Automated Detection of Branch Shaking Locations for Robotic Cherry Harvesting Using Machine Vision

Abstract

:1. Introduction

2. Materials and Methods

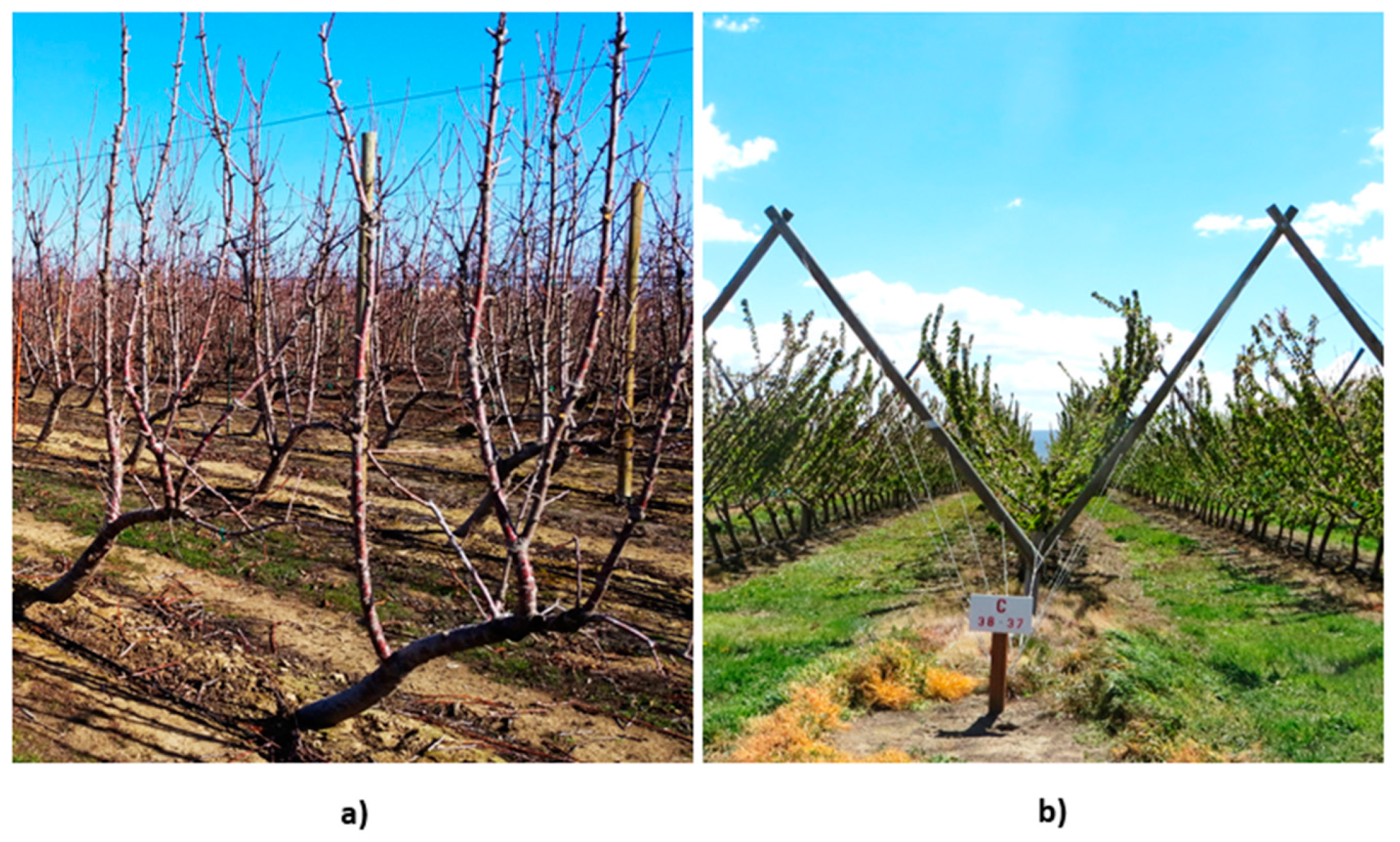

2.1. Test Orchard

2.2. Image Acquisition

2.3. Co-Registration of Depth and RGB Images

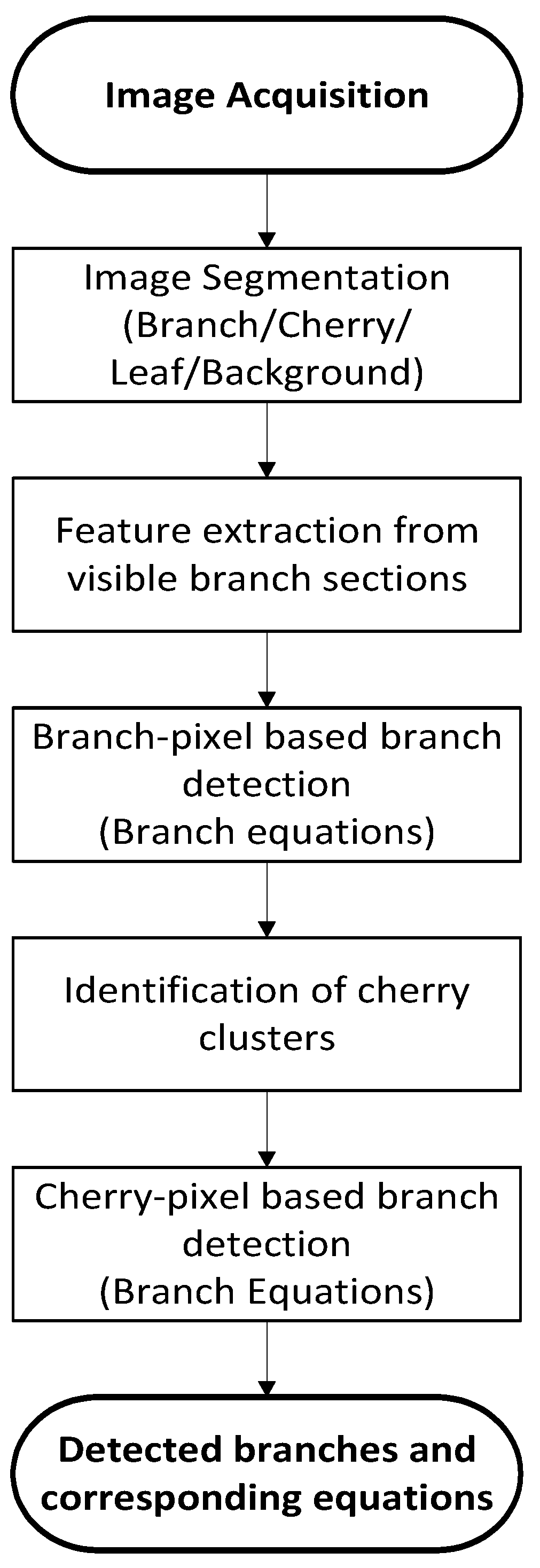

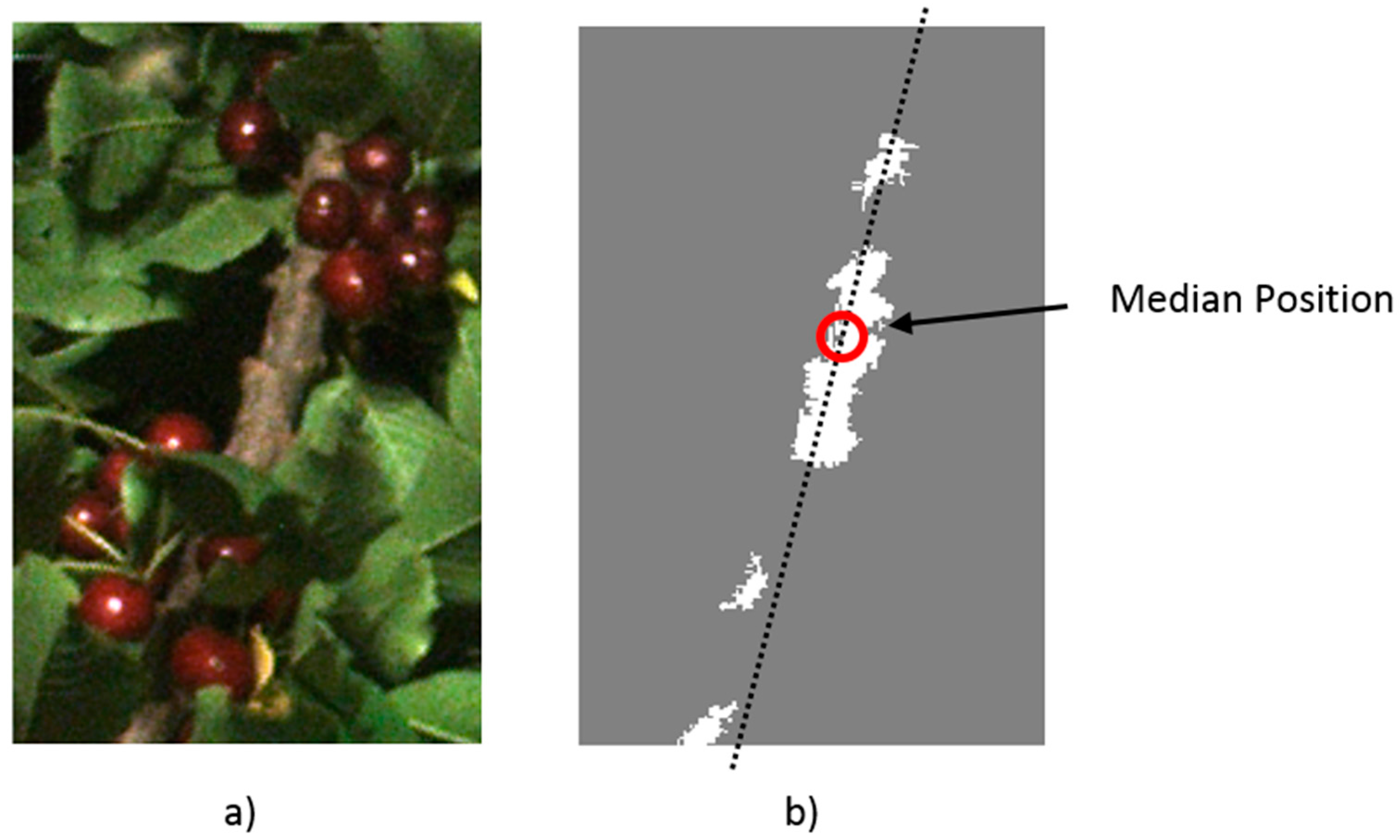

2.4. Branch Detection and Reconstruction

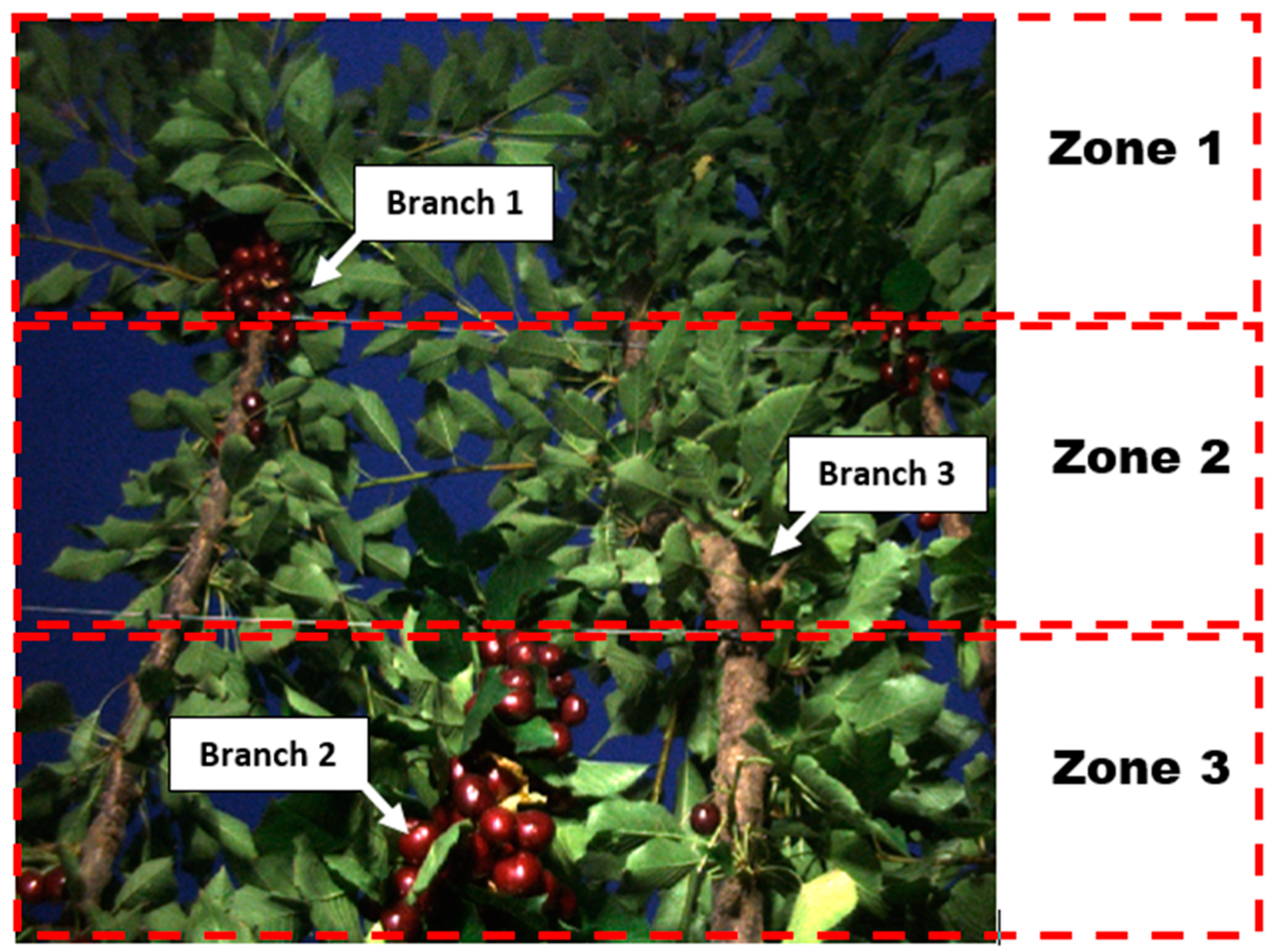

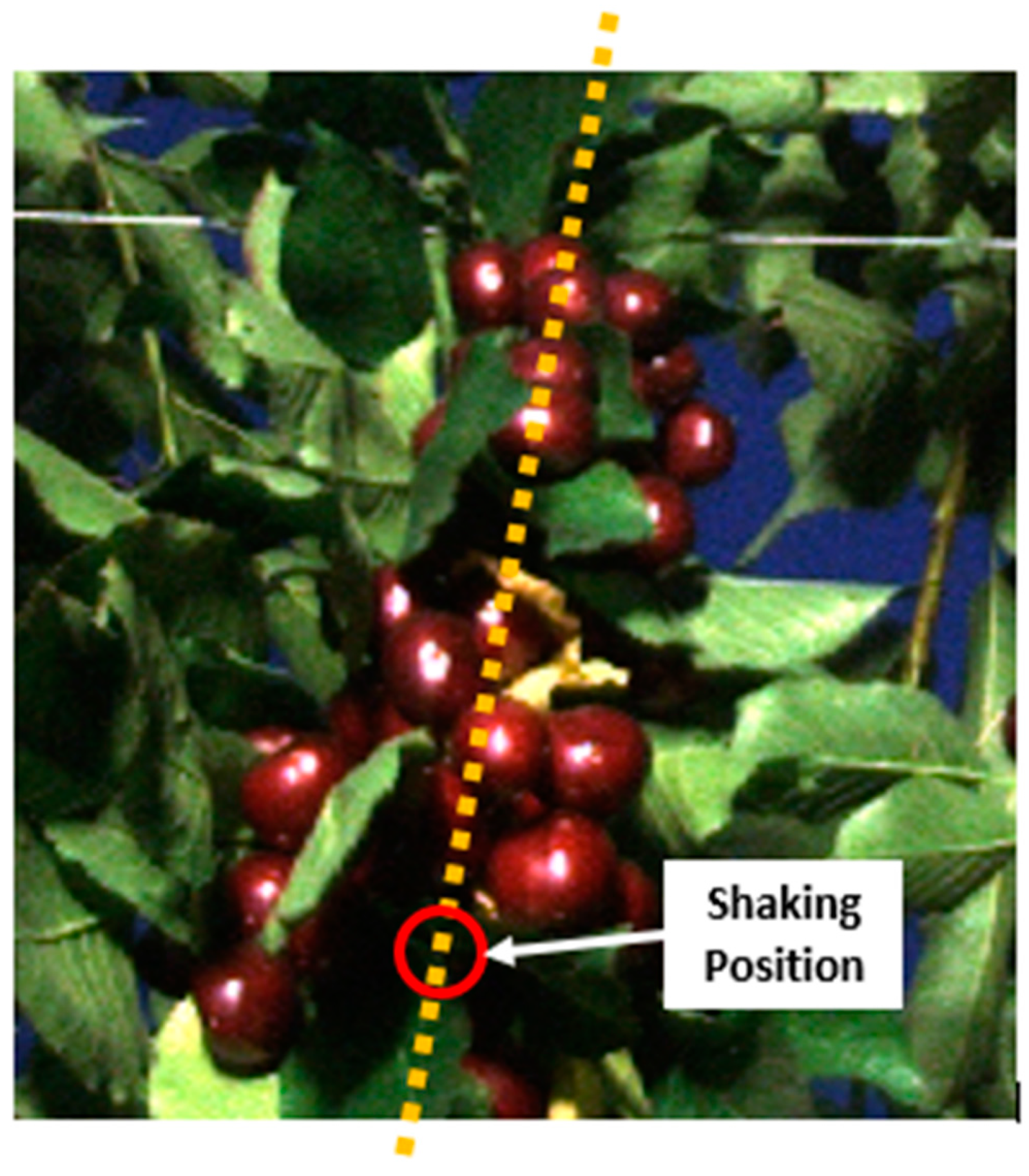

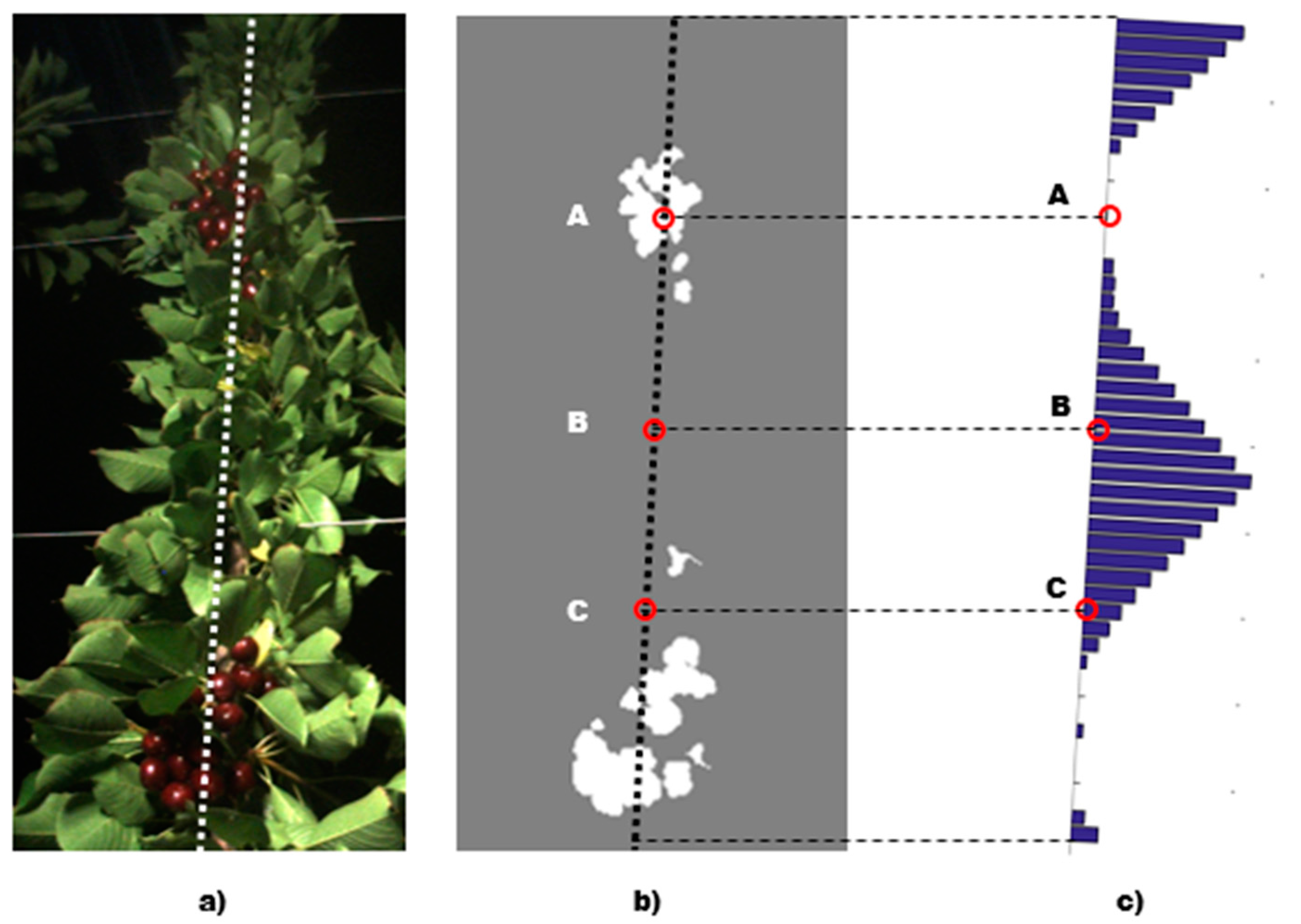

2.5. Determining Shaking Locations in Tree Branches

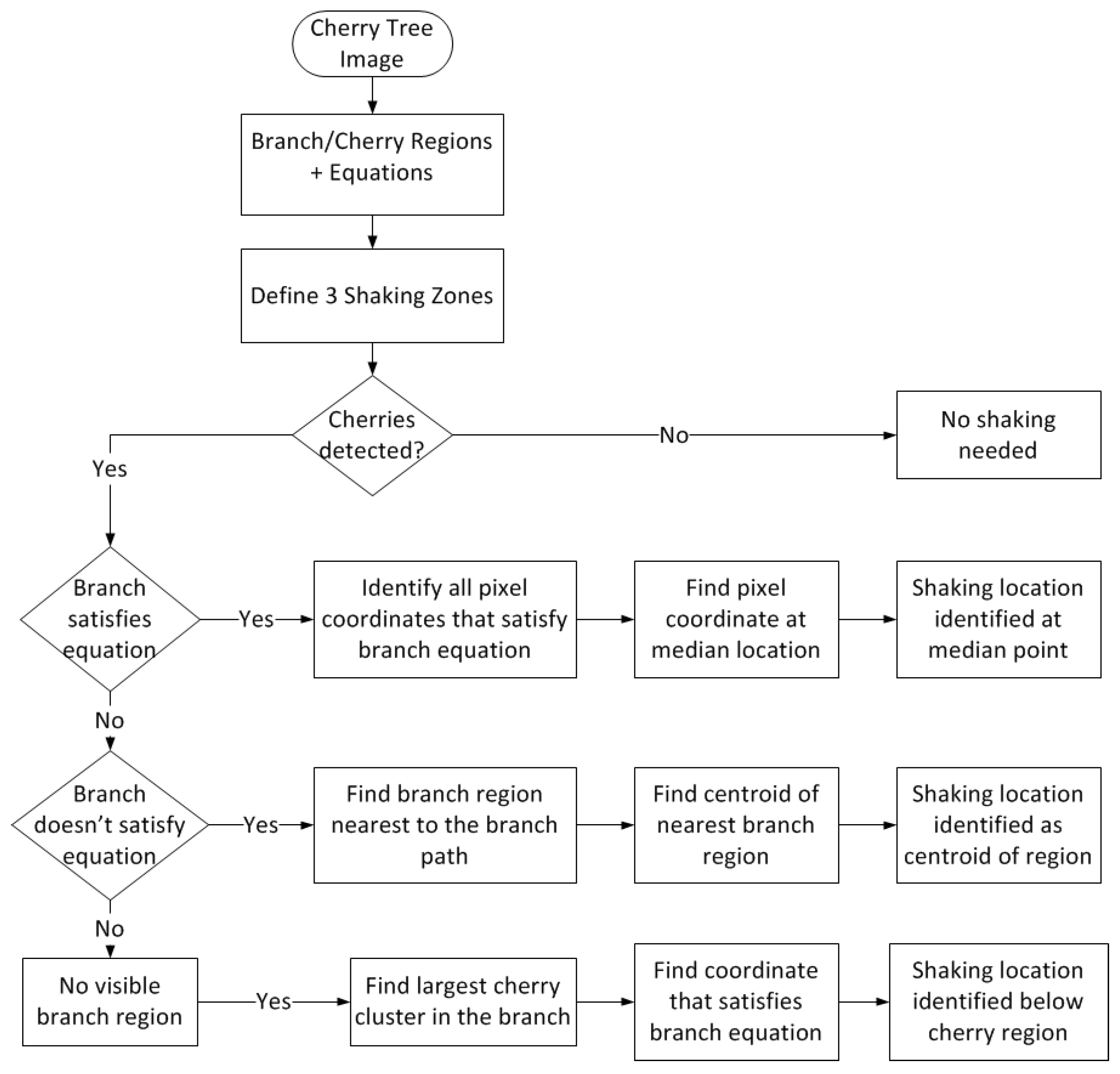

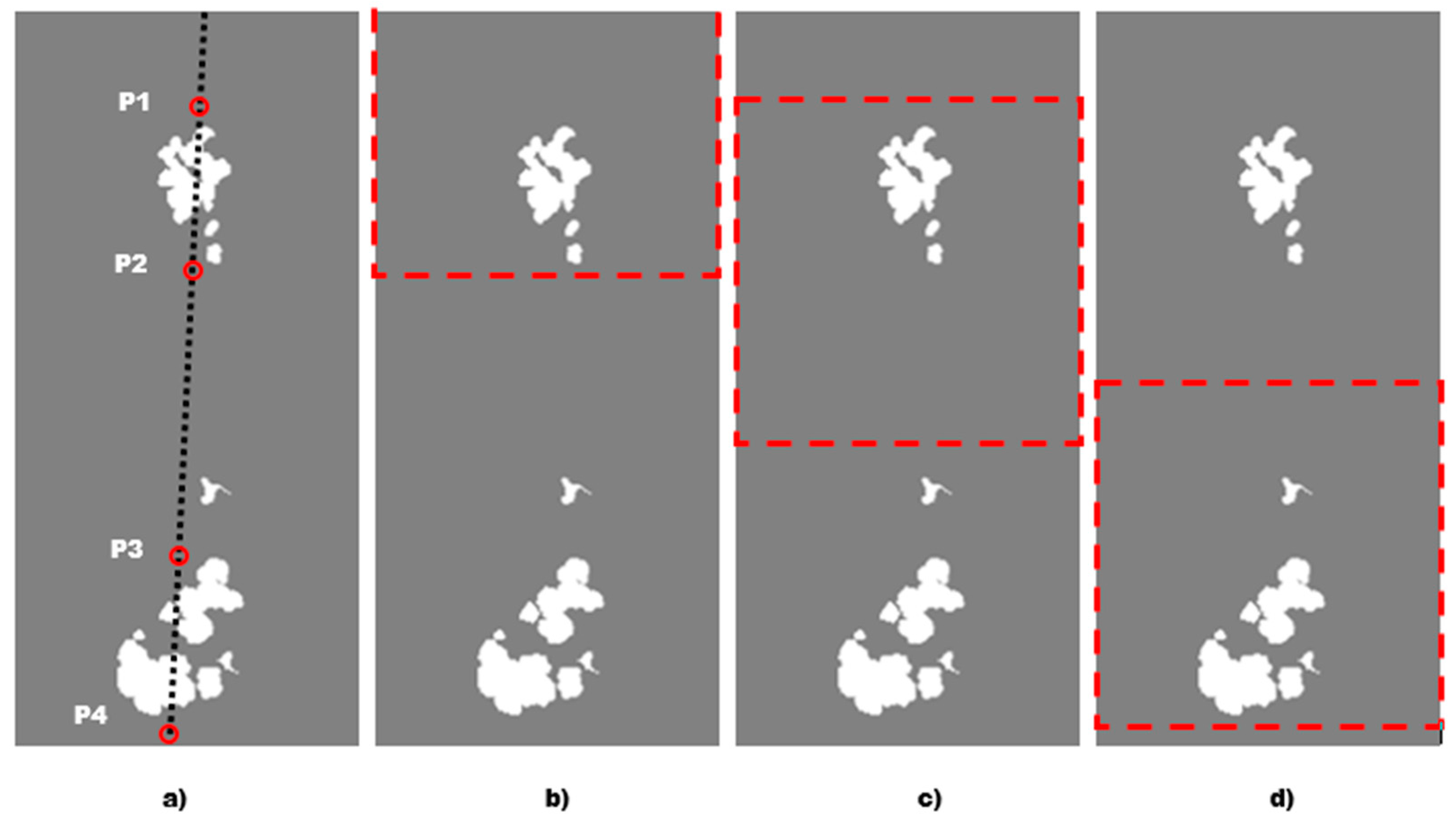

2.5.1. Determining Primary Shaking Positions

Scenario 1: Branch Section is Visible and Satisfies Branch Equation

Scenario 2: Branch Sections Visible but Does Not Satisfy Branch Equation

Scenario 3: Branch Sections Not Visible

2.5.2. Fruit Harvesting using Primary Shaking Positions

- (i).

- Harvesting at shaking location in zone 1 (top zone)

- (ii).

- Harvesting at shaking location in zone 3 (bottom zone)

- (iii).

- Harvesting at shaking location in zone 2 (mid zone), only if there were cherries remaining after previous shakings

2.5.3. Harvesting with Secondary Shaking Positions

3. Results and Discussion

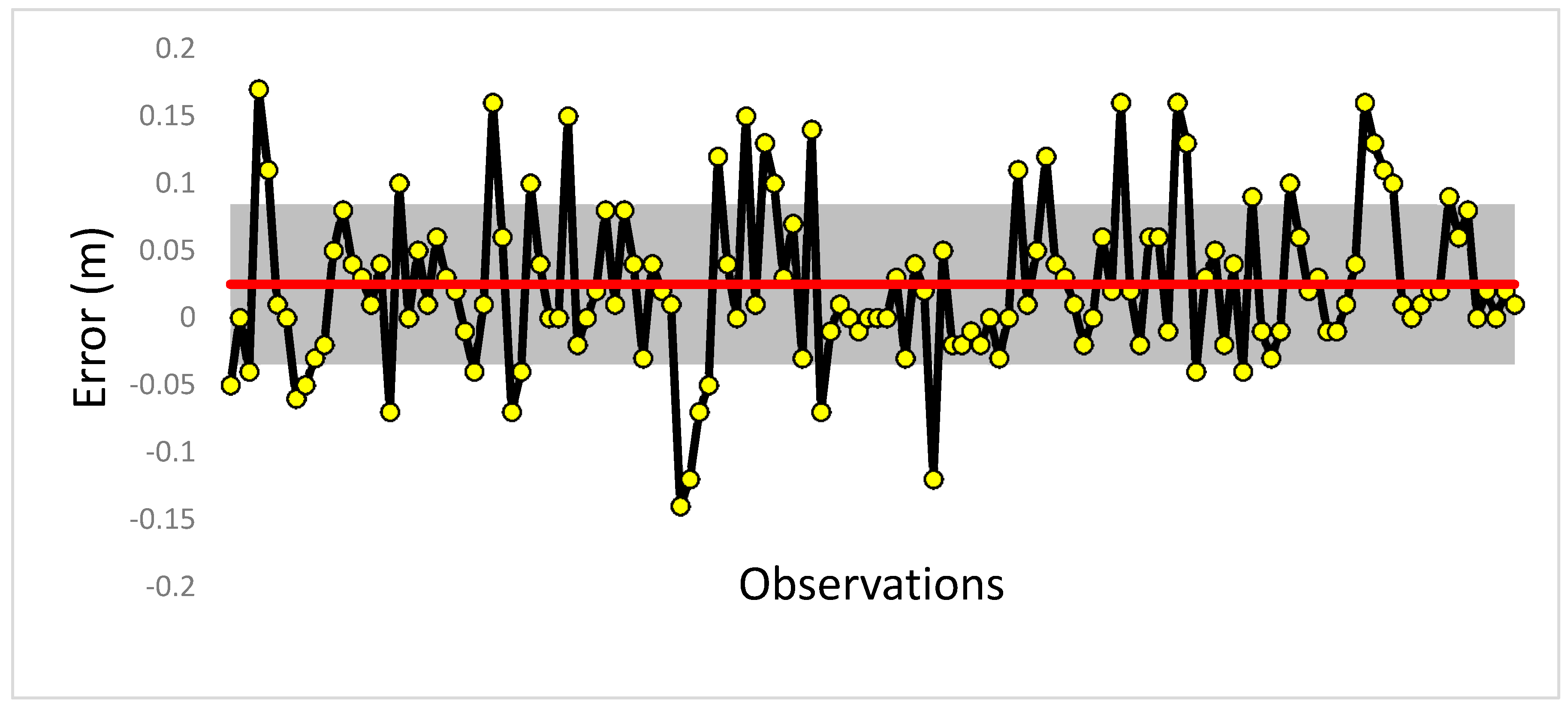

3.1. Mapping 3D Depth Information onto RGB Images

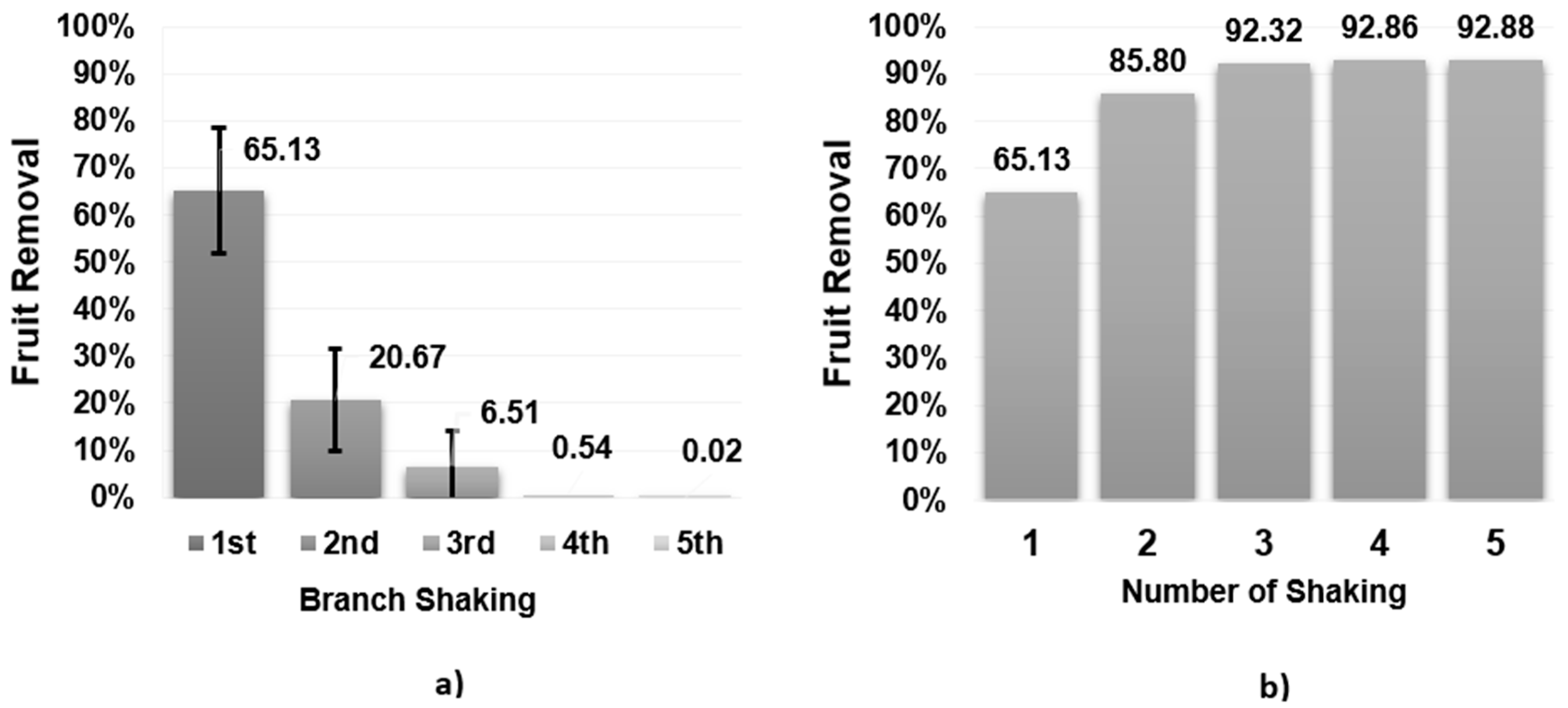

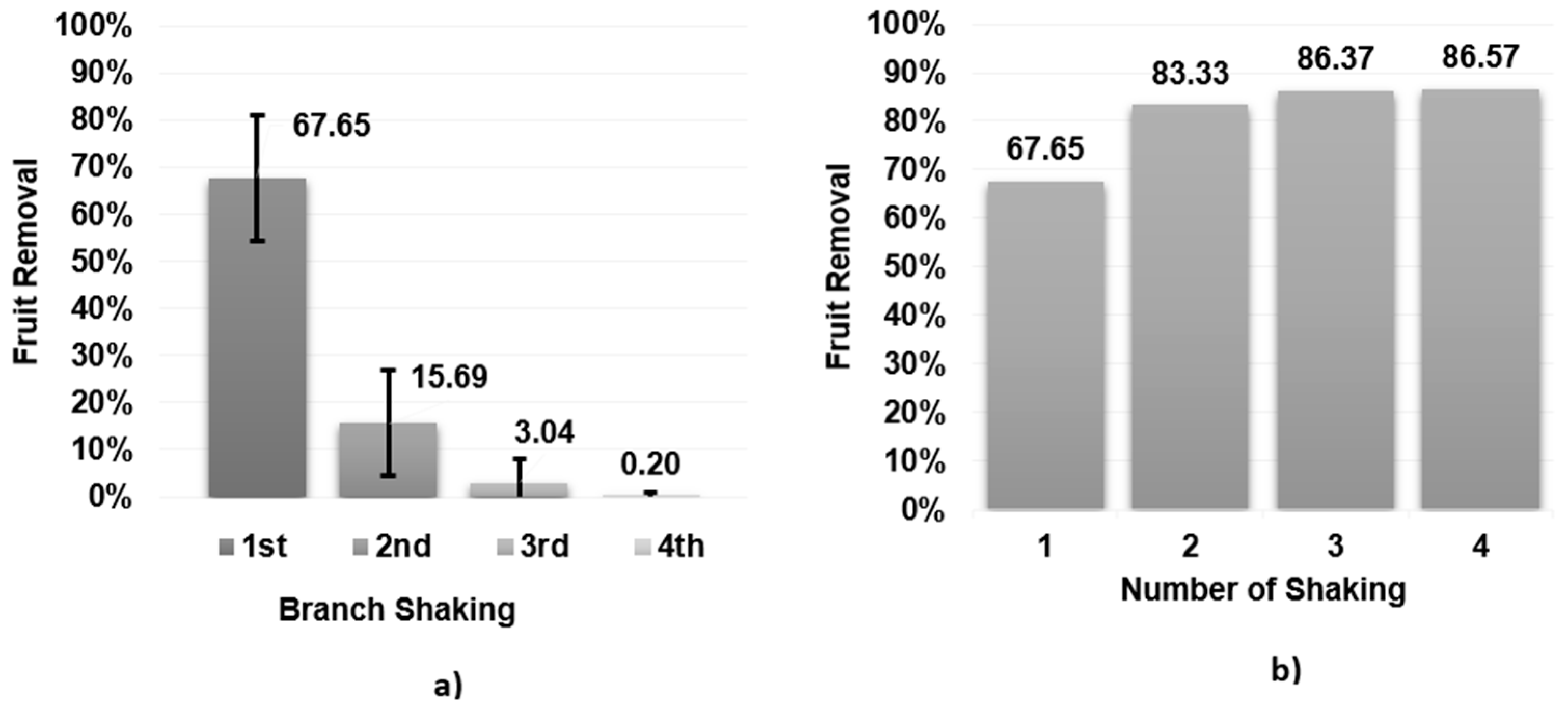

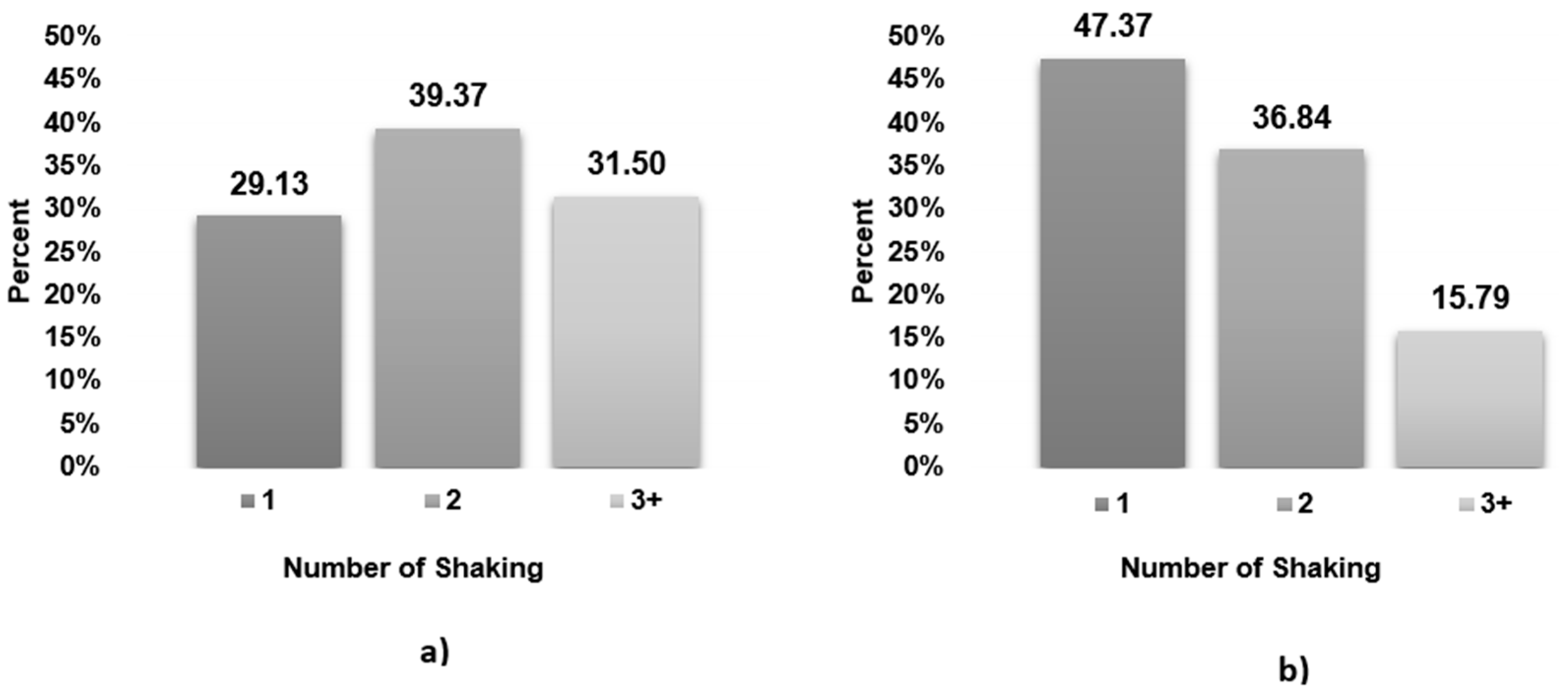

3.2. Fruit Removal Efficiency

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Halderson, J.L. Fundamental factors in mechanical cherry harvesting. Trans. ASAE 1966, 9, 681–684. [Google Scholar] [CrossRef]

- Seavert, C.F.; Whiting, M.D. Comparing the economics of mechanical and traditional sweet cherry harvest. In Proceedings of the IX International Symposium on Integrating Canopy, Rootstock and Environmental Physiology in Orchard Systems, Geneva, NY, USA, 4 August 2011; pp. 725–730. [Google Scholar]

- Baeten, J.; Donné, K.; Boedrij, S.; Beckers, W.; Claesen, E. Autonomous fruit picking machine: A robotic apple harvester. In Proceedings of the 6th International Conference on Field and Service Robotics, Chamonix Mont-Blanc, France, 9–12 July 2007; pp. 1–9. [Google Scholar]

- Ceres, R.; Pons, F.L.; Jimenez, A.R.; Martin, F.M.; Calderon, L. Design and implementation of an aided fruit-harvesting robot (Agribot). Ind. Robot 1988, 25, 337–346. [Google Scholar] [CrossRef]

- Tanigaki, K.; Fujiura, T.; Akase, A.; Imagawa, J. Cherry harvesting robot. Comput. Electron. Agric. 2008, 63, 65–72. [Google Scholar] [CrossRef]

- Zhao, D.; Lu, J.; Ji, W.; Zhang, Y.; Chen, Y. Design and control of an apple harvesting robot. Biosyst. Eng. 2011, 110, 112–122. [Google Scholar]

- Chen, D.; Du, X.; Zhang, Q.; Whiting, M.; Scharf, P.; Wang, S. Performance evaluation of mechanical cherry harvesters for fresh market grade fruits. Appl. Eng. Agric. 2012, 28, 483–489. [Google Scholar] [CrossRef]

- Du, X.; Chen, D.; Zhang, Q.; Scharf, P.A.; Whiting, M.D. Mechanical Harvesting of UFO Cherry: Investigation of Tree Plant Dynamics; ASABE Paper No. 1110523; ASABE: St. Joseph, MI, USA, 2011. [Google Scholar]

- Peterson, D.L.; Wolford, S.D. Mechanical harvester for fresh market quality stemless sweet cherries. Trans. ASAE 2001, 44, 481–485. [Google Scholar] [CrossRef]

- Erdoğan, D.; Güner, M.; Dursun, E.; Gezer, İ. Mechanical harvesting of apricots. Biosyst. Eng. 2003, 85, 19–28. [Google Scholar] [CrossRef]

- Peterson, D.L.; Whiting, M.D.; Wolford, S.D. Fresh-market quality tree fruit harvester part I: Sweet cherry. Appl. Eng. Agric. 2003, 19, 539–543. [Google Scholar]

- Peterson, D.L.; Wolford, S.D. Fresh-market quality tree fruit harvester part II: Apples. Appl. Eng. Agric. 2003, 19, 545–548. [Google Scholar]

- Whitney, J.D. Design and performance of an air shaker for citrus fruit removal. Trans. ASAE 1977, 20, 52–56. [Google Scholar] [CrossRef]

- Peterson, D.L.; Bennedsen, B.S.; Anger, W.C.; Wolford, S.D. A system approach to robotic bulk harvesting of apples. Trans. ASAE 1999, 42, 871–876. [Google Scholar] [CrossRef]

- Amatya, S.; Karkee, M.; Gongal, A.; Zhang, Q.; Whiting, M.D. Detection of cherry tree branches with full foliage in planar architecture for automated sweet-cherry harvesting. Biosyst. Eng. 2016, 146, 3–15. [Google Scholar] [CrossRef]

- Amatya, S.; Karkee, M. Integration of visible sections and cherry clusters for detecting cherry tree branches in dense foliage canopies. Biosyst. Eng. 2016, 149, 72–81. [Google Scholar] [CrossRef]

- Blanco-Roldán, G.L.; Gil-Ribes, J.A.; Kouraba, K.; Castro-García, S. Effects of trunk shaker duration and repetitions on removal efficiency for the harvesting of oil olives. Appl. Eng. Agric. 2009, 25, 329–334. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Zhang, Q.; Du, X.; Chen, D.; Karkee, M. Evaluation of the influence of shaking frequency and duration in mechanical harvesting of sweet cherry. Appl. Eng. Agric. 2013, 29, 607–612. [Google Scholar]

- Adrian, P.A.; Fridley, R.B.; Lorenzen, C. Forced vibration of a tree limb. Trans. ASAE 1965, 8, 473–475. [Google Scholar] [CrossRef]

- Zhou, J.; He, L.; Zhang, Q.; Karkee, M. Effect of excitation position of a handheld shaker on fruit removal efficiency and damage in mechanical harvesting of sweet cherry. Biosyst. Eng. 2014, 125, 36–44. [Google Scholar] [CrossRef]

- Larbi, P.A.; Karkee, M.; Amatya, S.; Zhang, Q.; Whiting, M.D. Modification and field evaluation of an experimental mechanical sweet cherry harvester. Appl. Eng. Agric. 2015, 31, 387–397. [Google Scholar]

- Larbi, P.A.; Karkee, M. Effects of orchard characteristics and operator performance on harvesting rate of a mechanical sweet cherry harvester. GSTF J. Agric. Eng. 2014, 1, 1–11. [Google Scholar] [CrossRef]

- Amatya, S.; Karkee, M. Detection of Cherry Tree Branches for Automated Shake-and-Catch Harvesting; ASABE Paper No. 152158372; ASABE: St. Joseph, MI, USA, 2015. [Google Scholar]

- Bouget, J.Y. Camera Calibration Toolbox for MATLAB. 2013. Available online: http://www.vision.caltech.edu/bouguetj/calib_doc/ (accessed on 30 August 2017).

- Gongal, A.; Silwal, A.; Amatya, S.; Karkee, M.; Zhang, Q.; Lewis, K. Apple crop-load estimation with over-the-row machine vision system. Comput. Electron. Agric. 2016, 120, 26–35. [Google Scholar] [CrossRef]

| Mean Error (m) | Mean Absolute Error (m) | RMSE (m) | |

|---|---|---|---|

| Visible Branch | 0.015 ± 0.046 | 0.034 ± 0.034 | 0.048 |

| Occluded Branch | 0.029 ± 0.065 | 0.052 ± 0.048 | 0.071 |

| Overall | 0.025 ± 0.060 | 0.047 ± 0.064 | 0.064 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amatya, S.; Karkee, M.; Zhang, Q.; Whiting, M.D. Automated Detection of Branch Shaking Locations for Robotic Cherry Harvesting Using Machine Vision. Robotics 2017, 6, 31. https://doi.org/10.3390/robotics6040031

Amatya S, Karkee M, Zhang Q, Whiting MD. Automated Detection of Branch Shaking Locations for Robotic Cherry Harvesting Using Machine Vision. Robotics. 2017; 6(4):31. https://doi.org/10.3390/robotics6040031

Chicago/Turabian StyleAmatya, Suraj, Manoj Karkee, Qin Zhang, and Matthew D. Whiting. 2017. "Automated Detection of Branch Shaking Locations for Robotic Cherry Harvesting Using Machine Vision" Robotics 6, no. 4: 31. https://doi.org/10.3390/robotics6040031

APA StyleAmatya, S., Karkee, M., Zhang, Q., & Whiting, M. D. (2017). Automated Detection of Branch Shaking Locations for Robotic Cherry Harvesting Using Machine Vision. Robotics, 6(4), 31. https://doi.org/10.3390/robotics6040031