A Backstepping Approach to Nonlinear Model Predictive Horizon for Optimal Trajectory Planning

Abstract

:1. Introduction

- Absence or limited consideration of the internal and external constraints imposed by the system and dynamic environment;

- Lack of repeatability in generating trajectories between a starting and ending configuration for a fixed initial vehicle state and environment scenario;

- Computational inefficiency in regenerating paths while moving between the start and terminal point;

- For some approaches, generating non-smooth paths that lead to jerky motions and create inefficiency in the vehicle’s power draw [23].

- Implementing the BSC method within NMPH to compensate for nonlinearities in order to reduce the non-convexity of the trajectory generation optimization problem;

- Demonstrating the versatility of the NMPH-BSC approach by using both a simplified and a higher-fidelity dynamics model of the drone;

- Using the NMPH optimization problem to predict both the reference trajectory as well as its rates of change for the onboard flight trajectory controller;

- Validating and evaluating the performance of the proposed approach in both simulation and hardware drone flight experiments.

2. Problem Formulation

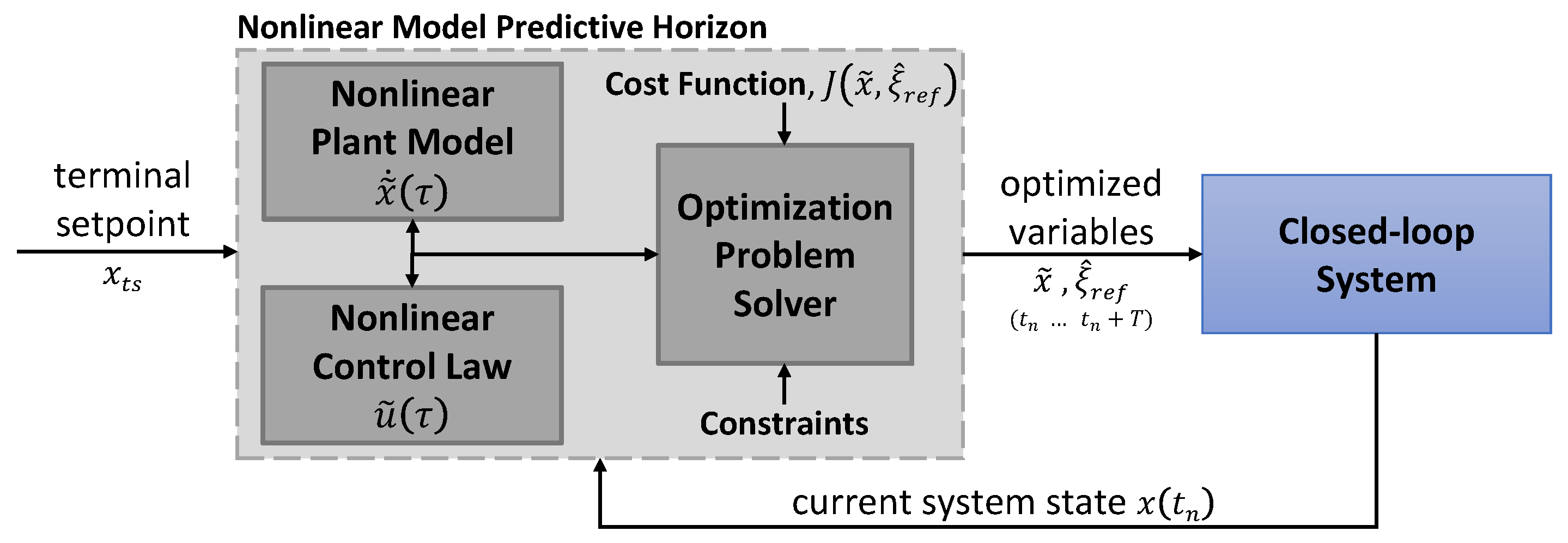

2.1. Nonlinear Model Predictive Horizon

- (1)

- Measure or estimate the current state of the actual closed-loop system;

- (2)

- Predict and by minimizing the cost function over the prediction horizon subject to the system dynamics (2b), control law (2c), and assigned constraints (2e);

- (3)

- Use the estimated reference trajectory (or the predicted output trajectory , as both converge to each other) as the reference trajectory of the actual closed-loop system;

- (4)

- Repeat Steps 1–3 until the drone vehicle approaches the terminal setpoint or the optimization problem produces an infeasible solution.

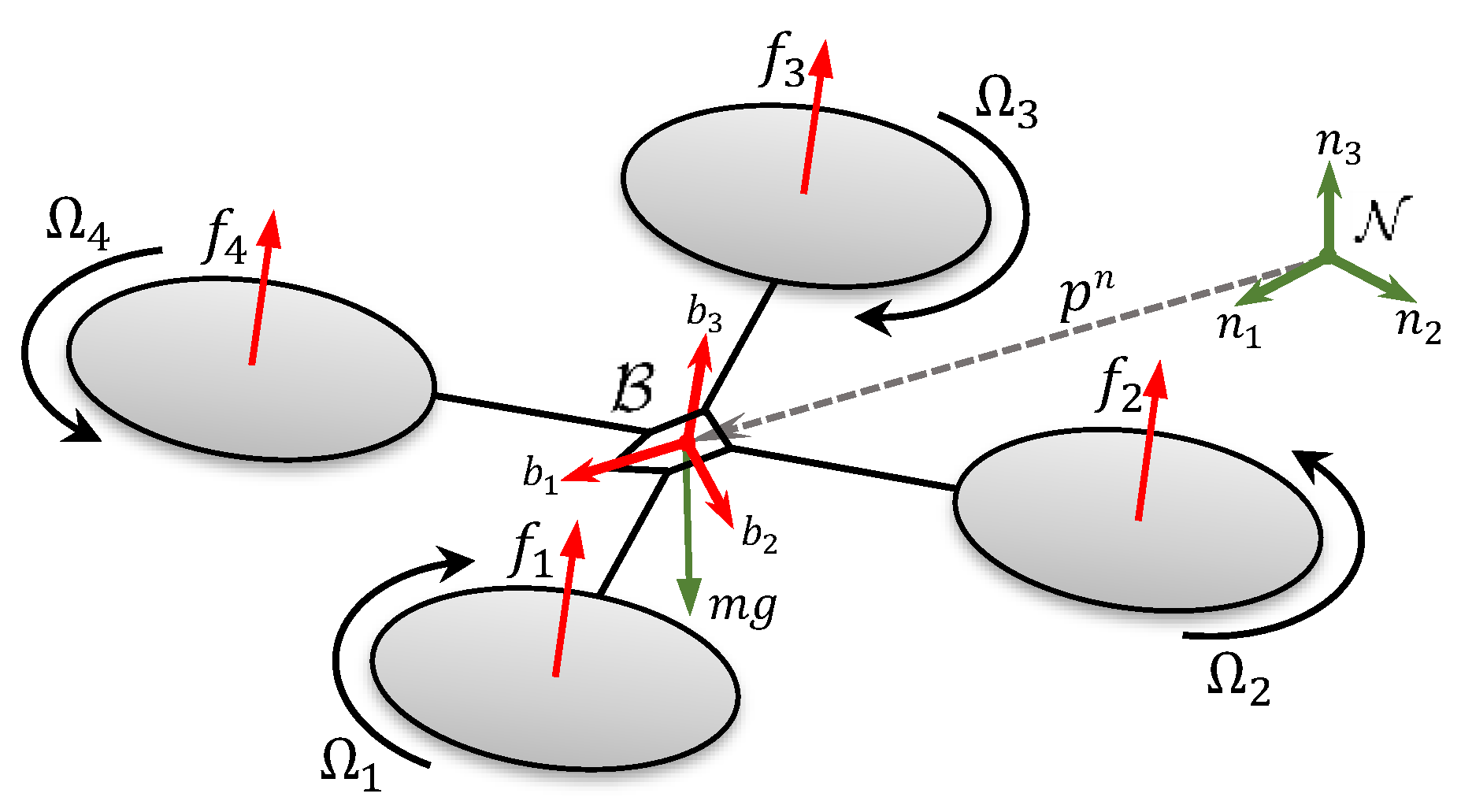

2.2. Drone Dynamics

2.3. Backstepping Control Design

2.4. Backstepping Control Law Integration within NMPH

- Associate the total thrust u and the desired roll and pitch angles , from (44) with and

- Associate the input torques , and from (29) with and , .

- Let be (2c) in the NMPH optimization problem, a function of the NMPH states and the estimated reference trajectories , where

- Solve the optimization problem (2), which leads to the prediction of the system states and the estimated reference trajectories . The latter is used as the reference trajectory for the actual closed-loop system.

3. Evaluation of NMPH-BSC

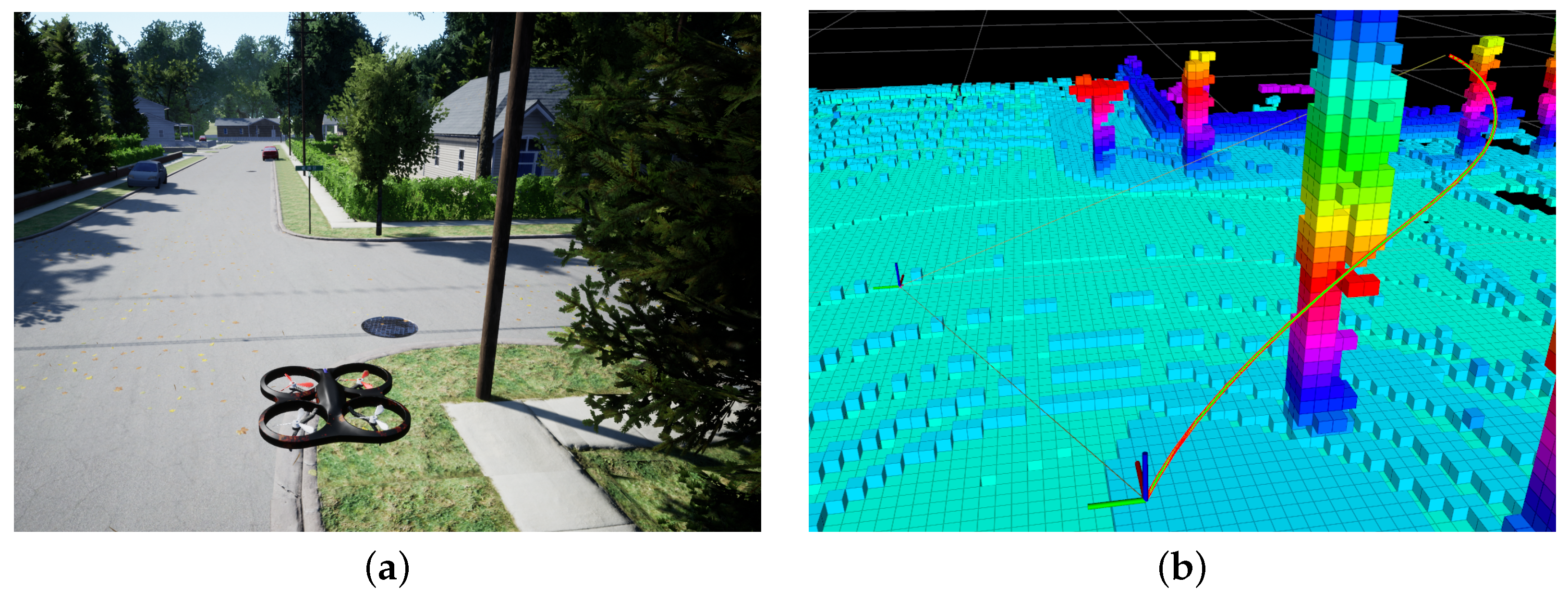

3.1. Simulation Environment

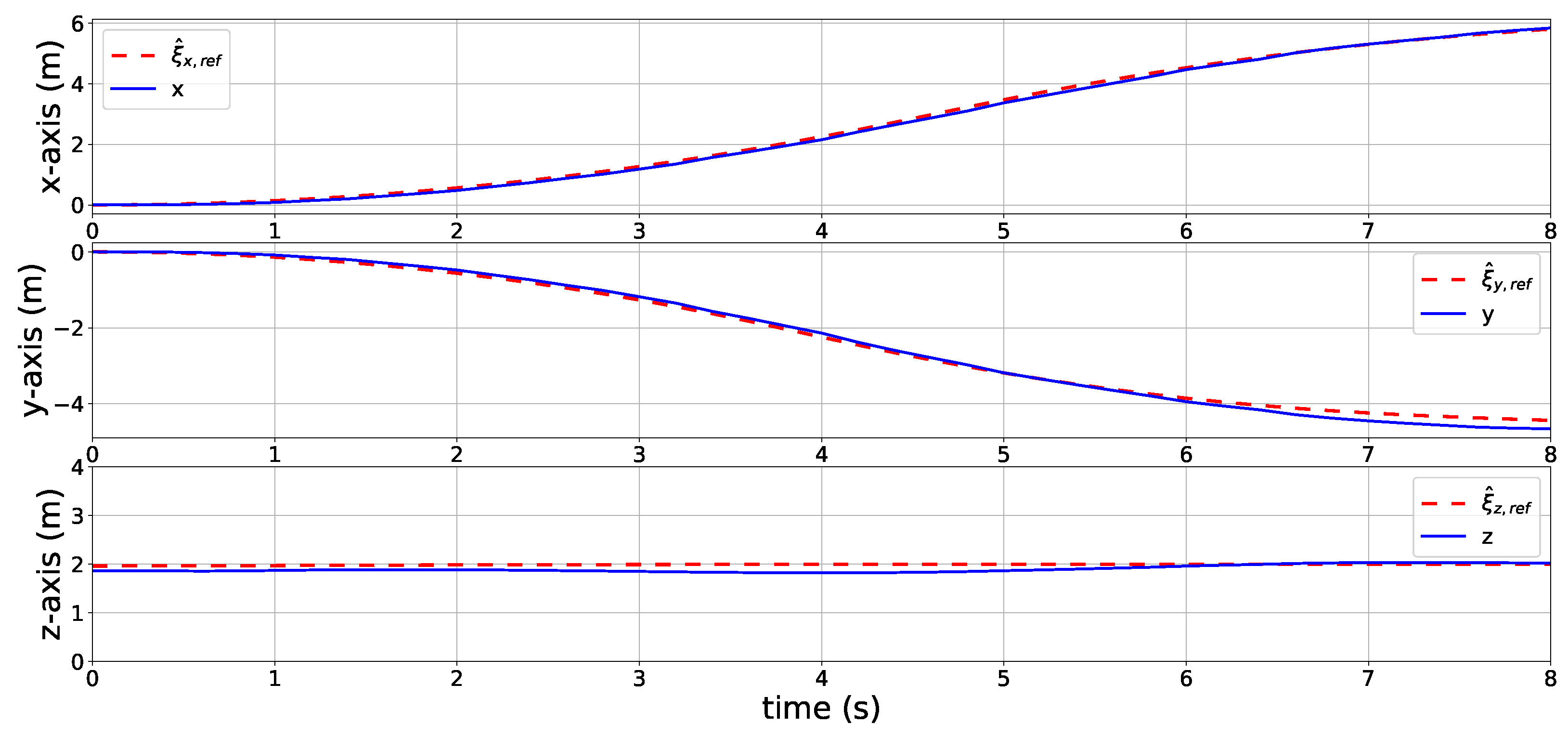

3.1.1. Trajectory Planning

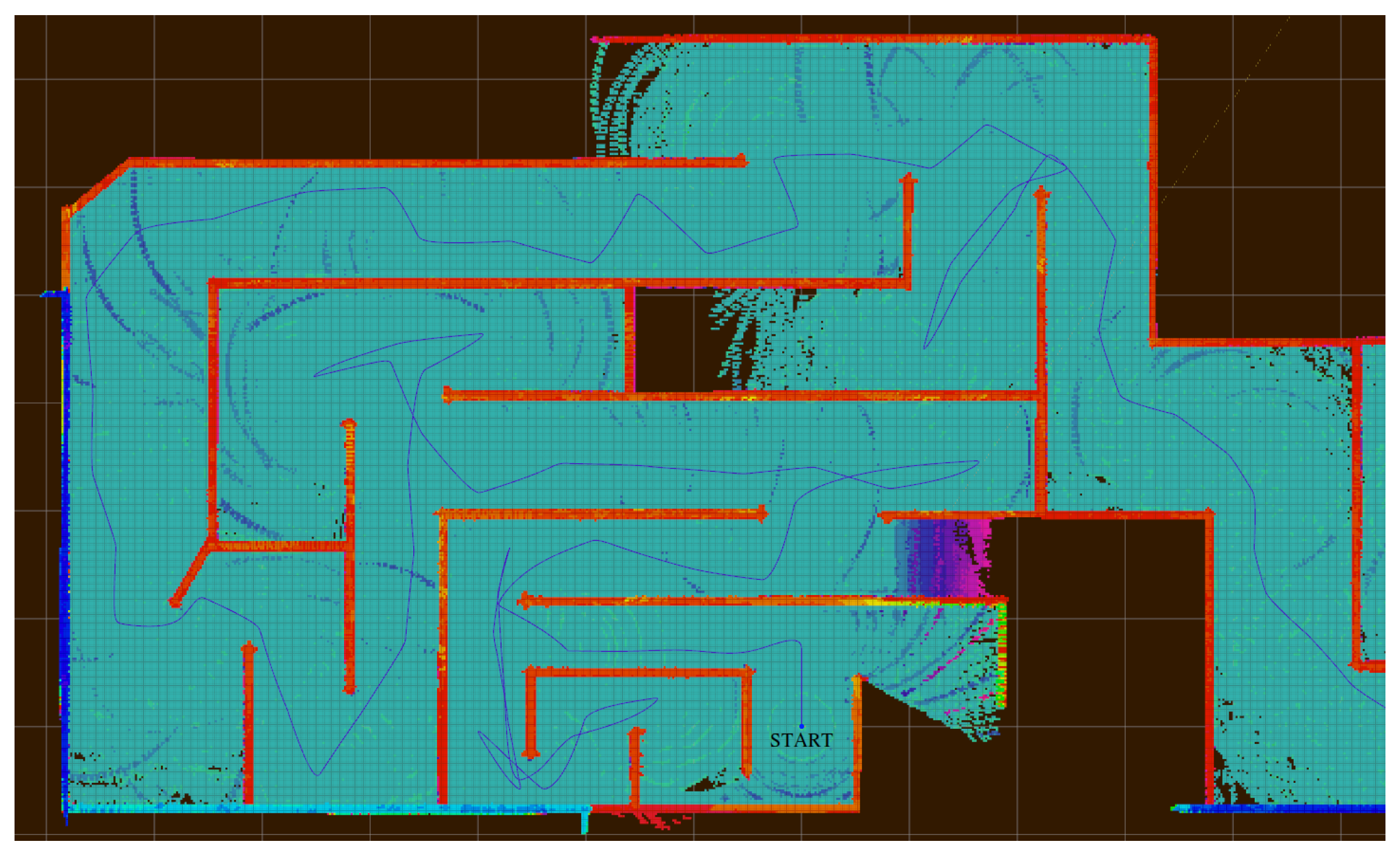

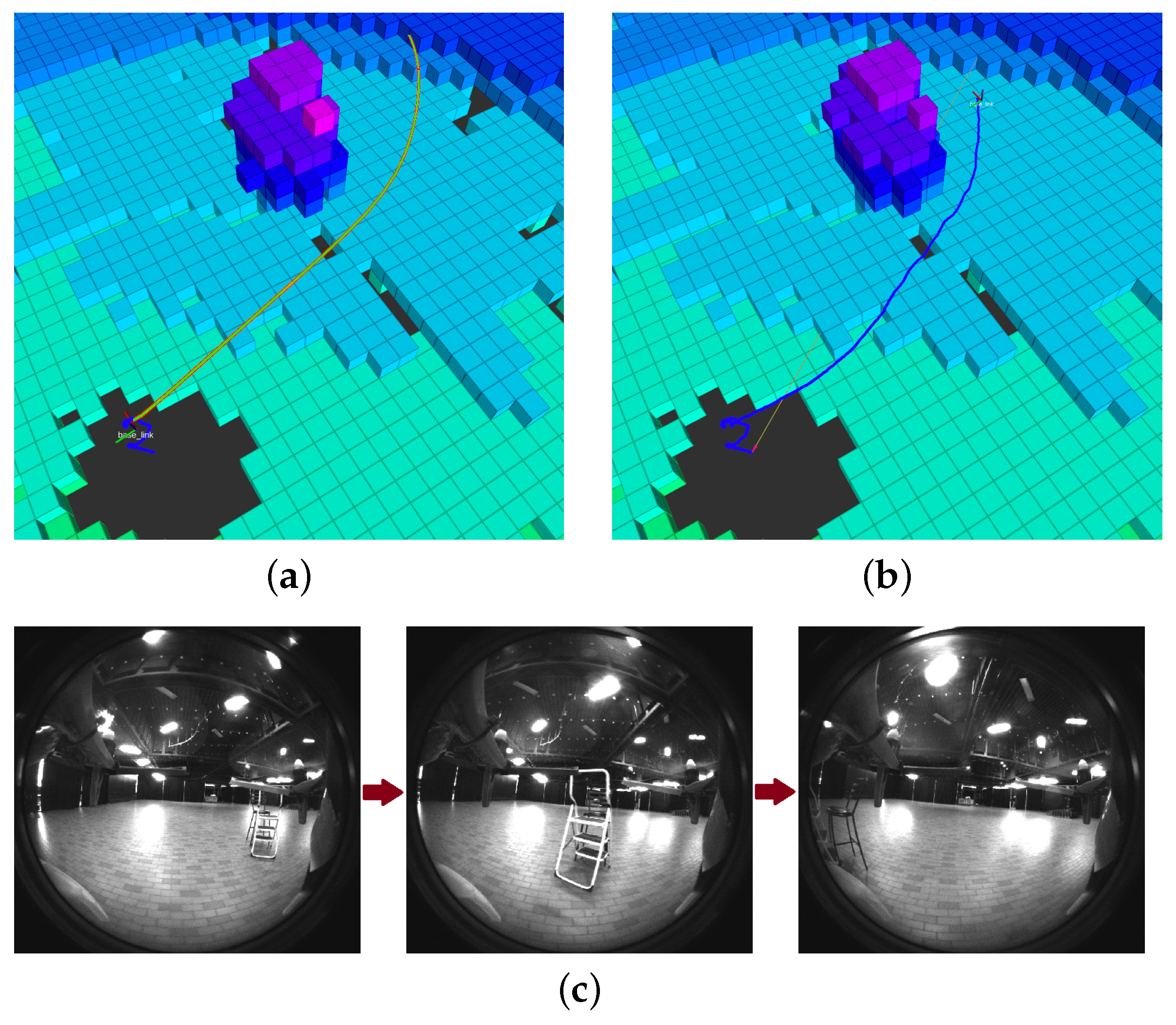

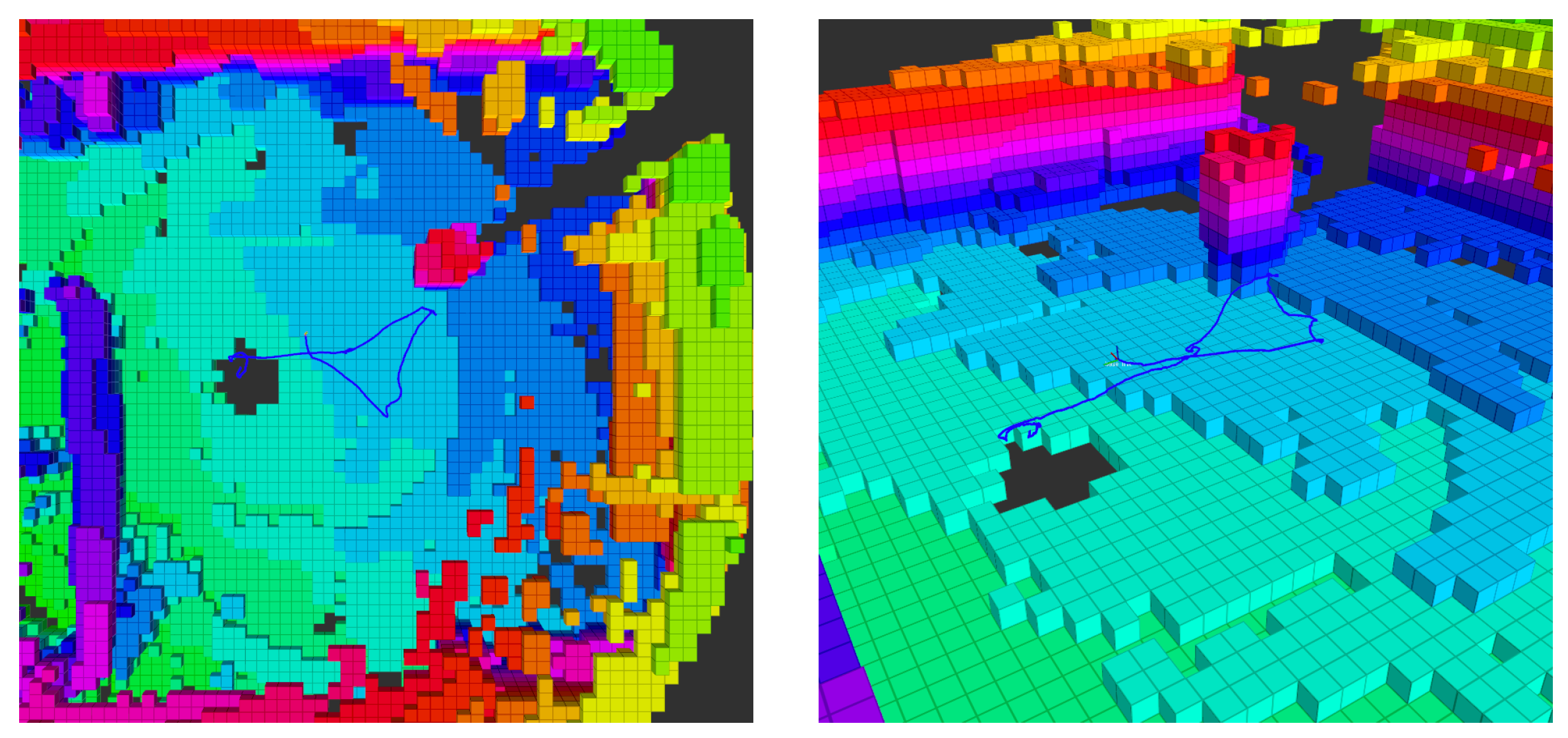

3.1.2. Exploration of Unknown Environment

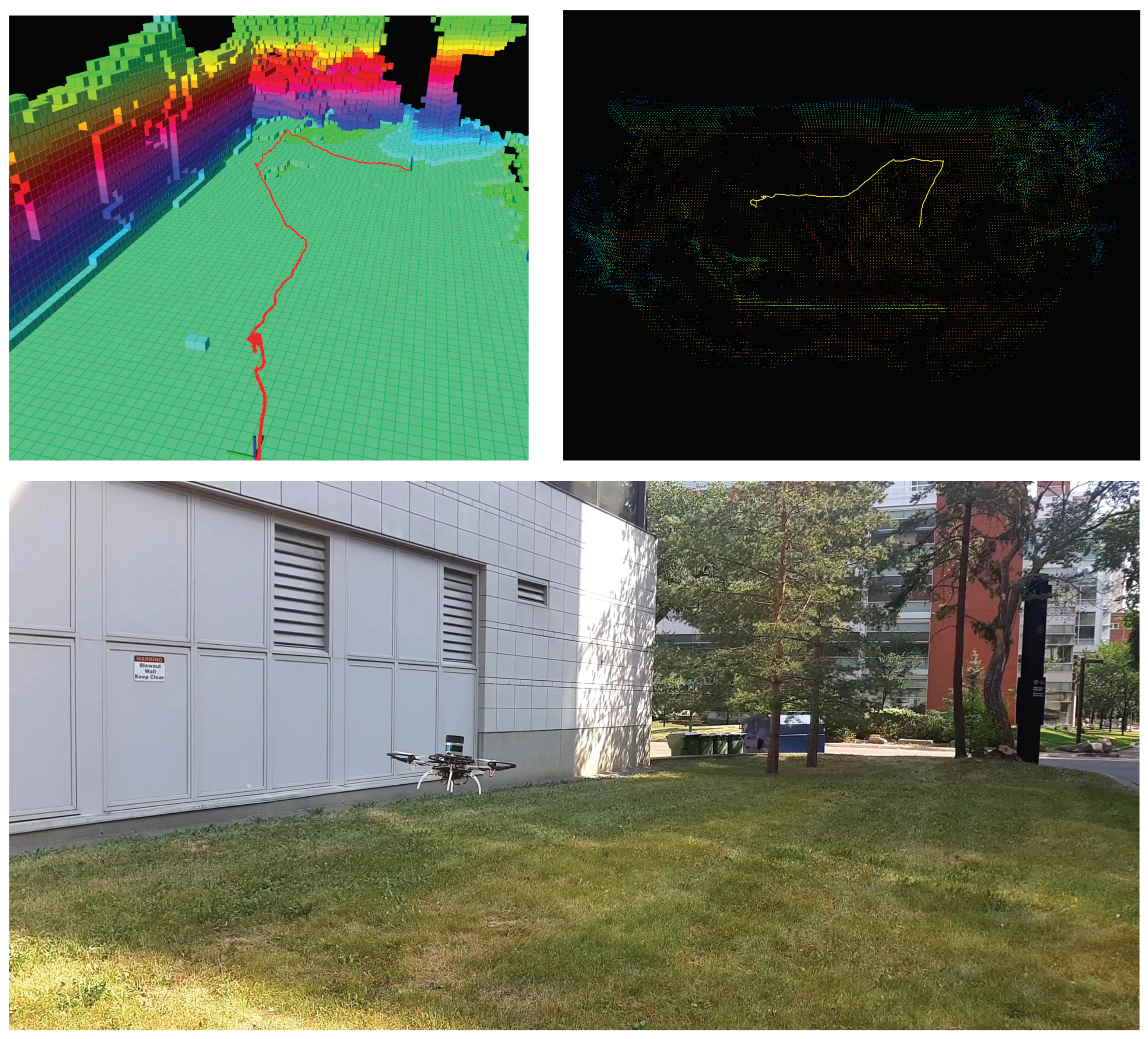

3.2. Hardware Flight Experiments

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Variable | Meaning |

| x, u, | System state, input and output vectors |

| X, U, | State, input and output spaces |

| Vector with k real-valued entries | |

| Reference (output) trajectory | |

| f, h, g | System dynamics, system output and feedback maps |

| Stabilization setpoint | |

| , , | Predicted state, input and output trajectories |

| Estimated reference trajectory | |

| Sampling time | |

| Error tolerance | |

| L, E | Stage and terminal cost functions |

| , , | State, input and output constraint sets |

| T | Prediction horizon |

| , , | State, output and terminal cost weighting matrices |

| ith obstacle constraint | |

| , | Navigation and body-fixed frame |

| , | Navigation and body frame basis vectors |

| SE(3), SO(3) | Special Euclidean and Special Orthogonal groups |

| Rotation matrix of relative to | |

| Position vector of vehicle’s frame origin relative to | |

| Vector of three Euler angles | |

| Roll, pitch and yaw Euler angles | |

| , , | Sine, cosine and tangent of angle |

| Set of integers | |

| , | Translational velocity vectors in frame and coordinates |

| Angular velocity vector in frame coordinates | |

| W | Transformation matrix (6) |

| Map from 3-element vector to skew-symmetric matrix | |

| Lie algebra associated to | |

| m | Mass of drone |

| , u | Thrust of ith propeller, total thrust |

| Torque about axis | |

| g | Acceleration due to gravity |

| , , | Thrust, torque and gravity vectors in (8) |

| Mass moment of inertia matrix of drone | |

| Rotational inertia of propeller | |

| Angular velocity of ith propeller | |

| Translational drag coefficient matrix | |

| Rotational drag coefficient matrix | |

| Desired Euler angles | |

| Tracking error vectors | |

| , | Vectors (24), (39), (45), (49) |

| Lyapunov function candidates | |

| Virtual control vectors | |

| Virtual inputs of the rotational subsystem | |

| , , , | Positive-definite diagonal gain matrices |

| , | Actual and desired position vectors of drone |

| Acronym | Meaning |

| GPS | Global Positioning System |

| LPA* | Lifelong Planning A* |

| ARA* | Anytime Reparing A* |

| PRM | Probabilistic Road-Map |

| RRT | Rapidly-Exploring Random Tree |

| RRG | Rapidly-Exploring Random Graph |

| ANN | Artificial Neural Network |

| GA | Genetic Algorithm |

| ACO | Ant Colony Optimization |

| PSO | Particle Swarm Optimization |

| SA | Simulated Annealing |

| CHOMP | Covariant Hamiltonian Optimization for Motion Planning |

| STOMP | Stochastic Trajectory Optimization for Motion Planning |

| NMPH | Nonlinear Model Predictive Horizon |

| BSC | Backstepping Control |

| FBL | Feedback Linearization |

| NMPC | Nonlinear Model Predictive Control |

| ENU | East, North, Up |

| ROS | Robot Operating System |

| NLP | Nonlinear Programming |

| SQP | Sequential Quadratic Programming |

| LiDAR | Light Detection and Ranging |

References

- Bergman, K.; Ljungqvist, O.; Glad, T.; Axehill, D. An optimization-based receding horizon trajectory planning algorithm. IFAC-PapersOnLine 2020, 53, 15550–15557. [Google Scholar] [CrossRef]

- Manoharan, A.; Sharma, R.; Sujit, P.B. Multi-AAV Cooperative Path Planning using Nonlinear Model Predictive Control with Localization Constraints. arXiv 2022, arXiv:2201.09285. [Google Scholar]

- Wu, D.M.; Li, Y.; Du, C.Q.; Ding, H.T.; Li, Y.; Yang, X.B.; Lu, X.Y. Fast velocity trajectory planning and control algorithm of intelligent 4WD electric vehicle for energy saving using time-based MPC. IET Intell. Transp. Syst. 2019, 13, 153–159. [Google Scholar] [CrossRef]

- Gasparetto, A.; Boscariol, P.; Lanzutti, A.; Vidoni, R. Path planning and trajectory planning algorithms: A general overview. In Motion and Operation Planning of Robotic Systems; Carbone, G., Gomez-Bravo, F., Eds.; Springer: Cham, Switzerland, 2015; Volume 29, pp. 293–308. [Google Scholar]

- Dijkstra, E.W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Hart, P.E.; Nilsson, N.J.; Raphael, B. A formal basis for the heuristic determination of minimum cost paths. IEEE Trans. Syst. Sci. Cybern. 1968, 4, 100–107. [Google Scholar] [CrossRef]

- Koenig, S.; Likhachev, M. Fast replanning for navigation in unknown terrain. IEEE Trans. Robot. 2005, 21, 354–363. [Google Scholar] [CrossRef]

- Al-Mutib, K.; AlSulaiman, M.; Emaduddin, M.; Ramdane, H.; Mattar, E. D* lite based real-time multi-agent path planning in dynamic environments. In Proceedings of the 2011 Third International Conference on Computational Intelligence, Modelling & Simulation, Langkawi, Malaysia, 20–22 September 2011; pp. 170–174. [Google Scholar]

- Likhachev, M.; Gordon, G.J.; Thrun, S. ARA*: Anytime A* with provable bounds on sub-optimality. In Advances in Neural Information Processing Systems; Thrun, S., Saul, L.K., Schölkopf, B., Eds.; MIT Press: Cambridge, MA, USA, 2004; Volume 16, pp. 767–774. [Google Scholar]

- Dolgov, D.; Thrun, S.; Montemerlo, M.; Diebel, J. Path planning for autonomous vehicles in unknown semi-structured environments. Int. J. Robot. Res. 2010, 29, 485–501. [Google Scholar] [CrossRef]

- Siméon, T.; Laumond, J.P.; Nissoux, C. Visibility-based probabilistic roadmaps for motion planning. Adv. Robot. 2000, 14, 477–493. [Google Scholar] [CrossRef]

- LaValle, S.M.; Kuffner, J.J. Rapidly-Exploring Random Trees: Progress and Prospects. In Algorithmic and Computational Robotics: New Directions; Donald, B.R., Lynch, K.M., Rus, D., Eds.; CRC Press: Boca Raton, FL, USA, 2001; pp. 293–308. [Google Scholar]

- Karaman, S.; Frazzoli, E. Sampling-based algorithms for optimal motion planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Khatib, O. Real-Time Obstacle Avoidance for Manipulators and Mobile Robots. Int. J. Robot. Res. 1986, 5, 90–98. [Google Scholar] [CrossRef]

- Iswanto, I.; Ma’arif, A.; Wahyunggoro, O.; Cahyadi, A.I. Artificial Potential Field Algorithm Implementation for Quadrotor Path Planning. Int. J. Adv. Comput. Sci. Appl. 2019, 10, 575–585. [Google Scholar] [CrossRef] [Green Version]

- Martin, P.; del Pobil, A.P. Application Of Artificial Neural Networks To The Robot Path Planning Problem. In Applications of Artificial Intelligence in Engineering IX; Adey, R., Rzevski, G., Russell, D., Eds.; WIT Press: Southampton, UK, 1994; pp. 73–80. [Google Scholar]

- Zhao, M.; Ansari, N.; Hou, E.S.H. Mobile manipulator path planning by a genetic algorithm. J. Field Robot. 1994, 11, 143–153. [Google Scholar] [CrossRef]

- Wang, H.J.; Xiong, W. Research on global path planning based on ant colony optimization for AUV. J. Mar. Sci. Appl. 2009, 8, 58–64. [Google Scholar] [CrossRef]

- Qiaorong, Z.; Guochang, G. Path planning based on improved binary particle swarm optimization algorithm. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; pp. 462–466. [Google Scholar]

- Martinez-Alfaro, H.; Flugrad, D.R. Collision-free path planning for mobile robots and/or AGVs using simulated annealing. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, San Antonio, TX, USA, 2–5 October 1994; Volume 1, pp. 270–275. [Google Scholar]

- Zhang, H.Y.; Lin, W.M.; Chen, A.X. Path planning for the mobile robot: A review. Symmetry 2018, 10, 450. [Google Scholar] [CrossRef]

- Sands, T. Flattening the Curve of Flexible Space Robotics. Appl. Sci. 2022, 12, 2992. [Google Scholar] [CrossRef]

- LaValle, S.M. Planning Algorithms; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar]

- Zucker, M.; Ratliff, N.; Dragan, A.D.; Pivtoraiko, M.; Klingensmith, M.; Dellin, C.M.; Bagnell, J.A.; Srinivasa, S.S. CHOMP: Covariant Hamiltonian optimization for motion planning. Int. J. Robot. Res. 2013, 32, 1164–1193. [Google Scholar] [CrossRef]

- Kalakrishnan, M.; Chitta, S.; Theodorou, E.; Pastor, P.; Schaal, S. STOMP: Stochastic trajectory optimization for motion planning. In Proceedings of the 2011 IEEE international conference on robotics and automation, Shanghai, China, 9–13 May 2011; pp. 4569–4574. [Google Scholar]

- Sandberg, A.; Sands, T. Autonomous Trajectory Generation Algorithms for Spacecraft Slew Maneuvers. Aerospace 2022, 9, 135. [Google Scholar] [CrossRef]

- Al Younes, Y.; Barczyk, M. Nonlinear Model Predictive Horizon for Optimal Trajectory Generation. Robotics 2021, 10, 90. [Google Scholar] [CrossRef]

- Krstic, M.; Kokotovic, P.V.; Kanellakopoulos, I. Nonlinear and Adaptive Control Design; John Wiley & Sons, Inc.: New York, NY, USA, 1995. [Google Scholar]

- Vaidyanathan, S.; Azar, A.T. Backstepping Control of Nonlinear Dynamical Systems; Academic Press: San Diego, CA, USA, 2020. [Google Scholar]

- Zhou, J.; Wen, C. Adaptive Backstepping Control of Uncertain Systems: Nonsmooth Nonlinearities, Interactions or Time-Variations; Springer: Heidelberg, Germany, 2008. [Google Scholar]

- Fadhel, F.S.; Noaman, S.F. The Generalized Backstepping Control Method for Stabilizing and Solving Systems of Multiple Delay Differential Equations. Al-Nahrain J. Sci. 2018, 150–156. [Google Scholar] [CrossRef]

- Ye, Z.; Mohamadian, H. Nonlinear backstepping control of multibody aerodynamic systems with equational modeling. In Proceedings of the 2009 IEEE International Conference on Control and Automation, Christchurch, New Zealand, 9–11 December 2009; pp. 1775–1779. [Google Scholar]

- Marino, R.; Tomei, P. Nonlinear Control Design: Geometric, Adaptive, and Robust; Prentice Hall: Hoboken, NJ, USA, 1995. [Google Scholar]

- Al Younes, Y.; Barczyk, M. Optimal Motion Planning in GPS-Denied Environments Using Nonlinear Model Predictive Horizon. Sensors 2021, 21, 5547. [Google Scholar] [CrossRef]

- Murray, R.M.; Li, Z.; Sastry, S.S. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Madani, T.; Benallegue, A. Control of a quadrotor mini-helicopter via full state backstepping technique. In Proceedings of the 45th IEEE Conference on Decision and Control, San Diego, CA, USA, 13–15 December 2006; pp. 1515–1520. [Google Scholar]

- Al Younes, Y.; Drak, A.; Noura, H.; Rabhi, A.; Hajjaji, A.E. Quadrotor position Control using cascaded adaptive integral backstepping controllers. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2014; Volume 565, pp. 98–106. [Google Scholar]

- Bouabdallah, S.; Siegwart, R. Full control of a quadrotor. In Proceedings of the 2007 IEEE/RSJ international conference on intelligent robots and systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 153–158. [Google Scholar]

- Basri, M.A.M.; Husain, A.R.; Danapalasingam, K.A. Enhanced backstepping controller design with application to autonomous quadrotor unmanned aerial vehicle. J. Intell. Robot. Syst. 2015, 79, 295–321. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, R.; Zhang, K.; Jiang, B.; Tao, G. Robust backstepping sliding-mode control and observer-based fault estimation for a quadrotor UAV. IEEE Trans. Ind. Electron. 2016, 63, 5044–5056. [Google Scholar] [CrossRef]

- Quigley, M.; Gerkey, B.; Conley, K.; Faust, J.; Foote, T.; Leibs, J.; Berger, E.; Wheeler, R.; Ng, A.Y. ROS: An open-source Robot Operating System. ICRAWorkshop on Open Source Software in Robotics, Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Houska, B.; Ferreau, H.; Diehl, M. ACADO Toolkit—An Open Source Framework for Automatic Control and Dynamic Optimization. Optim. Control Appl. Methods 2011, 32, 298–312. [Google Scholar] [CrossRef]

- Boggs, P.T.; Tolle, J.W. Sequential quadratic programming. Acta Numer. 1995, 4, 1–51. [Google Scholar] [CrossRef]

- Ferreau, H.; Kirches, C.; Potschka, A.; Bock, H.; Diehl, M. qpOASES: A parametric active-set algorithm for quadratic programming. Math. Program. Comput. 2014, 6, 327–363. [Google Scholar] [CrossRef]

- Shah, S.; Dey, D.; Lovett, C.; Kapoor, A. AirSim: High-Fidelity Visual and Physical Simulation for Autonomous Vehicles. In Field and Service Robotics; Hutter, M., Siegwart, R., Eds.; Springer: Cham, Switzerland, 2018; pp. 621–635. [Google Scholar]

- Meier, L.; Honegger, D.; Pollefeys, M. PX4: A node-based multithreaded open source robotics framework for deeply embedded platforms. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 6235–6240. [Google Scholar]

- Oleynikova, H.; Taylor, Z.; Fehr, M.; Siegwart, R.; Nieto, J. Voxblox: Incremental 3d euclidean signed distance fields for on-board mav planning. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 1366–1373. [Google Scholar]

- Dang, T.; Mascarich, F.; Khattak, S.; Papachristos, C.; Alexis, K. Graph-based path planning for autonomous robotic exploration in subterranean environments. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; pp. 3105–3112. [Google Scholar]

| Total Length of the Generated Paths | Average Path Length (between Terminal Points) | Exploration Time | Continuous Path Generation | |

|---|---|---|---|---|

| Graph-based | No | |||

| Graph-based & NMPH-FBL | (22.0% improvement) | (22.2% improvement) | (21.9% improvement) | Yes |

| Graph-based & NMPH-BSC |

(24.2% improvement) |

(24.3% improvement) |

(24.2% improvement) | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Younes, Y.; Barczyk, M. A Backstepping Approach to Nonlinear Model Predictive Horizon for Optimal Trajectory Planning. Robotics 2022, 11, 87. https://doi.org/10.3390/robotics11050087

Al Younes Y, Barczyk M. A Backstepping Approach to Nonlinear Model Predictive Horizon for Optimal Trajectory Planning. Robotics. 2022; 11(5):87. https://doi.org/10.3390/robotics11050087

Chicago/Turabian StyleAl Younes, Younes, and Martin Barczyk. 2022. "A Backstepping Approach to Nonlinear Model Predictive Horizon for Optimal Trajectory Planning" Robotics 11, no. 5: 87. https://doi.org/10.3390/robotics11050087

APA StyleAl Younes, Y., & Barczyk, M. (2022). A Backstepping Approach to Nonlinear Model Predictive Horizon for Optimal Trajectory Planning. Robotics, 11(5), 87. https://doi.org/10.3390/robotics11050087