Abstract

Electronic waste (e-waste) is the fastest-growing class of waste because of the remarkable demand for various electronic gadgets such as mobiles and laptops. Moreover, its improper disposal is life-threatening because it includes hundreds of different substances, many of which are toxic elements and pollutants that can leach to soil and surface and groundwater or be emitted into the air, causing a major negative impact on the environment and public health. As a result, studies on the sustainable management of e-waste have gained increasing attention from researchers globally in the last decade to explore practical strategies to reduce or utilize this special waste. This review aims to provide an in-depth understanding of the major aspects of e-waste, including its definition, composition, and the impact of its end-of-life disposal on human health and the environment, while also focusing on some practical sustainable solutions and strategies toward effective e-waste management. It will also discuss the production of electronics; global demand and the mining boom; and the pollution caused by mining. It will also highlight the importance of effective governmental regulations, with which electronics producers, e-waste generators, and recycling facilities should comply. The research perspectives and orientations highlighted within this review can help in providing guidelines for future research studies and in exploring opportunities for more effective management of e-waste toward a circular economy and sustainable development.

1. Introduction

Rapid economic development, urbanization, and technical advancement have resulted in the invention of various electronic gadgets that have greatly improved the quality of our lives [1,2,3]. According to Directive 2012/19/EU of the European council and parliament, electrical and electronic equipment (EEE) can be defined as any industrial or household equipment such as lighting equipment, medical devices, information technology equipment, and leisure items such as toys, computers, phones, and others that work on electromagnetic fields or electric currents [4,5]. At present, approximately 900 diverse types of EEE are available in the international market [6]. Such technological advances have brought numerous benefits to the society by making our life easier, but one of the major consequences of heavily relying on this modern technological advancement is the huge amounts of waste electrical and electronic equipment (WEEE) or electronic waste (E-waste) [7]. According to the digital report 2020, 4.57 billion internet and 5.15 mobile phone users were recorded, which accounts for around 60% of our global population [8]. Moreover, the increase in consumer demand for electronics, especially in the internet technology sector, due to the COVID-19 pandemic’s lockdowns and work-from-home situation has further increased e-waste generation, which has become worrisome as a global issue [9].

E-waste is a broad term for electronic and electrical equipment that is unwanted, obsolete, not working, or has reached the end of life in its service [10]. Many categories fall under e-waste, and its definition differs globally, resulting in its ununified definition, and therefore, in the way it is managed. Moreover, in some countries, some EEE items are not fully considered as e-waste and have regulations outside of the e-waste framework [11]. However, as per the European Union WEEE directive, it is defined as EEE that is discarded as waste, including its consumables, subassemblies, and all components that are present in it at the time when it is discarded [12]. WEEE includes both large appliances—“white goods” such as washing machines, refrigerators—and small personal EEE products—“brown goods”, such as mobile phones and computers [13]. Regarding its composition, it is complex physically and chemically since it contains metals, plastics, glass, ceramics, and toxic chemicals such as organic flame retardants, polychlorinated biphenyls (PCBs), and other toxic compounds [14]. Today’s world’s obsession with electrical and electronic equipment and the inappeasable desire for owning the latest devices have led to the creation of modern electronics with shorter life spans and other issues related to their design’s complexity [1,15]. Over 100 metals and other materials can be found in e-waste [9], and the quantities and composition of these materials vary for each EEE item depending on the equipment’s type, model, manufacturer, and its age when discarded [16].

According to the United Nations report, e-waste generation has increased sharply, reaching 53.6 million metric tons in 2019, elevated by 21% from 2015, and is projected to reach nearly 120 million metric tons by 2050 as a global burden [1,9,17]. Additionally, due to the high demand on electronics, the electronics industry has become notorious for being responsible for a heavy footprint of energy utilization and carbon emissions. The contribution of digital technologies to climate change is estimated to range from 1.4% to 5.9% for greenhouse gas emissions, of which around 31% is due to digital devices such as desktops, smartphones, netbooks and displays [18]. Overall, e-waste is a topic of concern because it makes a significant portion in solid waste and contains several toxic components and heavy metals that can adversely impact human and environmental health if not handled properly [1]. Additionally, e-waste contains many precious components such as gold that must be retrieved and utilized to conserve natural resources. Therefore, the issue of e-waste is quite complex and multifaceted [10]; it has good, bad, and ugly outcomes [19]. Hence, this review discusses the major concerns related to e-waste generation, composition, and its health and environmental impact, and highlights current sustainable approaches to deal with it. Around 175 reports from the literature that were published from 2018 to 2022 have been thoroughly studied by the authors and discussed in this review.

2. Digitalization and the Boom in Global Mining

The digitalization era is boosting the growing appetite for electronic devices, which is greatly impacting both low- and middle-income countries in many aspects. Most information and communication technologies and products (ICT) use a variety of metals, which are mostly extracted in countries that have uneven regulations, manufactured in hazardous sites, and discarded in the form of untreated toxic e-waste. High demand for these devices is fueling the global mining industry, which potentially involves economic gains but consequently also results in high demand for resources and land utilization and eventually leads to e-waste pollution [20]. Thus, the mineral and mining industry cannot be easily associated with sustainable development because of the major concerns related to the exploitation of earth’s limited resources [21]. The mining industry provides a variety of the raw minerals that are necessary components in various electronic products and services, but it also involves complex material cycles, including mining and processing operations. For that reason, the use of life cycle assessment for minerals and metals has become more common and important in the electronics industry [22].

Virgin mining is a process that involves the extraction of various metals from their ores. A high dependency of manufacturing industries on virgin mining results in unsustainable consumption and depletion of various natural resources [21]. To manufacture electronic devices, mining is essential to extract required minerals, which may include the need of “conflict minerals” such as tin, tungsten, and tantalum, termed as the three Ts. Gold and cobalt are also necessary for manufacturing various ICT products such as tablets, computers, and smartphones [18]. For instance, a smartphone contains around fifteen different metals, such as copper wiring, gold in the circuit, lithium-ion batteries, and many other metals, including rare-earth metals [20]. Therefore, material extraction globally was estimated to have increased 10-fold, from 7 billion tons in 1900 to around 68 billion tons in 2009. Considering this extraction rate, many of the elements’ primary reserves are in danger of disappearing within the next 50 years. Some elements such as strontium and manganese are at substantial risk of running out due to low crustal abundance, and indium is also at an alarming position and expected to be exhausted within 13 years due to its frequent application in semiconductors, solar cells, and display devices [23]. Due to the unconscious use of these natural resources, many environmental problems exist and will further increase with more consumption [24].

Apart from the risk of running out of essential elements’ resources (virgin), another concern is the impact of the rapid extraction of minerals through the application of various anthropogenic and informal activities that are detrimental to environmental and human health [25]. Mining and mineral processing techniques and industries are a major concern in many countries as they are increasingly contributing to climate change and global warming. Due to the increase in demand for electronics, metal exploration is getting deeper on the surface and requires heavy equipment to extract ore minerals present at lower levels. Therefore, these industries largely use heavy equipment that works on mechanical and electrical energy, in addition to heat that contributes to global warming [26]. Hence, the increase in the production of ICT equipment and other electronics has been associated with the increase in the carbon footprint globally, because such emissions are not only a result of EEE energy consumption but also because of the massive energy utilization that is required during their manufacturing process. Furthermore, mining processing of earth metals that is carried during the manufacturing of electronic devices and its waste generation are additional contributors to the CO2 footprint [27]. Mining and processing of raw resources do not only contribute to global warming but also produce huge amounts of waste that impact environmental and human health [28]. Overall, acid mine drainage, metal deposition, sedimentation, the impact on biodiversity, and waste generation are the main categories of environmental effects of mining and mineral processing for the electronics industry [26]. Scientific research largely highlights the environmental impact of electronics production, while the impact on society is less discussed, although the electronics industry also affects society, which can be termed as the human price/cost for inventing digital technology. For instance, the supply chain of computers is usually criticized for involving negative social practices such as child labor, forced labor, or excessive hours of work, which are mostly practiced in developing countries. According to some reports, labor abuse and lethal accidents are more prevalent in manufacturing and assembling industries [25,29].

3. E-Waste Pollution: A Global Challenge

The electronics industry is a cause of an emerging problem of massive e-waste generation [30]. E-waste includes any old, end-of-life EEE in addition to waste that might be produced by any device working on batteries or electricity, such as personal computers, mobile phones, electronic laboratory equipment, and other such devices, including any components discarded by users [31]. Some electronic products are being dumped by owners even before the product’s end of life, and very few of these electronics reach formal recycling units [1]. The two main reasons for the increase in e-waste generation is the lower prices of electronics and the progressive reduction in their lifespan. These have resulted in an increase in accessibility to electronic equipment to a massive number of people and have also increased the rate in which such devices become obsolete [32]. Furthermore, due to the rapid advancement and complexity of e-waste, it is hard to group them into useful categories [4,33].

Currently, e-waste is considered a top concern for sustainable consumption and production [33]. It is a burning topic in terms of sustainability, as it involves technology, economy, energy, communication, and culture, in addition to waste management, the ecosystem and human health, policy, and international affairs. It is a multidisciplinary challenge that is growing rapidly [12]. Reports indicated that the global e-waste generation increased to 53.6 Mt in 2019. Europe (12 Mt), USA (13.1 Mt), Indonesia (1.62 Mt), Japan (2.57 Mt), India (3.23 Mt), and China (10.1 Mt) are the major generators that are contributing to around 70% of the e-waste generated globally. About 17.4% of the globally generated e-waste was recycled, whereas the remaining 82.6% was either discarded, untreated, or informally processed [34]. It has been estimated that the amount of generated e-waste may go up to 74.7 Mt in 2030 (from 7.3 kg per capita in 2019 to 9.0 kg per capita in 2030) [1]. It is important to mention that most of the e-waste generated in North America and Europe is shipped to Asian, South American and African countries every year due to the lower cost of recycling and the possibility of illegal dumping in these countries or in the form of donations. A very small fraction of such e-waste is in working condition for secondhand use, but around 80% of such items do not work and end up in dumpsites or recycled in informal settings by low-skill workers, who manage it manually without proper PPE [35]. The yearly 5% to 10% increase in EEE that is prudently disposed is a major threat to the environment and human health [36]. Therefore, e-waste is an emerging problem within both developed and developing nations and requires special attention [15]. It contains various elements and compounds that include both valuable and toxic substances that are detrimental to both environment and human health [37,38]. So far, informal activities such as unregulated and demanding labor activities that involve the use of undeveloped equipment are profitable compared to formal activities in e-waste industry. Such practices account for 98% in developing countries [25]. The United Nations Sustainable Development Goal 12 (UN SDG 12) highlighted that only 20% of e-waste is properly recycled and the rest is indiscriminately disposed of, which has led to thousands of research studies over the past two decades on e-waste and its impact on the environment [39].

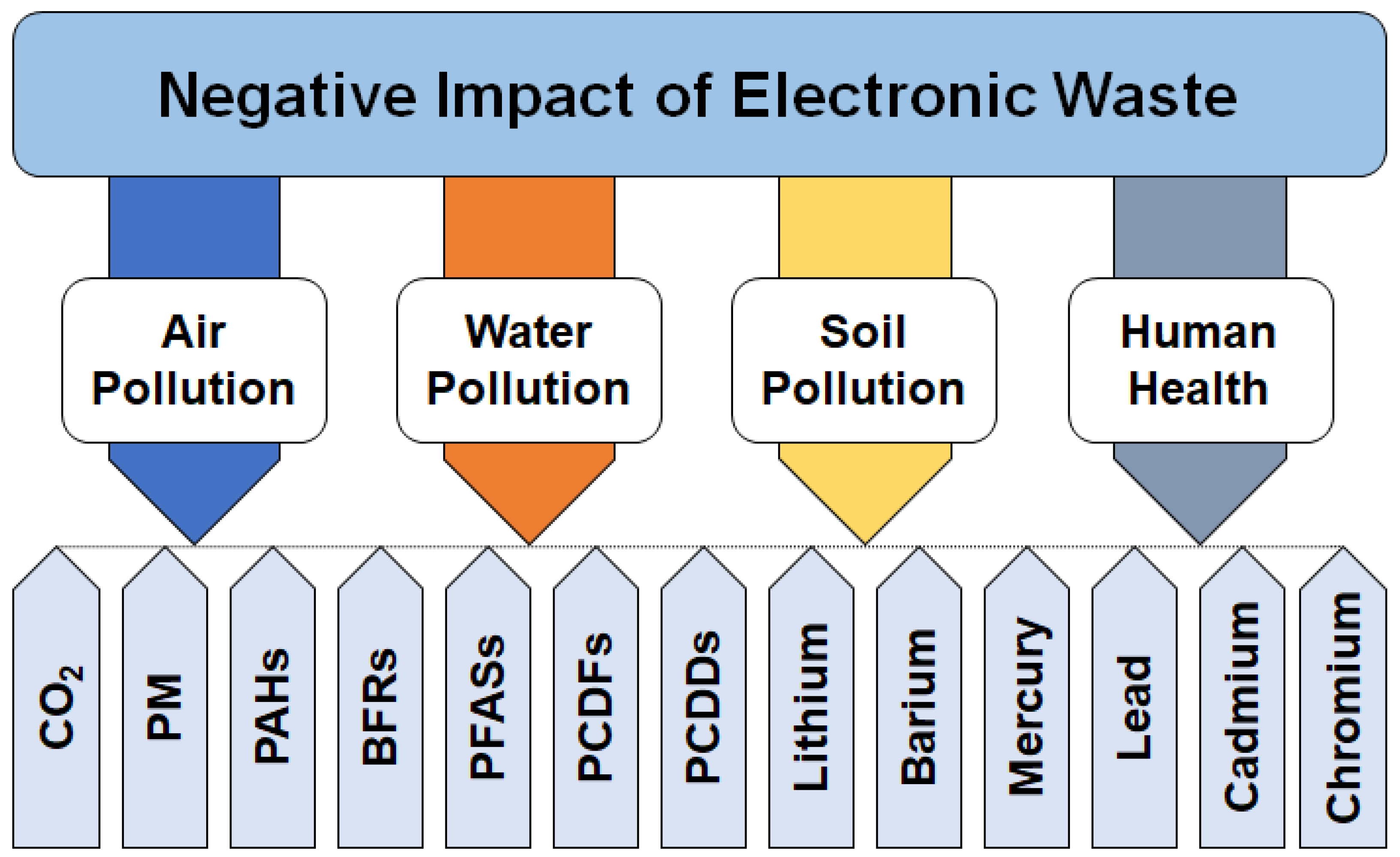

Air Pollution: The e-waste reported in 2019 (53.6 Mt) contained around 50 tons of mercury and 71 thousand tons of hazardous brominated flame retardants [14]. It could also be among the major causes of rare-earth-element (REE) pollution as it contains an elevated amount of REE concentrations in its products [40]. Heavy metal pollution is also generally expected at e-wastes’ dumping areas because of the massive use of metals in EEE such as copper in electric wiring and cadmium in batteries [41]. As EEE contains many essential components such as printed circuit boards and various toxic substances, its improper dumping and recycling can release several harmful substances that can adversely impact air, water, soil, food resources, and human health [14,42]. E-waste contains hazardous substances and toxic additives that if dispersed through improper treatment and disposal can pose a significant threat to air quality [43]. Moreover, the recycling activities of e-waste include transportation, dismantling of materials, and burning, in addition to the smelting of EEE for the recovery of metals such as gold and copper. Such procedures are practiced mostly in low- and middle-income countries with informal settings that can pollute air mainly because of the smelting and burning of e-waste, which release airborne pollutants [44]. Dismantling e-waste can also be a source of releasing volatile organic compounds [45]. Previous studies have revealed that diverse types of hazardous air pollutants can be released during e-waste combustion, which releases polyhalogenated aromatic hydrocarbons, hydrogen chloride, dioxins, polycyclic aromatic hydrocarbons, furans, and significant amounts of particulate matter (PM). In Thailand, open burning is still used to separate copper from the wires present in e-waste, which can pose a threat to workers through the inhalation of PM and other pollutants [46]. According to a previous study, illegal e-waste recycling was highlighted as a significant source of PM that exceeds acceptable limits [30]. Inappropriate e-waste recycling can also release various inorganic and organic pollutants such as heavy metals, polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), perfluoroalkyl and polyfluoroalkyl substances (PFASs), brominated flame retardants (BFRs), polychlorinated dibenzofurans (PCDFs), and polychlorinated dibenzodioxins (PCDDs) [47]. Figure 1 shows some of the major hazardous materials and emissions from e-waste.

Figure 1.

Major pollutants and hazardous materials that can be generated from e-waste when improperly dumped or managed.

Water Pollution: Many EEE items have toxic metals that can pollute water if disposed inappropriately. A single battery of a mobile phone is estimated to pollute six hundred thousand liters of water. Mercury is voluminous compound in e-waste that can exist in all three forms and can pollute water especially in the liquid form, which can last for centuries [8]. Results of a previous study indicated that uncontrolled e-waste recycling impacted fish, seafood, rice, and vegetables with heavy metals and livestock with persistent air pollutants [48]. Moreover, e-waste is mostly discarded and shipped from developed countries to other developing countries in Asia such as in Guiyu, where almost 70% of e-waste ends up. Reports showed that around 12.5% of such waste is recycled through primitive methods, which results in the leaching of toxic substances into the ecosystem. Apart from persistent organic pollutants, there are many heavy metals present in the groundwater and rivers of Guiyu, which make its water unsuitable for drinking and cooking [49]. Moreover, e-waste not only pollutes water but also can generate large amounts of wastewater during the process of collecting copper particles, for instance, during the used hydraulic shaking bed separation process [50].

Soil Pollution: E-waste has also a major impact on soil and its biological component. The pile up of e-waste in mountains and dumping sites, particularly in countries such as India, China, Pakistan, and African countries, has impacted the microbial community present at contaminated sites. Alteration in microbial community can significantly impact soil ecological function. For example, e-waste contains heavy metals such as mercury, lead, cadmium, nickel, arsenic, chromium, and persistent organic pollutants that can result in a reduction in the normal soil microbial biota [51]. For example, a study of an e-waste dismantling area in southeastern China indicated that such soil was badly contaminated with cadmium and copper because of unregulated e-waste’s dismantling activities [52]. Open burning is also a major source for releasing harmful substances and heavy metals into soil environments [35]. Many countries have reported the lethal impacts on soil ecosystems because of the discarding and recycling activities involved in e-waste management. Recycling activities such as plastic melting, the burning of circuits, recovering copper from wires, and recovering gold by the use of acidic substances might result in metal pollution [41]. Such activities can also result in surface soil pollution because of the presence of heavy metals in e-waste [53].

Impact on Human Health: E-waste pollution is considered to be a foremost threat to human health globally, as people can be exposed to it through multiple pathways. The literature is rich in reports that illustrate the potential health impacts of e-waste through ingestion and inhalation or through occupational exposure to e-waste [54]. A comparative cross-sectional study of e-waste workers and bystanders revealed that back pain, red itchy eyes, and other injuries related to work were more recurrent in e-waste workers than the control group [55]. According to a systematic review on the health consequences of e-waste exposure, people living near e-waste areas are exposed to significant amounts of persistent organic pollutants and heavy metals, and it was found that such toxic chemicals in elevated levels impact the neonatal growth and hormones of such population negatively [56]. A study in south Africa confirmed that human’s exposure to various toxics available in e-waste such as mercury, cadmium, and arsenic is catastrophic. A study in Ghana also showed that the burning of e-waste releases pollutants affecting respiration and causing asthma, eye irritation, and others [57]. Other potential health impacts of informal recycling and disposal result in contaminants being present in milk, body fluids, and blood, as well as abnormal reproductive growth, immunotoxicity, genotoxicity, damage of organs, and intellectual impairment [10]. Furthermore, preschool children’s oral health in e-waste regions was found to be susceptible to lead exposure, which increases the risk of dental issues such as periodontitis and other oral problems [58]. In conclusion, e-waste exposure has various devastating impacts on human health and should therefore be effectively treated [57].

4. Sustainable Approaches towards Effective E-Waste Management

Solid waste management is already considered a mammoth task in the majority of developing nations, and it has become even more complicated due to the invasion of e-waste and the short obsolescence rate of EEE [59]. E-waste is among the critical categories for decision-making processes in waste management [7]. Challenges in e-waste management arise due to inadequate financial support, lack of infrastructure, poor technical skills, and a lack of active community engagement [60,61]. Most countries that have an emerging economy have basic recycling processes, but studies have shown that emerging countries do not have end processing technologies for recovering materials from printed circuit boards. E-waste generation is directly impacted by a country’s GDP, and Balde et al. confirmed that it can be correlated to a country’s level of pollution [62]. The improper handling of e-waste adds various detrimental impacts such as degradation, pollution, contamination, and the release of toxic fumes into the natural environment, and although it only occupies 2 to 5% of the total solid volume, in terms of toxicity it plays a role of more than 70% [1]. Hence, improper disposal of e-waste is life-threatening due to the presence of toxic metals and pollutants [34]. In developing countries, the accumulation of carcinogens and xenobiotics has been reported in illegal recycling units, and such a type of poor e-waste management has become a major concern [63]. Therefore, efficient and proactive e-waste management should be compulsory all over the world and technosocioeconomic integrated strategies for e-waste recycling are required [64].

In recent years, studies on the sustainable waste management of e-waste have increasingly gained attention by researchers globally [65]. The environmental issues of the present and future, and the concept of green, clean, and sustainable processes for recovering or obtaining chemicals from both primary (natural) and secondary (manmade) resources, including e-waste, have become important topics of research [23]. E-waste’s heterogeneous composition and growing rate impose a need for a special waste management that involves adequate treatment to control pollution and valuable recovery of resources. Therefore, the circular economy (CE) approach can be taken as an alternative approach in this regard to achieve sustainability [66]. CE promotes the recirculation of useful materials in order to prevent pollution and for the purpose of secondary materials’ management. Moreover, extended producer responsibility can be one among the instruments to use secondary raw materials that are embedded in e-waste streams to overcome related risks of future supply chain [67]. Hence, CE is a sustainable economic development that substitutes traditional economic development through activities such as the useful utilization of materials (recycling, recovery), extending the lifespan of components in e-waste (repair, reuse or refurbish), and the implementation of smart use of EEE and e-waste (reduce, rethink, refuse) [68]. E-waste management techniques such as reducing and recycling play a vital role in tackling the problem of e-waste and also help in the establishment of CE [69]. Therefore, the e-waste problem can be solved by implementing the 3 Rs principle (reduce, reuse, recycle), which is a way to practice CE [70,71]. In this context, the 3Rs rule can mean reducing e-devices/e-waste, reusing possible e-products or e-waste, and recycling e-products that cannot be repaired. It is important to reduce e-waste in the first place, such as by keeping devices in good condition [72]. However, this 3Rs approach in e-waste management is arguably insufficient, in that it requires further multidisciplinary and collaborative approaches across governmental, nongovernments, and industries, as well as at the business and civil society levels [73]. Below are some of the possible approaches to efficiently manage e-products and e-waste.

4.1. Reuse of E-Waste

The reuse and recirculation of various materials and products are the basis of the circular economy concept. The innovative proposal of the circular economy can exhibit positive outcomes such as a reduction in demand of raw materials, a reduction in consumption of natural basic resources, job creation, and the prevention of adverse impacts stemming from the exploitation and processing of various natural resources [74]. Discussed below are some examples of the reuse of e-waste in different industries and sectors.

4.1.1. Refurbishing E-Waste

E-waste can be utilized through a remanufacturing process by means of which some of the specific parts of computers can be replaced with new versions in order to improve the total efficiency of such computers. The remanufacturing of computers can refer to the dismantlement, repairment, and upgrading of discarded computers to provide such devices with new life in addition to a warranty of being as good as a new product. This process is an ideal end-of-life option for discarded laptops or desktop computers [75,76]. The UK, USA, and Japan are leaders in this practice. There are many potential benefits of remanufacturing. For example, it helps in reducing carbon emissions due to the reduction in energy use [77]. It has been reported that remanufactured products compared with new ones can reduce cost by around 50%, save energy by nearly 60% and materials by around 70%, and prevent air pollution emissions by over 80% [78]. Thus, the environmental pollution caused during the remanufacturing process is less than the pollution caused by the manufacturing of new products [79]. Therefore, it is one of the effective strategies for the sustainable consumption and production of EEE by extending e-waste’s lifecycle [80,81].

4.1.2. E-Waste in Construction Industry

The utilization of e-waste is a partial solution to many ecological and environmental problems. The use of e-waste materials as construction materials not only helps to utilize e-waste materials in concrete, cement, and in other building components, but also helps in the minimization of the cost of concrete and cement production [82]. Moreover, the huge amount of concrete that is utilized as a construction material makes the availability of this raw material questioned. Therefore, other substitute materials are required, and in this regard, e-waste can be used as an alternative for aggregate in concrete [83]. Such replacement of aggregate with e-waste in concrete can help in mitigating environmental problems linked with plastic pollution. E-waste concrete is light in weight compared to other natural aggregate, which reduces the amount of fuel consumed during transportation, and its production cost is comparatively lower. The other advantages of e-waste concrete as a lightweight material include the minimization of the efforts in the handling and manufacturing processes, provision of sufficient thermal insulation, and it can also reduce the impact of earthquakes [84]. E-waste can be used as a source material in diverse forms such as coarse aggregate, binder and fiber in mortar, precast products, and concrete. Several researchers have used diverse types of e-waste plastics in cement composites, and numerous studies have been conducted in terms of using e-waste glass such as LCD glass as a building material in construction. Moreover, the polyvinylchloride (PVC) wire extracted from electric cables of e-waste can be utilized as PVC fiber (e-fiber) in concrete [85]. In conclusion, in the absence of a safe and economical recycling method, the use of e-waste in construction materials can be effective to reduce the amounts of e-waste sent to landfills [86].

4.1.3. E-Waste Plastics for Cell Culture Applications

Despite the environmental and economic significance of recovering plastics present in e-waste, they can be rarely recycled because of their complex composition and due to the toxic additives that have adverse impacts on human and environmental health [87,88]. Therefore, scientists have found a new way to use the plastics present in e-waste as an alternative to the plastics that are used in cell culture containers such as petri dishes in laboratories. A team from Nanyang Technology University of Singapore repurposed e-waste plastics in laboratory by simply subjecting it to sterilization before trying it in lab experiments. It was found out by the team that in comparison to cells produced on standard cell culture plates, over 95% of human stem cells seeded on plastics salvaged from discarded components of computers were still viable after a week. These findings indicate a new potential sustainable usage of e-waste plastics that accounts for around 20% of the 50 Mt of e-waste produced yearly worldwide. It will also reduce the huge amounts of plastic waste that is generated from biomedical research [89]. In another study, e-plastics were specifically reclaimed from discarded computer parts such as prismatic sheets and keyboards, which were first cleaned, sterilized, and systematically characterized in order to know their characteristics, then used for guiding the differentiation and growth of human adipose-derived mesenchymal stem cells. The study showed that the used e-plastics were comparable to commercial tissue-culture treatment plates in terms of their ability to sustain stem cell phenotype and maintain cell proliferation over the course of two weeks [87]. Other similar studies have also indicated significant savings in single-use plastics in addition to a reduction in waste generation [90].

4.2. Recycling of E-Waste

Recycling involves the processing of materials to regain the same high- or low-grade quality of the recycled materials. It involves the extraction of secondary materials from any discarded product or material. Such secondary materials extracted can be either subjected to upcycling (high quality or equal functionality) or downcycling (as it is). Upcycling should be preferred, but it is often not possible [91]. Generally, e-waste management includes five basic stages, namely collection, removal of toxics, preprocessing, end processing, and finally disposal of unrecyclables. The efficiency of e-waste recycling relies on the followed process and mainly on the dismantling and separation stages [92]. From an economic perspective, e-waste recycling is regarded as a gold mine because it can generate a number of precious materials such as gold, silver, platinum, palladium, iron, and copper. The majority of these materials in e-waste are technically retrievable and recyclable. Global e-waste, according to the United Nations University, is worth more than USD 62 billion in raw materials [93]. E-waste recycling can also help in solving employment related issues. For example, China hires around 100,000 of recycling workers in one of their recycling e-waste locations. It can also protect environment from hazardous materials and fumes and provides direct environmental savings, which include lower energy use, less environmental footprint, a lower amount of waste, and consequently lower social impact [94]. E-waste recycling can reduce cost by around 50% and saves 60% of energy and 70% of materials. Therefore, from a financial and environmental perspective, e-waste recycling is beneficial [95]. However, e-waste recycling is a very challenging process due to e-waste’s complex nature. E-waste can have several types of metals (61% of all types of metals), plastics (20%), glass (5%), wood (3%), ceramic (2%), rubber (1%), and other pollutants (5%) [96]. Hence, several methods and technologies have been adopted for e-waste recycling processes such as hydrometallurgy, pyrometallurgy, biometallurgy, and a combination of these methods. There are many challenges associated with each of them, such as the need for certain specific pretreatments [97]. Conventionally, pyrometallurgy and hydrometallurgy methods are used, but both have some advantages and disadvantages. For instance, hydrometallurgy requires huge investment and energy, as it is a thermal treatment. On the other hand, problems in pyrometallurgy include difficulties in controlling emissions and material quality because of the difference in the melting points of the various components of e-waste [97]. Furthermore, insufficient funds, a lack of treatment technologies, and inappropriate infrastructure are responsible for releasing hazardous pollutants that impact workers in recycling facilities due to the lack of effective PPE and poor knowledge. Uncontrolled recycling of e-waste can also result in huge waste effluents [98].

4.3. Urban Mining of E-Waste for Resource Recovery

E-waste is also termed as “urban mines” due to having a high content of metals that present around 61% of e-waste mass [99]. Therefore, e-waste is a potential source for recovering valuable secondary resources such as precious metals such as gold, silver, copper, iron, steel, etc. Considering these precious secondary resources, e-waste has become a heart of urban mining [7,100]. Urban mining in e-waste can be defined as a method to recover materials and energy from urban areas, particularly the anthropogenic stocks of e-waste, and it is considered to be a necessary process in order to achieve a circular economy [101]. The concept of urban mining is linked with resource efficiency, which covers landfill mining to the anthroposphere’s resource recovery, which can represent element concentrations that are often similar to or surpassing natural stocks [33]. A composition analysis of smartphones and mobile phones showed that smartphones contained roughly 260 diverse nonmetallic and metallic components, whereas cellphones had around 150. It also showed that 1 kg of smartphones has approximately 1600 mg of silver, 187 mg of gold, and 37 mg palladium (on average), while 1 kg of smartphones contains around 1733 mg of silver, 191 mg of gold, and 40 mg palladium (on average). This indicates that e-waste constitutes a possible resource for a secondary sustainable mining of precious and rare metals [102]. Metal recovery from e-waste through urban mining is a profitable business as it can significantly increase the recycling rate, and then such metals and other resources recovered from e-waste can be easily circulated back to the supply chain of resources [103]. Hence, urban mining is a method of closed-loop chain of supply that provides an effective alternative to e-waste management and sustainable utilization of mineral resources, in addition to a reduction in the intake of primary minerals, and consequently, it promotes circularity in the supply chain [74]. Apart from the valuable supply chain, urban mining of e-waste also creates employment and business opportunities to perform various e-waste activities such as the sorting, dismantling, or recycling stages, mostly in developing economies. Urban mining is also essential for achieving various United Nations Sustainable Development Goals (SDGs) 2030 such as SDG3, SDG6, SDG8, SDG11, and SDG12 [104,105,106]. As per the UN General Assembly in New York, e-waste was directly associated with SDG’s accomplishment, and all countries were therefore encouraged to retain a sustainable approach in e-waste management to reduce waste generation [100]. Recycling and urban mining together can decrease global warming and pollution and can improve the economy [107]. Despite the numerous benefits of e-waste, it is unfortunate to mention that only 15% of e-waste is utilized [100]. Envisioning a future in which 100% of e-waste is processed through formal activities, nearly 85 to 95% of the demand on the resources needed to produce electronics could be fulfilled [105].

4.4. Physical, Electrochemical, and Biotechnological Approaches for Metal Recovery from E-Waste

Metals from e-waste can be recovered through various methods, such as physical, thermochemical, chemical, hydrometallurgical, pyrometallurgical, and biometallurgical processes, or by applying a combination of these methods. Among these, physical methods are conventional, exhibiting low recovery efficiency and high consumption of energy compared to other methods [108]. Both metallic and nonmetallic parts of e-waste can be separated by physical extraction methods. Moreover, metals from e-waste might be extracted by implementing any of the three primary physical extraction techniques; particle shape-based separation, magnetic separation, and electrostatic separation. These methods involve easy extraction, inexpensive capital or running expense, and low carbon footprint, but they have a drawback of losing some essential metals due to insufficient metal release. Nearly 10 to 35% of essential metals are being lost from e-waste by these processes [109]. At present, pyrometallurgical extraction is mostly used for metals’ extraction from e-waste. It requires an elevated temperature in addition to significant amounts of chemicals that result in excessive costs. It also produces gaseous pollutants and dust, which makes it less environmentally friendly. Compared to this method, the hydrometallurgy method is used commercially, but it requires pretreatment that involves a series of reagents and chemicals, which releases significant quantities of acidic wastewater. Moreover, it is considered to be slow and not cost-effective [108]. The electrochemical-based metal recovery process involves leaching metals in ionic form in an appropriate electrolyte. This process is a selective metal recovery that uses fewer chemicals with precise and convenient control and less consumption of energy and has a lower environmental impact. Electrowinning and electrorefining are both primary methods towards the purification of metals from aqueous solution that contains huge metal ion concentrations on an industrial scale [110].

Among the various conventional technologies, including both chemical and machinal methods that have been employed for the extraction of metals from e-waste, microbial technologies are gaining more attention recently in the scientific community. Other technologies are either costly or cause secondary pollution, which requires treatment, but the biological approach is ecofriendly, particularly for metal recycling from e-waste. This approach is defined as applying microorganisms to transform or recover pollutants into less or nonhazardous forms by means of microbial metabolism. There are diverse mechanisms for the microbial remediation of metals, such as biotransformation, biosorption, bioaccumulation, bioleaching, and biomineralization. Microbes play a very important role in microbial technology by the leaching process of metal into the liquid phase [23]. The processes by which organisms convert their energy into biomass inside the congregated cellular structure is known as absorption or bioaccumulation. During this process, some hazardous metals of e-waste are accumulated (e.g., cadmium, uranium, chromium, and lead). Moreover, the biotransformation process occurs through biochemical reaction (oxidation and reduction) [111], whereas bioleaching is a natural event in which a variety of microorganisms participate in the process of dissolving the metals of e-waste. Furthermore, biosorption includes adsorption, ion exchange complexation, and precipitation, all of which are metabolically independent processes [112]. Metal recovery through biomediated processes is gaining increased commercial and academic interest because of its cost-effectiveness, lower environmental impact, and high metal selectivity [113].

4.5. Energy Recovery from E-Waste Plastics through Pyrolysis

E-waste can be regarded as a secondary source for both various metals and energy due to the presence of high polymeric materials and metal content [114]. A substantial portion of plastics and some metals can be recovered using an appropriate technology from the ones mentioned earlier [115]. To reduce greenhouse gas emissions from e-waste, the recycling of plastic waste for the replacement of virgin plastic is a preferable option, but for complex mixtures of plastics, energy recovery might be a better option [116]. At present, the disposal of plastic, aluminum, and rubber is problematic because the burning activity of such waste can pollute the environment, whereas this type of waste can be turned into useful products, e.g., heat, oil, gas, power, and biochar, by applying the process of pyrolysis [117,118]. Researchers have emphasized the use of thermochemical conversion technologies such as pyrolysis, incineration, and gasification techniques for waste-to-energy conversion [119]. Pyrolysis is basically a thermochemical processing technique, through which it is possible to exploit polymers in e-waste in addition to concentrating e-waste metals into a solid residue. This process can also be combined with other technologies in order to reduce the content of organic halides that arise from toxic brominated flame retardants, which are commonly used as additives in electronic products [120]. In general, the term pyrolysis refers to a material’s breakdown at an elevated temperature in an inert atmosphere. Through this breakdown, waste can be transformed through pyrolysis into three different forms such as liquid oil-like products, solid products such as char, and gas products such as syngas [121]. In terms of the pyrolysis of e-waste plastics, it is the thermal decomposition of polystyrene, polyethylene terephthalate, certain polyamides, and polymethylmethacrylate into monomers using temperatures of 400 to 980 °C in an oxygen-absent environment, resulting in products such as fuel gas (H2, CO, CO2, etc.), oils, and solid residues such as char or black carbon [122]. During pyrolysis, polymer macromolecular structures are broken down into smaller molecules, oligomers, and even monomeric units. In the degradation processes, inter- and intramolecular interactions change a portion of the species produced directly from the primary degradation reaction into secondary products. The extent and kind of these reactions rely on the temperature of the reaction and the products’ presence in the reaction zone, which are primarily influenced by the reactor design [123]. It is important to mention that diverse types of catalysts are used to improve the pyrolysis process [124]. Scientists’ attention is being drawn towards the thermochemical disposal of e-waste because it provides effective energy and product processing without burdening the ecosystem. Waste disposal and the recovery of synthetic fuels are both possible uses of plastic pyrolysis. For example, diesel generator burners can be fueled by the recovered pyrolysis oil [125]. It is a cost-effective and ecologically friendly process [126]. Therefore, energy and material recovery by utilizing thermal treatment can be considered a fundamental part of e-waste management [127].

4.6. Clean Hydrogen Fuel Extraction from E-Waste by Gasification

The most distinctive characteristic of e-waste is the constructional complexity of its components and their integration [128]. After the reuse and recycling of the various components of e-waste, a large amount of mixed waste is still left, which can become a nuisance. Therefore, energy generation from such residual waste offers a great solution for waste management, particularly if after all efforts of waste management are performed and further recycling is not economically feasible. Residual waste tends to be complex and heterogenous for recycling, but suitable for waste-to-energy processes. After implementing this process, the remaining waste will have a reduced volume and can be easily disposed [129]. E-waste consists of polymeric material and minerals and contains a high number of valuable metals that can be recovered. Through a process of gasification, the polymeric components can be converted into gaseous products (H2 and CO), which might be used for chemical synthesis or energy recovery [128,130]. This process is carried out under controlled gasifying conditions in which oxygen, air, or steam are used as a gasifying medium or agent. It requires postgasification cleaning of the synthetic gas to obtain the best H2-to-CO ratio [131]. A mixture of hydrogen and carbon monoxide is known as syngas, which can be used as a fuel or can be combusted in gas turbines for the production of electric power [132]. It can also be used as an energy source in various industries [133]. Gasification is a suitable method for providing a clean fuel and a sustainable substitution to incineration and landfilling in waste management. According to a previous research, gasifying mixed e-waste resulted in hydrogen concentrations of 82% and a hydrogen production yield of 33.6 mol/kg [134]. Other studies also explored the gasification process of plastics from the nonmetallic fraction of discarded printed circuit boards and phenolic boards [132].

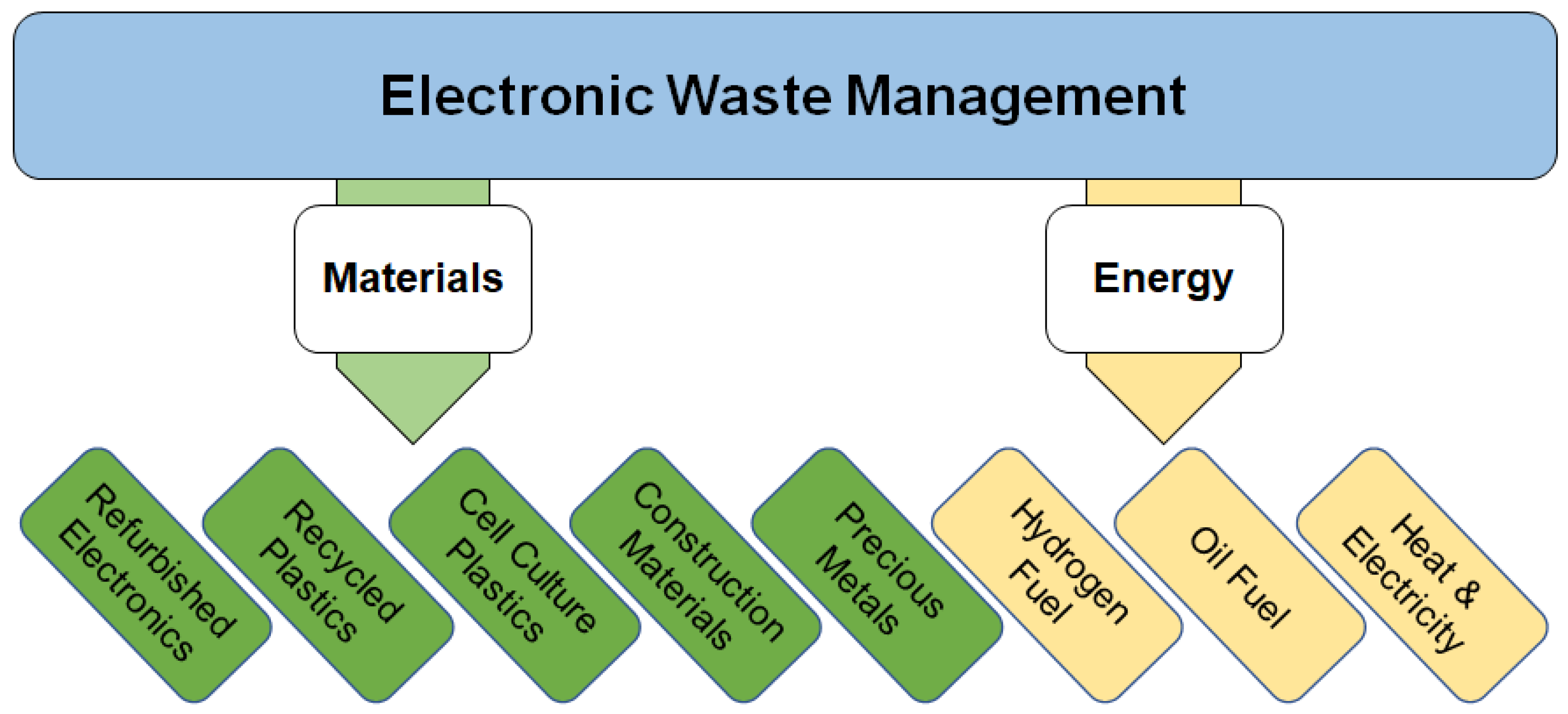

Overall, and as summarized in Figure 2, there are different possible routes for the utilization of e-waste to reduce its environmental and health impact and to bring its value back to the economy. The greenness and energy recovery efficiency of the thermal processes such as gasification, incineration, and pyrolysis that are used to convert e-waste to fuels or energy is strongly dependent on their operation conditions. They all exhibit environmental benefits, but gasification is usually more optimal to use environmentally and in terms of energy recovery [128,135]. Another report recommended the use of pyrolysis over gasification and incineration [136]. The selection of the optimal process may also depend on the targeted fuel nature; hydrogen, oil, or direct heat [128,135]. Regarding the processes that are used to recycle e-waste or convert it into useful materials, they are difficult to compare in terms of their greenness and efficacy because they can be physical, chemical, or biological, and operate at different severities and target different products [137,138,139].

Figure 2.

Possible routes for the conversion of e-waste to high-value materials and energy.

5. Ecofriendly Product Design and Manufacturing as an Alternative Solution

The rapid increase in demand for electronic products is costly for the environment because of the huge resource consumption and waste generation. Moreover, the growth in nongreen manufacturing technologies is a danger to humans and the environment that requires thorough investigations [140]. Therefore, green products and processes have become necessary for sustainable development [141]. Sustainable innovation is an idea to satisfy the needs of consumers with the least possible impact on the environment. This requires all production companies to strongly consider all the environmental factors related to raw materials’ usage in their products, energy consumption, and waste generation. This may require certain modifications in design, production, and services. By definition, it can be achieved by two approaches: (1) structural improvement and (2) part enhancement or innovation [142]. Hence, engineers and designers should design electronic products that are beneficial to society, the economy, and the environment. This can be achieved through adapting sustainable solutions that are eco-efficient by developing products using sustainable materials and less energy in both the production and usage stage, in addition to designing products that can be easily reused or recycled at their end-of-life stage [143].

The significant issues related to e-waste have to do with its volume and the usage of raw materials that are nonbiodegradable and hazardous to human and environmental health [144]. Previous research shows that about 80% of the environmental effects of e-waste can be realized in an early stage of the design phase of electronic products. Therefore, product developers can influence its entire lifecycle and the opportunity for its management when it becomes e-waste. The early design phase includes the selection of materials to be used, the production process, and the final product [145]. Hence, the future green electronics industry should consider the use of lower amounts of raw and renewable materials and less consumption of power. Ecodesign strives for the utilization of materials having less environmental impact, fewer resources, and lower materials usage in the manufacturing process, while generating less waste and pollution [146,147]. The flexible plastic substrates that are largely used in printed electronics cause major harm to the environment. A promising material class for environmentally friendly electronics is biodegradable materials. In an ideal scenario, such materials degrade into smaller, nontoxic components that are digested by enzymes or bacteria at rates comparable to how waste typically degrades. Such a degradation process should begin during the end-of-life stage of an electronic device, started by a trigger, and occur at a controlled rate in feasible environmental conditions [148]. Hence, biodegradable electronic devices are needed as a sustainable green solution for e-waste management because these natural materials have multiple benefits such as availability, low immunoreaction, and low cost, and most importantly, these devices reduce the adverse environmental impacts by causing no pollution, since they can degrade easily [149]. Biodegradable electronics reduce the environmental footprint of e-waste, and also enable electronics to be used in therapeutic and health-monitoring aspects because they also tend to be biocompatible [150]. For example, paper-based electronics have been studied in recent years to improve the sustainability and recyclability of printed electronics. At present, printed electronics from an environmental perspective are challenging because of the commonly used plastic substrates (polyethylene terephthalate (PET) or polyethylene naphthalate (PEN)) and metal inks. In contrast, biobased flexible substrates such as paperboards and papers derived from renewable resources are a source of cleaner opportunities as they result in a smaller environmental footprint. Furthermore, paper-based substrates are biodegradable, flexible, recyclable, deformable, less costly, and more thermally stable as compared to flexible plastic foils [151,152,153,154]. The use of flexible and biobased composites in the production of printed circuit board substrates has headed several researchers towards studying the feasibility of ecofriendly alternative substrates. Previous studies have investigated the use of lignin in brominated epoxy matrix, epoxidized linseed oil in conventional epoxy resin, and polylactic acid as substrates of printed circuit boards instead of PET [155,156,157]. Such possibilities provide effective routes for the reduction of e-waste [158].

Energy efficiency is a key challenge ahead in the field of electronics [159]. The consumption of energy can be reduced only if the energy efficiency of electronic devices is increased. The ultimate goal is to develop devices that are nearly zero-power electronics, and this challenge is in line with the goal of using cutting-edge nanoelectronics-based solutions [160,161]. Therefore, green technology is gaining importance because of the significant rise in e-waste, energy consumption, and global warming. Piotr Pazowski defined the fundamental approaches of green technology, which are green design, green manufacturing, green use, and green disposal [162]. The green use and disposal of electronics refers to the use and disposal phase of product by focusing on reducing power consumption and avoiding any damage to the environment. Moreover, green design means to make ecofriendly and power-efficient products, which use less power but can provide the same performance. This phase connects governmental bodies, companies, and environmental organizations for developing techniques and models to improve the economy and quality of environment, whereas green manufacturing aims to implement greener manufacturing methods that use recycled materials with reduced waste generation to make electronics [75,163,164].

Towards improving resource efficiency and material recovery in electronics, Fairphone has taken the lead by assessing the end-of-life (EOL) phase of their latest smartphones. As part of their mission, they are considering a closer view on how to obtain the majority of materials in their phones after they attain the end of their useful life and services. Fairphone intends to improve recycling, but this approach is not mainstream yet; however, this idea is receiving recognition, e.g., reports by Greenpeace have rated the design solution of the Fairphone as best in the categories of sustainable design and resource efficiency [165,166]. The ECOtronics project has been studying and developing sustainable electronics and optics to support the Finnish optics and electronics’ industry. The main purpose of this project is to reduce hazardous materials by replacing such components with biobased materials and creating green printing processes of electronics. It has been proven that the printing processes of electronics compared to traditional manufacturing process are more environmentally friendly [167,168].

6. Importance of Policies to Combat the Challenges of E-Waste Management

E-waste’s informal processing and disposal have raised critical concerns related to human and environmental health worldwide. Inadequacy of policies, deficient budgets, and unsatisfactory public awareness towards waste management are some key factors behind this situation [36]. Therefore, several legislative frameworks have been implemented to regulate e-waste management by adopting resource utilization and preventing pollution. At present, in various countries, e-waste legislations include restrictions on e-waste export or import and regulations on the recycling of some specific categories of e-waste, as well as involving extended producer responsibility (EPR) [169]. Many legislative documents are being activated under the guidance of EPR to minimize the impact of e-waste disposal. EPR shifts the financial or/and physical responsibility towards e-waste from municipalities to original producers and as a result provides physical/financial links between recyclers and producers. To some level, the EPR can be better viewed as a framework within policies that is based on three basic instruments: economic instruments, takeback requirements, and performance standards. Policymakers can choose from EPRs that can be adapted flexibly to regional and national values, economic contexts, and legislative particularities. EPR has been adopted by the USA, China, Japan, and various EU countries, as it is regarded to be a main guiding theory to maintain a recycling-oriented circular economy [170].

In today’s society, efficient e-waste management is regarded as a significant challenge, and most developing countries are struggling for policy direction regarding e-waste [171]. While the EU currently has an e-waste directive that sets the criteria for e-waste’s collection, treatment, and recovery, the majority of the African countries do not have overarching frameworks for the management of e-waste [172]. No doubt that many African countries are facing negative impacts from transboundary e-waste, as this region is gaining attention as a destination choice for e-waste dumping. For instance, Nigeria has a history of transboundary movement of hazardous wastes; it has influenced strict legislations as a response to such waste. Therefore, as shown by the Koko toxic waste disaster, the Harmful Waste Act 2004 was essentially passed to stop future transboundary movement and disposal of hazardous wastes in Nigeria. It forbids any unlawful actions involving the acquisition, sale, importation, transit, transportation, disposal, or storage of hazardous materials. It is not simply concerned with controlling the transboundary flow of e-waste, but also encompasses all facets of the EEE sector from cradle to grave through a life-cycle perspective [173]. Moreover, various global initiatives have been set forth to oppose unsound social and environmental practices in e-waste trade globally. First, the Basel convention discussed, under the umbrella of the UN Environment Program (mid-1980s), controlling the transboundary movement of hazardous waste, including e-waste, followed by the Basel ban amendment (in the 1990s) for more restrictions on the transport of hazardous waste from rich to poor countries [174].

Hence, e-waste management requires policy approaches based on sustainability principles and supported by science, technology, and innovation. It is clear that better e-waste management can help to achieve social, economic, and environmental benefits. In addition, the UN Sustainable Development Agenda 2030, which gave rise to the Sustainable Development Goals, calls for a radical transformation in this sector and pressures on rethinking the way relevant policies are defined, developed, put into practice, assessed, and managed [175].

7. Conclusions

E-waste is the solid waste class with the fastest rate of growth. It poses a severe environmental and human health risk because it includes a mixture of harmful inorganic and organic substances such as heavy metals, polychlorinated biphenyls, polycyclic aromatic hydrocarbons, and brominated flame retardants. Metals from e-waste can leak into water and soil, endangering the environment if such waste is disposed of in landfills without applying any prior treatment. Dioxins, acids, and furans are generated because of improper e-waste recycling methods such as open burning and acid baths that create these toxic and hazardous compounds. There are various adverse impacts of e-waste on air quality, soil, water, and human health that require special attention. Other than e-waste’s impact on public and environmental health, there are various adverse impacts of the global boom in mining processes to extract the metals that are needed for the manufacturing of electronics, since these activities are resulting in the depletion of various natural resources, some of which are in danger of running out. The mining industry is also among the major contributors to global warming because it is highly energy-intensive during the production and manufacturing stage of electronics. Electronic devices also consume a large amount of energy, which makes energy efficiency a major concern as well.

Management of e-waste differs from that of regular solid waste as it requires advanced techniques as well as environmentally friendly technologies. E-waste contains various valuable and base metals in large amounts, so this type of waste can be used as an alternative or a secondary source of various precious metals which are present in it. Utilization of e-waste as a secondary source of resources instead of using primary resources such as metal ores can help to reduce the pressure on such primary resources that are going through the risk of depletion. E-waste can be minimized and utilized in many feasible ways, such as by following the 3Rs rule, which includes a reduce, reuse, and recycle approach. Moreover, e-waste can be modified into other products by utilizing it in construction materials, remanufacturing it into new products, and repurposing e-waste plastics for cell culture applications in the laboratories. Formal recycling of e-waste is important to be performed for all components of e-waste that can be recycled, while other nonrecyclable resources in e-waste can be recovered through urban mining. Other approaches such as physical, electrochemical, and biotechnological methods can be used for metal recovery from e-waste. Moreover, energy recovery is possible from e-waste plastics through various methods, such as by means of the pyrolysis process, while clean hydrogen can also be extracted from e-waste components through gasification. Furthermore, apart from these sustainable approaches for effective e-waste management, one more alternative solution is to produce electronics with ecofriendly designs. Considering this objective, electronic products can be made using biodegradable and ecofriendly materials or by substituting harmful materials with less or nonharmful substances, such as by using biobased flexible substrates such as paperboards and paper. Furthermore, green technologies should be implemented that focus on green design, green manufacturing, green use, and green disposal of electronic products. E-waste management also requires policy approaches that are based on sustainability principles and supported by science, technology, and innovation. Efficient e-waste management can help to achieve social, economic, and environmental benefits. Several legislative frameworks have been implemented worldwide to regulate e-waste management for improving resource utilization and preventing pollution. They include restrictions on e-waste export or import and regulations on recycling some specific categories of e-waste, as well as involving extended producer responsibility.

Finally, some of the implementable recommendations provided by previous studies suggest that extended producer responsibility and the 3Rs strategy should be implemented in electronics manufacturing regulations in all countries to support the production of products that are planned for reuse rather than obsolescence. To monitor specific e-waste material generation globally, international integrated organizations should be set up, and it is also recommended to develop and carry out formal systems for the monitoring of e-waste and develop national legislations and regulations to control efficiently the flow of e-waste, in addition to adequate handling and recycling activities. It is also recommended to develop an accreditation system for the informal e-waste processing sector that is developed and used by governmental and nongovernmental organizations.

Author Contributions

Conceptualization, H.A. and S.T.G.; formal analysis, H.A. and S.T.G.; investigation, H.A. and S.T.G.; writing—original draft preparation, H.A. and S.T.G.; writing—review and editing, H.A.; supervision, H.A.; project administration, H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Saha, L.; Kumar, V.; Tiwari, J.; Rawat, S.; Singh, J.; Bauddh, K. Electronic waste and their leachates impact on human health and environment: Global ecological threat and management. Environ. Technol. Innov. 2021, 24, 102049. [Google Scholar]

- Tulchynska, S.; Popelo, O.; Marhasova, V.; Nusinova, O.; Zhygalkevych, Z. Monitoring of the Ecological Condition of Regional Economic Systems in the Context of Sustainable Development. J. Environ. Manag. Tour. 2021, 12, 1220–1228. [Google Scholar] [CrossRef] [PubMed]

- Seddon, A.W. Special feature: Measuring components of ecological resilience in long-term ecological datasets. Biol. Lett. 2021, 17, 20200881. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, D.; Ilankoon, I.; Kang, K.D.; Chong, M.N. Circular economy and household e-waste management in India: Integration of formal and informal sectors. Miner. Eng. 2022, 184, 107661. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Uddin, M.N.; Chowdhury, J.; Ahmed, S.; Uddin, M.; Mofijur, M.; Uddin, M. A review of the recent development, challenges, and opportunities of electronic waste (e-waste). Int. J. Environ. Sci. Technol. 2022, 1–8. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N.; Baumber, A.; Shumon, R.; Zaman, A.; Ali, F.; Hossain, R.; Sahajwalla, V. A global review of consumer behavior towards e-waste and implications for the circular economy. J. Clean. Prod. 2021, 316, 128297. [Google Scholar] [CrossRef]

- Ottoni, M.; Dias, P.; Xavier, L.H. A circular approach to the e-waste valorization through urban mining in Rio de Janeiro, Brazil. J. Clean. Prod. 2020, 261, 120990. [Google Scholar] [CrossRef]

- Rajesh, R.; Kanakadhurga, D.; Prabaharan, N. Electronic Waste: A critical assessment on the unimaginable growing pollutant, legislations and environmental impacts. Environ. Chall. 2022, 7, 100507. [Google Scholar] [CrossRef]

- Vishwakarma, S.; Kumar, V.; Arya, S.; Tembhare, M.; Dutta, D.; Kumar, S. E-waste in Information and Communication Technology Sector: Existing scenario, management schemes and initiatives. Environ. Technol. Innov. 2022, 27, 102797. [Google Scholar] [CrossRef]

- Purchase, D.; Abbasi, G.; Bisschop, L.; Chatterjee, D.; Ekberg, C.; Ermolin, M.; Fedotov, P.; Garelick, H.; Isimekhai, K.; Kandile, N.G. Global occurrence, chemical properties, and ecological impacts of e-wastes (IUPAC Technical Report). Pure Appl. Chem. 2020, 92, 1733–1767. [Google Scholar] [CrossRef]

- Tarek, A.; El-Haggar, S. Sustainable Guideline for Developing the E-Waste Sector in Egypt. J. Environ. Prot. 2019, 10, 1043. [Google Scholar] [CrossRef]

- Ghimire, H.; Ariya, P.A. E-wastes: Bridging the knowledge gaps in global production budgets, composition, recycling and sustainability implications. Sustain. Chem. 2020, 1, 154–182. [Google Scholar] [CrossRef]

- Ádám, B.; Göen, T.; Scheepers, P.T.; Adliene, D.; Batinic, B.; Budnik, L.T.; Duca, R.-C.; Ghosh, M.; Giurgiu, D.I.; Godderis, L. From inequitable to sustainable e-waste processing for reduction of impact on human health and the environment. Environ. Res. 2021, 194, 110728. [Google Scholar] [CrossRef] [PubMed]

- Lebbie, T.S.; Moyebi, O.D.; Asante, K.A.; Fobil, J.; Brune-Drisse, M.N.; Suk, W.A.; Sly, P.D.; Gorman, J.; Carpenter, D.O. E-waste in Africa: A serious threat to the health of children. Int. J. Environ. Res. Public Health 2021, 18, 8488. [Google Scholar] [CrossRef]

- Venugopal, G.; Kaari, M.; Ramakodi, M.P.; Manikkam, R. Bioleaching of Heavy Metals from e-Waste Using Actinobacteria. In Methods in Actinobacteriology; Springer: Berlin/Heidelberg, Germany, 2022; pp. 705–708. [Google Scholar]

- Andeobu, L.; Wibowo, S.; Grandhi, S. A systematic review of e-waste generation and environmental management of Asia Pacific countries. Int. J. Environ. Res. Public Health 2021, 18, 9051. [Google Scholar] [CrossRef] [PubMed]

- Pant, D.; Dhiman, V. An overview on environmental pollution caused by heavy metals released from e-waste and their bioleaching. In Advances in Environmental Pollution Management: Wastewater Impacts and Treatment Technologies, 1st ed.; Kumar, V., Kamboj, N., Payum, T., Singh, J., Kumar, P., Eds.; Agro Environ Media, Publication Cell of AESA, Agriculture and Environmental Science Academy: Haridwar, India, 2020; pp. 41–53. [Google Scholar]

- Singh, N.; Ogunseitan, O.A. Disentangling the worldwide web of e-waste and climate change co-benefits. Circ. Econ. 2022, 1, 100011. [Google Scholar] [CrossRef]

- Zhongming, Z.; Linong, L.; Xiaona, Y.; Wangqiang, Z.; Wei, L. New Research on Electronic Waste Reveals a Growing Environmental Problem Exported to Developing Countries; Global S&T Development Trend Analysis Platform of Resources and Environment: Lanzhou, China, 2021. [Google Scholar]

- van der Merwe, A.; Brugger, F. Case study: The digital device life cycle: From mining to e-waste. In Development Co-Operation Report 2021: Shaping a Just Digital Transformation; OECD Publishing: Paris, France, 2021. [Google Scholar]

- Jones, P.; Wynn, M.G. The circular economy, resilience, and digital technology deployment in the mining and mineral industry. Int. J. Circ. Econ. Waste Manag. 2021, 1, 16–32. [Google Scholar] [CrossRef]

- Segura-Salazar, J.; Lima, F.M.; Tavares, L.M. Life Cycle Assessment in the minerals industry: Current practice, harmonization efforts, and potential improvement through the integration with process simulation. J. Clean. Prod. 2019, 232, 174–192. [Google Scholar] [CrossRef]

- Awasthi, A.K.; Hasan, M.; Mishra, Y.K.; Pandey, A.K.; Tiwary, B.N.; Kuhad, R.C.; Gupta, V.K.; Thakur, V.K. Environmentally sound system for E-waste: Biotechnological perspectives. Curr. Res. Biotechnol. 2019, 1, 58–64. [Google Scholar] [CrossRef]

- Cambaz, N.; Taskin, E.G.; Ruzgar, A. Life cycle assessment of an office: Carbon footprint of an office staff. Environ. Res. Technol. 2018, 1, 34–39. [Google Scholar]

- Abalansa, S.; El Mahrad, B.; Icely, J.; Newton, A. Electronic waste, an environmental problem exported to developing countries: The GOOD, the BAD and the UGLY. Sustainability 2021, 13, 5302. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.P.; Saidur, R. A review on the impact of mining and mineral processing industries through life cycle assessment. J. Clean. Prod. 2019, 231, 1200–1217. [Google Scholar] [CrossRef]

- Belkhir, L.; Elmeligi, A. Assessing ICT global emissions footprint: Trends to 2040 & recommendations. J. Clean. Prod. 2018, 177, 448–463. [Google Scholar]

- Naik, S.; Eswari, J.S. Electrical waste management: Recent advances challenges and future outlook. Total Environ. Res. Themes 2022, 1, 100002. [Google Scholar] [CrossRef]

- Subramanian, K.; Yung, W.K. Modeling Social Life Cycle Assessment framework for an electronic screen product—A case study of an integrated desktop computer. J. Clean. Prod. 2018, 197, 417–434. [Google Scholar] [CrossRef]

- Gangwar, C.; Choudhari, R.; Chauhan, A.; Kumar, A.; Singh, A.; Tripathi, A. Assessment of air pollution caused by illegal e-waste burning to evaluate the human health risk. Environ. Int. 2019, 125, 191–199. [Google Scholar] [CrossRef]

- Dzah, C.; Agyapong, J.O.; Apprey, M.W.; Agbevanu, K.T.; Kagbetor, P.K. Assessment of perceptions and practices of electronic waste management among commercial consumers in Ho, Ghana. Sustain. Environ. 2022, 8, 2048465. [Google Scholar] [CrossRef]

- Olufokunbi, K.C.; Odejobi, O.A. A Computational Model For Electronic-Waste Dynamics. Ife J. Technol. 2018, 25, 39–44. [Google Scholar]

- Ramanayaka, S.; Keerthanan, S.; Vithanage, M. Urban mining of E-waste: Treasure hunting for precious nanometals. In Handbook of Electronic Waste Management; Elsevier: Amsterdam, The Netherlands, 2020; pp. 19–54. [Google Scholar]

- Nithya, R.; Sivasankari, C.; Thirunavukkarasu, A. Electronic waste generation, regulation and metal recovery: A review. Environ. Chem. Lett. 2021, 19, 1347–1368. [Google Scholar] [CrossRef]

- Acquah, A.A.; D’Souza, C.; Martin, B.J.; Arko-Mensah, J.; Dwomoh, D.; Nti, A.A.A.; Kwarteng, L.; Takyi, S.A.; Basu, N.; Quakyi, I.A. Musculoskeletal disorder symptoms among workers at an informal electronic-waste recycling site in Agbogbloshie, Ghana. Int. J. Environ. Res. Public Health 2021, 18, 2055. [Google Scholar] [CrossRef]

- Masud, M.H.; Akram, W.; Ahmed, A.; Ananno, A.A.; Mourshed, M.; Hasan, M.; Joardder, M.U.H. Towards the effective E-waste management in Bangladesh: A review. Environ. Sci. Pollut. Res. 2019, 26, 1250–1276. [Google Scholar] [CrossRef] [PubMed]

- Kiddee, P.; Pradhan, J.K.; Mandal, S.; Biswas, J.K.; Sarkar, B. An overview of treatment technologies of e-waste. In Handbook of Electronic Waste Management; Butterworth-Heinemann: Woburn, MA, USA, 2020; pp. 1–18. [Google Scholar]

- Olusegun, O.A.; Osuntogun, B.; Eluwole, T.A. Assessment of heavy metals concentration in soils and plants from electronic waste dumpsites in Lagos metropolis. Environ. Monit. Assess. 2021, 193, 582. [Google Scholar] [CrossRef] [PubMed]

- Maphosa, M.; Maphosa, V. A bibliometric analysis of the effects of electronic waste on the environment. Glob. J. Environ. Sci. Manag. 2022, 8, 589–606. [Google Scholar]

- Brewer, A.; Dror, I.; Berkowitz, B. Electronic waste as a source of rare earth element pollution: Leaching, transport in porous media, and the effects of nanoparticles. Chemosphere 2022, 287, 132217. [Google Scholar] [CrossRef]

- Kumar, P.; Fulekar, M. Multivariate and statistical approaches for the evaluation of heavy metals pollution at e-waste dumping sites. SN Appl. Sci. 2019, 1, 1506. [Google Scholar] [CrossRef]

- Abdelbasir, S.M.; Hassan, S.S.; Kamel, A.H.; El-Nasr, R.S. Status of electronic waste recycling techniques: A review. Environ. Sci. Pollut. Res. 2018, 25, 16533–16547. [Google Scholar] [CrossRef] [PubMed]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University/United Nations Institute for Training and Research, International Telecommunication Union, and International Solid Waste Association: Geneva, Switzerland, 2020. [Google Scholar]

- Kwarteng, L.; Baiden, E.A.; Fobil, J.; Arko-Mensah, J.; Robins, T.; Batterman, S. Air quality impacts at an E-waste site in Ghana using flexible, moderate-cost and quality-assured measurements. GeoHealth 2020, 4, e2020GH000247. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Liu, R.; Lin, Q.; Ma, S.; Li, G.; Yu, Y.; Zhang, C.; An, T. Volatile organic compounds in an e-waste dismantling region: From spatial-seasonal variation to human health impact. Chemosphere 2021, 275, 130022. [Google Scholar] [CrossRef] [PubMed]

- Bungadaeng, S.; Prueksasit, T.; Siriwong, W. Inhalation exposure to respirable particulate matter among workers in relation to their e-waste open burning activities in Buriram Province, Thailand. Sustain. Environ. Res. 2019, 29, 26. [Google Scholar] [CrossRef]

- Ahirwar, R.; Tripathi, A.K. E-waste management: A review of recycling process, environmental and occupational health hazards, and potential solutions. Environ.Nanotechnol. Monit. Manag. 2021, 15, 100409. [Google Scholar] [CrossRef]

- Lin, S.; Ali, M.U.; Zheng, C.; Cai, Z.; Wong, M.H. Toxic chemicals from uncontrolled e-waste recycling: Exposure, body burden, health impact. J. Hazard. Mater. 2022, 426, 127792. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Achal, V. Environmental and health impacts due to e-waste disposal in China—A review. Sci. Total Environ. 2020, 737, 139745. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Xu, Z. A review of current progress of supercritical fluid technologies for e-waste treatment. J. Clean. Prod. 2019, 227, 794–809. [Google Scholar] [CrossRef]

- Salam, M.; Varma, A. A review on impact of e-waste on soil microbial community and ecosystem function. Pollution 2019, 5, 761–774. [Google Scholar]

- Fang, J.; Zhang, L.; Rao, S.; Zhang, M.; Zhao, K.; Fu, W. Spatial variation of heavy metals and their ecological risk and health risks to local residents in a typical e-waste dismantling area of southeastern China. Environ. Monit. Assess. 2022, 194, 604. [Google Scholar] [CrossRef]

- Preeti, M.; Sayali, A. Scientometric Analysis of Research on End-of-life Electronic Waste and Electric Vehicle Battery Waste. J. Scientometr. Res. 2021, 10, 37–46. [Google Scholar] [CrossRef]

- Akram, R.; Ahmad, A.; Noreen, S.; Hashmi, M.Z.; Sultana, S.R.; Wahid, A.; Mubeen, M.; Zakir, A.; Farooq, A.; Abbas, M. Global trends of e-waste pollution and its impact on environment. In Electronic Waste Pollution; Springer: Berlin/Heidelberg, Germany, 2019; pp. 55–74. [Google Scholar]

- Fischer, D.; Seidu, F.; Yang, J.; Felten, M.K.; Garus, C.; Kraus, T.; Fobil, J.N.; Kaifie, A. Health consequences for e-waste workers and bystanders—A comparative cross-sectional study. Int. J. Environ. Res. Public Health 2020, 17, 1534. [Google Scholar] [CrossRef]

- Parvez, S.M.; Jahan, F.; Brune, M.-N.; Gorman, J.F.; Rahman, M.J.; Carpenter, D.; Islam, Z.; Rahman, M.; Aich, N.; Knibbs, L.D. Health consequences of exposure to e-waste: An updated systematic review. Lancet Planet. Health 2021, 5, e905–e920. [Google Scholar] [CrossRef]

- Maphosa, V.; Maphosa, M.; Tan, A. E-waste management in Sub-Saharan Africa: A systematic literature review. Cogent Bus. Manag. 2020, 7, 1814503. [Google Scholar] [CrossRef]

- Hou, R.; Huo, X.; Zhang, S.; Xu, C.; Huang, Y.; Xu, X. Elevated levels of lead exposure and impact on the anti-inflammatory ability of oral sialic acids among preschool children in e-waste areas. Sci. Total Environ. 2020, 699, 134380. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, V. E-waste: An emerging threat to “one health”. In Environmental Management of Waste Electrical and Electronic Equipment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 49–61. [Google Scholar]

- Rautela, R.; Arya, S.; Vishwakarma, S.; Lee, J.; Kim, K.-H.; Kumar, S. E-waste management and its effects on the environment and human health. Sci. Total Environ. 2021, 773, 145623. [Google Scholar] [CrossRef] [PubMed]

- Tutton, C.G.; Young, S.B.; Habib, K. Pre-processing of e-waste in Canada: Case of a facility responding to changing material composition. Resour. Environ. Sustain. 2022, 9, 100069. [Google Scholar] [CrossRef]

- Cordova-Pizarro, D.; Aguilar-Barajas, I.; Romero, D.; Rodriguez, C.A. Circular economy in the electronic products sector: Material flow analysis and economic impact of cellphone e-waste in Mexico. Sustainability 2019, 11, 1361. [Google Scholar] [CrossRef]

- Ravindra, K.; Mor, S. E-waste generation and management practices in Chandigarh, India and economic evaluation for sustainable recycling. J. Clean. Prod. 2019, 221, 286–294. [Google Scholar] [CrossRef]

- Ilankoon, I.; Ghorbani, Y.; Chong, M.N.; Herath, G.; Moyo, T.; Petersen, J. E-waste in the international context—A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. Waste Manag. 2018, 82, 258–275. [Google Scholar] [CrossRef]

- Ismail, H.; Hanafiah, M.M. A review of sustainable e-waste generation and management: Present and future perspectives. J. Environ. Manag. 2020, 264, 110495. [Google Scholar] [CrossRef]