Aromatic Volatile Substances in Different Types of Guangnan Dixu Tea Based on HS-SPME-GC-MS Odor Activity Value

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Tea Samples

2.2. Experimental Equipment

2.3. Extraction and Analysis of Volatile Compounds

2.3.1. Quantitative Descriptive Analysis

2.3.2. Pretreatment of Tea Samples

2.3.3. Headspace Solid-Phase Microextraction of Volatiles

2.4. Conditions for GC-MS Analysis

2.5. OAV Calculation for Volatiles

2.6. Data Processing

3. Results

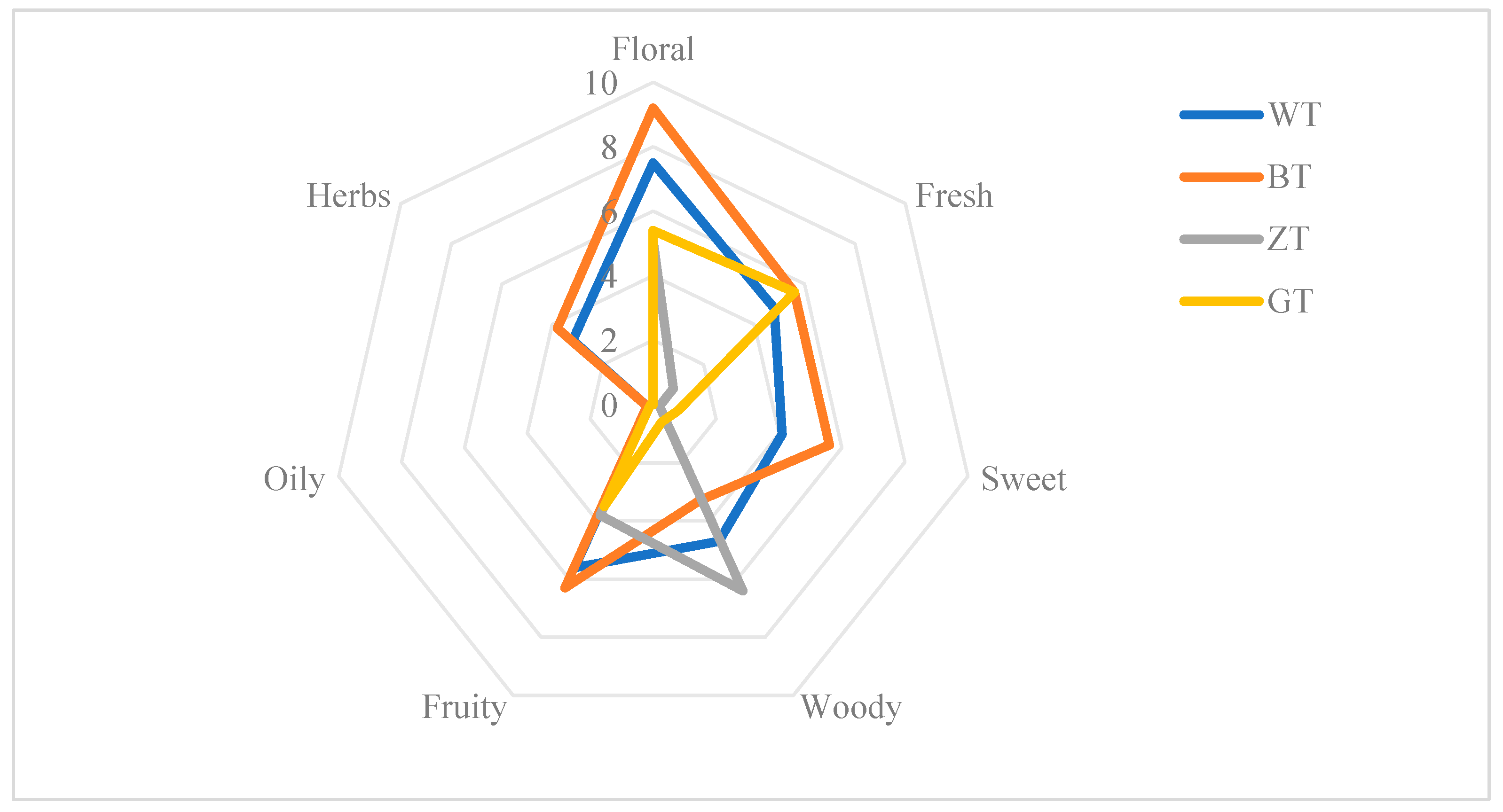

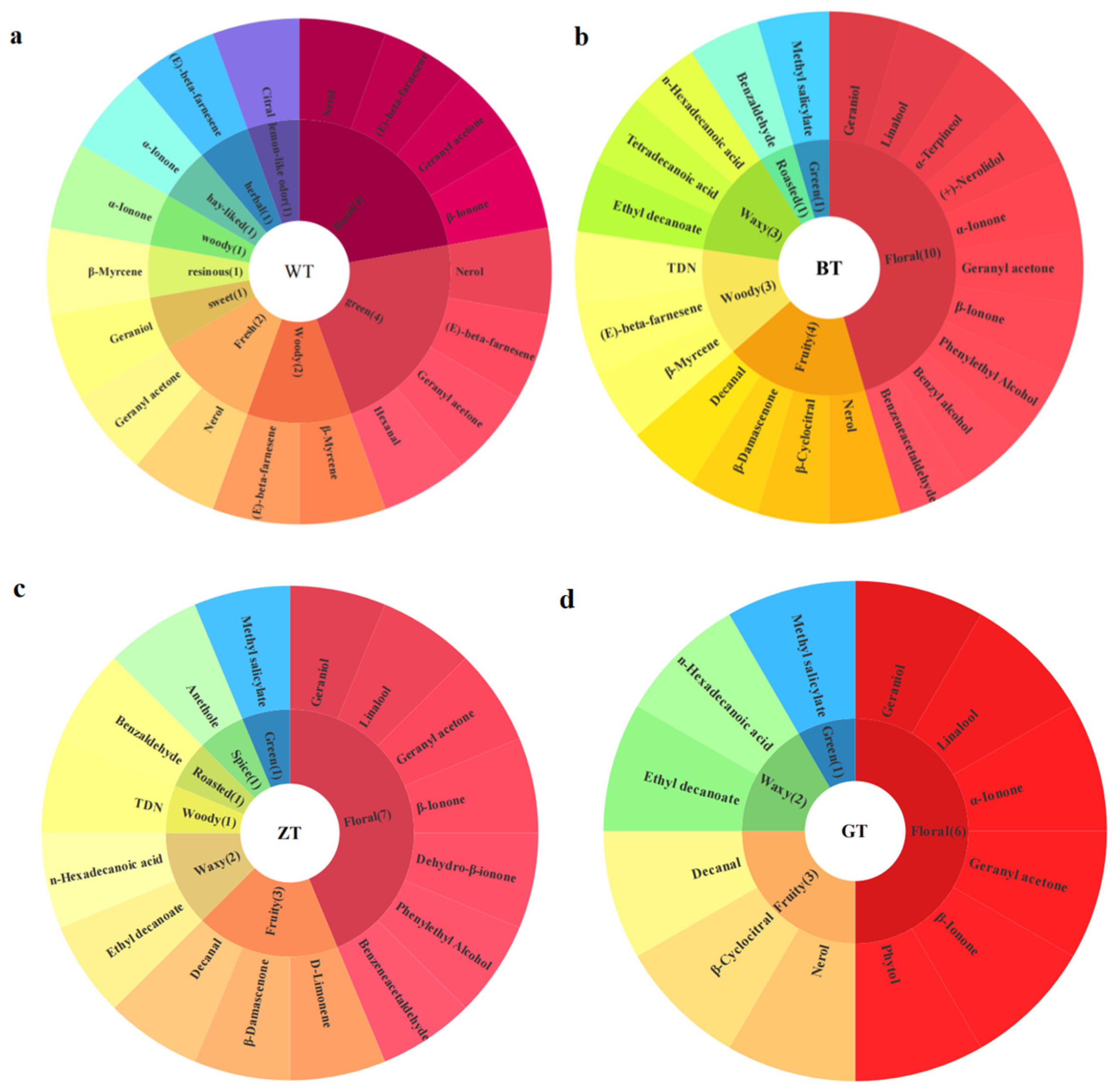

3.1. Results of Quantitative Descriptive Analysis

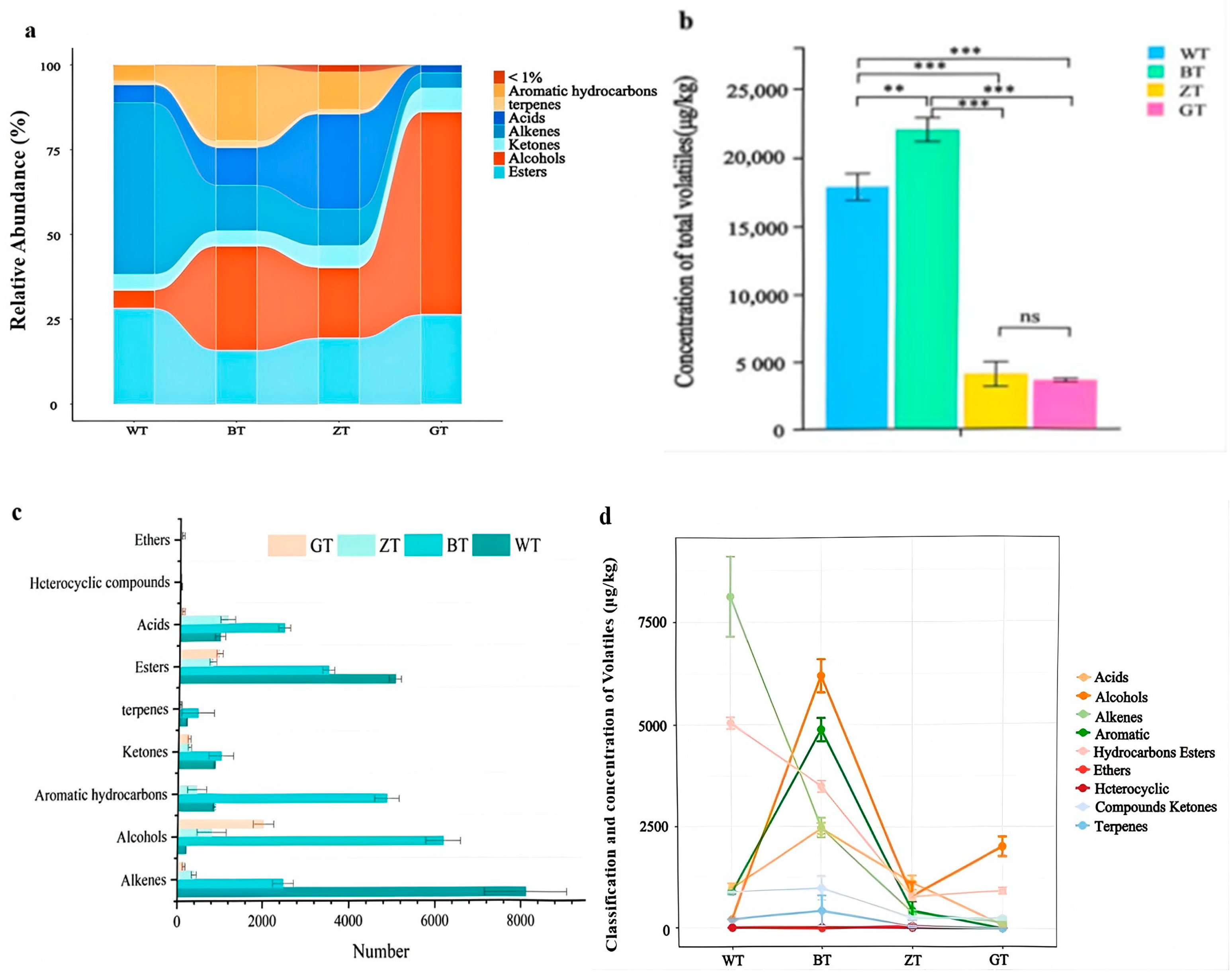

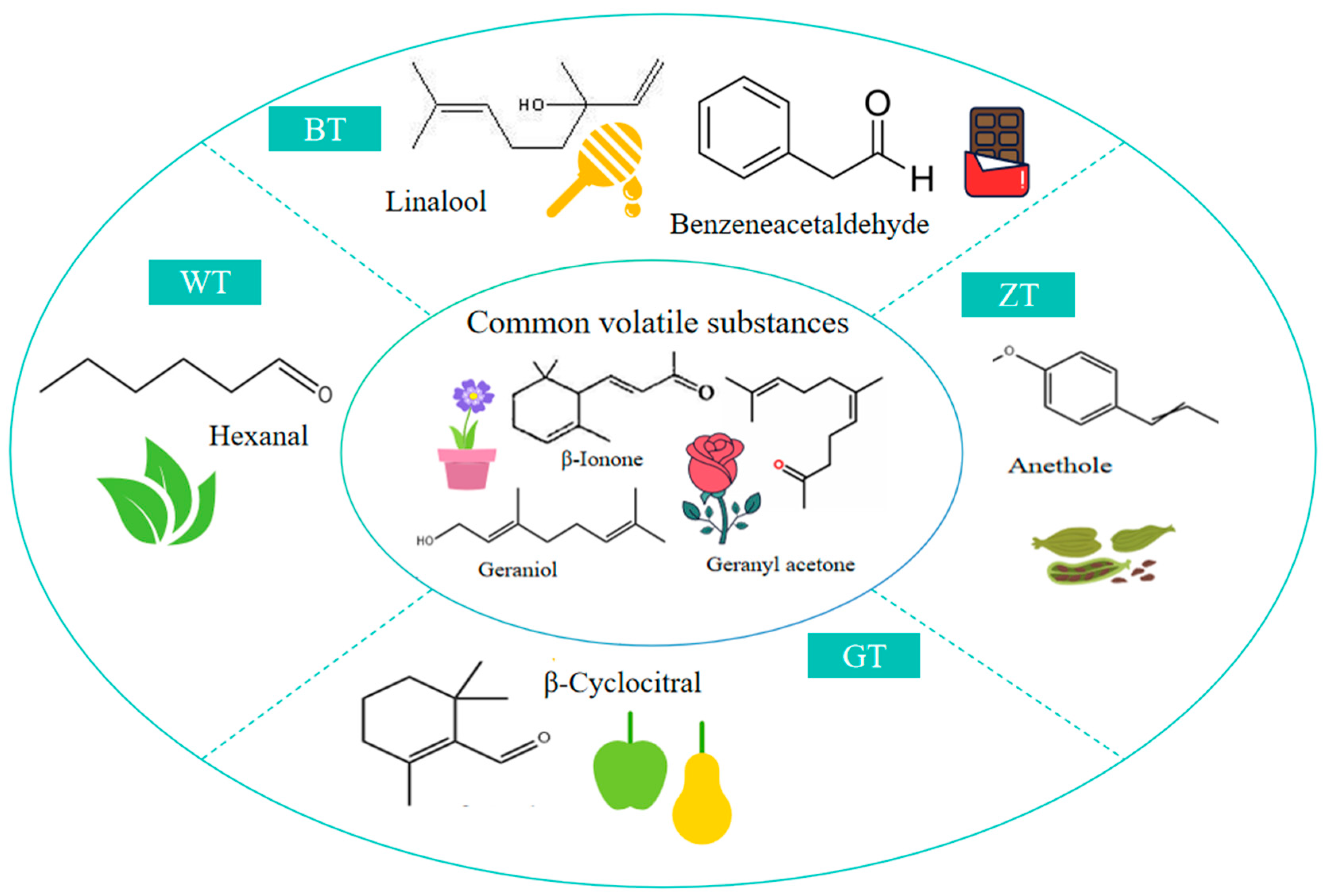

3.2. Analysis of Volatile Aroma Components

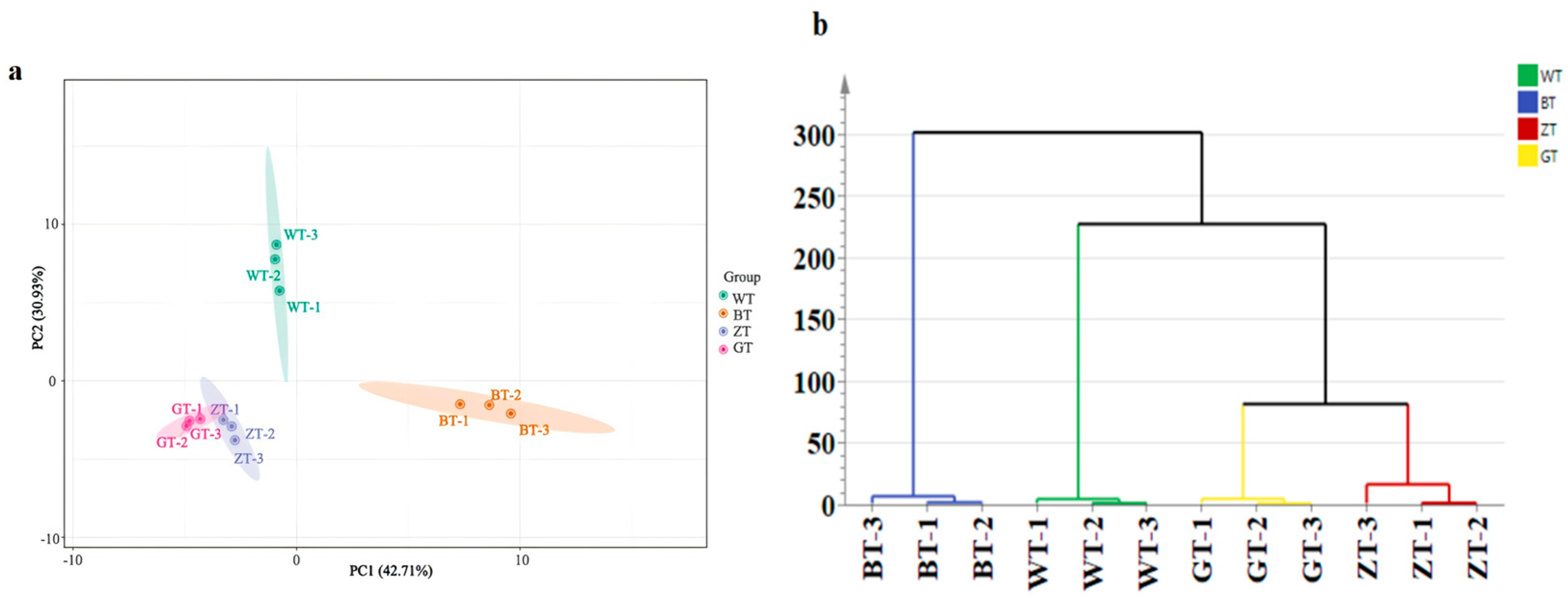

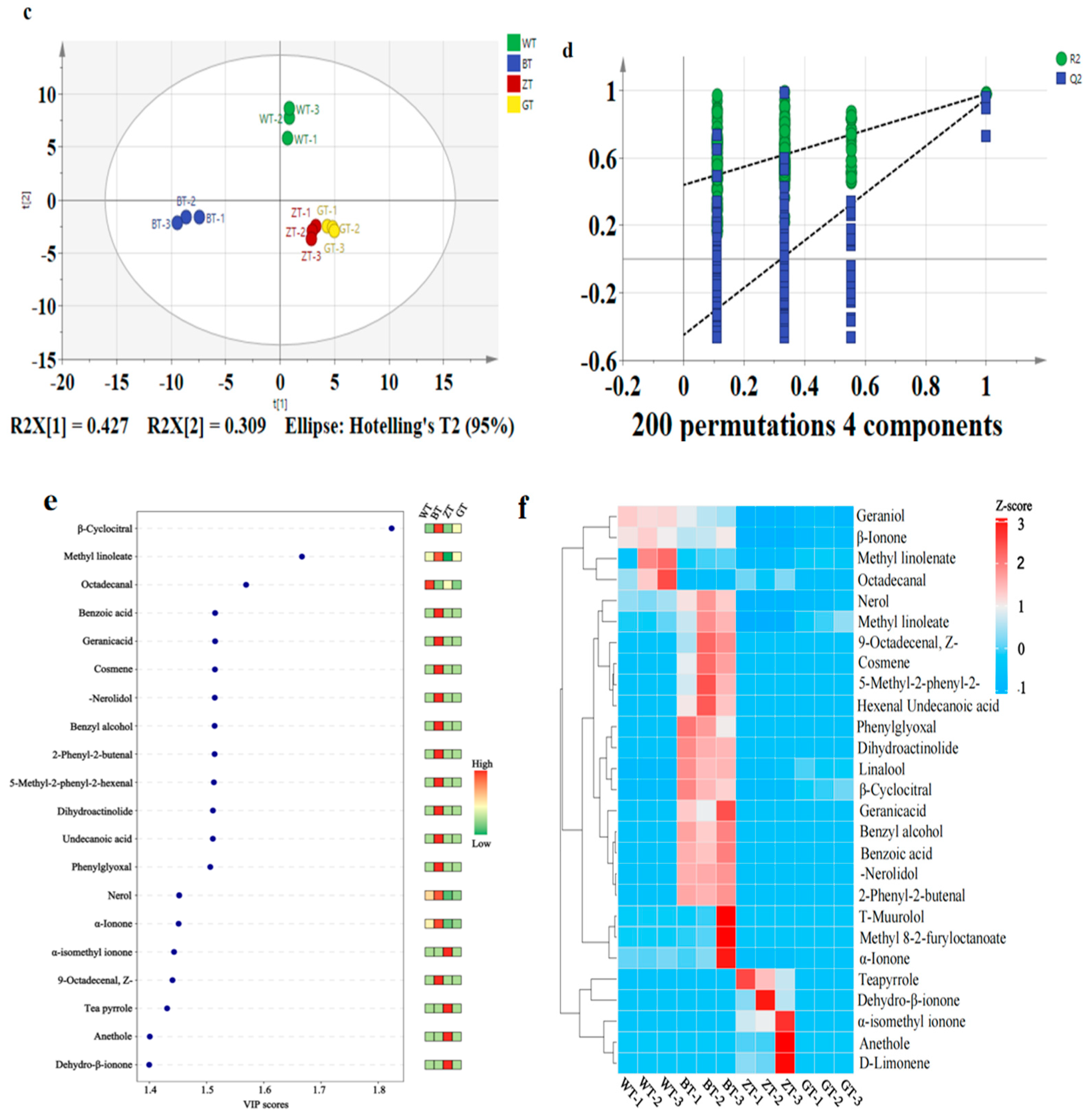

3.3. Multivariate Statistical Analysis of Volatile Aroma Components

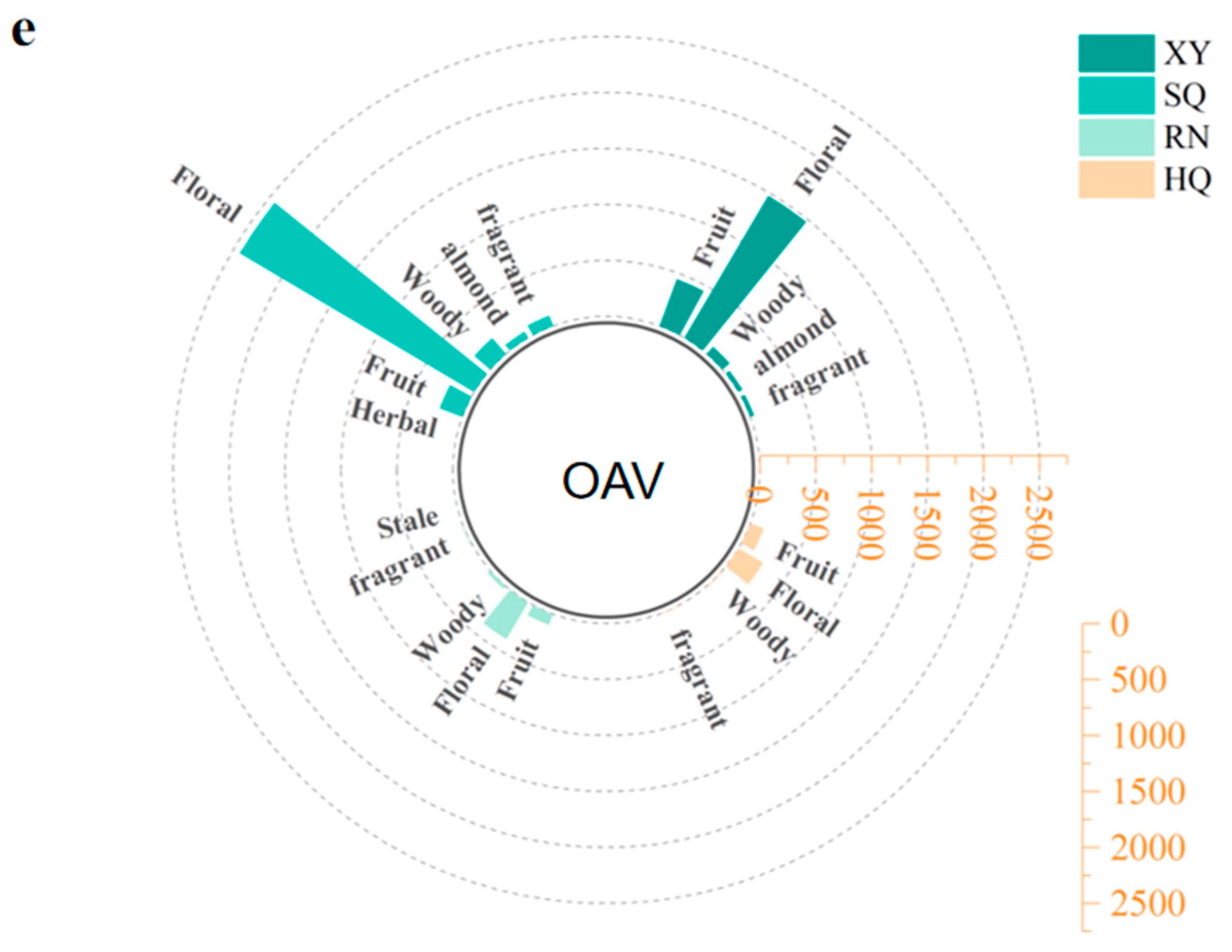

3.4. OAV Analysis of Differential Aroma Compounds

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Butt, M.S.; Ahmad, R.S.; Sultan, M.T.; Qayyum, M.M.N.; Naz, A. Green tea and anticancer perspectives: Updates from last decade. Crit. Rev. Food Sci. Nutr. 2015, 55, 792–805. [Google Scholar] [CrossRef]

- Liu, H.C.; Xu, Y.J.; Wu, J.J.; Wen, J.; Yu, Y.; An, K.; Zou, B. GC-IMS and olfactometry analysis on the tea aroma of yingde black teas harvested in different seasons. Food Rev. Int. 2021, 150, 110784. [Google Scholar] [CrossRef]

- Shen, J.Z.; Wang, Y.; Chen, C.S.; Ding, Z.; Hu, J.; Zheng, C.; Li, Y. Metabolite profiling of tea (Camellia sinensis L.) leaves in winter. Sci. Hortic. 2015, 192, 1–9. [Google Scholar] [CrossRef]

- Wang, P.J.; Gu, M.Y.; Shao, S.X.; Chen, X.; Hou, B.; Ye, N.; Zhang, X. Changes in non-volatile and volatile metabolites associated with heterosis in tea plants (Camellia sinensis). J. Agric. Food Chem. 2022, 70, 3067–3078. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Chen, Y.; Huang, Y.; Zheng, C.; Liao, S.; Xiao, L. Prediction of the quality of anxi tieguanyin based on hyperspectral detection technology. Foods 2024, 13, 4126. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Lian, X.Y.; Jin, L.; Li, D. Analysis of Key Aroma Components and Formation Mechanism of Chuanhong Gongfu Black Tea Based on HS-SPME-GC-MS. LWT Food Sci. Technol. 2025, 137, 1–14. [Google Scholar] [CrossRef]

- Tang, R.; Luo, Y.J.; Qu, J.; Lan, Z.Q.; Tao, Y.L. Study on the suitability of different tea types of ancient tea tree processing in Xinping County. J. Food Saf. Qual. Test. 2024, 15, 130–137. [Google Scholar] [CrossRef]

- Guan, Y.S. Promoting tea culture to support rural development. Yunnan Dly. 2025. [Google Scholar] [CrossRef]

- Chen, H.H.; Li, L.N.; Nie, Q.Y. Ultrasonic assisted extraction and antioxidant activity of polysaccharides from Diwei tea. Sci. Technol. Food Ind. 2020, 41, 179–184. [Google Scholar] [CrossRef]

- Liu, J.C.; Ren, X.F. Discussion on the Development Status and Countermeasures of Dixu Tea Industry in Guangnan County. South Agric. 2024, 18, 114–117. [Google Scholar]

- Xu, M.T.; Shao, S.X.; Chen, J.; Tian, H.W.; Xie, W.W.; Chen, X.M.; Ye, N.X.; Gao, S. Analysis of volatile components and key aroma components in Gongfu black tea from different tea tree varieties. Mod. Food Sci. Technol. 2023, 39, 281–290. [Google Scholar] [CrossRef]

- Si, H.Y.; Zhang, Y.; Wu, X.J.; Wang, C.; Xu, Y.Q.; Zhang, J. Research progress on aroma components of black tea. J. Tianjin Agric. Coll. 2023, 30, 74–81. [Google Scholar] [CrossRef]

- Jiu, M.L.; Du, M.J.; Yang, W.Q. The influence of shaping process on the main aroma components of Yunnan Fengqing black tea. J. Kunming Univ. 2017, 39, 46–49. [Google Scholar] [CrossRef]

- Si, Y.L.; Zhu, Y.; Ma, W.J.; Yang, G.Z.; Wang, M.Q.; Shi, J.; Peng, Q.H.; Lin, Z.; Lu, H. Research progress on volatile components of famous roasted green tea. Tea Sci. 2021, 41, 285–301. [Google Scholar] [CrossRef]

- Jin, L.; Lian, X.; Chen, Z.L.D. Characteristic aroma analysis and interaction study of key aroma compounds of chuanhong congou black tea. Eur. Food Res. Technol. =Z. Lebensm.-Unters.-Forsch. A 2024, 250, 441–454. [Google Scholar] [CrossRef]

- Su, D.; He, J.J.; Zhou, Y.Z.; Li, Y.L.; Zhou, H.J. Aroma effects of key volatile compounds in Keemun black tea at different grades: HS-SPME-GC-MS, sensory evaluation, and chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef]

- Mardiana, F.G.; Muhammad, D.R.A.; Affandi, D.R.; Ariviani, S. Sensory profile analysis of steamed brownies using Quantitative Descriptive Analysis (QDA). Earth Environ. Sci. 2021, 828, 12058. [Google Scholar] [CrossRef]

- Qian, Y.D. Aroma characterization of aged green tea using headspace solid-phase microextraction combined with GC/MS and GC-olfactometry. Abstr. Pap. Am. Chem. Soc. 2018, 256, 1074–1081. [Google Scholar] [CrossRef]

- Zhou, X.; Tian, D.; Zhou, H.; Dong, R.; Ma, C.; Ren, L.; Yang, X.; Wang, Q.; Chen, N.; Yang, L.; et al. Effects of Different Fermentation Methods on Flavor Quality of Liupao Tea Using GC-Q-TOF-MS and Electronic Nose Analyses. Foods 2024, 13, 2595. [Google Scholar] [CrossRef]

- Wei, H.; Zhou, H.; Huang, L.; Zhang, Q.; Teng, J.; Wei, B.; Xia, N.; Qin, R.; Zhu, P. Effect of baking treatment on quality, nonvolatile and volatile compounds of Liupao tea. Int. J. Food Sci. Technol. 2023, 58, 5154–5167. [Google Scholar] [CrossRef]

- Canellas, E.; Vera, P.; Domeno, C.; Alfaro, P.; Nerín, C. Atmospheric pressure gas chromatography coupled to quadrupole-time of flight mass spectrometry as a powerful tool for identification of nonintentionally added substances in acrylic adhesives used in food packaging materials. J. Chromatogr. A 2012, 1235, 141–148. [Google Scholar] [CrossRef]

- Zhang, J.X.; Xia, D.Z.; Li, T.H.; Wei, Y.; Feng, W.; Xiong, Z.; Huang, J.; Deng, W.W.; Ning, J. Effects of different over-fired drying methods on the aroma of Luan Guapian tea. Food Res. Int. 2023, 173, 113224. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Zhang, Y.; Zheng, N.; Zhang, Y.; Zhang, Y. Investigation of volatile organic compounds of whole-plant corn silage using hs-spme-gc-ms, hs-gc-ims and e-nose. Agriculture 2025, 15, 5. [Google Scholar] [CrossRef]

- Zhu, J.C.; Niu, Y.W.; Xiao, Z.B. Characterization of the key aroma compouns in laoshan green teas by application of odour activity value (OAV), gas chromatography-mass spectrometry-olfactometry (GC-MS-O) and comprehensive two-dimensional gas chromatography mass spectrometry (GC×GC-qMS). Food Chem. 2021, 339, 128–136. [Google Scholar] [CrossRef]

- Li, Y.; Wu, T.; Deng, X.; Tian, D.; Ma, C.; Wang, X.; Li, Y.; Zhou, H. Characteristic aroma compounds in naturally withered and combined withered γ-aminobutyric acid white tea revealed by HS-SPME-GC-MS and relative odor activity value. LWT 2023, 176, 114467. [Google Scholar] [CrossRef]

- Milheiro, J.; Filipe-Ribeiro, L.; Cosme, F.; Nunes, F.M. Development and validation of a multiple headspace solid-phase microextraction method for accurate and precise analysis of the aroma of Tawny and White Port wines. Food Chem. 2023, 421, 136154. [Google Scholar] [CrossRef]

- Guo, X.Y.; Tang, C. Aroma profiles of green tea made with fresh tea leaves plucked in summer. Food Chem. 2021, 363, 130328. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, W.J. Characterization of the key aroma compounds in Longjing tea using stir bar sorptive extraction (SBSE) combined with gas chromatography-mass spectrometry (GC-MS), gas chromatography-olfactometry (GC-O), odor activity value (OAV), and aroma recombination. Food Res. Int. 2020, 130, 130328. [Google Scholar] [CrossRef]

- Wang, Y.D.; Zeng, H.; Qiu, S.Z.; Han, H.; Wang, B. Identification of key aroma compounds and core functional microorganisms associated with aroma formation for Monascus-fermented cheese. Food Chem. 2023, 434, 137401. [Google Scholar] [CrossRef]

- Ayako, S.A. Identification and Characterization of Geranic Acid as a Unique Flavor Compound of Hops (Humulus lupulus L.) Variety Sorachi Ace. J. Agric. Food Chem. 2018, 66, 04395. [Google Scholar] [CrossRef]

- Wang, W.; Liu, F.; Xiao, L.D.; Liu, Y.Y. Comparative analysis of the quality of Yibin early tea processed from different tea tree varieties. J. Tea Commun. 2024, 51, 481–489. [Google Scholar] [CrossRef]

- Chen, S.X.; Luo, J.L.; Li, P.W.; Zhang, X.; Ao, C.W.; Li, J.H. Study on the effect of cleaning technology of fresh tea leaves on the quality of green tea. Mater. Sci. Forum 2020, 20, 160–167. [Google Scholar] [CrossRef]

- Gao, J.J.; Chen, D.; Peng, J.Y.; Wu, W.; Cai, L.S.; Cai, Y.W.; Tian, J.; Wan, Y.L.; Sun, W.J.; Huang, Y.; et al. Comparative analysis of chemical components between Yunnan white tea and Fuding white tea based on metabolomics. Tea Sci. 2022, 42, 623–637. [Google Scholar] [CrossRef]

- Qi, D.; Miao, A.; Cao, J.; Wang, W.; Chen, W.; Pang, S.; He, X.; Ma, C. Study on the effects of rapid aging technology on the aroma quality of white tea using GC-MS combined with chemometrics: In comparison with natural aged and fresh white tea. Food Chem. 2018, 265, 189–199. [Google Scholar] [CrossRef]

- Zou, Y.M.; Cai, W.Q.; Zhu, S.Y.; Wei, J.; Cui, L.L.; Zhou, X. Research progress on flavor compounds and characteristic aroma analysis of Fujian white tea. Process. Agric. Prod. 2023, 19, 84–89. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Chen, T.; Li, M.; Pang, Y.; Guo, C. Sensory and Quality Composition Analysis of Ancient Tree White Tea from Northern Guizhou in Different Regions. Food Technol. 2025, 50, 105–112. [Google Scholar] [CrossRef]

- Zheng, L.; Zhang, B.; Gong, X.G.; Wu, C.W.; Wu, M.M.; Jiang, M.H. Research on Volatile Components and Key Aroma Components of Bamboo Tube Tea. Yunnan Chem. Ind. 2021, 48, 73–75. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Tian, D.; Wang, C.; Huang, Y.; Luo, Y.; Zhang, X.; Li, L. Aromatic Volatile Substances in Different Types of Guangnan Dixu Tea Based on HS-SPME-GC-MS Odor Activity Value. Metabolites 2025, 15, 257. https://doi.org/10.3390/metabo15040257

Feng Y, Tian D, Wang C, Huang Y, Luo Y, Zhang X, Li L. Aromatic Volatile Substances in Different Types of Guangnan Dixu Tea Based on HS-SPME-GC-MS Odor Activity Value. Metabolites. 2025; 15(4):257. https://doi.org/10.3390/metabo15040257

Chicago/Turabian StyleFeng, Ying, Di Tian, Chaoliang Wang, Yong Huang, Yang Luo, Xiuqiong Zhang, and Lei Li. 2025. "Aromatic Volatile Substances in Different Types of Guangnan Dixu Tea Based on HS-SPME-GC-MS Odor Activity Value" Metabolites 15, no. 4: 257. https://doi.org/10.3390/metabo15040257

APA StyleFeng, Y., Tian, D., Wang, C., Huang, Y., Luo, Y., Zhang, X., & Li, L. (2025). Aromatic Volatile Substances in Different Types of Guangnan Dixu Tea Based on HS-SPME-GC-MS Odor Activity Value. Metabolites, 15(4), 257. https://doi.org/10.3390/metabo15040257