Industrial Production of Proteins with Pichia pastoris—Komagataella phaffii

Abstract

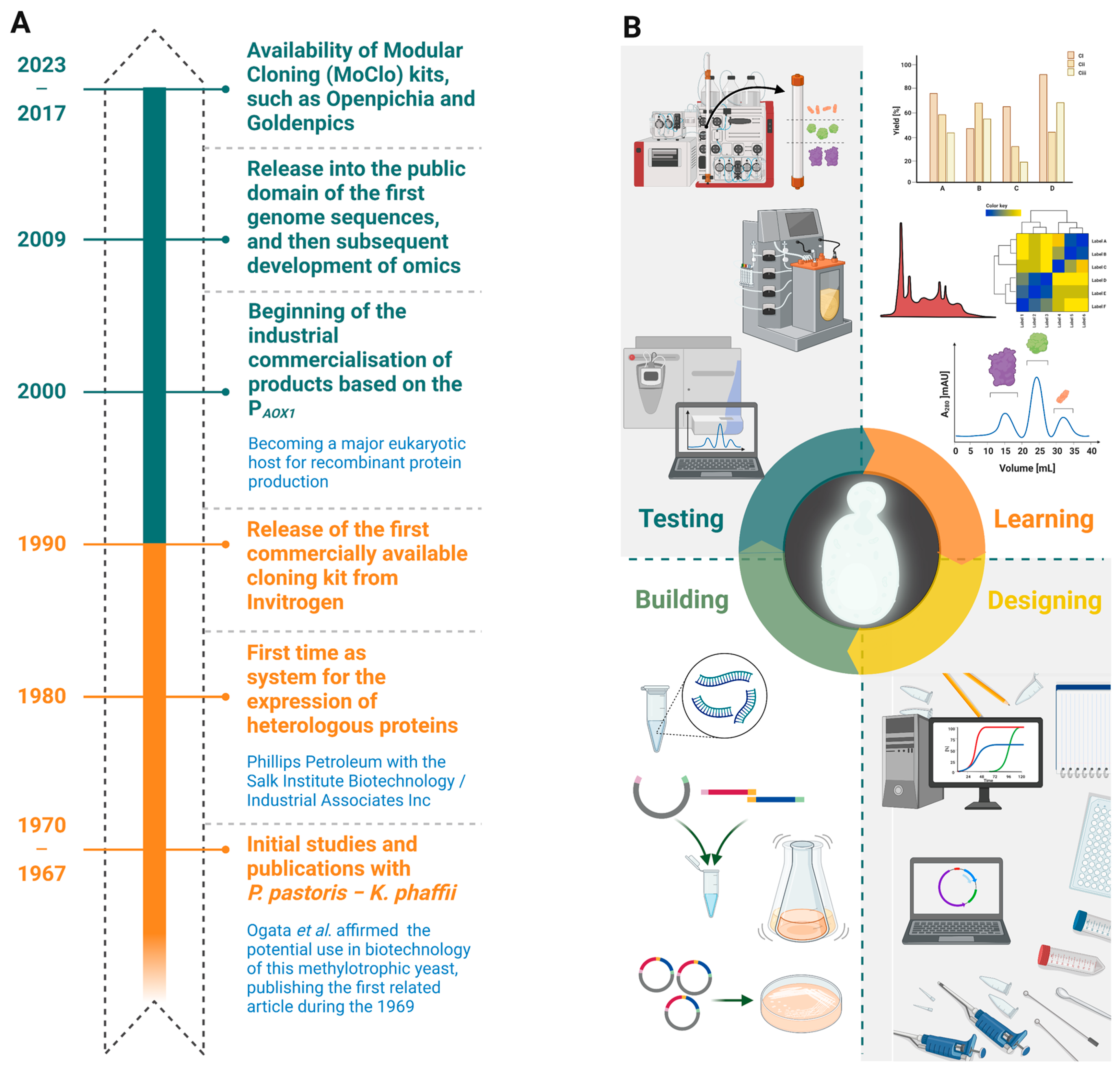

1. Introduction

| Patent Number | Title | Short Description | Status |

|---|---|---|---|

| CN101654674A (Granted in 2013) | “Enhanced pichia pastoris AOX1 promoter” | The invention provides different enhanced K. phaffii AOX1 promoters. | Active |

| CN106893726A (Granted in 2020) | “A kind of promoter and restructuring yeast strains” | The invention relates to the technical field of genetic engineering, disclosing a promoter and a recombinant yeast strain. | Active |

| EP3332005A1 (Granted in 2021) | “Promoter-variants” | The invention describes the isolated and/or artificial pG1-x promoter, a functional variant of the carbon source regulatable pG1 promoter of K. phaffii. | Active |

| US10428123B2 (Granted in 2019) | “Constitutive promoter” | The invention relates to an isolated nucleic acid sequence comprising a promoter, which is a native sequence of Pichia pastoris or a functionally active variant and also a method of producing a protein of interest under the control of the promoter. It further relates to a method to identify a constitutive promoter from eukaryotic cells. | Active |

| Patent Number | Title | Short Description | Status |

|---|---|---|---|

| JP2020072697A (Granted in 2021) | “Recombinant host cell for expressing proteins of interest” | The invention is related to the host cell improved in the capacity to express and/or secrete a protein of interest. | Active |

| AU2012300885A1 (Granted in 2017) | “Protein expression” | The invention relates to a genetically modified yeast cell comprising at least one recombinant promoter operably linked to at least one gene encoding a polypeptide or protein; a secretion cassette with a recombinant nucleic molecule encoding a protein or polypeptide of interest; and a method for producing a recombinant protein or polypeptide of interest using such a cell. | Active |

| AU2015248815A1 (Granted in 2021) | “Recombinant host cell engineered to overexpress helper proteins” | The invention is in the field of protein expression and generally relates to a method of expressing a protein of interest from a host cell—particularly, to improve a host cell’s capacity to express and/or secrete a protein of interest and to use it for protein expression. Furthermore, it uses cell culture technology to produce desired molecules for medical purposes or food products. | Active |

| AU2018241920A1 (Granted in 2022) | “Recombinant host cell with altered membrane lipid composition” | The invention generally relates to a method of expressing a protein of interest from a host cell, particularly to improve a host cell’s capacity to express and/or secrete a protein of interest. The invention also relates to cell culture technology and to culture cells that produce desired molecules for medical purposes or food products. | Active |

| US9873746B2 (Granted in 2018) | “Methods of synthesizing heteromultimeric polypeptides in yeast using a haploid mating strategy” | Methods are provided for the synthesis and secretion of recombinant proteins, preferably large mammalian proteins or hetero-multimeric proteins at high levels and for a prolonged time in polyploid (preferably diploid yeast). In a preferred embodiment, a first-expression vector is transformed into a first haploid cell; then, a second expression vector is transformed into a second haploid cell. The transformed haploid cells, each individually synthesizing a non-identical polypeptide, are identified and then genetically crossed or fused. The resulting diploid strains are utilized to produce and secrete fully assembled and biologically functional hetero-multimeric protein. | Active |

| WO2021198431A1 (Application filed in 2021) | “Helper factors for expressing proteins in yeast” | A method to produce a protein of interest in a yeast host cell that is modified to comprise, within one or more expression cassettes, heterologous nucleic acid molecules that encode for helper factors and a gene of interest. | Publication |

| WO2020200414A1 (Application filed in 2019) | “Protein production in mut-methylotrophic yeast” | A method to produce a protein of interest comprising the culturing of a recombinant methanol-utilization-pathway-deficient methylotrophic yeast (Mut−) host cell using methanol as a carbon source. The Mut− cell comprises a heterologous gene of interest expression cassette that comprises an expression cassette promoter operably linked to a gene of interest encoding a protein of interest. The Mut− cell is engineered by one or more genetic modifications to reduce the expression of a first and a second endogenous gene. | Publication |

2. Market of Recombinant Proteins Production

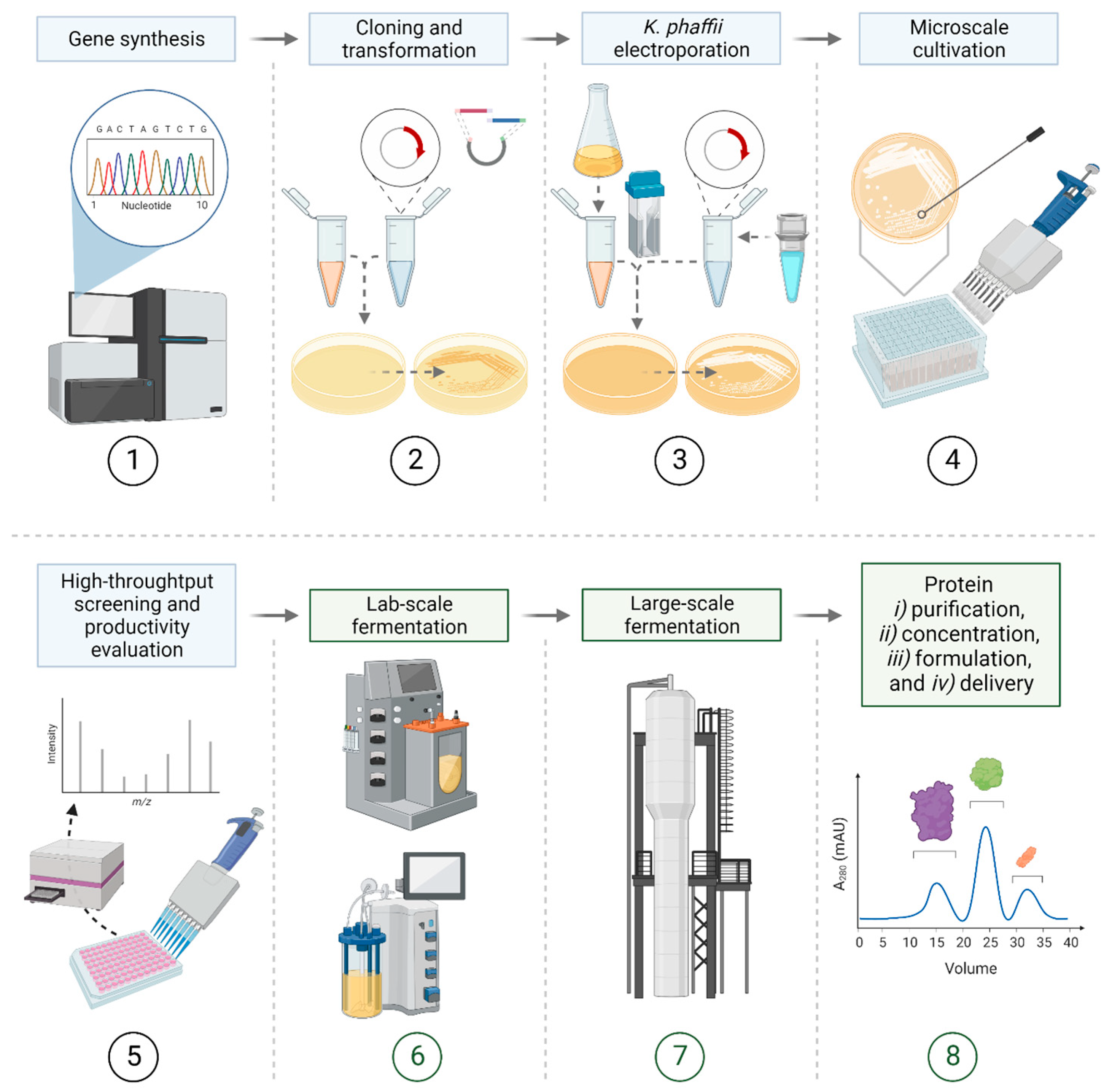

3. Producing Recombinant Proteins with K. phaffii: Advantages, Disadvantages, and Workflow

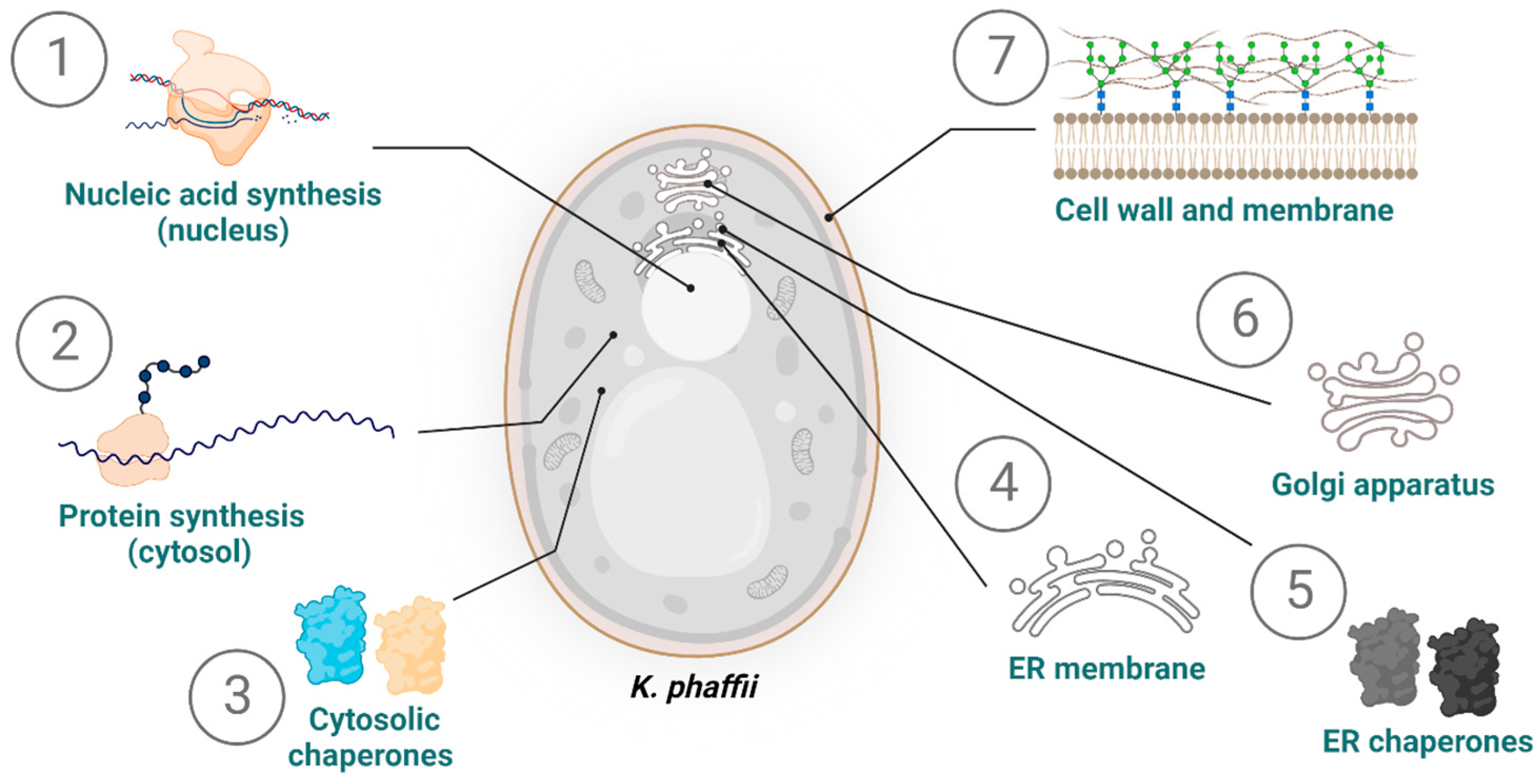

4. Protein Secretion: Bottlenecks of the Secretory Pathway

5. Oxidative Folding for Native Disulphide Bonds

6. Industrial Approaches for the Synthesis of the Recombinant Proteins with K. phaffii

| Company | Product | Description | Website |

|---|---|---|---|

| VALIDOGEN GmbH (Trakt, Grambach, Austria) | UNLOCK PICHIA—Pichia pastoris protein expression system | Development of strains, bioprocesses, protein purification, and enzyme engineering | validogen.com/pichia-pastoris/applications (accessed on 10 January 2023) |

| Bisy GmbH (Wünschendorf, Austria) | Pichia strains development, vectors, and biocatalysts | Development of vectors, strains, recombinant cytochrome P450 or lipases | bisy.at (accessed on 10 January 2023) |

| Ginkgo Bioworks (Boston, MA, USA) | Pichia pastoris strain and process development, patented methanol-free technology | Generation and development of strains; development of HTS/OMICS methods, workflows, fermentation and scale-up for a wide range of applications and industries | ginkgobioworks.com (accessed on 10 January 2023) |

| Lonza (Visp, Switzerland) | XS™ Pichia 2.0 Expression and Manufacturing Platform | Development of next generation therapeutics | lonza.com/news/2017-11-08-14-20 (accessed on 10 January 2023) |

| BioGrammatics (Carlsbad, CA, USA) | DIY Pichia Strain Construction, and Pichia GlycoSwitch Technology | Custom Pichia expression strain | biogrammatics.com (accessed on 10 January 2023) |

| BOLT THREADS (Emeryville, CA, USA) | MICROSILK™ | Sustainably produced textile spun from the proteins of the spider web | boltthreads.com (accessed on 10 January 2023) |

| IMPOSSIBLE™ FOODS (Oakland, CA, USA) | IMPOSSIBLE™ BURGER | Engineering K. phaffii to make components for a meat-free burger | impossiblefoods.com (accessed on 10 January 2023) |

| Dyax/Biotage® (Salem, OR, USA) | Kalbitor® (DX-88 ecallantide: recombinant kallikrein inhibitor protein) | Hereditary angioedema treatment | biotage.com (accessed on 10 January 2023) |

| Biocon (Bengaluru, India) | Insugen® (recombinant human insulin) | Diabetes therapy | biocon.com/products/key-therapeutic-areas/diabetes/ (accessed on 10 January 2023) |

| Mitsubishi Tanabe Pharma (Osaka, Japan) | Medway (recombinant human serum albumin) | Expansion of the blood volume | mt-pharma.co.jp/e/ (accessed on 10 January 2023) |

| Shantha/Sanofi (Telangana, India) | Shanvac ™ (recombinant hepatitis B vaccine) | Hepatitis B prevention | sanofi.com/en/your-health/vaccines/hepatitis-b (accessed on 10 January 2023) |

| Shantha/Sanofi (Telangana, India) | Shanferon™ (recombinant interferon-alpha 2b) | Hepatitis C and cancer treatment | sanofi.in (indiamart.com/proddetail/shanferon-1700786533.html) (accessed on 10 January 2023) |

| ThromboGenics/Oxurion (Leuven, Belgium) | Ocriplasmin (recombinant microplasmin) | Vitreomacular adhesion (VMA) treatment | oxurion.com (accessed on 10 January 2023) |

| Ablynx/Sanofi (Gent, Belgium) | Nanobody® ALX-0061 (recombinant anti-IL6 receptor single domain antibody fragment) | Rheumatoid arthritis treatment | ablynx.com (sanofi.com/en/science-and-innovation/research-and-development/technology-platforms/nanobody-technology-platform) (accessed on 10 January 2023) |

| Ablynx/Sanofi (Gent, Belgium) | Nanobody® ALX00171 (recombinant anti-RSV single domain antibody fragment) | Respiratory syncytial virus (RSV) infection treatment | ablynx.com (sanofi.com/en/science-and-innovation/research-and-development/technology-platforms/nanobody-technology-platform) (accessed on 10 January 2023) |

| Trillium/Pfizer Inc. (Brockville, Canada) | Heparin-binding EGF-like growth factor (HB-EGF) | Treatment of interstitial cystitis/bladder pain syndrome (IC/BPS) treatment | pfizer.com (accessed on 10 January 2023) |

| Verenium/DSM (Heerlen, Netherlands) | Purifine (recombinant phospholipase C) | Degumming of high phosphorus oils | dsm.com/corporate/home.html (accessed on 10 January 2023) |

| Roche (Mannheim, Germany) | Recombinant trypsin | Digestion of proteins | lifescience.roche.com (accessed on 10 January 2023) |

| Fibrogen (San Francisco, CA, USA) | Recombinant collagen | Medical research reagents/dermal filler | fibrogen.com (accessed on 10 January 2023) |

| Merck/Schering Plough Animal Health (San Francisco, CA, USA) | AQUAVAC IPN (recombinant infectious pancreatic necrosis virus capsid proteins) | Vaccines for infectious pancreatic necrosis in salmon | merck-animal-health.com/contact-us/ (accessed on 10 January 2023) |

| Phytex, LLC/United Animal Health (Sheridan, IN, USA) | Recombinant phytase | Animal feed additive | unitedanh.com (accessed on 10 January 2023) |

| The Nitrate Elimination Co. (Lake Linden, MI, USA) | Superior Stock recombinant nitrate reductase | Enzyme-based products for water testing and water treatment | nitrate.com/analytical-enzyme-applications/education (accessed on 10 January 2023) |

7. Main Bioreactor-Based Approaches to Produce Target Protein at Industrial Scale

8. Emerging Trends of the Biotechnological Applications via K. phaffii

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bustos, C.; Quezada, J.; Veas, R.; Altamirano, C.; Braun-Galleani, S.; Fickers, P.; Berrios, J. Advances in Cell Engineering of the Komagataella phaffii Platform for Recombinant Protein Production. Metabolites 2022, 12, 346. [Google Scholar] [CrossRef]

- Mastropietro, G.; Aw, R.; Polizzi, K.M. Expression of proteins in Pichia pastoris. In Methods in Enzymology; Elsevier: Amsterdam, The Netherlands, 2021; Volume 660, pp. 53–80. [Google Scholar] [CrossRef]

- Ergün, B.G.; Berrios, J.; Binay, B.; Fickers, P. Recombinant protein production in Pichia pastoris: From transcriptionally redesigned strains to bioprocess optimization and metabolic modelling. FEMS Yeast Res. 2021, 21, foab057. [Google Scholar] [CrossRef]

- Karbalaei, M.; Rezaee, S.A.; Farsiani, H. Pichia pastoris: A highly successful expression system for optimal synthesis of heterologous proteins. J. Cell. Physiol. 2020, 235, 5867–5881. [Google Scholar] [CrossRef]

- De Wachter, C.; Van Landuyt, L.; Callewaert, N. Engineering of Yeast Glycoprotein Expression. In Advances in Glycobiotechnology; Rapp, E., Reichl, U., Eds.; Springer: Cham, Switzerland, 2018; Volume 175, pp. 93–135. [Google Scholar]

- Corchero, J.L.; Gasser, B.; Resina, D.; Smith, W.; Parrilli, E.; Vázquez, F.; Abasolo, I.; Giuliani, M.; Jäntti, J.; Ferrer, P.; et al. Unconventional microbial systems for the cost-efficient production of high-quality protein therapeutics. Biotechnol. Adv. 2013, 31, 140–153. [Google Scholar] [CrossRef]

- Gasser, B.; Prielhofer, R.; Marx, H.; Maurer, M.; Nocon, J.; Steiger, M.; Puxbaum, V.; Sauer, M.; Mattanovich, D. Pichia pastoris: Protein production host and model organism for biomedical research. Futur. Microbiol. 2013, 8, 191–208. [Google Scholar] [CrossRef]

- Damasceno, L.M.; Huang, C.-J.; Batt, C.A. Protein secretion in Pichia pastoris and advances in protein production. Appl. Microbiol. Biotechnol. 2011, 93, 31–39. [Google Scholar] [CrossRef]

- Macauley-Patrick, S.; Fazenda, M.; McNeil, B.; Harvey, L.M. Heterologous protein production using the Pichia pastoris expression system. Yeast 2005, 22, 249–270. [Google Scholar] [CrossRef]

- Baghban, R.; Farajnia, S.; Ghasemi, Y.; Mortazavi, M.; Zarghami, N.; Samadi, N. New Developments in Pichia pastoris Expression System, Review and Update. Curr. Pharm. Biotechnol. 2018, 19, 451–467. [Google Scholar] [CrossRef]

- Laukens, B.; Jacobs, P.P.; Geysens, K.; Martins, J.; De Wachter, C.; Ameloot, P.; Morelle, W.; Haustraete, J.; Renauld, J.; Samyn, B.; et al. Off-target glycans encountered along the synthetic biology route toward humanized N -glycans in Pichia pastoris. Biotechnol. Bioeng. 2020, 117, 2479–2488. [Google Scholar] [CrossRef]

- Laukens, B.; De Wachter, C.; Callewaert, N. Engineering the Pichia pastoris N-Glycosylation Pathway Using the GlycoSwitch Technology. In Glyco-Engineering; Springer: New York, NY, USA, 2015; Volume 1321, pp. 103–122. [Google Scholar] [CrossRef]

- Raschmanová, H.; Weninger, A.; Knejzlík, Z.; Melzoch, K.; Kovar, K. Engineering of the unfolded protein response pathway in Pichia pastoris: Enhancing production of secreted recombinant proteins. Appl. Microbiol. Biotechnol. 2021, 105, 4397–4414. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Karbalaei, M.; Soleimanpour, S.; Mosavat, A.; Rezaee, S.A.; Ghazvini, K.; Farsiani, H. Practical Methods for Expression of Recombinant Protein in the Pichia pastoris System. Curr. Protoc. 2021, 1, e155. [Google Scholar] [CrossRef]

- Weis, R. High-Throughput Screening and Selection of Pichia pastoris Strains. In Recombinant Protein Production in Yeast; Gasser, B., Mattanovich, D., Eds.; Humana Press: New York, NY, USA, 2019; Volume 1923, pp. 169–185. [Google Scholar] [CrossRef]

- Gao, J.; Jiang, L.; Lian, J. Development of synthetic biology tools to engineer Pichia pastoris as a chassis for the production of natural products. Synth. Syst. Biotechnol. 2021, 6, 110–119. [Google Scholar] [CrossRef]

- Demir, I.; Çalık, P. Hybrid-architectured double-promoter expression systems enhance and upregulate-deregulated gene expressions in Pichia pastoris in methanol-free media. Appl. Microbiol. Biotechnol. 2020, 104, 8381–8397. [Google Scholar] [CrossRef]

- García-Ortega, X.; Cámara, E.; Ferrer, P.; Albiol, J.; Montesinos-Seguí, J.L.; Valero, F. Rational development of bioprocess engineering strategies for recombinant protein production in Pichia pastoris (Komagataella phaffii) using the methanol-free GAP promoter. Where do we stand? New Biotechnol. 2019, 53, 24–34. [Google Scholar] [CrossRef]

- Liu, Q.; Shi, X.; Song, L.; Liu, H.; Zhou, X.; Wang, Q.; Zhang, Y.; Cai, M. CRISPR–Cas9-mediated genomic multiloci integration in Pichia pastoris. Microb. Cell Factories 2019, 18, 1–11. [Google Scholar] [CrossRef]

- Vogl, T.; Sturmberger, L.; Fauland, P.C.; Hyden, P.; Fischer, J.E.; Schmid, C.; Thallinger, G.G.; Geier, M.; Glieder, A. Methanol independent induction in Pichia pastoris by simple derepressed overexpression of single transcription factors. Biotechnol. Bioeng. 2018, 115, 1037–1050. [Google Scholar] [CrossRef]

- Weinhandl, K.; Winkler, M.; Glieder, A.; Camattari, A. Carbon source dependent promoters in yeasts. Microb. Cell Factories 2014, 13, 5. [Google Scholar] [CrossRef]

- Vogl, T.; Glieder, A. Regulation of Pichia pastoris promoters and its consequences for protein production. New Biotechnol. 2012, 30, 385–404. [Google Scholar] [CrossRef]

- Mattanovich, D.; Callewaert, N.; Rouzé, P.; Lin, Y.-C.; Graf, A.; Redl, A.; Tiels, P.; Gasser, B.; De Schutter, K. Open access to sequence: Browsing the Pichia pastoris genome. Microb. Cell Factories 2009, 8, 53. [Google Scholar] [CrossRef]

- Prielhofer, R.; Barrero, J.J.; Steuer, S.; Gassler, T.; Zahrl, R.; Baumann, K.; Sauer, M.; Mattanovich, D.; Gasser, B.; Marx, H. GoldenPiCS: A Golden Gate-derived modular cloning system for applied synthetic biology in the yeast Pichia pastoris. BMC Syst. Biol. 2017, 11, 123. [Google Scholar] [CrossRef]

- Van Herpe, D.; Vanluchene, R.; Vandewalle, K.; Vanmarcke, S.; Wyseure, E.; Van Moer, B.; Eeckhaut, H.; Fijalkowska, D.; Grootaert, H.; Lonigro, C.; et al. OPENPichia: Building a free-to-operate Komagataella phaffii protein expression toolkit. bioRxiv 2022. [Google Scholar] [CrossRef]

- Guilliermond, A. Zygosaccharomyces pastori, nouvelle espèce de levures à copulation hétérogamique. Bull. Soc. Mycol. Fr. 1920, 36, 203–211. [Google Scholar]

- Zahrl, R.J.; Peña, D.A.; Mattanovich, D.; Gasser, B. Systems biotechnology for protein production in Pichia pastoris. FEMS Yeast Res. 2017, 17, fox068. [Google Scholar] [CrossRef]

- Yamada, Y.; Matsuda, M.; Maeda, K.; Mikata, K. The Phylogenetic Relationships of Methanol-assimilating Yeasts Based on the Partial Sequences of 18S and 26S Ribosomal RNAs: The Proposal of Komagataella Gen. Nov. (Saccharomycetaceae). Biosci. Biotechnol. Biochem. 1995, 59, 439–444. [Google Scholar] [CrossRef]

- Naumov, G.I.; Naumova, E.S.; Boundy-Mills, K.L. Description of Komagataella mondaviorum sp. nov., a new sibling species of Komagataella (Pichia) pastoris. Antonie van Leeuwenhoek 2018, 111, 1197–1207. [Google Scholar] [CrossRef]

- Ogata, K.; Nishikawa, H.; Ohsugi, M. Acetate Utilization for Yeast Cell Growth as Sole Carbon Source. Agric. Biol. Chem. 1969, 33, 977–978. [Google Scholar] [CrossRef]

- Cos, O.; Ramón, R.; Montesinos, J.L.; Valero, F. Operational strategies, monitoring and control of heterologous protein production in the methylotrophic yeast Pichia pastoris under different promoters: A review. Microb. Cell Factories 2006, 5, 17. [Google Scholar] [CrossRef]

- Cereghino, G. Applications of yeast in biotechnology: Protein production and genetic analysis. Curr. Opin. Biotechnol. 1999, 10, 422–427. [Google Scholar] [CrossRef]

- Cregg, J.M.; Vedvick, T.S.; Raschke, W.C. Recent Advances in the Expression of Foreign Genes in Pichia pastoris. Nat. Biotechnol. 1993, 11, 905–910. [Google Scholar] [CrossRef]

- Cregg, J.M.; Cereghino, J.L.; Shi, J.; Higgins, D.R. Recombinant Protein Expression in Pichia pastoris. Mol. Biotechnol. 2000, 16, 23–52. [Google Scholar] [CrossRef]

- Harder, W.; Veenhuis, M. Metabolism of one carbon compounds. In The Yeasts; Rose, A.H., Harrison, J.S., Eds.; Academic Press: London, UK, 1989; Volume 3, pp. 289–316. [Google Scholar] [CrossRef]

- Ata, O.; Ergün, B.G.; Fickers, P.; Heistinger, L.; Mattanovich, D.; Rebnegger, C.; Gasser, B. What makes Komagataella phaffii non-conventional? FEMS Yeast Res. 2021, 21, foab059. [Google Scholar] [CrossRef]

- Ozimek, P.; Veenhuis, M.; Van der Klei, I.J. Alcohol oxidase: A complex peroxisomal, oligomeric flavoprotein. FEMS Yeast Res. 2005, 5, 975–983. [Google Scholar] [CrossRef]

- Cámara, E.; Landes, N.; Albiol, J.; Gasser, B.; Mattanovich, D.; Ferrer, P. Increased dosage of AOX1 promoter-regulated expression cassettes leads to transcription attenuation of the methanol metabolism in Pichia pastoris. Sci. Rep. 2017, 7, srep44302. [Google Scholar] [CrossRef]

- Charoenrat, T.; Khumruaengsri, N.; Promdonkoy, P.; Rattanaphan, N.; Eurwilaichitr, L.; Tanapongpipat, S.; Roongsawang, N. Improvement of recombinant endoglucanase produced in Pichia pastoris KM71 through the use of synthetic medium for inoculum and pH control of proteolysis. J. Biosci. Bioeng. 2013, 116, 193–198. [Google Scholar] [CrossRef]

- Cregg, J.M.; Madden, K.R.; Barringer, K.J.; Thill, G.P.; Stillman, C.A. Functional characterization of the two alcohol oxidase genes from the yeast Pichia pastoris. Mol. Cell. Biol. 1989, 9, 1316–1323. [Google Scholar] [CrossRef]

- Brady, J.R.; Whittaker, C.A.; Tan, M.C.; Kristensen, D.L.; Ma, D.; Dalvie, N.C.; Love, K.R.; Love, J.C. Comparative genome-scale analysis of Pichia pastoris variants informs selection of an optimal base strain. Biotechnol. Bioeng. 2019, 117, 543–555. [Google Scholar] [CrossRef]

- Li, Z.; Xiong, F.; Lin, Q.; D’Anjou, M.; Daugulis, A.J.; Yang, D.S.; Hew, C.L. Low-Temperature Increases the Yield of Biologically Active Herring Antifreeze Protein in Pichia pastoris. Protein Expr. Purif. 2001, 21, 438–445. [Google Scholar] [CrossRef]

- Cregg, J.M.; Barringer, K.J.; Hessler, A.Y.; Madden, K.R. Pichia pastoris as a host system for transformations. Mol. Cell. Biol. 1985, 5, 3376–3385. [Google Scholar] [CrossRef]

- Tschopp, J.F.; Brust, P.F.; Cregg, J.M.; Stillman, C.A.; Gingeras, T.R. Expression of the lacZ gene from two methanol-regulated promoters in Pichia pastoris. Nucleic Acids Res. 1987, 15, 3859–3876. [Google Scholar] [CrossRef]

- Mohseni, A.H.; Soleimani, M.; Majidzadeh-A, K.; Taghinezhad-S, S.; Keyvani, H. Active Expression of Human Tissue Plasminogen Activator (t-PA) c-DNA from Pulmonary Metastases in the Methylotrophic Yeast Pichia pastoris KM71H Strain. Asian Pac. J. Cancer Prev. 2017, 18, 2249–2254. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, X.; Wu, S.; Wei, T.; Yu, L. High-yield production of the human lysozyme by Pichia pastoris SMD1168 using response surface methodology and high-cell-density fermentation. Electron. J. Biotechnol. 2014, 17, 311–316. [Google Scholar] [CrossRef]

- Jian, X.; Mahtar, W.N.A.W.; Chiew, S.P.; Miswan, N.; Yin, K.B. Potential use of Pichia pastoris strain SMD1168H expressing DNA topoisomerase I in the screening of potential anti-breast cancer agents. Mol. Med. Rep. 2019, 19, 5368–5376. [Google Scholar] [CrossRef]

- Ahmad, M.; Hirz, M.; Pichler, H.; Schwab, H. Protein expression in Pichia pastoris: Recent achievements and perspectives for heterologous protein production. Appl. Microbiol. Biotechnol. 2014, 98, 5301–5317. [Google Scholar] [CrossRef]

- Juturu, V.; Wu, J.C. Heterologous Protein Expression in Pichia pastoris: Latest Research Progress and Applications. Chembiochem 2017, 19, 7–21. [Google Scholar] [CrossRef]

- Xu, N.; Zhu, J.; Zhu, Q.; Xing, Y.; Cai, M.; Jiang, T.; Zhou, M.; Zhang, Y. Identification and characterization of novel promoters for recombinant protein production in yeast Pichia pastoris. Yeast 2017, 35, 379–385. [Google Scholar] [CrossRef]

- Yurimoto, H.; Oku, M.; Sakai, Y. Yeast Methylotrophy: Metabolism, Gene Regulation and Peroxisome Homeostasis. Int. J. Microbiol. 2011, 2011, 1–8. [Google Scholar] [CrossRef]

- Zhang, A.-L.; Luo, J.-X.; Zhang, T.-Y.; Pan, Y.-W.; Tan, Y.-H.; Fu, C.-Y.; Tu, F.-Z. Recent advances on the GAP promoter derived expression system of Pichia pastoris. Mol. Biol. Rep. 2008, 36, 1611–1619. [Google Scholar] [CrossRef]

- Mochizuki, S.; Hamato, N.; Hirose, M.; Miyano, K.; Ohtani, W.; Kameyama, S.; Kuwae, S.; Tokuyama, T.; Ohi, H. Expression and Characterization of Recombinant Human Antithrombin III in Pichia pastoris. Protein Expr. Purif. 2001, 23, 55–65. [Google Scholar] [CrossRef]

- Sreekrishna, K.; Brankamp, R.G.; Kropp, K.E.; Blankenship, D.T.; Tsay, J.-T.; Smith, P.L.; Wierschke, J.D.; Subramaniam, A.; Birkenberger, L.A. Strategies for optimal synthesis and secretion of heterologous proteins in the methylotrophic yeast Pichia pastoris. Gene 1997, 190, 55–62. [Google Scholar] [CrossRef]

- Spice, A.J.; Aw, R.; Polizzi, K.M. Cell-Free Protein Synthesis Using Pichia pastoris. In Cell-Free Gene Expression; Springer: Berlin/Heidelberg, Germany, 2022; pp. 75–88. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.-Q.; Li, J. Establishing a Eukaryotic Pichia pastoris Cell-Free Protein Synthesis System. Front. Bioeng. Biotechnol. 2020, 8, 536. [Google Scholar] [CrossRef]

- Aw, R.; Spice, A.J.; Polizzi, K.M. Methods for Expression of Recombinant Proteins Using a Pichia pastoris Cell-Free System. Curr. Protoc. Protein Sci. 2020, 102, e115. [Google Scholar] [CrossRef]

- Obaida, B.A.R.M. Yeasts as a Source of Single Cell Protein Production: A Review. Plant Arch. 2021, 21, 324–328. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Ma, M.; Zhao, P.; Ming, F.; Lu, Z.; Shi, J.; Fan, Q.; Liang, Q.; Jia, J.; et al. Co-expressing GroEL–GroES, Ssa1–Sis1 and Bip–PDI chaperones for enhanced intracellular production and partial-wall breaking improved stability of porcine growth hormone. Microb. Cell Factories 2020, 19, 35. [Google Scholar] [CrossRef]

- Rasala, B.A.; Mayfield, S.P. Photosynthetic biomanufacturing in green algae; production of recombinant proteins for industrial, nutritional, and medical uses. Photosynth. Res. 2014, 123, 227–239. [Google Scholar] [CrossRef]

- European Patent Office. Available online: https://www.epo.org/searching-for-patents.html (accessed on 28 December 2022).

- US7736629B2—Red Herbal Dentifrice—Google Patents. Available online: https://patents.google.com/patent/US7736629B2/en?oq=US+Pat.+No.+7%2C736%2C629+B2 (accessed on 28 April 2020).

- Highsmith, J. Biological Therapeutic Drugs: Technologies and Global Markets; BCC Research: Wellesley, MA, USA, 2015. [Google Scholar]

- Walsh, G. Biopharmaceutical benchmarks 2014. Nat. Biotechnol. 2014, 32, 992–1000. [Google Scholar] [CrossRef]

- Dewan, S.S. Global Markets for Enzymes in Industrial Use; BCC Research: Wellesley, MA, USA, 2017; p. 7215. [Google Scholar]

- BCC. Global Markets for Enzymes in Industrial Applications; BCC: Wellesley, MA, USA, 2021; Available online: https://www.bccresearch.com/market-research/biotechnology/global-markets-for-enzymes-in-industrial-applications.html (accessed on 10 January 2023).

- Rosano, G.L.; Ceccarelli, E.A. Recombinant protein expression in Escherichia coli: Advances and challenges. Front. Microbiol. 2014, 5, 172. [Google Scholar] [CrossRef]

- Rettenbacher, L.A.; Arauzo-Aguilera, K.; Buscajoni, L.; Castillo-Corujo, A.; Ferrero-Bordera, B.; Kostopoulou, A.; Moran-Torres, R.; Núñez-Nepomuceno, D.; Öktem, A.; Palma, A.; et al. Microbial protein cell factories fight back? Trends Biotechnol. 2022, 40, 576–590. [Google Scholar] [CrossRef]

- Rader, R.A.; Langer, E.S. Upstream Single-Use Bioprocessing Systems Future Market Trends and Growth Assessment. Bioprocess Int. 2012, 10, 12–18. [Google Scholar]

- Walsh, G. Biopharmaceutical benchmarks 2018. Nat. Biotechnol. 2018, 36, 1136–1145. [Google Scholar] [CrossRef]

- Tripathi, N.K.; Shrivastava, A. Recent Developments in Bioprocessing of Recombinant Proteins: Expression Hosts and Process Development. Front. Bioeng. Biotechnol. 2019, 7, 420. [Google Scholar] [CrossRef]

- VALIDOGEN GmbH White Paper, High Level Methanol-Free Phytase Production in Pichia Pastoris. Available online: https://www.validogen.com/pichia-pastoris/downloads (accessed on 10 January 2023).

- Sanchez-Garcia, L.; Martín, L.; Mangues, R.; Ferrer-Miralles, N.; Vázquez, E.; Villaverde, A. Recombinant pharmaceuticals from microbial cells: A 2015 update. Microb. Cell Fact. 2016, 15, 33. [Google Scholar] [CrossRef]

- Darby, R.A.J.; Cartwright, S.P.; Dilworth, M.V. Which Yeast Species Shall I Choose? Saccharomyces cerevisiae Versus Pichia pastoris (Review). In Recombinant Protein Production in Yeast: Methods and Protocols; Bill, R.M., Ed.; Humana Press: Totowa, NJ, USA, 2012; pp. 11–23. [Google Scholar]

- Khan, K.H. Gene Expression in Mammalian Cells and its Applications. Adv. Pharm. Bull. 2013, 3, 257–263. [Google Scholar] [CrossRef]

- Hamilton, S.R.; Bobrowicz, P.; Bobrowicz, B.; Davidson, R.C.; Li, H.; Mitchell, T.; Nett, J.H.; Rausch, S.; Stadheim, T.A.; Wischnewski, H.; et al. Production of Complex Human Glycoproteins in Yeast. Science 2003, 301, 1244–1246. [Google Scholar] [CrossRef]

- Wildt, S.; Gerngross, T.U. The humanization of N-glycosylation pathways in yeast. Nat. Rev. Genet. 2005, 3, 119–128. [Google Scholar] [CrossRef]

- Hamilton, S.R.; Davidson, R.C.; Sethuraman, N.; Nett, J.H.; Jiang, Y.; Rios, S.; Bobrowicz, P.; Stadheim, T.A.; Li, H.; Choi, B.-K.; et al. Humanization of Yeast to Produce Complex Terminally Sialylated Glycoproteins. Science 2006, 313, 1441–1443. [Google Scholar] [CrossRef]

- Jacobs, P.P.; Geysens, S.; Vervecken, W.; Contreras, R.; Callewaert, N. Engineering complex-type N-glycosylation in Pichia pastoris using GlycoSwitch technology. Nat. Protoc. 2008, 4, 58–70. [Google Scholar] [CrossRef]

- Heyland, J.; Fu, J.; Blank, L.M.; Schmid, A. Carbon metabolism limits recombinant protein production in Pichia pastoris. Biotechnol. Bioeng. 2011, 108, 1942–1953. [Google Scholar] [CrossRef]

- Ergun, B.G.; Çalık, P. Hybrid-architectured promoter design to engineer expression in yeast. In Methods in Enzymology; Academic Press: Cambridge, MA, USA, 2021; Volume 660, pp. 81–104. [Google Scholar] [CrossRef]

- Ergün, B.G.; Demir, I.; Özdamar, T.H.; Gasser, B.; Mattanovich, D.; Çalık, P. Engineered Deregulation of Expression in Yeast with Designed Hybrid-Promoter Architectures in Coordination with Discovered Master Regulator Transcription Factor. Adv. Biosyst. 2020, 4, e1900172. [Google Scholar] [CrossRef]

- Santoso, A.; Herawati, N.; Rubiana, Y. Effect of Methanol Induction and Incubation Time on Expression of Human Erythropoietin in Methylotropic Yeast Pichia pastoris. Makara J. Technol. 2012, 16, 5. [Google Scholar] [CrossRef]

- Farsiani, H.; Mosavat, A.; Soleimanpour, S.; Sadeghian, H.; Eydgahi, M.R.A.; Ghazvini, K.; Sankian, M.; Aryan, E.; Jamehdar, S.A.; Rezaee, S.A. Fc-based delivery system enhances immunogenicity of a tuberculosis subunit vaccine candidate consisting of the ESAT-6:CFP-10 complex. Mol. Biosyst. 2016, 12, 2189–2201. [Google Scholar] [CrossRef]

- Soleimanpour, S.; Farsiani, H.; Mosavat, A.; Ghazvini, K.; Eydgahi, M.R.A.; Sankian, M.; Sadeghian, H.; Meshkat, Z.; Rezaee, S.A. APC targeting enhances immunogenicity of a novel multistage Fc-fusion tuberculosis vaccine in mice. Appl. Microbiol. Biotechnol. 2015, 99, 10467–10480. [Google Scholar] [CrossRef]

- Bernauer, L.; Radkohl, A.; Lehmayer, L.G.K.; Emmerstorfer-Augustin, A. Komagataella phaffii as Emerging Model Organism in Fundamental Research. Front. Microbiol. 2021, 11, 607028. [Google Scholar] [CrossRef]

- Puxbaum, V.; Mattanovich, D.; Gasser, B. Quo vadis? The challenges of recombinant protein folding and secretion in Pichia pastoris. Appl. Microbiol. Biotechnol. 2015, 99, 2925–2938. [Google Scholar] [CrossRef]

- Delic, M.; Valli, M.; Graf, A.B.; Pfeffer, M.; Mattanovich, D.; Gasser, B. The secretory pathway: Exploring yeast diversity. FEMS Microbiol. Rev. 2013, 37, 872–914. [Google Scholar] [CrossRef]

- Tran, A.-M.; Nguyen, T.-T.; Nguyen, C.-T.; Huynh-Thi, X.-M.; Nguyen, C.-T.; Trinh, M.-T.; Tran, L.-T.; Cartwright, S.P.; Bill, R.M.; Tran-Van, H. Pichia pastoris versus Saccharomyces cerevisiae: A case study on the recombinant production of human granulocyte-macrophage colony-stimulating factor. BMC Res. Notes 2017, 10, 1–8. [Google Scholar] [CrossRef]

- Dragosits, M.; Stadlmann, J.; Graf, A.; Gasser, B.; Maurer, M.; Sauer, M.; Kreil, D.P.; Altmann, F.; Mattanovich, D. The response to unfolded protein is involved in osmotolerance of Pichia pastoris. BMC Genom. 2010, 11, 207. [Google Scholar] [CrossRef]

- Morton, C.L.; Potter, P.M. Comparison of Escherichia coli, Saccharomyces cerevisiae, Pichia pastoris, Spodoptera frugiperda, and COS7 Cells for Recombinant Gene Expression: Application to a Rabbit Liver Carboxylesterase. Mol. Biotechnol. 2000, 16, 193–202. [Google Scholar] [CrossRef]

- Jiao, L.; Zhou, Q.; Yan, Y. Efficient gene disruption by posttransformational directed internal homologous recombination in Pichia pastoris. Anal. Biochem. 2019, 576, 1–4. [Google Scholar] [CrossRef]

- Caramelo, J.J.; Parodi, A.J. Getting In and Out from Calnexin/Calreticulin Cycles. J. Biol. Chem. 2008, 283, 10221–10225. [Google Scholar] [CrossRef]

- Neubert, P.; Halim, A.; Zauser, M.; Essig, A.; Joshi, H.J.; Zatorska, E.; Larsen, I.S.B.; Loibl, M.; Castells-Ballester, J.; Aebi, M.; et al. Mapping the O-Mannose Glycoproteome in Saccharomyces cerevisiae. Mol. Cell. Proteom. 2016, 15, 1323–1337. [Google Scholar] [CrossRef]

- Whyteside, G.; Nor, R.M.; Alcocer, M.J.; Archer, D.B. Activation of the unfolded protein response in Pichia pastoris requires splicing of a HAC1 mRNA intron and retention of the C-terminal tail of Hac1p. FEBS Lett. 2011, 585, 1037–1041. [Google Scholar] [CrossRef] [PubMed]

- Hoseki, J.; Ushioda, R.; Nagata, K. Mechanism and components of endoplasmic reticulum-associated degradation. J. Biochem. 2009, 147, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Kohno, K. Stress-sensing mechanisms in the unfolded protein response: Similarities and differences between yeast and mammals. J. Biochem. 2009, 147, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Vembar, S.S.; Brodsky, J.L. One step at a time: Endoplasmic reticulum-associated degradation. Nat. Rev. Mol. Cell Biol. 2008, 9, 944–957. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, J.D.; Kaufman, R.J. The endoplasmic reticulum and the unfolded protein response. Semin. Cell Dev. Biol. 2007, 18, 716–731. [Google Scholar] [CrossRef]

- Zimmermann, R.; Eyrisch, S.; Ahmad, M.; Helms, V. Protein translocation across the ER membrane. Biochim. Biophys. Acta (BBA) -Biomembr. 2011, 1808, 912–924. [Google Scholar] [CrossRef]

- Matlack, K.E.; Misselwitz, B.; Plath, K.; Rapoport, T.A. BiP Acts as a Molecular Ratchet during Posttranslational Transport of Prepro-α Factor across the ER Membrane. Cell 1999, 97, 553–564. [Google Scholar] [CrossRef]

- Kampinga, H.H.; Craig, E.A. The HSP70 chaperone machinery: J proteins as drivers of functional specificity. Nat. Rev. Mol. Cell Biol. 2010, 11, 579–592, Erratum in Nat. Rev. Mol. Cell Biol. 2010, 11, 750. [Google Scholar] [CrossRef]

- Woycechowsky, K.J.; Raines, R.T. Native disulfide bond formation in proteins. Curr. Opin. Chem. Biol. 2000, 4, 533–539. [Google Scholar] [CrossRef]

- Wang, L.; Wang, C.-C. Oxidative protein folding fidelity and redoxtasis in the endoplasmic reticulum. Trends Biochem. Sci. 2022, 48, 40–52. [Google Scholar] [CrossRef]

- Naseem, M.U.; Tajti, G.; Gaspar, A.; Szanto, T.G.; Borrego, J.; Panyi, G. Optimization of Pichia pastoris Expression System for High-Level Production of Margatoxin. Front. Pharmacol. 2021, 12, 2454. [Google Scholar] [CrossRef] [PubMed]

- Navone, L.; Vogl, T.; Luangthongkam, P.; Blinco, J.-A.; Luna-Flores, C.H.; Chen, X.; von Hellens, J.; Mahler, S.; Speight, R. Disulfide bond engineering of AppA phytase for increased thermostability requires co-expression of protein disulfide isomerase in Pichia pastoris. Biotechnol. Biofuels 2021, 14, 80. [Google Scholar] [CrossRef]

- Bollok, M.; Resina, D.; Valero, F.; Ferrer, P. Recent patents on the Pichia pastoris expression system: Expanding the toolbox for recombinant protein production. Recent Pat. Biotechnol. 2009, 3, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Cregg, J.M. Method for High-Level Expression of Polypeptides in Yeast of the Genus Pichia. EP0226752, 1 July 1987. [Google Scholar]

- Barrigon, J.M.; Valero, F.; Montesinos, J.L. A macrokinetic model-based comparative meta-analysis of recombinant protein production by Pichia pastoris under AOX1 promoter. Biotechnol. Bioeng. 2015, 112, 1132–1145. [Google Scholar] [CrossRef] [PubMed]

- Looser, V.; Bruhlmann, B.; Bumbak, F.; Stenger, C.; Costa, M.; Camattari, A.; Fotiadis, D.; Kovar, K. Cultivation strategies to enhance productivity of Pichia pastoris: A review. Biotechnol. Adv. 2015, 33, 1177–1193. [Google Scholar] [CrossRef]

- Pichia.com. Available online: https://pichia.com/science-center/commercialized-products (accessed on 28 December 2022).

- Craven, S.; Whelan, J.; Glennon, B. Glucose concentration control of a fed-batch mammalian cell bioprocess using a nonlinear model predictive controller. J. Process. Control. 2014, 24, 344–357. [Google Scholar] [CrossRef]

- Kuprijanov, A.; Schaepe, S.; Simutis, R.; Lübbert, A. Model predictive control made accessible to professional automation systems in fermentation technology. Biosyst. Inf. Technol. 2013, 2, 26–31. [Google Scholar] [CrossRef]

- Dabros, M.; Schuler, M.M.; Marison, I.W. Simple control of specific growth rate in biotechnological fed-batch processes based on enhanced online measurements of biomass. Bioprocess Biosyst. Eng. 2010, 33, 1109–1118. [Google Scholar] [CrossRef]

- Veloso, A.C.A.; Rocha, I.; Ferreira, E.C. Monitoring of fed-batch E. coli fermentations with software sensors. Bioprocess Biosyst. Eng. 2008, 32, 381–388. [Google Scholar] [CrossRef]

- Soons, Z.; Voogt, J.; van Straten, G.; van Boxtel, A. Constant specific growth rate in fed-batch cultivation of Bordetella pertussis using adaptive control. J. Biotechnol. 2006, 125, 252–268. [Google Scholar] [CrossRef]

- De Pourcq, K.; De Schutter, K.; Callewaert, N. Engineering of glycosylation in yeast and other fungi: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 87, 1617–1631. [Google Scholar] [CrossRef] [PubMed]

- Gasser, B.; Saloheimo, M.; Rinas, U.; Dragosits, M.; Rodríguez-Carmona, E.; Baumann, K.; Giuliani, M.; Parrilli, E.; Branduardi, P.; Lang, C.; et al. Protein folding and conformational stress in microbial cells producing recombinant proteins: A host comparative overview. Microb. Cell Factories 2008, 7, 11. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, W.; Zhou, X.; Bai, P.; Cregg, J.M.; Zhang, Y. Catabolite Repression of Aox in Pichia pastoris Is Dependent on Hexose Transporter PpHxt1 and Pexophagy. Appl. Environ. Microbiol. 2010, 76, 6108–6118. [Google Scholar] [CrossRef]

- Cereghino, G.P.; Cereghino, J.L.; Ilgen, C.; Cregg, J.M. Production of recombinant proteins in fermenter cultures of the yeast Pichia pastoris. Curr. Opin. Biotechnol. 2002, 13, 329–332. [Google Scholar] [CrossRef] [PubMed]

- Wegner, E.H. Biochemical Conversions by Yeast Fermentation at High Cell Dendsities. US4617274, 14 October 1986. [Google Scholar]

- Spadiut, O.; Herwig, C. Dynamics in bioprocess development for Pichia pastoris. Bioengineered 2014, 5, 401–404. [Google Scholar] [CrossRef] [PubMed]

- Nocon, J.; Steiger, M.G.; Pfeffer, M.; Sohn, S.B.; Kim, T.Y.; Maurer, M.; Rußmayer, H.; Pflügl, S.; Ask, M.; Haberhauer-Troyer, C.; et al. Model based engineering of Pichia pastoris central metabolism enhances recombinant protein production. Metab. Eng. 2014, 24, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Inan, M.; Meagher, M.M. Rational Design and Optimization of Fed-Batch and Continuous Fermentations. In Pichia Protocols; Springer: Berlin/Heidelberg, Germany, 2007; Volume 389, pp. 43–63. [Google Scholar] [CrossRef]

- Garcia-Ortega, X.; Valero, F.; Montesinos-Seguí, J.L. Physiological state as transferable operating criterion to improve recombinant protein production in Pichia pastoris through oxygen limitation. J. Chem. Technol. Biotechnol. 2017, 92, 2573–2582. [Google Scholar] [CrossRef]

- Güneş, H.; Boy, E.; Ata, O.; Zerze, G.H.; Çalık, P.; Özdamar, T.H. Methanol feeding strategy design enhances recombinant human growth hormone production by Pichia pastoris. J. Chem. Technol. Biotechnol. 2014, 91, 664–671. [Google Scholar] [CrossRef]

- Garcia-Ortega, X.; Adelantado, N.; Ferrer, P.; Montesinos, J.L.; Valero, F. A step forward to improve recombinant protein production in Pichia pastoris: From specific growth rate effect on protein secretion to carbon-starving conditions as advanced strategy. Process. Biochem. 2016, 51, 681–691. [Google Scholar] [CrossRef]

- Çalık, P.; Ata, O.; Güneş, H.; Massahi, A.; Boy, E.; Keskin, A.; Öztürk, S.; Zerze, G.H.; Özdamar, T.H. Recombinant protein production in Pichia pastoris under glyceraldehyde-3-phosphate dehydrogenase promoter: From carbon source metabolism to bioreactor operation parameters. Biochem. Eng. J. 2015, 95, 20–36. [Google Scholar] [CrossRef]

- Lonza Pharma & Biotech, Tools for successful biologics—XS® Pichia Expression System. Available online: https://pharma.lonza.co.jp/-/media/Lonza/knowledge/Licensing/Pichia-Technical-Note-Update_0121_TSB_XS-TLI.pdf (accessed on 10 January 2023).

- Prielhofer, R.; Maurer, M.; Klein, J.; Wenger, J.; Kiziak, C.; Gasser, B.; Mattanovich, D. Induction without methanol: Novel regulated promoters enable high-level expression in Pichia pastoris. Microb. Cell Factories 2013, 12, 5. [Google Scholar] [CrossRef] [PubMed]

- Prielhofer, R.; Reichinger, M.; Wagner, N.; Claes, K.; Kiziak, C.; Gasser, B.; Mattanovich, D. Superior protein titers in half the fermentation time: Promoter and process engineering for the glucose-regulated GTH1 promoter of Pichia pastoris. Biotechnol. Bioeng. 2018, 115, 2479–2488. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Bao, J.; Nielsen, J. Biopharmaceutical protein production by Saccharomyces cerevisiae: Current state and future prospects. Pharm. Bioprocess. 2014, 2, 167–182. [Google Scholar] [CrossRef]

- Baumann, K.; Carnicer, M.; Dragosits, M.; Graf, A.B.; Stadlmann, J.; Jouhten, P.; Maaheimo, H.; Gasser, B.; Albiol, J.; Mattanovich, D.; et al. A multi-level study of recombinant Pichia pastoris in different oxygen conditions. BMC Syst. Biol. 2010, 4, 141. [Google Scholar] [CrossRef] [PubMed]

- Rebnegger, C.; Vos, T.; Graf, A.B.; Valli, M.; Pronk, J.T.; Daran-Lapujade, P.; Mattanovich, D. Pichia pastoris Exhibits High Viability and a Low Maintenance Energy Requirement at Near-Zero Specific Growth Rates. Appl. Environ. Microbiol. 2016, 82, 4570–4583. [Google Scholar] [CrossRef] [PubMed]

- Rebnegger, C.; Graf, A.B.; Valli, M.; Steiger, M.G.; Gasser, B.; Maurer, M.; Mattanovich, D. In Pichia pastoris, growth rate regulates protein synthesis and secretion, mating and stress response. Biotechnol. J. 2013, 9, 511–525. [Google Scholar] [CrossRef]

- Baumann, K.; Maurer, M.; Dragosits, M.; Cos, O.; Ferrer, P.; Mattanovich, D. Hypoxic fed-batch cultivation of Pichia pastoris increases specific and volumetric productivity of recombinant proteins. Biotechnol. Bioeng. 2007, 100, 177–183. [Google Scholar] [CrossRef]

- Takors, R. Scale-up of microbial processes: Impacts, tools and open questions. J. Biotechnol. 2012, 160, 3–9. [Google Scholar] [CrossRef]

- Formenti, L.R.; Nørregaard, A.; Bolic, A.; Hernandez, D.Q.; Hagemann, T.; Heins, A.-L.; Larsson, H.; Mears, L.; Mauricio-Iglesias, M.; Krühne, U.; et al. Challenges in industrial fermentation technology research. Biotechnol. J. 2014, 9, 727–738. [Google Scholar] [CrossRef]

- Sin, G.; Gernaey, K.V.; Lantz, A.E. Good modelling practice (GMoP) for PAT applications: Propagation of input uncertainty and sensitivity analysis. Biotechnol Prog. 2009, 25, 1043–1053. [Google Scholar] [CrossRef]

- Meyer, H.P.; Minas, W.; Schmidhalter, D. Industrial Biotechnology: Products and Processes; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2017. [Google Scholar] [CrossRef]

- Mattanovich, D.; Branduardi, P.; Dato, L.; Gasser, B.; Sauer, M.; Porro, D. Recombinant protein production in yeasts. In Recombinant Gene Expression; Springer: Berlin/Heidelberg, Germany, 2012; Volume 824, pp. 329–358. [Google Scholar] [CrossRef]

- Balasundaram, B.; Harrison, S.; Bracewell, D.G. Advances in product release strategies and impact on bioprocess design. Trends Biotechnol. 2009, 27, 477–485. [Google Scholar] [CrossRef] [PubMed]

- Berrios, J.; Flores, M.-O.; Díaz-Barrera, A.; Altamirano, C.; Martínez, I.; Cabrera, Z. A comparative study of glycerol and sorbitol as co-substrates in methanol-induced cultures of Pichia pastoris: Temperature effect and scale-up simulation. J. Ind. Microbiol. Biotechnol. 2017, 44, 407–411. [Google Scholar] [CrossRef] [PubMed]

- Carly, F.; Niu, H.; Delvigne, F.; Fickers, P. Influence of methanol/sorbitol co-feeding rate on pAOX1 induction in a Pichia pastoris Mut+ strain in bioreactor with limited oxygen transfer rate. J. Ind. Microbiol. Biotechnol. 2016, 43, 517–523. [Google Scholar] [CrossRef] [PubMed]

- Canales, C.; Altamirano, C.; Berrios, J. Effect of dilution rate and methanol-glycerol mixed feeding on heterologous Rhizopus oryzae lipase production with Pichia pastoris Mut+phenotype in continuous culture. Biotechnol. Prog. 2015, 31, 707–714. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.W.; Yin, H.X.; Yi, X.P.; Zhang, A.L.; Luo, J.X.; Zhang, T.Y.; Fu, C.Y.; Zhang, Z.H.; Shen, J.C.; Chen, L.P. Constitutive expression of barley α-amylase in Pichia pastoris by high-density cell culture. Mol. Biol. Rep. 2011, 39, 5805–5810. [Google Scholar] [CrossRef] [PubMed]

- Baumann, K.; Adelantado, N.; Lang, C.; Mattanovich, D.; Ferrer, P. Protein trafficking, ergosterol biosynthesis and membrane physics impact recombinant protein secretion in Pichia pastoris. Microb. Cell Factories 2011, 10, 93. [Google Scholar] [CrossRef] [PubMed]

- Jordà, J.; Jouhten, P.; Cámara, E.; Maaheimo, H.; Albiol, J.; Ferrer, P. Metabolic flux profiling of recombinant protein secreting Pichia pastoris growing on glucose:methanol mixtures. Microb. Cell Factories 2012, 11, 57. [Google Scholar] [CrossRef]

- Tang, S.; Potvin, G.; Reiche, A.; Zhang, Z. Modeling of Phytase Production by Cultivation of Pichia pastoris Under the Control of the GAP Promoter. Int. J. Chem. React. Eng. 2010, 8. [Google Scholar] [CrossRef]

- Khasa, Y.P.; Khushoo, A.; Srivastava, L.; Mukherjee, K. Kinetic studies of constitutive human granulocyte-macrophage colony stimulating factor (hGM-CSF) expression in continuous culture of Pichia pastoris. Biotechnol. Lett. 2007, 29, 1903–1908. [Google Scholar] [CrossRef]

- Gasser, B.; Maurer, M.; Gach, J.; Kunert, R.; Mattanovich, D. Engineering of Pichia pastoris for improved production of antibody fragments. Biotechnol. Bioeng. 2006, 94, 353–361. [Google Scholar] [CrossRef]

- Nasr, M.M.; Krumme, M.; Matsuda, Y.; Trout, B.L.; Badman, C.; Mascia, S.; Cooney, C.L.; Jensen, K.D.; Florence, A.; Johnston, C.; et al. Regulatory Perspectives on Continuous Pharmaceutical Manufacturing: Moving from Theory to Practice. J. Pharm. Sci. 2017, 106, 3199–3206. [Google Scholar] [CrossRef] [PubMed]

- Gernaey, K.V.; Cervera-Padrell, A.E.; Woodley, J.M. Development of continuous pharmaceutical production processes supported by process systems engineering methods and tools. Futur. Med. Chem. 2012, 4, 1371–1374. [Google Scholar] [CrossRef] [PubMed]

- Gernaey, K.V.; Woodley, J.M.; Sin, G. Introducing mechanistic models in Process Analytical Technology education. Biotechnol. J. 2009, 4, 593–599. [Google Scholar] [CrossRef] [PubMed]

- Croughan, M.S.; Konstantinov, K.B.; Cooney, C. The future of industrial bioprocessing: Batch or continuous? Biotechnol. Bioeng. 2015, 112, 648–651. [Google Scholar] [CrossRef] [PubMed]

- Walther, J.; Godawat, R.; Hwang, C.; Abe, Y.; Sinclair, A.; Konstantinov, K. The business impact of an integrated continuous biomanufacturing platform for recombinant protein production. J. Biotechnol. 2015, 213, 3–12. [Google Scholar] [CrossRef]

- Seresht, A.K.; Cruz, A.L.; de Hulster, E.; Hebly, M.; Palmqvist, E.A.; van Gulik, W.; Daran, J.-M.; Pronk, J.; Olsson, L. Long-term adaptation of Saccharomyces cerevisiae to the burden of recombinant insulin production. Biotechnol. Bioeng. 2013, 110, 2749–2763. [Google Scholar] [CrossRef]

- Curvers, S.; Linnemann, J.; Klauser, T.; Wandrey, C.; Takors, R. Recombinant protein production with Pichia pastoris in con-tinuous fermentation—Kinetic analysis of growth and product formation. Eng. Life Sci. 2022, 2, 229. [Google Scholar] [CrossRef]

- Weninger, A.; Fischer, J.E.; Raschmanová, H.; Kniely, C.; Vogl, T.; Glieder, A. Expanding the CRISPR/Cas9 toolkit for Pichia pastoris with efficient donor integration and alternative resistance markers. J. Cell. Biochem. 2017, 119, 3183–3198. [Google Scholar] [CrossRef]

- Baumschabl, M.; Prielhofer, R.; Mattanovich, D.; Steiger, M.G. Fine-Tuning of Transcription in Pichia pastoris Using dCas9 and RNA Scaffolds. ACS Synth. Biol. 2020, 9, 3202–3209. [Google Scholar] [CrossRef]

- Lehmayer, L.; Bernauer, L.; Emmerstorfer-Augustin, A. Applying the auxin-based degron system for the inducible, reversible and complete protein degradation in Komagataella phaffii. Iscience 2022, 25, 104888. [Google Scholar] [CrossRef]

- Ito, Y.; Ishigami, M.; Terai, G.; Nakamura, Y.; Hashiba, N.; Nishi, T.; Nakazawa, H.; Hasunuma, T.; Asai, K.; Umetsu, M.; et al. A streamlined strain engineering workflow with genome-wide screening detects enhanced protein secretion in Komagataella phaffii. Commun. Biol. 2022, 5, 1–12. [Google Scholar] [CrossRef]

- Alva, T.R.; Riera, M.; Chartron, J.W. Translational landscape and protein biogenesis demands of the early secretory pathway in Komagataella phaffii. Microb. Cell Factories 2021, 20, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Huangfu, J.; Xu, Y.; Li, C.; Li, J. Overexpressing target helper genes enhances secretion and glycosylation of recombinant proteins in Pichia pastoris under simulated microgravity. J. Ind. Microbiol. Biotechnol. 2016, 43, 1429–1439. [Google Scholar] [CrossRef] [PubMed]

- Staudacher, J.; Rebnegger, C.; Dohnal, T.; Landes, N.; Mattanovich, D.; Gasser, B. Going beyond the limit: Increasing global translation activity leads to increased productivity of recombinant secreted proteins in Pichia pastoris. Metab. Eng. 2022, 70, 181–195. [Google Scholar] [CrossRef] [PubMed]

- Mäkelä, M.R.; Hildén, K.S.; Kuuskeri, J. Fungal Lignin-Modifying Peroxidases and H2O2-Producing Enzymes. In Encyclopedia of Mycology; Zaragoza, Ó., Casadevall, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 247–259. [Google Scholar] [CrossRef]

- Rieder, L.; Ebner, K.; Glieder, A.; Sørlie, M. Novel molecular biological tools for the efficient expression of fungal lytic polysaccharide monooxygenases in Pichia pastoris. Biotechnol. Biofuels 2021, 14, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Tan, H.; Li, S.; Zhang, M.; Che, J.; Li, K.; Chen, W.; Yin, H. Application of engineered yeast strain fermentation for oligogalacturonides production from pectin-rich waste biomass. Bioresour. Technol. 2020, 300, 122645. [Google Scholar] [CrossRef]

- Shirke, A.; White, C.; Englaender, J.A.; Zwarycz, A.S.; Butterfoss, G.L.; Linhardt, R.J.; Gross, R.A. Stabilizing Leaf and Branch Compost Cutinase (LCC) with Glycosylation: Mechanism and Effect on PET Hydrolysis. Biochemistry 2018, 57, 1190–1200. [Google Scholar] [CrossRef]

- Liu, M.; Yang, S.; Long, L.; Cao, Y.; Ding, S. Engineering a Chimeric Lipase-cutinase (Lip-Cut) for Efficient Enzymatic Deinking of Waste Paper. Bioresources 2017, 13, 981–996. [Google Scholar] [CrossRef]

- Sarp, S.; Hernandez, S.G.; Chen, C.; Sheehan, S.W. Alcohol Production from Carbon Dioxide: Methanol as a Fuel and Chemical Feedstock. Joule 2020, 5, 59–76. [Google Scholar] [CrossRef]

- Gassler, T.; Sauer, M.; Gasser, B.; Egermeier, M.; Troyer, C.; Causon, T.; Hann, S.; Mattanovich, D.; Steiger, M.G. The industrial yeast Pichia pastoris is converted from a heterotroph into an autotroph capable of growth on CO2. Nat. Biotechnol. 2019, 38, 210–216. [Google Scholar] [CrossRef]

- Urui, M.; Yamada, Y.; Ikeda, Y.; Nakagawa, A.; Sato, F.; Minami, H.; Shitan, N. Establishment of a co-culture system using Escherichia coli and Pichia pastoris (Komagataella phaffii) for valuable alkaloid production. Microb. Cell Factories 2021, 20, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Zuo, Y.; Xiao, F.; Gao, J.; Ye, C.; Jiang, L.; Dong, C.; Lian, J. Establishing Komagataella phaffii as a Cell Factory for Efficient Production of Sesquiterpenoid α-Santalene. J. Agric. Food Chem. 2022, 70, 8024–8031. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Tian, L.; Liu, Q.; Zhang, Y.; Cai, M. Engineered dynamic distribution of malonyl-CoA flux for improving polyketide biosynthesis in Komagataella phaffii. J. Biotechnol. 2020, 320, 80–85. [Google Scholar] [CrossRef]

- Zirpel, B.; Degenhardt, F.; Zammarelli, C.; Wibberg, D.; Kalinowski, J.; Stehle, F.; Kayser, O. Optimization of Δ 9 -tetrahydrocannabinolic acid synthase production in Komagataella phaffii via post-translational bottleneck identification. J. Biotechnol. 2018, 272–273, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Moser, S.; Strohmeier, G.A.; Leitner, E.; Plocek, T.J.; Vanhessche, K.; Pichler, H. Whole-cell (+)-ambrein production in the yeast Pichia pastoris. Metab. Eng. Commun. 2018, 7, e00077. [Google Scholar] [CrossRef] [PubMed]

- Wriessnegger, T.; Augustin, P.; Engleder, M.; Leitner, E.; Müller, M.; Kaluzna, I.; Schürmann, M.; Mink, D.; Zellnig, G.; Schwab, H.; et al. Production of the sesquiterpenoid (+)-nootkatone by metabolic engineering of Pichia pastoris. Metab. Eng. 2014, 24, 18–29. [Google Scholar] [CrossRef]

| Strain | Genotype | Phenotype | Application | Ref. |

|---|---|---|---|---|

| Y-11430 | Wild Type | --- | Highest activity of genes involved in methanol utilization | [41] |

| X-33 | Wild Type | --- | Selection of Zeocin™—resistant expression vectors | [42] |

| GS115 | his4 | Mut+, His− | Selection of expression vectors containing his4 | [43] |

| KM71 | his4, aox1:ARG4, arg4 | MutS, His− | Selection of expression vectors containing his4 to generate strains with MutS phenotype | [44] |

| KM71H | aox1:ARG4, arg4 | MutS | Selection of Zeocin™-resistant expression vectors to generate strains with MutS phenotype | [45] |

| SMD1168 | his4, pep4 | Mut+, His−, pep4− | Selection of expression vectors containing his4 to generate strains without protease A activity | [46] |

| SMD1168H | pep4 | Mut+, pep4− | Selection of Zeocin™-resistant expression vectors to generate strains without protease A activity | [47] |

| SMD1165 | his4, prb1 | Mut+, His−, prb1− | Selection of expression vectors containing his4 to generate strains without proteinase B activity | [48] |

| MC100-3 | arg4, his4, aox1:ARG4, aox2:Phis4 | Mut−, His− | Unable to grow on methanol | [49] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barone, G.D.; Emmerstorfer-Augustin, A.; Biundo, A.; Pisano, I.; Coccetti, P.; Mapelli, V.; Camattari, A. Industrial Production of Proteins with Pichia pastoris—Komagataella phaffii. Biomolecules 2023, 13, 441. https://doi.org/10.3390/biom13030441

Barone GD, Emmerstorfer-Augustin A, Biundo A, Pisano I, Coccetti P, Mapelli V, Camattari A. Industrial Production of Proteins with Pichia pastoris—Komagataella phaffii. Biomolecules. 2023; 13(3):441. https://doi.org/10.3390/biom13030441

Chicago/Turabian StyleBarone, Giovanni Davide, Anita Emmerstorfer-Augustin, Antonino Biundo, Isabella Pisano, Paola Coccetti, Valeria Mapelli, and Andrea Camattari. 2023. "Industrial Production of Proteins with Pichia pastoris—Komagataella phaffii" Biomolecules 13, no. 3: 441. https://doi.org/10.3390/biom13030441

APA StyleBarone, G. D., Emmerstorfer-Augustin, A., Biundo, A., Pisano, I., Coccetti, P., Mapelli, V., & Camattari, A. (2023). Industrial Production of Proteins with Pichia pastoris—Komagataella phaffii. Biomolecules, 13(3), 441. https://doi.org/10.3390/biom13030441