Proximity Operations and Three Degree-of-Freedom Maneuvers Using the Smartphone Video Guidance Sensor

Abstract

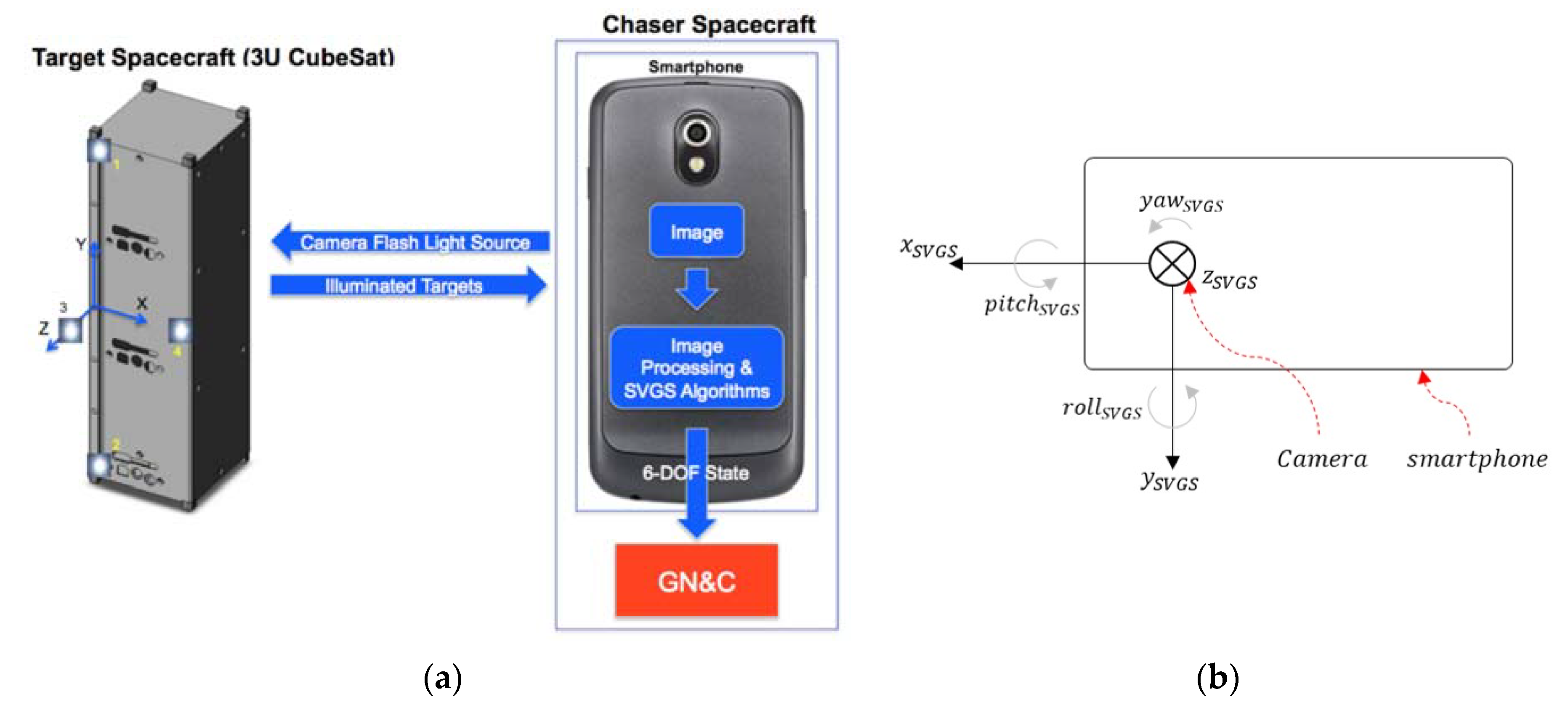

1. Introduction

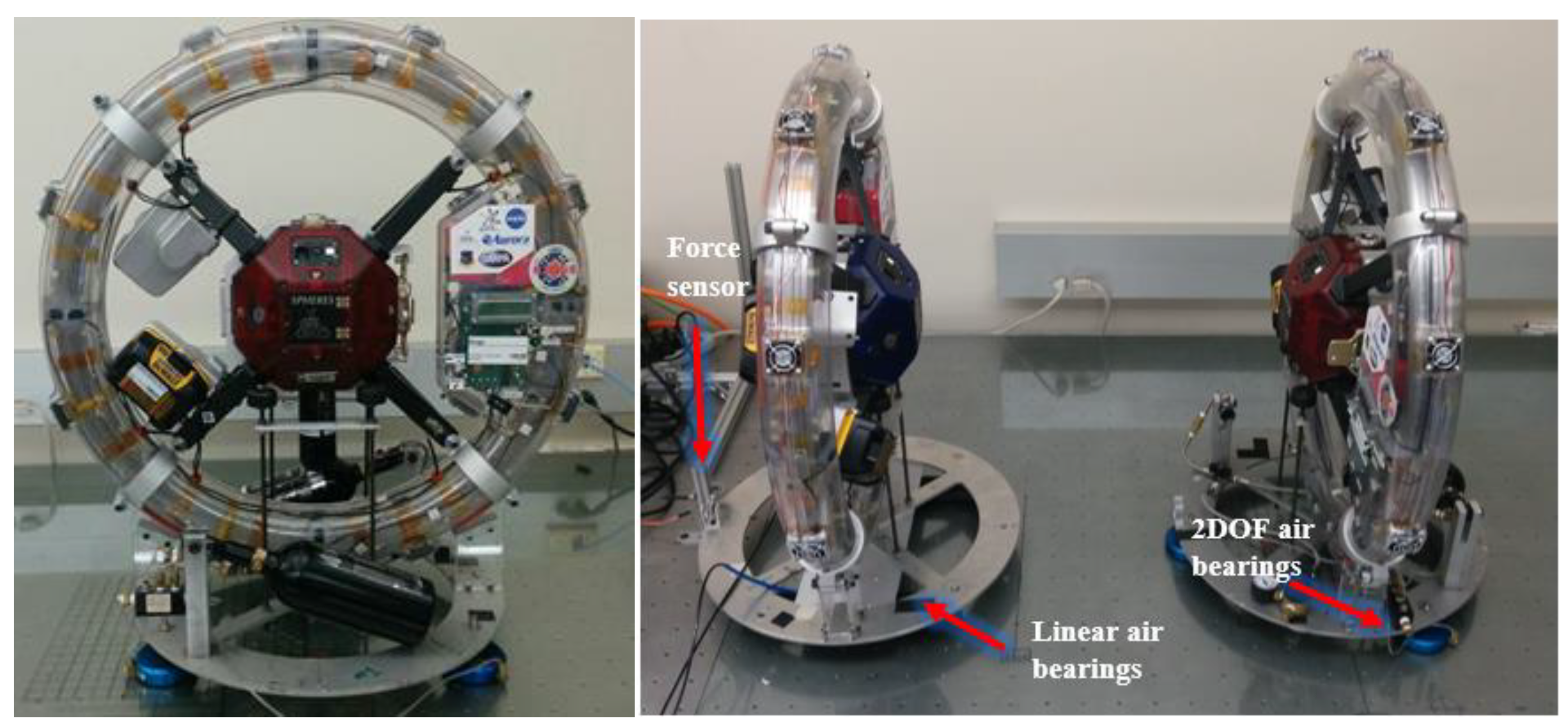

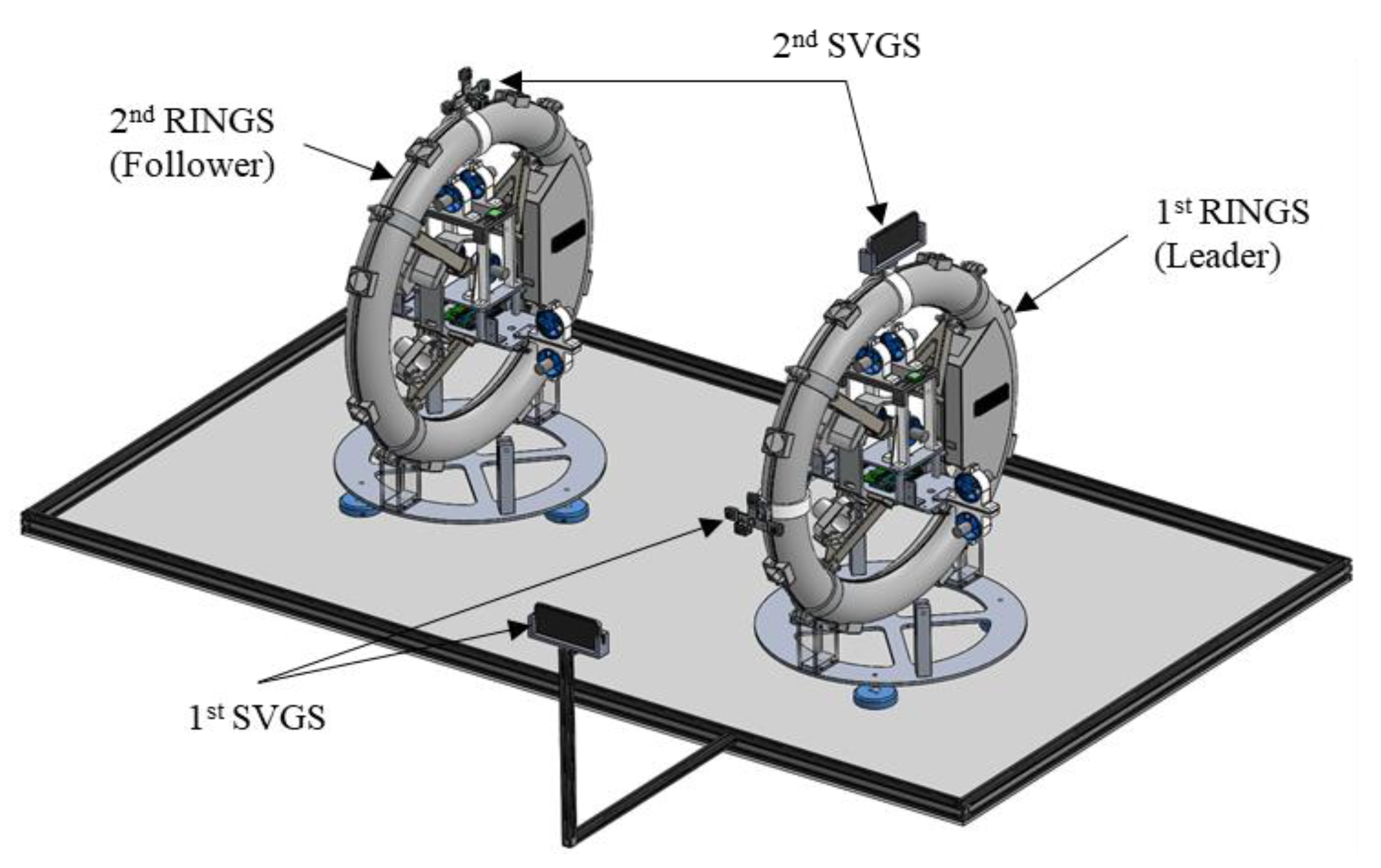

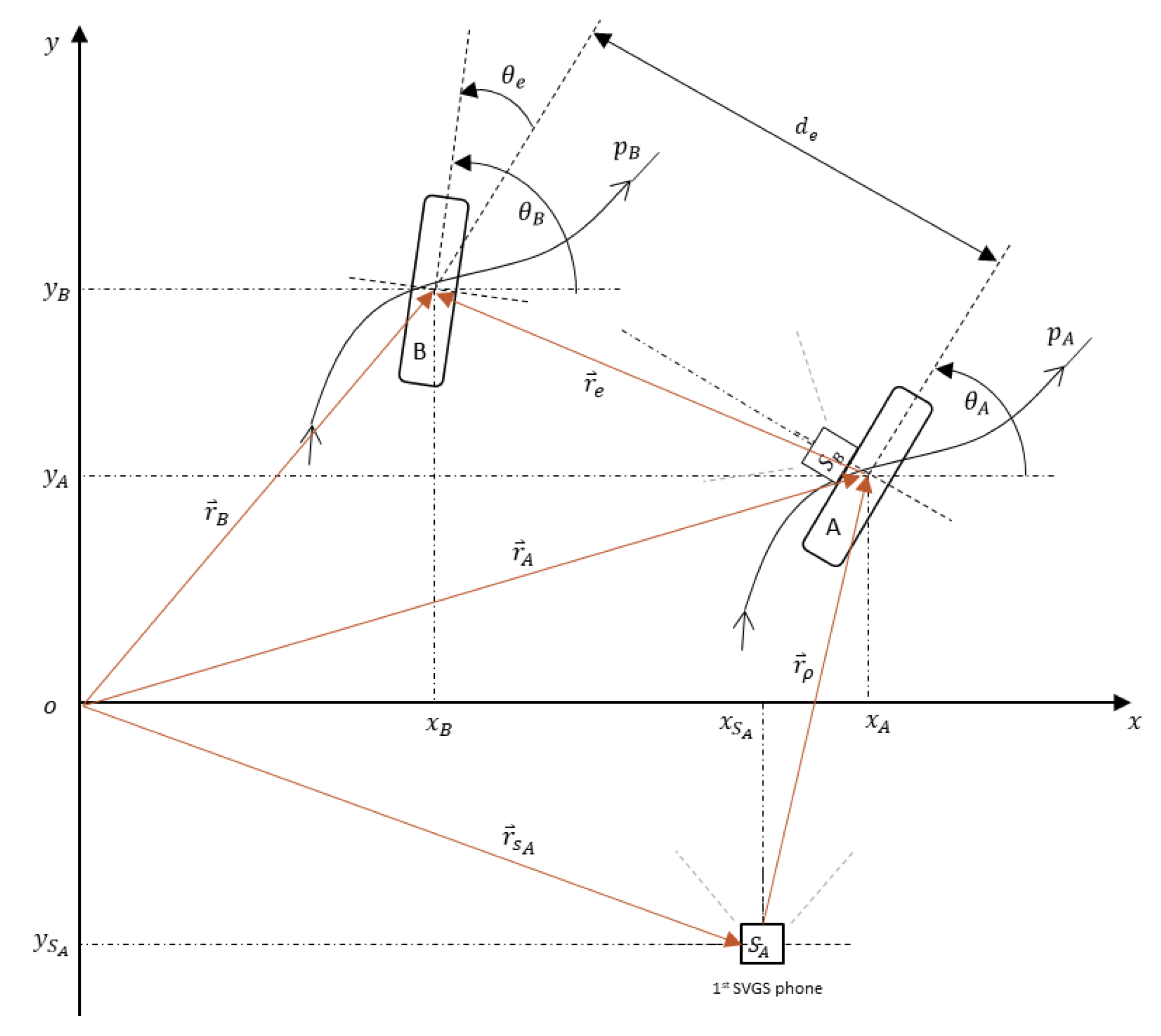

2. Materials and Methods

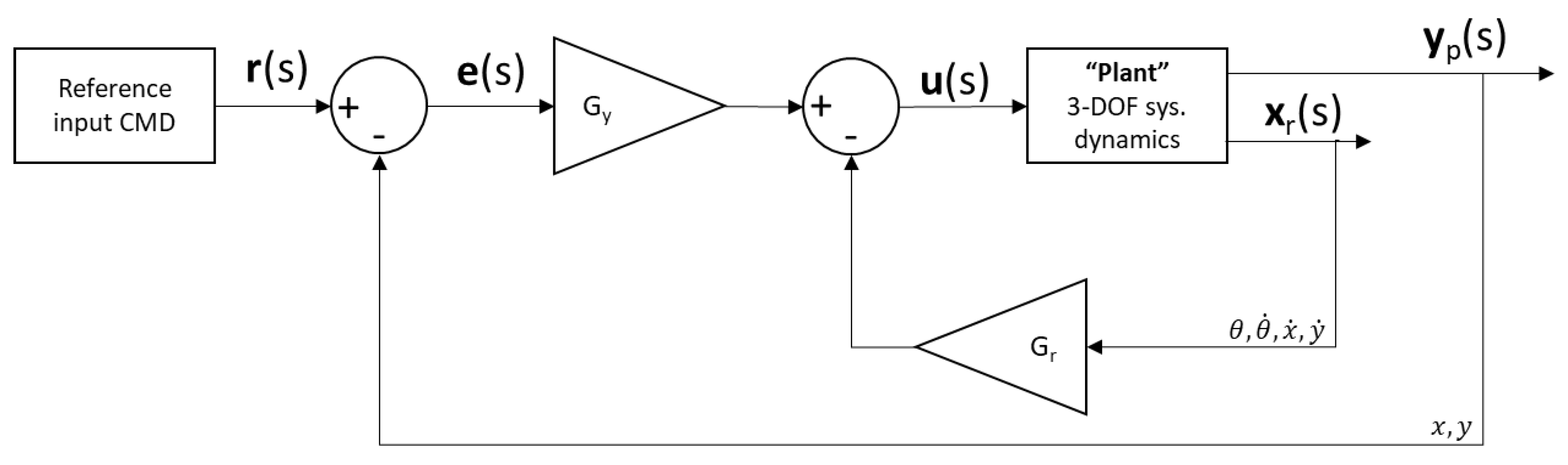

2.1. State-Space Model of the 3-DOF Ground Motion Platform

2.2. System Identification of the 3-DOF Motion Dynamics

2.3. 3-Degree of Freedom Motion Control via LQG-Servo

2.4. Path Following and Formation Maneuvers

3. Results

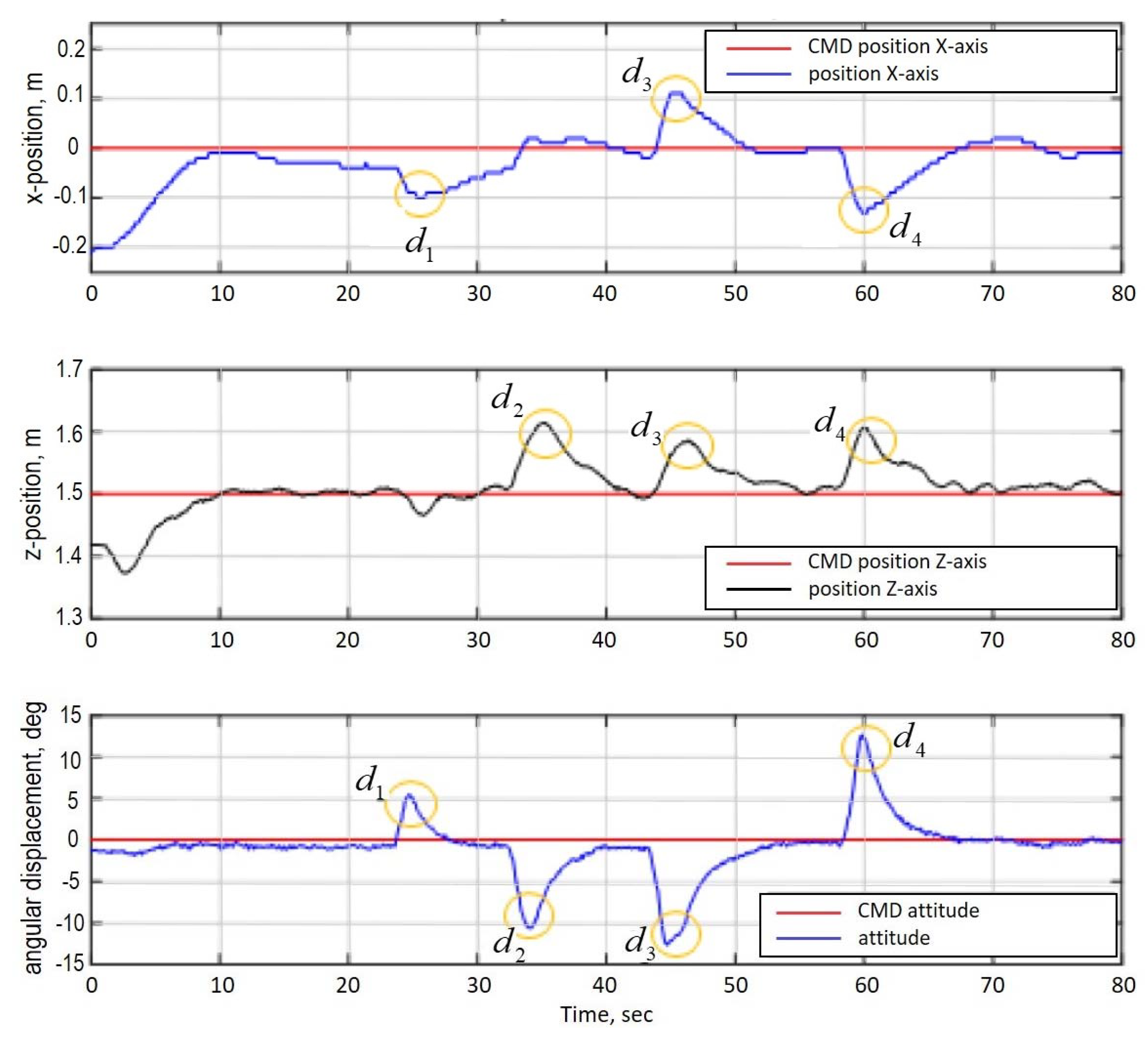

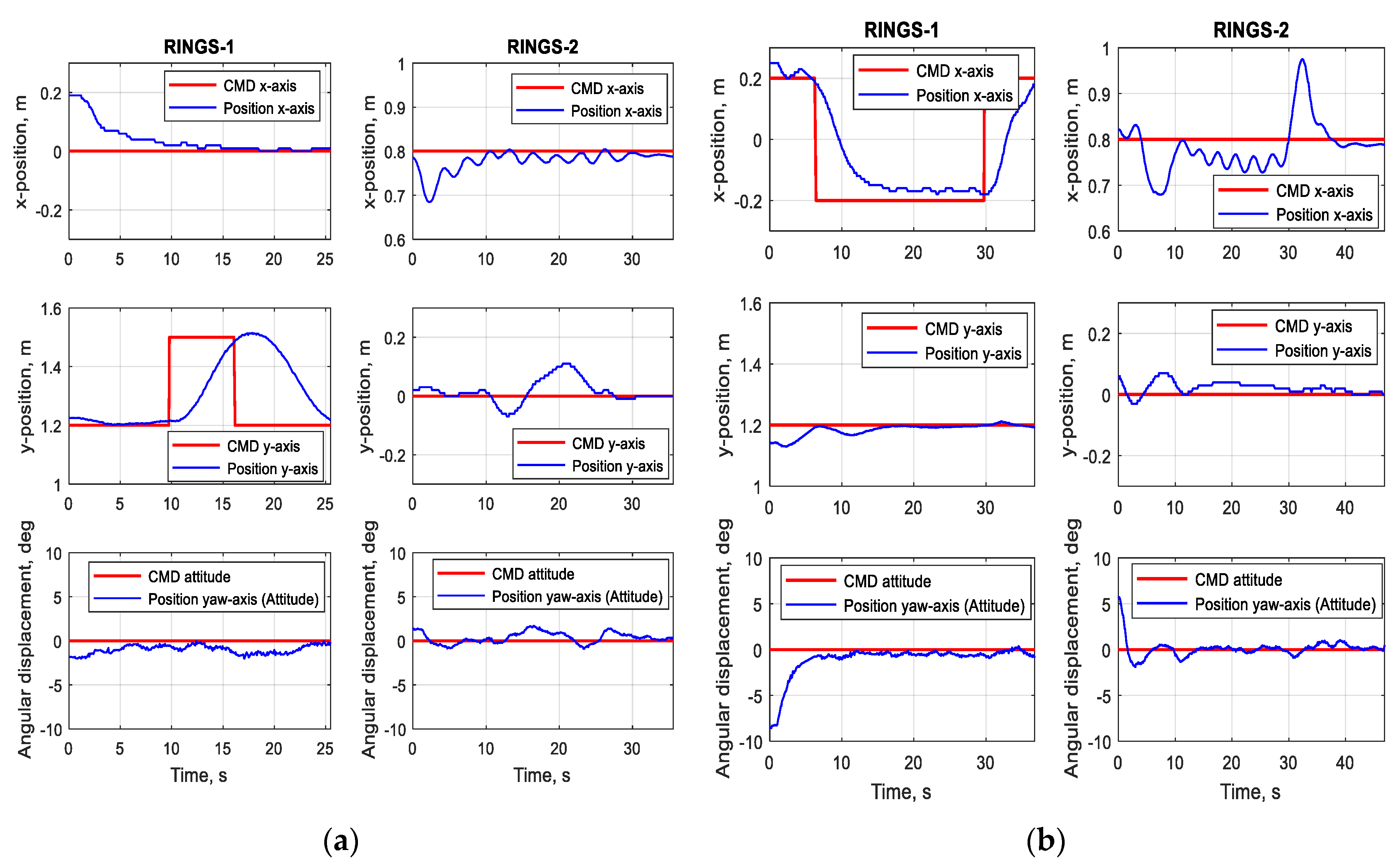

3.1. Response to Single Axis and Dual Axes Commands, and Response to External Disturbances

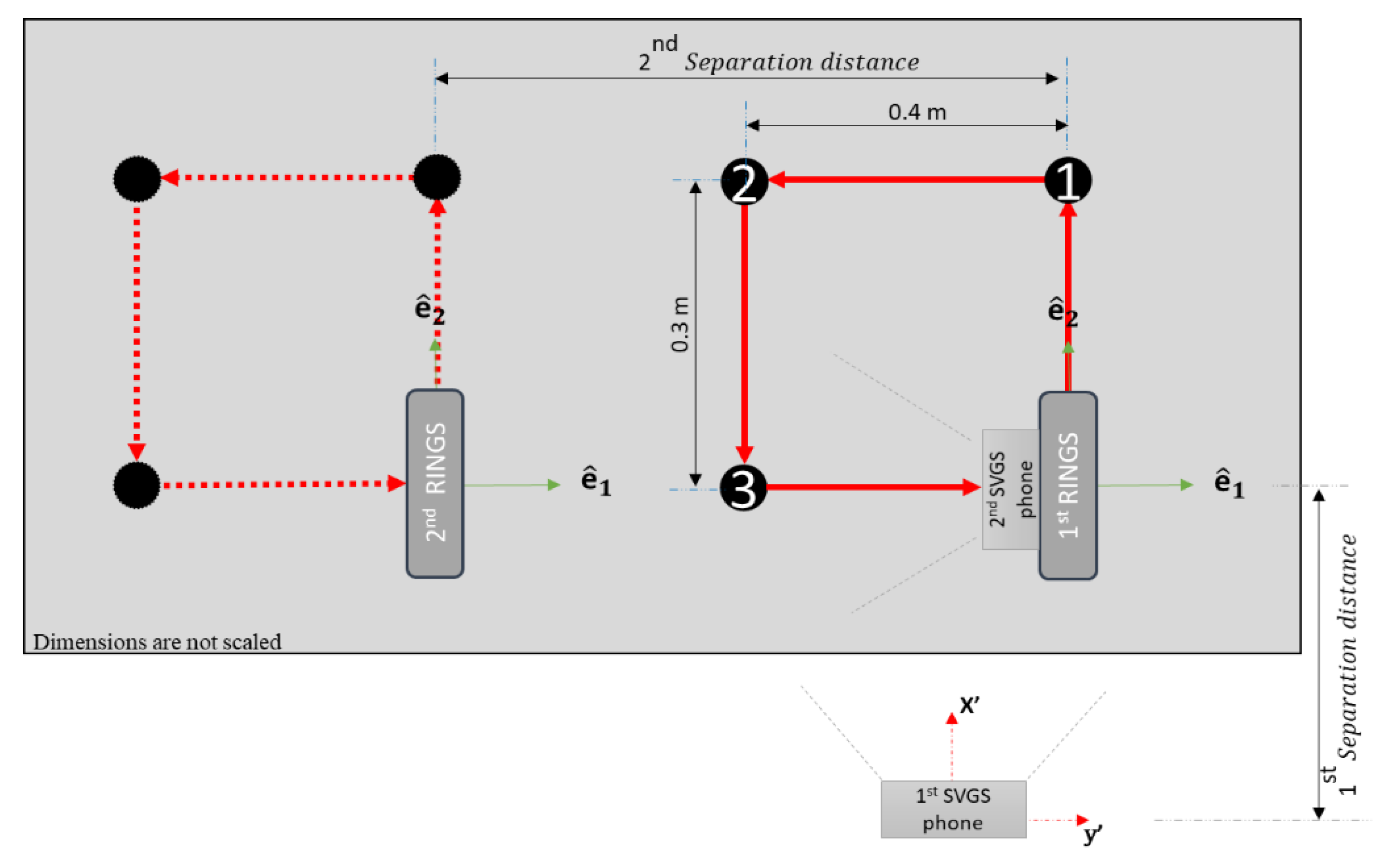

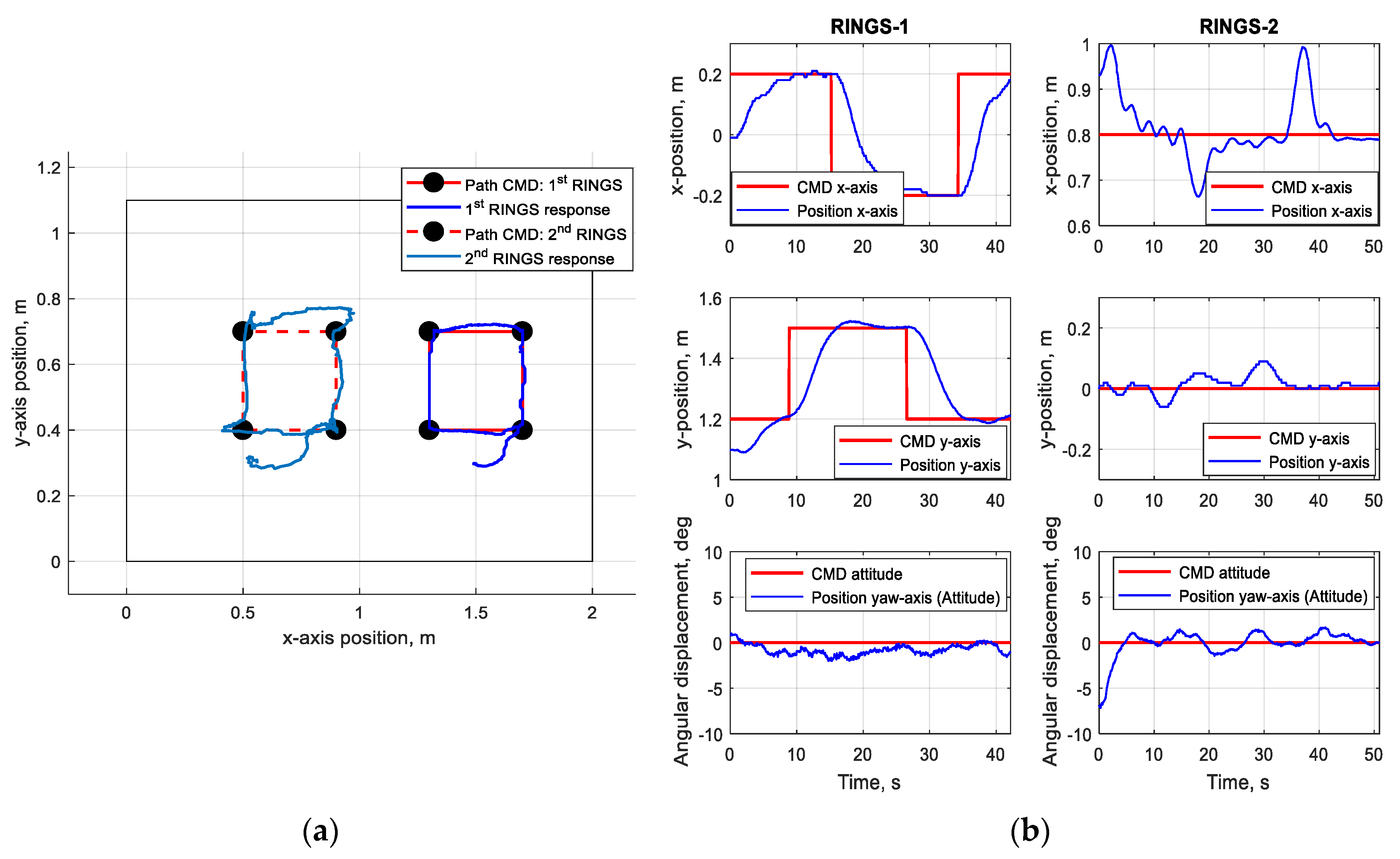

3.2. Performance in Proximity Operations and Path Following Maneuvers

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Valmorbida, A.; Mazzucato, M.; Aboudan, A.; Tronco, S. Test of attitude control maneuvers with a Satellite Formation Flight testbed. In Proceedings of the 2014 IEEE Metrology for Aerospace Conference, Benevento, Italy, 29–30 May 2014; pp. 439–444. [Google Scholar]

- Nag, S.; LeMoigne, J.; Miller, D.W.; Weck, O. A framework for orbital performance evaluation in Distributed Space Missions for earth observation. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–20. [Google Scholar]

- Burns, R.; McLaughlin, C.; Leitner, J.; Martin, M. Tech Sat 21: Formation design, control, and simulation. In Proceedings of the 2000 IEEE Aerospace Conference, Big Sky, MT, USA, 18–25 March 2000; Volume 7, pp. 19–25. [Google Scholar]

- Martin, M.; Klupar, P.; Kilberg, S.; Winter, J. Techsat 21: Revolutionizing Space Missions Using Microsatellites; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001. [Google Scholar]

- Coulter, D. NASA’s Terrestrial Planet Finder mission: The search for habitable planets. In Proceedings of the Towards Other Planets: 2003 Darwin TPF Conference, Heidelberg, Germany, 22–25 April 2003; pp. 47–54. [Google Scholar]

- Mauro, G.D.; Lawn, M.; Bevilacqua, R. Survey on Guidance Navigation and Control Requirements for Spacecraft Formation-Flying Missions. AIAA J. Guid. Control Dyn. 2018, 41, 3. [Google Scholar] [CrossRef]

- Sabol, C.; Burns, R.; McLaughlin, C.A. Satellite Formation Flying Design and Evolution. AIAA J. Spacecr. Rocket. 2001, 38, 270–278. [Google Scholar] [CrossRef]

- Lane, C.M. Formation Design in Eccentric Orbits Using Linearized Equations of Relative Motion. AIAA J. Guid. Control Dyn. 2006, 29, 146–160. [Google Scholar] [CrossRef]

- Lee, D. Guidance, Navigation and Control System for Autonomous Proximity Operations and Docking of Spacecraft. Ph.D. Thesis, Missouri University of Science and Technology, Missouri, MO, USA, 2009. [Google Scholar]

- Becker, C.; Howard, R.; Rakoczy, J. Smartphone Video Guidance Sensor for Small Satellites. In Proceedings of the 27th Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 10–15 August 2013. [Google Scholar]

- Carter, C. Robust Targeting for the Smartphone Video Guidance Sensor; Document ID 20170012383; NASA Marshall Space Flight Center: Huntsville, AL, USA, 2017.

- Rakoczy, J. Application of the Photogrammetric Collinearity Equations to the Orbital Express Advanced Video Guidance Sensor Six Degree-of-Freedom Solution; NASA Marshall Space Flight Center: Huntsville, AL, USA, 2003.

- Howard, R.T.; Heaton, A.F.; Pinson, R.M.; Carrington, C.K. Orbital Express Advanced Video Guidance Sensor. In Proceedings of the 2008 IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2008. [Google Scholar]

- Bryan, T.C.; Howard, R.; Johnson, J.E.; Lee, J.E.; Murphy, L.; Spencer, S.H. Next Generation Advanced Video Guidance Sensor. In Proceedings of the 2008 IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2008. [Google Scholar]

- Mullins, L.; Lomas, A. Advanced Video Guidance Sensor Inverse Perspective Algorithm; Technical Memorandum; NASA Marshall Space Flight Center: Huntsville, AL, USA, 2003.

- Howard, R.; Bryan, T.; Lee, J.; Robertson, B. Next generation advanced video guidance sensor: Development and test. In Proceedings of the American Astronomical Society Conference, Long Beach, CA, USA, 4–8 January 2009. [Google Scholar]

- Howard, R.T.; Bryan, T.C.; Brewster, L.L.; Lee, J.E. Proximity operations and docking sensor development. In Proceedings of the 2009 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2009. [Google Scholar]

- Howard, R.; Book, M.; Bryan, T. Video-based sensor for tracking 3-dimensional targets. In Proceedings of the Atmospheric Propagation, Adaptive Systems, and Laser Radar Technology for Remote Sensing Conference, Barcelona, Spain, 25–28 September 2000; Volume 4167. [Google Scholar]

- Na, Y.; Bang, H.; Mok, S. Vision-Based Relative Navigation Using Dual Quaternion for Spacecraft Proximity Operations. Int. J. Aeronaut. Space Sci. 2019, 20, 1010–1023. [Google Scholar] [CrossRef]

- Moffitt, F.H.; Mikhail, E.M. Photogrammetry; Harper & Row: New York, NY, USA, 1980. [Google Scholar]

- Porter, A.K.; Alinger, D.J.; Sedwick, R.J.; Merk, J.; Opperman, R.A.; Buck, A. Demonstration of Electromagnetic Formation Flight and Wireless Power Transfer. AIAA J. Spacecr. Rocket. 2014, 51, 1914–1923. [Google Scholar] [CrossRef]

- Alinger, D. System Analysis and Design for the Resonant Inductive Near-Field Generation System (RINGS). Master’s Thesis, University of Maryland, College Park, MD, USA, 2013. [Google Scholar]

- Alinger, D.J.; Porter, A.K.; Sedwick, R.J. Optimization of Resonant Inductive Wireless Power Transfer Using Multilayer Flat Spiral Coils. AIAA J. Spacecr. Rocket. 2015, 52, 560–568. [Google Scholar] [CrossRef]

- Miller, D.; Saenz-Otero, A.; Wertz, J.; Chen, A.; Berkowski, G.; Brodel, C. SPHERES: A testbed for long duration satellite formation flying in micro-gravity conditions. In Proceedings of the AAS/AIAA Space Flight Mechanics Meeting, Clearwater, FL, USA, 23–26 January 2000. [Google Scholar]

- Greenwood, D.T. Principles of Dynamics, 2nd ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1987. [Google Scholar]

- Aslanov, V.; Kruglov, G.; Yudintsev, V. Newton–Euler equations of multibody systems with changing structures for space applications. Acta Astronaut. 2011, 68, 2080–2087. [Google Scholar] [CrossRef]

- Ljung, L. System Identification: Theory for the User, 2nd ed.; Pearson: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Huerta, F.; Pizarro, D.; Cobreces, S.; Rodriguez, F.J.; Giron, C.; Rodriguez, A. LQG Servo Controller for the Current Control of Grid-Connected Voltage-Source Converters. IEEE Trans. Ind. Electron. 2012, 59, 4272–4284. [Google Scholar] [CrossRef]

- Panigrahi, R.; Subudhi, B.; Panda, P.C. A Robust LQG Servo Control Strategy of Shunt-Active Power Filter for Power Quality Enhancement. IEEE Trans. Power Electron. 2016, 31, 2860–2869. [Google Scholar] [CrossRef]

- Chen, J.; Chen, M. Application of LQG controller in antenna servo control system. In Proceedings of the 3rd International IEEE Conference on Information Science and Technology, San Francisco, CA, USA, 6–8 December 2013. [Google Scholar]

- Anderson, B.D.O.; Moore, J.B. Optimal Filtering; Dover Publications: Dover, UK, 2005. [Google Scholar]

- Chen, S.Y. Kalman Filter for Robot Vision: A Survey. IEEE Trans. Ind. Electron. 2012, 59, 4409–4420. [Google Scholar] [CrossRef]

- Auger, F.; Hilairet, M.; Guerrero, J.M.; Monmasson, E.; Orlowska-Kowalska, T.; Katsura, S. Industrial Applications of the Kalman Filter: A Review. IEEE Trans. Ind. Electron. 2013, 60, 5458–5471. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hariri, N.; Gutierrez, H.; Rakoczy, J.; Howard, R.; Bertaska, I. Proximity Operations and Three Degree-of-Freedom Maneuvers Using the Smartphone Video Guidance Sensor. Robotics 2020, 9, 70. https://doi.org/10.3390/robotics9030070

Hariri N, Gutierrez H, Rakoczy J, Howard R, Bertaska I. Proximity Operations and Three Degree-of-Freedom Maneuvers Using the Smartphone Video Guidance Sensor. Robotics. 2020; 9(3):70. https://doi.org/10.3390/robotics9030070

Chicago/Turabian StyleHariri, Nasir, Hector Gutierrez, John Rakoczy, Richard Howard, and Ivan Bertaska. 2020. "Proximity Operations and Three Degree-of-Freedom Maneuvers Using the Smartphone Video Guidance Sensor" Robotics 9, no. 3: 70. https://doi.org/10.3390/robotics9030070

APA StyleHariri, N., Gutierrez, H., Rakoczy, J., Howard, R., & Bertaska, I. (2020). Proximity Operations and Three Degree-of-Freedom Maneuvers Using the Smartphone Video Guidance Sensor. Robotics, 9(3), 70. https://doi.org/10.3390/robotics9030070