Application of Barycentric Coordinates and the Jacobian Matrix to the Analysis of a Closed Structure Robot

Abstract

1. Introduction

1.1. Literature Review

1.2. Background and Related Works

- –

- Home configuration—the execution of tasks begins from this position. It is determined by the manufacturer, and its exact location is reported by sensors.

- –

- End configurations—they are determined by the variation limits of the joint coordinates. They usually depend on the physical limitations, but it is possible to set software restrictions.

- –

- Singular configurations—these are configurations in which the robot qualitatively changes its properties. Physically, the number of DoF of the robot in such a configuration decreases. Mathematically, the rank of the Jacobian matrix decreases with them. These configurations are usually undesirable because controlling the robot near them becomes very difficult or impossible (see [9] (p. 116)).

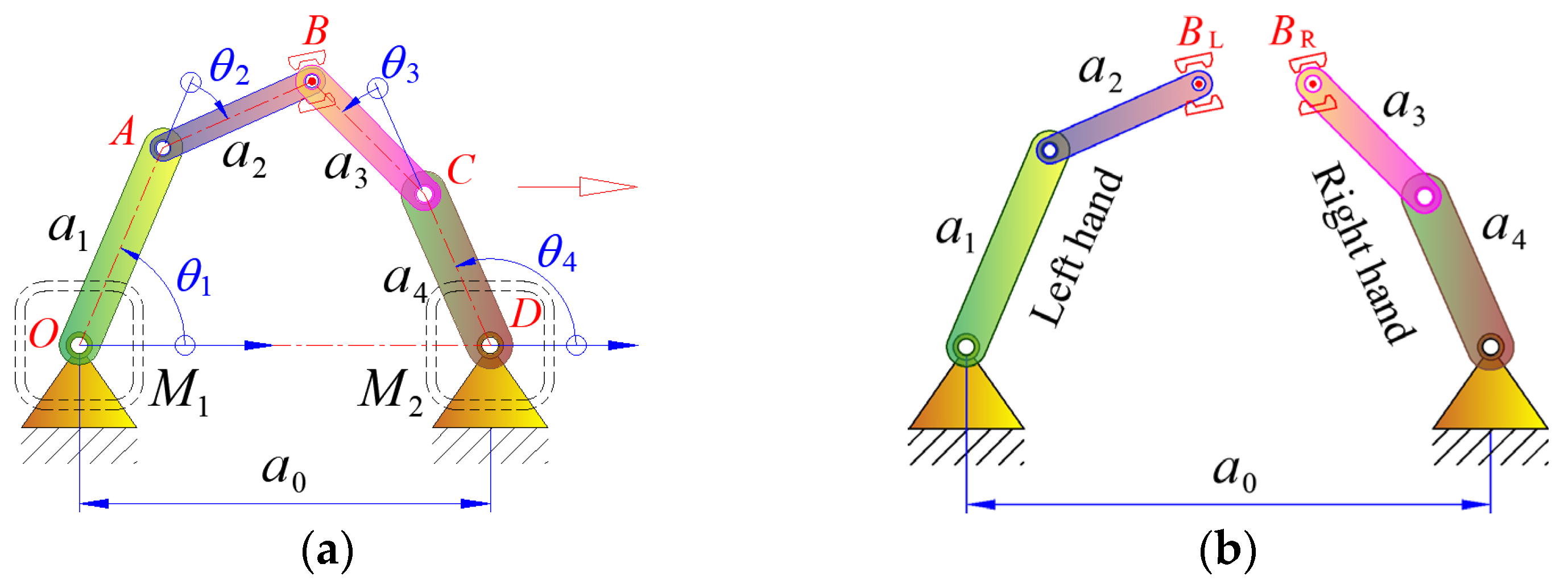

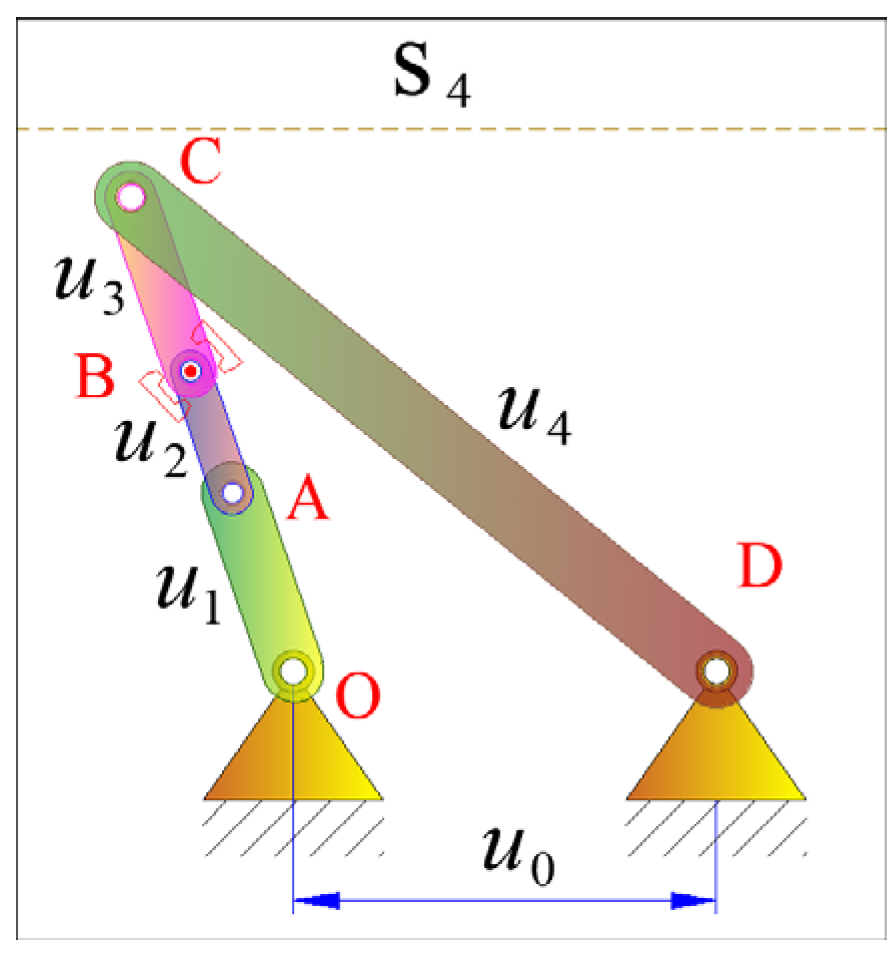

2. Materials and Methods

2.1. Determining the Relevant Dimensions of the Links and the Barycentric Coordinates

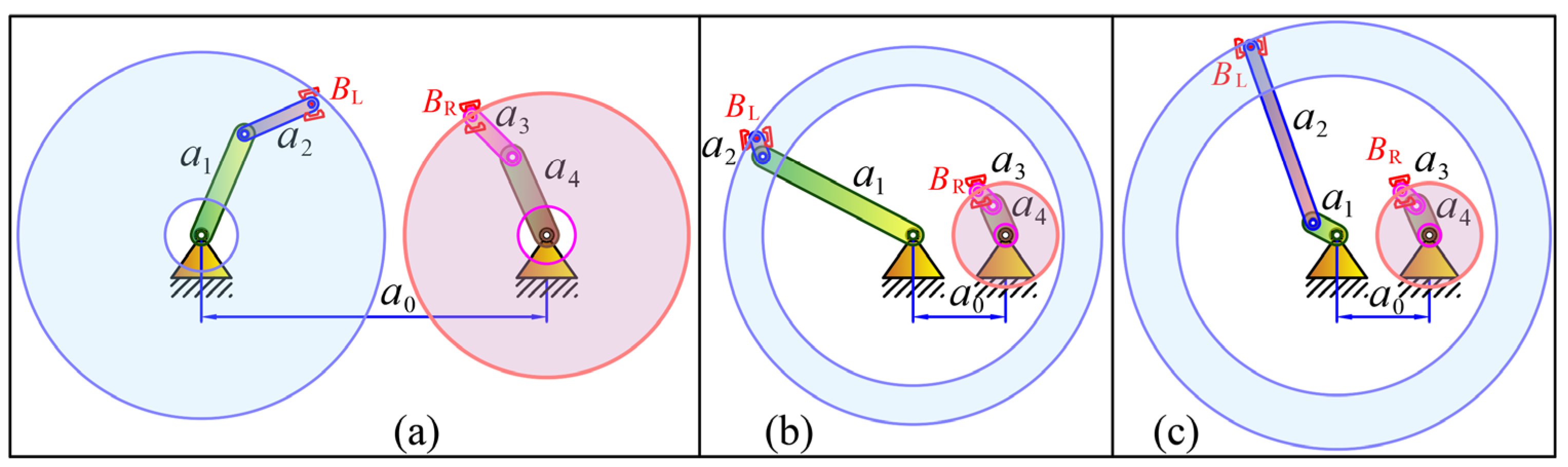

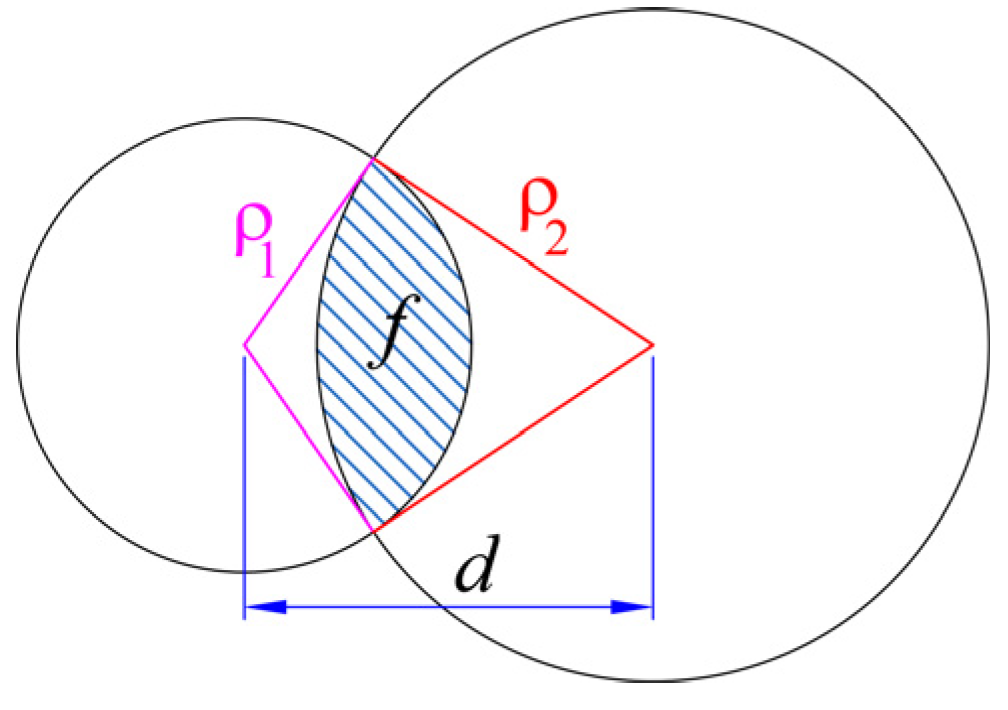

2.2. Existence of a Mechanism

2.3. Analysis of the Joint Angles

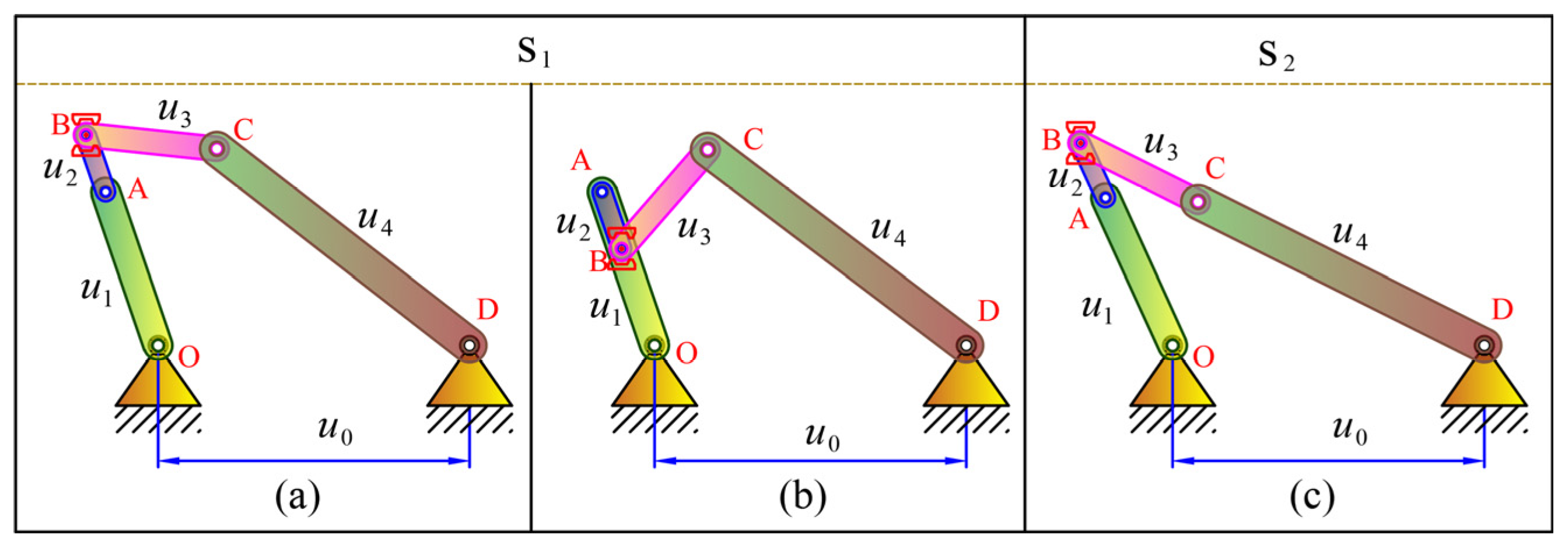

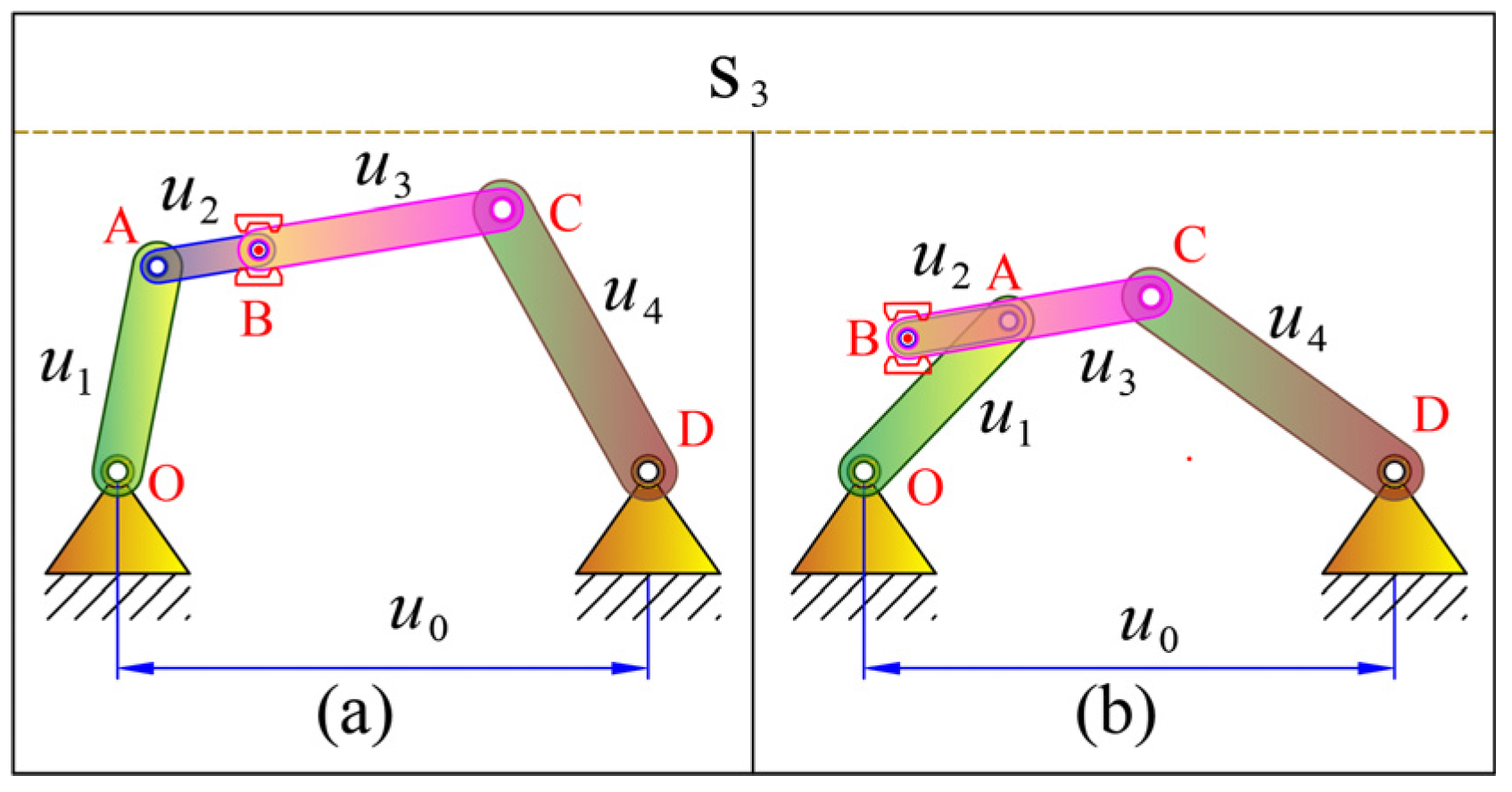

2.4. Solving the Determinant of the Jacobian Matrix Analytically to Define Different Types of Singular Configurations and Exploring How the Rank of the Matrix Changes

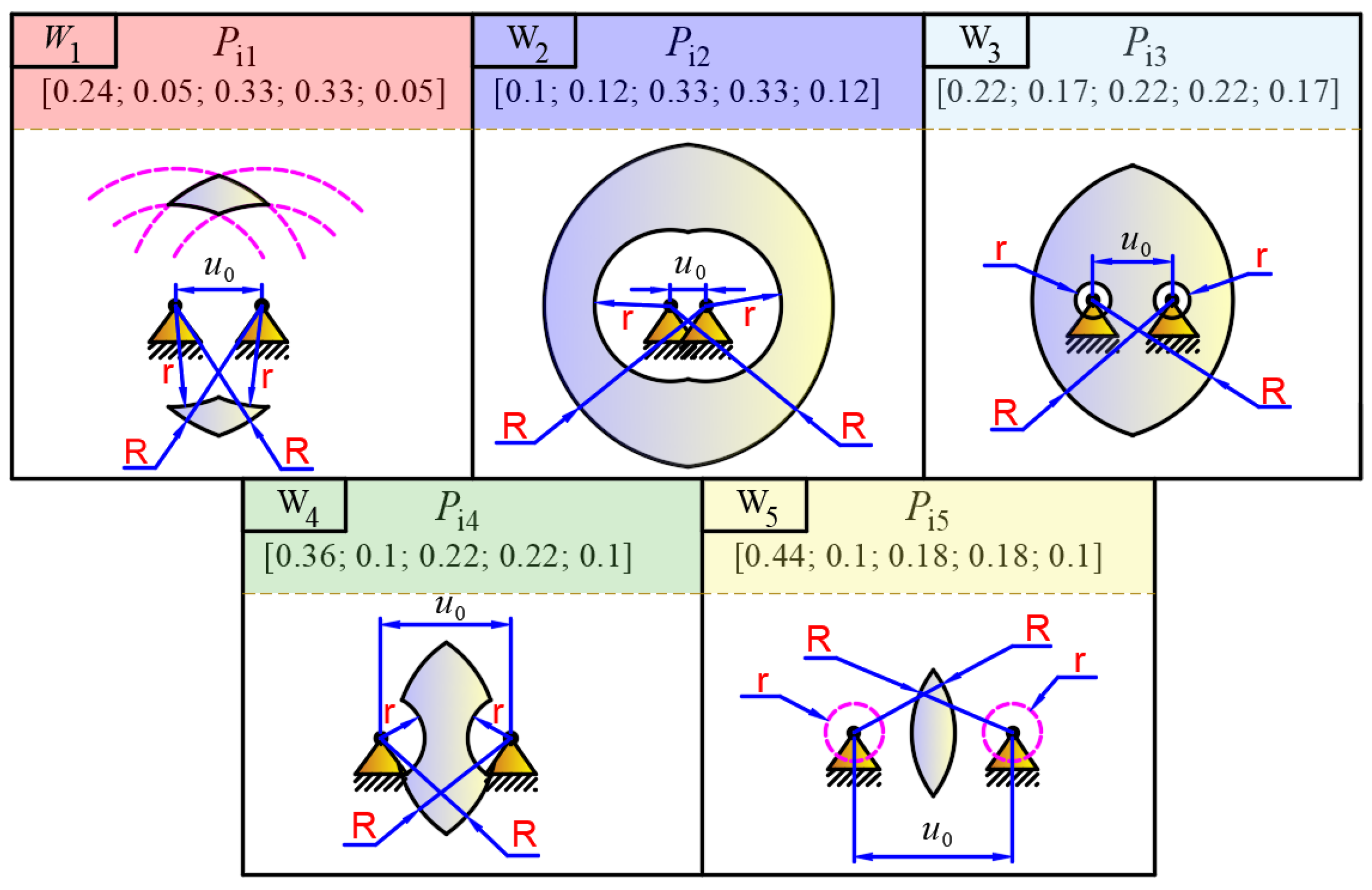

- —Robots that can move in the plane and that could only fall into singular configurations, for which and the rank of J decreases by one (i.e., or );

- —Robots that can move in the plane and that could fall into singular configurations, for which and the rank of J decreases by one or two (i.e., , or );

- —Robots that could fall into singular configurations as in and , and that could enter into a configuration, for which ;

- —Robots that could fall into singular configurations as in , and , and that could enter into a configuration, for which .

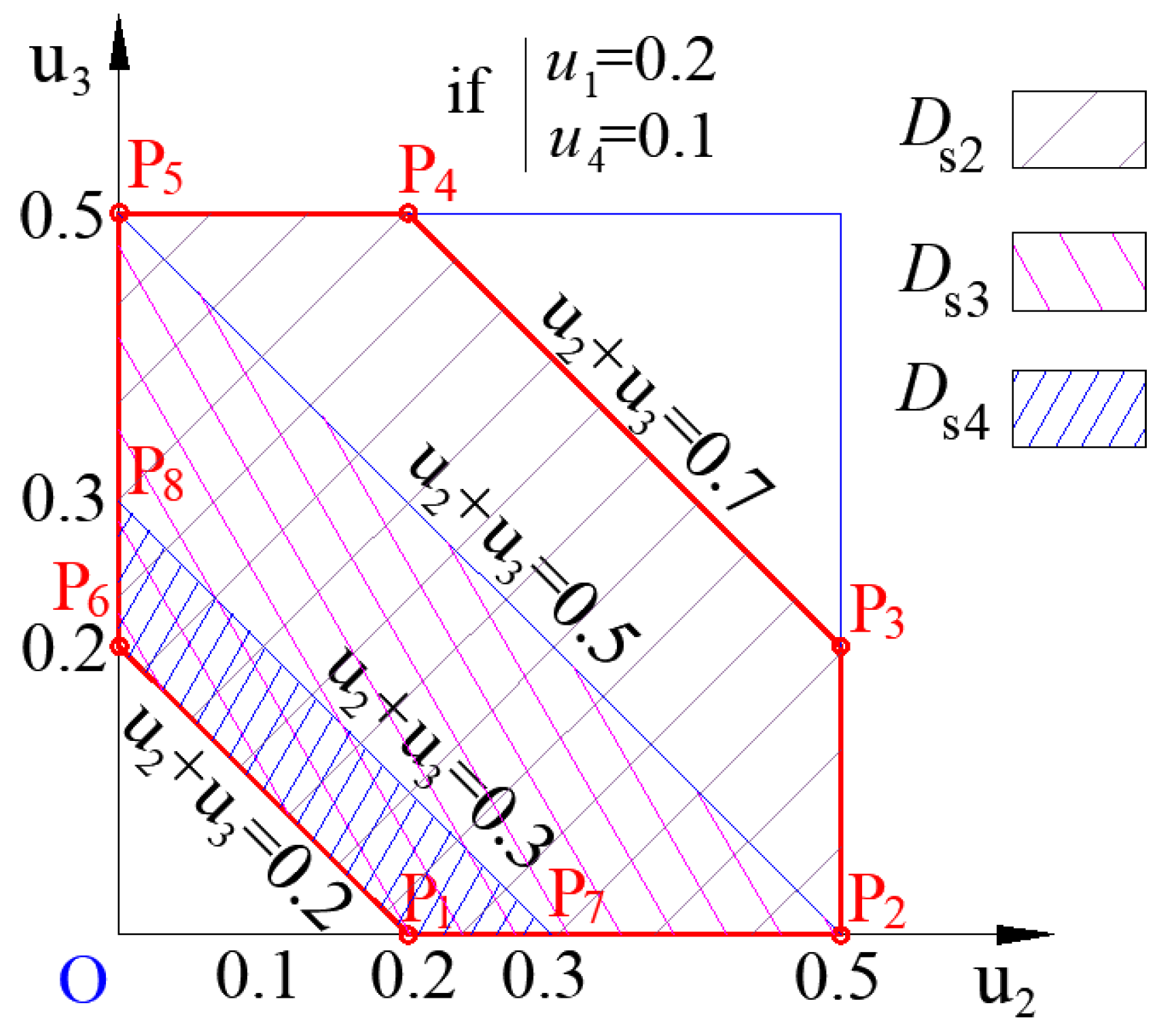

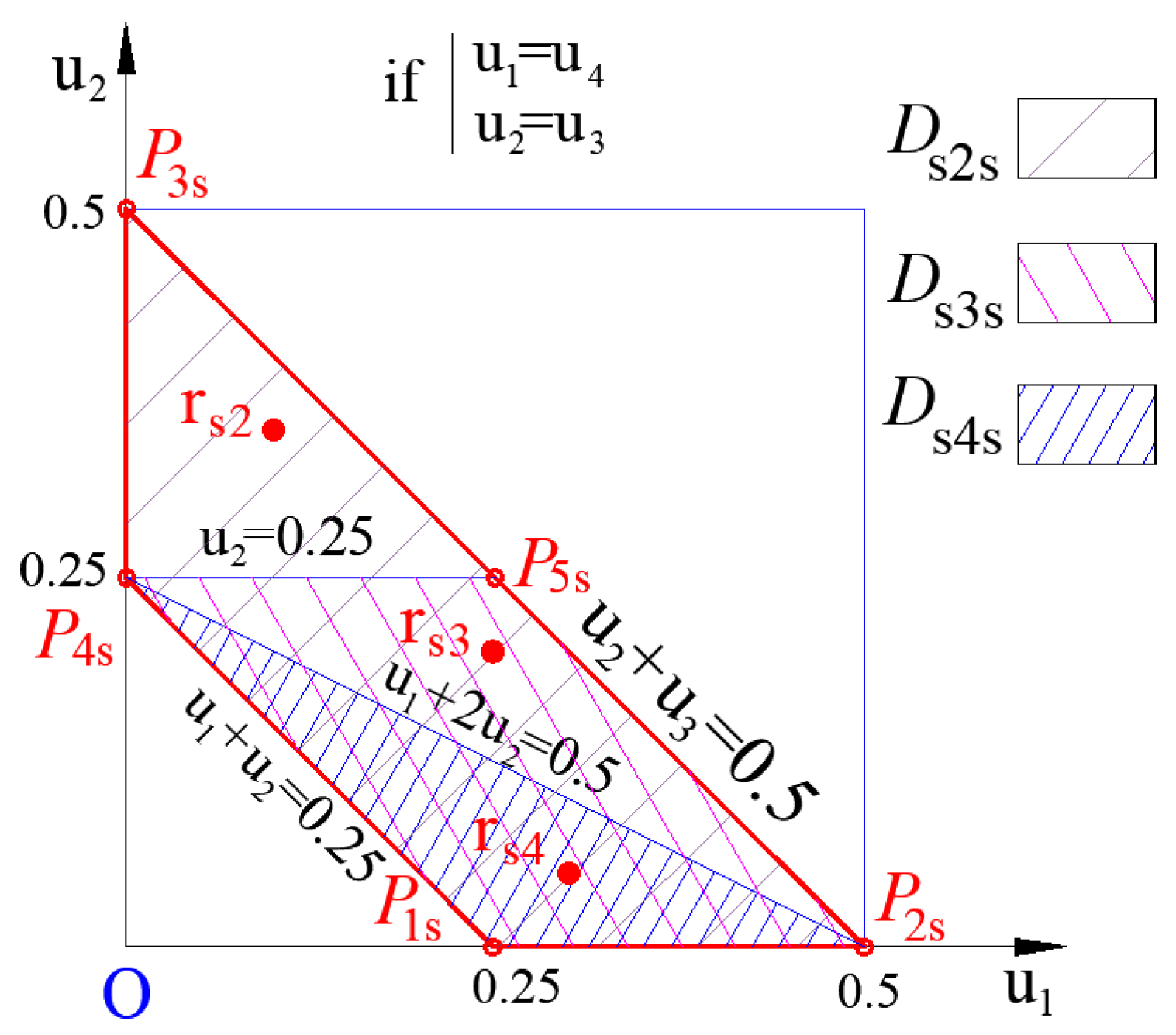

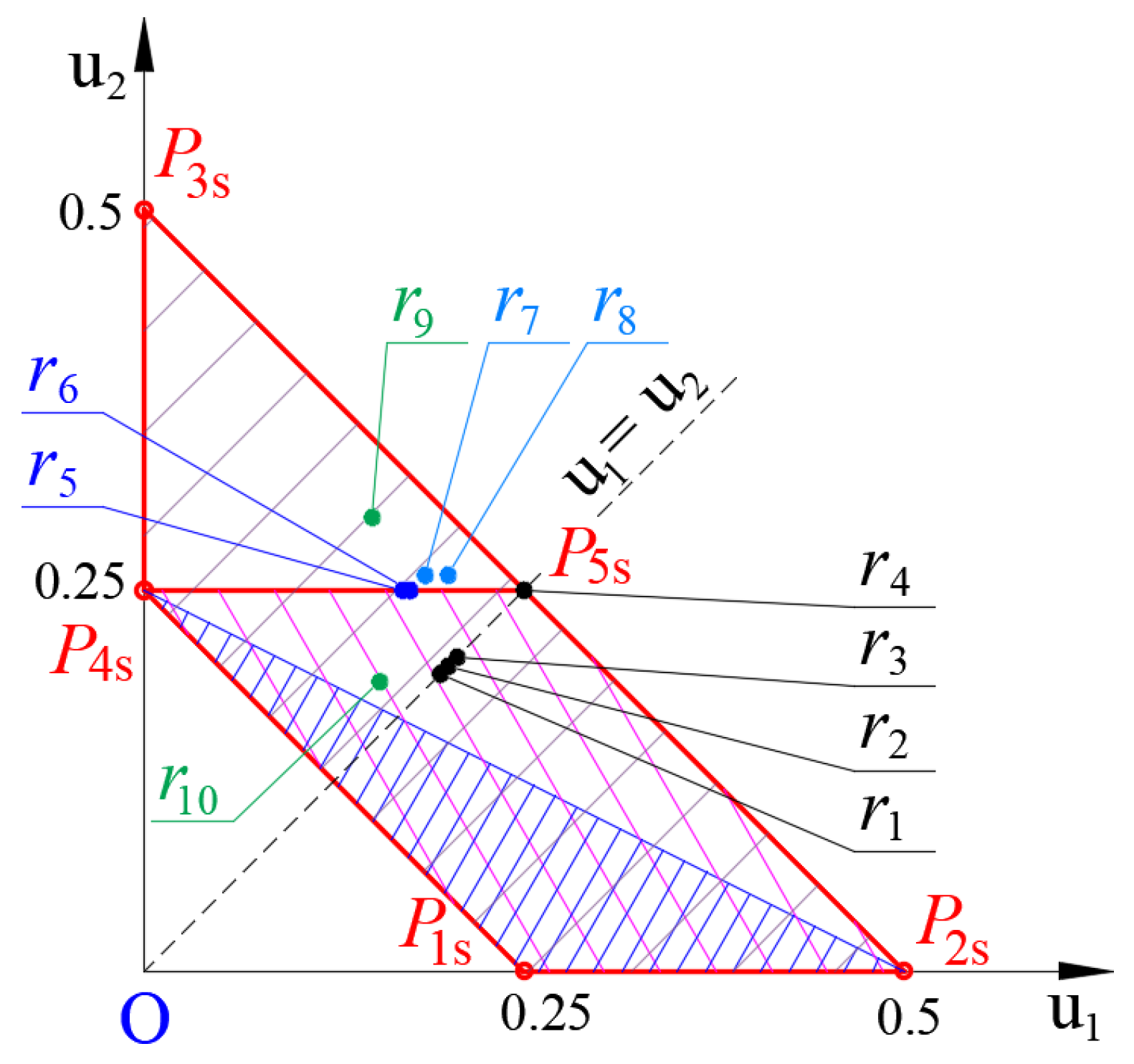

2.5. Defining the Conditions for in RLBS, for Which Different Types of Singular Configurations Occur

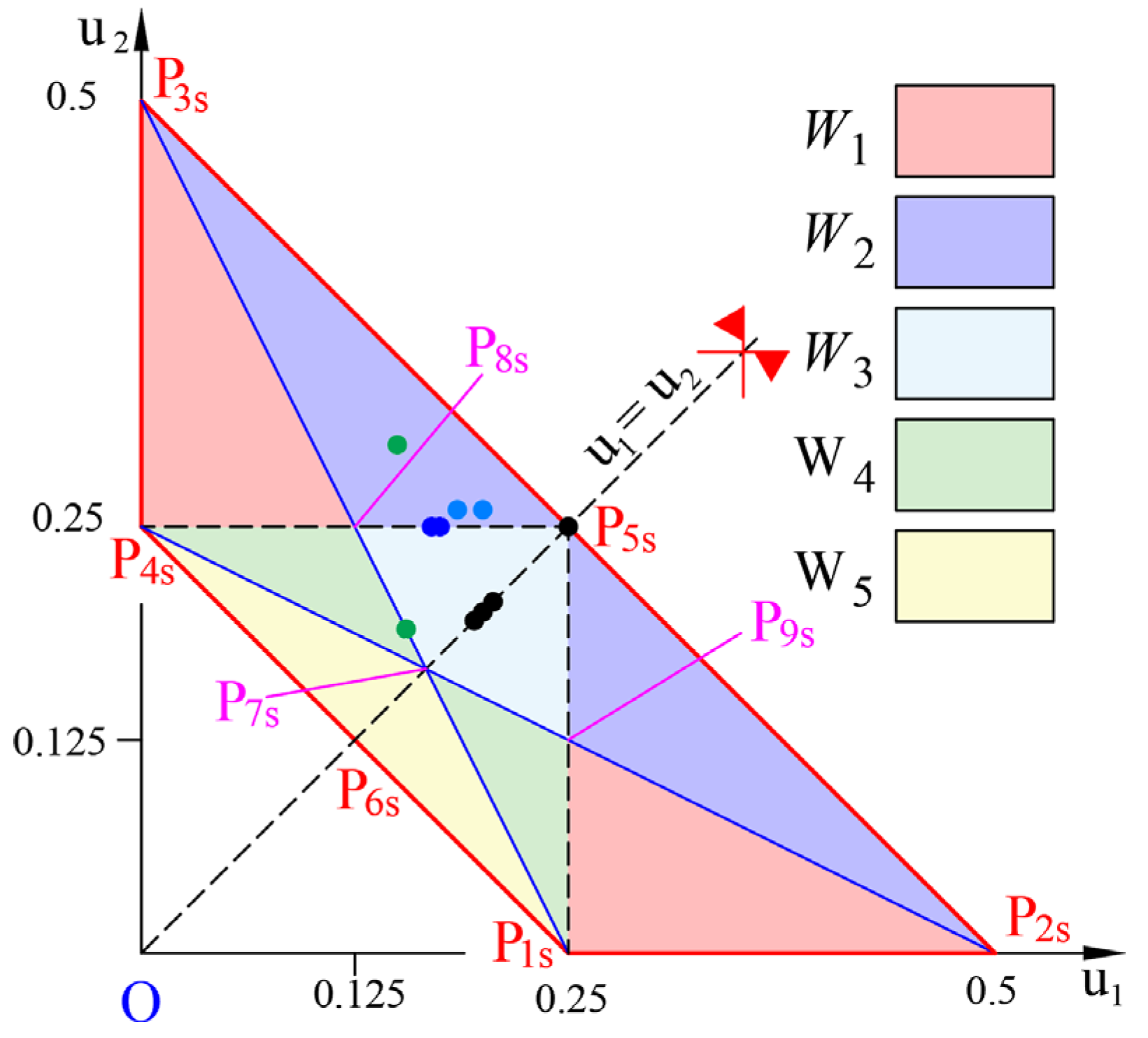

2.6. Workspace Analysis

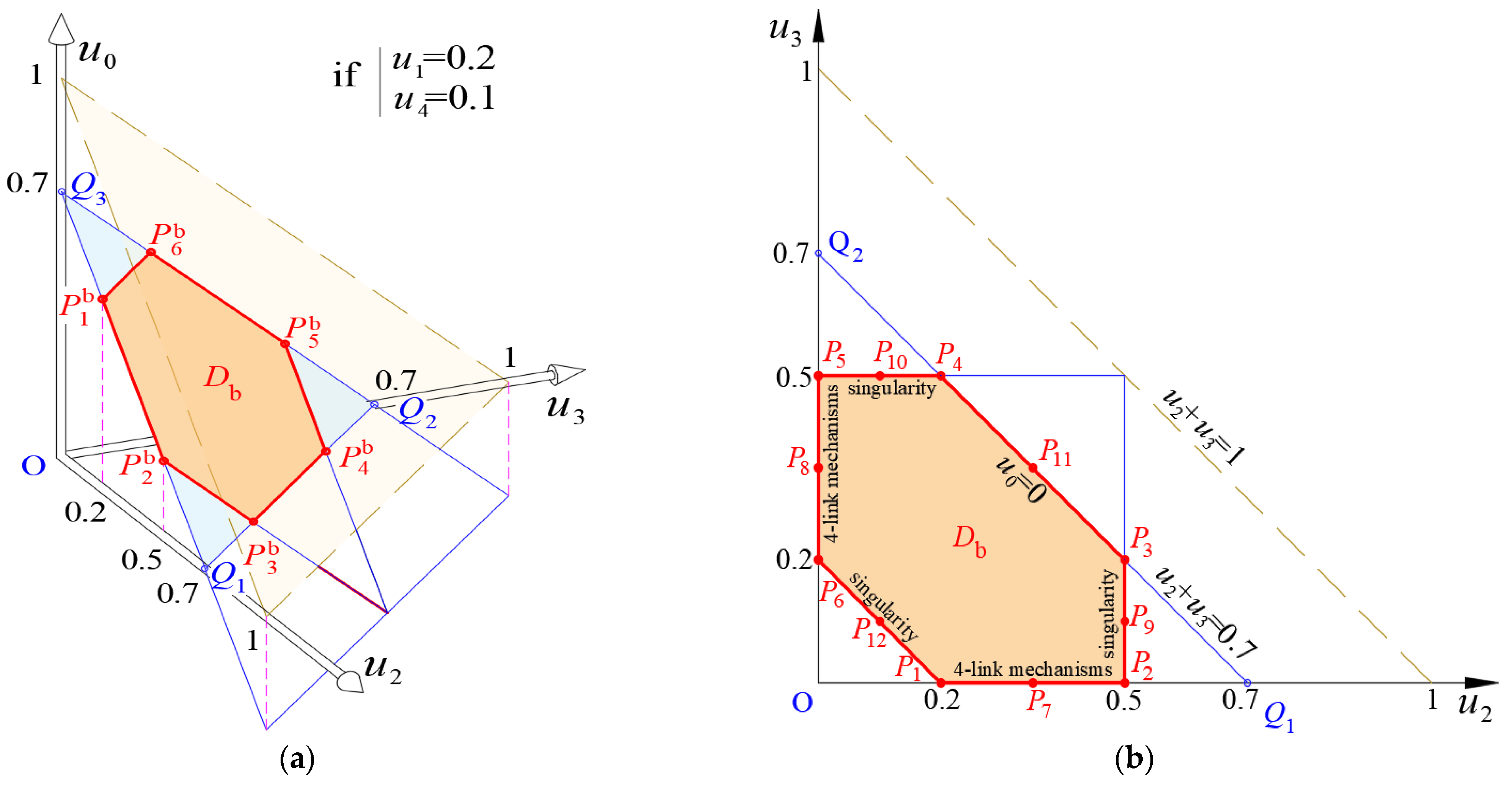

3. Results

3.1. Example 1: Defining the Domain , the Geometric Properties, and the Singular Configurations of a Closed 5-Link Asymmetric Mechanism

3.2. Example 2: Examining the RLBS Coordinates of Robots from the Literature

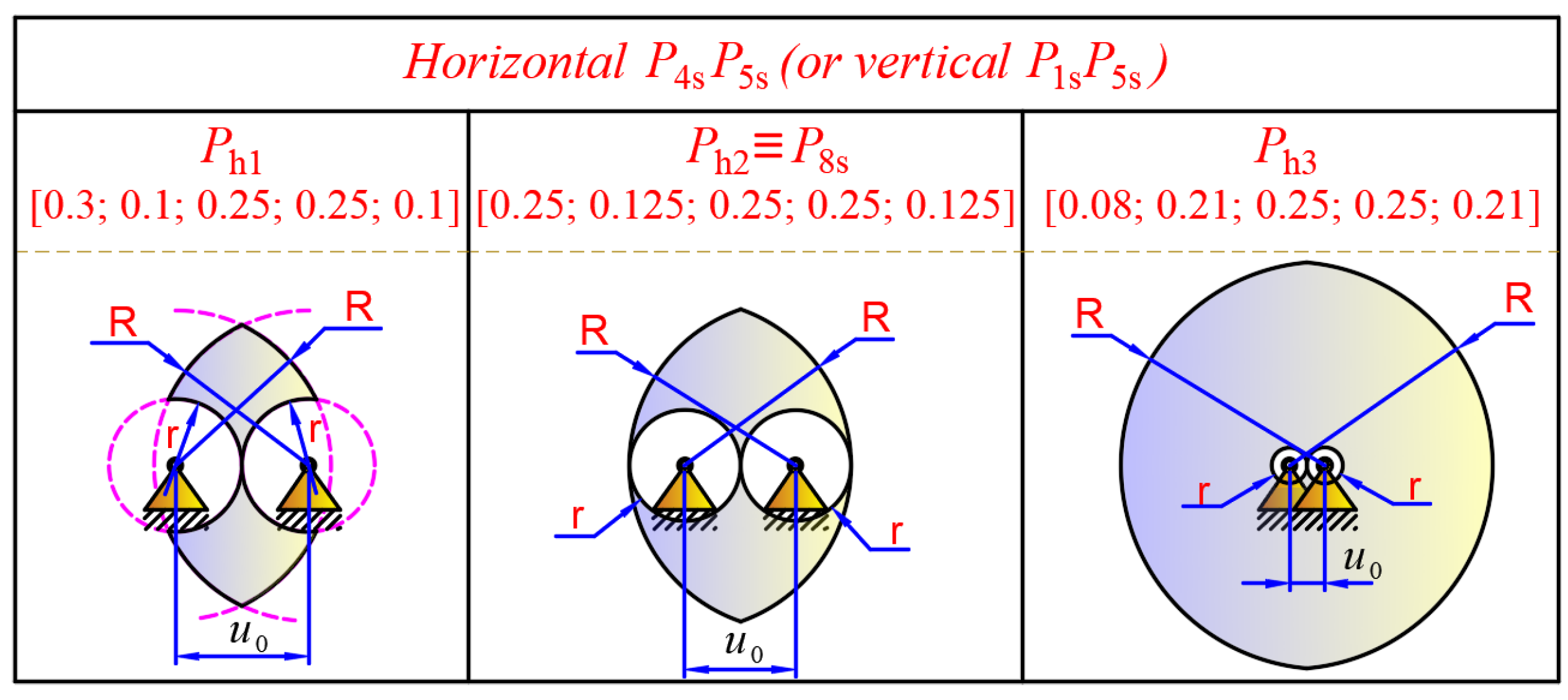

3.3. Example 3: Symmetric Mechanisms

4. Discussion

4.1. Discussion of the Method and the Definitions

4.2. Discussion of Examples

4.2.1. Example 1

4.2.2. Example 2

4.2.3. Example 3

4.3. Advantages and Disadvantages

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramirez, D.; Kotlarski, J.; Ortmaier, T. Combined Structural and Dimensional Synthesis of Serial Robot Manipulators. In ROMANSY 21—Robot Design, Dynamics and Control, Proceedings of the 21st CISM-IFToMM Symposium, Udine, Italy, 20–23 June 2016; CISM International Centre for Mechanical Sciences; Parenti-Castelli, V., Schiehlen, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; Volume 569, pp. 207–216. [Google Scholar] [CrossRef]

- Schappler, M.; Jahn, P.; Raatz, A.; Ortmaier, T. Combined Structural and Dimensional Synthesis of a Parallel Robot for Cryogenic Handling Tasks. In Annals of Scientific Society for Assembly, Handling and Industrial Robotics 2021; Schüppstuhl, T., Tracht, K., Raatz, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 65–77. [Google Scholar] [CrossRef]

- Rodriguez, E.; Riaño, C.; Alvares, A.; Bonnard, R. Design and dimensional synthesis of a Linear Delta robot with single legs for additive manufacturing. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 536. [Google Scholar] [CrossRef]

- Xu, Q.; Zhan, Q.; Tian, X. Link Lengths Optimization Based on Multiple Performance Indexes of Anthropomorphic Manipulators. IEEE Access 2021, 9, 20089–20099. [Google Scholar] [CrossRef]

- Tesfaye, O.T.; Hirpa, G.L.; Addisu, K. Review and synthesis of a walking machine (Robot) leg mechanism. In Proceedings of the 9th International Conference on Manufacturing Science and Education—MSE 2019 Trends in New Industrial Revolution, Sibiu, Romania, 5–7 June 2019; Volume 290. [Google Scholar] [CrossRef]

- Yang, Z.; Vigen, A. Design and Synthesis of Single-Actuator Walking Robots via Coupling of Linkages. Front. Mech. Eng. 2020, 6, 609340. [Google Scholar] [CrossRef]

- Chavdarov, I.; Naydenov, B. Design and kinematics of a 3-D printed walking robot Big Foot, overcoming obstacles. Int. J. Adv. Robot. Syst. 2019, 16, 1329. [Google Scholar] [CrossRef]

- Otani, T.; Takanishi, A.; Nakamura, M.; Kimura, K. Optimization of Link Length Fitting between an Operator and a Robot with Digital Annealer for a Leader-Follower Operation. Robotics 2022, 11, 12. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics Modelling, Planning and Control; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-1-84996-634-4. Available online: https://link.springer.com/book/10.1007/978-1-84628-642-1 (accessed on 6 August 2024).

- Afshari, A.; Meghdari, A. New Jacobian Matrix and Equations of Motion for a 6 d.o.f Cable-Driven Robot. Int. J. Adv. Robot. Syst. 2007, 4, 8. [Google Scholar] [CrossRef]

- Jostein, L.; Damiano, V. Improved Jacobian matrix estimation applied to snake robots. Front. Robot. AI 2023, 10, 1190349. [Google Scholar] [CrossRef]

- Lenar, J. A new method for calculating the Jacobian for a robot manipulator. Robotica 1983, 1, 205–209. [Google Scholar] [CrossRef]

- Anisimov, D.; Deng, C.; Hormann, K. Subdividing Barycentric Coordinates. Comput. Aided Geom. Des. 2016, 43, 172–185. [Google Scholar] [CrossRef]

- Michael, S.F. Generalized Barycentric Coordinates and Applications; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Li, D.; Zhao, Q. Distributed Relative Localization Algorithms for Multi-Robot Networks: A Survey. Sensors 2023, 23, 2399. [Google Scholar] [CrossRef]

- Patiny, O. Design, Modelling and Tests of a Barycenter Offset Locomotion Mechanism for Cylindrical Robots. Preprints 2021, 2021030492. [Google Scholar] [CrossRef]

- Tingting, S.; Jinhao, L.; Jianli, W.; Jianting, Z. A Barycenter Control Method for the Bioinspired Forest Chassis Robot on Slope. Hindawi J. Robot. 2021, 2021, 5528746. [Google Scholar] [CrossRef]

- Raucent, B.; Campion, G.; Bastin, G.; Samin, J.C.; Willems, P.Y. On the identification of the barycentric parameters of robot manipulators from external measurements. In Proceedings of the 1991 IEEE International Conference on Robotics and Automation, Sacramento, CA, USA, 6 August 1991; Volume 2, pp. 1169–1174. [Google Scholar] [CrossRef]

- Chavdarov, I. Kinematics and Force Analysis of a Five-Link Mechanism by the Four Spaces Jacoby Matrix. Probl. Eng. Cybern. Robot. 2005, 55, 21. [Google Scholar]

- Shin, H.; Lee, D. A New Decoupling Method for Explicit Stiffness Analysis of Kinematically Redundant Planar Parallel Kinematic Mechanism. Math. Probl. Eng. 2015, 2015, 957269. [Google Scholar] [CrossRef]

- Cemal, F.; Hayrettin, C. Real time controlled two dof five bar robot manipulator. In Proceedings of the International Symposium of Mechanism and Machine Science, Baku, Azerbaijan, 11–14 September 2017. [Google Scholar]

- Vathan, L.B.; Kumar, H.; Brighton, I.; John, H. Kinematic Analysis of Five-Bar Mechanism in Industrial Robotics. In Proceedings of the International Conference on Advances in Design & Manufacturing, Tamil Nadu, India, 5–7 December 2014; National Institute of Technology—India: Tiruchirappalli, India, 2014. [Google Scholar]

- Shen, H.; Liu, Y.; Wu, H.; Hu, C.; Wang, S. Forward and Inverse Kinematics for a Novel Double Scara Robot. IOP Conf. Ser. Earth Environ. Sci. 2018; 170, 042088. [Google Scholar] [CrossRef]

- Campos, L.; Bourbonnais, F.; Bonev, I.; Bigras, P. Development of a Five-bar Parallel Robot with Large Workspace. In Proceedings of the ASME 2010 International Design Engineering Technical Conferences &Computers and Information in Engineering Conference IDETC/CIE, Montreal, QC, Canada, 15–18 August 2010. [Google Scholar]

- Coman, G.C.; Serban, C.; Nicolescu, A.F. Virtual prototyping, physical structure development and PC control of a double arm (five link) SCARA robot. IOP Conf. Ser. Mater. Sci. Eng. 2019, 591, 012075. [Google Scholar] [CrossRef]

- Lou, Y.; Liu, G.; Li, Z. Randomized Optimal Design of Parallel Manipulators. IEEE Trans. Autom. Sci. Eng. 2008, 5, 223–233. [Google Scholar] [CrossRef]

- Tien, D.; Hee-Jun, K.; Quang, V. A method for optimal kinematic design of five-bar planar parallel manipulators. In Proceedings of the 2013 International Conference on Control, Automation and Information Sciences (ICCAIS), Nha Trang, Vietnam, 25–28 November 2013; pp. 7–11. [Google Scholar] [CrossRef]

- Bonev, I. User’s Manual for the DexTAR Five-Bar Parallel Robot. Mecademic. 2015. Available online: https://www.mitsubishielectric.com/fa/products/rbt/robot/pmerit/micro/spec.html (accessed on 7 August 2024). [CrossRef]

- Chavdarov, I.; Naydenov, B. Algorithm for Determining the Types of Inverse Kinematics Solutions for Sequential Planar Robots and Their Representation in the Configuration Space. Algorithms 2022, 15, 469. [Google Scholar] [CrossRef]

- Chaparro-Rico, B.D.M.; Cafolla, D.; Ceccarelli, M.; Castillo-Castaneda, E. NURSE-2 DoF Device for Arm Motion Guidance: Kinematic, Dynamic, and FEM Analysis. Appl. Sci. 2020, 10, 2139. [Google Scholar] [CrossRef]

- Bourbonnais, F.; Bigras, P.; Bonev, I.A. Minimum-Time Trajectory Planning and Control of a Pick-and-Place Five-Bar Parallel Robot. IEEE/ASME Trans. Mechatron. 2015, 20, 740–749. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Russo, M.; Cafolla, D.; Chaparro-Rico, B.D.M. Operation Safety of a 2-DoF Planar Mechanism for Arm Rehabilitation. Inventions 2021, 6, 85. [Google Scholar] [CrossRef]

- Kavala, D.; Yildiz, A.; Kopmaz, O. Optimal Design of a Five-Bar Planar Manipulator and Its Controller by Using Different Algorithms for Minimum Shaking Forces and Moments for the Largest Trajectory in a Usable Workspace. Machines 2022, 10, 971. [Google Scholar] [CrossRef]

| n | Literary Source | Robot Link Lengths [m] | [m] | Point in RLBS (Calculated from Equation (7)) | |

|---|---|---|---|---|---|

| [24,31] | 1.195 | 0.31 | |||

| [20,23] | 5 | 0.34 | |||

| [25] | 0.97 | 0.39 | |||

| [29,30] | 0.72 | 0.79 | |||

| [21] | 0.119 | 0.38 | |||

| RP-1AH [28] | 0.565 | 0.41 | |||

| RP-3AH [28] | 0.765 | 0.49 | |||

| RP-5AH [28] | 1.005 | 0.57 | |||

| [27] | [0.68; 1;1.9721;1.9721;1] | 6.6242 | 0.44 | ||

| 0.26 | 0.16 | ||||

| [32] | [0.222; 0.189; 0.165; 0.164; 0.196] | 0.936 | 0.27 |

| Configuration (Point in Configuration Space) | Designation | Point in RLBS | Designation | |

|---|---|---|---|---|

| Description | Defines the relative position of the robot’s links. Represented by a vector. | Defines a set of robots with the same ratio between the lengths of their links. Represented by a vector. | ||

| Configuration space | Designation C | RLBS | Designation D | |

| Description | n—dimensional parallelepiped, where n is equal to the number of DoFs of the robot (usually coincides with the number of its motors). If there are obstacles in the workspace C is divided into free workspace— and workspace, occupied by obstacles—. It is useful for controlling robots. | Part of an n-dimensional plane in which the mechanism is defined. n is equal to the number of robot links. D is divided into regions in which link ratios with similar kinematic properties are defined. It is useful for designing robots. | ||

| Limits of the configuration space | Limits of the RLBS | |||

| Description | Determined by the joints’ limits. | Determined by conditions for assembling the mechanism and the requirement for positive dimensions of the links. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chavdarov, I. Application of Barycentric Coordinates and the Jacobian Matrix to the Analysis of a Closed Structure Robot. Robotics 2024, 13, 152. https://doi.org/10.3390/robotics13100152

Chavdarov I. Application of Barycentric Coordinates and the Jacobian Matrix to the Analysis of a Closed Structure Robot. Robotics. 2024; 13(10):152. https://doi.org/10.3390/robotics13100152

Chicago/Turabian StyleChavdarov, Ivan. 2024. "Application of Barycentric Coordinates and the Jacobian Matrix to the Analysis of a Closed Structure Robot" Robotics 13, no. 10: 152. https://doi.org/10.3390/robotics13100152

APA StyleChavdarov, I. (2024). Application of Barycentric Coordinates and the Jacobian Matrix to the Analysis of a Closed Structure Robot. Robotics, 13(10), 152. https://doi.org/10.3390/robotics13100152