1. Introduction

In recent years, robotics has experienced exponential growth in the study and utilization of soft materials. Human–machine interaction is fundamental for several applications: soft materials enable safer, more adaptable, and lifelike interfaces that can better accommodate and respond to the nuances of human movements and intentions. The creation and development of soft materials have allowed for the development of a whole series of new technologies, and have revolutionized several processes. A classic example concerns the field of endoscopy [

1], where the use of soft materials has allowed for the development of more effective endoscopes, ensuring results equal to or better than traditional endoscopes, but with a significant increase in patient comfort. PneuNet-type actuators, a specialized subset of soft actuators, excel in providing enhanced compliance, a greater range of force and expansion, simpler control mechanisms, increased durability, and ease of manufacture, setting them apart in the design and functionality of sophisticated robotic systems [

2]. They rely on the deformation of the bellows, caused by pressurized air, to perform a controlled movement triggered by the contact between the humps of the bellow [

3]. PneuNet actuators are part of a family of soft actuators that also includes foam actuators [

4]. Different designs, characterized by alternative bellows configurations [

5,

6], allow for them to perform various types of movement such as stretching, bending, and rotation. This makes PneuNet actuators very versatile. Soft actuators are often integrated to form robotic grippers, enabling versatile and adaptive grasping of objects with varying shapes and sizes. In this context, recent advancements in soft-robotic grippers have introduced designs utilizing pneumatic multi-chambers made of silicone rubber, significantly enhancing gripping capabilities. This kind of device achieves remarkable performance, including substantial pull-off forces and the ability to handle a wide range of object shapes and weights [

7,

8]. A widely adopted design seeks to mimic, for obvious reasons, the shape and features of the human hand with varying degrees of fidelity. Robotic hands can be categorized by features such as the number of fingers, the actuation technology, and the ability to change finger positions around the palm. Common solutions include three [

9] or four fingers [

10,

11,

12,

13], with tendons and bellow actuators [

14,

15] being the most used technologies.

To enhance the versatility and efficiency of grasping operations, some gripper models have been designed to allow for variations in their overall configuration, making them suitable for a wide range of tasks. This involves adjusting the soft actuators and repositioning them according to the specific needs. The fingers’ movement can be independent [

16] or dependent [

10] (i.e., the fingers move together generally by means of a single actuation system). Although studies have almost exclusively focused on the realization of hands with fingers characterized by a fixed layout (five fingers—defining an anthropomorphic layout in [

17,

18] or less [

19,

20]), recently, increasing interest has been paid towards reconfigurable architectures. In this context, an extensive literature search identified a limited development of pneumatically actuated reconfigurable grippers. A noteworthy example can be found in [

21], where the authors present a gripper with three fingers arranged at 120° angles featuring a design where each finger can move radially away from the center of the palm in parallel. Additionally, each finger can rotate around its own axis. All gripper movements (lengthening and shortening, rotation and bending) are obtained by means of six PneuNet actuators. The gripper is reported to approximately generate a 20 N grasping force. While this last solution can show good adaptability, its complexity, involving six different actuators, partially limits the applicability of the presented solution. Moreover, its design limits certain operations, especially the grasping of large cylindrical objects, highlighting the need for a new approach.

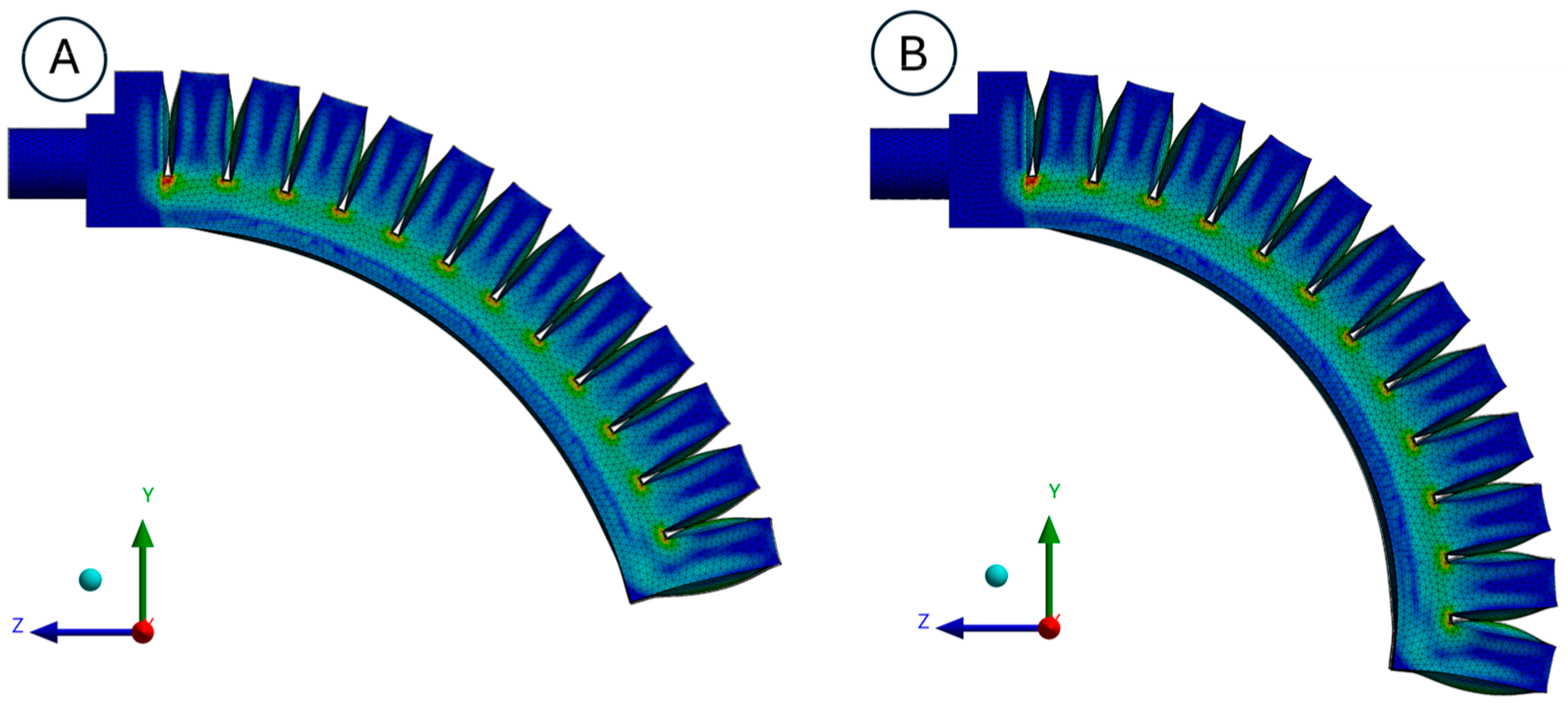

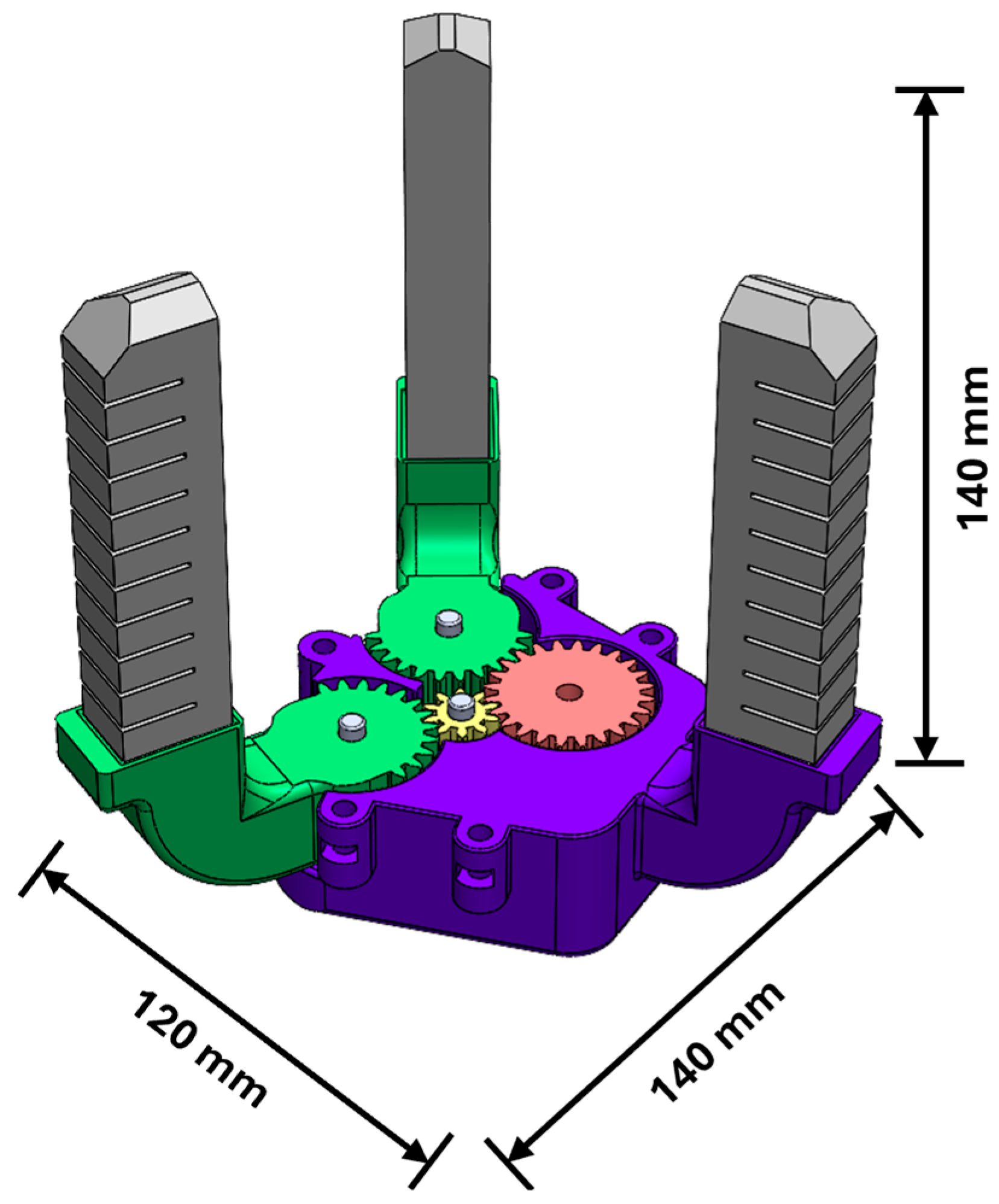

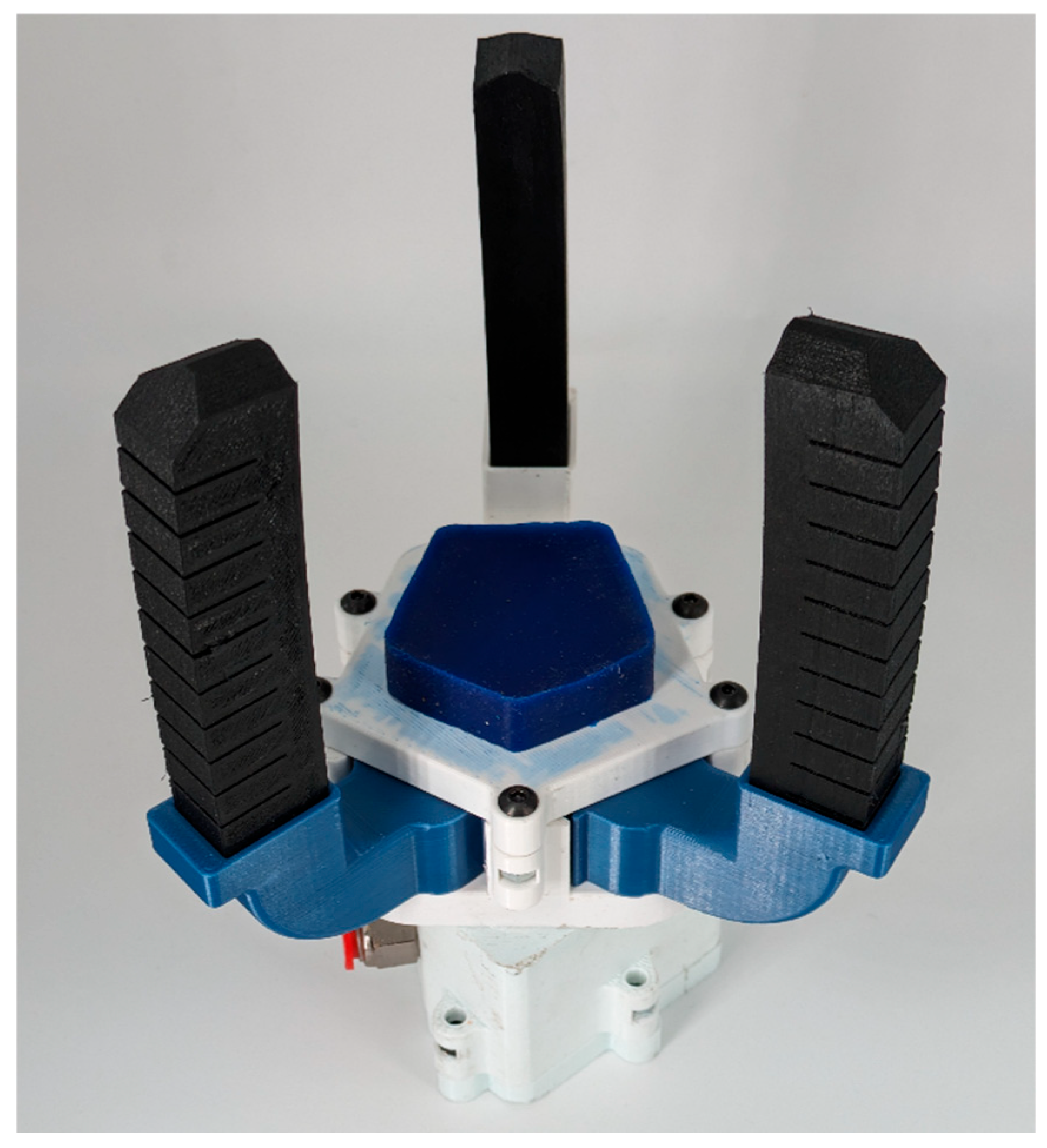

To overcome these limitations, this work presents the design, fabrication, and experimental characterization of an anthropomorphic soft robotic gripper prototype intended for rehabilitation and assistive robotics applications, where safe and adaptive human interaction is essential. The proposed device comprises three elastomeric fingers fabricated in thermoplastic polyurethane (TPU) using fused filament fabrication (FFF) 3D printing that ensure compliant contact with both biological tissue and rigid objects. The present paper discusses the development of such a gripper; its main innovations lay in the use of material extrusion 3D printing technology for the fabrication of all the components, with consequent advantages in terms of manufacturing time, customization, and cost reduction. The integration of an integrated rotary pneumatic system allows for fast and efficient reconfiguration and design variations for future applications. The design of the gripper is guided by the application of design for additive manufacturing principles, which has allowed for the use of 3D printing technology for all of the main components. Grippers making use of soft and flexible elements to ensure safe human interaction, but pose challenges in predicting behavior due to the (generally) hyperelastic characteristics of soft materials. To address this aspect, we developed and validated a Finite Element (FE) model of the actuators, featuring a material model suitable for reproducing the behavior of the actual material used in the printing process. This FE model of the actuator helps in the evaluation of the effects caused by changes in the geometry or in the operative conditions, improving the design workflow and the achievable performance.

Overall, the combination of an anthropomorphic layout, mechanical compliance, manufacturability via FFF, and straightforward pneumatic control makes the proposed gripper a versatile candidate both for rehabilitation-oriented devices and as an assistive end-effect in pick-and-place tasks.

The structure of the present article is as follows:

Section 2.1 discusses the PneuNet soft actuator integrated into the gripper;

Section 2.2 describes the FE approach used to optimize the actuator’s geometry and predict its behavior;

Section 2.3 details the design of the finger support;

Section 2.4 outlines the design of the pneumatic rotary actuator developed for the reconfiguration mechanism;

Section 2.5 explains the fabrication and actuation of the gripper;

Section 3.1 presents the results of the grasping force tests, while

Section 3.2 discusses the results of the grasping adaptability tests; and finally,

Section 4 provides concluding remarks and possible future developments.

3. Validation Tests

Once the functioning of the gripper was verified, a series of experimental tests aimed at measuring the grasping forces and adaptability on different objects were carried out.

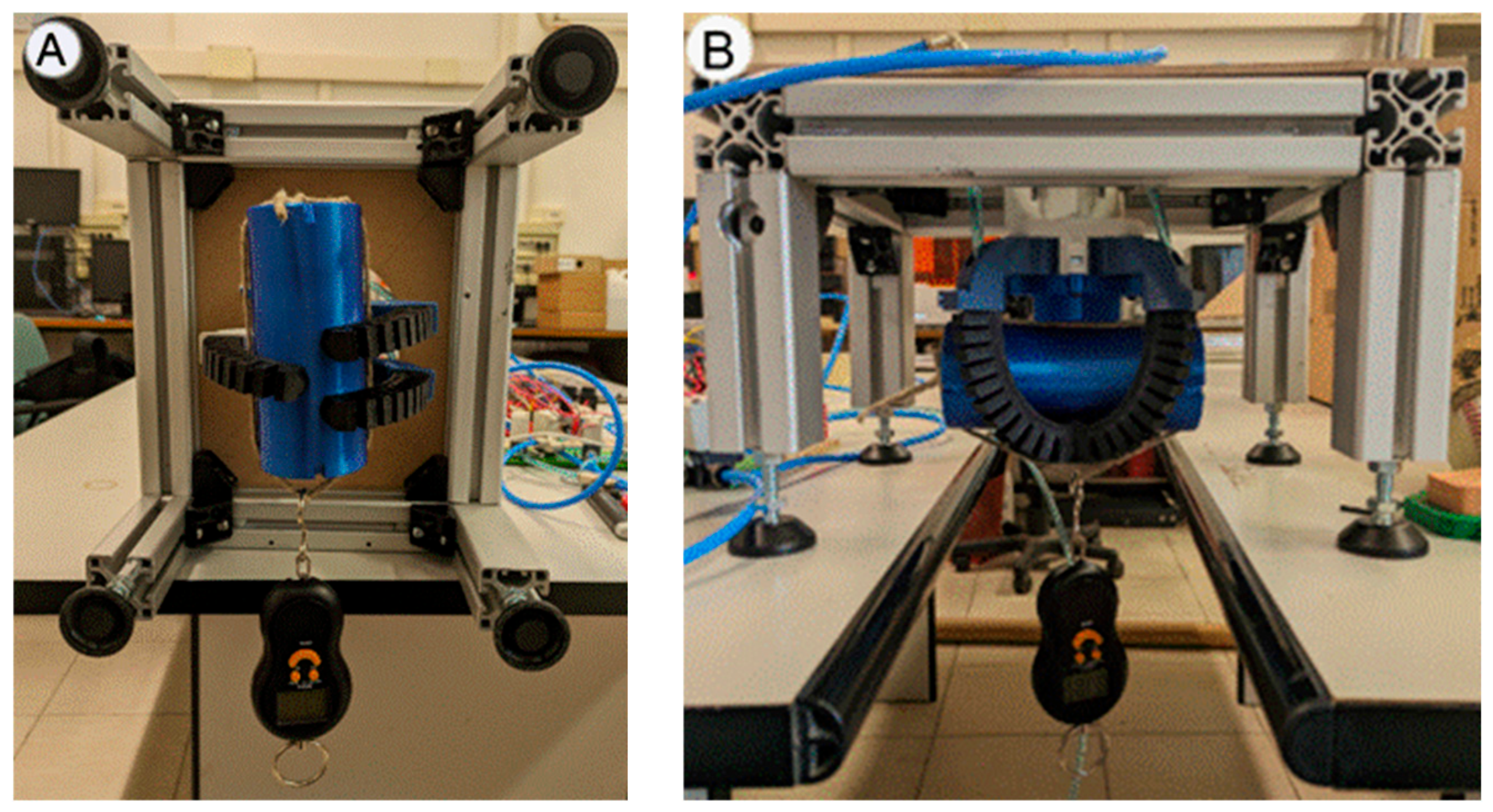

3.1. Grasping Force Test

The test was carried out by placing the test object in the center of the gripper palm and actuating the fingers at maximum pressure, i.e., 3 bar. These tests were realized using a set of three objects with typical shapes such as parallelepiped, cylinder, and sphere (

Figure 10).

The force was measured and recorded using a digital dynamometer (sensitivity of 0.05 N) by pulling the object along the transversal and normal directions, respectively, shown in

Figure 11.

Both transversal and normal forces were measured on all sample objects in the two-finger configurations (“claw” and “120°”) and with both palms, PLA and silicone. For each sample object, five measurements were taken for each of the two configurations. The average values and standard deviation for the PLA palm are shown in

Table 5, and those for the silicone palm are shown in

Table 6.

Experimental data show a significant increase in grasping forces with the use of the silicone palm, especially in the transversal force. It is also interesting to note that, even in the case of the normal forces, there is a slight increase in grasping forces when using the silicone palm. This is due to the greater deformability of silicone allowing the palm to adapt more closely to the shape of the object and thereby provide a better grip. Following the tests for the maximum grasping force generated by the manipulator, further experimental tests were carried out to assess the effect of a change in finger actuation pressure. A new series of measurements with transversal force was carried out by reducing operating pressure to 2.5 bar and 2 bar. The test was carried out with the manipulator equipped with the silicone palm on the spherical and cylindrical samples using, respectively, “120°” and “claw” finger configurations. Tests results are shown in

Table 7 and

Table 8.

The trend of the variation in the grasping force as a function of finger actuation pressure can be seen in

Figure 16. The trend, to a good approximation, can be considered linear.

It is appropriate to compare our gripper with others to evaluate performance. However, it is not appropriate to include grippers based on different technologies, as this would lead to incorrect comparisons. Focusing on pneumatically actuated soft robotic grippers, performance metrics from the literature highlight a diverse range of force capabilities:

Tawk et al. [

25] developed a modular soft gripper leveraging 3D-printed components, achieving a maximum lifting force of approximately 1.9 N under a pressure of 1.5 bar.

Wichiramala et al. [

26] characterized the grasping forces of a 3D-printed TPU pneumatic actuator, which reached a peak force of about 2 N at 4 bar during blocked-force tests. These studies underscore the modest force outputs achieved with lightweight, flexible designs.

Dilibal et al. [

27] introduced a custom-made soft gripper with embedded force sensors for industrial applications, attaining a maximum grasping force of 7.8 N at a lower pressure of 0.7 bar.

Hao et al. [

28] took a different approach with a four-fingered soft robotic gripper fabricated from soft silicone. Their design achieved a maximum “pull-off force” of approximately 13.5 N at 0.7 bar, reflecting a combination of material compliance and effective mechanical design.

The proposed gripper achieves a peak grasping force of 17 N at 3 bar, which is competitive with grippers that use more complex actuation systems. Its performance is enhanced by a reconfigurable mechanism that allows for adaptation to various object geometries. However, individual actuators exhibit reduced blocked force compared to some of the alternatives mentioned earlier, due to material and fabrication constraints. While this limitation was an intentional compromise in the prototypal phase to validate the feasibility of the proposed concept, future iterations will focus on improving performance by optimizing the material properties and refining the manufacturing process.

3.2. Adaptability Test

As a final test, it was decided to carry out a series of tabletop grasping tests on objects characterized by different shapes and sizes, such as fruit and vegetables, to assess which configuration, between claw and 120°, performed the best. This type of object is commonly used as benchmark to evaluate the grasping capabilities of a soft gripper. The objects are shown in

Figure 17, and their dimensions and weights are reported in

Table 9.

For test validation purposes, ten grasping attempts were made on each object. For each attempt, the object was placed on the plane at the center of the manipulator. The gripper was positioned with the palm parallel to the plane, with the elongated fingers’ tip almost touching the surface. As a result, the palm was positioned at a rough distance of 95 mm. The test was deemed successful if the gripper could lift the object off the plane and hold it firmly, as shown in

Figure 18.

Table 10 reports the results of the test in terms of success rate.

Experimental results show that the object’s weight does not significantly affect grasping performance. Shape and dimensions, on the other hand, do; small objects, such as the potato, give the gripper a hard time, as do particular shapes such as the banana. The results of the egg test also show that the 120° configuration is more effective on spherically shaped objects. It is also important to highlight that surface characteristics might play an important role when combined with specific shapes; specifically, a smoother surface is more prone to slipping and can increase the chances of a missed grasping action. However, it should be noted that these tests were performed by placing the sample objects under the gripper and testing the gripper’s ability to grasp and lift them; this type of adaptability test is more difficult than the simple test of holding an object between the fingers. Despite the greater difficulty of the test, the gripper performed well. The test highlighted a possible direction for future improvements, implementing a different geometry for the distal part of the fingers, optimized for grasping small objects and increasing the dexterity of the system. In particular, certain geometries, such as claw-like structures or fingertip extensions, are designed to enhance precision and stability during delicate manipulation tasks. Future activities will be devoted to this purpose.

4. Conclusions

The aim of this study was the development of the hardware and main systems to pursue proof of concept of the gripper. This study began with an analysis of the state of the art in the field of soft grippers, with particular focus on pneumatic actuation and its potential for safe and adaptive interaction in rehabilitation and assistive robotics. The initial search through the Scopus and Web of Science databases led us to the creation of a gripper that was easier to make, implement, and control than those found in the literature, but which still manages to provide significant gripping force and has good adaptability to different objects. The development of this gripper led to the creation of a prototypal device capable of reconfiguring the fingers by means of an entirely pneumatic actuation, characterized by dimensions comparable to those of a human hand. Using FFF 3D printing, it was possible to realize a series of prototypes aimed at evaluating the functionality of alternative solutions. The gripper demonstrated rapid reconfiguration (≈0.5 s) and grasping forces exceeding 17 N on rigid targets, while functional tests confirmed adaptability to objects of varying shapes and sizes. Considering the grasping tests, it could be seen that the different finger configurations have variable effectiveness depending on the object to be grasped. Obviously, the shape and characteristics of the finger play a major role in determining its grasping performance. The current implementation still presents limitations due to the large number of components. The 2/2 valves were chosen for their ease of control; future developments could replace the four valves used for the rotary mechanism with a single 5/3 valve, thereby reducing overall system complexity and dimensions. This would also allow us to reduce the overall dimensions. The results achieved in this study lay the basis for further research into the most effective shapes and dimensions for the fingers, particularly in regard to fingertips. Moreover, future work could be oriented toward the experimentation of refined control strategies. With this respect, active control could be enabled by integrating force/deflection sensors in the actuators or applying computer vision techniques to monitor gripper–object interactions. The integration of a pressure regulation controlled by the Arduino could enable the device to perform dynamic grasping and adjust the forces exerted by the actuators with respect to the object grasped and its characteristics. The ultimate goal of this research is the integration of a control strategy that is able to recognize, through a network of different sensors, the ideal grasping conditions for a given object in terms of gripper configuration, exerted forces, and the relative position of the gripper with respect to the target. In conclusion, it can be said that the aim of this study, to realize a reconfigurable soft gripper, has been successfully achieved. The combination of versatility offered by the two possible finger configurations and the grasping forces generated by the gripper provides the robotic hand with a wide range of applications. Although the forces developed by our gripper may not surpass those of some existing examples, its adaptability and feasibility underline its innovative potential. This limitation, however, reflects the intentional prototypal focus of the current design phase, with future developments expected to deliver substantial improvements.

To significantly enhance both the intelligence and holding force of the device—aligning with the requirements for advanced manipulation—future work will focus on integrating high-performance components. In particular, improving active control and proprioception necessitates the inclusion of flexible bending sensors within the soft actuators [

29]. This sensory feedback is essential for closing the control loop, enabling the system to accurately monitor the gripper’s deformation and kinematic state in real time. Such a capability facilitates dynamic grasping and compensates for the inherent non-linearities of soft materials.

Additionally, to substantially increase holding force and functional versatility, the next design iteration will incorporate bio-inspired adhesive fibrillar surfaces [

30] at the fingertips. Drawing inspiration from gecko adhesion, these microstructured surfaces exploit high shear forces and van der Waals interactions to achieve a robust grip, significantly expanding load capacity and ensuring stable attachment, particularly on complex geometries where friction-based gripping is limited.

The successful integration of these sensory and performance-enhancing features is paramount to realizing a truly intelligent and adaptable soft robotic hand.