Abstract

The customer-oriented approach is actively developing within the global trend of the modern industrial revolution that is Industry 4.0. The focus on customer interests has led to cooperation and integration in supply chains, improving their efficiency and increasing transparency, awareness, and trust. However, an issue emerging in this scenario is that conventional supply chain management (SCM) procedures are unable to identify the potential proposal for a particular user. Modern businesses need to build integrated supply chains, which require well-developed infrastructure and easily available complementary services, relying on logistics as a networking technology. Supply chains of this generation grow from traditional individual desynchronized economic relations (linear models with some feedback and the simplest network configurations) to scalable, adaptable, harmonized partner networks. The logistics potential allows additional income by reducing the total costs of participants in the network, thus increasing the competitiveness of companies; this can be implemented based on new models of interaction in the current digital environment through, firstly, system integration. Our goal consists of identifying the essential characteristics of system integration and substantiating the methods for its implementation in the digital economy. The study is based on the analysis of global best practices, considering the reports from leading consulting companies and competent analytical agencies. We have confirmed that the role of a virtual system integrator of supply chains belongs to logistics platforms; the effects of a transition to platform business models are discussed in detail.

1. Introduction

Today, logistics is influenced by innovations, new technologies, changes according to the changing priorities and targets of companies, and changing competitiveness conditions that increase their complexity. The complexity always implies the need for integration, choosing the technologies for mutually profitable cooperation and interaction formats, including those in supply chains that are adequate to the economic conditions. In fact, supply chains are ordered sequences of suppliers and customers; each customer can simultaneously be a supplier, and vice versa, the supplier can be a customer (at a higher level). The concept of the supply chain, proposed by Oliver and Webber in 1982 [1], has undergone major changes over the past decades [2,3]. Modern supply chains have a complex and multilevel structure, the main characteristic of which is a clear and logical sequence of actions for each participant [4]. This gives us reason to talk about the network architecture of supply chains in which each participant (company or separate structural unit) provides each other with products or services, adding a certain consumption value to the product. The supply chains of many companies include agreed terms for supplying materials, components, finished products, and their delivery to specific markets. In total, this justifies the network architecture of the logistics system [5].

The main problems associated with virtual integration are as follows. Virtual integration solves many issues related to the organization of interaction but, at the same time, generates specific vulnerabilities due to the integration. The general problems inherent in integration can be divided into three groups:

- -

- uncertainty of the conditions for making decisions (external environment);

- -

- uncertainty of partners’ actions, which cannot be fully controlled;

- -

- uncertainty of the goals of the participants.

The severity of these problems decreases with the transition to virtual integration, where the interaction of people (and sometimes decision-making) transitions to the level of machine-to-machine interaction and integration of information systems; at the same time, the influence of subjective factors decreases but does not disappear. The degree of achievement of integration goals is determined using a preselected criterion. When organizing joint activities, the difficulty lies in the fact that each participant has his own interest, his own criterion, and his own strategy for achieving the goal. The participants also have their own goals, although they do not contradict the general goal of integration. This leads to the formulation of a multicriteria problem with interrelated criteria.

At the same time, it is virtual integration that gives rise to a number of specific problems related to information security. First of all, it is the relevance and reliability of data and the creation of secure channels for data transfer, ensuring their integrity and lawful use.

Finally, a combination of traditional and informational problems can cause their joint manifestation within the framework of cyber–physical systems, which are virtual integrators.

Along with the proper development of the supply chains, the scale of managerial tasks was also changed; the theory and methods for supply chain creation and management were developed. Open innovation is an emerging concept describing how companies use external and internal ideas and internal and external paths to market their products and services as these companies look to advance their technology. Christensen et al. [6] addressed how the open innovation concept can be analyzed from an industrial dynamics perspective, considering the specific measures that different companies take to manage open innovation from the standpoint of their differential positions within the innovation system in question, the nature and stage of maturity of the technological regime, and the particular value proposition pursued by companies. A concept model of open innovation, built up in [7], is intended for exploring existing open innovation channels, which can be useful to motivate engineering research to increase the development of open innovation and new open business models.

2. Theoretical Fundamentals and Research Methodology

2.1. Literature Review

The authors agree that the concept of “cognitive automation” is the base of the Fourth Industrial Revolution [8], providing the transition towards the model of a fully synchronized network logistics system, with the supply chain being adaptive to client demands [9]. New digital technologies allow the modeling of the dynamic nature of human performance and the investigation of human behavior within a sociotechnical system [10]. The Logistic 4.0 concept can be considered a concept of collaboration between different partners (both industrial and nonindustrial ones) on the basis of digital technologies [11].

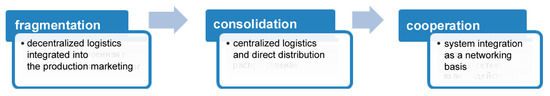

What used to be a purely operational logistics function that focused on supplying the needs of production and delivering products to users has evolved over time into a full-scale supply chain management concept (SCM) that requires an adequate level of integration (Figure 1).

Figure 1.

Logistics integration evolution.

For a long time, the focus in a company’s logistics management has been aimed at improving individual functions concerning a specific product. In this case, neither related processes nor other products from the same product group were taken into account. Supply chain management (SCM) [12] offers an alternative to this approach. The essence of the concept is to coordinate material, financial, and information flows within the value chain, including the business partners of the enterprise (suppliers, manufacturers, distributors, and consumers of the product).

However, despite significant changes in composition, structure, and organization, conventional supply chains have remained uncoordinated. Their functioning was a sequence of discrete measures in the development, planning, purchasing, production, distribution, and delivery of products. The situation changed fundamentally with the beginning of digitalization and the digital business transformation that came with it [13,14].

The digitalization of the logistics business and the digital transformation of supply chains that is taking place within the framework of the global trend are primarily due to the changed expectations of customers. The modern industrial revolution introduces production in the period of mass individualization [15]. Customer expectations that are more accurate and individual encourage companies to develop customer-oriented and, ideally, customer-centric, reliable, and transparent supply chains. In fact, these transformations have already begun. According to the study by the consulting company PwC, based on a survey of more than 2000 respondents, more than 30% of companies believe that they have already begun their digital transformation, and, in general, more than 70% are planning to do this over the next five years; an increase in efficiency by 4.1% annually while simultaneously increasing revenue by 2.9% per year is expected [16].

Supply chain digital transformation tools constitute an information and communication technology (ICT) stack. First of all, these are cloud computing, communication technologies, the Internet of Things, artificial intelligence, blockchain technology, and analytical tools [17,18], the convergence of which provides new efficiency levels in combination with more conventional supply chain management systems and business networks. Blockchain technology can guarantee the transparency of supply chains. It allows tracking information about the product origin, placing orders, and performing transactions in a digital trust environment. Rather than optimizing an individual business, blockchain as a means of information exchange (by guaranteeing reliability and inalterability) provides the main effect precisely in the interaction of partners who can better integrate their processes and accelerate them by getting rid of complex checks, thanks to transparency and reliable data exchange [19].

Emphasis is placed on achieving a positive result in common with the customer; this is the highest meaning of an oriented approach in logistics, the very concept of which supposes the customization of services and their personalized production, with options of supplier participation not only in the formation of the proposal package but also in the order design. In this case, the concept of the general economic importance of customer relationship management (CRM) [20,21] can act as an element borrowed from the current practice for applying scientific knowledge as well as special logistics concepts, in particular, the concept of vendor managed inventory (VMI) [22].

In the absence of official interpretations, a virtual enterprise can be understood as an open, dynamic business system based on the formation of single information space by legally independent business entities to share process resources to fulfill a customer’s order, namely, to build and implement a customer value chain, from sources of raw materials to delivery of the products to end-users [23].

Recently, the platform concept has become extremely popular and is used in various ways [24,25]. Often, the term “platform” refers to a type of technology rather than a business solution. For example:

- a computing platform is a development tool and environment for operating computer systems and applications;

- a platform as a service is a category of computing services that provide a computing platform and a set of solutions in the form of an online service.

The companies that have managed to build and manage large networks around themselves have achieved the greatest success in the modern world. This is the essence of the procedure for the operation of platform business models [26]. In some cases, the platforms are created by an association of companies that are equal partners [27].

Some industries that rely on complex logistics procedures have already begun to transform due to the ability of platforms to coordinate the flow of transport, resources, and products using highly efficient algorithms that bring supply and demand together. The potential of logistics as a technology for supply chain management, integration, cooperation, and coordination of network interaction is fully implemented by creating logistics platforms [28,29].

The logistics platform means a combination of information, technology, as well as software and hardware (hardware, telecommunication lines, and peripheral equipment) that jointly provide for customer service and transaction processing [30]. The effect of resource sharing is expressed in improved service and reduced transaction costs.

In this case, the customers are provided with the opportunity of omni-channel access to services through the integration of communication channels as part of the logistics platforms. In the content of platform solutions, the omni-channel implements the unity of technology and interaction methods using digital channels. By creating an alternative to existing contact centers, it provides businesses with a seamless customer experience [31].

2.2. Theoretical Fundamentals

2.2.1. Network Logistics System: Supply Chain Networks

The logistics potential, as a networking management technology, allows the gain of additional income by reducing the total costs of participants in the network and, thereupon, increasing the competitiveness of companies; this can be implemented based on new models of interaction in the current digital environment.

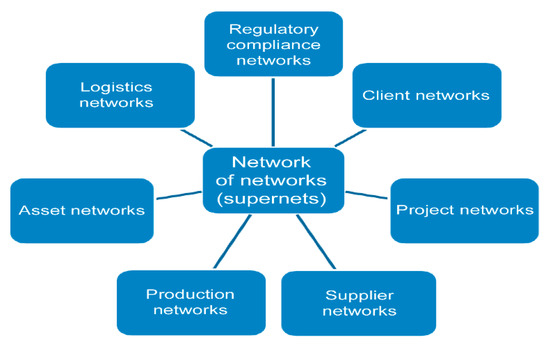

Figure 2 shows the networks implementing constant interaction between customers, suppliers, manufacturers, and operators of transport services to form supernetworks, one of the current business trends [32,33].

Figure 2.

Super network composition and topology.

2.2.2. Supply Chain Digitalization Tools

The Internet of Things is a concept that implies equipment with sensors and the connection of many objects to the internet, which makes it possible to implement remote monitoring and online control and management of processes, including automated processes. Currently, two major areas have emerged: Internet of Things (IoT) and Industrial Internet of Things (IIoT). Instrumentally, these technologies are very similar; the key difference is in their purpose—if the main task of the Internet of Things is to acquire all kinds of data that will be used in priority to build models and forecasts, then the purpose of the Industrial Internet of Things is to automate production by remotely managing resources and capacity based on sensor readings.

The specialists of The Hackett Group, Inc., a strategic consulting company involved in comparative analysis and the implementation of best practices, prepared a special review regarding the role of analytics in supply chain digitalization [34]. It substantiates that advanced analytics and the respective decision-making will be in the spotlight of company executives since they are the basis for digital logistics transformation.

The Hackett Group has found out that most industry leaders (66%) have an understanding of the significance level of advanced analytics. The informational basis for the use of analytical tools is understood as the collection, integration, and systematization of significant amounts of data as well as their processing using Big Data technologies.

Big Data is a collection of approaches, tools, and methods intended to process structured, semistructured and unstructured data from various independent sources in order to obtain perceivable results. Big Data is characterized by a significant volume, variety, and speed of updating, which makes standard methods and tools for data processing insufficiently effective [35].

According to the McKinsey Consulting Company, the approach to supply chain management using predictive analytics based on Big Data can reduce delivery time to several hours [36]. Amazon, an American retailer, already has a patent for a predictive shipment model that assumes that the starting point of goods delivery begins before the placement of the order. In other words, as soon as the customer completes the purchase, the product will have already been launched into the supply chain by the “smart” system”, to be redirected to the customer.

ICT development has led to the formation of qualitatively new conditions in which new business models and organizational mechanisms are becoming economically justified.

2.2.3. Practices for Digital Transformation of Supply Chains

The organizational characteristic of the digitalization of logistics is, inter alia, the transition from the integration of front and back offices (contact centers) and the functioning of coordination logistics centers to system integration, ensuring a high customer focus in logistics services.

The customer-oriented approach is a key sign of logistics adaptation and its adherence to the ideas and trends of the modern industrial revolution, Industry 4.0. The transition from mass service to individual services for everyone fundamentally changes the procedures of interactions and assumes the involvement of the logistics service provider in the customer’s business.

Virtual enterprise activity is needed to achieve system business integration, which is provided by the platform solutions. The platform is interpreted in business as a model that allows the combination of two or more interrelated groups of products for increasing the profits of all participants; in the context of digitalization, we are talking about digital platforms. The digital platform is a business model that is entirely based on high-level technologies that provide profits by means of the exchange between two or more independent groups of participants. The platforms of basic configuration bring together manufacturers and end-users directly for the opportunity of peer-to-peer interaction without the participation of intermediaries. For an alternative interpretation, the digital platform is a system of algorithm-driven mutually beneficial relationships between a significant number of independent participants in the industry or field of activity, carried out in a single information environment, leading to a decrease in transaction costs due to the use of a package of digital technologies for data processing and change in the labor specialization system.

Digital platforms emerged in the 1990s thanks to the heavy growth of ICT and the global expansion of the internet. Platform operating principles differ from conventional business practices, which are mostly based on a linear worldview that does not correspond to the current level of network technology expansion. Since the industrial revolution, when technologies that were new for their time appeared, such as steam power and railways, large companies with vertical integration have emerged, and the linear business model has dominated. All industrial giants of the 20th century (Standard Oil (New York, NY, USA), General Motors (Detroit, MI, USA), General Electric (Boston, MA, USA), Walmart (Bentonville, AR, USA), Toyota (Nagoya, Japan)) worked according to the linear model: each of them created a product or service and then sold it to the consumer.

According to the line of the value chain, value also increases linearly; thus, the term “linear business” appeared. In the 20th century, these models dominated for a reason; based on top-down planning and hierarchical organizational models, companies created value and effectively disseminated it to their target audiences. The supply chains were also linear and consisted of processes that were repeated over and over again to create value; the information in this process also moved linearly. The conventional company’s supply chains, which were considered one of the main areas gaining competitive advantage in the 20th century, were the basis of these linear value streams and information dissemination.

However, this approach had its cost: the most valuable assets were the internal resources that the company owned and operated. To create a linear business, it is necessary to open large factories, invest in human capital assets, and work out new supply channels in order to be able to create products and promote them to the market as a result. In the 21st century, the supply chain is no longer the main business value aggregator. Modern companies and individuals are connected through networks, and, therefore, value is transferred directly between them. The new business value aggregator is represented by networks. As the interconnectedness of everything in the world grows, the company’s immediate assets are not as valuable as resources to which it can be connected.

2.3. Methodology

The research methodology of the article includes the logic of analysis, the scientific sources (such as both literature and databases), as well as practical examples (duly described in various reports). While choosing the journal articles, we used the following logic. The effective servicing of demand has always been the priority purpose of the supply chain formation. Conventional SCM procedures are unable to identify the essence of the value of the potential proposal for a particular user and how to realize this proposal most efficiently. However, these particular requirements are aimed at satisfying modern supply chains, the purpose of which is to provide a fundamentally new type of networking. The operating environment created in this way significantly changes the requirements for the operators—the logistics providers. 3PL and 4PL service providers are being replaced by 5PL providers, who will systematically implement the comprehensiveness principle in customer service when using the resources of a networked business organization, primarily information business organizations. Essentially, the transition to the 5PL level prolongs the operation of the “party logistics” (PL) concept, taking into account the fact that a prerequisite for organizing the work of 5PL providers should be the creation of a global information technology space. This succession means that 5PL-providers, along with 4PL-ones, must focus on strategic supply chain management. They do not assume the presence of tangible assets, and, herewith, they are guided by the “virtual enterprise” model.

We assume that the definitions regarding the blockchain concept in supply chain management can be examined from the point of view that blockchain technology allows us to

- strengthen the integration framework for the interaction of participants in supply chains;

- remove unnecessary intermediaries and, thereby, reduce costs;

- prevent illegal trade in goods and other fraud attempts;

- reduce the time of document circulation by an order of magnitude.

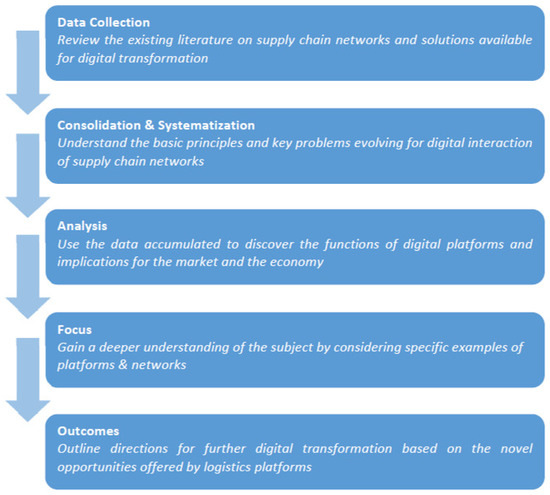

For the purposes of our study, we considered the key types of supply chain networks, the issues they are facing, and the main tools currently available for solving them. The research methodology is outlined in Figure 3.

Figure 3.

Flowchart of research methodology.

Two key principles of the platform business are under consideration: the product service format (Everything-as-a-Service) and the fluid payment format (Pay-as-You-Go) provide benefits. The platforms create the digital infrastructure of markets by eliminating intermediaries and hierarchical relationships and distributing innovative products, services, and business models.

The basic functions of the digital platform are shown in Figure 4.

Figure 4.

Basic platform partner involvement

The collected examples are spread over various cases of virtual integration in logistics networks.

2.3.1. European Logistics Platform

Logistics enables the physical aspects of supply chain management as it delivers the right thing to the right place at the right time and at the right cost. By doing so, it is the backbone of the European economy. In fact, logistics is the single biggest industry sector in the EU: it generates €1 trillion of revenue and provides employment to over 7 million Europeans in all European industries (http://www.european-logistics-platform.eu/). An example of the integration of business processes with complementary resources and competencies based on logistics is Dubai World Central (DWC)—a globally integrated transport and logistics platform covering countries and markets in Europe, Africa, Southeast Asia, and the Far East. The United Arab Emirates (UAE) is exploiting its natural competitive advantage—geography, the historical role of trade, and modern tourism. Geographically, Dubai occupies the position of “gateway” to the countries of the Middle East, Asia, and North Africa and specializes in servicing international cargo flows between India, Southeast Asia, Africa, the Far East, and Europe. In recent years, Dubai has rapidly transformed into one of the world’s re-export hubs. Infrastructure facilities—Al Maktoum airport and Jebel Ali seaport (the largest container port between Singapore and Rotterdam), an industrial center for the preparation of transportation and delivery of perishable and cold-processed food, possessing the latest technologies and occupying key positions in the perishable food market—are interconnected by a common logistic area and operate on a common operating platform, with direct access to the UAE road network and air and sea corridors, which reduces the time of sea–air/air–sea cargo flow. The operating platform operates in a free economic zone; as a result, transport and logistics services are provided with an unprecedented level of availability, speed, and efficiency. In Portugal, 12 logistics platforms have been identified according to criteria such as strategically defined zones with specialized infrastructure that allows the provision of high-quality services, and the availability of several modes of transport (with the possibility of their combination), and competitive costs of the services provided. Together, they form a national logistics platform that enhances Portugal’s role as a “natural gateway” to Europe (http://www.eurasiancommission.org/)

2.3.2. Provenance

Every product has a story. The Provenance platform (foundation year: 2014; location: London, UK; total funding: USD1.1 million; website: www.provenance.org) helps shoppers to track a product’s history and identify counterfeits. The Provenance platform is designed to help brands and retailers build customer trust by providing key information on each product: materials, ingredients, suppliers, manufacturing processes, equipment involved, storage conditions, and transportation. Each stage of a product’s life cycle (its “history”) is tracked and recorded on the blockchain, after which this information is verified and made publicly available. Anyone can join Provenance. To do this, you need to create a business profile and add information about your company and product, including any awards or certificates it has received. Once the profile has been created, the product details must be entered by adding information about materials, ingredients, equipment, processes, and the associated social or environmental impacts. Then you need to invite the involved retailers and transport companies to cooperate, who will add information about storage and transportation conditions. This creates a complete “history” of the product, which can be viewed using the Provenance app or integrated into the company’s website, e-receipts, or issued via a URL and/or QR code.

2.3.3. Ship Chain

A logistics platform based on Ethereum, the ShipChain blockchain (foundation year: 2017; location: Los Angeles, USA; total funding: USD30 million; website: shipchain.io), has no gas fees and is much faster. This logistic blockchain startup focuses on the transportation of goods and allows you to track the transportation of any goods from the moment of shipment from the place of production to the final delivery to the client’s doorstep using their application. ShipChain is a member of the Blockchain in Transport Alliance (BiTA) and has been promoting its product for widespread use by freight forwarding companies. The system uses the immutability and decentralization of blockchain technology and IoT devices to collect information about the movement and conditions of the transportation of goods in real-time, thus creating a “history” of the life cycle of the product. In addition, ShipChain allows you to automate a significant part of the logistics processes related to the exchange of data (graphics, for example), document flow, and financial calculations. Payment can be made using the ERC20 SHIP token. On a technical level, the ShipChain blockchain is a modified version of Ethereum, which is distinguished by the absence of transaction fees in the form of “gas” and the ability to create side chains using the Loom Network. Thanks to this, the platform has no problems with scalability and speed of operations.

2.3.4. Waltonchain

Software for IoT technologies (foundation year: 2016; location: Shenzhen, China; total funding: USD10 million; website: www.waltonchain.org)—one of the many enterprise-grade logistics and supply chain solutions that integrate RFID and IoT data into the blockchain. The project is named after the inventor of RFID tags, Charles Walton, and has nothing to do with the chain retailer Walmart. The startup is well supported in China and other Southeast Asian countries and has a number of interesting partnerships.

2.3.5. Yojee

A platform with its own brains. As a service, Yojee is more focused on continental rather than sea routes (foundation year: 2010; location: Singapore; total funding: USD17 million; website: www.yojee.com). The platform leverages IoT, artificial intelligence (AI), blockchain, and deep machine learning to help logistics companies with fleet coordination, cargo tracking, invoicing, job management, and driver assessment—all in real-time. Yojee currently works with more than 30,000 vehicles and clients from Singapore, Indonesia, and Cambodia. The main feature of Yojee is its focus on small and medium businesses, rather than large corporate solutions and market capture. You can use the startup service for only USD100 per month (up to 1000 items per month). Additionally, Yojee is easy to connect to other business platforms.

2.3.6. VeChain

The VeChain logistics platform (foundation year: 2017; location: Singapore; total funding: USD230 million; website: www.vechain.com) is a startup for the development and deployment of blockchain-based decentralized applications focused on improving logistics processes. It leverages IoT devices and networks, connecting them to a distributed ledger so that companies can integrate their payment and data management systems with the VeChain Thor protocol. VeChain has partnerships with car manufacturers BMW and Groupe Renault, consulting companies PwC Asia and NRCC, and global quality assurance and risk management company DNV GL. The project team actively collaborates with the Universities of Michigan and Oxford to improve their technologies.

2.3.7. TE-Food

The TE-Food food tracking platform (foundation year: 2015; location: Albstadt, Germany; total funding: USD19 million; website: www.tefoodint.com; www.te-food.com) is a startup trying to bring food manufacturers, distributors, retailers, and consumers together to eliminate food fraud and reduce logistics costs for companies. To do this, TE-Food uses RFID tags to track when and where food was produced, under what conditions the raw materials were grown, and when it was delivered to the supermarket. All this is recorded in the blockchain and provided to the buyer via QR codes. TE-Food is mainly focused on developing countries since this is where such a solution is most needed. Today, the project has business relations with more than 6000 companies, makes 400,000 transactions per day, and serves 100 million people.

2.3.8. MediLedger

The MediLedger project deals with the logistics of medical supplies (foundation year: 2017; location: San Francisco, California, USA; total funding: USD16 million; website: www.mediledger.com). The project was launched by Chronicled in 2017 to provide traceability for pharmaceuticals under the Drug Supply Chain Security Act (DSCSA), which will take effect on 27 November 2019. The MediLedger blockchain is used to achieve three goals:

- First, to store synchronized public data, ensuring that all participants in the network share a common “source of truth”.

- Secondly, to ensure the confidentiality of data on transactions. This is needed for compliance with business ethics and DSCSA.

- Finally, DSCSA uses smart contracts to enforce business rules and execute transactions within the system. In addition, the system ensures maximum protection of users’ personal data, ensuring that they will not be published, transferred, sold, or used without the knowledge and consent of their source. The information on the MediLedger network is so well protected that not even a Chronicled manager has access to it unless their source allows it.

2.3.9. T-Mining

The T-Mining startup develops software for logistics (year of foundation: unavailable; location: Antwerp, Belgium; total funding: not announced; website: www.t-mining.be). The startup develops software that improves the efficiency of logistics and transport through better data exchange and secure transfer of ownership. Unlike other projects like VeChain or ShipChain, T-Mining development is not a platform; it is a framework. The startup develops tools and ready-made template solutions that can be easily and quickly integrated into existing logistics systems. T-Mining is currently testing three applications: (1) Safe transfer of the container—ensures that only a driver (user) authorized in the blockchain can pick up the container at the terminal and initiate its movement along the supply chain; (2) safe document flow—uses smart contracts and digital documents to automate document flow in logistics; (3) chain collaboration—improves operational efficiency through secure data exchange and more trusting collaboration between different parties in the supply chain.

2.3.10. SKYFchain

The SKYFchain platform manages automated systems (foundation year: 2017; location: Tallinn, Estonia; total funding: USD5 million; website: www.skyfchain.io) and is an open platform for recording all key events with cargo robots and all their interactions in the supply chain. The first cargo drone on the SKYFchain operating platform was a vertical takeoff and landing aircraft called SKYF. It can fly 8 h without refueling and has a 250 kg (550 lb) payload. SKYF’s first customers were the logistics, agriculture, and oil and gas industries. Although SKYF is a development of SKYFchain, the project is open to other drone operators and is ready to include third-party land and sea cargo robots/unmanned cargo vehicles in its system. Basically, the startup is creating a marketplace where drone operators and shippers can find each other for mutually beneficial cooperation.

Zero1 Capital leverages blockchain, cloud computing, and machine learning to create a platform to help small and medium-sized enterprises around the world in early-stage supply chain finance (foundation year: 2017; location: Madrid, Spain; total funding: not announced; website: www.zero1capital.com). It is another platform for lending/financing a business that is tailored for the launch of supply chains.

2.3.11. SUKU

SUKU is a logistics SaaS platform (foundation year: 2018; location: Grand Cayman, Midlands, Cayman Islands; total funding: not announced; website: www.suku.world). The SUKU project is created by Citizens Reserve and is led by Eric Piscini, a former blockchain leader at Deloitte. It offers a scalable enterprise platform that makes supply chains and logistics more efficient, transparent, and secure. In addition, SUKU has a buy-and-sell marketplace and a reputation system with intelligent matchmaking to enhance business opportunities for users (https://merehead.com/ru/blog/blockchain-startups-in-logistics/).

The reality of the prospects for the formation of ecosystems has been proven by foreign experience, in particular by the Alibaba Group, which has managed to build a global ecosystem for the Chinese market. The system is formed by the main business of the group—online trading based on AliExpress, Alibaba.com, TaoBao.com, Tmall.com, and 1688.com. The system also includes the financial division of Ant Financial, Aliyun cloud services, Cainiao logistics network, and the online service Advertising Alimama, with its film studio, web browser, video portal, and operating system. With its entry into foreign markets, Alibaba actively attracts local players to its ecosystem. For example, in Russia, the AliExpress marketplace, which is part of Alibaba, is one of the most popular online resources. According to SimilarWeb, 24 million users visit it monthly, which is 1/3 of all Russian Internet users. From the point of view of macroeconomic consequences, the change of priorities—the refusal to achieve the efficiency of individual business processes on the line of the interaction of “supplier–consumer” in favor of customer focus—means overcoming the practice of inflationary development, which consists of shifting growing costs to subsequent links in the chain. The move from the end consumer to the manufacturer marks the transition to a fundamentally new, digital business model of logistics that increases the efficiency of all ecosystem participants.

2.3.12. The Case of Russia

In Russia, the ideas of the platform and ecosystem approach are being implemented in the activities of Russian railways. Eight digital platforms have been created, each of which is the basic element of the IT infrastructure for the key areas of activity of Russian railways:

- -

- multimodal passenger transportation;

- -

- multimodal cargo transportation;

- -

- transport and logistics hubs;

- -

- operator of linear infrastructure;

- -

- e-commerce logistics operator;

- -

- management of the transportation process;

- -

- locomotive complex;

- -

- non-production processes.

In the future, based on the integration of platforms, a business ecosystem built on the principles of mobility as a service (MaaS) and multimodality, the operation of which has effects on customers, the market, society, and the state, is planned. One of the Russian examples is the TRAFFIC digital cargo transportation platform presented at the ComTrans exhibition. The developer is BIA-Technologies. It takes into account the experience of cooperation with major carriers such as the Delovye Linii Group of Companies. The platform verifies and admits the flights of a specific shipper only if those carriers meet its admission criteria. In this way, the shipper is provided with a customizable risk management tool. The TRAFFIC platform is an aggregator connecting shipping customers and commercial carriers. It also provides related services: monitoring of current market prices for transportation; online insurance using a smart-contract system; order tracking, if necessary; financing by factoring and other options. For four months of testing, 1200 freight carriers with a total vehicle fleet of 52 thousand units were connected to the platform. The platform allows the reduction of downtime between unloading and loading and the workload on personnel (logisticians, dispatchers, managers) by 50% and 30%, respectively, and halves the time for selecting a machine. For shippers, working on the platform allows them to get a service at the best price and to monitor the price index over time. The trading system implemented on the platform allows you to combine different procurement models to achieve target budgets and deadlines (https://pr.dellin.ru/smi/osobennosti-natsionalnoj-tsifrovizatsii-traffic-nadezhdy/).

When everything is connected to a single network, collaboration gets to a new level.

- The regulatory compliance networks create conditions in which supply chains of various complexity levels unfold and operate.

- The customer networks create a market-driven environment where the response to changing customer sentiment and changing demand, as well as transparency of relationships, is critical.

- The project networks implement and develop collaboration in the design process and allow the exchange of drawings, design documentation, models, and 3D structures with other departments and companies; they also manage the changes.

- The supplier networks simplify the selection, adaptation, and compliance of suppliers and their materials with the regulatory requirements and optimize interorganizational interaction.

- The enterprise networks allow internal and external partners to work in a single global space.

- The asset networks optimize activities through the sharing of technical data, real-time and predictive analytics, and diagnostic services through machine-to-machine (M2M) communication.

- The logistics networks track materials, parts, assets, and products throughout their entire life cycle.

2.4. Ecosystem Approach to Virtual Integration

The interest in the integration of logistics systems has evolved along with the development of the concepts of logistics and supply chain management. Over the years, supply chain models have transformed from their simplest linear forms and more advanced interactive configurations to network logistics structures, initially centralized and rather tightly regulated, to network agglomerations. It has been theoretically proven and empirically confirmed that network structures based on the driving force of business and social communications, supported by digital technologies, offer fundamentally broader opportunities for development.

Integration in novel network logistics systems is dynamic; it happens in real-time with thousands of business partners or end-users. Such a process requires next-generation integration architecture that is capable of supporting these processes and open standards that can be easily adopted by third parties.

A virtual integrator that is adequate to modern conditions can be formed within the framework of the ecosystem approach, interpreting economic systems of all levels as living social organisms subject to continuous variability under the influence of new conditions and new motivations of the participants. The concept of an ecosystem is borrowed from ecology, acquiring new semantic overtones in business: these are dynamic communities developing jointly, consisting of a variety of actors who create and receive new content in the process of both interaction and competition. Competitive advantages in the new world arise from knowing when and how to build ecosystems and from the ability to manage ecosystems, ensuring their continued growth and continuous improvement.

The term “business ecosystem” is associated with the concept of collaboration, which represents the highest, interactive form of cooperation. Collaboration is understood in literature as the process of formal and informal agreements between autonomous players, acting together to create rules and organizations to regulate their interactions and activities or solving tasks that unite them. Moreover, these common rules are shared by all participants, bringing them mutual benefits; the actual coordination can occur continuously.

A business ecosystem is an open system of existing dynamic interaction between economic entities in the external environment; therefore, relationships of competition, cooperation, and coevolution are formed in them.

Business ecosystems are network structures that have vague boundaries. Theoretical studies and scientific discussions have described a model variety of business ecosystems, characterizing their various aspects. A business ecosystem is most commonly interpreted as a network environment that acts as a catalyst for the interaction of participants in the process of formation, accumulation, exchange, and distribution of knowledge and resources. The business ecosystem formalizes many of the efforts of its participants, producing a synergistic effect.

The concept of business ecosystems renews the traditional concept of integration by forming its basic distinctive features.

Today, business is becoming a collective rather than an individual effort, requiring conditions for the collaboration of legally independent entities. The theory of business ecosystems demonstrates how to achieve a synergistic effect through the interaction of subjects in an open network environment.

The collaborative nature of the participants interacting in a business ecosystem, rather than their functional roles, is the key factor:

- -

- innovative ecosystems are living social organisms based on self-regulating mechanisms, which are largely determined by their own internal structural specifics, where organizations, institutions, and their relationships are constantly updated;

- -

- the cornerstone of an ecosystem is the relationship through which the elements of the ecosystem grow. Each of its parts increases the chances of survival by connecting with the rest of the ecosystem. Conversely, the survival of an ecosystem increases with the number of its participants;

- -

- any ecosystem includes not only participants but also a set of complementary platforms for various purposes, within which interactive relationships evolve. Taken together, these platforms form a landscape whose quality influences the business activity of participants, governing their functioning within the ecosystem and, accordingly, the contribution of participants to the overall efficiency of the entire ecosystem.

The theory of business ecosystems provides answers on how to achieve a synergistic effect through the interaction of subjects in an open network environment.

There is a demand for organizing integrated logistics services for customers, making it necessary to provide different platform solutions and work with various types of platforms integrated around IT logistics platforms; logistics ecosystems show much promise in this regard.

An ecosystem is a new systemic solution that should be the driver of the development of logistics business in the digital economy. It fully reflects the modern practical aspects of logistics.

The ecosystem approach is a natural continuation of and the next stage in the evolution of the platform approach—ecosystems will grow directly from platforms. Ecosystems are developing bidirectional dynamic integration with multiple business partners and customers in real-time. Business ecosystems have vague boundaries and are represented by network structures. The ecosystem is an open system of existing dynamic interaction between interacting enterprises or between the system and the environment; therefore, relationships of competition, cooperation, and coevolution are formed between them. Any ecosystem includes suppliers, leading manufacturers, market intermediaries (including agents and channels for the movement of goods, as well as those who sell related products and services), competitors, and other interested parties. Over time, they coevolve, increase their capabilities and expand their roles, and strive to comply with the directions set by the leading companies. The ecosystem approach puts forward a number of important principles that diverge from the attitudes of static system models. Firstly, if static systems can be regulated exclusively by the method from above, through external influence on organizations and institutions, then the ecosystem has its own market mechanisms of self-development, that is, it is controlled by the method from below, which creates the prerequisites for the continuity of adaptation processes, eliminating excessive external interference. Second, the ecosystem approach focuses not so much on the participants in the system themselves but on the nature and dynamics of their interactions (with each other and with potential participants). The main idea of the ecosystem is interconnection. Through interconnection, the elements of the ecosystem grow. Each part of it increases the chances of survival by connecting with the rest of the ecosystem. At the same time, the possibility of ecosystem survival increases with the increase in the number of entities associated with it. Ecosystems are fostering next-generation integration architecture that can support these processes and the introduction of open standards that can be easily adopted by external parties. The organization of interaction on new principles is provided by digital means of communication (social networks, instant messengers, platforms, collaboration services); the Internet of Things is also referred to as communication tools in a broad sense. In the future, integrations with external ecosystems will force companies to interact with many partners, covering a wide range of functions, from customer search to social advertising and payment solutions. The companies that hold leadership roles in an ecosystem can change over time, and the ecosystem leader function is valued by the community because it allows members to move towards shared visions to align their interests and find mutually supportive roles.

3. Results

3.1. Platform-Based Business Solutions: Principles and Effects of Platform Interaction

In recent years, the list of platforms has expanded significantly, primarily due to the growth of capacities and the spread of the internet; many companies work as platforms themselves. The eBay platform has combined buyers and sellers together; the Uber platform has done the same for passengers and drivers, the Airbnb platform for travelers and property owners, and the Apple platform for applications distribution. None of these companies use the linear business model; each of them is an example of a successful business platform. The platforms allow consumers and manufacturers to communicate directly with each other to exchange goods, services, and information. To provide this exchange, the platforms gather around large, growing, easily accessible networks of users and resources. The platforms create communities and markets within which the users interact and transact. The platforms do not own the means of production, creating the means of communication instead; in this sense, they correspond to the virtual enterprise concept.

The following examples have already become canonical:

- The smartphone-based Uber service was launched in one city (San Francisco) in March 2009. In a decade, it has turned the conventional taxi service “upside-down” in more than 200 cities around the world, where it operates without a single owned car.

- Chinese retail giant Alibaba offers nearly a billion products. In this case, the Alibaba platform does not own a single product from its range.

- Facebook is the largest media mogul in the world without creating a single original creative product.

Linear business creates value through manufacturing products or providing services; platforms create value by making connections and using them for transactions.

It is the platform models that enable companies to expand at an unprecedented rate. In contrast to the giants of the 20th century, platform development is nonlinear. When the linear business has a new participant, there is only one new relationship—a new supplier of a resource or a buyer of a product. When a new participant appears on a platform (network), it can potentially make links with all other participants; some links are duplicated. In other words, platforms develop exponentially. As a result, platform business models are much more profitable and scalable in comparison with linear business models.

Different platforms approach the implementation of these functions differently, but a successful platform will necessarily implement each of them. These functions define the infrastructure on which the network relies and provides for easy and efficient transactions. The platforms create open networks with high involvement of the participants, which are always supervised and managed at the same time.

The digital platform business model is based on three key conditions:

- Network effect. By bringing market participants together, the platforms promote a constant cyclical increase in volumes: more consumers attract more sellers and partners, and vice versa. This diversifies costs and risks, shifting them from the businesses themselves to the network. As it evolves, the network acts as a system integrator and coordinator, distributing the load among an ever-increasing number of participants.

- Consistency of technologies. Automation, advanced analytics, cloud technologies, artificial intelligence, and the Internet of Things in synergy create a fundamentally new service economy, where the products and services are delivered to consumers quickly, dynamically, and on-demand, are paid according to the actual scope of application, and flexibly scaled depending on the current needs of the customer.

- Open data. Carefully protected data obtained from operations and transactions on the platform are open and available not only to all participants but also to new applicants. With access to a huge stream of current information, new members can develop new offers and services. Additionally, since the developments are initially based on the data of already-working service options, the new products integrate seamlessly with the existing solutions.

These digital logistics platforms fully embody the advantages of the platform business model.

3.2. Logistics Platform as a Virtual System Integrator

Transport and logistics are resource-intensive areas of activity that have hardly been exposed to digitalization and the influence of digital business models. Logistics and distribution centers, warehouses, and terminal complexes were actively constructed, but large infrastructure projects were not properly balanced with the development of industrial production centers, localization of consumer demand, industrial complexes, and economic zones and were not supported by business activity and commodity and human flows, which must ensure the loading and efficient use of transport and logistics infrastructure.

Large logistics companies had a comparative competitive advantage thanks to high fixed prices and extensive transport fleets, which were an insurmountable entry barrier for competitors. However, the increasingly common platform approach in business does not require such company resources.

Instead of logistics coordination centers in their physical form, information technology logistics platforms have been created, each of which is a network cooperation space designed to create customer value through coordinated logistics interactions at the regional, national, or international level. The logistics platform is the tool that provides for full use of logistics potential as a technology for managing supply chains (and network interaction in general) in their modern network format. The platforms that can aggregate market participants online can manage efficient logistics and delivery systems at a minimal cost.

There are two approaches to the formation of digital logistics platforms: the territorial principle of integration and the information principle [37].

The regional platforms created on a territorial basis are an element of transport infrastructure, under which centralized control of the transport and logistics companies’ activities is carried out. The digital platforms of this type include equal partners, and the main effect of their creation is an increase in the value of services provided through the interaction of various entities of the transport and logistics sector at a qualitatively new level. An example of the platform created on a territorial basis is the European Logistics Platform, under which the companies such as DHL, P&G, Volvo, Michelin, and the European Rail Freight Association operate.

The digital logistics platform formation based on the information integration principle allows the creation of an integrator, under which interorganizational interaction is carried out to simultaneously to solve two problems—service improvement and transaction cost reduction. An example of this digital platform is the national logistics platform of China, LOGINK, which is currently recognized as one of the most advanced platforms created as part of the formation of the digital economy. LOGINK coordinates the transport and logistics spheres of China, Japan, and Korea, which joined many information flows and also contributed to the development of small and medium-sized businesses in logistics [38].

The second type of integration provides for full implementation of the information benefits of digital platforms:

- data acquisition and analysis in the supply chains for their subsequent sharing (data sharing) and exchange to increase the efficiency of interaction of all participants in logistics processes and management decision-making;

- ensuring the interoperability of processes and systems used by various transport modes;

- unification of logistics data exchange standards based on the exchange of standardized electronic documents.

Under the conditions of digital economy formation, the translogistic platform concept has appeared [39]. A translogistic platform is an economic space of the network interaction (cooperation) of companies that is structured by a single/common process of product manufacturing and a single (built according to common standards) technology for managing the business network that coordinates participants in the integrated value chain in regional, national, and global markets.

The key characteristic in all the cases is network interaction based on logistics, which is characterized by voluntary participation, coordination of actions, openness, trust between participants, and the presence of a coordinator for network cooperation.

4. Discussion: Network Logistics Systems and Open Innovation

Network logistics systems could be considered from the point of view of the open innovation concept. Taking into account that Christensen et al. [6] analyzed the open innovation concept from an industrial dynamics perspective, we discuss the connection between the network logistics system and the open innovation models with regard to the following main issues:

- -

- growth of the platform business model as an entrepreneurial ecosystem and its effects on regional development;

- -

- open platform innovation: creating value from internal and external innovation;

- -

- entrepreneurial cyclical dynamics of open innovation;

- -

- open platform strategies and innovation: granting access vs. devolving control;

- -

- micro- and macrodynamics of open innovation with a quadruple-helix model;

- -

- the culture for open innovation dynamics;

- -

- unraveling the process from closed to open innovation: evidence from mature, asset-intensive industries.

Undoubtedly, the nature of the connection between the network logistics system and open innovation models can be studied on the basis of the logic of an open innovation engineering model; both open-innovation engineering channels and determining ways of operating the channels through conceptual experiments are considered by JinHyo Joseph Yun [7]. This fundamental work considers the important research question of open innovation channels and their operation as a knowledge funnel to conquer the growth limit of capitalism in the fourth industrial revolution. The effects of mechanism design (fundamental to the study of incentives and information [40]) can be expanded and implemented for developing new business models from open innovation and Schumpeterian new combinations [41,42] as well as being an open-innovation-based business model design compass [43]. Open innovation engineering channels mean open-source computing, the theory of solving inventive problems (TRIZ), open supply chain management (SCM), system dynamics, mechanism design, or Big Data. This scientific research can be treated as a fundamental theory for our consideration of the collaboration within entrepreneurial ecosystems.

One of the most important issues to be considered is the fact that open innovations allow interacting people and organizations to create ecosystems. Chesbrough notes that the main trend in the development of open innovation is with regard to digital transformation [44]. It involves business models—the logic of creating and capturing value—that dynamically transcend organizational boundaries within that innovation ecosystem [45]. Hence, small organizations are able to rapidly increase their influence in the market on the basis of open innovations that are defined by Clayton M. Christensen as being disruptive. He examined the complexity and inconsistency of innovation [46].

The complexity of knowledge can be investigated using the quadruple-helix model [47], which differs from the fundamental triple-helix model of innovation by adding a fourth helix (the “media-based and culture-based public”) to “university–industry–government relations” (the three helices developed by Etzkowitz and Leydesdorff [48]), generating a national innovation system: academia/universities, industry, and state/government. Leydesdorff explained that the metaphor of a triple-helix model could be considered as a basis for making extensions to the model to more than three helices [49]. The abovementioned quadruple helix and the later suggested quintuple helix, being ecologically sensitive [50], could be treated as universal and, in a wide sense, be extended to an N-tuple-helix model [51].

We agree with a very interesting point of view of Pustovrh, Rangus, and Drnovšek, who assumed that the open innovation paradigm could be useful in analyzing the collaborations among stakeholders within an entrepreneurial ecosystem and supporting the key integrative role of a business accelerator within such a system in open innovation research over the past few years [52]. Open innovation could be treated as the theoretical framework for collaborative innovation in view of the “lean” approach extending from the usual “lean startup” [53] to the methodology of the “lean” entrepreneurship approach in large companies. The collaboration can be considered the main feature of digital ecosystems [54], while implementing business acceleration programs, being the preseed investment, with an emphasis on intensive mentoring, networking, and an educational program for cohorts or classes of startups, is considered by Miller and Bound [55]. The culture for open innovation considers the collaboration emerging among entrepreneurial actors, organizations, and institutions, which formally and informally coalesce to connect, mediate, and govern performance within the local entrepreneurial environment [56].

The authors rely on the argument that modern supply chains have evolved from traditional linear models (based on the individual, desynchronized business relationships and simple network configurations, with few feedback loops) into scalable, adaptable, harmonized partner networks. With regard to the verification of the methodology, the following statement can be substantiated.

The methodological provisions are formed on the basis of the analysis of best practices, the identification of problems, and the identification of tools for their resolution. The authors of the article revealed and empirically confirmed that network structures based on the driving force of business and social communications open fundamentally broader opportunities for development.

In the fullest understanding, the logistics platform includes special organizational structures capable of coordinating the processes of physical distribution, including internal and external (export-import) flows and forms of association of economically and legally independent participants in the supply chains and networks, to achieve common strategic and tactical goals for optimizing the physical distribution process with the lowest labor, material, and financial costs. It provides access to services and information, supporting the logistics activities of companies, and forms an environment of unlimited interaction (cooperation) in the value chains. Our findings are confirmed by other researchers (for example, Kapustina et al. [57]).

The interaction arrangement based on new principles is provided by digital means of communication (social networks, messaging services, platforms, collaboration services). In a wide sense, the Internet of Things is also referred to as communication tools [58,59,60]. Cloud computing is an information technology concept for providing ubiquitous and convenient network access on-demand to a shared pool of configurable computing resources that can be quickly provisioned and released with minimum operational costs or interactions with a service provider. Cloud technologies have decisively contributed to the formation of the digital economy, which is not limited only to the process component but also includes an economic component. In particular, the development of cloud technologies has led to the emergence of concepts such as Production-on-Demand and Everything-as-a-Service, which have become the framework of many business models and the principle of economic interactions in the digital environment [61,62,63,64].

The study is based on the analysis of best practices, which have identified the logical foundations and qualitative features of the current generation of supply chains. This analysis has, first of all, methodological value: it allows us to highlight the main constituent elements of the studied objects and phenomena, to determine the parameters characterizing their functioning and development, to establish connections between them, and provide the fundamental possibility of a formalized description. Qualitative research is a “premodel” in the sense that it is a methodological approximation to a rigorous mathematical model. At the same time, already at the stage of qualitative research, it is possible to build models of the functioning of systems and the course of processes; however, these are models of a special, meaningful, and descriptive plan. Qualitative research and modeling methods are prevalent in the analysis of complex systems and processes, primarily socioeconomic, in which qualitative patterns are more significant than quantitative characteristics. In a number of models of complex objects and phenomena, qualitative models occupy an intermediate position: they are based on the understanding of basic logical laws and serve as a theoretical foundation for the construction of rigorous mathematical models and the practical use of the latter. As far as mathematical modeling is concerned, this task has not yet been solved and remains outside the scope of the study. However, the results of the conducted logical and qualitative analysis give grounds to assert logical–semantic, structural, and cause-and-effect modeling as well as strict formalized methods for analyzing graphs and networks. These are methods of structuring and studying the topology of networks, including determining “components of connectivity” (small groups of interaction) and the connections between them (strength of weak ties) and methods of constructing and optimizing traffic routes. This determines the direction of further research.

5. Conclusions

The expanding and increasing complexity of supply chains places particular demands on integration. Transportation and logistics companies are entering an era of unprecedented change amid the rapid development of digital technologies and rising customer expectations. New technologies are helping to improve efficiency and create more collaborative operating models.

The authors have substantiated that the coordination of interests presupposes the presence of a coordinating center, namely, an integrator, which, in the context of globalization and integration, becomes virtual and acquires the features of a cyber–physical system, the role of which can be played by transport and logistics platforms. The key success factors of the platform business model, which allows the consolidation of assets, the gain of economies of scale, and the provision of quality services at competitive costs, have been identified and formulated in a proof-of-concept.

We have tried to theoretically prove and empirically confirm that the future of logistics platforms is ecosystems, i.e., sets of business and IT solutions linked into a single contour, uniting as many players as possible in the field of logistics and related markets, accompanied by adequate software. Anyone who can combine and provide high-quality support for these services will become a leader.

Logistics business digitalization and the digital transformation of supply chains taking place within the framework of the global trend are primarily due to changed customer expectations. The new industrial revolution introduced manufacturing in a period of mass customization, redefining the logistics role and the need for more flexible, transparent, and demand-driven supply chains and integrated business models. In the case of increasing interaction complexity and the emergence of the digital economy, it is justified to form a virtual system integrator, the role of which is played by both logistics platforms and ecosystems.

A virtual system integrator:

- unites all participants in a supply chain and coordinates logistics operations and networking;

- provides a complexity of transportation and logistics services;

- relies on ICTs that provide for access to a common information space, information transparency of contacts, online monitoring capabilities, access to common databases of enterprises participating in the market, information about their functional capabilities (competencies), and process operations;

- ensures that common process standards and regulations are established for the operation of a common operating platform, which provides inclusion to a network of cooperation between partners and customers;

- creates a basis for effective coordination of network cooperation management to simultaneously solve two problems—service quality improvement and cost reduction.

Logistics platforms and ecosystems have a process and organizational basis that provides for network interaction to form a common economic space for integrated services in network logistics. The process basis of a logistics platform is formed by supply chain management models and ICT, which ensure the online functioning processes and control of the business and the developed transport and logistics infrastructure as a basis for interfacing all types of transport and organizing multimodal transportation and warehouse and terminal facilities.

The technological basis forms a common operating platform that allows the implementation of common technology standards and regulations.

The organizational framework consists of the procedures for coordinating and managing network interaction, which involves the systematic combination of logistics-based integration mechanisms.

Author Contributions

All authors have contributed substantially to the entire work reported. All authors have read and approved the final manuscript. Conceptualization, V.S.; methodology, V.S. and G.S..; writing—drafting, V.S.; writing—inputs, V.S. and G.S.; writing—reviewing and editing, V.S. and G.S.

Funding

The study was supported by the Academic Excellence Project 5-100 proposed by Peter the Great St. Petersburg Polytechnic University.

Data Availability Statement

Data sharing is not applicable to this article.

Acknowledgments

The authors would like to thank the anonymous referees for their very useful suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Oliver, R.K.; Webber, M.D. Supply-Chain Management: Logistics Catches up with Strategy. In The Roots of Logistics; Klaus, P., Müller, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 183–194. ISBN 9783642279218/9783642279225. [Google Scholar]

- Hahn, G.J. Industry 4.0: A supply chain innovation perspective. Int. J. Prod. Res. 2020, 58, 1425–1441. [Google Scholar] [CrossRef]

- Scherbakov, V.; Silkina, G. Logistics of smart supply chains. Int. Conf. Digit. Technol. Logist. Infrastruct. 2019, 1, 66–71. [Google Scholar]

- Dehgani, R.; Jafari Navimipour, N. The impact of information technology and communication systems on the agility of supply chain management systems. Kybernetes 2019, 48, 2217–2236. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Landry, T.D. Supply Chain Process Integration: A Theoretical Framework. J. Bus. Logist. 2009, 30, 27–46. [Google Scholar] [CrossRef]

- Christensen, J.F.; Olesen, M.H.; Kjær, J.S. The industrial dynamics of Open Innovation—Evidence from the transformation of consumer electronics. Res. Policy 2005, 34, 1533–1549. [Google Scholar] [CrossRef]

- Yun, J.J.; Kim, D.; Yan, M.R. Open innovation engineering—preliminary study on new entrance of technology to market. Electronics 2020, 9, 791. [Google Scholar] [CrossRef]

- Di Nardo, M.D.; Forino, D.; Murino, T. The evolution of man–machine interaction: The role of human in Industry 4.0 paradigm. Prod. Manuf. Res. 2020, 8, 20–34. [Google Scholar] [CrossRef]

- Di Nardo, M. Developing a conceptual framework model of industry 4.0 for industrial management. Ind. Eng. Manag. Syst. 2020, 19, 551–560. [Google Scholar] [CrossRef]

- di Nardo, M.; Gallo, M.; Madonna, M.; Santillo, L.C. A conceptual model of human behaviour in socio-technical systems. In International Conference on Intelligent Software Methodologies, Tools, and Techniques; Springer: Cham, Switzerland, 2015; Volume 532, pp. 598–609. [Google Scholar]

- Di Nardo, M.; Clericuzio, M.; Murino, T.; Sepe, C. An economic order quantity stochastic dynamic optimization model in a logistic 4.0 environment. Sustainability 2020, 12, 4075. [Google Scholar] [CrossRef]

- Shibin, K.T.; Dubey, R.; Gunasekaran, A.; Hazen, B.; Roubaud, D.; Gupta, S.; Foropon, C. Examining sustainable supply chain management of SMEs using resource based view and institutional theory. Ann. Oper. Res. 2020, 290, 301–326. [Google Scholar] [CrossRef]

- Ellram, L.M.; Murfield, M.L.U. Supply chain management in industrial marketing–Relationships matter. Ind. Mark. Manag. 2019, 79, 36–45. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Schwab, K.; Davis, N. Shaping the Fourth Industrial Revolution; Word Economic Forum: Geneva, Switzerland, 2018; ISBN 9781944835149/9781944835132. [Google Scholar]

- Industry 4.0: How Digitization Makes the Supply Chain More Efficient, Agile, and Customer-focused. Available online: https://www.strategyand.pwc.com/gx/en/insights/2016/digitization-more-efficient.html (accessed on 2 February 2021).

- Su, Y.; Qin, J.; Yang, P.; Jiang, Q. A Supply Chain-Logistics Super-Network Equilibrium Model for Urban Logistics Facility Network Optimization. Math. Probl. Eng. 2019, 2019, 5375282. [Google Scholar] [CrossRef]

- Nagurney, A. Networks in economics and finance in Networks and beyond: A half century retrospective. Networks 2019, 77, 50–65. [Google Scholar] [CrossRef]

- Silkina, G. From analogue to digital tools of business control: Succession and transformation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 497, 012018. [Google Scholar] [CrossRef]

- Casino, F.; Dasaklis, T.K.; Patsakis, C. A systematic literature review of blockchain-based applications: Current status, classification and open issues. Telemat. Inform. 2019, 36, 55–81. [Google Scholar] [CrossRef]

- Rožman, N.; Vrabič, R.; Corn, M.; Požrl, T.; Diaci, J. Distributed logistics platform based on blockchain and IoT. Procedia CIRP 2019, 81, 826–831. [Google Scholar] [CrossRef]

- Mahajan, S.; Saha, S.; Macias, A. Analytics: Laying the Foundation for Supply Chain DigitalTransformation—The Hackett Group. 2017. Available online: https://thebigcurriculumproject.files.wordpress.com/2018/12/hackett-analytics-supply-chain-digital-1711.pdf (accessed on 2 February 2021).

- Franks, B.C.N.-H. The Analytics Revolution: How to Improve Your Business by Making Analytics Operational in the Big Data Era; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2014; ISBN1 9781118976760. ISBN2 9781118976753. [Google Scholar]

- Supply Chain 4.0—the Next-Generation Digital Supply Chain. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/supply-chain-40--the-next-generation-digital-supply-chain# (accessed on 2 February 2021).

- Zerbino, P.; Aloini, D.; Dulmin, R.; Mininno, V. Big Data-enabled Customer Relationship Management: A holistic approach. Inf. Process. Manag. 2018, 54, 818–846. [Google Scholar] [CrossRef]

- Akbari, M. Logistics outsourcing: A structured literature review. Benchmarking Int. J. 2018, 25, 1548–1580. [Google Scholar] [CrossRef]

- Sainathan, A.; Groenevelt, H. Vendor managed inventory contracts—coordinating the supply chain while looking from the vendor’s perspective. Eur. J. Oper. Res. 2019, 272, 249–260. [Google Scholar] [CrossRef]

- Esposito, E.; Evangelista, P. Investigating virtual enterprise models: Literature review and empirical findings. Int. J. Prod. Econ. 2014, 148, 145–157. [Google Scholar] [CrossRef]

- Moazed, A.; Johnson, N.C.N.-H.M.M. Modern Monopolies: What it Takes to Dominate the 21st-Century Economy, 1st ed.; St. Martin’s Press: New York, NY, USA, 2016; ISBN 9781250091895. [Google Scholar]

- Parker, G.; Van Alstyne, M.; Choudary, S.P. Platform Revolution: How Networked Markets are Transforming the Economy and How to Make Them Work for You, 1st ed.; W. W. NORTON & COMPANY: New York, NY, USA, 2016; ISBN 9780393249132. [Google Scholar]

- Eckhardt, J.T.; Ciuchta, M.P.; Carpenter, M. Open innovation, information, and entrepreneurship within platform ecosystems. Strateg. Entrep. J. 2018, 12, 369–391. [Google Scholar] [CrossRef]

- Barenji, A.V.; Wang, W.M.; Li, Z.; Guerra-Zubiaga, D.A. Intelligent E-commerce logistics platform using hybrid agent based approach. Transp. Res. Part E Logist. Transp. Rev. 2019, 126, 15–31. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking big data analytics and operational sustainability practices for sustainable business management. J. Clean. Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]