TGPSO: An Adaptive Gait Optimization Algorithm for Hexapod Robots in Multi-Terrain Environments

Abstract

1. Introduction

- Terrain-induced sinkage risks: Foot penetration into soft substrates creates entrapment scenarios where traditional extraction methods prove inadequate, yet current approaches lack sinkage-aware control mechanisms.

- Substrate-dependent parameter optimization: Different ground materials (rock, sand, clay) require distinct combinations of step size, height, and frequency due to varying stiffness, damping, and friction properties, but existing methods employ fixed-weight objective functions that cannot adapt to these material-specific requirements.

- Limited global search capability: Traditional PSO algorithms demonstrate poor convergence when handling the multimodal optimization landscapes created by terrain heterogeneity, frequently becoming trapped in local optima that correspond to suboptimal gait configurations.

2. Materials and Methods

2.1. Problem Modeling

2.1.1. Problem Description and Definition

- Real-time terrain identification based on foot subsidence.

- Dynamic allocation of multi-objective weights under different terrains.

- Global optimization solving under strongly coupled gait parameter conditions.

- Step Size ∈ [0, 0.3] m; Stpheight ∈ [0, 0.2] m; StepFrequency ∈ [0.5, 2] Hz;

- Stability constraints: center of mass fluctuation < 0.05 m;

- Energy consumption constraints: joint torque shall not exceed the rated torque of the motor;

- Terrain adaptability constraints: foot-end sinkage < 0.5 m.

2.1.2. Hexapod Robot System Modeling

2.1.3. System Architecture and Methodology Overview

- Position and velocity measurements: Transformer sensor modules sample at 1 kHz simulation time.

- IMU data acquisition: Three-axis accelerometer and AHRS (Attitude and Heading Reference System) modules provide orientation and angular velocity data at 1 kHz simulation rate.

- Contact force sensors: Integrated within the foot–ground contact model, updating at the solver’s variable step rate.

2.1.4. Mechanical Modeling of Foot–Ground Interaction

2.2. Algorithm Design

2.2.1. Multi-Objective Optimization Problem Modeling

2.2.2. PSO Algorithm

2.2.3. TGPSO Algorithm Design

2.2.4. Terrain-Aware Reward Function Framework with Dynamic Weight Allocation

3. Results

3.1. Simulation Environment Setup

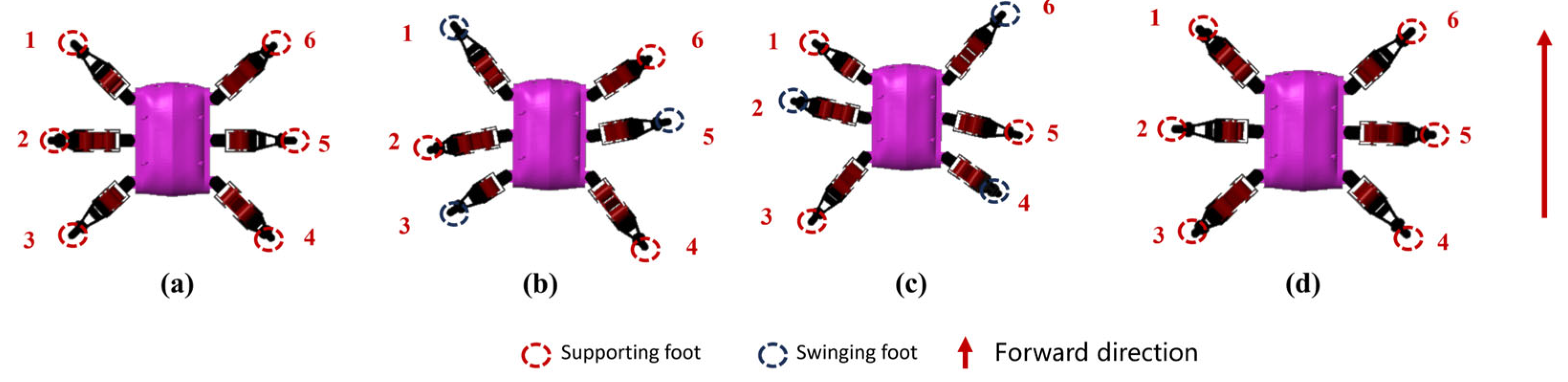

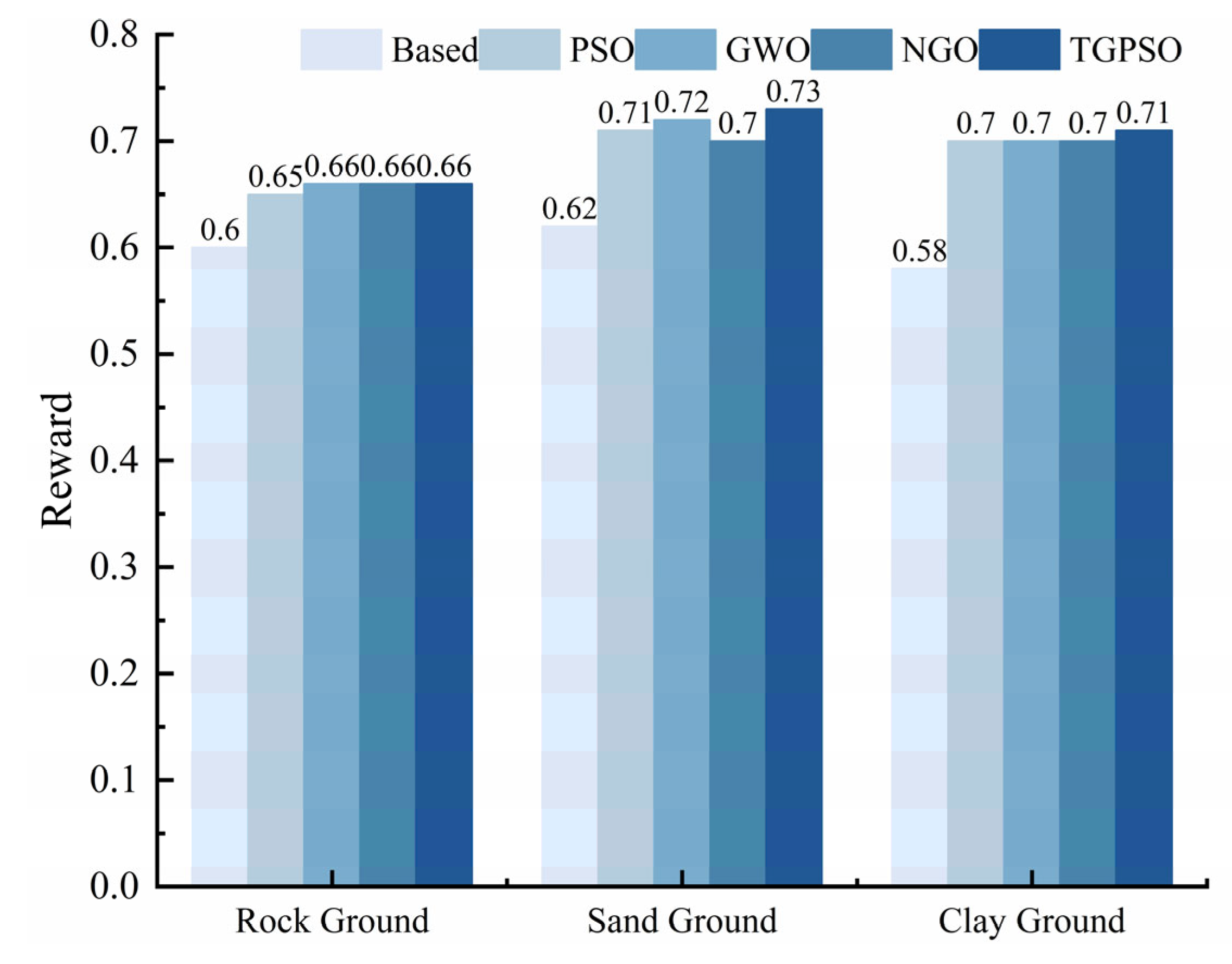

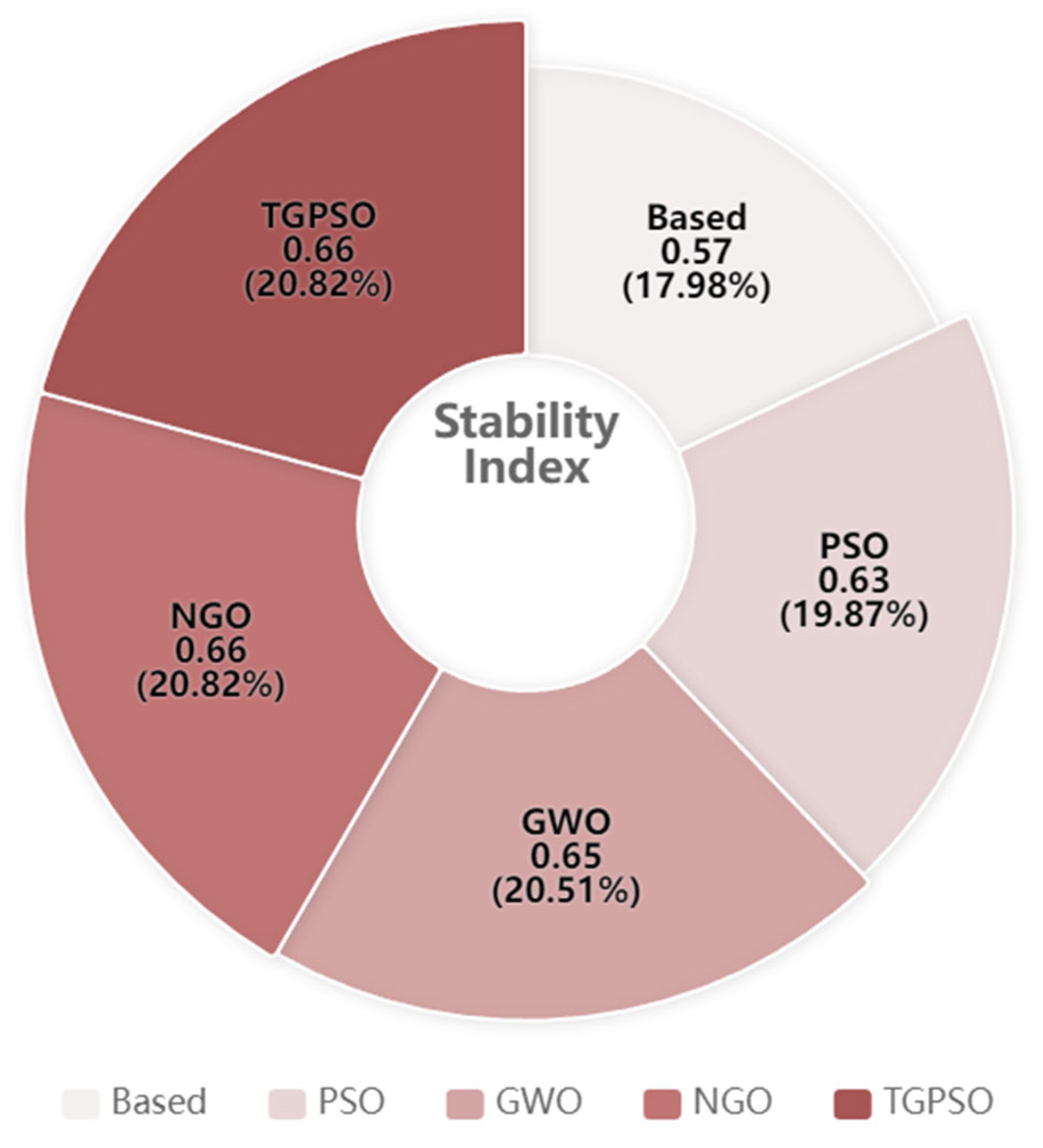

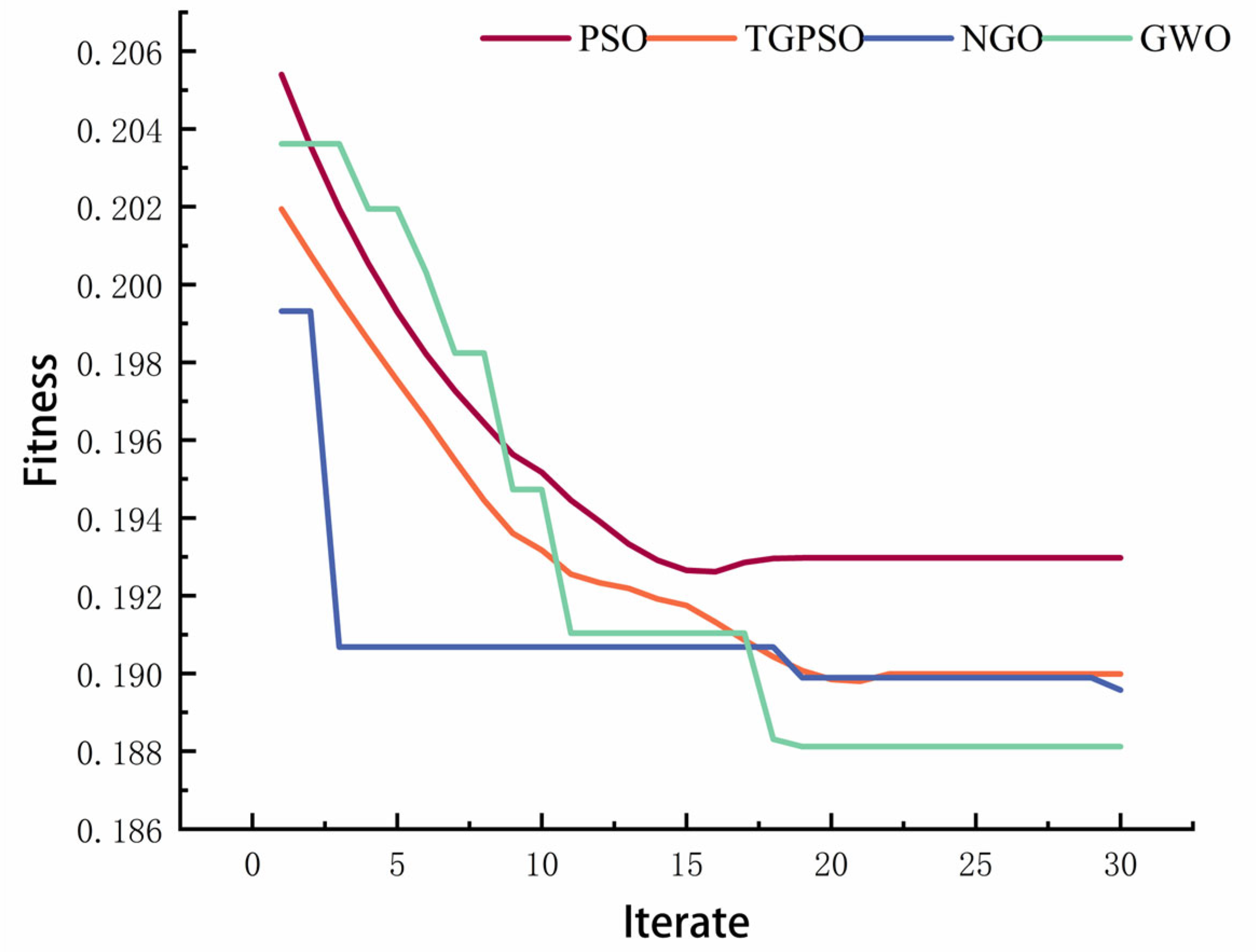

3.2. Gait Simulation Parameter Design and Results

4. Discussion

4.1. Rock Ground

4.2. Sand Ground

4.3. Clay Ground

5. Conclusions

- Proposed the TGPSO optimization algorithm, which integrates foot sinkage detection mechanisms and dynamic weight adjustment strategies. Through Latin hypercube sampling, linearly decreasing inertia weights, and stagnation exploration mechanisms, it effectively addresses the local optima entrapment issues inherent in traditional PSO algorithms, significantly enhancing global search capabilities and convergence stability.

- Established a unified terrain-adaptive reward function framework that dynamically adjusts the weighting coefficients for speed, stability, and transportation cost based on foot sinkage measurements. For three typical terrain types— rock ground, sand ground, and clay ground—adaptive adjustment of optimization objectives was achieved.

- Validation through the Simulink of MatlabR2023b simulation platform demonstrated that the TGPSO algorithm achieved superior locomotion performance across all terrain conditions, while exhibiting excellent performance in center-of-mass fluctuation control, fully demonstrating the algorithm’s technical advantages in multi-material surface motion control.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, H.; Xin, G.; Zhong, G.; Mistry, M. Gait and Trajectory Rolling Planning and Control of Hexapod Robots for Disaster Rescue Applications. Robot. Auton. Syst. 2017, 95, 13–24. [Google Scholar] [CrossRef]

- Jadeja, R.; Trivedi, T.; Surve, J. Survivor Detection Approach for Post Earthquake Search and Rescue Missions Based on Deep Learning Inspired Algorithms. Sci. Rep. 2024, 14, 25047. [Google Scholar] [CrossRef]

- Lee, S.; Azhari, M.B.; Kang, G.; Günes, O.; Han, D.; Shim, D.H. A Collaborative Team of UAV-Hexapod for an Autonomous Retrieval System in GNSS-Denied Maritime Environments. arXiv 2024, arXiv:2410.09606. [Google Scholar]

- Kuo, L.S.; Lin, Y.; Sheng, V.S.; Kuo, L.S.; Jheng, S.J. Development an Intelligent Power Detection System for Mobile Robots. In Proceedings of the 2008 27th Chinese Control Conference, Kunming, China, 16-18 July 2008; IEEE: New York, NY, USA, 2008; pp. 637–641. [Google Scholar]

- Chen, G.; Han, Y.; Li, Y.; Shen, J.; Tu, J.; Yu, Z.; Zhang, J.; Cheng, H.; Zhu, L.; Dong, F. Autonomous Gait Switching Method and Experiments of a Hexapod Walking Robot for Mars Environment with Multiple Terrains. Intel. Serv. Robot. 2024, 17, 533–553. [Google Scholar] [CrossRef]

- Guo, Y.-Q.; Luo, W.-H.; Xu, Z.-D.; Shu, B.-M.; Yang, D.-K. Research on the Design and Gait Planning of a Hexapod Robot Based on Improved Triangular Gait for Lunar Exploration. Appl. Sci. 2023, 14, 260. [Google Scholar] [CrossRef]

- Coelho, J.; Ribeiro, F.; Dias, B.; Lopes, G.; Flores, P. Trends in the Control of Hexapod Robots: A Survey. Robotics 2021, 10, 100. [Google Scholar] [CrossRef]

- Roennau, A.; Heppner, G.; Nowicki, M.; Dillmann, R. LAURON V: A Versatile Six-Legged Walking Robot with Advanced Maneuverability. In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besacon, France, 8–11 July 2014; IEEE: New York, NY, USA, 2014; pp. 82–87. [Google Scholar]

- Huang, S.; Zheng, M.; Hu, Z.; Liu, P.X. Enhancing Hexapod Robot Mobility on Challenging Terrains: Optimizing CPG-Generated Gait with Reinforcement Learning. Neurocomputing 2025, 622, 129328. [Google Scholar] [CrossRef]

- Ouyang, W.; Chi, H.; Pang, J.; Liang, W.; Ren, Q. Adaptive Locomotion Control of a Hexapod Robot via Bio-Inspired Learning. Front. Neurorobot. 2021, 15, 627157. [Google Scholar] [CrossRef]

- Yin, Y.; Gao, F.; Sun, Q.; Zhao, Y.; Xiao, Y. Smart Gait: A Gait Optimization Framework for Hexapod Robots. Chin. J. Mech. Eng. 2024, 37, 15. [Google Scholar] [CrossRef]

- Zhang, Z.; He, W.; Wu, F.; Quesada, L.; Xiang, L. Development of a Bionic Hexapod Robot with Adaptive Gait and Clearance for Enhanced Agricultural Field Scouting. Front. Robot. AI 2024, 11, 1426269. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Fan, X.; Ding, L.; Wang, J.; Liu, T.; Gao, H. Fault-Tolerant Tripod Gait Planning and Verification of a Hexapod Robot. Appl. Sci. 2020, 10, 2959. [Google Scholar] [CrossRef]

- Sun, Y.; Zong, C.; Pancheri, F.; Chen, T.; Lueth, T.C. Design of Topology Optimized Compliant Legs for Bio-Inspired Quadruped Robots. Sci. Rep. 2023, 13, 4875. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, R.; Wang, X.; Gao, W.; Chen, Y. A Motion Control Strategy for a Blind Hexapod Robot Based on Reinforcement Learning and Central Pattern Generator. Symmetry 2025, 17, 1058. [Google Scholar] [CrossRef]

- Luneckas, M.; Luneckas, T.; Udris, D.; Plonis, D.; Maskeliūnas, R.; Damaševičius, R. A Hybrid Tactile Sensor-Based Obstacle Overcoming Method for Hexapod Walking Robots. Intel. Serv. Robot. 2021, 14, 9–24. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A Review on Genetic Algorithm: Past, Present, and Future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Kneiding, H.; Balcells, D. Augmenting Genetic Algorithms with Machine Learning for Inverse Molecular Design. Chem. Sci. 2024, 15, 15522–15539. [Google Scholar] [CrossRef]

- Shi, Y.; Eberhart, R. A Modified Particle Swarm Optimizer. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings. IEEE World Congress on Computational Intelligence (Cat. No.98TH8360), Anchorage, AK, USA, 4–9 May 1998; IEEE: New York, NY, USA, 1998; pp. 69–73. [Google Scholar]

- Chen, X.-B.; Gao, F. Energy Expenditure of Trotting Gait Under Different Gait Parameters. Chin. J. Mech. Eng. 2017, 30, 943–950. [Google Scholar] [CrossRef]

- Tao, C.; Xue, J.; Zhang, Z.; Cao, F.; Li, C.; Gao, H. Gait Optimization Method for Humanoid Robots Based on Parallel Comprehensive Learning Particle Swarm Optimizer Algorithm. Front. Neurorobot. 2021, 14, 600885. [Google Scholar] [CrossRef]

- Walas, K.; Schmidt, A.; Kraft, M.; Fularz, M. Hardware Implementation of Ground Classification for a Walking Robot. In Proceedings of the 9th International Workshop on Robot Motion and Control, Kuslin, Poland, 3–5 July 2013; IEEE: New York, NY, USA, 2013; pp. 110–115. [Google Scholar]

- Brooks, C.A.; Iagnemma, K.D.; Dubowsky, S. Visual Wheel Sinkage Measurement for Planetary Rover Mobility Characterization. Auton. Robot. 2006, 21, 55–64. [Google Scholar] [CrossRef]

- Saranli, U.; Buehler, M.; Koditschek, D.E. RHex: A Simple and Highly Mobile Hexapod Robot. Int. J. Robot. Res. 2001, 20, 616–631. [Google Scholar] [CrossRef]

- Choi, S.; Ji, G.; Park, J.; Kim, H.; Mun, J.; Lee, J.H.; Hwangbo, J. Learning Quadrupedal Locomotion on Deformable Terrain. Sci. Robot. 2023, 8, eade2256. [Google Scholar] [CrossRef]

- Vulpi, F.; Milella, A.; Marani, R.; Reina, G. Recurrent and Convolutional Neural Networks for Deep Terrain Classification by Autonomous Robots. J. Terramechanics 2021, 96, 119–131. [Google Scholar] [CrossRef]

- Vangen, A.; Barnwal, T.; Olsen, J.A.; Alexis, K. Terrain Recognition and Contact Force Estimation Through a Sensorized Paw for Legged Robots. In Proceedings of the 2023 21st International Conference on Advanced Robotics (ICAR), Abu Dhabi, United Arab Emirates, 5 December 2023; IEEE: New York, NY, USA; pp. 605–612. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; ISBN 0 521 25576 7. [Google Scholar]

- Inman, D.J. Engineering Vibration, 4th ed.; Pearson: London, UK, 2014; ISBN 978-0-13-356071-8. [Google Scholar]

- Ding, L.; Gao, H.; Deng, Z.; Song, J.; Liu, Y.; Liu, G.; Iagnemma, K. Foot–Terrain Interaction Mechanics for Legged Robots: Modeling and Experimental Validation. Int. J. Robot. Res. 2013, 32, 1585–1606. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Q.; Sun, Y.; Wang, N. Research and Analysis on Energy Consumption of Underwater Hexapod Robot Based on Typical Gait. In Intelligent Robotics and Applications; Liu, X.-J., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2021; Volume 13015, pp. 14–24. ISBN 978-3-030-89133-6. [Google Scholar]

- Brodoline, I.; Sauvageot, E.; Viollet, S.; Serres, J.R. Shaping the Energy Curves of a Servomotor-Based Hexapod Robot. Sci. Rep. 2024, 14, 11675. [Google Scholar] [CrossRef] [PubMed]

- Luneckas, M.; Luneckas, T.; Kriaučiūnas, J.; Udris, D.; Plonis, D.; Damaševičius, R.; Maskeliūnas, R. Hexapod Robot Gait Switching for Energy Consumption and Cost of Transport Management Using Heuristic Algorithms. Appl. Sci. 2021, 11, 1339. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Dehghani, M.; Hubalovsky, S.; Trojovsky, P. Northern Goshawk Optimization: A New Swarm-Based Algorithm for Solving Optimization Problems. IEEE Access 2021, 9, 162059–162080. [Google Scholar] [CrossRef]

| Ground Type | Stiffness (N/m) | Damping (N/(m/s)) | Dynamic Friction | Static Friction | Density (kg/m3) |

|---|---|---|---|---|---|

| Rock Ground | 0.52 | 0.55 | 1800 | ||

| Sand Ground | 9000 | 0.6 | 0.65 | 1700 | |

| Clay Ground | 3900 | 0.5 | 0.55 | 1600 |

| Ground Type | Step Size (m) | Step Height (m) | Step Frequency (Hz) | v (m/s) | Standard Deviation (mm) | COT | Reward |

|---|---|---|---|---|---|---|---|

| Rock Ground | 0.153 | 0.076 | 0.64 | 0.21 | 0.4 | 6.8 | 0.66 |

| Sand Ground | 0.30 | 0.143 | 2.00 | 0.41 | 1.3 | 39.1 | 0.73 |

| Clay Ground | 0.117 | 0.01 | 0.84 | 0.31 | 2.6 | 21.7 | 0.71 |

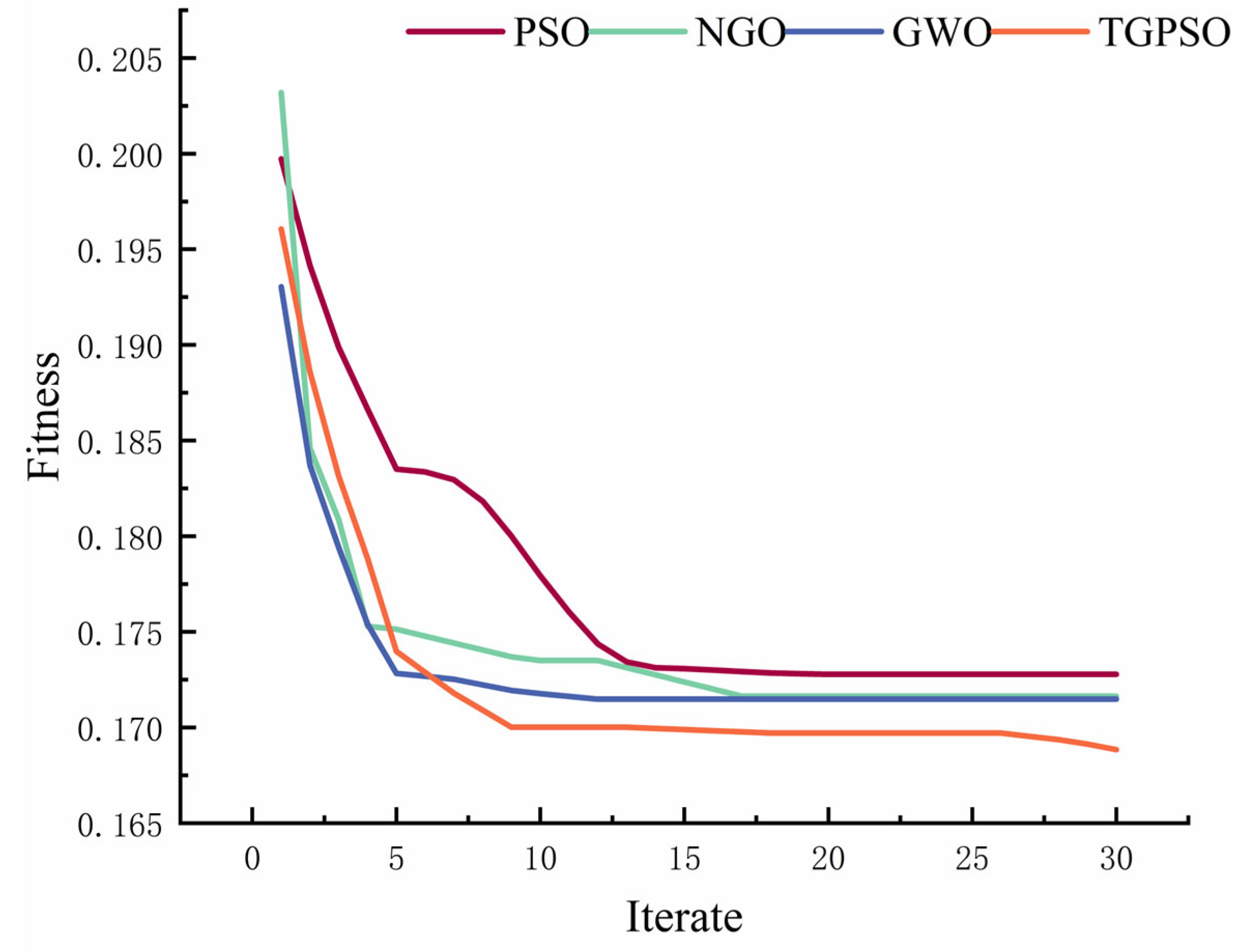

| Ground Type | Algorithm Type | Step Size (m) | Step Height (m) | Step Frequency (Hz) | Reward |

|---|---|---|---|---|---|

| Rock Ground | Based | 0.18 | 0.07 | 1 | 0.6 |

| PSO | 0.073 | 0.037 | 1.1 | 0.65 | |

| GWO | 0.097 | 0.048 | 0.77 | 0.66 | |

| NGO | 0.086 | 0.043 | 0.76 | 0.66 | |

| TGPSO | 0.153 | 0.076 | 0.63 | 0.66 | |

| Sand Ground | Based | 0.18 | 0.07 | 1 | 0.62 |

| PSO | 0.3 | 0.148 | 2.0 | 0.71 | |

| GWO | 0.29 | 0.144 | 1.98 | 0.72 | |

| NGO | 0.3 | 0.145 | 1.88 | 0.70 | |

| TGPSO | 0.3 | 0.143 | 2.00 | 0.73 | |

| Clay Ground | Based | 0.18 | 0.07 | 1 | 0.58 |

| PSO | 0.115 | 0.031 | 0.65 | 0.70 | |

| GWO | 0.136 | 0.01 | 0.5 | 0.70 | |

| NGO | 0.132 | 0.04 | 0.57 | 0.70 | |

| TGPSO | 0.117 | 0.01 | 0.84 | 0.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, G.; Chen, W.; Du, J.; Liu, Y.; Luo, Y.; Qin, H. TGPSO: An Adaptive Gait Optimization Algorithm for Hexapod Robots in Multi-Terrain Environments. Robotics 2025, 14, 139. https://doi.org/10.3390/robotics14100139

Bai G, Chen W, Du J, Liu Y, Luo Y, Qin H. TGPSO: An Adaptive Gait Optimization Algorithm for Hexapod Robots in Multi-Terrain Environments. Robotics. 2025; 14(10):139. https://doi.org/10.3390/robotics14100139

Chicago/Turabian StyleBai, Guiqiang, Weixu Chen, Jingang Du, Yang Liu, Yanting Luo, and Hongde Qin. 2025. "TGPSO: An Adaptive Gait Optimization Algorithm for Hexapod Robots in Multi-Terrain Environments" Robotics 14, no. 10: 139. https://doi.org/10.3390/robotics14100139

APA StyleBai, G., Chen, W., Du, J., Liu, Y., Luo, Y., & Qin, H. (2025). TGPSO: An Adaptive Gait Optimization Algorithm for Hexapod Robots in Multi-Terrain Environments. Robotics, 14(10), 139. https://doi.org/10.3390/robotics14100139