Dual-Loop Control of Cable-Driven Snake-like Robots

Abstract

:1. Introduction

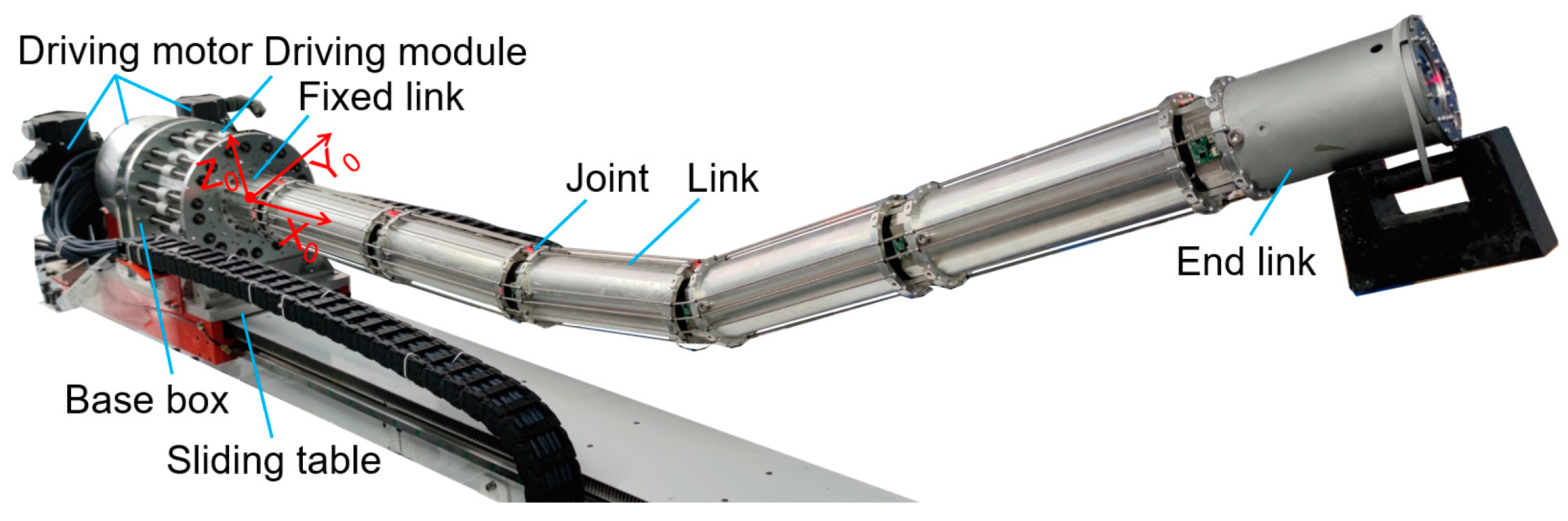

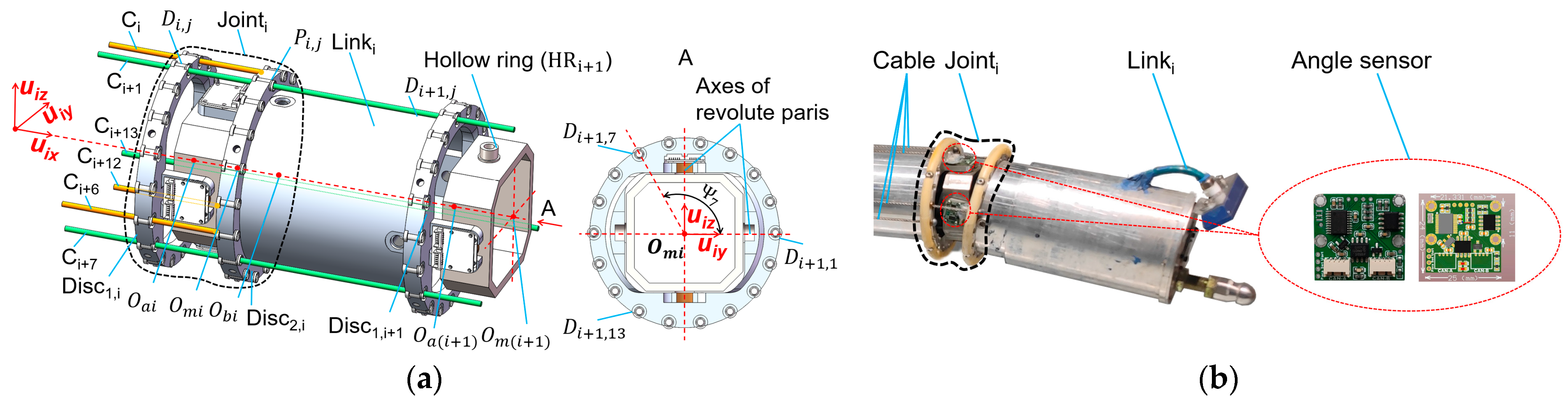

2. Mechanical Structure

3. Kinematics Modelling

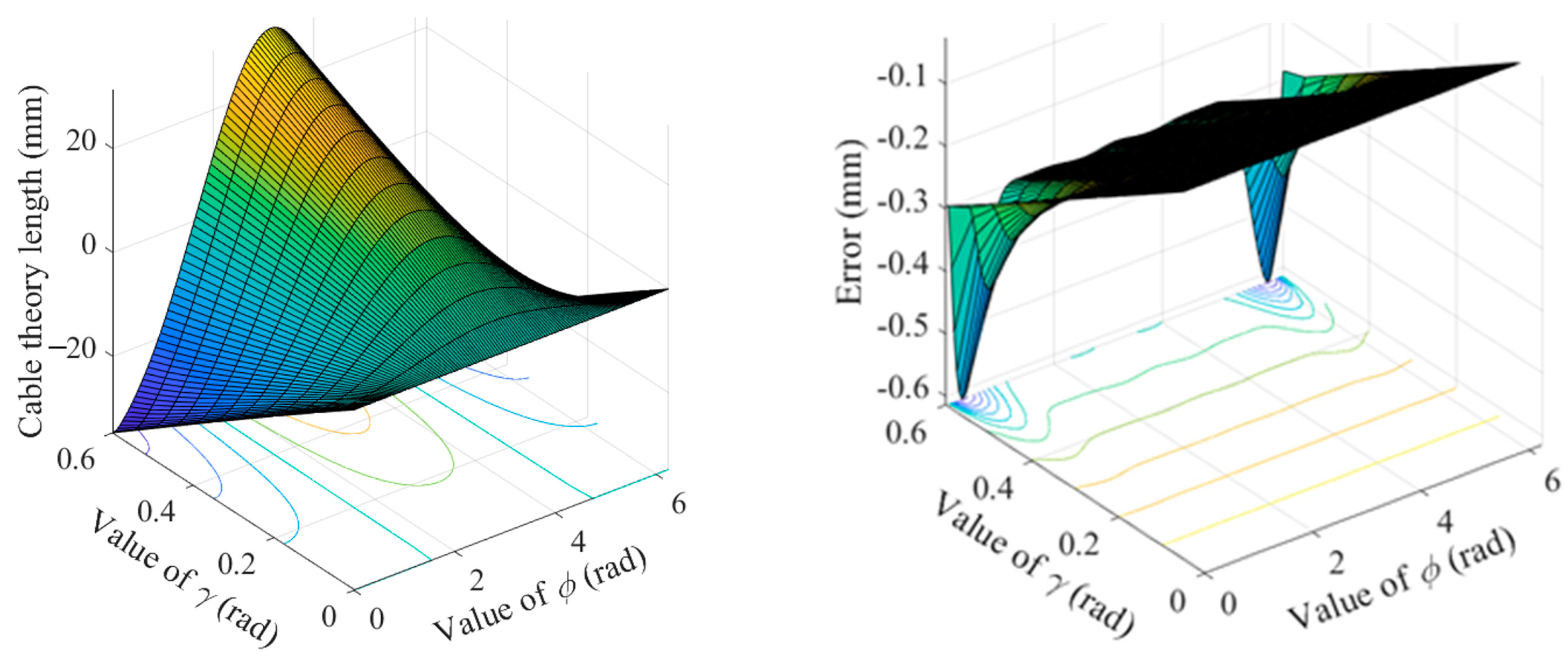

3.1. Mapping between Link Eigen Vectors and Cable Lengths

- (1)

- Every cable is tensioned. Then, the cables’ lengths are approximately equal to the distances between corresponding holes, so the inverse mapping method is the same as the first mapping method.

- (2)

- Two of the cables that drive the joint are tensioned, but the other is slack. Then, the two cables’ lengths are approximately equal to the distances between the corresponding holes. Thus, compared to the first mapping situation’s method, just the verification equation is canceled.

- (3)

- More than one of the cables is slack. In this case, the inverse mapping cannot be performed.

3.2. Mapping between Link Eigen Vectors and Joint Angles

- (1)

- Forward mapping, .

- (2)

- Inverse mapping, .

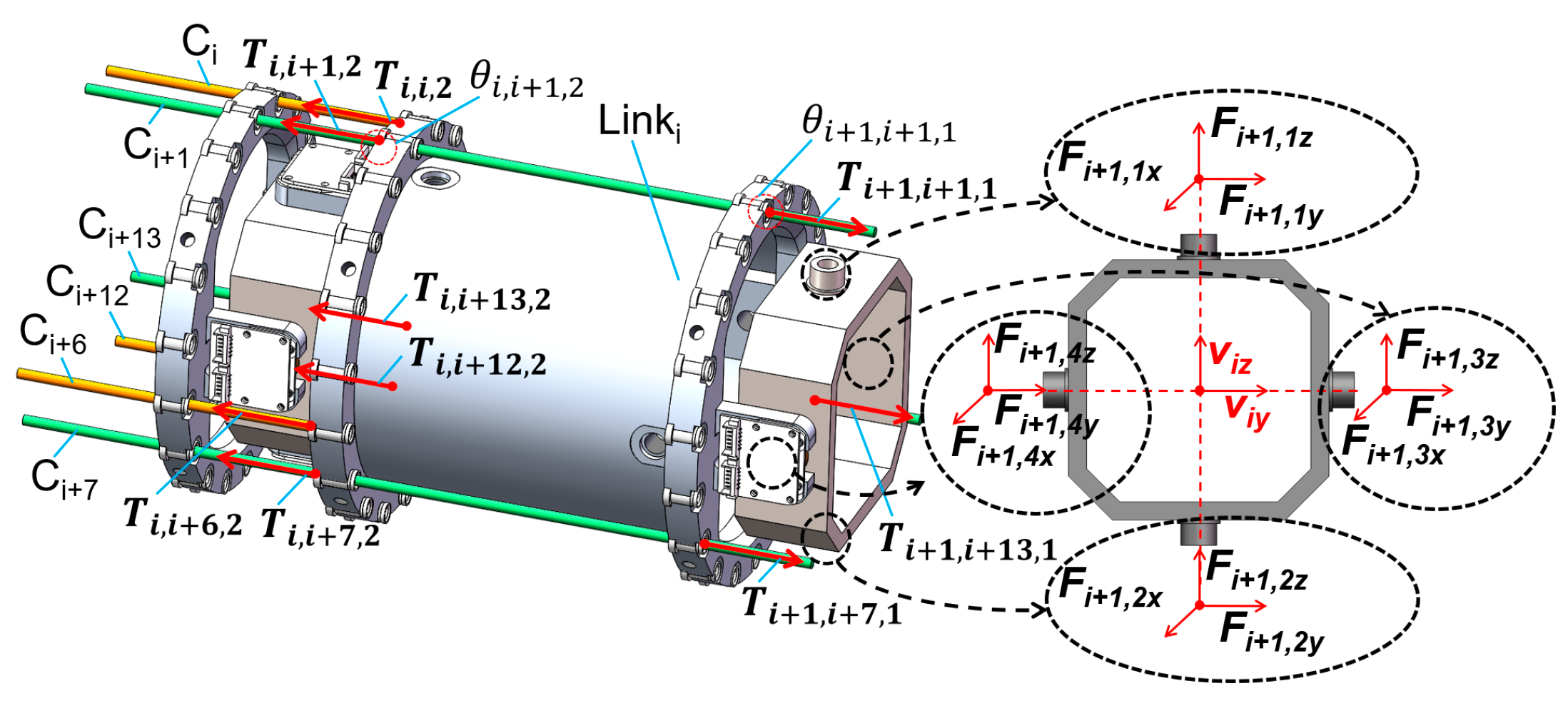

4. Inverse Dynamics

4.1. Mechanical Analysis

- (1)

- The acting forces from distal , . They can be decomposed into six forces with known action lines and directions, . The moment of them about is denoted as .

- (2)

- The acting forces from , . Similarly, they can also be decomposed into six forces with known action lines and directions, . The moment of them about is denoted as .

- (3)

- Gravity force, .

- (4)

- Inertia force and moment, .

- (1)

- The known cable forces from the cables which are fixed on . The moment of them about is denoted as .

- (2)

- The unknown cable forces from the cables which are fixed on . The moment of them about is denoted as .

- (3)

- The acting forces from distal , (if is the end link, the forces can be taken as environment forces). The moment of the forces about is set as .

- (4)

- The acting forces from proximal , . The moment of the forces about is denoted as .

- (5)

- Gravity force, . The moment of the force about is denoted as .

- (6)

- Inertia force and moment, , . The moment of about is denoted as .

4.2. Newton–Euler Method

5. Dual-Loop Control Strategy

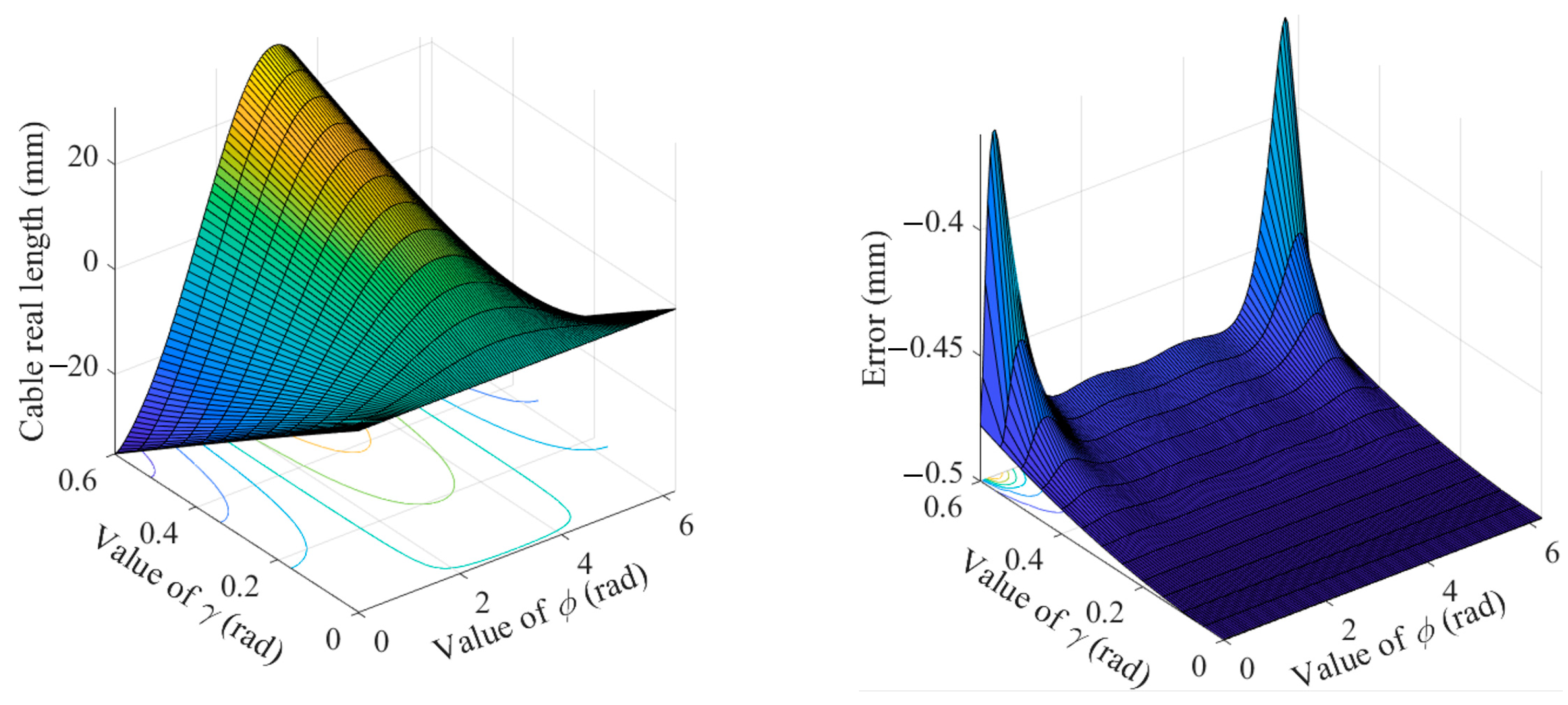

5.1. Errors Analysis

5.2. Practicability of Dual-Loop Control

- (1)

- According to the expected joint angle, the expected cable theory length is calculated. will be taken as cable real length and input into the CSR’s driving system.

- (2)

- According to , the motor moves to drive the joint.

- (3)

- According to the feedback joint angle , the feedback hole real distance is calculated.

- (4)

- According to , is updated to .

- (5)

- According to the updated , the motor moves to drive the joint.

- (6)

- and (7) The steps from (3) to (5) are executed in an endless loop.

5.3. Dual-Loop Control Strategy

6. Experimental Results and Discussion

6.1. Single Joint Test

6.2. Multiple Joints Test

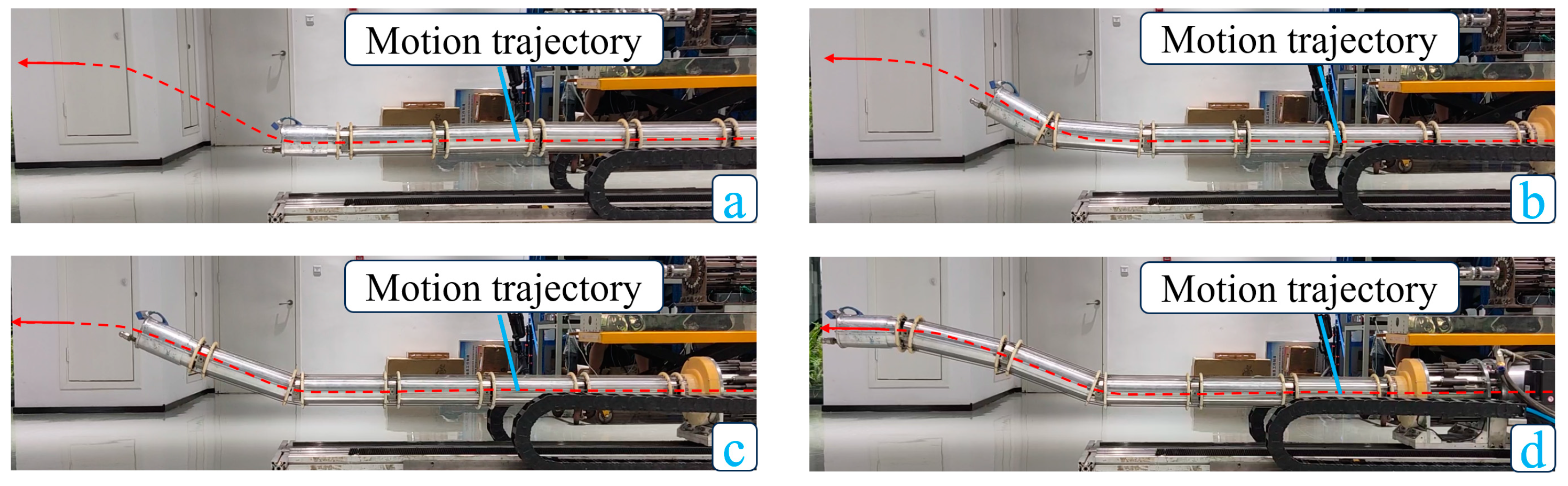

6.3. Continuous Motion Test

6.4. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chirikjian, G.S.; Burdick, J.W. An obstacle avoidance algorithm for hyper-redundant manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 625–631. [Google Scholar]

- Liu, T.; Xu, W.; Yang, T.; Li, Y. A hybrid active and passive cable-driven segmented redundant manipulator: Design, kinematics, and planning. IEEE/ASME Trans. Mechatron. 2021, 26, 930–942. [Google Scholar] [CrossRef]

- Chikhaoui, M.T.; Lilge, S.; Kleinschmidt, S.; Burgner-Kahrs, J. Comparison of modeling approaches for a tendon actuated continuum robot with three extensible segments. IEEE Robot. Automat. Lett. 2019, 4, 989–996. [Google Scholar]

- Liao, B.; Zang, H.; Chen, M.; Wang, Y.; Lang, X.; Zhu, N.; Yang, Z.; Yi, Y. Soft rod-climbing robot inspired by winding locomotion of snake. Soft Robot. 2020, 7, 500–511. [Google Scholar] [CrossRef] [PubMed]

- Hannan, M.W.; Walker, I.D. Kinematics and the implementation of an elephant’s trunk manipulator and other continuum style robots. J. Robot. Syst. 2003, 20, 45–63. [Google Scholar] [CrossRef]

- Kim, J.; Kwon, S.; Moon, Y.; Kim, K. Cable-movable rolling joint to expand workspace under high external load in a hyper-redundant manipulator. IEEE/ASME Trans. Mechatron. 2022, 27, 501–512. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum robots for medical applications: A survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Hong, W.; Xie, L.; Liu, J.; Sun, Y.; Li, K.; Wang, H. Development of a novel continuum robotic system for maxillary sinus surgery. IEEE/ASME Trans. Mechatron. 2018, 23, 1226–1237. [Google Scholar] [CrossRef]

- Xu, K.; Zhao, J.; Fu, M. Development of the SJTU unfoldable robotic system (SURS) for single port laparoscopy. IEEE/ASME Trans. Mechatron. 2015, 20, 2133–2145. [Google Scholar] [CrossRef]

- Buckingham, R.; Graham, A. Nuclear snake-arm robots. Ind. Rob. 2012, 39, 6–11. [Google Scholar] [CrossRef]

- Tonapi, M.M.; Godage, I.S.; Walker, I.D. Next generation rope-like robot for in-space inspection. In Proceedings of the 2014 IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2014; pp. 1–13. [Google Scholar]

- Chavan, P.; Murugan, M.; Unnikkannan, E.V.; Singh, A.; Phadatare, P. Modular snake robot with mapping and navigation: Urban search and rescue robot. In Proceedings of the 2015 International Conference on Computing Communication Control and Automation, Pune, India, 26–27 February 2015. [Google Scholar]

- Tsukagoshi, H.; Kitagawa, A.; Segawa, M. Active hose: An artificial elephant’s nose with maneuverability for rescue operation. In Proceedings of the IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; pp. 2454–2459. [Google Scholar]

- Naccarato, F.; Hughes, P.C. Inverse kinematics of variable-geometry truss manipulators. J. Robot. Syst. 1991, 8, 249–266. [Google Scholar] [CrossRef]

- Chirikjian, G.S.; Burdick, J.W. A geometric approach to hyper-redundant manipulator obstacle avoidance. J. Mech. Des. 1992, 114, 580–585. [Google Scholar] [CrossRef]

- Chirikjian, G.S.; Burdick, J.W. A modal approach to hyper-redundant manipulator kinematics. IEEE Trans. Robot. Autom. 1994, 10, 343–354. [Google Scholar] [CrossRef]

- Xie, H.; Wang, C.; Li, S.; Hu, L.; Yang, H. A geometric approach for follow-the-leader motion of serpentine manipulator. Int. J. Adv. Robot. Syst. 2019, 16, 172988141987463. [Google Scholar] [CrossRef]

- Sreenivasan, S.; Goel, P.; Ghosal, A. A real-time algorithm for simulation of flexible objects and hyper-redundant manipulators. Mech. Mach. Theory 2010, 45, 454–466. [Google Scholar] [CrossRef]

- Aristidou, A.; Lasenby, J. FABRIK: A fast, iterative solver for the Inverse Kinematics problem. J. Robot. Syst. 2011, 73, 243–260. [Google Scholar] [CrossRef]

- Rodriguez, G. Kalman filtering, smoothing, and recursive robot arm forward and inverse dynamics. IEEE J. Rob. Autom. 1987, 3, 624–639. [Google Scholar] [CrossRef]

- Falkenhahn, V.; Mahl, T.; Hildebrandt, A.; Neumann, R.; Sawodny, O. Dynamic modeling of bellows-actuated continuum robots using the Euler–Lagrange formalism. IEEE Trans. Robot. 2015, 31, 1483–1496. [Google Scholar] [CrossRef]

- Campisano, F.; Caló, S.; Remirez, A.; Chandler, J.; Obstein, K.; Webster, R.; Valdastri, P. Closed-loop control of soft continuum manipulators under tip follower actuation. Int. J. Robot. Res. 2021, 40, 923–938. [Google Scholar] [CrossRef]

- Xu, W.; Liu, T.; Li, Y. Kinematics, dynamics, and control of a cable-driven hyper-redundant manipulator. IEEE/ASME Trans. Mechatron. 2018, 23, 1693–1704. [Google Scholar] [CrossRef]

- Li, W.; Huang, X.; Yan, L.; Cheng, H.; Liang, B.; Xu, W. Force sensing and compliance control for a cable-driven redundant manipulator. IEEE/ASME Trans. Mechatron. 2023, 1–12. [Google Scholar] [CrossRef]

- Tran, L.D.; Zhang, Z.; Yeo, S.H.; Sun, Y.C.; Yang, G.L. Control of a cable-driven 2-DOF joint module with a flexible backbone. In Proceedings of the IEEE Conference on Sustainable Utilization and Development in Engineering and Technology (STUDENT), Semenyih, Malaysia, 20–21 October 2011; pp. 150–155. [Google Scholar]

- Sun, Z.; Wang, Z.; Phee, S.J. Modeling and motion compensation of a bidirectional tendon-sheath actuated system for robotic endoscopic surgery. Comput. Methods Programs Biomed. 2015, 119, 77–87. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Zhang, Y.; Huang, F.; Li, J.; Chen, Z.; Song, W.; Zhu, S.; Gu, J. Design and kinematic control of the cable-driven hyper-redundant manipulator for potential underwater applications. Appl. Sci. 2019, 9, 1142. [Google Scholar] [CrossRef]

- Roesthuis, R.J.; Misra, S. Steering of multisegment continuum manipulators using rigid-link modeling and FBG-based shape sensing. IEEE Trans. Robot. 2016, 32, 372–382. [Google Scholar] [CrossRef]

- Park, Y.-L.; Ryu, S.C.; Black, R.J.; Chau, K.K.; Moslehi, B.; Cutkosky, M.R. Exoskeletal force-sensing end-effectors with embedded optical fiber-Bragg-grating sensors. IEEE Trans. Robot. 2009, 25, 1319–1331. [Google Scholar] [CrossRef]

- Bajo, A.; Simaan, N. Hybrid motion/force control of multi-backbone continuum robots. Int. J. Robot. Res. 2016, 35, 422–434. [Google Scholar] [CrossRef]

- Xu, X.; Xie, H.; Wang, C.; Yang, H. Kinematic and dynamic models of hyper -redundant manipulator based on link eigenvectors. IEEE/ASME Trans. Mechatron. 2023, 1–13. [Google Scholar] [CrossRef]

| Controller Name | Property | Value |

|---|---|---|

| Force controller | (mm/N) | 1.67 × 10−5 |

| (mm/N) | 0.5 | |

| (mm) | Within 0.02 | |

| Position controller | 0.04 | |

| 0.5 | ||

| (mm) | Within 0.02 | |

| PID controller | Value of ’s element | 0.5–1.5 |

| Value of ’s element | 0.1–0.5 | |

| Value of ’s element | 0.1–0.3 | |

| 0.01 |

| Reference Angles | Feedback Angles | ||

|---|---|---|---|

| Open-Loop | Single-Loop | Dual-Loop | |

| Reference Angles | Feedback Angles | ||

|---|---|---|---|

| Open-Loop | Single-Loop | Dual-Loop | |

| Reference Angles | Feedback Angles | ||

|---|---|---|---|

| Open-Loop | Single-Loop | Dual-Loop | |

| Reference Angles | Feedback Angles | ||

|---|---|---|---|

| Open-Loop | Single-Loop | Dual-Loop | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Wang, C.; Xie, H.; Wang, C.; Yang, H. Dual-Loop Control of Cable-Driven Snake-like Robots. Robotics 2023, 12, 126. https://doi.org/10.3390/robotics12050126

Xu X, Wang C, Xie H, Wang C, Yang H. Dual-Loop Control of Cable-Driven Snake-like Robots. Robotics. 2023; 12(5):126. https://doi.org/10.3390/robotics12050126

Chicago/Turabian StyleXu, Xiantong, Chengzhen Wang, Haibo Xie, Cheng Wang, and Huayong Yang. 2023. "Dual-Loop Control of Cable-Driven Snake-like Robots" Robotics 12, no. 5: 126. https://doi.org/10.3390/robotics12050126

APA StyleXu, X., Wang, C., Xie, H., Wang, C., & Yang, H. (2023). Dual-Loop Control of Cable-Driven Snake-like Robots. Robotics, 12(5), 126. https://doi.org/10.3390/robotics12050126