.; Rączka, A.; Strach, M.; Szpyra, R. Precyzyjne pomiary drgań budowli przy użyciu naziemnego radaru interferometrycznego. Arch. Fotogram. Kartogr. Teledetekcji 2009, 19, 123–142. [Google Scholar]

- Szafarczyk, A. Możliwości zastosowania naziemnej interferometrii radarowej w górnictwie. In Geomatyka górnicza—Praktyczne zastosowania; Krawczyk, A., Dyczko, A., Eds.; Fundacja dla Akademii Górniczo-Hutniczej im. Stanisława Staszica: Kraków, Poland, 2013; pp. 67–80. [Google Scholar]

- Gabriel, A.K.; Goldstein, R.M.; Zebker, H.A. Mapping small elevation changes over large areas: Differential radar interferometry. J. Geophys. Res. 1989, 94, 9183. [Google Scholar] [CrossRef]

- Perski, Z. Applicability of ERS-1 and ERS-2 insar for land subsidence monitoring in the Silesian coal mining region, Poland. In Proceedings of the International Archives of Photogrametry and Remote Sensing Vol. XXXII Part 7. ISPRS Commission VII, Working Group 6, Budapest, Hungary, 1–4 September 1998; pp. 555–558. [Google Scholar]

- Jiang, X.; Min, X.; Ye, T.; Li, X.; Hu, X. Monitoring the subsidence at different periods in high underground water level coal mine areas using differential interferometric synthetic aperture radar (D-InSAR). Geocarto Int. 2023, 38, 1–11. [Google Scholar] [CrossRef]

- Ferretti, A.; Prati, C.; Rocca, F. Permanent scatterers in SAR interferometry. IEEE Trans. Geosci. Remote Sens. 2001, 39, 8–20. [Google Scholar] [CrossRef]

- Xia, Y.; Kaufmann, H.; Guo, X. Differential SAR interferometry using corner reflectors. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Toronto, ON, Canada, 24–28 June 2002; Volume 2, pp. 1243–1246. [Google Scholar] [CrossRef]

- Ren, H.; Zhao, Y.; Xiao, W.; Hu, Z. A review of UAV monitoring in mining areas: Current status and future perspectives. Int. J. Coal Sci. Technol. 2019, 6, 320–333. [Google Scholar] [CrossRef]

- Puniach, E.; Gruszczyński, W.; Stoch, T.; Mrocheń, D.; Ćwiąkała, P.; Sopata, P.; Pastucha, E.; Matwij, W. Determination of the coefficient of proportionality between horizontal displacement and tilt change using UAV photogrammetry. Eng. Geol. 2023, 312, 106939. [Google Scholar] [CrossRef]

- Westoby, M.; Brasington, J.; Glasser, N.; Hambrey, M.; Reynolds, J. ‘Structure-from-Motion’ photogrammetry: A low-cost, effective tool for geoscience applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef]

- Magiera, W.; Vārna, I.; Mitrofanovs, I.; Silabrieds, G.; Krawczyk, A.; Skorupa, B.; Apollo, M.; Maciuk, K. Accuracy of Code GNSS Receivers under Various Conditions. Remote Sens. 2022, 14, 2615. [Google Scholar] [CrossRef]

- Gao, J.-X.; Hu, H. Advanced GNSS technology of mining deformation monitoring. Procedia Earth Planet. Sci. 2009, 1, 1081–1088. [Google Scholar] [CrossRef]

- Lian, X.; Li, Z.; Yuan, H.; Hu, H.; Cai, Y.; Liu, X. Determination of the Stability of High-Steep Slopes by Global Navigation Satellite System (GNSS) Real-Time Monitoring in Long Wall Mining. Appl. Sci. 2020, 10, 1952. [Google Scholar] [CrossRef]

- Vrublova, D.; Kapica, R.; Gibesova, B.; Mudruňka, J.; Struś, A. Application of GNSS technology in surface mining. Geod. Cartogr. 2016, 42, 122–128. [Google Scholar] [CrossRef]

- Liu, H.; Pan, W.; Hu, Y.; Li, C.; Yuan, X.; Long, T. A Detection and Tracking Method Based on Heterogeneous Multi-Sensor Fusion for Unmanned Mining Trucks. Sensors 2022, 22, 5989. [Google Scholar] [CrossRef]

- Longley, P.; Goodchild, M.; Maguire, D.; Rhind, D. Geographic Information Systems and Science, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Filipova, S.; Filipov, D.; Raeva, P. Creating 3D model of an open pit quarry by UAV imaging and analysis in GIS. In Proceedings of the International Conference on Cartography and GIS, Albena, Bulgaria, 13–17 June 2016; Volume 6, p. 652. [Google Scholar]

- Kapageridis, I. The Future of Mine Planning Software—New Tools and Innovations. In Proceedings of the International Mining Congress and Exhibition of Turkey, Antalya, Turkey, 14–17 April 2005. [Google Scholar]

- Fotheringham, M.; Paudyal, D.R. Combining terrestrial scanned datasets with UAV point clouds for mining operations. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2021, V-4-2021, 129–138. [Google Scholar] [CrossRef]

- Choi, Y.; Baek, J.; Park, S. Review of GIS-based applications for mining: Planning, operation, and environmental management. Appl. Sci. 2020, 10, 2266. [Google Scholar] [CrossRef]

- Katakwa, T.; Musingwini, C.; Genc, B. Online database of mine planning and peripheral software used in the South African mining industry. J. S. Afr. Inst. Min. Metall. 2013, 113, 497–504. [Google Scholar]

- Krawczyk, A. Geomatics and Mining Geoinformation—Their Practical Applications and Development Barriers, 1st ed.; Dissertations Monographs; AGH University of Science and Technology Press: Kraków, Poland, 2019. (In Polish) [Google Scholar]

- Krawczyk, A. Proposal of Redefinition of the Terms Geomatics and Geoinformatics on the Basis of Terminological Postulates. ISPRS Int. J. Geo-Inf. 2022, 11, 557. [Google Scholar] [CrossRef]

- Krawczyk, A. Attempt at the systematics of storing attributes and topology of geometric objects in geographic information systems. Stud. Inform. 2011, 2B/32, 189–201. (In Polish) [Google Scholar]

- Coulthard, M.A.; Journet, N.C.; Swindells, C.F. Integration of stress analysis into mine excavation design. In Proceedings of the U.S. Symposium on Rock Mechanics, Norman, OK, USA, 10–12 July 1991; p. 451. [Google Scholar]

- Bonham-Carter, G.F. Geographic Information Systems for Geoscientists: Modelling with GIS; Number 13; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Micromine. MICROMINE Launches Micromine 2011. WWW Page. 2011. Available online: http://www.micromine.com/sites/default/files/MICROMINE-20Launches-20Micromine-202011.pdf (accessed on 20 June 2014).

- Wang, J.; Guo, D. The building and development of China’s Mine Geographic Information System. China Coal 1996, 6, 24–27. [Google Scholar]

- Li, R.; Saxena, N.K. Development of an integrated marine geographic information system. Mar. Geod. 1993, 16, 293–307. [Google Scholar] [CrossRef]

- Qi, A.; Wu, L.; Yang, K.; Hu, D.; Yin, Z.; Deng, Z. Development and application of mine geographical information system. In Computer Applications in the Mineral Industries; CRC Press: Boca Raton, FL, USA, 2001; pp. 825–828. [Google Scholar]

- Péter, S.; Péter, M. Specialized mining GIS system MineGIS SMZ Jelšava. Acta Montan. Slovaca 2005, 10, 377–379. [Google Scholar]

- Lukichev, S.V.; Nagovitsyn, O.V. Modeling Objects and Processes within a Mining Technology as a Framework for a System Approach to Solve Mining Problems. J. Min. Sci. 2018, 54, 1041–1049. [Google Scholar] [CrossRef]

- Vinogradov, A.; Ivanov, A.; Gerasimov, A.; Ovsyannikov, A. The Geological and Mining-Surveyor Support of the Drilling and Blasting Operations at the Open-Cut Mines with the Use of the Mining–Geological Informational GIS GEOMIX System. Ferr. Metall. Bull. Sci. Tech. Econ. Inf. 2015, 10, 32–35. [Google Scholar]

- Cardoso, J.; Rocha, A.; Lopes, J.C. M-GIS—Mobile and Interoperable Access to Geographic Information. In Electronic Government. EGOV 2004; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2004; pp. 400–405. [Google Scholar] [CrossRef]

- Tang, W.S.M.; Selwood, J. Mobile Geographic Information Services (M-GIS): Technology That Changes the Way We Navigate Our World. In Proceedings of the IAPRS, COMMISSION II, IAPRS, Xi’an, China, 20–23 August 2002; Volume 34. [Google Scholar]

- Gunn, S. Mobile Geographic Information Systems (MGIS). In The Encyclopedia of Archaeological Sciences; Wiley Blackwell: Hoboken, NJ, USA, 2018; pp. 1–4. [Google Scholar] [CrossRef]

- El Fhel, B.; Sardi, L.; Idri, A. A Requirements Catalog of Mobile Geographic Information System for Data Collection. In Trends and Applications in Information Systems and Technologies. WorldCIST 2021; Springer: Cham, Switzerland, 2021; pp. 324–336. [Google Scholar] [CrossRef]

- Dubuisson, B. La Photogrammétrie des Plans Topographiques et Parcellaires; Eyrolles: Paris, France, 1969. [Google Scholar]

- Bédard, Y. Geomatics. In Encyclopedia of Geographic Information Science; Kemp, K., Ed.; Sage Publications: Thousand Oaks, CA, USA, 2008; pp. 195–197. [Google Scholar]

- Molenaar, M. Status and problems of geographical information systems. The necessity of a geoinformation theory. ISPRS J. Photogramm. Remote Sens. 1991, 46, 85–103. [Google Scholar] [CrossRef]

- Longley, P.A.; Brooks, S.; Macmillan, W.; McDonnell, R. Geocomputation: A Primer; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Carranza, E.J.M. Geocomputation of mineral exploration targets. Comput. Geosci. 2011, 37, 1907–1916. [Google Scholar] [CrossRef]

- Allison, M.L.; Snyder, W.S.; Walker, J.D. Geoinformatics: A nascent revolution in the Earth Sciences. GSA Today 2002, 12, 17. [Google Scholar] [CrossRef]

- Gewin, V. Mapping opportunities. Nature 2004, 427, 376–377. [Google Scholar] [CrossRef]

- Goodchild, M.F. GIScience, Geography, Form, and Process. Ann. Assoc. Am. Geogr. 2004, 94, 709–714. [Google Scholar] [CrossRef]

- Šíma, J. Geomatics and geoinformatics in modern information society–projection of new trends into their curricula at the University of West Bohemia in Pilsen. In Proceedings of the Scientia Est Potentia–Knowledge Is Power, FIG Commission 2 Symposium, Prague, Czech Republic, 7–9 June 2007; pp. 7–9. [Google Scholar]

- MK, C.; Pal, D.; Ahmad, M.; Singh, R. Application of Geomatic Information Technology in Mineral Industry. MINETECH 2001, 22, 17–25. [Google Scholar]

- Pavlis, N.K. Geomatic methods for the analysis of data in the Earth sciences. Eos Trans. Am. Geophys. Union 2001, 82, 339. [Google Scholar] [CrossRef]

- Gond, V.; Bluteau, J.; Kotchi, S.O.; Koné, B.B.; Linares, S. Geomatics, a monitoring tool for illegal gold-mining in French Guiana; [La géomatique, outil de surveillance de l’orpaillage clandestin en guyane française]. Can. J. Lat. Am. Caribb. Stud. 2009, 34, 177–193. (In French) [Google Scholar] [CrossRef]

- Khichar, R.; Upadhyay, S.S. Wireless sensor networks and their applications in geomatics: Case study on developments in developing countries. Appl. Geomat. 2010, 2, 43–48. [Google Scholar] [CrossRef]

- Cadoppi, P.; Camanni, G.; Damiano, A.; Fusetti, E.; Monticelli, F.; Perotti, L.; Perrone, G. 3D model reconstruction of mineralizations in Alpine context. Examples of geomatics approach on the talc mineralization mine in Germanasca Valley and the Balangero asbestos mine (Western Alps). Rend. Online Soc. Geol. Ital. 2010, 11, 63–64. [Google Scholar]

- Blachowski, J.; Górniak-Zimroz, J.; Milczarek, W.; Pactwa, K. Applications of Geomatics in Surface Mining. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042009. [Google Scholar] [CrossRef]

- Blachowski, J.; Górniak-Zimroz, J.; Milczarek, W.; Pactwa, K. Applications of geomatics in underground mining. Int. Multidiscip. Sci. GeoConf. SGEM 2017, 17, 799–810. [Google Scholar]

- Nguyen, L.Q.; Vo, D.N.; Vo, M.C. Advanced Mining Geomatic Technologies Serving Open-Pit Mining Operation in Vietnam. J. Min. Earth Sci. 2020, 61, 125–133. [Google Scholar] [CrossRef]

- Popescu, E.; Popescu, C.A.; Herbei, M.V.; Horablaga, A.; Smulea, A. 3D modeling of waste dumps in order to ecology of mining areas. Agrolife Sci. J. 2020, 9, 240–249. [Google Scholar]

- Perfetti, L.; Teruggi, S.; Achille, C.; Fassi, F. Rapid and low-cost photogrammetric survey of hazardous sites, from measurements to VR dissemination. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, 48, 207–214. [Google Scholar] [CrossRef]

- Krawczyk, A. Mining geomatics as an application of geomatics methods in mining geodesy. Ann. Geomat. 2004, 2, 172–180. (In Polish) [Google Scholar]

- Michalak, J. Geomatyka (geoinformatyka)—Czy nowa dyscyplina? Przegląd Geol. 2000, 48, 673–678. [Google Scholar]

- Paradis, M. From geodesy to geomatics. Can. Surv. 1981, 35, 262–268. [Google Scholar] [CrossRef]

- Coutts, B. The name game: Again. Geomat. World 2017, 26, 14–15. [Google Scholar]

- Romme, G. The Quest for Professionalism: The Case of Management and Entrepreneurship; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Xiao, W.G. On the Establishment of Independent Coordinate System for Mining Area Integration. Nonferr. Met. Sci. Eng. 2009, 23, 15–17. (In Chinese) [Google Scholar]

- Sokoła-Szewioła, V.; Poniewiera, M.; Pomykoł, M. Algorithm of transformation between the local system Borowa Góra and the state system PL-2000 on the example of PG Silesia. IOP Conf. Ser. Earth Environ. Sci. 2018, 198, 012014. [Google Scholar] [CrossRef]

- Warchala, M.; Leszczyński, R.; Jędrzejec, M. Ujednolicenie układów współrzędnych stosowanych w KGHM „Polska Miedź” S.A. In Proceedings of the Szkoła Eksploatacji Podziemnej 2011; Kicki, J., Ed.; IGSMiE: Kraków, Poland, 2011. [Google Scholar]

- Biljecki, F.; Zhao, J.; Stoter, J.; Ledoux, H. Revisiting the concept level of detail in 3D city modelling. In Proceedings of the 8th 3DGeoInfo Conference & WG II/2 Workshop, Istanbul, Turkey, 27–29 November 2013; ISPRS Archives Volume II-2/W1;. ISPRS, Copernicus Publications: Göttingen, Germany, 2013. [Google Scholar]

- Galica, D. An Attempt to Use Computer Graphics for the Cartographic Presentation of Mine Workings. Master’s Thesis, AGH University of Science and Technology, Kraków, Poland, 2008. (In Polish). [Google Scholar]

- Krawczyk, A.; Kula, R. Analysis of variants of arc-suscesible case models of mining excavations in view of computer processing. Ann. Geomat. 2013, XI, 51–61. (In Polish) [Google Scholar]

- McCullough, A.; Barr, S.; James, P. A Typology of Real-Time Parallel Geoprocessing for the Sensor Web Era. In Proceedings of the Integrating Sensor Web and Web-Based Geoprocessing, CEUR Workshop Proceedings, Utrecht, The Netherlands, 18 April 2011; Volume 712. [Google Scholar]

- Wang, J.; Bi, L.; Wang, L.; Jia, M.; Mao, D. A mining technology collaboration platform theory and its product development and application to support China’s digital mine construction. Appl. Sci. 2019, 9, 5373. [Google Scholar] [CrossRef]

- Dyczko, A. Modeling of quality parameters of the coking coal as a process of adapting the output to the contracted parameters. Acta Montan. Slovaca 2022, 27, 11–26. [Google Scholar]

- Banerjee, T.K.; Roy, S.; Dey, S. A GIS solution for an integrated underground coal mine management: A conceptual framework. J. Manag. Policies Pract. 2014, 2, 129–143. [Google Scholar]

- Dyczko, A. Construction of a heuristic architecture of a production line management system in the JSW SA Mining Group in the context of output stabilization, quality improvement and the maximization of economic effects. Miner. Resour. Manag. 2021, 37, 219–238. [Google Scholar]

- Cox, S.J.D. XMML—A standards conformant XML language for transfer of exploration data. ASEG Ext. Abstr. 2004, 2004, 1–4. [Google Scholar] [CrossRef]

- Sen, M.; Duffy, T. GeoSciML: Development of a generic GeoScience Markup Language. Comput. Geosci. 2005, 31, 1095–1103. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Qu, H.; Wu, Z. GML-based 3D spatial data model for geoscience information in coal mines. In Proceedings of the 2013 21st International Conference on Geoinformatics, Kaifeng, China, 20–22 June 2013. [Google Scholar] [CrossRef]

- Albertoni, R.; Martino, M.D.; Podestà, P.; Abecker, A.; Wössner, R.; Schnitter, K. LusTRE: A framework of linked environmental thesauri for metadata management. Earth Sci. Inform. 2018, 11, 525–544. [Google Scholar] [CrossRef]

- Ma, X.; Wu, C.; Carranza, E.J.M.; Schetselaar, E.M.; van der Meer, F.D.; Liu, G.; Wang, X.; Zhang, X. Development of a controlled vocabulary for semantic interoperability of mineral exploration geodata for mining projects. Comput. Geosci. 2010, 36, 1512–1522. [Google Scholar] [CrossRef]

- Inostroza, P.; Pezo, A.C.; Nieto, A. SOMI: Towards a Standard Representation of Mining Objects. IFAC Proc. Vol. 2009, 42, 303–307. [Google Scholar] [CrossRef]

- Li, D.; Shen, X.; Wang, L. Connected Geomatics in the big data era. Int. J. Digit. Earth 2018, 11, 139–153. [Google Scholar] [CrossRef]

- Jeansoulin, R. Review of Forty Years of Technological Changes in Geomatics toward the Big Data Paradigm. ISPRS Int. J. Geo-Inf. 2016, 5, 155. [Google Scholar] [CrossRef]

- Ming, J.; Zhang, L.; Sun, J.; Zhang, Y. Analysis models of technical and economic data of mining enterprises based on big data analysis. In Proceedings of the 2018 IEEE 3rd International Conference on Cloud Computing and Big Data Analysis (ICCCBDA), Chengdu, China, 20–22 April 2018; pp. 224–227. [Google Scholar]

- Kosydor, P.; Warchala, E.; Krawczyk, A.; Piórkowski, A. Determinants of large-scale spatial data processing in Polish mining. AIP Conf. Proc. 2020, 2209, 040007. [Google Scholar] [CrossRef]

- Qi, C.C. Big data management in the mining industry. Int. J. Miner. Metall. Mater. 2020, 27, 131–139. [Google Scholar] [CrossRef]

- Zhang, S.X. Augmented Reality on Longwall Face for Unmanned Mining. Appl. Mech. Mater. 2010, 40–41, 388–391. [Google Scholar] [CrossRef]

- van Wyk, E.; de Villiers, R. Virtual Reality Training Applications for the Mining Industry. In Proceedings of the AFRIGRAPH ’09: Proceedings of the 6th International Conference on Computer Graphics, Virtual Reality, Visualisation and Interaction in Africa, Pretoria, South Africa, 4–6 February 2009; Association for Computing Machinery: New York, NY, USA, 2009; pp. 53–63. [Google Scholar] [CrossRef]

- Bednarz, T.; James, C.; Widzyk-Capehart, E.; Caris, C.; Alem, L. Distributed Collaborative Immersive Virtual Reality Framework for the Mining Industry. In Machine Vision and Mechatronics in Practice; Springer: Berlin/Heidelberg, Germany, 2015; pp. 39–48. [Google Scholar] [CrossRef]

- Brzychczy, E.; Trzcionkowska, A. Process-Oriented Approach for Analysis of Sensor Data from Longwall Monitoring System. In Advances in Intelligent Systems and Computing; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 611–621. [Google Scholar] [CrossRef]

- Mining.com. Maptek Brings Augmented Reality to the Mining Industry. WWW Page. 2013. Available online: http://www.mining.com/web/maptek-brings-augmented-reality-to-the-mining-industry (accessed on 22 March 2019).

- Blachowski, J.; Chrzanowski, A.; Szostak-Chrzanowski, A. Application of GIS Methods in Assessing Effects of Mining Activity on Surface Infrastructure. Arch. Min. Sci. 2014, 59, 307–321. [Google Scholar] [CrossRef]

- Asr, E.T.; Kakaie, R.; Ataei, M.; Mohammadi, M.R.T. A review of studies on sustainable development in mining life cycle. J. Clean. Prod. 2019, 229, 213–231. [Google Scholar] [CrossRef]

- Simon, S.; Nyamsuren, E.; Kruiger, H.; Xu, H. Why geographic data science is not a science. Geogr. Compass 2020, 14, e12537. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for implementing the strategic initiative INDUSTRIE 4.0. Final. Rep. Ind. 2013, 4, 82. [Google Scholar]

- Hazrathosseini, A.; Afrapoli, A.M. The advent of digital twins in surface mining: Its time has finally arrived. Resour. Policy 2023, 80, 103155. [Google Scholar] [CrossRef]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Mourtzis, D. Digital twins in industry 4.0. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 277–316. [Google Scholar] [CrossRef]

- Blais, J.R.; Esche, H. Geomatics and the new cyber-infrastructure. Geomatica 2008, 62, 11–22. [Google Scholar]

- Maus, V.; Giljum, S.; Gutschlhofer, J.; da Silva, D.M.; Probst, M.; Gass, S.L.B.; Luckeneder, S.; Lieber, M.; McCallum, I. A global-scale data set of mining areas. Sci. Data 2020, 7, 289. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, S.; Sant’eva, E.; Bakanov, M.; Sobik, L.; Lopukhinsky, L. Integration of Environmental Information in a Mining Region Using a Geoportal. E3S Web Conf. 2021, 278, 01013. [Google Scholar] [CrossRef]

- Werner, T.; Bebbington, A.; Gregory, G. Assessing impacts of mining: Recent contributions from GIS and remote sensing. Extr. Ind. Soc. 2019, 6, 993–1012. [Google Scholar] [CrossRef]

- Buczyńska, A.; Blachowski, J.; Bugajska-Jędraszek, N. Analysis of Post-Mining Vegetation Development Using Remote Sensing and Spatial Regression Approach: A Case Study of Former Babina Mine (Western Poland). Remote Sens. 2023, 15, 719. [Google Scholar] [CrossRef]

- Hardie, A. The Development and Present State of Web-GIS. Cartography 1998, 27, 11–26. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawczyk, A. Mining Geomatics. ISPRS Int. J. Geo-Inf. 2023, 12, 278. https://doi.org/10.3390/ijgi12070278

Krawczyk A. Mining Geomatics. ISPRS International Journal of Geo-Information. 2023; 12(7):278. https://doi.org/10.3390/ijgi12070278

Chicago/Turabian StyleKrawczyk, Artur. 2023. "Mining Geomatics" ISPRS International Journal of Geo-Information 12, no. 7: 278. https://doi.org/10.3390/ijgi12070278

APA StyleKrawczyk, A. (2023). Mining Geomatics. ISPRS International Journal of Geo-Information, 12(7), 278. https://doi.org/10.3390/ijgi12070278