Advances in Forest Robotics: A State-of-the-Art Survey

Abstract

1. Introduction

2. Materials and Methods

3. Robotic Applications in Forest

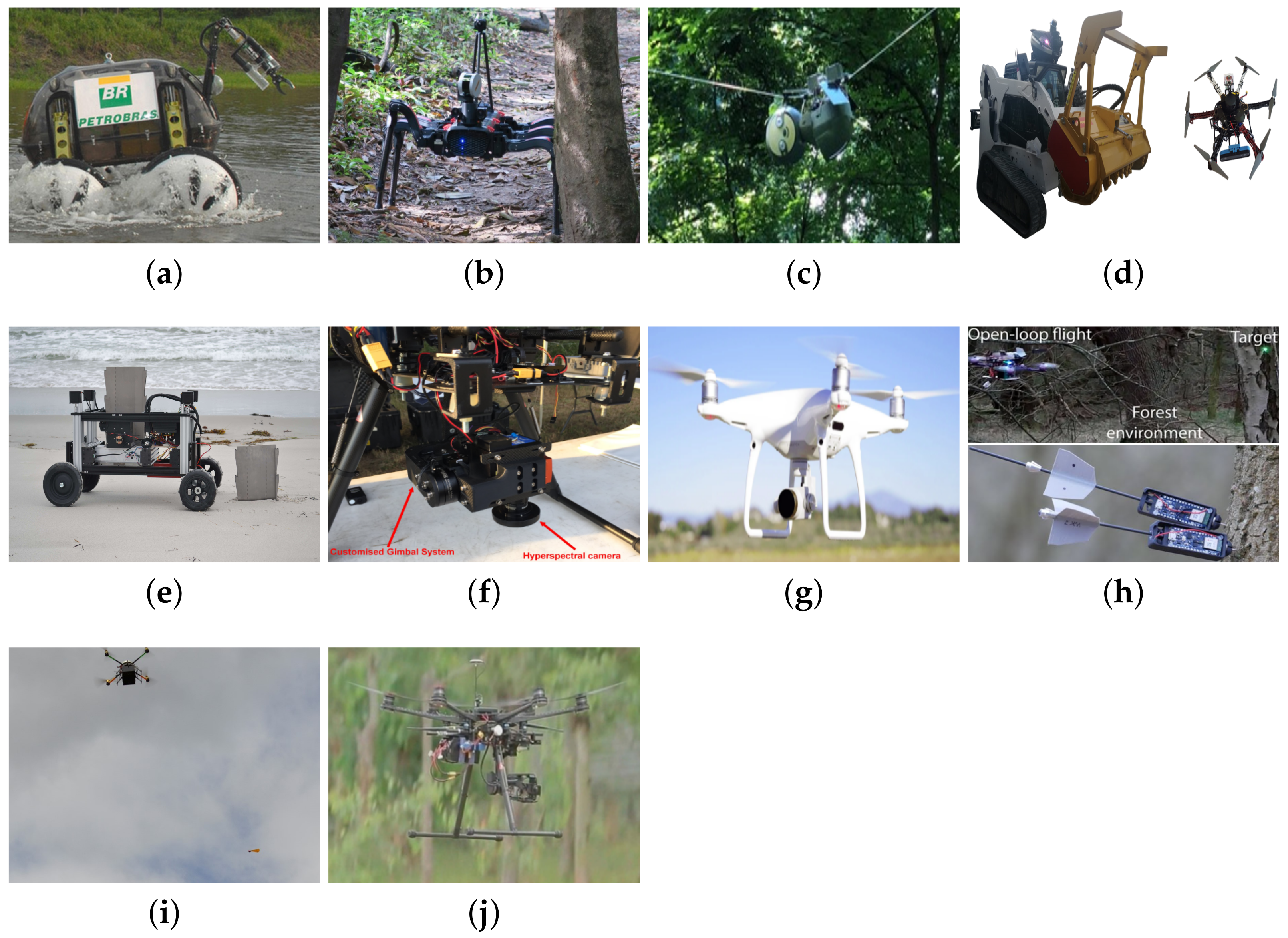

3.1. Robotic Applications for Environmental Preservation and Monitoring of Forests

- Monitoring: The Chico Mendes robot monitors possible gas leaks in the interior of the Amazon and the SlothBot monitors the ambient temperature and luminosity. Therefore, the locomotion system is directly affected by the type of environmental monitoring to be performed.

- Swarm: Forest are unstructured environments. This characteristic directly affects the time of travel and the execution of any tasks to be performed. Therefore, the integration of the concept of swarm of robots with robots of different types of locomotion systems (land, air or sea) can compensate for the time of executing tasks in such environments.

- Artificial intelligence: Artificial intelligence was used in conjunction with robotic systems in identification processes, using natural environment characteristics (vegetation indexes) and CNN.

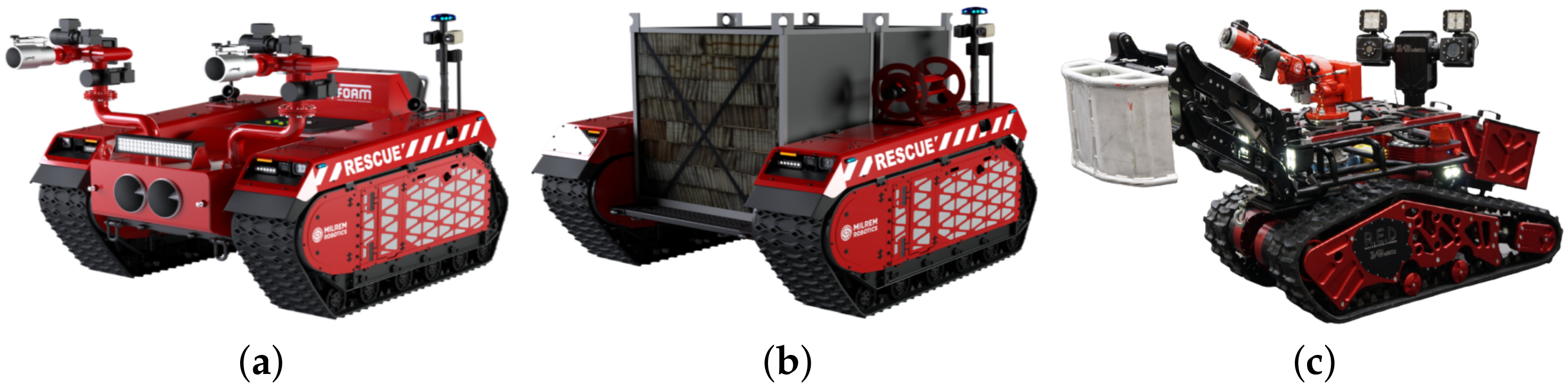

3.2. Robotic Applications for Wildfire Fighting

- Weight and Payload: To transport more equipment and/or injured people with less environmental impact (less soil compaction), the robotic system should be light and capable of transporting large payloads. Therefore, the robot + payload set must have a low center of gravity to avoid falls during firefighting activities.

- Water Flow: To reduce the spread of fires is desirable to apply a large water flow, since water reduces the temperature existing in place, removing the existing heat of reaction, putting out the fire. Therefore, the greater is the water flow (9464 L/min for Thermite RS3), the faster the fire will go out and the more forest areas will be preserved.

- Velocity: Although the water flow helps the firefighting, to control large-scale fires with a limited number of robots, the faster the robot travels the more areas can be covered. In this sense, robotic systems must be agile and easy to move around in hostile and difficult to access terrains.

- Autonomy: The firefighting activity requires time to remove all the heat from the place, and, in the case of a forest fire, delays in the firefighting can mean the extinguishment of species of fauna and flora. Therefore, the greater is the autonomy of the robot, the longer is the period in which the robot will remain firefighting and, consequently, more species of fauna and flora can be saved.

- Grade and side slope: Although all the robots analyzed are capable of operating on types of surfaces commonly found in urban and rural areas, such as concrete and clay soil, each robot in Table 2 has a different maximum grade and side slope. In this sense, the higher are these values, the greater is its ability to operate in rugged environments.

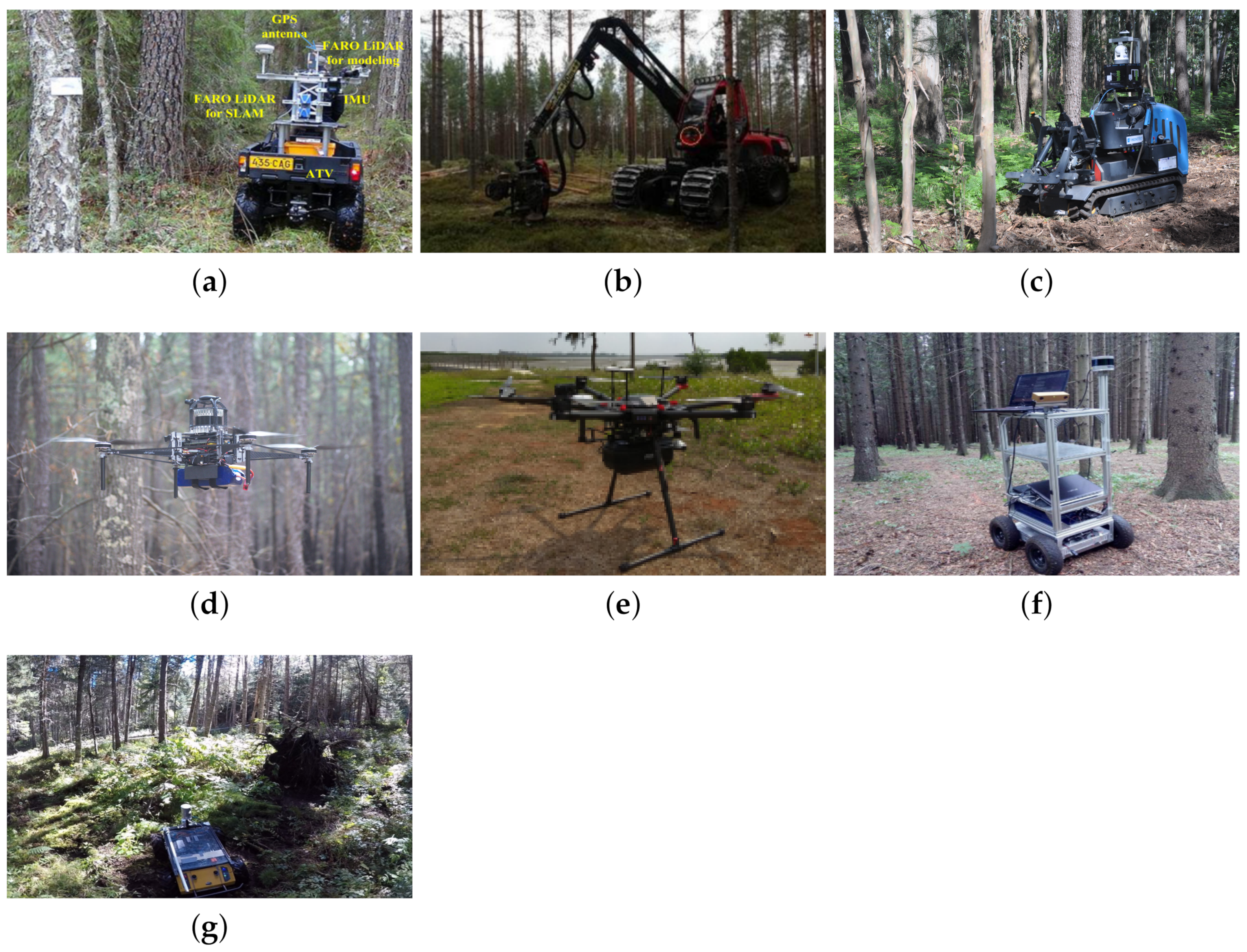

3.3. Robotic Applications in Forest for Inventory Operations

- Used Sensors: Although in forest environments the signals from GNSS devices are severely impaired, some applications use such devices, while in others the navigation was accomplished exclusively by LiDAR sensors.

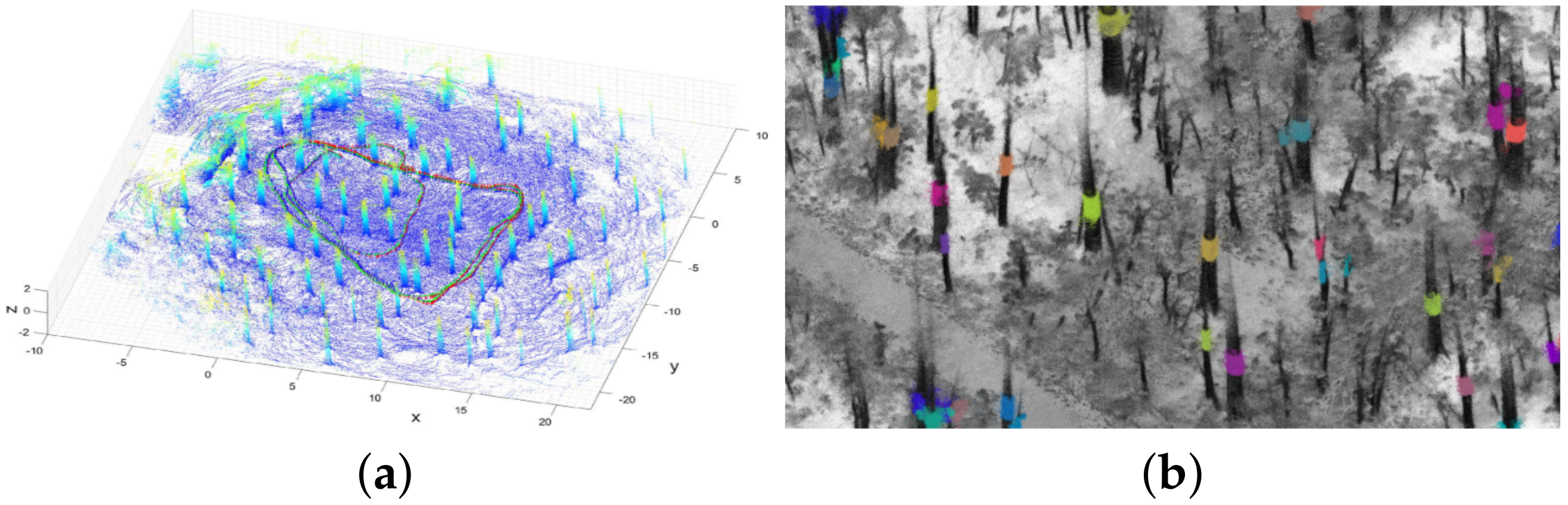

- SLAM: Several types of SLAM were used since, although all applications are in forest environments, each type of forest (tropical, temperate), in each season and each type of soil can directly interfere with the navigation technique used. For example, the LOAM technique discarded by Reis et al. [28] was used by Li et al. [9] and obtained satisfactory results.

3.4. Robotic Applications in Forest for Planting, Pruning and Harvesting

- Used Sensors: As most applications were teleoperated, few sensors were used and, therefore, this strategy enhances cost reduction.

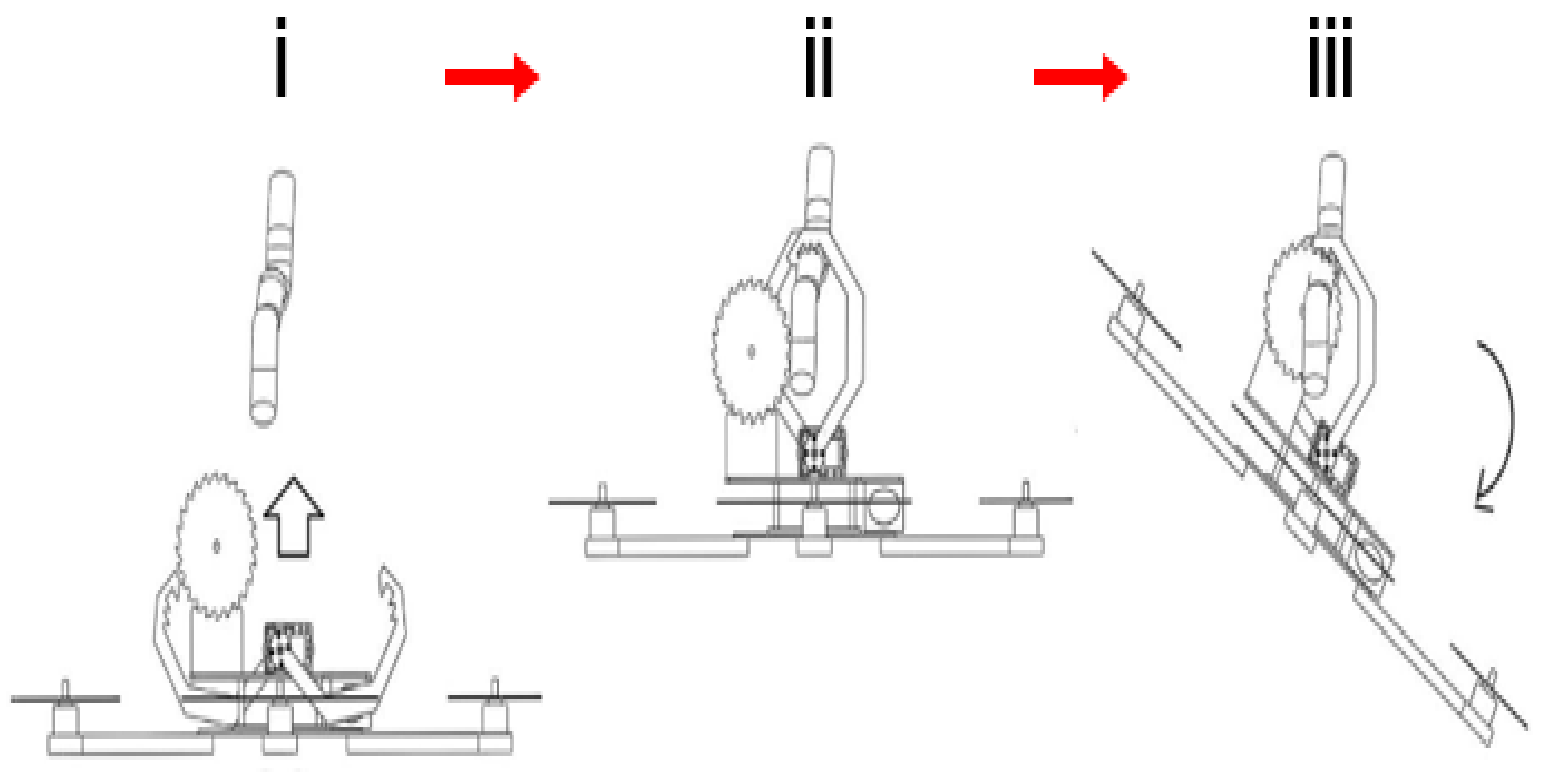

- Used Actuators: Different reasons for pruning result in different locomotion and cutting systems. Thus, periodic pruning tasks were performed using UAV (with mini saws), whereas daily log harvesting tasks were performed by legged robots (with chain saws).

- Locomotion Systems: The reasons for using certain types of locomotion must not only be well defined, but they must also exhibit results that satisfy the forest machine market.

4. Discussion

4.1. Unsolved Issues

4.1.1. IoT-Based Smart Forest

4.1.2. Navigation Systems

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of the World’s Forests 2020. Forests, Biodiversity and People; FAO: Rome, Italy, 2020; p. 214. [Google Scholar] [CrossRef]

- FAO. The State of the World’s Forests 2018. Forest Pathways to Sustainable Development; FAO: Rome, Italy, 2018; p. 139. [Google Scholar]

- Paiva, P.F.P.R.; Ruivo, M.d.L.P.; Júnior, O.M.d.S.; Maciel, M.d.N.M.; Braga, T.G.M.; de Andrade, M.M.N.; dos Santos Junior, P.C.; da Rocha, E.S.; de Freitas, T.P.M.; Leite, T.V.d.S.; et al. Deforestation in protect areas in the Amazon: A threat to biodiversity. Biodivers. Conserv. 2020, 29, 19–38. [Google Scholar] [CrossRef]

- Boer, M.M.; Dios, V.R.; Bradstock, R.A. Unprecedented burn area of Australian mega forest fires. Nat. Clim. Chang. 2020, 10, 171–172. [Google Scholar] [CrossRef]

- Spaniol, R.L.; Mendonça, M.d.S.; Hartz, S.M.; Iserhard, C.A.; Stevens, M. Discolouring the Amazon Rainforest: How deforestation is affecting butterfly coloration. Biodivers. Conserv. 2020, 29, 2821–2838. [Google Scholar] [CrossRef]

- CRED. Economic, Losses, Poverty & Disasters: 1998–2017; CRED: Bengaluru, India, 2018; p. 33. [Google Scholar]

- Oliveira, L.F.P.; Manera, L.T.; Luz, P.D.G. Smart Traffic Light Controller System. In Proceedings of the 2019 Sixth International Conference on Internet of Things: Systems, Management and Security (IOTSMS), Granada, Spain, 22–25 October 2019; pp. 155–160. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Manera, L.T.; Luz, P.D.G. Development of a Smart Traffic Light Control System with Real-Time Monitoring. IEEE Internet Things J. 2020, 8, 3384–3393. [Google Scholar] [CrossRef]

- Li, Q.; Nevalainen, P.; Queralta, J.P.; Heikkonen, J.; Westerlund, T. Localization in Unstructured Environments: Towards Autonomous Robots in Forests with Delaunay Triangulation. Remote Sens. 2020, 12, 1870. [Google Scholar] [CrossRef]

- Freitas, G.; Gleizer, G.; Lizarralde, F.; Hsu, L.; Reis, N.R.S. Kinematic reconfigurability control for an environmental mobile robot operating in the Amazon rain forest. J. Field Robot. 2010, 27, 197–216. [Google Scholar] [CrossRef]

- Reis, N.R.S. Desenvolvimento de tecnologias como conjunto de ferramentas e suporte às atividades e pesquisas socioambientais na Amazônia brasileira: Mobilidade e acessibilidade em áreas de várzea. Master’s Thesis, Universidade Federal do Amazonas, Manaus, Amazonas, Brazil, 2010. [Google Scholar]

- CSIRO. Amazon 360: Testing Self-Navigation in a Novel Landscape. 2020. Available online: https://algorithm.data61.csiro.au/amazon-360-testing-self-navigation-in-a-novel-landscape/ (accessed on 8 March 2021).

- Notomista, G.; Emam, Y.; Egerstedt, M. The SlothBot: A Novel Design for a Wire-Traversing Robot. IEEE Robot. Autom. Lett. 2019, 4, 1993–1998. [Google Scholar] [CrossRef]

- Couceiro, M.S.; Portugal, D.; Ferreira, J.F.; Rocha, R.P. SEMFIRE: Towards a new generation of forestry maintenance multi-robot systems. In Proceedings of the 2019 IEEE/SICE International Symposium on System Integration (SII), Paris, France, 14–16 January 2019; pp. 270–276. [Google Scholar]

- Melenbrink, N.; Werfel, J. Autonomous Sheet Pile Driving Robots for Soil Stabilization. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 339–345. [Google Scholar]

- Sandino, J.; Pegg, G.; Gonzalez, F.; Smith, G. Aerial Mapping of Forests Affected by Pathogens Using UAVs, Hyperspectral Sensors, and Artificial Intelligence. Sensors 2018, 18, 944. [Google Scholar] [CrossRef]

- Fujimoto, A.; Haga, C.; Matsui, T.; Machimura, T.; Hayashi, K.; Sugita, S.; Takagi, H. An End to End Process Development for UAV-SfM Based Forest Monitoring: Individual Tree Detection, Species Classification and Carbon Dynamics Simulation. Forests 2019, 10, 680. [Google Scholar] [CrossRef]

- Farinha, A.; Zufferey, R.; Zheng, P.; Armanini, S.F.; Kovac, M. Unmanned Aerial Sensor Placement for Cluttered Environments. IEEE Robot. Autom. Lett. 2020, 5, 6623–6630. [Google Scholar] [CrossRef]

- Pounds, P.; Singh, S. Samara: Biologically Inspired Self-Deploying Sensor Networks. IEEE Potentials 2015, 34, 10–14. [Google Scholar] [CrossRef]

- Gonzalez, L.F.; Montes, G.A.; Puig, E.; Johnson, S.; Mengersen, K.; Gaston, K.J. Unmanned Aerial Vehicles (UAVs) and Artificial Intelligence Revolutionizing Wildlife Monitoring and Conservation. Sensors 2016, 16, 97. [Google Scholar] [CrossRef] [PubMed]

- Apparatus, F. Firefighting Robotic Vehicle System. 2020. Available online: https://www.fireapparatusmagazine.com/fire-apparatus/firefighting-robotic-vehicle-system/#gref (accessed on 9 March 2021).

- Milrem Robotics. Multiscope Rescue with Hydra. 2020. Available online: https://milremrobotics.com/product/multiscope-rescue-hydra/ (accessed on 9 March 2021).

- Milrem Robotics. Multiscope Rescue Hose Cartridge. 2020. Available online: https://milremrobotics.com/product/firehouse-container/ (accessed on 9 March 2021).

- Shark Robotics. Colossus. 2020. Available online: https://www.shark-robotics.com/shark-robots (accessed on 10 March 2021).

- Magirus. Magirus AirCore. 2020. Available online: https://www.magirusgroup.com/de/en/products/special-vehicles/aircore/ (accessed on 10 March 2021).

- Howe & Howe. Thermite-First Commercial Firefighting Robot Sold in the U.S. 2020. Available online: https://www.howeandhowe.com/civil/thermite (accessed on 10 March 2021).

- Tang, J.; Chen, Y.; Kukko, A.; Kaartinen, H.; Jaakkola, A.; Khoramshahi, E.; Hakala, T.; Hyyppä, J.; Holopainen, M.; Hyyppä, H. SLAM-Aided Stem Mapping for Forest Inventory with Small-Footprint Mobile LiDAR. Forests 2015, 6, 4588–4606. [Google Scholar] [CrossRef]

- Reis, R.; Santos, F.N.S.; Santos, L. Forest Robot and Datasets for Biomass Collection. In Robot 2019: Fourth Iberian Robotics Conference; Springer: Berlin/Heidelberg, Germany, 2020; pp. 152–163. [Google Scholar] [CrossRef]

- Chen, S.W.; Nardari, G.V.; Lee, E.S.; Qu, C.; Liu, X.; Romero, R.A.F.; Kumar, V. SLOAM: Semantic Lidar Odometry and Mapping for Forest Inventory. IEEE Robot. Autom. Lett. 2020, 5, 612–619. [Google Scholar] [CrossRef]

- Wang, D.; Wan, B.; Liu, J.; Su, Y.; Guo, Q.; Qiu, P.; Wu, X. Estimating aboveground biomass of the mangrove forests on northeast Hainan Island in China using an upscaling method from field plots, UAV-LiDAR data and Sentinel-2 imagery. Int. J. Appl. Earth Obs. Geoinf. 2020, 85, 101986. [Google Scholar] [CrossRef]

- Pierzchała, M.; Giguère, P.; Astrup, R. Mapping forests using an unmanned ground vehicle with 3D LiDAR and graph-SLAM. Comput. Electron. Agric. 2018, 145, 217–225. [Google Scholar] [CrossRef]

- Tremblay, J.F.; Béland, M.; Gagnon, R.; Pomerleau, F.; Giguère, P. Automatic three-dimensional mapping for tree diameter measurements in inventory operations. J. Field Robot. 2020, 37, 1328–1346. [Google Scholar] [CrossRef]

- Shan, T.; Englot, B. LeGO-LOAM: Lightweight and Ground-Optimized Lidar Odometry and Mapping on Variable Terrain. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 4758–4765. [Google Scholar] [CrossRef]

- Giusti, A.; Guzzi, J.; Cireşan, D.C.; He, F.; Rodríguez, J.P.; Fontana, F.; Faessler, M.; Forster, C.; Schmidhuber, J.; Caro, G.D.; et al. A Machine Learning Approach to Visual Perception of Forest Trails for Mobile Robots. IEEE Robot. Autom. Lett. 2016, 1, 661–667. [Google Scholar] [CrossRef]

- Baril, D.; Grondin, V.; Deschênes, S.; Laconte, J.; Vaidis, M.; Kubelka, V.; Gallant, A.; Giguère, P.; Pomerleau, F. Evaluation of Skid-Steering Kinematic Models for Subarctic Environments. In Proceedings of the 2020 17th Conference on Computer and Robot Vision (CRV), Ottawa, ON, Canada, 13–15 May 2020; pp. 198–205. [Google Scholar] [CrossRef]

- Zhou, S.; Xi, J.; McDaniel, M.W.; Nishihata, T.; Salesses, P.; Iagnemma, K. Self-supervised learning to visually detect terrain surfaces for autonomous robots operating in forested terrain. J. Field Robot. 2012, 29, 277–297. [Google Scholar] [CrossRef]

- Birch, N.; Rhodes, T. Engineering co-op Students Build Tree-Planting Robot to Help Fight Deforestation. 2016. Available online: https://www.uvic.ca/news/topics/2016+building-a-tree-planting-robot+ring (accessed on 11 March 2021).

- Milrem Robotics. Multiscope Forester Planter. 2020. Available online: https://milremrobotics.com/product/robotic-forester-planter/ (accessed on 11 March 2021).

- Milrem Robotics. Multiscope Forester Brushcutter. 2020. Available online: https://milremrobotics.com/product/robotic-forester-brushcutter/ (accessed on 11 March 2021).

- Ishigure, Y.; Hirai, K.; Kawasaki, H. A pruning robot with a power-saving chainsaw drive. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; pp. 1223–1228. [Google Scholar] [CrossRef]

- Molina, J.; Hirai, S. Aerial pruning mechanism, initial real environment test. Robot. Biomim. 2017, 4, 15. [Google Scholar] [CrossRef] [PubMed]

- Meaclem, C.V.; Shao, L.; Parker, R.; Gutschmidt, S.; Hann, C.E.; Milne, B.J.E.; Chen, X. Sensor guided biped felling machine for steep terrain harvesting. In Proceedings of the 2014 IEEE International Conference on Automation Science and Engineering (CASE), New Taipei, Taiwan, 18–22 August 2014; pp. 984–989. [Google Scholar] [CrossRef]

- Billingsley, J.; Visala, A.; Dunn, M. Robotics in Agriculture and Forestry. In Springer Handbook of Robotics; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2008; pp. 1065–1077. [Google Scholar] [CrossRef]

- Ponsse. The Cut-To-Length Method. 2020. Available online: https://www.ponsse.com/cut-to-length#/ (accessed on 12 March 2021).

- Zhang, C.; Yong, L.; Chen, Y.; Zhang, S.; Ge, L.; Wang, S.; Li, W. A Rubber-Tapping Robot Forest Navigation and Information Collection System Based on 2D LiDAR and a Gyroscope. Sensors 2019, 19, 2136. [Google Scholar] [CrossRef] [PubMed]

- Halme, A.; Hartikainen, K.; Kärkkäinen, K. Terrain Adaptive Motion and Free Gait of a Six-Legged Walking Machine. IFAC Proc. Vol. 1993, 26, 1–7. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Rossini, F.L. Modeling, Simulation and Analysis of Locomotion Patterns for Hexapod Robots. IEEE Latin Am. Trans. 2018, 16, 375–383. [Google Scholar] [CrossRef]

- Oliveira, L.F.P.; Silva, M.F.; Moreira, A.P. Agricultural Robotics: A State of the Art Survey. In 23rd International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines (CLAWAR 2020); Gradetsky, V., Tokhi, M., Bolotnik, N., Silva, M., Virk, G., Eds.; CLAWAR Association Ltd.: High Wycombe, UK, 2020; pp. 279–286. [Google Scholar] [CrossRef]

- FAO. World Food and Agriculture–Statistical pocketbook 2019; FAO: Rome, Italy, 2019; p. 254. [Google Scholar]

- World Bank Group. Land Area. 2020. Available online: https://data.worldbank.org/indicator/AG.LND.TOTL.K2?name_desc=false (accessed on 12 March 2021).

- Iqbal, J.; Xu, R.; Sun, S.; Li, C. Simulation of an Autonomous Mobile Robot for LiDAR-Based In-Field Phenotyping and Navigation. Robotics 2020, 9, 46. [Google Scholar] [CrossRef]

- Aguiar, A.S.; Santos, F.N.; Cunha, J.B.; Sobreira, H.; Sousa, A.J. Localization and Mapping for Robots in Agriculture and Forestry: A Survey. Robotics 2020, 9, 97. [Google Scholar] [CrossRef]

- Santos, L.C.; Aguiar, A.S.; Santos, F.N.; Valente, A.; Petry, M. Occupancy Grid and Topological Maps Extraction from Satellite Images for Path Planning in Agricultural Robots. Robotics 2020, 9, 77. [Google Scholar] [CrossRef]

- Lever, J.H.; Delaney, A.J.; Ray, L.E.; Trautmann, E.; Barna, L.A.; Burzynski, A.M. Autonomous GPR Surveys using the Polar Rover Yeti. J. Field Robot. 2013, 30, 194–215. [Google Scholar] [CrossRef]

| Robot | Final Application | Locomotion System | Localization Sensors | Sensors Used to Perform the Task |

|---|---|---|---|---|

| Chico Mendes [10] | Preservation and monitoring | Wheel-Legged | Global Positioning System (GPS) | Water probe, gas sensor and 3D camera |

| Legged robot [12] | Monitoring | Legged | Light Detection and Ranging (LiDAR) | RGB camera |

| SlothBot [13] | Monitoring | Wire traversing | – | Temperature and luminosity |

| Ranger and Scout [14] | Preservation and monitoring | Caterpillar and Unmanned Aerial Vehicle (UAV) | Global Navigation Satellite System (GNSS) and LiDAR | Stereo, multispectral and infrared cameras |

| Romu [15] | Preservation | Four-wheel drive (4WD) | – | – |

| UAV robot 1 [16] | Monitoring | UAV | GPS | Hyperspectral camera |

| UAV robot 2 [17] | Monitoring | UAV | GPS | RGB camera |

| UAV robot 3 [18] | Monitoring | UAV | – | RGB camera |

| UAV robot 4 [19] | Monitoring | UAV | – | Temperature, humidity and pressure |

| UAV robot 5 [20] | Preservation and monitoring | UAV | GPS and Inertial Measurement Unit (IMU) | Thermal and RGB cameras |

| Robot | Locomotion System | Weight (kg) | Payload Weight (kg) | Water Flow (L/min) | Velocity (km/h) | Autonomy (h) | Grade Slope (°) | Side Slope (°) |

|---|---|---|---|---|---|---|---|---|

| Fire Ox [21] | Six-wheel drive (6WD) | – | – | – | – | – | 30 | – |

| Multiscope Rescue with Hydra [22] | Caterpillar | 1630 | 1200 | 3000 | 20 | 12 | 30 | – |

| Multiscope Rescue Hose Cartridge [23] | Caterpillar | 1630 | 1200 | – | 20 | 15 | 30 | – |

| Magirus AirCore TAF35 [25] | Caterpillar | 3900 | – | 4700 | 9 | 7 | 30 | 15 |

| Thermite RS1 [26] | Caterpillar | 725 | – | 4732 | 9.65 | 20 | 26.57 | 19.29 |

| Thermite RS3 [26] | Caterpillar | 1588 | – | 9464 | 12.87 | 20 | 26.57 | 19.29 |

| Colossus [24] | Caterpillar | 500 | 500 | – | 4.5 | 12 | 40 | 35 |

| Robot | Locomotion System | Used Sensors | Computer Vision Algorithm |

|---|---|---|---|

| FGI ROAMER R2 [27] | 4WD | GNSS, IMU, LiDAR | SLAM + IMU |

| Komatsu Forest 931.1 [9] | 4WD | RTK GNSS, LiDAR | LOAM |

| AgRob V18 [28] | Caterpillar | GNSS, LiDAR, thermal and RGB cameras | LeGO-LOAM |

| ARDrone [34] | UAV | RGB and grayscale cameras | DNN |

| Forest robot 1 [29] | UAV | LiDAR | SLOAM |

| Forest robot 2 [30] | UAV | LiDAR | G-LiDAR-S2 model |

| Superdroid [31] | 4WD | GPS, LiDAR, IMU and stereo camera | 3D graph-SLAM |

| Husky A200 [32] | 4WD | LiDAR, IMU, encoders and RGB camera | DBH estimation |

| Warthog [35] | 4WD | LiDAR, IMU and encoders | ICP algorithm |

| Pioneer 3-AT [36] | 4WD | XB3 camera and LiDAR | LIDAR/camera-based |

| Final Application | Robot | Locomotion System | Sensors | Actuators |

|---|---|---|---|---|

| Planting | TreeRover [37] | 4WD | GNSS | Compressed air machine |

| Multiscope Forester Planter [38] | Caterpillar | – | Forester planter | |

| Multiscope Forester Brushcutter [39] | Caterpillar | – | Forester brushcutter | |

| Pruning | Pruning robot 1 [40] | 4WS | Posture sensor | Chainsaw |

| Pruning robot 2 [41] | UAV | Back-electromotive force module | Circular saw | |

| Pruning robot 3 [42] | Legged robot | LiDAR and RGB camera | – | |

| Harvesting | MECANT [46] | Legged robot | – | – |

| Walking forest harvester [43] | Legged robot | – | Chainsaw on a robotic arm | |

| Harvester CTL [44] | Legged robot | – | Chainsaw on a robotic arm | |

| Harvesting robot [45] | Caterpillar | LiDAR and gyroscope | Gauss-Newton |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Forest Robotics: A State-of-the-Art Survey. Robotics 2021, 10, 53. https://doi.org/10.3390/robotics10020053

Oliveira LFP, Moreira AP, Silva MF. Advances in Forest Robotics: A State-of-the-Art Survey. Robotics. 2021; 10(2):53. https://doi.org/10.3390/robotics10020053

Chicago/Turabian StyleOliveira, Luiz F. P., António P. Moreira, and Manuel F. Silva. 2021. "Advances in Forest Robotics: A State-of-the-Art Survey" Robotics 10, no. 2: 53. https://doi.org/10.3390/robotics10020053

APA StyleOliveira, L. F. P., Moreira, A. P., & Silva, M. F. (2021). Advances in Forest Robotics: A State-of-the-Art Survey. Robotics, 10(2), 53. https://doi.org/10.3390/robotics10020053