Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia

Abstract

1. Introduction

- RQ1. What are the key determinants of the maturity of SC4.0?

- RQ2. How do these determinants interrelate with one another?

2. Literature Review

2.1. Industry 4.0 Readiness and Maturity Assessment

2.2. Industry 4.0 in Developing Countries

2.3. Supply Chain 4.0

2.4. Theoretical Lens: SC4.0 Maturity Model

2.5. Agility, Ambidexterity, and Open Innovation

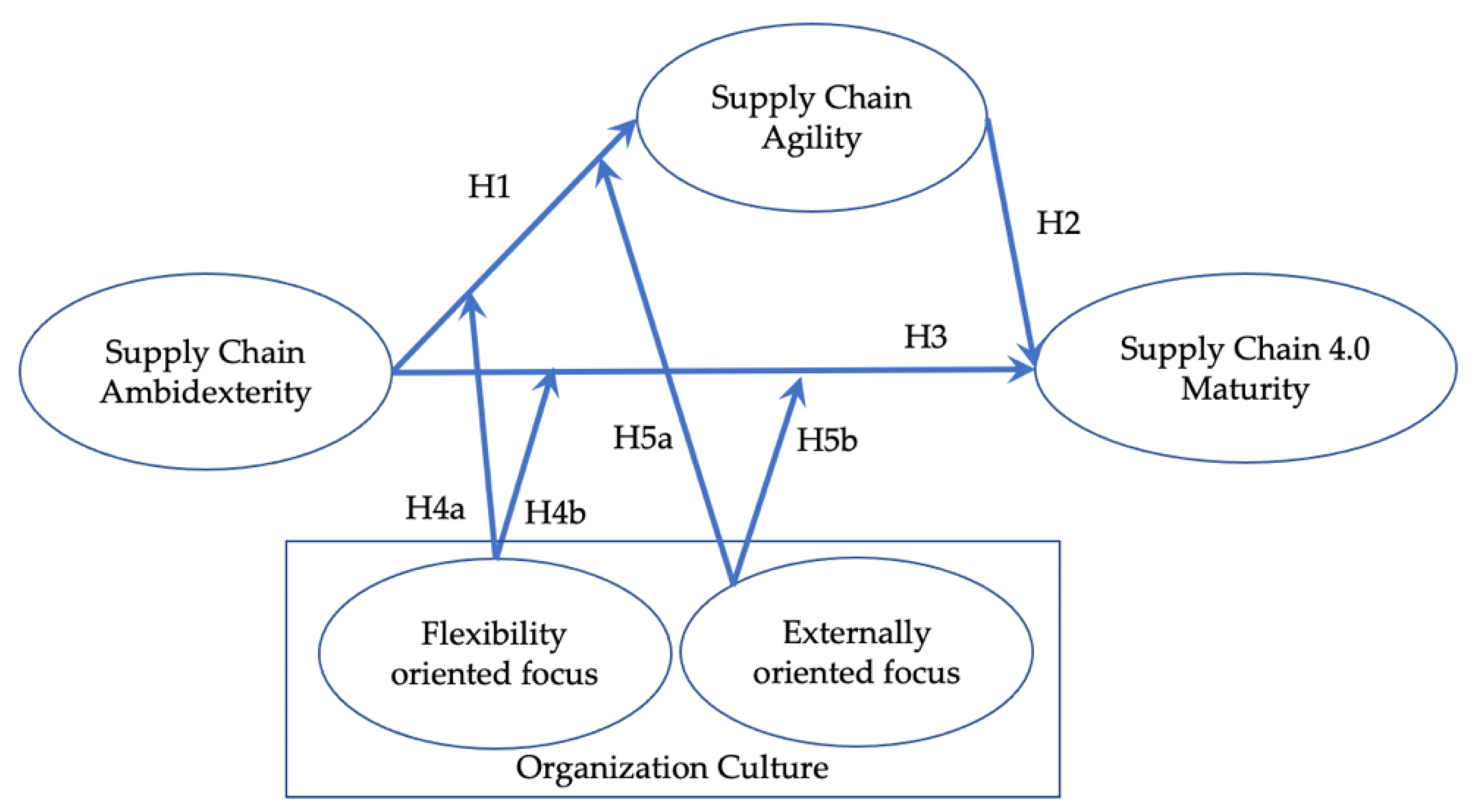

3. Hypotheses Development

3.1. Positive Association between Supply Chain Ambidexterity and Agility

3.2. Positive Association between Supply Chain Agility and Maturity

3.3. Positive Association between Supply Chain Ambidexterity and Maturity

3.4. Moderating Roles of Organization Culture

4. Methodology

4.1. Sample and Data Collection

4.2. Profile of Respondents

4.3. Measures

4.4. Data Analysis

5. Results

5.1. Instrument Evaluation

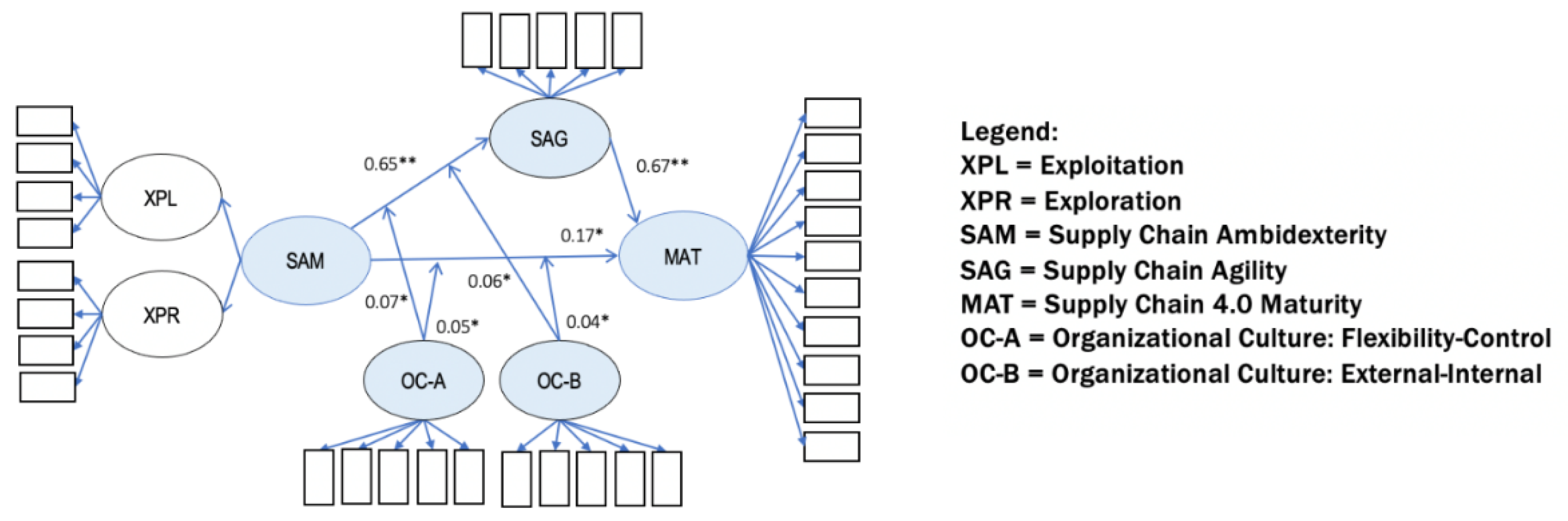

5.2. Hypotheses Testing

6. Discussion

6.1. SC4.0 Maturity as the Driver for SC Performance

6.2. SC4.0 Maturity and Growth

6.3. The Importance of Culture to SC 4.0 Maturity for Indonesian Companies

6.4. Agility, Ambidexterity, and Open Innovation

7. Conclusions and Future Work

7.1. Theoretical Implications

7.2. Practical Implications

7.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Dimension (Source) | Indicator | Estimate | Cronbach’s Alpha | |

|---|---|---|---|---|

| Exploitation (Kristal et al. [65]) | AMBI2 | In order to stay competitive, our supply chain managers focus on improving our existing technologies. | deleted | 0.857 |

| AMBI3 | Leveraging our current supply chain technologies is important to our firm’s strategy. | 0.6512 | ||

| AMBI4 | Our managers focus on developing strong competencies in our existing supply chain processes. | 0.6816 | ||

| AMBI6 | We continually experiment to find new solutions that will improve our supply chain. | 0.6258 | ||

| Exploration (Kristal et al. [65]) | AMBI1 | In order to stay competitive, our supply chain (distributor) managers focus on reducing operations. | 0.5262 | 0.883 |

| AMBI5 | We proactively pursue new supply chain solutions. | 0.7125 | ||

| AMBI7 | To improve our supply chain, we continually explore new opportunities. | 0.5240 | ||

| AMBI8 | We are constantly seeking novel approaches in order to solve supply chain problems. | 0.5903 | ||

| Dimension (Source) | Indicator | Estimate | Cronbach’s Alpha | |

|---|---|---|---|---|

| Agility (Blome et al. [63]) | AGI1 | We are able to adapt our services and/or products sufficiently fast to new customer requirements. | 0.6363 | 0.908 |

| AGI2 | We are able to react sufficiently fast to new market developments. | 0.7474 | ||

| AGI3 | We are able to react to significant increases and decreases in demand as fast as required by the market. | 0.6614 | ||

| AGI4 | We are always able to adjust our product portfolio as fast as required by the market. | 0.6713 | ||

| AGI5 | We are able to react adequately fast to supply-side changes, e.g., compensate for spontaneous supplier outages, delivery failures, market shortages. | 0.7322 | ||

| Dimension | Indicator | Estimate | Cronbach’s Alpha | |

|---|---|---|---|---|

| Flexibility-Control (Yunus and Tadisina [123]) | OC1 |

| 0.5160 | 0.786 |

| OC2 |

| 0.5988 | ||

| OC3 |

| 0.7307 | ||

| OC4 |

| 0.5917 | ||

| OC5 |

| 0.7410 | ||

| External-Internal (Yunus and Tadisina [123]) | OC6 |

| 0.5956 | 0.733 |

| OC7 |

| 0.6383 | ||

| OC8 |

| 0.5744 | ||

| OC9 |

| 0.6724 | ||

| OC10 |

| 0.4984 | ||

| Dimension (Source) | Indicator | Estimate | Cronbach’s Alpha | |

|---|---|---|---|---|

| Strategic Outcomes (Frederico et al. [46]) | MAT1 | The extent of cost reduction because of more efficient suppliers. | deleted | 0.930 |

| MAT2 | The extent of benefit experienced by customers and suppliers from digital supply chain initiatives. | 0.5897 | ||

| MAT3 | The extent of added value and competitive advantage of the company from digital supply chain initiatives. | 0.6339 | ||

| Technological Advancements (Frederico et al. [46]) | MAT4 | How good is measurement, transparency, and process integration to prevent from disruption in production planning and process? | deleted | |

| MAT9 | The extent to which the application of technology provides benefits to the supply chain process. | 0.5867 | ||

| MAT10 | The extent to which digital supply chain is a priority of the company’s strategy. | 0.6711 | ||

| MAT11 | The extent of information technology infrastructure support in digital supply chain initiative. | 0.5924 | ||

| Processes Performance (Frederico et al. [46]) | MAT5 | How good is the collaboration with supply chain partners? | deleted | |

| MAT6 | The extent of responsiveness and flexibility. | 0.5924 | ||

| MAT7 | The level of waste in the supply chain process. | deleted | ||

| MAT8 | The strength of the relationship between systems, machines, and people. | 0.5544 | ||

| Managerial Capability (Frederico et al. [46]) | MAT12 | The support of the company leadership in digital supply chain initiatives. | 0.6297 | |

| MAT13 | The extent to which organizational development and employee competence can support the implementation of digital supply chain. | 0.6880 | ||

| MAT14 | The strength of the coordination between all supply chain partners. | 0.5541 | ||

| 1 | Available online: https://datareportal.com/reports/digital-2021-indonesia (accessed on 20 March 2022). |

| 2 | Available online: https://www.statista.com/statistics/1235476/indonesia-e-commerce-growth-rate/#statisticContainer (accessed on 20 March 2022). |

| 3 | Available online: https://www.investindonesia.go.id/en/why-invest/indonesia-economic-update/making-indonesia-4.0-indonesias-strategy-to-enter-the-4th-generation-of-ind (accessed on 20 March 2022). |

| 4 | Available online: https://www.kearney.com/operations-performance-transformation/indonesia-4.0-the-transformation-opportunity (accessed on 20 March 2022). |

| 5 | Available online: https://www.pwc.com/gx/en/industries/industries-4.0/landing-page/industry-4.0-building-your-digital-enterprise-april-2016.pdf (accessed on 20 March 2022). |

References

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Zekhnini, K.; Cherrafi, A.; Bouhaddou, I.; Benghabrit, Y.; Garza-Reyes, J.A. Supply chain management 4.0: A literature review and research framework. Benchmarking 2020, 28, 465–501. [Google Scholar] [CrossRef]

- Gayialis, S.P.; Kechagias, E.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A.; Tatsiopoulos, I.P. An approach for creating a blockchain platform for labeling and tracing wines and spirits. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Nantes, France, 5–9 September 2021; pp. 81–89. [Google Scholar]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Liao, S.-H.; Hu, D.-C.; Ding, L.-W. Assessing the influence of supply chain collaboration value innovation, supply chain capability and competitive advantage in Taiwan’s networking communication industry. Int. J. Prod. Econ. 2017, 191, 143–153. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; de Sousa Jabbour, A.B.L.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Miloulis, D.M.; Chatzistelios, G.; Gayialis, S.P.; Papadopoulos, G.A. Applying a System Dynamics Approach for the Pharmaceutical Industry: Simulation and Optimization of the Quality Control Process. arXiv 2021, arXiv:2112.05951. [Google Scholar] [CrossRef]

- Gayialis, S.P.; Kechagias, E.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. A Predictive Maintenance System for Reverse Supply Chain Operations. Logistics 2022, 6, 4. [Google Scholar] [CrossRef]

- Choudhury, A.; Behl, A.; Sheorey, P.A.; Pal, A. Digital supply chain to unlock new agility: A TISM approach. Benchmarking 2021, 28, 2075–2109. [Google Scholar] [CrossRef]

- Yunus, E.N. The mark of industry 4.0: How managers respond to key revolutionary changes. Int. J. Product. Perform. Manag. 2021, 70, 1213–1231. [Google Scholar] [CrossRef]

- Boddin, D. The Role of Newly Industrialized Economies in Global Value Chains; International Monetary Fund: Washington, DC, USA, 2016. [Google Scholar]

- Da Silva, V.L.; Kovaleski, J.L.; Pagani, R.N. Technology transfer in the supply chain oriented to industry 4.0: A literature review. Technol. Anal. Strateg. Manag. 2019, 31, 546–562. [Google Scholar] [CrossRef]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Bogoviz, A.V.; Osipov, V.S.; Chistyakova, M.K.; Borisov, M.Y. Comparative analysis of formation of industry 4.0 in developed and developing countries. In Industry 4.0: Industrial Revolution of the 21st Century; Springer: Berlin/Heidelberg, Germany, 2019; pp. 155–164. [Google Scholar]

- Hidayatno, A.; Destyanto, A.R.; Hulu, C.A. Industry 4.0 Technology Implementation Impact to Industrial Sustainable Energy in Indonesia: A Model Conceptualization. Energy Procedia 2019, 156, 227–233. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Tripathi, S.; Gupta, M. A holistic model for Global Industry 4.0 readiness assessment. Benchmarking 2021, 28, 3006–3039. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.; Carlsson, D.; Almström, P.; Centerholt, V.; Hallin, M. Industry 4.0 readiness in manufacturing companies: Challenges and enablers towards increased digitalization. Procedia Cirp 2019, 81, 1113–1118. [Google Scholar] [CrossRef]

- Ramanathan, K.; Samaranayake, P. Assessing Industry 4.0 readiness in manufacturing: A self-diagnostic framework and an illustrative case study. J. Manuf. Technol. Manag. 2021, 33, 468–488. [Google Scholar] [CrossRef]

- Santos, R.C.; Martinho, J.L. An Industry 4.0 maturity model proposal. J. Manuf. Technol. Manag. 2020, 31, 1023–1043. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Gavião, L.O.; Ivson, P.; de Mattos Nascimento, D.L.; Garza-Reyes, J.A. A fuzzy rule-based industry 4.0 maturity model for operations and supply chain management. Int. J. Prod. Econ. 2021, 231, 107883. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Baumann, F.W.; Roller, D. Additive Manufacturing, Cloud-Based 3D Printing and Associated Services—Overview. J. Manuf. Mater. Process. 2017, 1, 15. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Makris, D.; Hansen, Z.N.L.; Khan, O. Adapting to supply chain 4.0: An explorative study of multinational companies. Supply Chain Forum 2019, 20, 116–131. [Google Scholar] [CrossRef]

- Schmidt, B.; Rutkowsky, S.; Petersen, I.; Klötzke, F.; Wallenburg, C.; Einmahl, L. Digital Supply Chains: Increasingly Critical for Competitive Edge. European AT Kearney, WHU Logistics Study 2015. Available online: https://www.kearney.com/operations-performance-transformation/article?/a/digital-supply-chains-increasingly-critical-for-competitive-edge (accessed on 20 March 2022).

- Tanque, M.; Foxwell, H.J. Big data and cloud computing: A review of supply chain capabilities and challenges. Explor. Converg. Big Data Internet Things 2018, 1–28. [Google Scholar] [CrossRef]

- Geissbauer, R.; Vedsø, J.; Schrauf, S. A Strategist’s Guide to Industry 4.0: Global Businesses Are about to Integrate Their Operations into a Seamless Digital Whole, and Thereby Change the World. 2016. Available online: https://www.strategy-business.com/article/A-Strategists-Guide-to-Industry-4.0 (accessed on 20 March 2022).

- Ferrantino, M.J.; Koten, E.E. Understanding Supply Chain 4.0 and Its Potential Impact on Global Value Chains. In Global Value Chain Development Report 2019; World Trade Organizatio: Geneva, Switzerland, 2019; pp. 103–119. [Google Scholar]

- Alicke, K.; Rexhausen, D.; Seyfert, A. Supply Chain 4.0 in Consumer Goods; Mckinsey Co.: Atlanta, GA, USA, 2017; Volume 1. [Google Scholar]

- Swanson, D. The impact of digitization on product offerings: Using direct digital manufacturing in the supply chain. In Proceedings of the 50th Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 4–7 January 2017. [Google Scholar]

- Dossou, P.-E. Impact of Sustainability on the supply chain 4.0 performance. Procedia Manuf. 2018, 17, 452–459. [Google Scholar] [CrossRef]

- LaBerge, L.; O’Toole, C.; Schneider, J.; Smaje, K. How COVID-19 Has Pushed Companies over the Technology Tipping Point—And Transformed Business Forever; Mckinsey Co.: Atlanta, GA, USA, 2020. [Google Scholar]

- Fraser, P.; Moultrie, J.; Gregory, M. The use of maturity models/grids as a tool in assessing product development capability. In Proceedings of the IEEE International Engineering Management Conference, Cambridge, UK, 18–20 August 2002; Volume 241, pp. 244–249. [Google Scholar]

- Done, A. Developing Supply Chain Maturity. In IESE Business School of University of Navarra, Working Paper WP-898. 2011. Available online: https://media.iese.edu/research/pdfs/DI-0898-E.pdf (accessed on 20 March 2022).

- Lahti, M.; Shamsuzzoha, A.H.M.; Helo, P. Developing a maturity model for Supply Chain Management. Int. J. Logist. Syst. Manag. 2009, 5, 654–678. [Google Scholar] [CrossRef]

- McCormack, K.; Bronzo Ladeira, M.; de Oliveira, M.P.V. Supply chain maturity and performance in Brazil. Supply Chain Manag. 2008, 13, 272–282. [Google Scholar] [CrossRef]

- Reyes, H.G.; Giachetti, R. Using experts to develop a supply chain maturity model in Mexico. Supply Chain Manag. Int. J. 2010, 15, 415–424. [Google Scholar] [CrossRef]

- Söderberg, L.; Bengtsson, L. Supply chain management maturity and performance in SMEs. Oper. Manag. Res. 2010, 3, 90–97. [Google Scholar] [CrossRef]

- Aboelmaged, M.G. Predicting e-readiness at firm-level: An analysis of technological, organizational and environmental (TOE) effects on e-maintenance readiness in manufacturing firms. Int. J. Inf. Manag. 2014, 34, 639–651. [Google Scholar] [CrossRef]

- Bititci, U.S.; Garengo, P.; Ates, A.; Nudurupati, S.S. Value of maturity models in performance measurement. Int. J. Prod. Res. 2015, 53, 3062–3085. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity and research agenda. Supply Chain Manag. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- Hizam-Hanafiah, M.; Soomro, M.A. The situation of technology companies in industry 4.0 and the open innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 34. [Google Scholar] [CrossRef]

- Del Giudice, M.; Scuotto, V.; Papa, A.; Tarba, S.Y.; Bresciani, S.; Warkentin, M. A self-tuning model for smart manufacturing SMEs: Effects on digital innovation. J. Prod. Innov. Manag. 2021, 38, 68–89. [Google Scholar] [CrossRef]

- Nobakht, M.; Hejazi, S.R.; Akbari, M.; Sakhdari, K. Exploring the relationship between open innovation and organisational ambidexterity: The moderating effect of entrepreneurial orientation. Innovation 2021, 23, 71–92. [Google Scholar] [CrossRef]

- Cepeda, J.; Arias-Pérez, J. Information technology capabilities and organizational agility: The mediating effects of open innovation capabilities. Multinatl. Bus. Rev. 2018, 27, 198–216. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Chun, D. The Effect of Knowledge Sharing on Ambidextrous Innovation: Triadic Intellectual Capital as a Mediator. J. Open Innov. Technol. Mark. Complex. 2022, 8, 25. [Google Scholar] [CrossRef]

- Puriwat, W.; Tripopsakul, S. Exploring Factors Influencing Open Innovation Adoption in SMEs: The Evidence from Emerging Markets. Emerg. Sci. J. 2021, 5, 533–544. [Google Scholar] [CrossRef]

- Liao, S.; Liu, Z.; Ma, C. Direct and configurational paths of open innovation and organisational agility to business model innovation in SMEs. Technol. Anal. Strateg. Manag. 2019, 31, 1213–1228. [Google Scholar] [CrossRef]

- Hwang, B.-N.; Lai, Y.-P.; Wang, C. Open innovation and organizational ambidexterity. Eur. J. Innov. Manag. 2021. [Google Scholar] [CrossRef]

- Van Lieshout, J.W.; Nijhof, A.H.; Naarding, G.J.; Blomme, R.J. Connecting strategic orientation, innovation strategy, and corporate sustainability: A model for sustainable development through stakeholder engagement. Bus. Strategy Environ. 2021, 30, 4068–4080. [Google Scholar] [CrossRef]

- Solaimani, S.; van der Veen, J. Open supply chain innovation: An extended view on supply chain collaboration. Supply Chain Manag. 2021. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M.C. Understanding the role of logistics capabilities in achieving supply chain agility: A systematic literature review. Supply Chain Manag. Int. J. 2012, 17, 438–453. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N.N. A framework for assessing value chain agility. Int. J. Oper. Prod. Manag. 2006, 26, 118–140. [Google Scholar] [CrossRef]

- Carvalho, H.; Azevedo, S.G.; Cruz-Machado, V. Agile and resilient approaches to supply chain management: Influence on performance and competitiveness. Logist. Res. 2012, 4, 49–62. [Google Scholar] [CrossRef]

- Sambamurthy, V.; Bharadwaj, A.; Grover, V. Shaping agility through digital options: Reconceptualizing the role of information technology in contemporary firms. MIS Q. 2003, 27, 237–263. [Google Scholar] [CrossRef]

- Tavani, S.N.; Sharifi, H.; Ismail, H.S. A study of contingency relationships between supplier involvement, absorptive capacity and agile product innovation. Int. J. Oper. Prod. Manag. 2014, 34, 65–92. [Google Scholar] [CrossRef]

- O’Reilly, C.A.; Tushman, M.L. Organizational Ambidexterity in Action: How Managers Explore and Exploit. Calif. Manag. Rev. 2011, 53, 5–22. [Google Scholar] [CrossRef]

- Blome, C.; Schoenherr, T.; Kaesser, M. Ambidextrous Governance in Supply Chains: The Impact on Innovation and Cost Performance. J. Supply Chain Manag. 2013, 49, 59–80. [Google Scholar] [CrossRef]

- Im, G.; Rai, A. Knowledge Sharing Ambidexterity in Long-Term Interorganizational Relationships. Manag. Sci. 2008, 54, 1281–1296. [Google Scholar] [CrossRef]

- Kristal, M.M.; Huang, X.; Roth, A.V. The effect of an ambidextrous supply chain strategy on combinative competitive capabilities and business performance. J. Oper. Manag. 2010, 28, 415–429. [Google Scholar] [CrossRef]

- Partanen, J.; Kohtamäki, M.; Patel, P.C.; Parida, V. Supply chain ambidexterity and manufacturing SME performance: The moderating roles of network capability and strategic information flow. Int. J. Prod. Econ. 2020, 221, 107470. [Google Scholar] [CrossRef]

- March, J.G. Exploration and exploitation in organizational learning. Organ. Sci. 1991, 2, 71–87. [Google Scholar] [CrossRef]

- Wang, S.L.; Luo, Y.; Maksimov, V.; Sun, J.; Celly, N. Achieving Temporal Ambidexterity in New Ventures. J. Manag. Stud. 2019, 56, 788–822. [Google Scholar] [CrossRef]

- Tushman, M.L.; O’Reilly, C.A. Ambidextrous Organizations: Managing Evolutionary and Revolutionary Change. Calif. Manag. Rev. 1996, 38, 8–29. [Google Scholar] [CrossRef]

- Gibson, C.B.; Birkinshaw, J. The Antecedents, Consequences, and Mediating Role of Organizational Ambidexterity. Acad. Manag. J. 2004, 47, 209–226. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Dynamic supply chain capabilities. Int. J. Oper. Prod. Manag. 2018, 38, 2266–2285. [Google Scholar] [CrossRef]

- Lee, S.M.; Rha, J.S. Ambidextrous supply chain as a dynamic capability: Building a resilient supply chain. Manag. Decis. 2016, 54, 2–23. [Google Scholar] [CrossRef]

- Rojo, A.; Llorens-Montes, J.; Perez-Arostegui, M.N. The impact of ambidexterity on supply chain flexibility fit. Supply Chain Manag. Int. J. 2016, 21, 433–452. [Google Scholar] [CrossRef]

- Patel, P.C.; Terjesen, S.; Li, D. Enhancing effects of manufacturing flexibility through operational absorptive capacity and operational ambidexterity. J. Oper. Manag. 2012, 30, 201–220. [Google Scholar] [CrossRef]

- Dubey, R.; Singh, T.; Gupta, O.K. Impact of Agility, Adaptability and Alignment on Humanitarian Logistics Performance: Mediating Effect of Leadership. Glob. Bus. Rev. 2015, 16, 812–831. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Gunasekaran, A.; Adeleye, E.O.; Sivayoganathan, K. Agile supply chain capabilities: Determinants of competitive objectives. Eur. J. Oper. Res. 2004, 159, 379–392. [Google Scholar] [CrossRef]

- Shukor, A.A.A.; Newaz, M.S.; Rahman, M.K.; Taha, A.Z. Supply chain integration and its impact on supply chain agility and organizational flexibility in manufacturing firms. Int. J. Emerg. Mark. 2021, 16, 1721–1744. [Google Scholar] [CrossRef]

- Power, D.J.; Sohal, A.S.; Rahman, S.U. Critical success factors in agile supply chain management—An empirical study. Int. J. Phys. Distrib. Logist. Manag. 2001, 31, 247–265. [Google Scholar] [CrossRef]

- Schönsleben, P. With agility and adequate partnership strategies towards effective logistics networks. Comput. Ind. 2000, 42, 33–42. [Google Scholar] [CrossRef]

- Overby, E.; Bharadwaj, A.; Sambamurthy, V. Enterprise agility and the enabling role of information technology. Eur. J. Inf. Syst. 2006, 15, 120–131. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. Achieving supply chain agility through IT integration and flexibility. Int. J. Prod. Econ. 2008, 116, 288–297. [Google Scholar] [CrossRef]

- Christopher, M. The Agile Supply Chain: Competing in Volatile Markets. Ind. Mark. Manag. 2000, 29, 37–44. [Google Scholar] [CrossRef]

- Gu, M.; Yang, L.; Huo, B. The impact of information technology usage on supply chain resilience and performance: An ambidexterous view. Int. J. Prod. Econ. 2021, 232, 107956. [Google Scholar] [CrossRef]

- Huo, B.; Han, Z.; Prajogo, D. Antecedents and consequences of supply chain information integration: A resource-based view. Supply Chain Manag. 2016, 21, 661–677. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Rai, A.; Pavlou, P.A.; Im, G.; Du, S. Interfirm IT capability profiles and communications for cocreating relational value: Evidence from the logistics industry. MIS Q. 2012, 36, 233–262. [Google Scholar] [CrossRef]

- Singh, A.; Hess, T. How chief digital officers promote the digital transformation of their companies. MIS Q. Exec. 2017, 16, 202–220. [Google Scholar]

- Subramani, M. How do suppliers benefit from information technology use in supply chain relationships? MIS Q. 2004, 28, 45–73. [Google Scholar] [CrossRef]

- Greenough, R.M.; Tjahjono, B. An interactive electronic technical manual for an advanced aerospace assembly machine. Int. J. Adv. Manuf. Technol. 2007, 33, 1045–1055. [Google Scholar] [CrossRef][Green Version]

- Alzoubi, H.; Yanamandra, R. Investigating the mediating role of information sharing strategy on agile supply chain. Uncertain Supply Chain Manag. 2020, 8, 273–284. [Google Scholar] [CrossRef]

- Kim, M.; Chai, S. The impact of supplier innovativeness, information sharing and strategic sourcing on improving supply chain agility: Global supply chain perspective. Int. J. Prod. Econ. 2017, 187, 42–52. [Google Scholar] [CrossRef]

- Bovel, D.; Martha, J. From Supply Chain to Value Net. J. Bus. Strategy 2000, 21, 24–28. [Google Scholar] [CrossRef]

- Luo, X.; Wu, C.; Rosenberg, D.; Barnes, D. Supplier selection in agile supply chains: An information-processing model and an illustration. J. Purch. Supply Manag. 2009, 15, 249–262. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Lean and agile supply chain strategies and supply chain responsiveness: The role of strategic supplier partnership and postponement. Supply Chain Manag. 2013, 18, 571–582. [Google Scholar] [CrossRef]

- Roberts, N.; Grover, V. Investigating firm’s customer agility and firm performance: The importance of aligning sense and respond capabilities. J. Bus. Res. 2012, 65, 579–585. [Google Scholar] [CrossRef]

- Tarafdar, M.; Qrunfleh, S. Agile supply chain strategy and supply chain performance: Complementary roles of supply chain practices and information systems capability for agility. Int. J. Prod. Res. 2017, 55, 925–938. [Google Scholar] [CrossRef]

- Tse, Y.K.; Zhang, M.; Akhtar, P.; MacBryde, J. Embracing supply chain agility: An investigation in the electronics industry. Supply Chain Manag. 2016, 21, 140–156. [Google Scholar] [CrossRef]

- Um, J. The impact of supply chain agility on business performance in a high level customization environment. Oper. Manag. Res. 2017, 10, 10–19. [Google Scholar] [CrossRef]

- Yang, J. Supply chain agility: Securing performance for Chinese manufacturers. Int. J. Prod. Econ. 2014, 150, 104–113. [Google Scholar] [CrossRef]

- Ojha, D.; Acharya, C.; Cooper, D. Transformational leadership and supply chain ambidexterity: Mediating role of supply chain organizational learning and moderating role of uncertainty. Int. J. Prod. Econ. 2018, 197, 215–231. [Google Scholar] [CrossRef]

- He, Z.-L.; Wong, P.-K. Exploration vs. Exploitation: An Empirical Test of the Ambidexterity Hypothesis. Organ. Sci. 2004, 15, 481–494. [Google Scholar] [CrossRef]

- Kortmann, S. The Mediating Role of Strategic Orientations on the Relationship between Ambidexterity-Oriented Decisions and Innovative Ambidexterity. J. Prod. Innov. Manag. 2015, 32, 666–684. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Müller, E.; Hopf, H. Competence Center for the Digital Transformation in Small and Medium-Sized Enterprises. Procedia Manuf. 2017, 11, 1495–1500. [Google Scholar] [CrossRef]

- Webb, B.R.; Schlemmer, F. Predicting web services performance from internet performance: An empirical study of resources and capabilities in e-business SMEs. J. Knowl. Manag. 2008, 12, 137–155. [Google Scholar] [CrossRef]

- Scuotto, V.; Arrigo, E.; Candelo, E.; Nicotra, M. Ambidextrous innovation orientation effected by the digital transformation. Bus. Process. Manag. J. 2020, 26, 1121–1140. [Google Scholar] [CrossRef]

- Benitez, J.; Castillo, A.; Llorens, J.; Braojos, J. IT-enabled knowledge ambidexterity and innovation performance in small U.S. firms: The moderator role of social media capability. Inf. Manag. 2018, 55, 131–143. [Google Scholar] [CrossRef]

- Tamayo-Torres, J.; Ruiz-Moreno, A.; Lloréns-Montes, F.J. The influence of manufacturing flexibility on the interplay between exploration and exploitation: The effects of organisational learning and the environment. Int. J. Prod. Res. 2011, 49, 6175–6198. [Google Scholar] [CrossRef]

- Huang, M.-C.; Yen, G.-F.; Liu, T.-C. Reexamining supply chain integration and the supplier’s performance relationships under uncertainty. Supply Chain Manag. 2014, 19, 64–78. [Google Scholar] [CrossRef]

- Cao, Q.; Gedajlovic, E.; Zhang, H. Unpacking Organizational Ambidexterity: Dimensions, Contingencies, and Synergistic Effects. Organ. Sci. 2009, 20, 781–796. [Google Scholar] [CrossRef]

- Liu, Y.; Liao, Y.; Li, Y. Capability configuration, ambidexterity and performance: Evidence from service outsourcing sector. Int. J. Prod. Econ. 2018, 200, 343–352. [Google Scholar] [CrossRef]

- Agrawal, P.; Narain, R.; Ullah, I. Analysis of barriers in implementation of digital transformation of supply chain using interpretive structural modelling approach. J. Model. Manag. 2020, 15, 297–317. [Google Scholar] [CrossRef]

- Detert, J.R.; Schroeder, R.G.; Mauriel, J.J. A Framework for Linking Culture and Improvement Initiatives in Organizations. Acad. Manag. Rev. 2000, 25, 850–863. [Google Scholar] [CrossRef]

- Cameron, K.S.; Quinn, R.E. Diagnosing and Changing Organizational Culture: Based on the Competing Values Framework; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Gupta, A.K.; Smith, K.G.; Shalley, C.E. The Interplay Between Exploration and Exploitation. Acad. Manag. J. 2006, 49, 693–706. [Google Scholar] [CrossRef]

- Anderson, N.; De Dreu, C.K.W.; Nijstad, B.A. The routinization of innovation research: A constructively critical review of the state-of-the-science. J. Organ. Behav. 2004, 25, 147–173. [Google Scholar] [CrossRef]

- Berkhout, A.J.; Van Der Duin, P.A. New ways of innovation: An application of the cyclic innovation model to the mobile telecom industry. Int. J. Technol. Manag. 2007, 40, 294–309. [Google Scholar] [CrossRef]

- Calatayud, A.; Mangan, J.; Christopher, M. The self-thinking supply chain. Supply Chain Manag. 2019, 24, 22–38. [Google Scholar] [CrossRef]

- Pagani, M. Digital business strategy and value creation: Framing the dynamic cycle of control points. MIS Q. 2013, 37, 617–632. [Google Scholar] [CrossRef]

- Du, W.D.; Pan, S.L.; Huang, J. How a Latecomer Company Used IT to Redeploy Slack Resources. MIS Q. Exec. 2016, 15, 3. [Google Scholar]

- Gust, G.; Neumann, D.; Flath, C.M.; Brandt, T.; Ströhle, P. How a traditional company seeded new analytics capabilities. MIS Q. Exec. 2017, 16, 215–230. [Google Scholar]

- World Bank. Manufacturing, Value Added (% of GDP)—Indonesia; World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Yunus, E.N.; Tadisina, S.K. Drivers of supply chain integration and the role of organizational culture. Bus. Process. Manag. J. 2016, 22, 89–115. [Google Scholar] [CrossRef]

- Anderson, J.C.; Gerbing, D.W. Structural equation modeling in practice: A review and recommended two-step approach. Psychol. Bull. 1988, 103, 411. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis; Pearson: London, UK, 2006; Volume 6, pp. 18–32. [Google Scholar]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879. [Google Scholar] [CrossRef]

- Gerbing, D.W.; Anderson, J.C. An Updated Paradigm for Scale Development Incorporating Unidimensionality and Its Assessment. J. Mark. Res. 1988, 25, 186–192. [Google Scholar] [CrossRef]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Asdecker, B.; Felch, V. Development of an Industry 4.0 maturity model for the delivery process in supply chains. J. Model. Manag. 2018, 13, 840–883. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Stachowiak, A. The framework of logistics 4.0 maturity model. In Proceedings of the International Conference on Intelligent Systems in Production Engineering and Maintenance, Wroclaw, Poland, 17–18 September 2018; pp. 771–781. [Google Scholar]

- Alamsjah, F.; Asrol, M. Inter-island Logistics and the Role of an Agile Supply Chain to Achieve Supply Chain Performance: Initial Findings. In Proceedings of the 2021 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Marina Bay Sands, Singapore, 13–16 December 2021; pp. 270–274. [Google Scholar]

- Flynn, B.B.; Koufteros, X.; Lu, G. On Theory in Supply Chain Uncertainty and its Implications for Supply Chain Integration. J. Supply Chain Manag. 2016, 52, 3–27. [Google Scholar] [CrossRef]

- Simangunsong, E.; Hendry, L.C.; Stevenson, M. Supply-chain uncertainty: A review and theoretical foundation for future research. Int. J. Prod. Res. 2012, 50, 4493–4523. [Google Scholar] [CrossRef]

- Tseng, P.-H.; Liao, C.-H. Supply chain integration, information technology, market orientation and firm performance in container shipping firms. Int. J. Logist. Manag. 2015, 26, 82–106. [Google Scholar] [CrossRef]

- Menon, N.; Ghee Chua, S.; Dobberstein, N.; Choi, J.; Ranganathan, S.; Monga, N. The ASEAN Digital Revolution; AT Kearney: Singapore, 2016. [Google Scholar]

- Afrianto, I.; Djatna, T.; Arkeman, Y.; Sitanggang, I.S.; Hermadi, I. Disrupting Agro-industry Supply Chain in Indonesia with Blockchain Technology: Current and Future Challenges. In Proceedings of the 2020 8th International Conference on Cyber and IT Service Management (CITSM), Pangkal, Indonesia, 23–24 October 2020; pp. 1–6. [Google Scholar]

- Hofstede, G. What did GLOBE really measure? Researchers’ minds versus respondents’ minds. J. Int. Bus. Stud. 2006, 37, 882–896. [Google Scholar] [CrossRef]

- Irawanto, D.W. An analysis of national culture and leadership practices in Indonesia. J. Divers. Manag. 2009, 4, 41–48. [Google Scholar] [CrossRef]

- Laforet, S. Effects of organisational culture on organisational innovation performance in family firms. J. Small Bus. Enterp. Dev. 2016, 23, 379–407. [Google Scholar] [CrossRef]

- Uzkurt, C.; Kumar, R.; Semih Kimzan, H.; Eminoğlu, G. Role of innovation in the relationship between organizational culture and firm performance. Eur. J. Innov. Manag. 2013, 16, 92–117. [Google Scholar] [CrossRef]

- Yun, J.J.; Zhao, X.; Jung, K.; Yigitcanlar, T. The culture for open innovation dynamics. Sustainability 2020, 12, 5076. [Google Scholar] [CrossRef]

- Maloney, W.F.; Molina, C. Are Automation and Trade Polarizing Developing Country Labor Markets, Too? World Bank Policy Research Working Paper. 2016. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2887777 (accessed on 28 December 2020).

- Tuan, L.T. Organisational ambidexterity and supply chain agility: The mediating role of external knowledge sharing and moderating role of competitive intelligence. Int. J. Logist. Res. Appl. 2016, 19, 583–603. [Google Scholar] [CrossRef]

- O’Reilly, C.A.; Tushman, M.L. Organizational Ambidexterity: Past, Present, and Future. Acad. Manag. Perspect. 2013, 27, 324–338. [Google Scholar] [CrossRef]

- Shao, Z. Interaction effect of strategic leadership behaviors and organizational culture on IS-Business strategic alignment and Enterprise Systems assimilation. Int. J. Inf. Manag. 2019, 44, 96–108. [Google Scholar] [CrossRef]

- Varshney, D.; Varshney, N.K. Workforce agility and its links to emotional intelligence and workforce performance: A study of small entrepreneurial firms in India. Glob. Bus. Organ. Excell. 2020, 39, 35–45. [Google Scholar] [CrossRef]

| Profiles | Frequency | Percentage |

|---|---|---|

| Occupation | ||

| Owner | 35 | 22.7% |

| Director/equivalent | 36 | 23.4% |

| Senior manager/general manager/equivalent | 36 | 23.4% |

| Manager/equivalent | 36 | 23.4% |

| Supervisor | 7 | 4.5% |

| Staff | 4 | 2.6% |

| Work experience | ||

| <3 years | 18 | 11.7% |

| 3–5 years | 35 | 22.7% |

| 5–10 years | 46 | 29.9% |

| 10–15 years | 26 | 16.9% |

| ≥15 years | 29 | 18.8% |

| Firm ownership | ||

| State-owned enterprise | 14 | 9.1% |

| Private company | 54 | 35.1% |

| Joint venture | 60 | 39.0% |

| Foreign investment | 21 | 13.6% |

| Foundation | 5 | 3.2% |

| Firm size | ||

| 10–49 | 33 | 21.4% |

| 50–99 | 8 | 5.2% |

| 100–249 | 17 | 11.0% |

| 250–499 | 17 | 11.0% |

| 500–999 | 21 | 13.6% |

| 1000–4999 | 41 | 26.6% |

| >5000 | 17 | 11.0% |

| χ2 | df | χ2/df | CFI | TLI | NFI | NNFI | RMSEA | |

|---|---|---|---|---|---|---|---|---|

| SAM | 25.14 | 13 | 1.9 | 0.981 | 0.970 | 0.963 | 0.970 | 0.0779 |

| SAG | 3.46 | 5 | 0.7 | 1.000 | 1.006 | 0.993 | 1.006 | 0.0000 |

| OC | 62.34 | 34 | 1.8 | 0.931 | 0.908 | 0.863 | 0.908 | 0.0736 |

| Path | β + | p-Value | Conclusion |

|---|---|---|---|

| SAM → SAG | 0.6543 | 0.0000 | H1 is supported |

| SAM → MAT | 0.1645 | 0.0357 | H2 is supported |

| SAG → MAT | 0.6692 | 0.0000 | H3 is supported |

| SAM → SAG → MAT | 0.2695 | 0.0000 | (Test of mediation) |

| OC-A x SAM → SAG | 0.0672 | 0.0238 | H4a is supported |

| OC-B x SAM → SAG | 0.0587 | 0.0238 | H4b is supported |

| OC-A x SAM → MAT | 0.0422 | 0.0238 | H5a is supported |

| OC-B x SAM → MAT | 0.0368 | 0.0238 | H5b is supported |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alamsjah, F.; Yunus, E.N. Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. J. Open Innov. Technol. Mark. Complex. 2022, 8, 83. https://doi.org/10.3390/joitmc8020083

Alamsjah F, Yunus EN. Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(2):83. https://doi.org/10.3390/joitmc8020083

Chicago/Turabian StyleAlamsjah, Firdaus, and Erlinda N. Yunus. 2022. "Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 2: 83. https://doi.org/10.3390/joitmc8020083

APA StyleAlamsjah, F., & Yunus, E. N. (2022). Achieving Supply Chain 4.0 and the Importance of Agility, Ambidexterity, and Organizational Culture: A Case of Indonesia. Journal of Open Innovation: Technology, Market, and Complexity, 8(2), 83. https://doi.org/10.3390/joitmc8020083