An Innovation Framework of Medical Organic Cannabis Traceability in Digital Supply Chain

Abstract

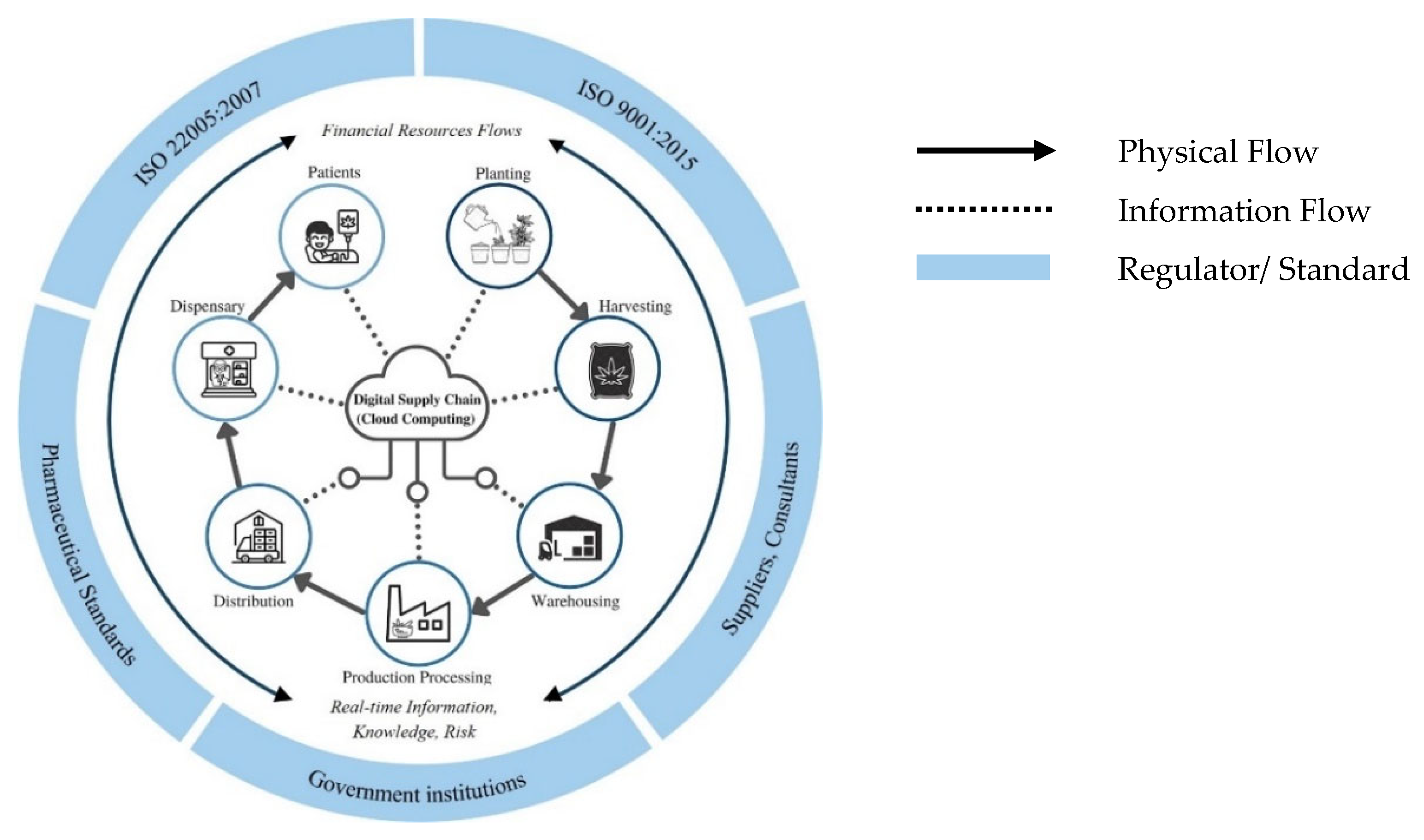

1. Introduction

- (1)

- To identify the CSFs of MOCT in the digital supply chain;

- (2)

- To use the innovation framework of CSFs of MOCT in the DSC;

- (3)

- To classify the CSFs based on their driving and dependence powers.

2. Literature Review

2.1. Supply Chain

2.2. Review of Critical Success Factor

2.2.1. Supply Chain Visibility

2.2.2. System Reliability

2.2.3. Technology Maturity

2.2.4. Harmonized Strategic Orientation

2.2.5. Financial Capability

2.2.6. Staff Awareness

2.2.7. Manager Attention

2.2.8. Communication

2.2.9. Inter-Organizational Collaboration

2.2.10. Training

2.2.11. Standardization

2.2.12. Government Regulations

2.2.13. Government Support

2.2.14. Customer Awareness

3. Research Process

4. Evaluation and Results

4.1. Agreement Index

4.2. Total Interpretive Structural Modeling Analysis

4.2.1. Development of Structural Self-Interaction Matrix (SSIM)

- V: the relationship or influence “Ci” leads to “Cj”,

- A: the relationship or influence “Cj” leads to “Ci”,

- X: the relationship or influence “Ci” and “Cj” both lead to each other,

- O: no relationship or influence between “Ci” and “Cj”,

4.2.2. Development of Initial Reachability Matrix (IRM)

4.2.3. Development of Final Reachability Matrix (FRM)

4.2.4. Process of the FRM to Level Partitions

4.2.5. Development of Total Interpretive Structural Modeling (TISM)

4.3. Fuzzy MICMAC Analysis

4.3.1. Development of the Binary Direct Relationship Matrix

4.3.2. Process of the Fuzzy Direct Relationship Matrix (FDRM)

4.3.3. Development of Fuzzy Stabilized Matrix

4.3.4. Creation of the Conclusive Dependence–Driving Diagram

5. Discussion

5.1. TISM for Innovation Framework of Medical Organic Cannabis Traceability

5.2. Conclusive Dependence–Driving Power Diagram

5.3. Comparison of TISM and Conclusive Dependence–Driving Power Diagram

5.4. TISM and Its Relation with Open Innovation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- 2020 Global Report on Cannabis Policy. Available online: https://www.theworldlawgroup.com/writable/documents/news/6.25.2020-Final-Cannabisi-Guide.pdf (accessed on 22 July 2022).

- Grotenhermen, F.; Müller-Vahl, K. Medicinal uses of marijuana and cannabinoids. CRC Crit. Rev. Plant. Sci. 2016, 35, 378–405. [Google Scholar] [CrossRef]

- Bridgeman, M.B.; Abazia, D.T. Medicinal cannabis history, pharmacology, and implications for the acute care Setting. Pharm. Ther. 2017, 42, 180–188. [Google Scholar]

- Davies, C.; Bhattacharyya, S. Cannabidiol as a potential treatment for psychosis. Ther. Adv. Psychopharmacol. 2019, 9, 16. [Google Scholar] [CrossRef]

- Marcoux, R.; Holmes, L.; Vogenberg, F.R.; Pharm, B. Regulatory and legislative disparities with cannabis present challenges to P&T committees and health care providers. Pharm. Ther. 2019, 44, 290–293. [Google Scholar]

- WHO. Guidelines on Good Manufacturing Practices (GMP) for Herbal Medicines. Available online: https://apps.who.int/iris/handle/10665/43672 (accessed on 22 July 2022).

- International Organization for Standardization. ISO 22005:2007 Traceability in the Feed and Food Chain—General Principles and Basic Requirements for System Design and Implementation. Available online: https://www.iso.org/standard/36297.html (accessed on 22 July 2022).

- Talbot, J.C.C.; Nilsson, B.S. Pharmacovigilance in the pharmaceutical industry. Br. J. Clin. Pharmacol. 1998, 45, 427–431. [Google Scholar] [CrossRef] [PubMed]

- WHO. Pharmacovigilance Indicators: A Practical Manual for the Assessment of Pharmacovigilance Systems. Available online: https://apps.who.int/iris/bitstream/handle/10665/186642/9789241508254_eng.pdf (accessed on 22 July 2022).

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Morales, S.O.C.; Aldrette-Malacara, A. Digital supply chain model in Industry 4.0. J. Manuf. Technol. Manag. 2019, 31, 887–933. [Google Scholar] [CrossRef]

- Romero-Torres, A. Asymmetry of stakeholders’ perceptions as an obstacle for collaboration in inter-organizational projects: The case of medicine traceability projects. Int. J. Manag. Proj. Bus. 2019, 13, 467–482. [Google Scholar] [CrossRef]

- Ogbome, A.C.; Smart, R.G.; Weber, T.; Birchmore-Timney, C. Who is using cannabis as a medicine and why: An exploratory study. J. Psychoact. Drugs. 2000, 32, 435–443. [Google Scholar]

- Hazekamp, A. An evaluation of the quality of medicinal grade cannabis in the Netherlands. Cannabinoids 2006, 1, 1–9. [Google Scholar]

- Shcherbakov, V.; Silkina, G. Supply chain management open innovation: Virtual integration in the network logistics system. J. Open Innov. Technol. Mark. Complex. 2021, 7, 54. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital supply chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Iddris, F. Digital supply chain: Survey of the literature. Int. J. Bus. Manag. Sci. 2018, 9, 47–61. [Google Scholar]

- Sahara, C.R.; Paluluh, J.D.E.; Aamer, A.M. Exploring the Key Factor Categories for the Digital Supply Chain. In Proceedings of the 9th International Conference on Operations and Supply Chain Management (OSCM), Ho Chi Minh, Vietnam, 15–18 December 2019. [Google Scholar]

- Teodorescu, M.; Korchagina, E. Applying blockchain in the modern supply chain management: Its implication on open innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 80. [Google Scholar] [CrossRef]

- Tornatzky, L.G.; Fleischer, M. Technological Innovation as a Process. In The Processes of Technological Innovation; Fleischer, L.G., Ed.; Lexington Books: Lexington, KY, USA, 2007; pp. 27–50. [Google Scholar]

- Baker, J. The Technology-Organization-Environment Framework. In Information Systems Theory: Explaining and Predicting Our Digital Society; Dwivedi, Y.K., Scott, L.M., Schneberger, L., Systems, I.S., Eds.; University of Hamburg: Hamburg, Germany, 2012; pp. 231–243. [Google Scholar]

- Hastig, G.M.; Sodhi, M.M.S. Blockchain for supply chain traceability: Business requirements and critical success factors. Prod. Oper. Manag. 2020, 29, 935–954. [Google Scholar] [CrossRef]

- Da Silva, R.B.; de Mattos, C.A. Critical success factors of a drug traceability system for creating value in a pharmaceutical supply chain (PSC). Int. J. Environ. Res. Public Health 2019, 16, 1972. [Google Scholar] [CrossRef] [PubMed]

- Klein, K.; Scholl, J.H.G.; Vermeer, N.S.; Broekmans, A.W.; Puijenbroek, E.P.V.; De Bruin, M.L.; Stolk, P. Traceability of biologics in the Netherlands: An analysis of information-recording systems in clinical practice and spontaneous ADR reports. Drug. Saf 2016, 39, 185–192. [Google Scholar] [CrossRef]

- Rotunno, R.; Cesarotti, V.; Bellman, A.; Introna, V.; Benedetti, M. Impact of track and trace integration on pharmaceutical production systems. Int. J. Eng. Bus. Manag. 2014, 6, 1–11. [Google Scholar] [CrossRef]

- Yang, K.; Shen, H.; Forte, D.; Bhunia, S.; Tehranipoor, M. Hardware-enabled pharmaceutical supply chain security. ACM Trans. Des. Autom. Electron. Syst. 2017, 23, 1–26. [Google Scholar] [CrossRef]

- PricewaterhouseCoopers’ Health Research Institute. Unlocking the Power of Pharmacovigilance An Adaptive Approach to an Evolving Drug Safety Environment. Available online: https://www.pwc.com/th/en/publications/assets/pharmacovigilance_final.pdf (accessed on 22 July 2022).

- Pan American Health Organization. Good Pharmacovigilance Practices for the Americas. 2011. Available online: https://www.paho.org/en/documents/good-pharmacovigilance-practices-americas-2011 (accessed on 22 July 2022).

- Jeetu, G.; Anusha, G. Pharmacovigilance: A worldwide master key for drug safety monitoring. J. Young Pharm. 2010, 2, 315–320. [Google Scholar] [CrossRef]

- Babigumira, J.B.; Stergachis, A.; Choi, H.L.; Dodoo, A.; Nwokike, J.; Garrison, L.P., Jr. A framework for assessing the economic value of pharmacovigilance in low- and middle-income countries. Drug. Saf. 2014, 37, 127–134. [Google Scholar] [CrossRef][Green Version]

- Bepari, A.; Niazi, S.K.; Rahman, I.; Dervesh, A.M. The comparative evaluation of knowledge, attitude, and practice of different health-care professionals about the pharmacovigilance system of India. J. Adv. Pharm. Technol. Res. 2019, 10, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, B. Factors influencing requirements traceability practice. Commun. ACM 1998, 41, 37–44. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Liu, F.; Fu, Z.; Mu, W. Strengths and limitations on the operating mechanisms of traceability system in agro food. China. Food Control 2010, 21, 825–829. [Google Scholar] [CrossRef]

- Faisal, M.N.; Talib, F. Implementing traceability in Indian food-supply chains: An interpretive structural modelling approach. J. Foodserv. Bus. Res. 2016, 19, 171–196. [Google Scholar] [CrossRef]

- Thakur, M.; Hurburgh, C.R. Framework for implementing traceability system in the bulk grain supply chain. J. Food Eng. 2009, 95, 617–626. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M.I.; Abidi, M.H.; Al-Ahmari, A. Implementing traceability systems in specific supply chain management (SCM) through critical success factors (CSFs). Sustainability 2018, 10, 204. [Google Scholar] [CrossRef]

- Duan, Y.; Miao, M.; Wang, R.; Fu, Z.; Xu, M. A framework for the successful implementation of food traceability systems in China. Inf. Soc. 2017, 33, 226–242. [Google Scholar] [CrossRef]

- Maro, S.; Anjorin, A.; Wohlrab, R.; Steghöfer, J.P. Traceability Maintenance: Factors and guidelines. In Proceedings of the 31st IEEE/ACM International Conference on Automated Software Engineering, Singapore, 3–7 September 2016; pp. 414–425. [Google Scholar]

- Shankar, R.; Gupta, R.; Pathak, D.K. Modelling critical success factors of traceability for food logistics system. Transp. Res. E Logist. Transp. Rev. 2018, 119, 205–222. [Google Scholar] [CrossRef]

- Deblonde, M.; de Graaff, R.; Brom, F. An ethical toolkit for food companies: Reflections on its use. J. Agric. Environ. Ethics. 2007, 20, 99–118. [Google Scholar] [CrossRef][Green Version]

- Islam, S.; Cullen, J.M. Food traceability: A generic theoretical framework. Food Control 2021, 123, 107848. [Google Scholar] [CrossRef]

- Purwandoko, P.B.; Seminar, K.B.; Sutrisno; Sugiyanta. Framework for Design of Traceability System on Organic Rice Certification. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 23–25 October 2017; Volume 147, p. 012044. [Google Scholar]

- Gichure, J.N.; Wahome, R.G.; Njage, P.M.K.; Karuri, E.G.; Nzuma, J.M.; Karantininis, K. Factors influencing extent of traceability along organic fresh produce value chains: Case of kale in Nairobi, Kenya. Org. Agric. 2016, 7, 293–302. [Google Scholar] [CrossRef]

- Vieira, L.M.; de Barcellos, M.D.; Hoppe, A.; da Silva, S.B. An analysis of value in an organic food supply chain. Br. Food J. 2013, 115, 1454–1472. [Google Scholar] [CrossRef]

- Lindh, H.; Olsson, A. Communicating imperceptible product attributes through traceability: A case study in an organic food supply chain. Renew. Agric. Food Syst. 2010, 25, 263–271. [Google Scholar] [CrossRef]

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital supply chain: Challenges and future directions. Supply Chain Forum. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Agrawal, P.; Narain, R.; Ullah, I. Analysis of barriers in implementation of digital transformation of supply chain using interpretive structural modelling approach. J. Model. Manag. 2020, 15, 297–317. [Google Scholar] [CrossRef]

- Denolf, J.M.; Trienekens, J.H.; Wognum, P.M.; van der Vorst, J.G.A.J.; Omta, S.W.F. Towards a framework of critical success factors for implementing supply chain information systems. Comput. Ind. 2015, 68, 16–26. [Google Scholar] [CrossRef]

- Sengar, A.; Sharma, V.; Agrawal, R.; Bharati, K. Government Policies & Rural Development—An Enabler Modelling for Indian Rural Markets. In Proceedings of the e-Journal—First Pan IIT International Management Conference, Uttarakhand, India, 27 March 2022. [Google Scholar]

- Heyder, M.; Theuvsen, L.; Hollmann-Hespos, T. Investments in tracking and tracing systems in the food industry: A PLS analysis. Food Policy 2012, 37, 102–113. [Google Scholar] [CrossRef]

- Almanasreh, E.; Moles, R.; Chen, T.F. Evaluation of methods used for estimating content validity. Res. Soc. Adm. Pharm. 2019, 15, 214–221. [Google Scholar] [CrossRef]

- Wynd, C.A.; Schmidt, B.; Schaefer, M.A. Two quantitative approaches for estimating content validity. West. J. Nurs. Res. 2003, 25, 508–518. [Google Scholar] [CrossRef]

- Rodrigues, I.B.; Adachi, J.D.; Beattie, K.A.; MacDermid, J.C. Development and validation of a new tool to measure the facilitators, barriers and preferences to exercise in people with osteoporosis. BMC Musculoskelet. Disord. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Polit, D.F.; Beck, C.T.; Owen, S.V. Focus on research methods: Is the CVI an acceptable indicator of content validity? Appraisal and recommendations. Res. Nurs. Health 2007, 30, 459–467. [Google Scholar] [CrossRef] [PubMed]

- Sushil. Interpreting the interpretive structural model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [Google Scholar] [CrossRef]

- Hasan, Z.; Dhir, S.; Dhir, S. Modified total interpretive structural modelling (TISM) of asymmetric motives and its drivers in Indian bilateral CBJV. Benchmarking 2019, 26, 614–637. [Google Scholar] [CrossRef]

- Mishra, N.; Singh, A.; Rana, N.P.; Dwivedi, Y.K. Interpretive structural modelling and fuzzy MICMAC approaches for customer centric beef supply chain: Application of a big data technique. Prod. Plan. Control 2017, 28, 945–963. [Google Scholar] [CrossRef]

- Mohanty, M. Assessing sustainable supply chain enablers using total interpretive structural modelling approach and fuzzy-MICMAC analysis. Manag. Environ. Qual. An Int. J. 2018, 29, 216–239. [Google Scholar] [CrossRef]

- Hasanuzzaman; Bhar, C. Development of a framework for sustainable improvement in performance of coal mining operations. Clean Technol. Environ. Policy 2019, 21, 1091–1113. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Mani, V.; Mathivathanan, D.; Rajak, S. Evaluation of antecedents to social sustainability practices in multi-tier Indian automotive manufacturing firms. Int. J. Prod. Res 2021, 1–22. [Google Scholar] [CrossRef]

- Balaji, M.; Arshinder, K. Modelling the causes of food wastage in Indian perishable food supply chain. Resour. Conserv. Recycl. 2016, 114, 153–167. [Google Scholar]

- Bhosale, V.A.; Kant, R. An integrated ISM fuzzy MICMAC approach for modelling the supply chain knowledge flow enablers. Int. J. Prod. Res. 2016, 54, 7374–7399. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mishra, P.; Ruiz-García, L. Food traceability: New trends and recent advances. A review. Food Control 2015, 57, 393–401. [Google Scholar] [CrossRef]

- Barge, P.; Gay, P.; Merlino, V.; Tortia, C. Item-level Radio-Frequency Identification for the traceability of food products: Application on a dairy product. J. Food Eng. 2014, 125, 119–130. [Google Scholar] [CrossRef]

- Chandra, D.; Kumar, D. A fuzzy MICMAC analysis for improving supply chain performance of basic vaccines in developing countries. Expert Rev. Vaccines 2018, 17, 263–281. [Google Scholar] [CrossRef] [PubMed]

- Alamsjah, F.; Yunus, E.N. Achieving Supply Chain 4.0 and the importance of agility, ambidexterity, and organizational culture: A case of Indonesia. J. Open Innov. Technol. Mark. Complex. 2022, 8, 83. [Google Scholar] [CrossRef]

- Bari, A.B.M.M.; Siraj, M.T.; Paul, S.K.; Khan, S.A. A Hybrid Multi-Criteria Decision-Making approach for analysing operational hazards in heavy fuel oil-based power plants. Decis. Anal. J. 2022, 3, 100069. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Agarwal, V.; Mathiyazhagan, K.; Saikouk, T.; Appolloni, A. Modeling the pressures for sustainability adoption in the Indian automotive context. J. Clean. Prod. 2022, 342, 130972. [Google Scholar] [CrossRef]

- Kumar, V.; Vrat, P.; Shankar, R. Factors influencing the implementation of Industry 4.0 for sustainability in manufacturing. Glob. J. Flex. Syst. Manag. 2022, 23, 453–478. [Google Scholar] [CrossRef]

- Gadekar, R.; Sarkar, B.; Gadekar, A. Model development for assessing inhibitors impacting industry 4.0 implementation in Indian manufacturing industries: An integrated ISM-Fuzzy MICMAC approach. Int. J. Syst. Assur. Eng. Manag. 2022. [Google Scholar] [CrossRef]

- Shukla, M.; Shankar, R. An extended Technology-Organization-Environment framework to investigate smart manufacturing system implementation in small and medium enterprises. Comput. Ind. Eng. 2022, 163, 107865. [Google Scholar] [CrossRef]

- Ullah, S.; Khan, F.U.; Ahmad, N. Promoting sustainability through green innovation adoption: A case of manufacturing industry. Environ. Sci. Pollut. Res. 2022, 29, 21119–21139. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Fatma, N. Effective adoption of remanufacturing practices: A step towards circular economy. J. Remanufacturing 2022, 12, 167–185. [Google Scholar] [CrossRef]

- Abujaber, A.A.; Nashwan, A.J.; Fadlalla, A. Enabling the adoption of machine learning in clinical decision support: A total interpretive structural modeling approach. Inform. Med. Unlocked 2022, 33, 101090. [Google Scholar] [CrossRef]

- Sindhu, S. Digital health care services in post COVID-19 scenario: Modeling the enabling factors. Int. J. Pharm. Healthc. Mark. 2022, 16, 412–428. [Google Scholar] [CrossRef]

- Desingh, V.; Baskaran, R. Internet of Things adoption barriers in the Indian health-care supply chain: An ISM-Fuzzy MICMAC approach. Int. J. Health Plann. Manag. 2022, 37, 318–351. [Google Scholar] [CrossRef]

- Sharma, R.; Kannan, D.; Darbari, J.D.; Jha, P.C. Analysis of collaborative sustainable practices in multi-tier food supply chain using integrated TISM-Fuzzy MICMAC model: A supply chain practice view. J. Clean. Prod. 2022, 354, 131271. [Google Scholar] [CrossRef]

- Priyadarshini, J.; Singh, R.K.; Mishra, R.; Bag, S. Investigating the interaction of factors for implementing additive manufacturing to build an antifragile supply chain: TISM-MICMAC approach. Oper. Manag. Res. 2022, 15, 567–588. [Google Scholar] [CrossRef]

- Singh, S.; Agrawal, V.; Mohanty, R.P. Multi-Criteria Decision Analysis of significant enablers for a competitive supply chain. J. Adv. Manag. Res. 2022, 19, 414–442. [Google Scholar] [CrossRef]

- Xiahou, X.; Li, Z.; Zuo, J.; Wang, Z.; Li, K.; Li, Q. Critical success factors for the implementation of urban regeneration REITs in China: A TISM–MICMAC based approach. Eng. Constr. Archit. Manag. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Khan, A.; Yu, R.; Liu, T.; Guan, H.; Oh, E. Drivers towards adopting modular integrated construction for affordable sustainable housing: A Total Interpretive Structural Modelling (TISM) method. Buildings 2022, 12, 637. [Google Scholar] [CrossRef]

- Aggarwal, G.; Jain, V.; Ajmera, P.; Garza-Reyes, J.A. Modeling and analysing the barriers to the acceptance of energy-efficient appliances using an ISM-DEMATEL approach. J. Model. Manag. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Ali, S.M.; Ahmed, S.; Ahmed, H.N.; Sharmin, A.; Rahman, R. Reducing plastic pollutants through catalyzing consumer roles: A novel application of Fuzzy Total Interpretive Structural Modeling. J. Clean. Prod. 2022, 335, 130327. [Google Scholar] [CrossRef]

- Soroka-potrzebna, H. Barriers of Knowledge Management in virtual project teams: A TISM Model. Procedia Comput. Sci. 2022, 207, 800–809. [Google Scholar] [CrossRef] [PubMed]

- Arora, K.; Siddiqui, A.A. Resource capabilities and sustainable export performance: An application of m-TISM for Indian Manufacturing MSMEs. Qual. Manag. J. 2022, 29, 125–144. [Google Scholar] [CrossRef]

- Bamel, U.; Kumar, S.; Lim, W.M.; Bamel, N.; Meyer, N. Managing the dark side of digitalization in the future of work: A Fuzzy TISM approach. J. Innov. Knowl. 2022, 7, 100275. [Google Scholar] [CrossRef]

- Foli, S. Total Interpretive Structural Modelling (TISM) and MICMAC approach in analysing knowledge risks in ICT-Supported collaborative project. VINE J. Inf. Knowl. Manag. Syst. 2022, 52, 394–410. [Google Scholar] [CrossRef]

- Ahmad, N.; Quadri, N.N.; Qureshi, M.R.N.; Alam, M.M. Relationship modeling of critical success factors for enhancing sustainability and performance in E-Learning. Sustainability 2018, 10, 4776. [Google Scholar] [CrossRef]

| Reference | Technology | Organization | Environment | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supply Chain Visibility | System Reliability | Technology Maturity | Harmonized Strategic Orientation | Financial Capabilities | Staff Awareness | Manager Attention | Communication | Inter-Organizational Collaboration | Training | Standardization | Government Regulation | Government Support | Customer Awareness | |

| Pharmaceutical Traceability | ||||||||||||||

| [21] | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| [22] | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| [11] | √ | √ | √ | √ | √ | √ | √ | |||||||

| [23] | √ | √ | √ | |||||||||||

| [24] | √ | √ | √ | √ | ||||||||||

| [25] | √ | √ | ||||||||||||

| Pharmacovigilance Traceability | ||||||||||||||

| [26] | √ | √ | √ | |||||||||||

| [27] | √ | √ | √ | √ | √ | √ | ||||||||

| [28] | √ | √ | √ | √ | ||||||||||

| [29] | √ | √ | √ | |||||||||||

| [30] | √ | √ | √ | √ | ||||||||||

| [9] | √ | |||||||||||||

| Food Traceability | ||||||||||||||

| [31] | √ | √ | √ | √ | √ | √ | √ | |||||||

| [32] | √ | √ | √ | √ | ||||||||||

| [33] | √ | |||||||||||||

| [34] | √ | √ | ||||||||||||

| [35] | √ | √ | √ | √ | √ | √ | √ | |||||||

| [36] | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||

| [37] | √ | √ | √ | |||||||||||

| [38] | √ | √ | √ | √ | ||||||||||

| [39] | √ | |||||||||||||

| [40] | √ | √ | ||||||||||||

| Organic Traceability | ||||||||||||||

| [41] | √ | √ | √ | √ | √ | √ | √ | √ | ||||||

| [42] | √ | √ | √ | √ | ||||||||||

| [43] | √ | |||||||||||||

| [44] | √ | √ | √ | √ | √ | √ | ||||||||

| Digital Supply Chain | ||||||||||||||

| [15] | √ | √ | √ | √ | √ | √ | √ | |||||||

| [45] | √ | √ | √ | √ | √ | |||||||||

| [10] | √ | √ | √ | √ | √ | |||||||||

| [46] | √ | √ | √ | √ | √ | √ | ||||||||

| [16] | √ | √ | √ | √ | ||||||||||

| [17] | √ | √ | √ | √ | √ | √ | ||||||||

| [47] | √ | √ | √ | √ | √ | √ | √ | |||||||

| Proposed Innovation Framework for MOCT | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| No | Factors | Definition | References |

|---|---|---|---|

| 1. | Supply Chain Visibility (C1) | Ability to track raw materials and customer’s demands in the supply chain in real time from upstream to downstream | [9,10,15,16,17,21,22,39,41,44,45,46] |

| 2. | System Reliability (C2) | The efficiency and quality of being trusted that a traceability system will accurately perform specified tasks under the stated environmental conditions | [22,24,25,36,41,47] |

| 3. | Technology Maturity (C3) | Mature technology development to improve the efficiency of business performance in the digital supply chain | [10,11,15,16,17,21,22,23,24,27,31,35,38] |

| 4. | Harmonized Strategic Orientation (C4) | The harmonized plan that ensures that the organizations in the supply chain pursue the same future business goals | [11,15,17,26,31,34,36,37,38,44,45,46,47] |

| 5. | Financial Capability (C5) | The state of being capable or power of finance of an organization | [21,22,27,31,32,36,41,46] |

| 6. | Staff Awareness (C6) | The staff understands that the processes of work and information recording in the traceability system are essential according to the policy, goals, and vision of the organization | [15,23,29,30,31,41,42,45] |

| 7. | Manager Attention (C7) | Persons responsible for managing or directing an organization and controlling the results of the job are key performance indicators | [17,21,22,31,32,35,42,45,46,47] |

| 8. | Communication (C8) | A process of exchanging information or ideas between people through a standard system of behavior or symbols and signs | [15,16,17,21,22,26,29,30,35,36,46,47] |

| 9. | Inter-organizational Collaboration (C9) | Cooperation among business organizations in the same supply chain in a friendly and trusted manner | [11,15,16,17,21,22,35,44,45,46,47] |

| 10. | Training (C10) | The process of learning the skills through introducing, clarifying, and understanding a particular job or activity | [11,27,30,31,35,36,37,41,42,47] |

| 11. | Standardization (C11) | The process of ensuring that traceability systems of the same type all have the same basic features or technology type to assure consistency and regularity throughout the supply chain | [10,11,15,21,22,24,25,26,31,32,35,36,41,42,44,47] |

| 12. | Government Regulations (C12) | The rules of government to control and make sure that business is operating according to a standard or requirements of operation | [21,22,23,24,27,29,34,36,38,40,41,44] |

| 13. | Government Support (C13) | The ability of the government to help or encourage the organization to implement a traceability system to succeed | [11,22,27,32,35,36,41] |

| 14. | Customer Awareness (C14) | The realization of a customer of the information about products, ingredients, services, and customer rights, which will support making the right decision and making the right choice for safety | [10,11,22,27,30,33,36,38,40,43,44] |

| Experts | Expert Profile/Position | Area Expertise | Experience |

|---|---|---|---|

| Expert 1 | Academician, Researcher | Agriculture, Farming | >24 Years |

| Expert 2 | Organic and Cannabis Farmer, Consultant | Organic Cannabis | >6 Years |

| Expert 3 | Cannabis Consultant and Researcher | Cannabis Supply Chain | >5 Years |

| Expert 4 | Associate Professor, Cannabis Researcher | Logistics and Supply Chain | >20 Years |

| Expert 5 | Pharmacist, Government Pharmaceutical Organization | Cannabis System | >20 Years |

| Expert 6 | Pharmacist, Director of Division, Ministry of Health | Herbal Medicine | >19 Years |

| Expert 7 | Academician, Pharmacist, Consultant | Enterprise Architecture, Health System | >12 Years |

| Expert 8 | Academician, Pharmacist, Researcher | Thai Herbal Medicine | >30 Years |

| Expert 9 | Pharmacist, Professional Level | Herb Products for Patients | >25 Years |

| Expert 10 | Physician, Regional Manager | Oncologist | >12 Years |

| Factors | E 1 | E 2 | E 3 | E 4 | E 5 | E 6 | E 7 | E 8 | E 9 | E 10 | Agreement Number | I-CVI | k* | Evaluation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 4 | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 4 | 4 | 10 | 1.00 | 1.00 | Excellent |

| C2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 10 | 1.00 | 1.00 | Excellent |

| C3 | 4 | 4 | 4 | 4 | 2 | 3 | 4 | 2 | 4 | 4 | 8 | 0.80 | 0.79 | Excellent |

| C4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 10 | 1.00 | 1.00 | Excellent |

| C5 | 2 | 4 | 2 | 4 | 3 | 3 | 4 | 3 | 3 | 4 | 8 | 0.80 | 0.79 | Excellent |

| C6 | 4 | 4 | 3 | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 10 | 1.00 | 1.00 | Excellent |

| C7 | 4 | 4 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 10 | 1.00 | 1.00 | Excellent |

| C8 | 2 | 3 | 4 | 4 | 4 | 3 | 4 | 4 | 2 | 3 | 8 | 0.80 | 0.79 | Excellent |

| C9 | 4 | 4 | 3 | 4 | 2 | 3 | 4 | 2 | 4 | 4 | 8 | 0.80 | 0.79 | Excellent |

| C10 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 10 | 1.00 | 1.00 | Excellent |

| C11 | 4 | 4 | 4 | 4 | 3 | 4 | 3 | 3 | 4 | 4 | 10 | 1.00 | 1.00 | Excellent |

| C12 | 4 | 4 | 4 | 4 | 4 | 4 | 2 | 4 | 4 | 3 | 9 | 0.90 | 0.90 | Excellent |

| C13 | 3 | 4 | 2 | 4 | 4 | 3 | 4 | 4 | 3 | 2 | 8 | 0.80 | 0.79 | Excellent |

| C14 | 4 | 4 | 4 | 4 | 2 | 3 | 4 | 3 | 4 | 2 | 8 | 0.80 | 0.79 | Excellent |

| CSFs | C14 | C13 | C12 | C11 | C10 | C9 | C8 | C7 | C6 | C5 | C4 | C3 | C2 | C1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | A | O | O | O | O | A | O | O | O | O | A | A | V | |

| C2 | O | O | O | O | O | O | A | A | A | O | O | A | ||

| C3 | O | A | O | O | V | A | O | O | O | A | A | |||

| C4 | A | O | A | A | O | V | V | V | O | V | ||||

| C5 | O | O | O | O | O | O | O | O | O | |||||

| C6 | O | O | O | O | X | O | O | X | ||||||

| C7 | O | O | O | O | V | O | O | |||||||

| C8 | O | O | O | O | A | O | ||||||||

| C9 | X | V | X | V | O | |||||||||

| C10 | O | O | O | O | ||||||||||

| C11 | O | O | A | |||||||||||

| C12 | A | V | ||||||||||||

| C13 | O | |||||||||||||

| C14 |

| CSFs | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C3 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| C4 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| C5 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C6 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| C7 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| C8 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| C9 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 |

| C10 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 |

| C11 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| C12 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 0 |

| C13 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| C14 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 |

| CSFs | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | Dri. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| C2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| C3 | 1 | 1 | 1 | 0 | 0 | 1* | 1* | 1* | 0 | 1 | 0 | 0 | 0 | 0 | 7 |

| C4 | 1 | 1* | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 1* | 1* | 1* | 1* | 1* | 14 |

| C5 | 1* | 1* | 1 | 0 | 1 | 1* | 1* | 1* | 0 | 1* | 0 | 0 | 0 | 0 | 8 |

| C6 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1* | 0 | 1 | 0 | 0 | 0 | 0 | 5 |

| C7 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1* | 0 | 1 | 0 | 0 | 0 | 0 | 5 |

| C8 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 2 |

| C9 | 1 | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1 | 1 | 1 | 1 | 14 |

| C10 | 0 | 1* | 0 | 0 | 0 | 1 | 1* | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 5 |

| C11 | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 14 |

| C12 | 1* | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 1 | 1* | 1 | 1 | 1 | 1* | 14 |

| C13 | 1* | 1* | 1 | 0 | 0 | 1* | 1* | 1* | 0 | 1* | 0 | 0 | 1 | 0 | 8 |

| C14 | 1 | 1* | 1* | 1 | 1* | 1* | 1* | 1* | 1 | 1* | 1* | 1 | 1* | 1 | 14 |

| Dep. | 9 | 14 | 8 | 5 | 6 | 11 | 11 | 12 | 5 | 11 | 5 | 5 | 6 | 5 |

| CSFs | Reachability Set | Antecedent Set | Intersection | Level |

|---|---|---|---|---|

| C1 | 1,2 | 1,3,4,5,9,11,12,13,14 | ||

| C2 | 2 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 2 | I |

| C3 | 1,2,3,6,7,8,10 | 3,4,5,9,11,12,13,14 | ||

| C4 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 4,9,11,12,14 | ||

| C5 | 1,2,3,5,6,7,8,10 | 4,5,9,11,12,14 | ||

| C6 | 2,6,7,8,10 | 3,4,5,6,7,9,10,11,12,13,14 | ||

| C7 | 2,6,7,8,10 | 3,4,5,6,7,9,10,11,12,13,14 | ||

| C8 | 2,8 | 3,4,5,6,7,8,9,10,11,12,13,14 | ||

| C9 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 4,9,11,12,14 | ||

| C10 | 2,6,7,8,10 | 3,4,5,6,7,9,10,11,12,13,14 | ||

| C11 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 4,9,11,12,14 | ||

| C12 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 4,9,11,12,14 | ||

| C13 | 1,2,3,6,7,8,10,13 | 4,9,11,12,13,14 | ||

| C14 | 1,2,3,4,5,6,7,8,9,10,11,12,13,14 | 4,9,11,12,14 |

| CSFs | C2 | C1 | C8 | C6 | C7 | C10 | C3 | C5 | C13 | C4 | C9 | C11 | C12 | C14 | Level |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C2 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | I |

| C1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | II |

| C8 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | II |

| C6 | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | III |

| C7 | 1 | 0 | 1* | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | III |

| C10 | 1* | 0 | 1 | 1 | 1* | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | III |

| C3 | 1 | 1 | 1* | 1* | 1* | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | IV |

| C5 | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | V |

| C13 | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | V |

| C4 | 1* | 1 | 1 | 1* | 1 | 1* | 1 | 1 | 1* | 1 | 1 | 1* | 1* | 1* | VI |

| C9 | 1* | 1 | 1* | 1* | 1* | 1* | 1 | 1* | 1 | 1* | 1 | 1 | 1 | 1 | VI |

| C11 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1* | 1 | 1* | 1* | VI |

| C12 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1 | 1 | 1 | 1 | 1* | VI |

| C14 | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1 | 1* | 1 | 1 | VI |

| Level | I | II | II | III | III | III | IV | V | V | VI | VI | VI | VI | VI |

| Relationship | No Influence | Very Week | Week | Medium | Strong | Very Strong | Complete Influence |

|---|---|---|---|---|---|---|---|

| Scale value | 0 | 0.1 | 0.3 | 0.5 | 0.7 | 0.9 | 1 |

| CSFs | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C3 | 0.7 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 |

| C4 | 0.7 | 0 | 0.5 | 0 | 0.7 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0 | 0 | 0 | 0 |

| C5 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C6 | 0 | 0.7 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 |

| C7 | 0 | 0.7 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 |

| C8 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C9 | 0.7 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.7 | 0.5 | 0.5 | 0.3 |

| C10 | 0 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0.7 | 0 | 0 | 0 | 0 | 0 | 0 |

| C11 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C12 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0.7 | 0 | 0.9 | 0 |

| C13 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C14 | 0.7 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0.3 | 0 | 0 |

| CSFs | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | Dri. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 |

| C2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C3 | 0.7 | 0.9 | 0 | 0 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0.7 | 0 | 0 | 0 | 0 | 4.4 |

| C4 | 0.7 | 0.7 | 0.6 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0.3 | 8.9 |

| C5 | 0.6 | 0.6 | 0.6 | 0 | 0 | 0.6 | 0.6 | 0.6 | 0 | 0.6 | 0 | 0 | 0 | 0 | 4.2 |

| C6 | 0 | 0.7 | 0 | 0 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0.7 | 0 | 0 | 0 | 0 | 3.5 |

| C7 | 0 | 0.7 | 0 | 0 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0.7 | 0 | 0 | 0 | 0 | 3.5 |

| C8 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 |

| C9 | 0.7 | 0.7 | 0.6 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0.3 | 8.9 |

| C10 | 0 | 0.7 | 0 | 0 | 0 | 0.7 | 0.7 | 0.7 | 0 | 0.7 | 0 | 0 | 0 | 0 | 3.5 |

| C11 | 0.7 | 0.7 | 0.6 | 0.9 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0.3 | 9.1 |

| C12 | 0.7 | 0.7 | 0.6 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | 0.9 | 0.3 | 9.3 |

| C13 | 0.3 | 0.3 | 0.3 | 0 | 0 | 0.3 | 0.3 | 0.3 | 0 | 0.3 | 0 | 0 | 0 | 0 | 2.1 |

| C14 | 0.7 | 0.7 | 0.6 | 0.9 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | 0.5 | 0.3 | 9.1 |

| Dep. | 5.1 | 8.8 | 3.9 | 3.9 | 3.5 | 7.2 | 7.2 | 7.2 | 3.5 | 7.2 | 3.5 | 2.5 | 2.9 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pookkaman, W.; Samanchuen, T. An Innovation Framework of Medical Organic Cannabis Traceability in Digital Supply Chain. J. Open Innov. Technol. Mark. Complex. 2022, 8, 196. https://doi.org/10.3390/joitmc8040196

Pookkaman W, Samanchuen T. An Innovation Framework of Medical Organic Cannabis Traceability in Digital Supply Chain. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(4):196. https://doi.org/10.3390/joitmc8040196

Chicago/Turabian StylePookkaman, Weerapat, and Taweesak Samanchuen. 2022. "An Innovation Framework of Medical Organic Cannabis Traceability in Digital Supply Chain" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 4: 196. https://doi.org/10.3390/joitmc8040196

APA StylePookkaman, W., & Samanchuen, T. (2022). An Innovation Framework of Medical Organic Cannabis Traceability in Digital Supply Chain. Journal of Open Innovation: Technology, Market, and Complexity, 8(4), 196. https://doi.org/10.3390/joitmc8040196