In Search of Complementary Extraction Methods for Comprehensive Coverage of the Escherichia coli Metabolome

Abstract

:1. Introduction

2. Materials and Methods

2.1. Generation of Cell Free Extracts

2.2. Extraction Methods

2.3. Chromatography

2.4. Mass Spectrometry Acquisition

2.5. Data Analysis

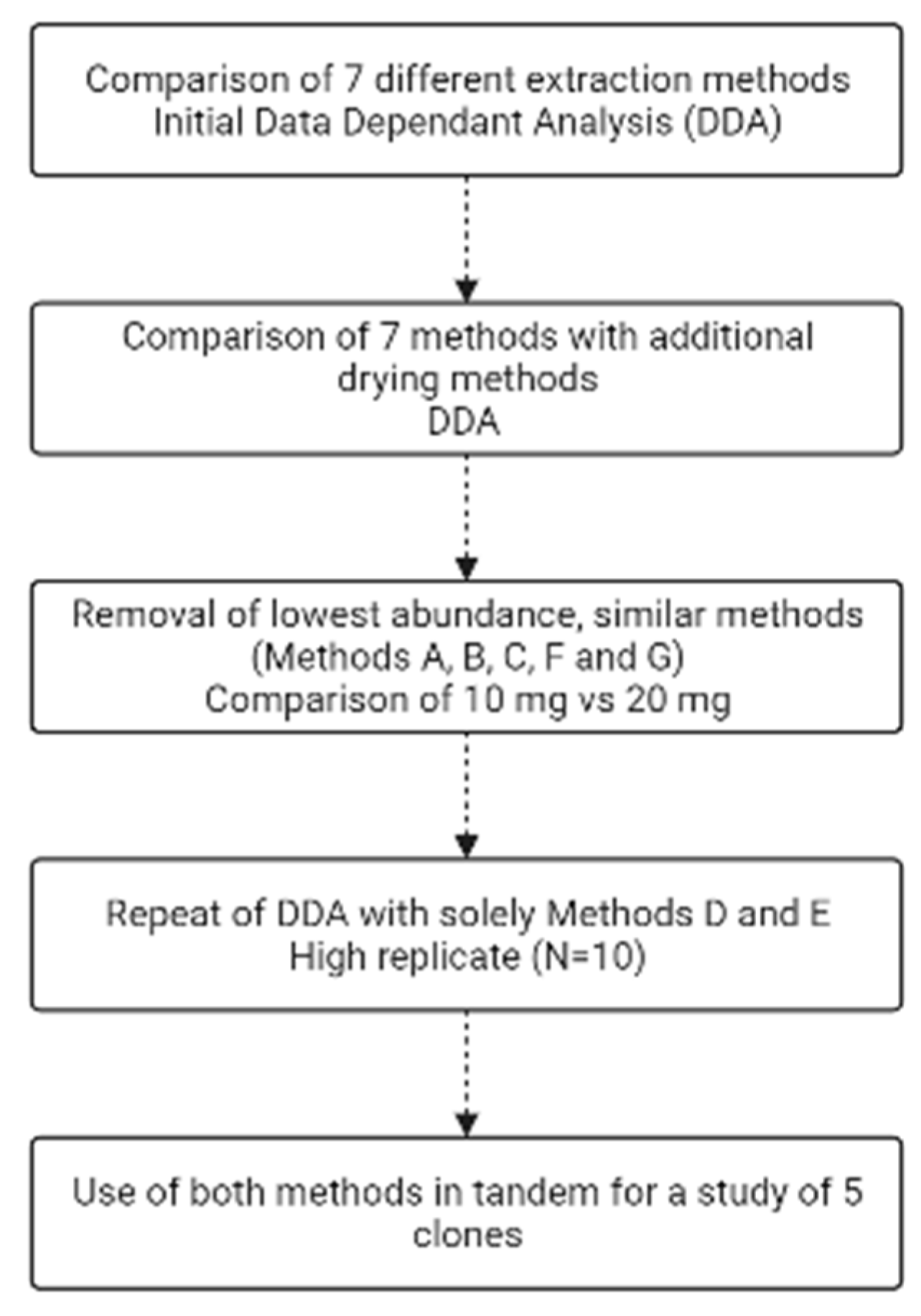

2.6. Experimental Steps Undertaken

3. Results

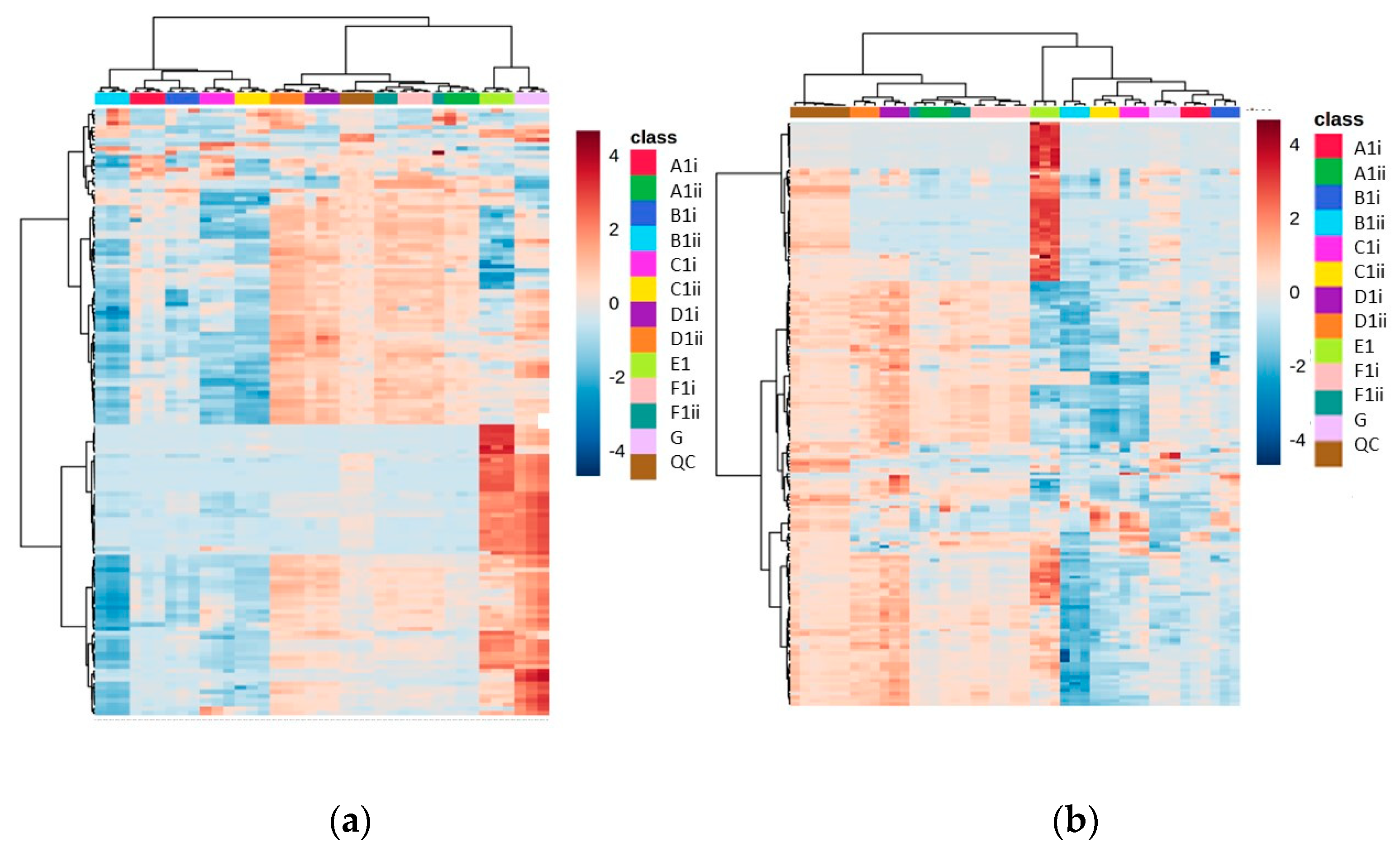

3.1. Creating the Analytical Landscape with a Range of Methods

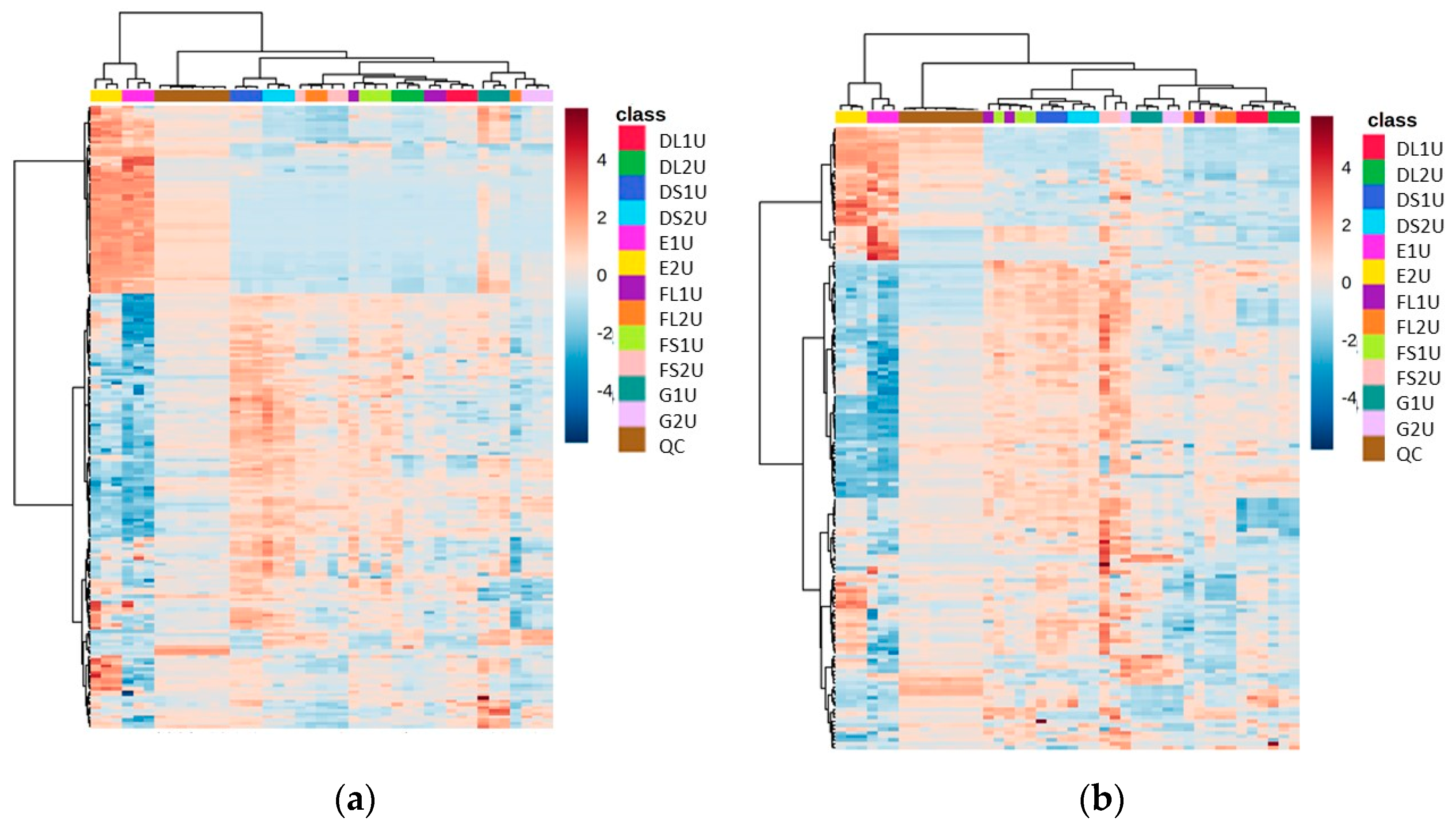

3.2. Comparison of 10 mg vs. 20 mg Starting Biomass (Focusing on Methods D, E, F and G) Revealed No Significant Difference between the Two Starting Masses While Filtration Resulted in Poor Reproducibility

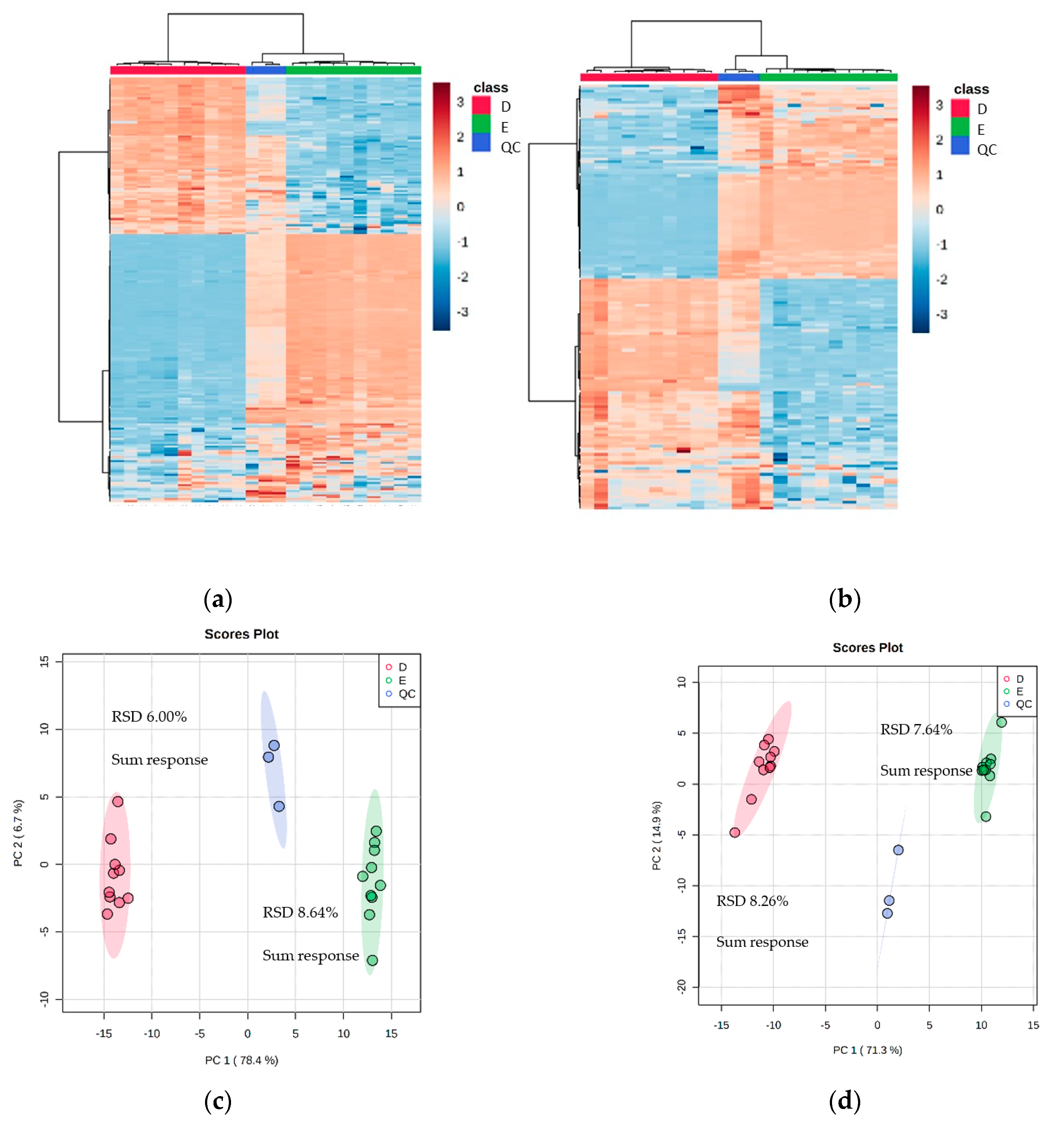

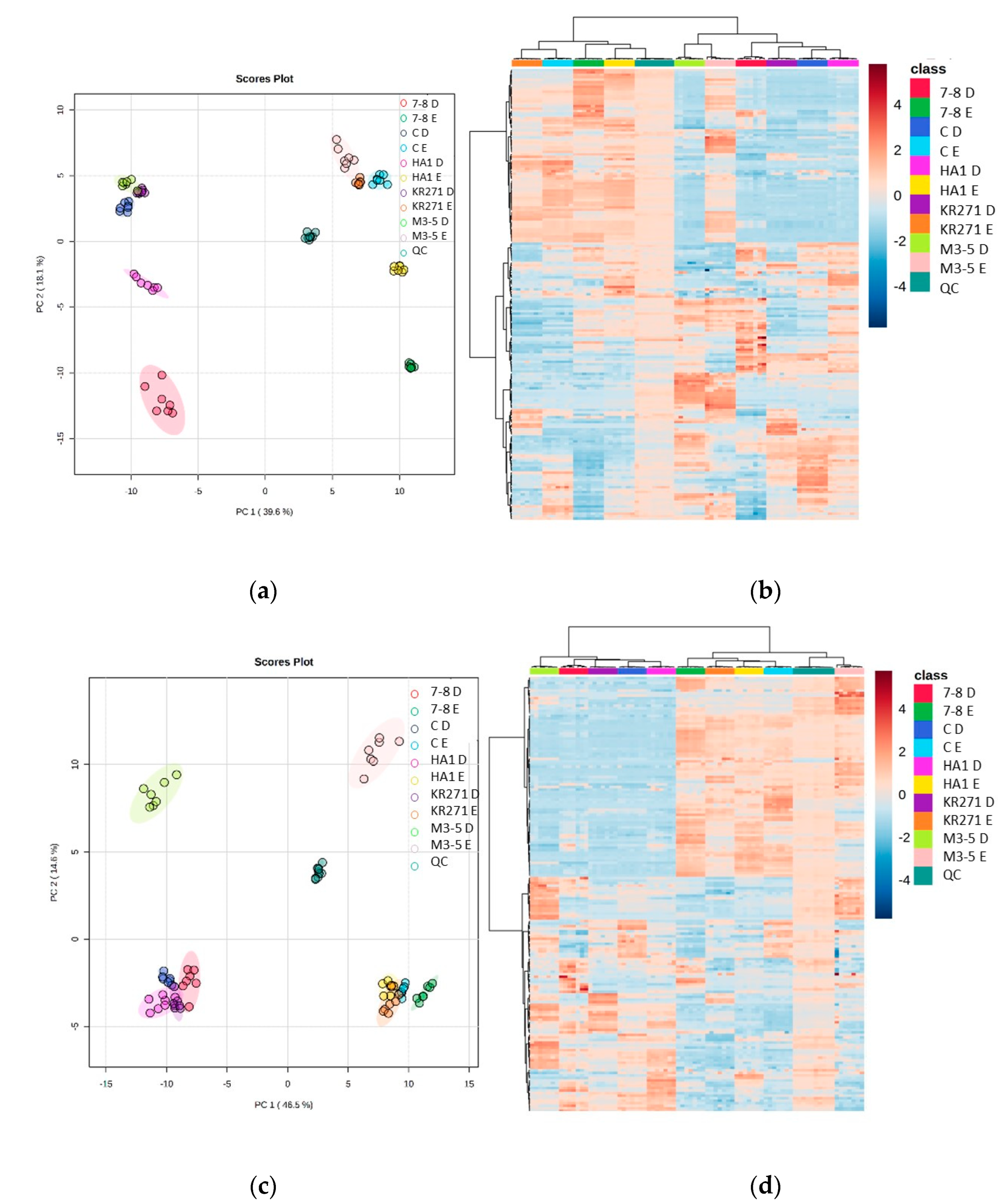

3.3. High Replicate Experiment Focusing on Methods D and E Demonstrated Stark Complementarity

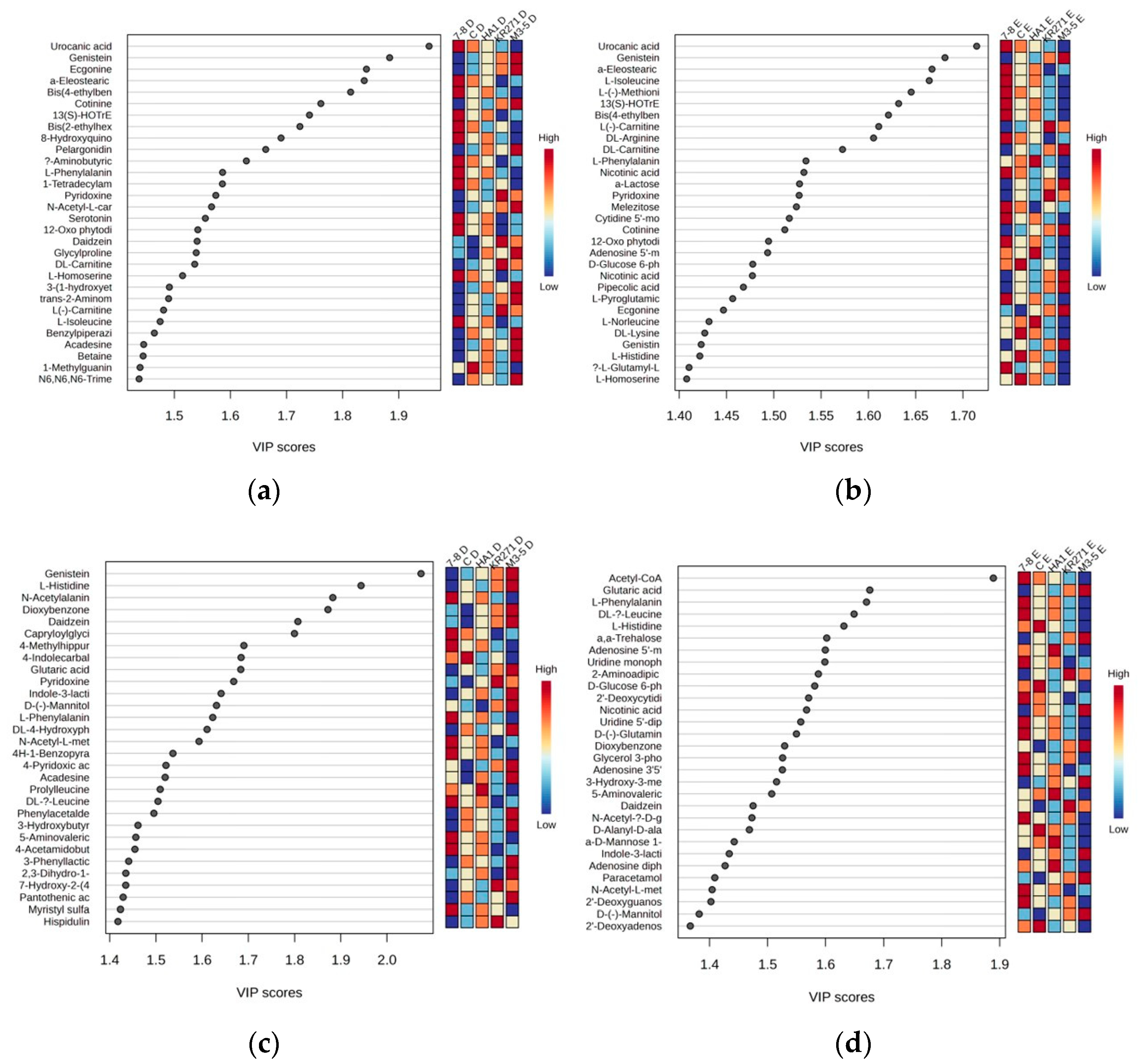

3.4. Utilizing a Dual Extraction Methodology Revealed Significant Differences between Recombinant E. coli BL21(DE3) Clones

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, A.C.; Jewison, T.; Wilson, M.; Liu, Y.; Knox, C.; Djoumbou, Y.; Lo, P.; Mandal, R.; Krishnamurthy, R.; Wishart, D.S. ECMDB: The E. coli Metabolome Database. Nucleic Acids Res. 2013, 41, D625–D630. [Google Scholar] [CrossRef] [PubMed]

- Chae, Y.K.; Kim, S.H.; Markley, J.L. Relationship between recombinant protein expression and host metabolome as determined by two-dimensional NMR spectroscopy. PLoS ONE 2017, 12, e0177233. [Google Scholar] [CrossRef] [PubMed]

- Kirkwood, J.S.; Maier, C.; Stevens, J.F. Simultaneous, untargeted metabolic profiling of polar and nonpolar metabolites by LC-Q-TOF mass spectrometry. Curr. Protoc. Toxicol. 2013, 56, 4.39.1–4.39.12. [Google Scholar] [CrossRef] [PubMed]

- Pinu, F.R.; Villas-Boas, S.G.; Aggio, R. Analysis of Intracellular Metabolites from Microorganisms: Quenching and Extraction Protocols. Metabolites 2017, 7, 53. [Google Scholar] [CrossRef] [PubMed]

- Rabinowitz, J.D.; Kimball, E. Acidic Acetonitrile for Cellular Metabolome Extraction from Escherichia coli. Anal. Chem. 2007, 79, 6167–6173. [Google Scholar] [CrossRef] [PubMed]

- Wong, M.W.K.; Braidy, N.; Pickford, R.; Sachdev, P.S.; Poljak, A. Comparison of Single Phase and Biphasic Extraction Protocols for Lipidomic Studies Using Human Plasma. Front. Neurol. 2019, 10, 879. [Google Scholar] [CrossRef] [PubMed]

- Hwangbo, M.; Chu, K.-H. Recent advances in production and extraction of bacterial lipids for biofuel production. Sci. Total Environ. 2020, 734, 139420. [Google Scholar] [CrossRef]

- Prasad Maharjan, R.; Ferenci, T. Global metabolite analysis: The influence of extraction methodology on metabolome profiles of Escherichia coli. Anal. Biochem. 2003, 313, 145–154. [Google Scholar] [CrossRef]

- Manier, S.K.; Meyer, M.R. Impact of the used solvent on the reconstitution efficiency of evaporated biosamples for untargeted metabolomics studies. Metabolomics 2020, 16, 34. [Google Scholar] [CrossRef]

- Zambelloni, R.; Connolly, J.P.R.; Huerta Uribe, A.; Burgess, K.; Marquez, R.; Roe, A.J. Novel compounds targeting the enterohemorrhagic Escherichia coli type three secretion system reveal insights into mechanisms of secretion inhibition. Mol. Microbiol. 2017, 105, 606–619. [Google Scholar] [CrossRef]

- Jozefczuk, S.; Klie, S.; Catchpole, G.; Szymanski, J.; Cuadros-Inostroza, A.; Steinhauser, D.; Selbig, J.; Willmitzer, L. Metabolomic and transcriptomic stress response of Escherichia coli. Mol. Syst. Biol. 2010, 6, 364. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Rinas, U. Recombinant protein production-associated metabolic burden reflects anabolic constraints and reveals similarities to a carbon overfeeding response. Biotechnol. Bioeng. 2021, 118, 94–105. [Google Scholar] [CrossRef]

- Gagnebin, Y.; Tonoli, D.; Lescuyer, P.; Ponte, B.; de Seigneux, S.; Martin, P.-Y.; Schappler, J.; Boccard, J.; Rudaz, S. Metabolomic analysis of urine samples by UHPLC-QTOF-MS: Impact of normalization strategies. Anal. Chim. Acta 2017, 955, 27–35. [Google Scholar] [CrossRef]

- Kim, J.; Kim, K.H. Effects of minimal media vs. complex media on the metabolite profiles of Escherichia coli and Saccharomyces cerevisiae. Process Biochem. 2017, 57, 64–71. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

| Method | Solvents | Ratio |

|---|---|---|

| A | Methanol:Water | 4:1 |

| B | Methanol:Chloroform | 3:1 |

| C | Chloroform:Methanol (:Water) | 2:1 (:1.2) |

| D/G | Acetonitrile:Water | 4:1 |

| E/F | Methanol:Water:Chloroform | 3:1:1 |

| Filtered Before Injection | Unfiltered Before Injection | ||||

| Extraction method | Starting Biomass (mg) | Vacuum Concentration | Lyophilization | Vacuum Concentration | Lyophilization |

| D | 10 | DS1F | DL1F | DS1U | DL1U |

| 20 | DS2F | DL2F | DS2U | DL2U | |

| F | 10 | FS1F | FL1F | FS1U | FL1U |

| 20 | FS2F | FL2F | FS2U | FL2U | |

| (a) | |||||

| Extraction Method | Starting Biomass (mg) | Filtered Before Injection | Unfiltered Before Injection | ||

| E | 10 | E1F | E1U | ||

| 20 | E2F | E2U | |||

| G | 10 | G1F | G1U | ||

| 20 | G2F | G2U | |||

| (b) | |||||

| Positive Mode | Negative Mode | ||

|---|---|---|---|

| Extraction | Features | Extraction | Features |

| DL1F | 840 | DL1F | 1300 |

| DL1U | 787 | DL1U | 1201 |

| DL2F | 73 | DL2F | 1134 |

| DL2U | 742 | DL2U | 1106 |

| DS1F | 1131 | DS1F | 1669 |

| DS1U | 1206 | DS1U | 1703 |

| DS2F | 133 | DS2F | 1577 |

| DS2U | 955 | DS2U | 1515 |

| E1F | 68 | E1F | 856 |

| E1U | 140 | E1U | 658 |

| E2F | 573 | E2F | 1418 |

| E2U | 675 | E2U | 1009 |

| FL1F | 506 | FL1F | 1327 |

| FL1U | 355 | FL1U | 929 |

| FL2F | 710 | FL2F | 571 |

| FL2U | 536 | FL2U | 532 |

| FS1F | 900 | FS1F | 1386 |

| FS1U | 843 | FS1U | 1195 |

| FS2F | 947 | FS2F | 956 |

| FS2U | 81 | FS2U | 1200 |

| G1F | 272 | G1F | 558 |

| G1U | 886 | G1U | 1326 |

| G2F | 214 | G2F | 1170 |

| G2U | 165 | G2U | 1461 |

| QC | 1325 | QC | 2115 |

| Clone/Extraction Method | Pos Average RSD | Neg Average RSD |

|---|---|---|

| 7-8 D | 31.01 | 41.29 |

| 7-8 E | 16.47 | 32.98 |

| C D | 18.59 | 28.54 |

| C E | 16.24 | 25.67 |

| HA1 D | 28.14 | 33.30 |

| HA1 E | 18.09 | 26.72 |

| KR271 D | 19.11 | 25.70 |

| KR271 E | 17.62 | 31.32 |

| M3-5 D | 21.84 | 39.24 |

| M3-5 E | 27.75 | 45.29 |

| Average | 21.49 | 33.00 |

| Extraction Method | Positive Mode | Negative Mode |

|---|---|---|

| D | 367 | 463 |

| E | 340 | 528 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gould, H.; Cheung, W.; Finnigan, J.D.; Muñoz-Muñoz, J.; Charnock, S.J.; Black, G.W. In Search of Complementary Extraction Methods for Comprehensive Coverage of the Escherichia coli Metabolome. Metabolites 2023, 13, 1010. https://doi.org/10.3390/metabo13091010

Gould H, Cheung W, Finnigan JD, Muñoz-Muñoz J, Charnock SJ, Black GW. In Search of Complementary Extraction Methods for Comprehensive Coverage of the Escherichia coli Metabolome. Metabolites. 2023; 13(9):1010. https://doi.org/10.3390/metabo13091010

Chicago/Turabian StyleGould, Henry, William Cheung, James D. Finnigan, José Muñoz-Muñoz, Simon J. Charnock, and Gary W. Black. 2023. "In Search of Complementary Extraction Methods for Comprehensive Coverage of the Escherichia coli Metabolome" Metabolites 13, no. 9: 1010. https://doi.org/10.3390/metabo13091010

APA StyleGould, H., Cheung, W., Finnigan, J. D., Muñoz-Muñoz, J., Charnock, S. J., & Black, G. W. (2023). In Search of Complementary Extraction Methods for Comprehensive Coverage of the Escherichia coli Metabolome. Metabolites, 13(9), 1010. https://doi.org/10.3390/metabo13091010