Abstract

The socio-economic transformations taking place nowadays bring about the necessity to transform the currently dominating linear paradigm of economic growth. The basis for such a transformation is, first of all, the implementation of sustainable systems of production and consumption, so that they evolve into companies implementing the assumptions of a closed-circle economy. Although the concept of such an economy has been widely accepted by both researchers and practitioners, there is still a lack of thorough recognition of the determinants of its application at the organizational level. Attempting to fill this research gap, this paper addresses the conceptual link between companies’ eco-innovation activities and the CE paradigm. It attempts to assess the importance of eco-innovation, both technological and nontechnological in nature, as determinants of the implementation of the concept of a closed-loop economy. The prospects for the implementation of a closed-loop economy are described, then the concepts and types of eco-innovation are organized, and finally the role of eco-innovation as a catalyst for the implementation of the CE concept is explained. The article also indicates the most important management practices, understood as strategic actions necessary in the process of generating and implementing innovations leading to the realization of the idea of reverse material flows. As a consequence of the discussion, the proposition suggested herein is to develop the existing circular business models by taking into account the eco-innovative activities of enterprises. The article is also an attempt to start a discussion on the category of open eco-innovations and to popularize the practice of open access to eco-innovations.

1. Introduction

Despite increasing environmental degradation, most of the world’s economies still operate on a traditional linear model of economic activity based on cheap energy and readily available resources. This model, known as “take-make-dispose” [1,2] is characterized by a unidirectional flow of materials: from raw materials that are transformed into products and ultimately into waste. However, this linear approach to production and consumption processes does not take into account the environmental burdens and natural limits to economic growth resulting from, for example, climate change due to increasing greenhouse gas emissions and the depletion of nonrenewable resources (i.e., fossil fuels or mineral resources). An alternative to the linear model of resource use is the concept of a circular economy (CE), the implementation of which can partially address the problems of climate change, resource scarcity, fossil fuel dependence, population growth, high competitiveness, and expansion of global markets [3,4,5,6].

The transformation towards a circular economy requires a significant transformation of existing production and consumption systems [7]. Changes on both the supply and demand sides are therefore necessary, amounting to the design and implementation of circular business models and the realization of sustainable consumption patterns. Many scholars emphasize the key role of innovation in this regard and argue that it is ecological innovation that is the necessary factor to support the use and circulation of resources in a deliberately and sustainably renewable system [1,6,8]. The underlying basis for this approach is the idea of ecological innovations that constitute new solutions leading to the avoidance or reduction in adverse environmental impacts, according to the assumption that reducing the negative influence of production and consumption activities on the environment is the main feature of ecological changes.

Following such a research perspective, the aim of this article is to assess the importance of eco-innovation as a determinant of implementation of a closed-loop economy. An important methodological decision is to limit the consideration to the organizational level (proper to management science), in accordance with the assumption that the reference point for programs, projects, strategies, and policies implemented in the meso and macroeconomic perspective is always the actions taken by individual units. It is obvious that the implementation of CE requires institutional and regulatory support, but the importance of these factors is analogous to the role of regulations and taxes in stimulating proenvironmental technical changes [8,9].

2. Methodical Approach

The starting point for the realization of the assumed aim of the study was to move away from a uniform conceptualization of eco-innovative activities and to distinguish in this regard technological and nontechnological changes [7], i.e., product, process and organizational eco-innovations.

Then, based on a critical review of the new academic and nonacademic literature, selected management practices, understood as strategic activities necessary in the process of generating and implementing eco-innovations leading to the realization of the idea of a closed-loop economy, were identified and synthetically described. The research was based on a review of the topical literature relevant to the subject matter of the study, using Web of Science (WoS) and Scopus and, to a limited extent, the so-called gray literature as a contextual element. The analysis was conducted over the last ten years and used the search terms “eco-innovation”, “business models”, and “circular economy” as all are relevant to the concept and the theoretical framework developed. In this way, this article not only fits into the most current and dynamically developing research area, which is the link between eco-innovations, business models, and a closed-loop economy, but also attempts to fill that highlighted in the literature [2,7] research gap relating to the identification of specific practices that support the generation and implementation of eco-innovations necessary for closing material flows.

At this point, it should also be noted that the implementation of the described management practices in companies is a complex logistical and economic challenge, and consequently requires undertaking cooperation with various stakeholders [2]. Since the generation and implementation of circular products or processes is embedded in both intra and interorganizational activities and procedures, it is therefore important to also include the concept of open innovation (OI) in the considerations [10,11,12].

The need to involve different stakeholder groups (suppliers, consumers, research and scientific institutions, environmental organizations, etc.) in companies’ eco-innovation activities has been repeatedly highlighted in the literature [13,14,15]. However, the paradigm of open innovation is particularly relevant to the design and implementation of circular business models and the realization of sustainable consumption patterns. In this context, it is worth quoting the definition of open innovation by Chesbrough and Bogers, according to which OI means “distributed innovation process based on purposively managed knowledge flows across organizational boundaries, using pecuniary and non-pecuniary mechanisms in line with the organization’s business model” [16]. According to such—widely used in the literature—logic, undertaking collaboration with stakeholders not only determines the business model of a company but also offers the possibility of realizing a win–win scenario, i.e., achieving “external” environmental and social benefits thanks to closing material flow loops and at the same time “internal” economic benefits [15,17,18].

On the other hand, the open innovation paradigm can be seen as a necessary strategy to manage customer relationships by leveraging their knowledge and experience in the eco-design process and, more importantly, gaining their acceptance for the subsequent launch of circular products [2]. In this view, an open innovation strategy (based, for example, on crowdsourcing) is indispensable to realize sustainable consumption patterns.

In conclusion, the eco-innovation activities carried out by enterprises, which boil down to generating and implementing eco-innovations (product, process, and organizational), thanks to the use of circular and “open” management practices (i.e., eco-design or building green supply chains), can bring benefits not only to eco-innovators but also to the whole society. This is because it is one of the most important tools for achieving the goals of sustainable development, i.e., development “that meets the needs of the present generation without compromising the ability of future generations to meet their own needs” [19].

3. The Concept and Prospects of Implementing a Closed-Loop Economy

The CE concept is customarily considered at the meso or macroeconomic level, i.e., it includes models and indicators for the economy as a whole, or for particular regions of it. The idea refers to the realization of sustainable development goals and takes into account the assumptions underlying such concepts as industrial ecology, cradle to cradle theory, regenerative design, biomimicry, and the blue economy. In searching for a universal definition, many researchers refer to a report by the Ellen MacArthur Foundation, which states that “circular economy is an industrial system that is restorative or regenerative by intention and design” ([20], p. 7). Liu [21] and Lieder and Rashid [22] define CE as an economic system that is less dependent on depleting natural resources than traditional economies by implementing a spiral-loop system that minimizes the flow of materials and energy without reducing the potential for economic growth and development.

Putting aside the definitional differences, CE represents an economic paradigm shift [5], as it represents a shift from the traditional and linear economic model towards closing material flow loops through different types of actions undertaken, i.e., reuse, repair, recovery or recycling of existing materials and products so that they can become inputs in subsequent production processes [1,23]. The core of the CE concept is to create feedback cycles: resource–product–resource, following the 3R principle (reduce, recycle, reuse). Reduce means that for a given level of production, it is possible to reduce resource inputs and increase production efficiency at the same time. Recycle indicates that waste can be transformed for further use. Reuse, on the other hand, means that processed materials become inputs in subsequent production processes [6,21].

The concept of CE has been present in the scientific literature almost since the middle of the 20th century, but the implementation of initiatives leading to its realization occurred only in the first decades of the 21st century [1], first in China, Japan, and the U.S., and now, following recommendations from the European Commission, in many EU countries. In 2018, the European Commission defined a framework to monitor the implementation of the CE concept in member countries, which consists of ten indicators covering four thematic areas: production and consumption, waste management, secondary raw materials, competitiveness, and innovation [24]. This defined scope of reporting reflects the logic of the EU’s 2050 climate neutrality goal under the Green Deal [25].

The idea of a closed-circuit economy, which promotes the reverse flow of materials with the lowest possible use of natural resources and the lowest possible environmental costs, is now widely implemented in Finland, France, the Netherlands, Great Britain, and Sweden, just to mention some of them [26]. Among the countries of Central and Eastern Europe, where initiatives leading to the transformation of the linear model into a circular one are taken, we can also mention Poland, where in the second decade of the twenty-first century, actions were initiated to develop a set of tools, not only legislative, providing conditions for the implementation of the CE concept throughout the country. These also include the “Roadmap for transformation towards a closed-loop economy” adopted in 2019 by the Council of Ministers [27].

This goal is also served by the recently completed “OTO-GOZ” project, which resulted in the development of a set of measurement indicators to assess progress in the transformation of the Polish economy towards CE, both at the mesoeconomic (regions) and macroeconomic levels [28].

At this point, however, it should be noted that any projects, programs, and strategies enacted and implemented at the meso and macroeconomic levels ultimately boil down to actions taken by individual economic actors. In other words, it is the behavioral changes of both entrepreneurs and users—boiling down to the design and implementation of circular business models and the realization of sustainable consumption patterns—that determine the transformation of CE-directed regions and economies.

Notably, the events that took place in 2020–2022, especially the COVID-19 pandemic and the outbreak of war in Ukraine, significantly affected the realization of the assumptions, and even more, the possibility of achieving them in the assumed time horizon without serious economic perturbations.

Considered from the perspective of management science, the business model of an enterprise’s operations includes—in a gross simplification—the organizational and financial architecture for creating, delivering, and capturing value, leading to the enterprise’s competitive advantage and, ultimately, profit [26,29]. However, for a firm’s business model to represent a paradigm shift in doing business according to the 3Rs principle, it must be circular in nature. According to the most commonly used definition in the literature by Linder and Williander ([22] p. 183), a circular business model means “a business model in which the conceptual logic for value creation is based on utilizing economic value retained in products after use in the production of new offerings”. In other words, the essence of a circular business model is to exploit business opportunities in such a way that a company can create value not only economically but also socially and environmentally. Indeed, the key role of the circular business model is to “incorporate the circular economy principles into a design or redesign of business activities and partnerships and to create a cost and revenue structure, which is compatible both with sustainability and with profitability” ([30] p. 275). Proposals for making such a concept a reality also find application in the three-element division of value propositions [31] and the creation of a sustainable value proposition [32].

On the other hand, however, equally important for the implementation of the CE concept is the realization of sustainable consumption patterns by users. Such actions not only lead to the reduction in food waste, waste production, and pollution, but also strengthen the environmental awareness of consumers [33] and induce changes in the way users interact with products and services (ownership, leasing, sharing, etc.) [7].

In conclusion, according to the described logic, the implementation of the CE concept in the long term will depend on how companies create added value, as well as how consumers perceive it. However, for such activities to be successful, it is necessary for companies to undertake innovative activities, including in particular the generation and implementation of various types of ecological innovations [1,6,7] and building and maintaining relationships with customers, leading to closing material flow loops [34].

4. The Concept and Types of Ecological Innovations

The terms eco-innovation, eco-innovation, green innovation, environmental innovation, and sustainable innovation are generally used interchangeably. The concept was developed in the mid-1990s, and one of the first definitions of eco-innovation was by Fussler and James [35], indicating that they are new products, processes or services that offer value to both the company and the consumer while significantly reducing harmful environmental impacts. One of the most frequently cited definitions of eco-innovation in the literature is that by Kemp and Pearson [36], according to which “eco-innovation is the production, assimilation or exploitation of a product, production process, service or management or business method that is novel to the organization (developing or adopting it) and which results, throughout its life cycle, in a reduction in environmental risk, pollution and other negative impacts of resources use (including energy use) compared to relevant alternatives”. A key aspect of such a framing of eco-innovation is to focus on the actual environmental impact of these innovations (i.e., their effects), rather than just the intentional actions (i.e., the motivation). In such a perspective, it does not matter whether the environmental consequences are the main purpose of generating and implementing eco-innovations or whether they are an unintended side effect [13,37]. Finally, with respect to innovation benefits, researchers indicate that the generation and implementation of eco-innovations leads to economic benefits [38], as well as social and environmental benefits, i.e., reduction in pollution [39] or optimization of natural resource use [40]. In this way, undertaking eco-innovative activities by companies not only provides a basis for building circular business models, but also leads to proenvironmental changes in consumption patterns and—ultimately—to the construction of a system in which the economy, society, and the environment are coordinated in achieving sustainable development goals [8,26].

In conventional terms, researchers [41] distinguish between product innovations—concerning changes in the products produced by firms or the services they provide—and process innovations, representing changes in the ways in which those products are produced or those services are provided. The Oslo Manual [42] also supplements the above classification with organizational innovations. According to the criterion of benefits generated by a given solution in comparison with the use of alternative solutions, Kemp and Pearson [36] classify eco-innovations into environmental technologies, organizational innovation for the environment, product and service innovation offering environmental benefits, and green system innovations. This division is conceptually consistent with the OECD methodology, although it also takes into account broader system solutions, i.e., alternative production and consumption systems beyond the organizational perspective. Despite the existence of many other holistic typologies of eco-innovations (cf. [38,43] providing a multilevel research framework, the conventional division of eco-innovation into product, process, and organizational is one of the most commonly used in the literature [37,39,44,45] classification at the organizational level. Therefore, this is the approach adopted in this paper.

5. Eco-Innovations as Determinants of Closed-Loop Economy Implementation

Product eco-innovation refers to new or significantly improved (in terms of its characteristics or uses) products or services, the implementation of which leads to minimizing the use of nonrenewable resources, avoiding the use of toxic materials, and reducing the use of renewable resources, so as not to exceed the biological capacity of the planet to renew them [46]. Product eco-innovations are the most marketable type of innovation, but to be a tool for implementing CE concepts they must be designed to be fully reusable through repairing, maintaining, remanufacturing, recycling, and cascading the use of components and materials. As a rule, such products (known as “circular products”) provide value, which can also be virtualized or subject to collaborative consumption [34].

A number of new product development models have been proposed in the literature that take the form of a sequence of interconnected stages that make up the broad life cycle of these products. When considering eco-product innovations that can support the transition from a linear to a circular model, it is first necessary to consider all stages of their life cycle, from idea generation through product development and commercialization [47,48] to their various forms of recovery. In this context, a useful managerial practice is so-called product stewardship, an approach used by companies that focuses on minimizing all environmental impacts over the full life cycle of products [46]. On the other hand, however, it is necessary to define the main environmental impacts (relating to the use of materials, energy, and the generation of pollutants, including waste) already at the product conception stage [49]. It is worth emphasizing that not all products generate harmful environmental impacts at every stage of their life cycle, but all products impact the environment at—at least—one of the stages [50]. For example, the use of raw materials that emit fewer pollutants in the manufacturing process of products may consequently lead to an increased environmental burden at the recycling or reuse stage of these products [51].

A key aspect of developing product eco-innovations to support the implementation of CE is therefore the product concept—i.e., its design—which must be aligned with the goals of a circular economy [52]. Therefore, an important practice in this area is the so-called eco-design (eco-design, design for environment, and sustainable product design). It involves identifying environmental aspects related to the product and then including them in the design process at the earliest possible stage of its development [53]. In the traditional approach, the essential role in the product design process is played by such aspects as: functionality, safety, ergonomics, durability, quality or costs. In the case of eco-design, an additional criterion is taken into account, namely the evaluation of the product design from the point of view of its environmental impact.

The literature indicates that eco-design plays a key role in making the idea of a closed-loop economy a reality [7,34]. This is because the effective design of green products is the basis for developing effective eco-innovation strategies and moving towards environmental sustainability [46]. For this to happen, however, it is necessary for companies to make wider use of analytical techniques that support eco-design, leading to an optimization of products in terms of resource efficiency (e.g., Material Input Per Service Unit (MIPS) and—more advanced—an analysis of the environmental impact of the product, the so-called Life Cycle Assessment (LCA)) [54,55].

The introduction of extended producer responsibility practices is also an important incentive for businesses to improve product design to reduce the amount of materials used and waste generated, to reuse, use recycling and other forms of recovery (i.e., closing material flow loops), and to introduce extended producer responsibility practices. These involve placing the responsibility for the negative environmental burdens created at the end of the product life cycle on the original producer [46] and are one of the most effective managerial practices for circular economy transition.

Green labeling refers to the placing of information on products indicating that they fulfill a number of criteria relating to environmental protection, health protection, and resource efficiency [46]. Moreover, they provide information that a product is more environmentally friendly than other products in the same category with similar performance and functional characteristics. The eco-labeling of packaging means that it is, for example, biodegradable when composted or recycled and can be reused [56].

Eco-labels are an important practice through which companies not only maintain customer relationships but also can manage changes in customer habits as a result of selling circular products or services. In this perspective, eco-labels are seen as one of the most important determinants of the implementation of sustainable consumption patterns. Environmental certificates (product labels) also contribute to the creation of an ecological image of companies, as well as verbal and visual identification of eco-innovations implemented by them. According to Porter and van der Linde [9], by appropriately shaping an environmentally friendly image, innovators can introduce higher prices for green products. If consumers’ environmental awareness increases (thanks to such certifications), the expected increase in market demand will stimulate the generation of further eco-innovations supporting the implementation of the CE concept [8].

Process eco-innovation involves the introduction of new or significantly improved production methods and refers to changes in production processes that neutralize or minimize negative environmental impacts compared with the use of alternatives [14]. They are usually framed by researchers [44] in two broad categories, as end-of-pipe and clean technologies.

In the context of implementing the CE concept, the application of clean technologies refers to the reduction in the harmful environmental impact of production processes [57] and includes significant changes in the production process, including material-saving technologies, energy-saving technologies, technologies that reduce or eliminate pollution, and solutions that prevent postproduction waste [46,51].

An important management practice that supports the development of process eco-innovations that determine the realization of the idea of a closed-loop economy is the optimization of processes for resource efficiency [7,34], including in particular the improvement of material eco-efficiency and energy efficiency. Material eco-efficiency is a strategic approach leading to a reduction in the amount of materials used per unit of production [46]. Energy eco-efficiency, on the other hand, refers to practices aimed at increasing energy savings through, for example, the introduction of intelligent energy management systems and the use of nonconventional and renewable energy sources [46]. The literature also emphasizes that the development and implementation of process eco-innovations—by achieving material and energy savings—leads to a greater rationalization of the use of renewable and nonrenewable resources and, as a result, to a significant reduction in the economic costs of the companies’ production activities [9].

Eco-innovations that support the adoption of the closed-loop economy concept can be technological and nontechnological [7]. In this context, an important determinant of the implementation of CE is also organizational eco-innovations, which relate to the implementation of new, environmentally friendly organizational methods in the principles of operation adopted by enterprises, in the organization of the workplace or in relations with the environment [58]. Organizational eco-innovations refer to new management strategies aimed at reducing the negative environmental impact of production (service) activities of enterprises. Typical management practices leading to the implementation of such innovations are the introduction of environmental management systems (EMS) [59,60,61], including the standards of the International Standards Organization (ISO 14001), the European Union Environmental Management and Auditing Scheme (EMAS), and green-supply chain management [46].

Environmental management systems (EMS) means “an organizational change within corporations and an internally motivated effort at environmental self-regulation by adopting management practices that integrate the environment into production decisions, identifying opportunities for pollution and waste reductions, and implementing plans to make continuous improvements in production methods and environmental performance” ([62], p. 539). As indicated by Frondel et al. [59], ESM may also include: environmental reporting, environmental performance monitoring, and performance evaluation.

Currently, among the environmental management systems, the most important are the standards of the International Standards Organization (ISO 14001) and the European Union Environmental Management and Auditing Scheme (EMAS). The main difference of the ISO with respect to the EMAS was that it was freely available, meaning that any organization, regardless of its profile, that wanted to embrace proenvironmental activities could apply for certification. However, since EMAS II came into force, the difference between the two schemes is only formal [55].

Another strategic practice leading to the generation and implementation of organizational eco-innovations is also green supply-chain management (GrSCM), defined by Srivastava [63] as “integrating environmental thinking into supply-chain management”. The need to close material flow loops in the supply chain points to the need for logistics systems that incorporate responsible natural resource management [64], of which the application of reverse logistics is a key element. The purpose of extending supply chains with reverse flows is to create added value by managing the waste generated at each stage of the value creation chain. The recovery of value according to the logic of reverse logistics is derived from the application of many processes, including, among others, repair and reuse of products and materials, refurbishment, remanufacturing, cannibalization (recovery of a relatively small number of used parts), and recycling [65].

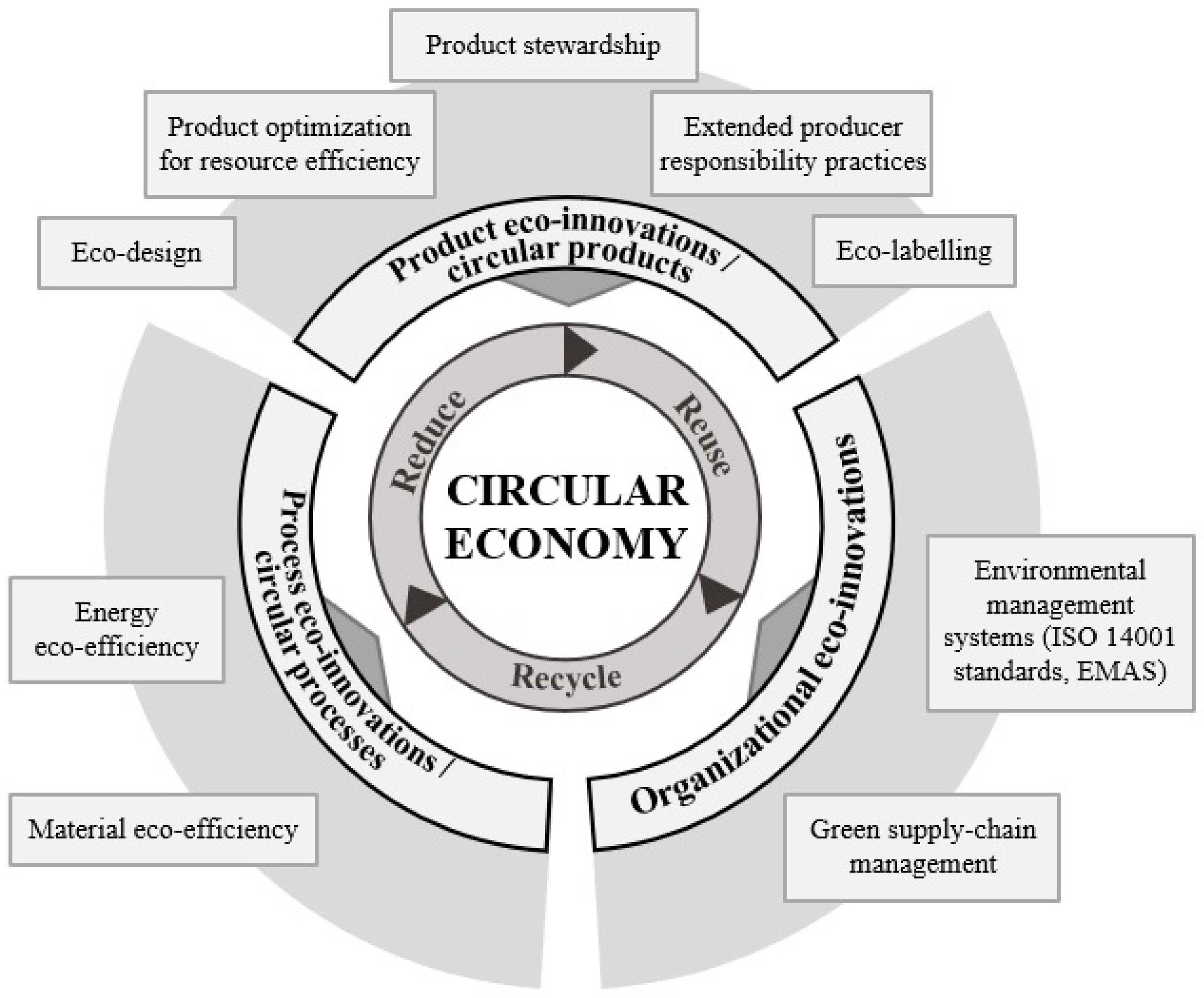

A synthetic illustration of the considerations presented above, indicating the role and importance of product, process, and organizational eco-innovations in the implementation of a closed-loop economy, is the conceptual model shown in Figure 1.

Figure 1.

Managerial practices promoting the generation and implementation of eco-innovations for circular economy transition.

The analysis of the impact of the generation and implementation of eco-innovations leading to the realization of the idea of a circular economy, through the use of management practices presented in Figure 1, requires highlighting three key issues, which are the subject of further consideration. First, the development and implementation of eco-innovations acts as a catalyst in the transition from a linear to a circular model also due to the existence of interdependencies between the different types of eco-innovations. Doran and Ryan [14] conclude that companies that invest in the development of process eco-innovations are at the same time more likely to be involved in the introduction of new eco-products to the market, bear lower risks associated with their development, and are better protected from potential imitators. In contrast, Rennings and Rammer [66] reason that firms introducing material-saving and energy-efficient technologies devote significantly more resources to environmental R&D activities than other firms. In contrast, Gerstlberger, et al. [45] indicate that the generation and implementation of product eco-innovations improves the energy efficiency level of manufacturing companies. Finally, the implementation of process eco-innovations (clean technologies) is supported by the implementation of environmental management systems, which is confirmed by the results of studies conducted by Rennings et al. [67] and Wagner [68]. Moreover, Horbach et al. [37] conclude that environmental management systems determine the use of clean technologies because they help overcome information incompleteness in companies. In a similar context, Rehfeld et al. [69] identify a statistically significant relationship between environmental management system certification and eco-innovations planned by the companies studied.

The second point is that the management practices presented in Figure 1 are intertwined, and their use is not just a strategic response by businesses to existing (or anticipated) environmental legislation, but a proactive effort to close material flow loops. Moreover, the choice of appropriate tools illustrated by the R abbreviation (Reduce, Reuse, Recycle, Rework, Refurbish, Reclaim, Remanufacture, Reverse logistics, etc.) depends largely on the configuration of resources, capabilities, and core competencies possessed by enterprises.

Finally, the last point is the need to involve different stakeholder groups in the eco-innovation activities carried out by companies. This involvement, of course, primarily concerns supply chain partners—customers and suppliers, in particular, can exert significant influence on companies’ decisions leading to the implementation of environmental practices [46,70]. Such activities translate not only into building long-term partnerships along the supply chain, but also into the need to transform the designed business models so that they take into account not only the paradigm of a closed-loop economy but also the paradigm of open innovation.

6. Eco-Innovation as a Determinant of Business Model Transformation

Another level of integration in combining the concepts of eco-innovation and the circular economy may be the points of their mutual integration, i.e., the practices described above, each of which can be a source of open innovation [71].

The concept of open innovation assumes a bidirectional approach to knowledge exchange [54]. Both in terms of acquiring it from other entities and in terms of providing it to potential beneficiaries, the preservation of proecological and proinnovative conditions for the implementation of this exchange, within the framework of creating a sustainable business model, remains unchanged. Creating open innovations on the basis of integration processes of eco-innovations generated and implemented within circular business models, creates additional opportunities for the realization of sustainable development assumptions, but at the same time, increases the social and economic importance of eco-business. In time, it may also lead to the creation of a new category of business entities that form a network of proenvironmental stakeholders and even a new type of open innovation of ecological nature, i.e., open eco-innovations.

Continuing the undertaken scientific discourse, one should also consider this transformation of eco-innovation into open eco-innovation through the prism of the concept of dynamic open innovation [72,73]. The recent literature indicates two paths for implementing this approach. The first path assumes that the transformation process runs through the stages defined from “open innovation” through “complex adaption” to “evolutionary change dynamics”. This is called open innovation microdynamics. However, in the context of the aforementioned socio-political events of recent years, the process recognized as open innovation macrodynamics may turn out to be more justified, i.e., the transformation from “market open innovation” through “closed open innovation” to “social open innovation”. However, one should not limit oneself to the above-mentioned approaches because the literature proposes other approaches in the field of open innovation dynamics. The aspect of culture for open innovation dynamics or entrepreneurial cyclical dynamics of open innovation should also be mentioned here [72,73,74].

Geissdoerfer et al. [75] conclude that by undertaking the implementation of four sustainable business model innovations i.e., (1) sustainable start-ups, (2) sustainable business model transformation, (3) sustainable business model diversification, and (4) sustainable business model acquisition, certain types of models can be implemented. Based on these, sustainable business models can be classified into just four groups, including (1) circular business models, (2) social enterprises, (3) bottom of the pyramid solutions, and (4) product–service systems. Within the discussed issues, the most interesting group is the circular business models. They are characterized by creating sustainable value, employ proactive multistakeholder management, and have a long-term perspective. However, in addition to these attributes, the processes include closed, slowed down, intensified, dematerialized, or narrow resource loops.

In the context of the discussion on the role of eco-innovation as a determinant of the implementation of the CE concept, it should be noted that eco-innovation may also significantly condition the design and implementation of sustainable business models, leading in consequence to the transformation of these models into circular business models. Including multidimensional eco-innovation activities in circular business models significantly broadens the scope of implemented processes, going beyond the mentioned feedback loops of resource flow.

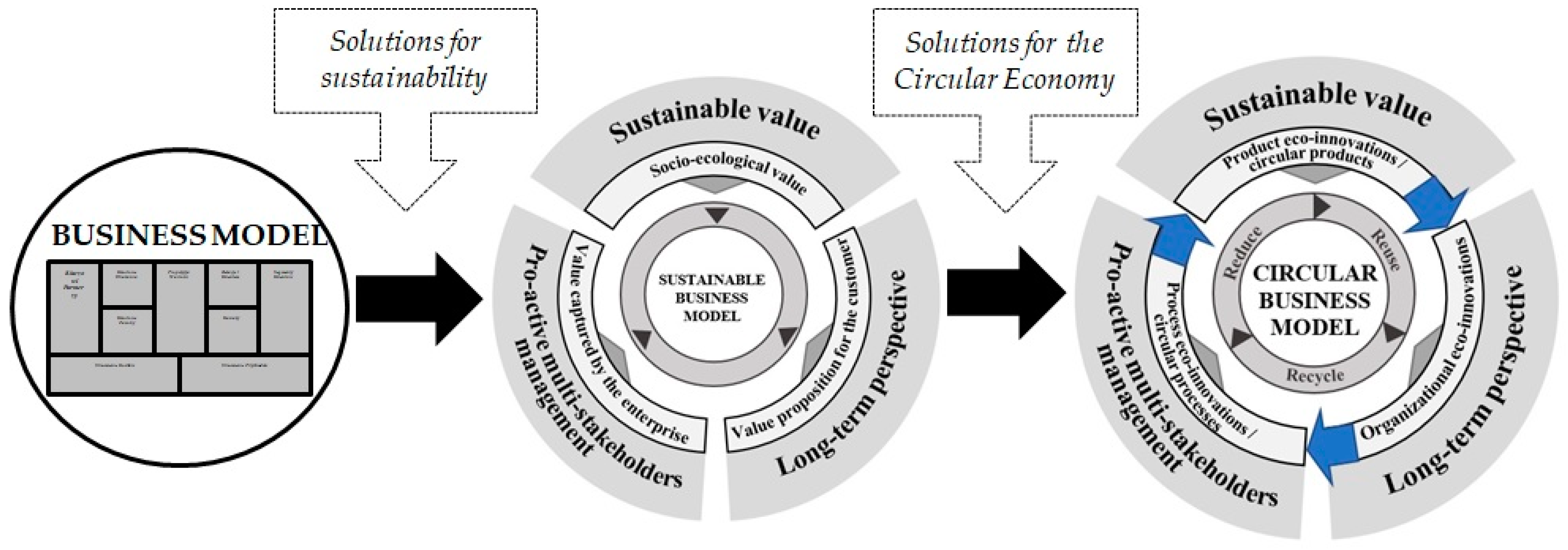

It seems that the business model can take a more advanced form precisely thanks to the implementation of circular eco-innovation solutions, as presented in Figure 2. A key premise resulting from such a conceptual approach is also the fact that the transformation of business models is based on both the idea of their circularity (resulting in closing material flow loops and reducing pollution) and their openness (resulting in designing and implementing open eco-innovations).

Figure 2.

The transformation of the business model into a circular business model involving eco-innovations. Source: own study.

Although this concept is not found in the literature, it seems reasonable to consider pointing out the uniqueness of such eco-innovations in the modern world. Open process eco-innovations especially should form a set of universally accessible solutions.

The transformation shown in Figure 2 envisions a three-stage transformation of the business model. In its initial form, it may include a traditional form in which the distribution of components is formulated around the value proposition and the value captured by the business. Of course, the structure of such models can be formed according to any concept, although the structure adopted incorporates the CANVAS concept of Ostervalder and Pigneur [76].

The inclusion in the model of an extended value proposition with sustainable value (in accordance with the concept of sustainable value [77]), but also a long-term perspective of the actions taken in terms of business impacts and a wide range of stakeholder relationships, has achieved the form of a sustainable business model. However, due to the elitist nature of sustainable models, the processes involved in the operation of such a model were generally directed to limited parts of the supply chain or to incidental cooperation with contractors pursuing similar sustainable goals and was even more limited in its dealings with customers. The transformation of models along the lines of a circular economy is therefore becoming an important transformation.

The circular business model takes into account not only the assumptions of sustainable models, as it directs business processes towards sustainable activity, but also tries to create mutual relations in such a way as to achieve a closed circuit in terms of material flows, energy production, and reduction in pollution emission at the same time. However, what may distinguish circular business models may be the inclusion of the perspective of creating such a model in accordance with the idea of eco-innovation.

The perspective of creating circular business models based on eco-innovations, especially open eco-innovations, can organize the range of processes undertaken and relationships within the business model, focusing managers’ attention especially on the eco-innovation implementation practices described above.

7. Discussion and Conclusions

To sum up the above discussion on the role and importance of eco-innovation as a determinant of implementation of the circular economy concept, it is worth pointing out that it plays an extremely important role, and in the perspective of the coming decades, it may even be a strategic element of implementation of the circular economy concept. Eco-innovation activities carried out by companies, including the generation and implementation of various types of eco-innovations (product, process, and organizational) and leading to the implementation of the sustainable development idea, is an important part of many processes’ characteristic of a closed-loop economy. Moreover, considering eco-innovation as central to building circular business models can increase the socio-economic efficiency of the activities carried out by enterprises by using the synergy effect.

The paper represents a novelty that can be characterized in terms of three both theoretical and practical dimensions. Firstly, it focuses on integrating various approaches and concepts that are different in nature but share a common logical background, as they represent the need to change the business philosophy of modern enterprises.

Secondly, the article attempts to initiate a discussion of the category of open eco-innovations, whose development and implementation lead to the lowest possible use of natural resources and thus to incurring the lowest environmental costs.

In the practical dimension—given the fact that the identification of conditions for the implementation of a circular economy model is challenging—the novelty of the considerations presented comes to identifying essential management practices, i.e., the strategic actions necessary in the process of generating and implementing eco-innovations leading to the realization of the CE paradigm.

It is also necessary to note that the implementation of such concepts, which consequently aim at achieving proecological goals, and thus at the effective implementation of sustainable development assumptions, has an undeniable social value. On one hand, it reveals itself in the social effects of company functioning and through symbiosis with local community but also in the ecological effects of global range.

One of the most important limitations of the analysis carried out is the fact that the eco-innovation activities carried out by companies are extremely complex and multidimensional in nature, and therefore difficult to conceptualize clearly. Therefore, Figure 1 does not take into account all existing dependencies and interactions but presents only a simplified picture of them.

We should also point out the limitation resulting from the very essence of the closed-loop economy, because for some products or materials closing the loop of their flow is impossible to achieve (e.g., some materials are not recyclable). In other words, some production processes will generate waste, and the closed circle depicted in the figures is only an ideal model.

The weakness of the considerations undertaken in the article is also the lack of possibility of their empirical verification, as the proposed integration of eco-innovation with the processes occurring in enterprises implementing circular economy is still insufficiently recognized. This limitation represents, at the same time, the most significant opportunity for future empirically based studies. An interesting and valuable direction for future research may therefore be to conduct—within the designed scope of content—quantitative or qualitative studies (e.g., in-depth interviews or case studies) verifying the assumed transformation of the business model from a practical perspective.

The main difficulty is to convince such companies to develop and implement eco-innovations, as this raises many new difficulties and requires additional costs. Reducing the risk of doing business is of course understandable, especially as the consequences of the COVID-19 pandemic and, in some countries, the effects of the war in Ukraine are still being borne. It is therefore worth further efforts to broaden the discussion on the role of eco-innovation in the context of a transition to circular economy not only through theoretical but also empirical publications. This paper is a first step towards achieving this goal. The further efforts of the authors are therefore focused on undertaking empirical research of such outlined conceptual perspectives, which include eco-innovation as changes not only of ecological nature, but also of circular and open nature, i.e., necessary actions taken by companies that lead to the implementation of CE concepts.

Author Contributions

Conceptualization, M.P. and A.R.S.; methodology, M.P.; formal analysis, M.P.; investigation, M.P.; resources, M.P.; writing—original draft preparation, A.R.S. and M.P.; writing—review and editing, M.P. and A.R.S.; supervision, M.P.; funding acquisition, A.R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was published as part of the statutory research ROZ 1: 13/010/BK_22/0065 at the Silesian University of Technology, Faculty of Organization and Management.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- de Jesus, A.; Lammi, M.; Domenech, T.; Vanhuyse, F.; Mendonça, S. Eco-Innovation Diversity in a Circular Economy: Towards Circular Innovation Studies. Sustainability 2021, 13, 10974. [Google Scholar] [CrossRef]

- Eisenreich, A.; Füller, J.; Stuchtey, M. Open Circular Innovation: How Companies Can Develop Circular Innovations in Collaboration with Stakeholders. Sustainability 2021, 13, 13456. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The History and Current Applications of the Circular Economy Concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Sehnem, S.; Farias, S.L.; Pereira, S.; Correia, G.; Kuzma, E. Circular economy and innovation: A look from the perspective of organizational Capabilities. Bus. Strategy Environ. 2022, 31, 236–250. [Google Scholar] [CrossRef]

- Vence, X.; Pereira, Á. Eco-innovation and Circular Business Models as drivers for a circular economy. Contaduría Y Adm. 2019, 64, 1–19. [Google Scholar] [CrossRef] [Green Version]

- de Jesus, A.; Mendonça, S. Lost in Transition? Drivers and Barriers in the Eco-innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef] [Green Version]

- Porter, M.E.; van der Linde, C. Green and Competitive: Ending the Stalemate. Harv. Bus. Rev. 1995, 73, 120–133. [Google Scholar]

- Chesbrough, H.; Rosenbloom, R.S. The role of the business model in capturing value from innovation: Evidence from Xerox Corporation’s technology spin-off companies. Ind. Corp. Chang. 2002, 11, 529–555. [Google Scholar] [CrossRef] [Green Version]

- Chesbrough, H.W. Open Innovation: The New Imperative for Creating and Profiting from Technology; Harvard Business School Press: Boston, MA, USA, 2003. [Google Scholar]

- Chesbrough, H.W. The era of open innovation. MIT Sloan Manag. Rev. 2003, 44, 35–41. [Google Scholar]

- Carrillo-Hermosilla, J.; del Río, P.; Könnölä, T. Diversity of Eco-Innovations: Reflections from Selected Case Studies. J. Clean. Prod. 2010, 18, 1073–1083. [Google Scholar] [CrossRef]

- Doran, J.; Ryan, G. The Importance of the Diverse Drivers and Types of Environmental Innovation for Firm Performance. Bus. Strategy Environ. 2016, 25, 102–119. [Google Scholar] [CrossRef]

- Díaz-García, C.; González-Moreno, Á.; Sáez-Martínez, F.J. Eco-Innovation: Insights from a Literature Review, Innovation: Management. Policy Pract. 2015, 17, 6–23. [Google Scholar] [CrossRef]

- Chesbrough, H.; Bogers, M. Explicating Open Innovation: Clarifying an emerging paradigm for understanding innovation. In New Frontiers in Open Innovation; Chesbrough, H., Vanhaverbeke, W., West, J., Eds.; Oxford University Press: Oxford, UK, 2014. [Google Scholar]

- Horbach, J. Determinants of Environmental Innovation-New Evidence from German Panel Data Sources. Res. Policy 2008, 37, 163–173. [Google Scholar] [CrossRef] [Green Version]

- Kesidou, E.; Demirel, P. On the Drivers of Eco-Innovations: Empirical Evidence from the UK. Res. Policy 2012, 41, 862–870. [Google Scholar] [CrossRef]

- WCED. Our Common Future, World Commission on Environment and Development; Oxford University Press: London, UK, 1987.

- Ellen MacArthur Foundation. Towards the Circular Economy. Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://www.ellenmacarthurfoundation.org (accessed on 28 May 2022).

- Liu, J.Y. Circular Economy and Environmental Efficiency—The Case of Traditional Hakka Living System. Procedia—Soc. Behav. Sci. 2012, 57, 255–260. [Google Scholar] [CrossRef] [Green Version]

- Linder, M.; Williander, M. Circular Business Model Innovation: Inherent Uncertainties. Bus. Strategy Environ. 2017, 26, 182–196. [Google Scholar] [CrossRef]

- Romero, D.; Molina, A. Green Virtual Enterprise Breeding Environments: A Sustainable Industrial Development Model for a Circular Economy. In Collaborative Networks in the Internet of Services; Camarinha-Matos, L.M., Xu, L., Afsarmanesh, H., Eds.; IFIP Advances in Information and Communication Technology: Bournemouth, UK, 2012; Volume 380, pp. 427–436. [Google Scholar]

- European Commission. Which Indicators Are Used to Monitor the Progress towards a Circular Economy? 2022. Available online: https://ec.europa.eu/eurostat/web/circular-economy/indicators (accessed on 28 May 2022).

- European Parliament. How the EU Wants to Achieve a Circular Economy by 2050. 2022. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20210128STO96607/how-the-eu-wants-to-achieve-a-circular-economy-by-2050 (accessed on 28 May 2022).

- Kanda, W.; Geissdoerfer, M.; Hjelm, O. From circular business models to circular business ecosystems. Bus. Strategy Environ. 2021, 30, 2814–2829. [Google Scholar] [CrossRef]

- Polish Ministry of Economic Development and Technology. Rada Ministrów Przyjęła Projekt Mapy Drogowej GOZ. 2019. Available online: https://www.gov.pl/web/rozwoj-technologia/rada-ministrow-przyjela-projekt-mapy-drogowej-goz (accessed on 6 May 2022).

- Polish Circular Hotspot. Projekt OTO-GOZ. 2022. Available online: http://circularhotspot.pl/pl/oto-goz (accessed on 28 May 2022).

- Pichlak, M. Projektowanie modeli biznesowych w branżach twórczych. In Scientific Papers of the Silesian University of Technology, Series: Organization and Management; Publishing House of the Silesian University of Technology: Gliwice, Poland, 2015; p. 86. [Google Scholar]

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strategy Environ. 2019, 28, 274–285. [Google Scholar] [CrossRef]

- Butler, R.W.; Szromek, A.R. Incorporating the Value Proposition for Society with Business Models of Health Tourism Enterprises. Sustainability 2019, 11, 6711. [Google Scholar] [CrossRef] [Green Version]

- Wybrańczyk, K.; Szromek, A. Proposal of Value for Customer of Spas: Expectations of Spa Patients and Tourist in Polish Spas. Sustainability 2019, 11, 3598. [Google Scholar]

- Prieto-Sandoval, V.; Jacka, C.; Santos, X.; Baumgartner, R.J.; Ormazabal, M. Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Responsib. Environ. Manag. 2019, 266, 1473–1484. [Google Scholar] [CrossRef] [Green Version]

- Franzo, S.; Urbinati, A.; Chiaroni, D.; Chiesa, V. Unravelling the design process of business models from linear to circular: An empirical investigation. Bus. Strategy Environ. 2021, 30, 2758–2772. [Google Scholar] [CrossRef]

- Fussler, C.; James, P. Eco-Innovation: A Breakthrough Discipline for Innovation and Sustainability; Pitman Publishing: London, UK, 1996. [Google Scholar]

- Kemp, R.; Pearson, P. Final Report of the MEI Project Measuring Eco-Innovation; MEI: Eindhoven, The Netherlands, 2007. [Google Scholar]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of Eco-Innovations by Type of Environmental Impact—The Role of Regulatory Push/Pull, Technology Push and Market Pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef] [Green Version]

- Eco-Innovation—Towards a Taxonomy and a Theory. In Proceedings of the DRUID Conference Entrepreneurship and Innovation. Available online: https://conference.druid.dk/Druid/infoSite.xhtml?itemId=331 (accessed on 12 July 2022).

- Eco-Innovation—Final Report for Sectoral Innovation Watch. Available online: http://www.bioin.or.kr/InnoDS/data/upload/policy/1227694141381.pdf (accessed on 12 July 2022).

- Sarkar, A.N. Promoting Eco-Innovations to Leverage Sustainable Development of Eco-Industry and Green Growth. Eur. J. Sustain. Dev. 2013, 2, 171–224. [Google Scholar]

- Damanpour, F. Organizational Innovation: A Meta-Analysis of Effects of Determinants and Moderators. Acad. Manag. J. 1991, 34, 555–590. [Google Scholar]

- OECD. Oslo Handbook; Principles of Collecting and Interpreting Data on Innovation: Warsaw, Poland, 2008. [Google Scholar]

- Rennings, K. Redefining Innovation—Eco-Innovation Research and the Contribution from Ecological Economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar] [CrossRef]

- Triguero, A.; Moreno-Mondéjar, L.; Davia, M.A. Drivers of Different Types of Eco-Innovation in European SMEs. Ecol. Econ. 2013, 92, 25–33. [Google Scholar] [CrossRef]

- Gerstlberger, W.; Knudsen, M.P.; Dachs, B.; Schröter, M. Closing the Energy-Efficiency Technology Gap in European Firms? Innovation and Adoption of Energy Efficiency Technologies. J. Eng. Technol. Manag. 2016, 40, 87–100. [Google Scholar] [CrossRef]

- Albino, V.; Balice, A.; Dangelico, R.M. Environmental Strategies and Green Product Development: An Overview on Sustainability-Driven Companies. Bus. Strategy Environ. 2009, 18, 83–96. [Google Scholar] [CrossRef]

- Kahn, K.B. Understanding innovation. Bus. Horiz. 2018, 61, 453–460. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V.; Frattini, F. The role of digital technologies in open innovation processes: An exploratory multiple case study analysis. RD Manag. 2020, 50, 136–160. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P.; Pujari, D. Developing Sustainable New Products in the Textile and Upholstered Furniture Industries: Role of External Integrative Capabilities. J. Prod. Innov. Manag. 2013, 30, 642–658. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, J.W. Integrating Suppliers into Green Product Innovation Development: An Empirical Case Study in the Semiconductor Industry. Bus. Strategy Environ. 2011, 20, 527–538. [Google Scholar] [CrossRef]

- Loiseau, E.; Saikku, L.; Antikainen, R.; Droste, N.; Hansjürgens, B.; Pitkänen, K.; Leskinen, P.; Kuikman, P.; Thomsen, M. Green Economy and Related Concepts: An Overview. J. Clean. Prod. 2016, 139, 361–371. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Ekoprojektowanie—Holistyczne podejście do projektowania. Probl. Ekol. 2010, 14, 116–120. [Google Scholar]

- Llorach-Massana, P.; Farreny, R.; Oliver-Sola, J. Are Cradle to Cradle certified products environmentally preferable? Analysis from an LCA approach. J. Clean. Prod. 2015, 93, 243–250. [Google Scholar] [CrossRef] [Green Version]

- Pichlak, M. Innowacje Ekologiczne, Zdolności Dynamiczne i Efektywność Organizacji; CeDeWu: Warszawa, Poland, 2020. [Google Scholar]

- Szymańska-Brałkowska, M.; Wiśniewska, M.Z.; Malinowska, E. Oznakowanie Ekologiczne Produktów i Opakowań—Wybrane Ekoznaki; Wyd. Uniwersytetu Gdańskiego: Sopot, Poland, 2014. [Google Scholar]

- Duczkowska-Kądziel, A.; Duda, J.; Wasilewski, M. Innowacyjne czyste technologie szansą rozwoju przemysłu. In Innowacje w Zarządzaniu i Inżynierii Produkcji; Knosala, R., Ed.; Oficyna Wydawnicza Polskiego Towarzystwa Zarządzania Produkcją: Opole, Poland, 2013. [Google Scholar]

- Matejun, M. Zarządzanie innowacjami ekologicznymi we współczesnym przedsiębiorstwie. In Rozwój—Zrównoważonyzarządzanie Innowacjami Ekologicznymi; Grądzki, R., Matejun, M., Eds.; Wyd. Media Press: Łódź, Poland, 2009. [Google Scholar]

- Frondel, M.; Horbach, J.; Rennings, K. What Triggers Environmental Management and Innovation? Empirical Evidence for Germany. Ecol. Econ. 2008, 66, 153–160. [Google Scholar] [CrossRef] [Green Version]

- Iraldo, F.; Testa, F.; Frey, M. Is an environmental management system able to influence environmental and competitive performance? The case of the eco-management and audit scheme (EMAS) in the European Union. J. Clean. Prod. 2009, 17, 1444–1452. [Google Scholar] [CrossRef]

- Ziegler, A.; Nogareda, J. Environmental Management Systems and Technological Environmental Innovations: Exploring the Causal Relationship. Res. Policy 2009, 38, 885–893. [Google Scholar] [CrossRef] [Green Version]

- Khanna, M.; Anton, W.R.Q. Corporate environmental management: Regulatory and market-based pressures. Land Econ. 2002, 78, 539–558. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Wu, H.J.; Dunn, S.C. Environmentally Responsible Logistics Systems. Int. J. Phys. Distrib. Logist. Manag. 1995, 25, 20–39. [Google Scholar] [CrossRef]

- Wadhwa, S.; Madaan, J.; Chan, F.T.S. Flexible decision modeling of reverse logistics system: A value adding MCDM approach for alternative selection. Robot. Comput.-Integr. Manuf. 2009, 25, 460–469. [Google Scholar] [CrossRef]

- Rennings, K.; Rammer, C. Increasing Energy and Resource Efficiency through Innovation—An Explorative Analysis using Innovation Survey Data. Czech J. Econ. Financ. 2009, 59, 442–459. [Google Scholar] [CrossRef] [Green Version]

- Rennings, K.; Ziegler, A.; Ankele, K.; Hoffmann, E. The Influence of Different Characteristics of the EU Environmental Management and Auditing Scheme on Technical Environmental Innovations and Economic Performance. Ecol. Econ. 2006, 57, 45–59. [Google Scholar] [CrossRef]

- Wagner, M. On the Relationship between Environmental Management, Environmental Innovation and Patenting: Evidence from German Manufacturing Firms. Res. Policy 2007, 36, 1587–1602. [Google Scholar] [CrossRef]

- Rehfeld, K.M.; Rennings, K.; Ziegler, A. Integrated Product Policy and Environmental Product Innovations: An Empirical Analysis. Ecol. Econ. 2007, 61, 91–100. [Google Scholar] [CrossRef] [Green Version]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Yun, J.J.; Zhao, X.; Wu, J.; Yi, J.C.; Park, K.; Jung, W. Business model, open innovation, and sustainability in car sharing industry-Comparing three economies. Sustainability 2020, 12, 1883. [Google Scholar] [CrossRef] [Green Version]

- Yun, J.J.; Zhao, X.; Jung, K.; Yigitcanlar, T. The Culture for Open Innovation Dynamics. Sustainability 2020, 12, 5076. [Google Scholar] [CrossRef]

- Yun, J.J.; Liu, Z. Micro- and Macro-Dynamics of Open Innovation with a Quadruple-Helix Model. Sustainability 2019, 11, 3301. [Google Scholar] [CrossRef] [Green Version]

- Yun, J.J.; Lee, M.; Park, K.; Zhao, X. Open Innovation and Serial Entrepreneurs. Sustainability 2019, 11, 5055. [Google Scholar] [CrossRef] [Green Version]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; WILEY: Hoboken, NJ, USA, 2010; p. 59. [Google Scholar]

- Evans, S.; Vladimirova, D.; Holgado, M.; Van Fossen, K.; Yang, M.; Silva, E.; Barlow, C. Business model innovation for sustainability: Towards a unified perspective for creation of sustainable business models. Bus. Strat. Environ. 2017, 26, 1–13. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).