1. Introduction

Spinning is the lifeblood industry of the textile industry, where the fiber is drawn-out, twisted, and wrapped onto a bobbin by using state-of-the-art twisting techniques. The ring-spinning production process includes opening and cleaning (opening, blending, and cleaning take place in a blow room), carding, pre-combed drawing, lap forming, combing, post-combed drawing, simplex, ring-spinning, and winding. The spinning process is dynamic, implicating multiple discrete workshops, and around more than 80 production pieces of equipment are used during it. The spindle’s speed when spinning can reach up to 25,000 r/min and the spindle is the leading apparatus of these extremely sophisticated systems. Though these smart, or intelligent systems, are relatively efficient, they also suffer from various problems; particularly in the draw-out workshop, manual handling can distribution has a large number of demanding tasks, and there is a long turnover period in semi-finished products.

Recent years have seen an increase in the amount of the flow-shops with identical counterpart machines, like those in the spinning industry, that have gone through upgrades towards becoming intelligent automation industries from labor-intense sectors [

1]. As discussed in [

2], a smart spinning system is a system that contains multiple computing elements (sensors and actuators) and a processing unit, all managed by restraining the data. Based on flow of information, the data are pre-processed and a command is sent to the actuator to perform a pre-programmed action that can detect changes in their surroundings and react to them to produce a practical outcome. Scheduling is inevitable in these smart spinning cyber–physical production systems (CPPS). Due to their strong computational, analytical, and processing capabilities, intelligent mechatronic systems like automated guided vehicles (AGVs) are vital to assure stability and competence [

3]. These smart transport systems equipped with radio waves, vision cameras, magnets, or lasers for navigation (automatic guiding devices) that can walk-along a preset guidance path to complete a series of horizontal transport operations. An approach developed in [

4] at a particular changing state of moving vehicles and production equipment had the feature of processing multiple semi-finished products at the same time within the premises of production logistics. A distributed method of discrete-event simulation for highly distributed manufacturing systems was discussed in [

5]. The required time to complete work orders, the amount of energy used to transport the loads, and the utilization of work stations are the highest performance standards for AGV material handling systems [

6,

7], all of which are widely used to relocate material in modern, flexible manufacturing systems [

8] and which affect the effectiveness of manufacturing processes by enhancing their efficiency. Though the benefits of allowing for AGV job preemptions can be significant, few studies have considered pre-emptive scheduling in the context of flow-shop predictive modeling. For example, in [

9,

10], AGV dispatching and cooperative waterborne AGVs prediction models were addressed, and a class of precedence constraints was proposed.

Various literature reviews have been proposed during the last decade about the impact of AGVs in smart industries. AGVs have economic, environmental, and technical advantages. They also come with three main problems: AGV scheduling, AGV path planning, and AGV control system implementation [

11,

12,

13]. AGVs scheduling of a more flexible, modular, and intelligent manufacturing system does not require much time and budget for initial installation. Stetter et al. developed a virtual diagnostic sensor design for production tasks to solve the problem of task scheduling and coordination control by an AGV system [

14]. A concise overview of guide-path design, estimating the number of locations and parking, pickup, and delivery points that considered the number of required vehicles was given by Małopolski [

15], and a fault control strategy was given by Witczak [

16]. There have been fewer scholarly studies on the battery management of AGVs to obtain more productive hours and increase the flexibility of manufacturing systems—still, an effort was made by Kabir et al. in this regard [

17]. A cooperative AGV-based production system depends on its efficiency, effectiveness, availability, and reliability by predicting AGV-battery remaining useful life (RUL) [

18,

19,

20]. CPPS-based investigations and solutions, i.e., the bottleneck of supply chain management for material handling and production manufacturing, have been presented for complex material flows [

21,

22,

23,

24]. When answering this problem, one must cope with difficulties connected with flow-shop scheduling, as well as those imposed by the resource constraints that must be satisfied in the whole system at every moment [

25,

26,

27].

This work was inspired to resolve the confronting problems of scheduling in real-time can distribution and path planning in the continuous production of spinning by using a mixed flow-shop predictive modeling method. The related problems are as follows: (a) How to solve a general problem of AGV scheduling and path planning to prevent conflict and deadlock in parallel machines flow-shop? How does a spinning CPPS deal with scheduling tasks in mass production? Additionally, how to deploy AGVs to work together to process real-time tasks?

The main contributions of this paper are as follows:

To effectively reduce the makespans and total completion time. To the best of our knowledge, this is the first time a novel approach that handles both cross-region shared resource and inter-regional independent resource pools.

Based on the intended categories of scheduling tasks, an AGV transportation route strategy is developed for mass production in spinning CPPS.

A mathematical model for real-time task processing for dissimilar cotton and polyester processing in multi-AGV scheduling is designed to prevent conflict and deadlock by assigning different tasks: AGV assignments, AGV sorting, and task sources.

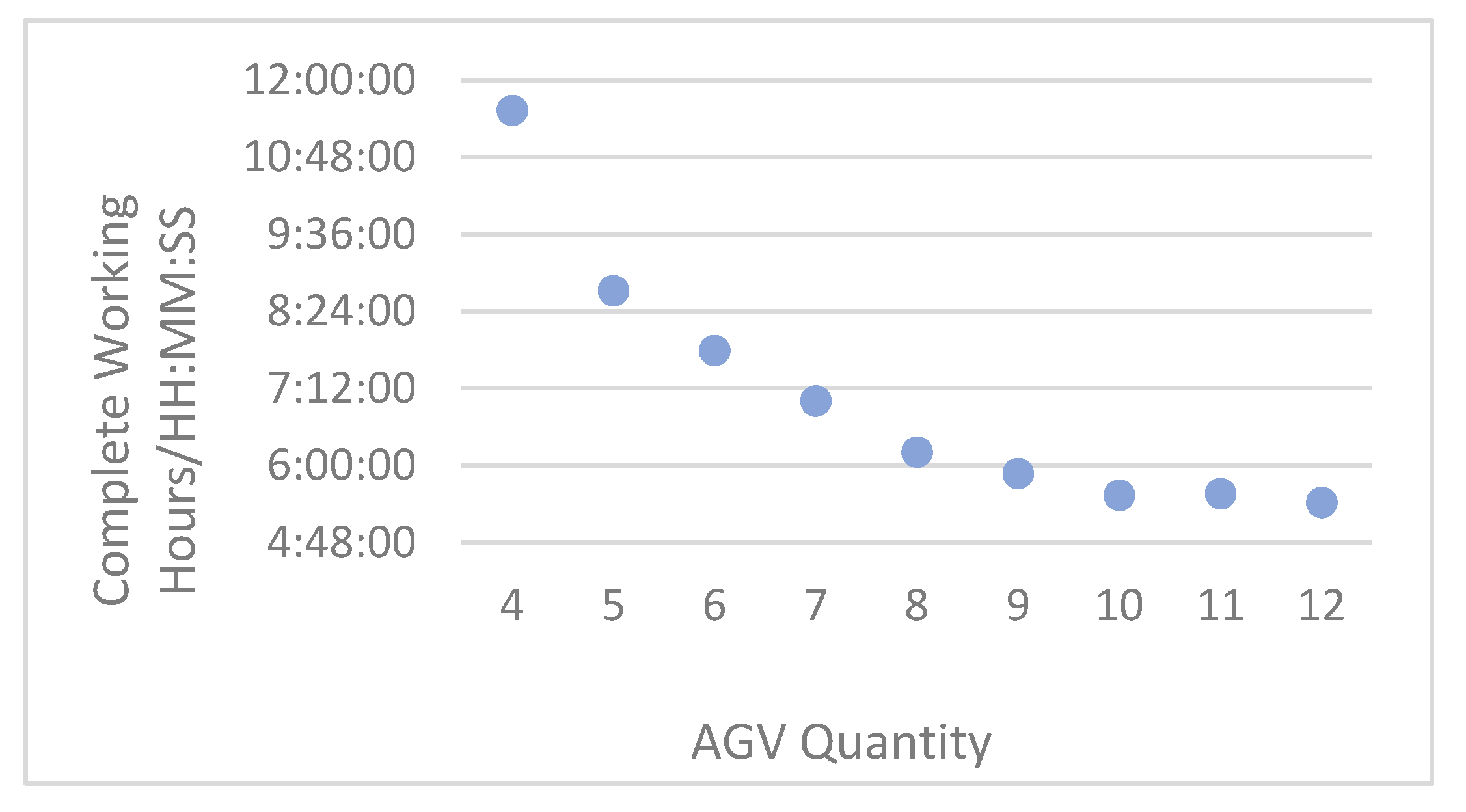

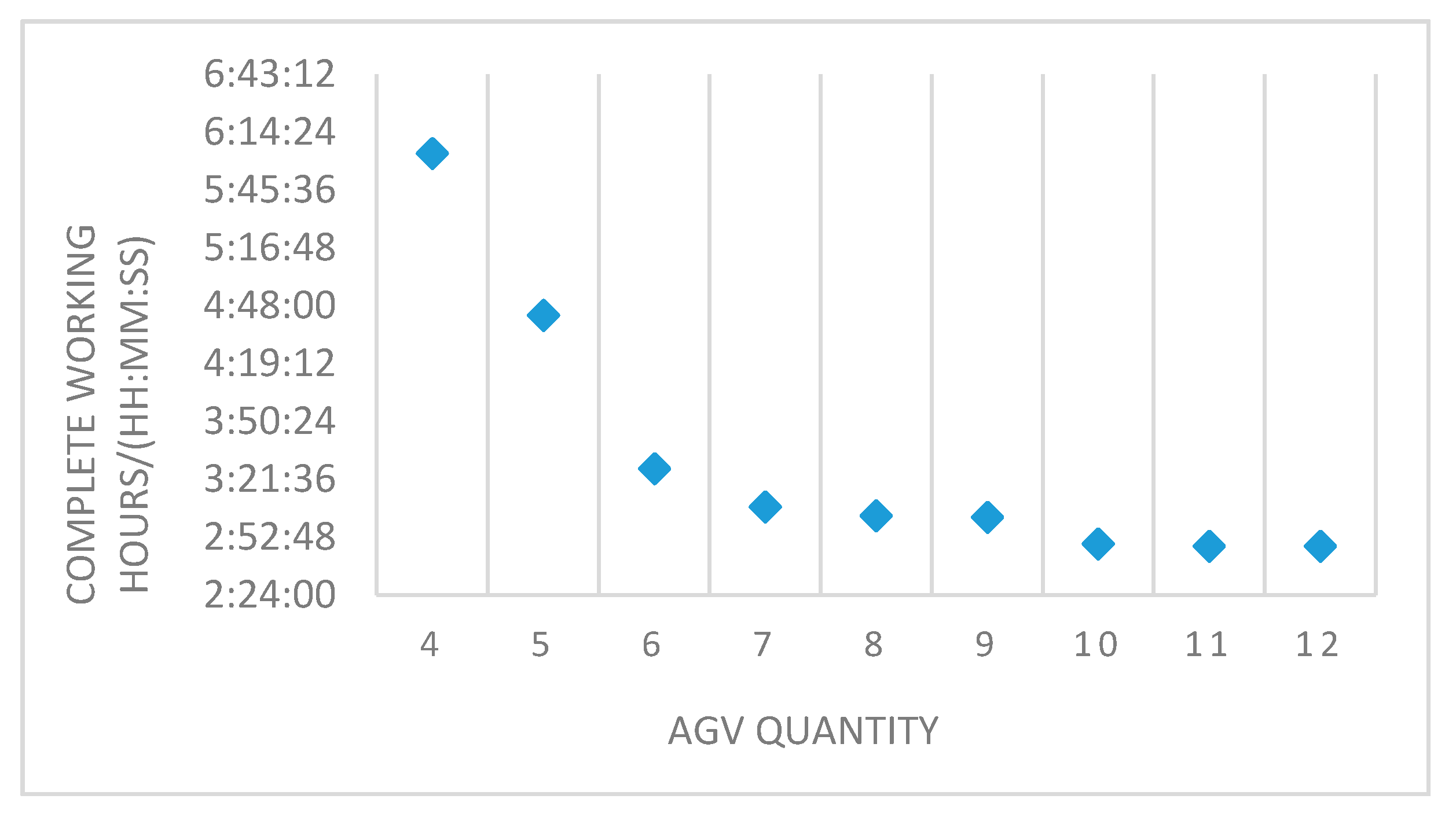

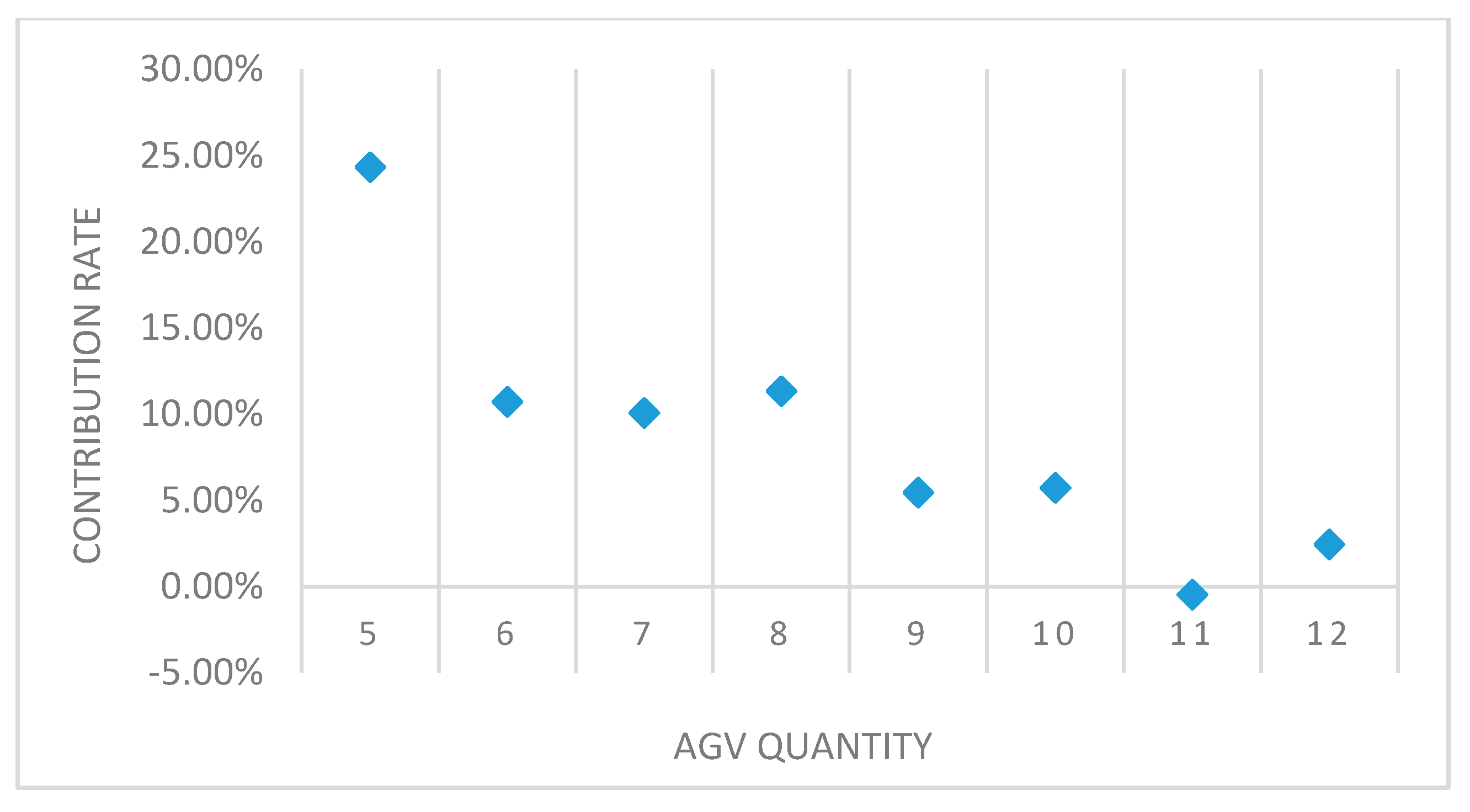

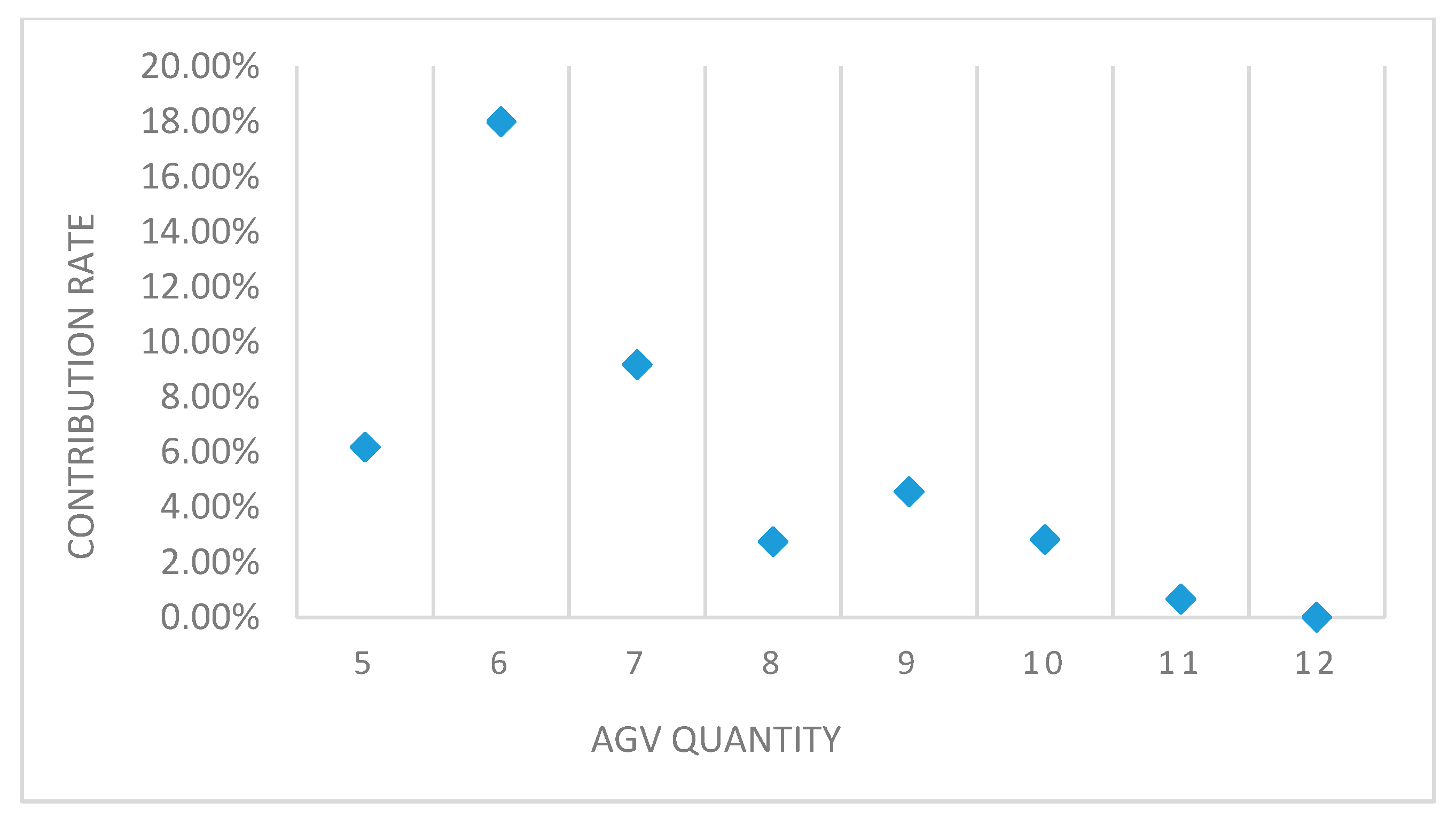

Our results demonstrate the adequacy of the presented methods when the number of AGVs intensifies to a certain extent, as increasing the of number AGVs decreased the completion time drop sharply, which reduces the AGV utilization.

The paper is organized as follows:

Section 2 imparts a comprehensive background of the analysis of the production process of the spinning workshop, a mathematical model of multi-AGV scheduling, model assumptions, object function, and the uniqueness constraint.

Section 3 concentrates on the explanation of the multi-AGV scheduling simulation modeling, simulation model construction, and the AGV resource pool strategy-based bottleneck analysis.

Section 4 emphasizes the results by doing a comparative study of two AGV resource pool strategies and a comprehensive analysis of multi-AGV scheduling in the process flow. Finally, conclusions are summarized in

Section 5.

2. Analysis of the Production Process of the Spinning Workshop

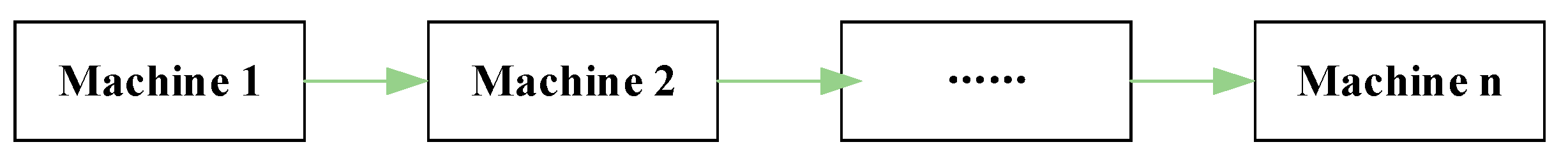

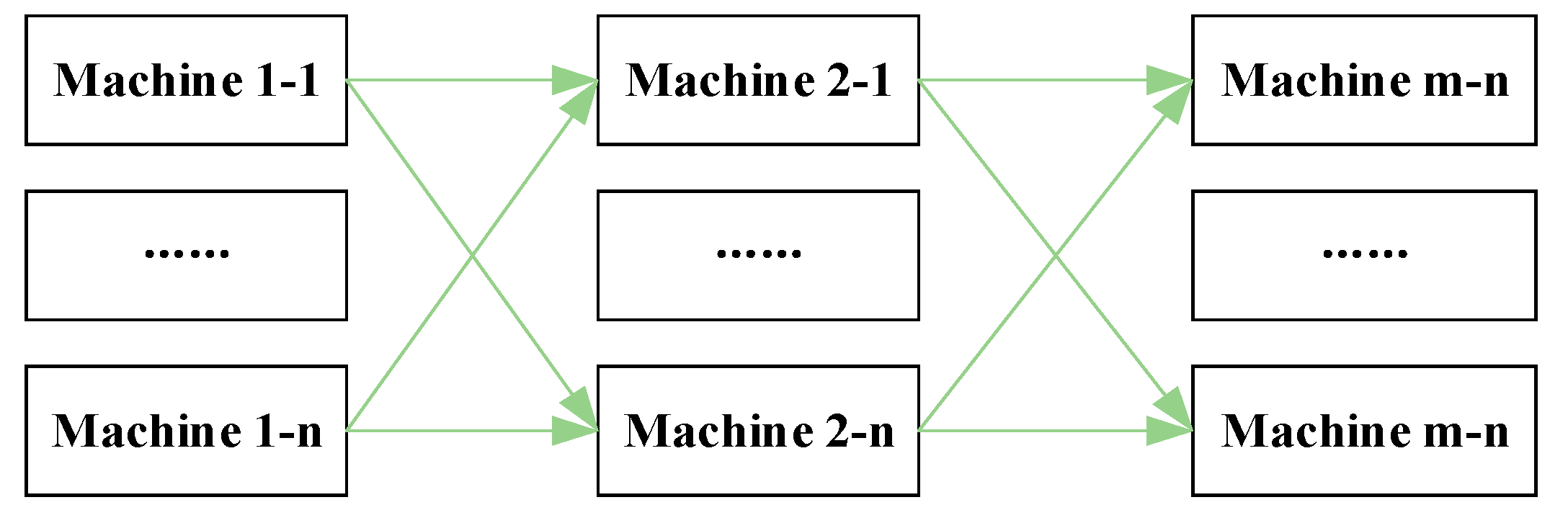

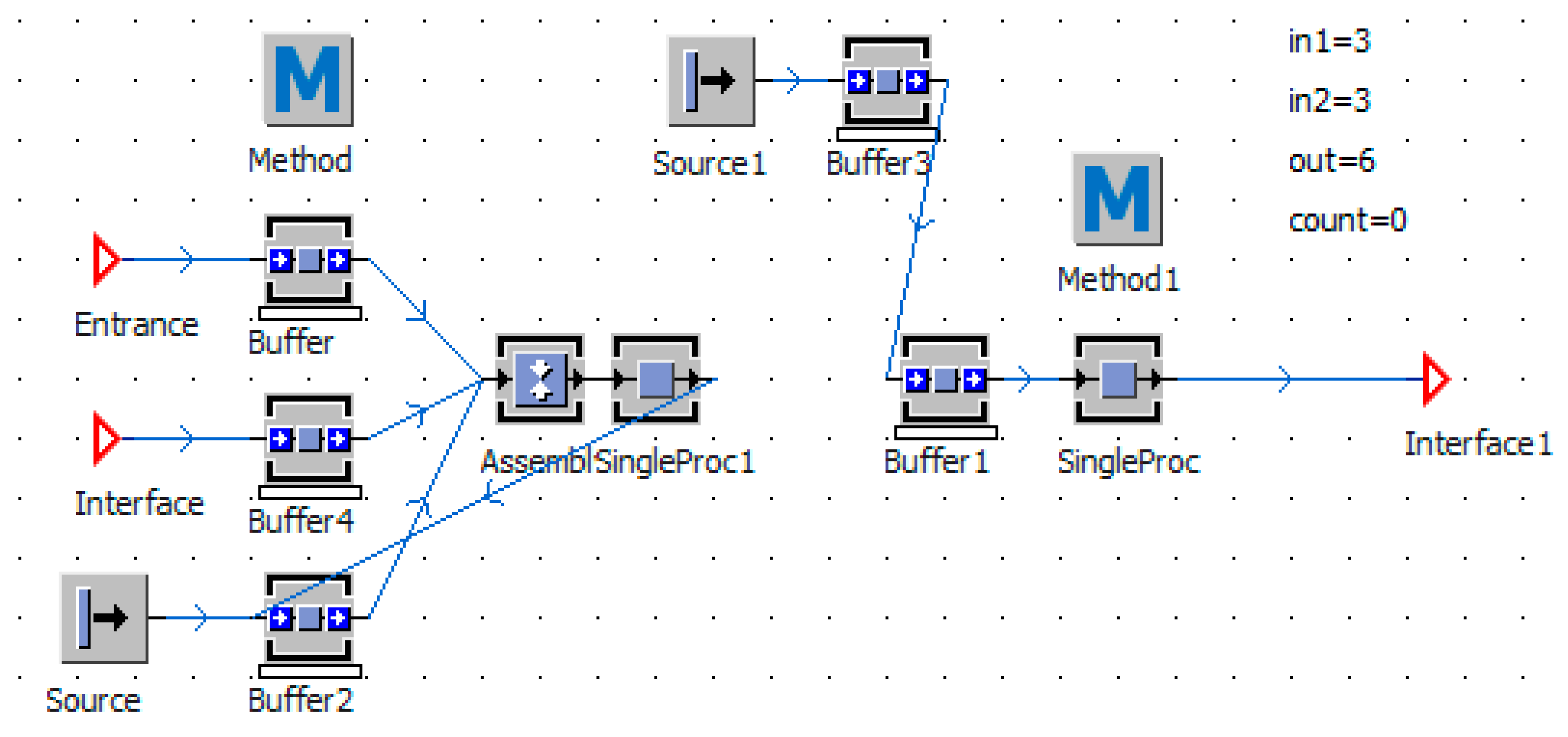

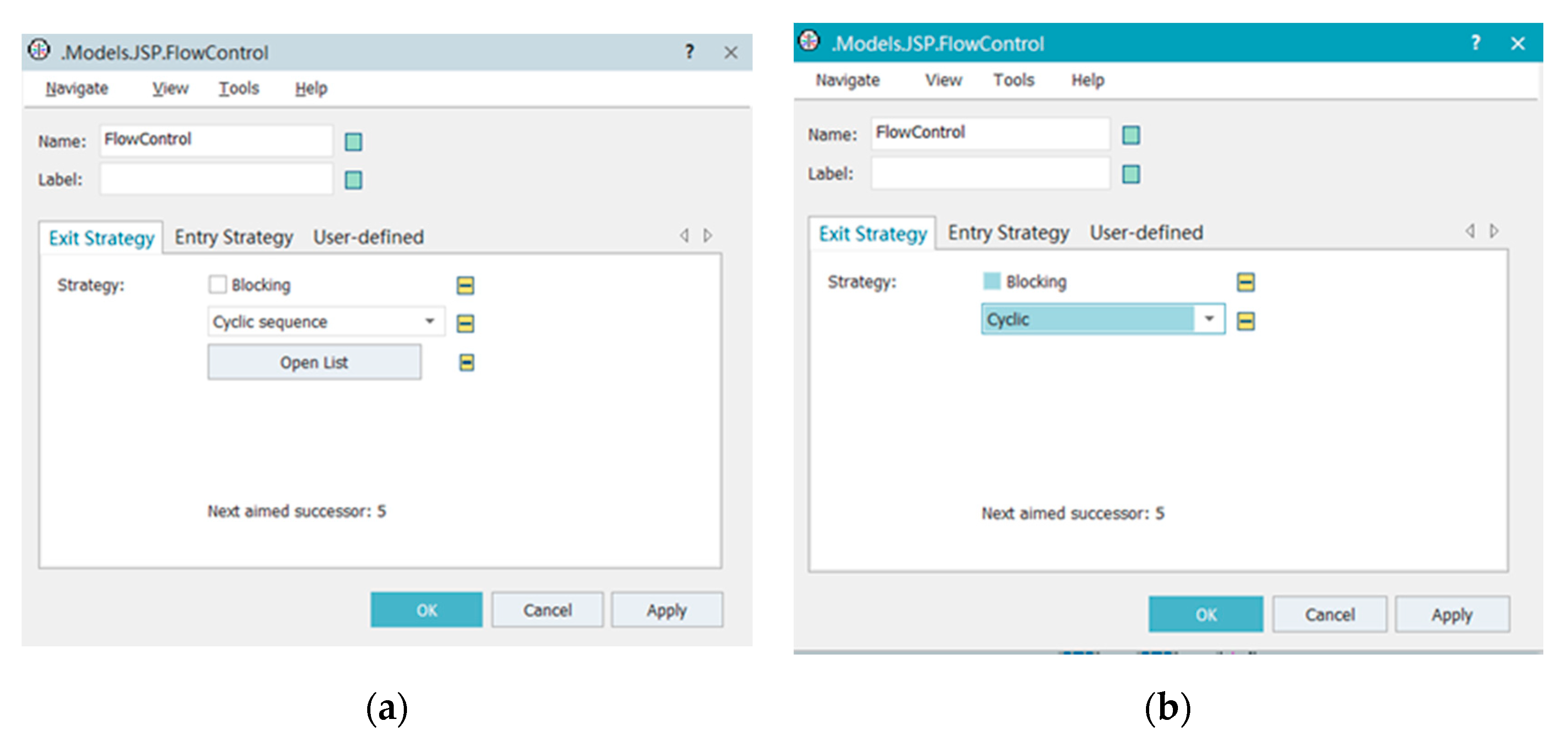

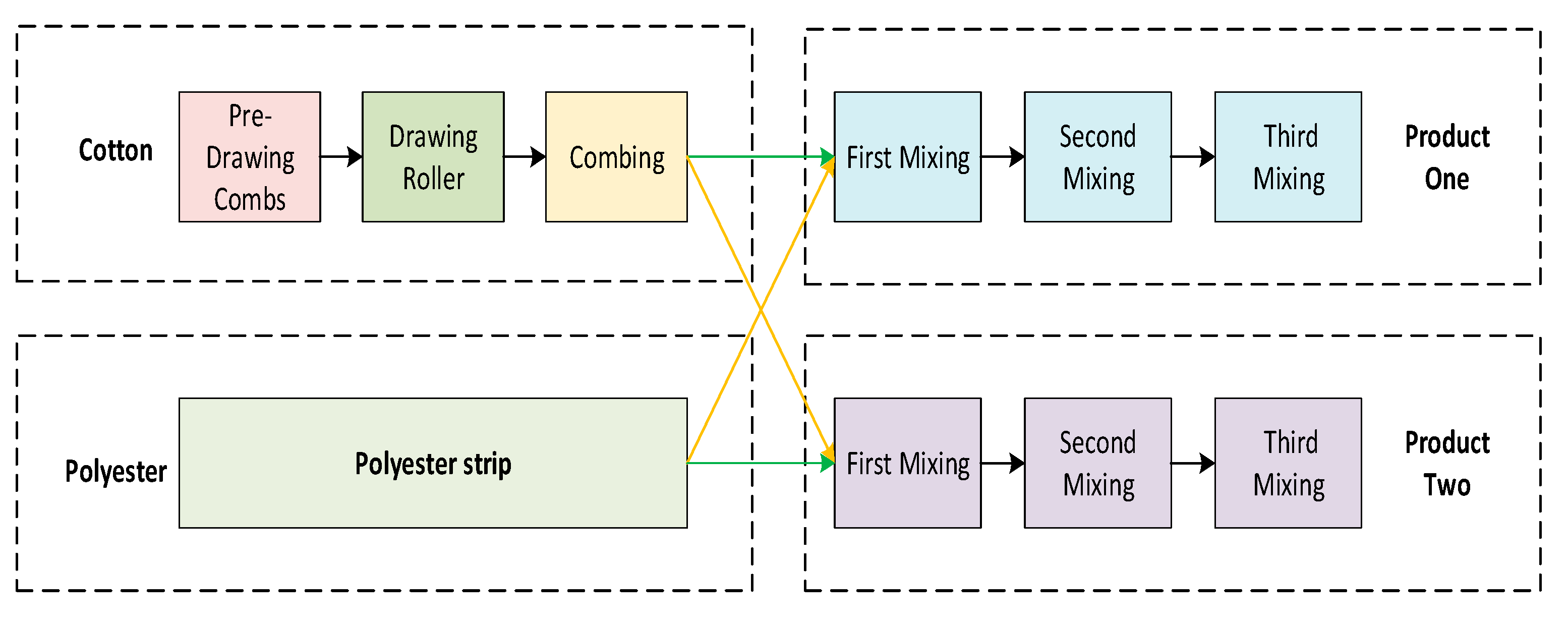

We tried to examine previously-discussed drawing shops to improve our earlier presented approach in two key areas: First, the series structure, where the raw materials for each process only depend on one process and the same processed products used for another process, is shown in

Figure 1. The second parallel structure, in which the raw material of each procedure depends on multiple processes or the product of one process used as the raw material of other various processes, is shown in

Figure 2.

A traditional draw shop has a low-level of automation, and semi-finished products in various processes mainly rely on manual transportation. On the other hand, the efficiency of manual handling is poor, and it cannot meet the demand for rapid response, which has become a bottleneck for speeding up production lines, which causes higher labor costs and a more significant workload for employees, thus resulting in insufficient production. The usage of an AGV instead of manual handling between traditional production processes can effectively improve the automation level of a workshop [

28,

29,

30]. By relying on information technology to enhance the accurate response capabilities of an AGV, it can achieve precisely guided tasks such as advanced stocking and rapid shipment, which avoid the traditional experience of employees [

31,

32]. The ability to rely on AGVs can effectively improve the production efficiency of a workshop.

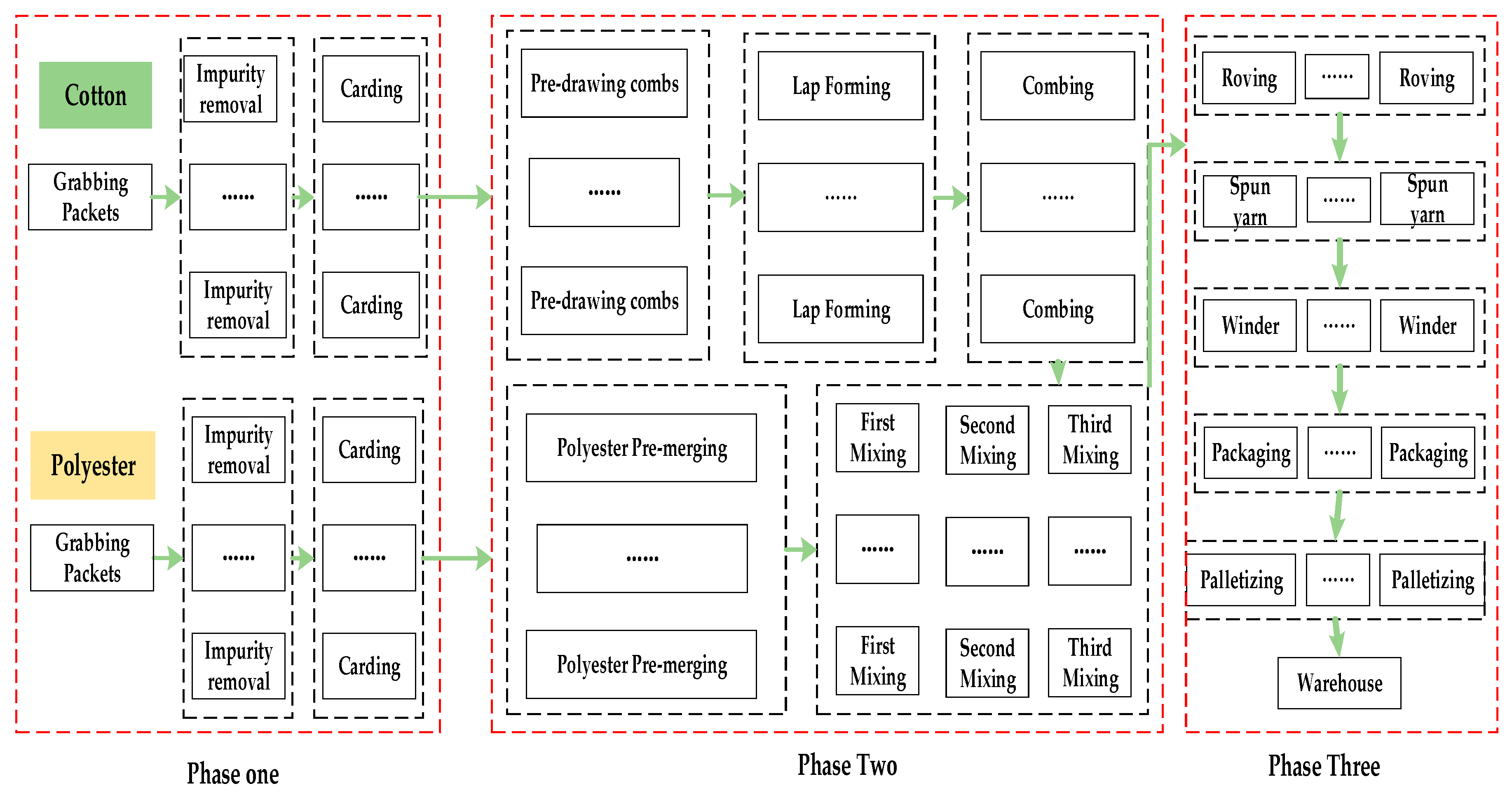

A spinning workshop is a mixed-flow workshop. A typical production line contains multiple operational processes that involve various workshops. The corresponding process sequence must be satisfied with numerous methods. Therefore, a spinning workshop is regarded as a multi-stage parallel production assembly-line system.

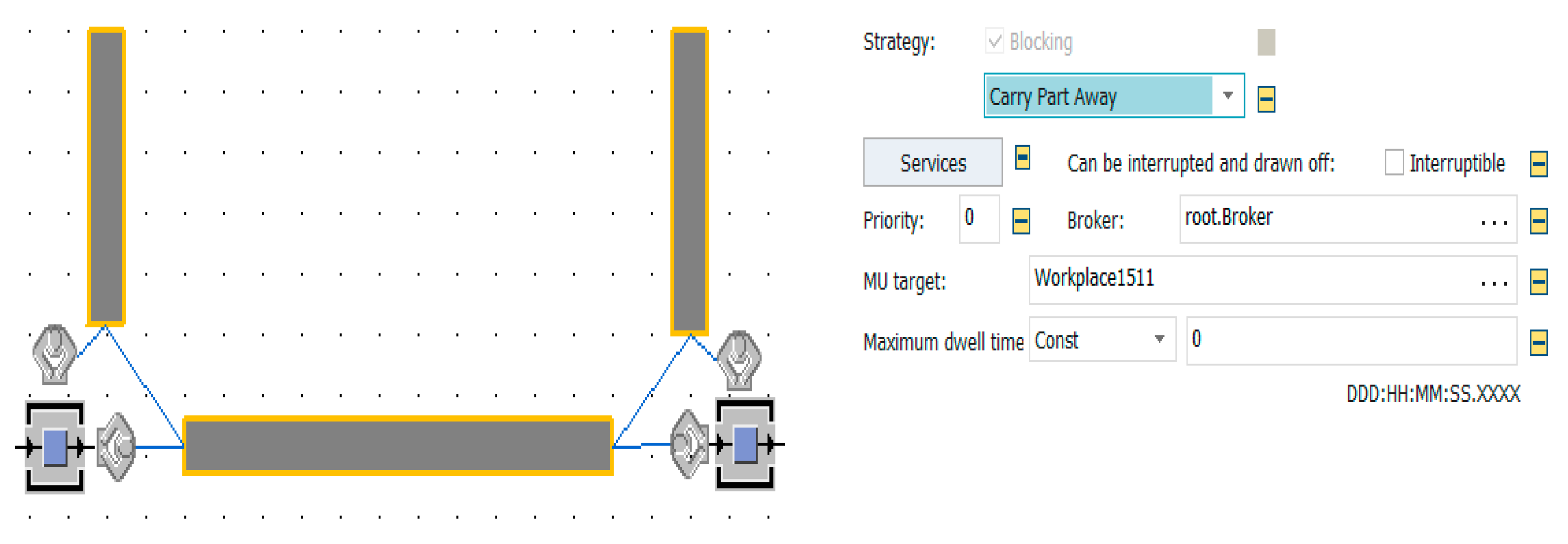

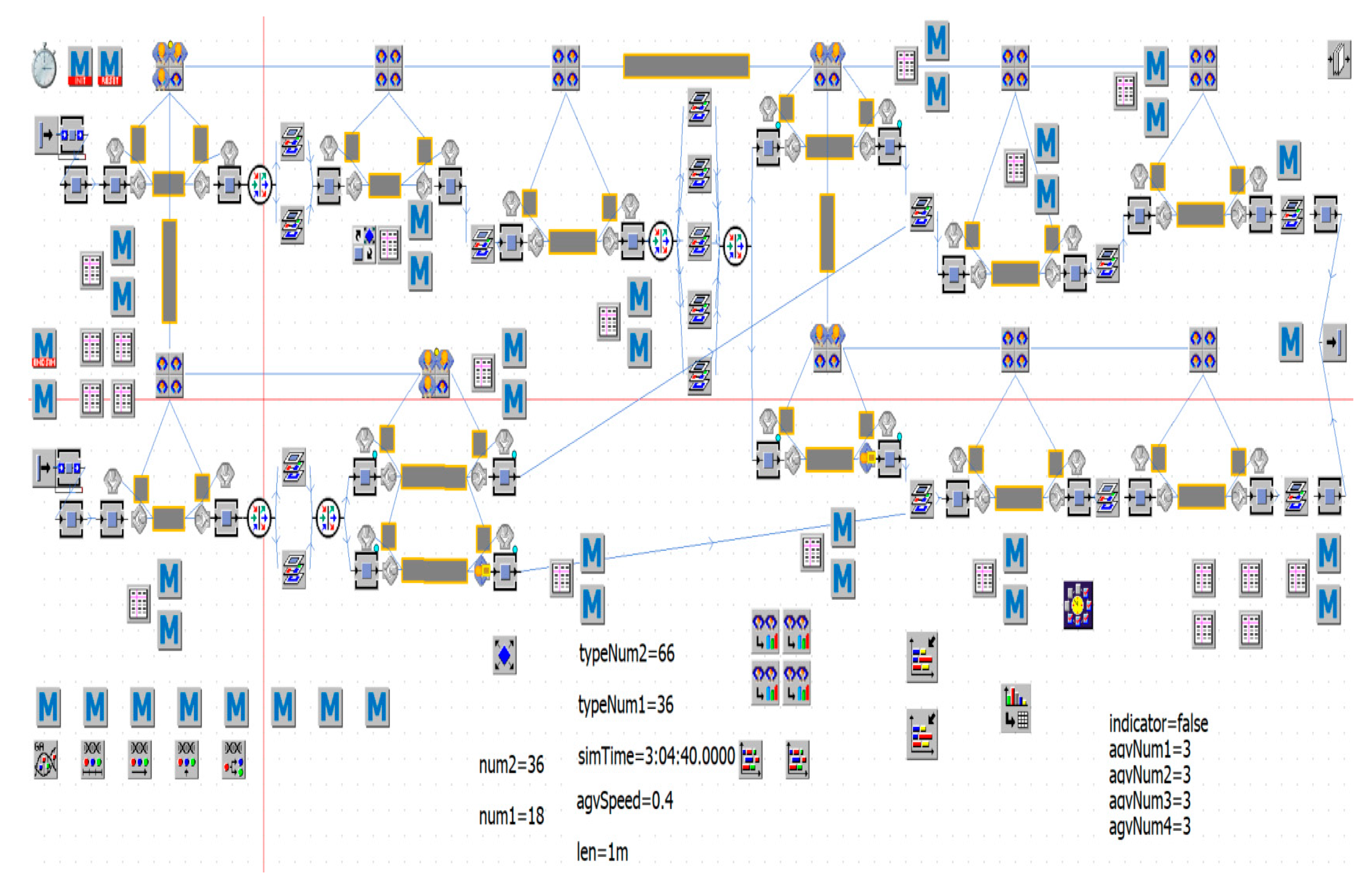

Figure 3 illustrates the ring-spinning production process of a spinning workshop, the first stage explains the opening and cleaning of the cotton bales and then the carding, mainly to remove impurities from cotton or polyester and to produce strip-shaped semi-finished products. The second stage is primarily to pre-draw and to draw after carding. The density of cotton or polyester is not uniform. Pre-drawing and drawing further mix the raw materials evenly, and mixing the two raw materials of cotton and polyester produces semi-finished products with different ratios. Phase 3 is thickness and thinness, and the purpose of it is further processing that makes the final products ready for the customer’s demands according to the desired radius size. It can be observed from the figure that each stage in the flow-process includes multiple processes, each process performed by one machine or numerous identical machines, and each process relies on semi-finished products of one or more operations as raw materials. The mixing process in a spinning and drawing workshop uses cotton slivers produced in the combing process and polyester slivers produced in the polyester process as the raw materials. In contrast, the mixing process uses the products from the first process as raw materials. This article mainly studies the two-stage workshop in the production stage. For convenience, it is called the drawing-out flow-shop.

2.1. Mathematical Model of Multi-AGV Scheduling

2.1.1. Processing Equipment Definition

Multiple parallel processes at the same level represent multiple production lines of different semi-finished products, and a production line of semi-finished products is composed of multiple serial processes. Keep in mind that the workshop has level operations, is the number of product lines under the -level operations, and represents the number of continuing operations of the z-product line. Under each process, there are identical pieces of processing equipment for processing, and denotes the machine that executes the process . Each piece of processing equipment has different attributes: in addition to the production efficiency of the processing equipment, there is the production time per unit of product, the type and quantity of raw material required for processing, the batch produced the number of products processed in one batch, starting processing time, and processing completion time. Among these, the production efficiency of the equipment, the type and quantity of raw materials, and the number of products obtained in one processing are the input of the model, and the other variables are the amounts of decisions.

2.1.2. Raw Material and Product Definition

Considering the particularity of assembly line production, the processing raw material of one device is a semi-finished product produced by another device, so the total number of products are represented by ; is the process required for the process processing, indicating the process comes from the raw material of the process; represents the total number of finished products processed by the process ; and represents the finished product of the process .

In addition to the initial raw materials of the assembly line, all raw materials contain two attributes: one is the processing completion time of the process, and is the transportation cut-off time of the process. The state of the material after the start of processing becomes the product status; therefore, one does not need to consider the initial processing properties of the material.

2.1.3. AGV Definition

Considering that there are identical AGVs in a spinning draw frame, each AGV transports between any two machines, and the transportation time depends on the actual physical distance and road conditions between the two machines.

An AGV car has two walking states in its scheduling system. One is without-load when the car receives a transportation task and it needs to travel from the current position to the starting position of the transport task without-load. The car is currently in the initial position of transportation without-load, and the distance covered by it is 0. The second is with-load, that is, the trolley runs from the initial position of the transportation task to the end position of the transportation task. Each AGV contains different attributes, including with-load start time, without-load end time, the without-load starting point for a transport task, load start time, load end time, load line for a transport task, and specific raw materials for means of transport.

2.1.4. Overall Variable Definition

Table 1 shows that the process

for each machine must start processing after collecting the number of raw materials, that is, the process

must collect all the required raw materials before it can be processed once, and this is recorded as a processing batch. When

, it is the first sub-process of each level process. The raw materials of this sub-process may depend on a variety of semi-finished products of the previous level process where

; when

, it means that it depends on the same level. The semi-finished products of the same product line in the process are used as raw materials, and, at this time,

,

, and

.

Table 2 shows the definition of time decision variables:

2.2. Model Assumptions

2.2.1. Processing Equipment and Processing Assumptions

There is only one product per piece of processing equipment, considering that some machines process different proportions of raw materials to produce various products. This article defines them as separate machines, i.e., each machine is set to handle one type of product. In an actual environment, the parameters of a machine are different when producing different products. During the production process of an assembly line, the machine does not automatically adjust settings.

The processing equipment responsible for the same process has the same processing performance.

2.2.2. AGV Transportation Route Assumptions

The transportation efficiency of each AGV cart is the same, and the speed remains the same during transportation [

33].

The capacity of each AGV can only transport unit quantities of raw materials, and the mass and volume of each unit of raw materials does not exceed the AGVs rated load.

There is sufficient avoidance space at intersections and around the equipment, and the AGV avoidance passage time is negligible.

AGV loading and unloading time are included in the transportation time.

The vehicle has no faults during transportation [

34,

35].

The model only considers the process that requires AGV transportation and simplifies the process that does not require AGV transportation. The first-stage process is the first-stage process that requires an AGV to participate in shipping, and the last-stage process is what happens subsequently.

2.3. Object Function

In this study, the AGV scheduling plan with the highest production efficiency in the drawing shop was studied. The objective function was to minimize the time required for the drawing shop to complete all finished products, i.e., to reduce the maximum completion time. Here, Equation (1) defines U as the complete set.

2.4. Uniqueness Constraint

Unique constraints include those on processing materials, production equipment, and the AGV.

2.4.1. Raw-Material Processing Uniqueness

Each processing raw material corresponds one-to-one with the process, batch, and production equipment. In this case, only the goods to be transported by the AGV cart can be determined to determine the transport route of the cart and a set that restricts one batch under one process on one machine. Equation (2) defines the input raw materials of a specified process that can only be attributed to one batch under the procedure for processing. Equation (3) represents the constraint on the batch to which raw materials belong in the first step of each stage of the production line. Equation (4) indicates that the batch belongs to the raw material constraint in other levels of each stage of the production line. The products of a specified process can only be produced by a batch under this process, as shown in Equation (5).

2.4.2. AGV Uniqueness Constraint

Raw material j is transported only in one AGV transportation process, as shown in Equations (6) and (7). Since the first process of each stage of the production line is different from other means, the situation of

p is discussed separately in Equations (6) and (7).

2.4.3. Unique Constraints of Production Equipment

Concerning the limitation on processing equipment, a machine processes only one raw material at a time, and this constraint is determined by the attributes of the processing equipment for different processes in the drawing shop, as shown in Equations (8) and (9). When

p = 1, the raw materials for machining may come from different production lines. When

p > 1, the raw materials for machining come from the same production line. Additionally, one machine can only produce one product at a time. Equation (10) defines the processing equipment of the same process that provides the same number of products in one operation, and the number of products produced by the processing equipment of different methods is not necessarily the same.

5. Conclusions and Future Work

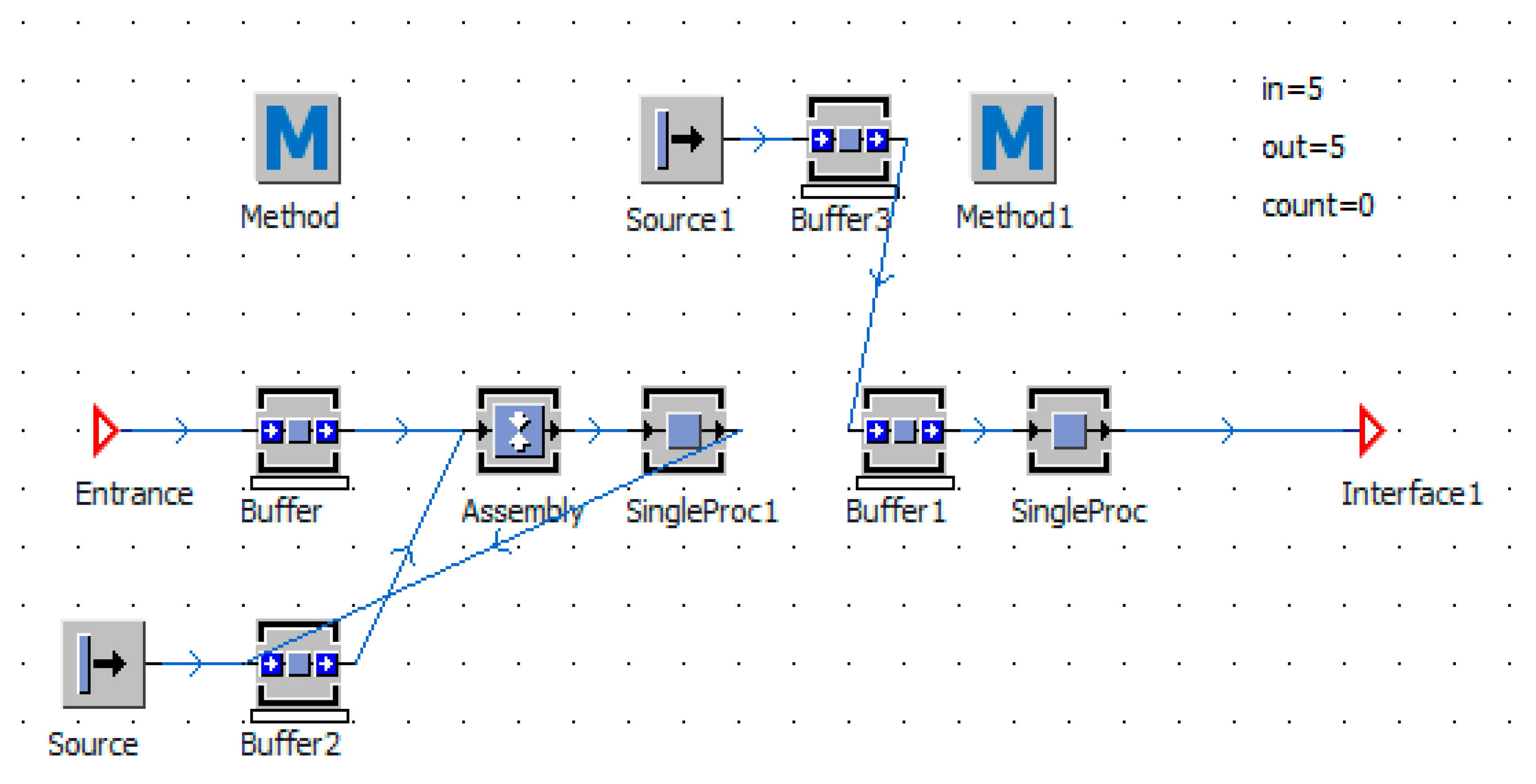

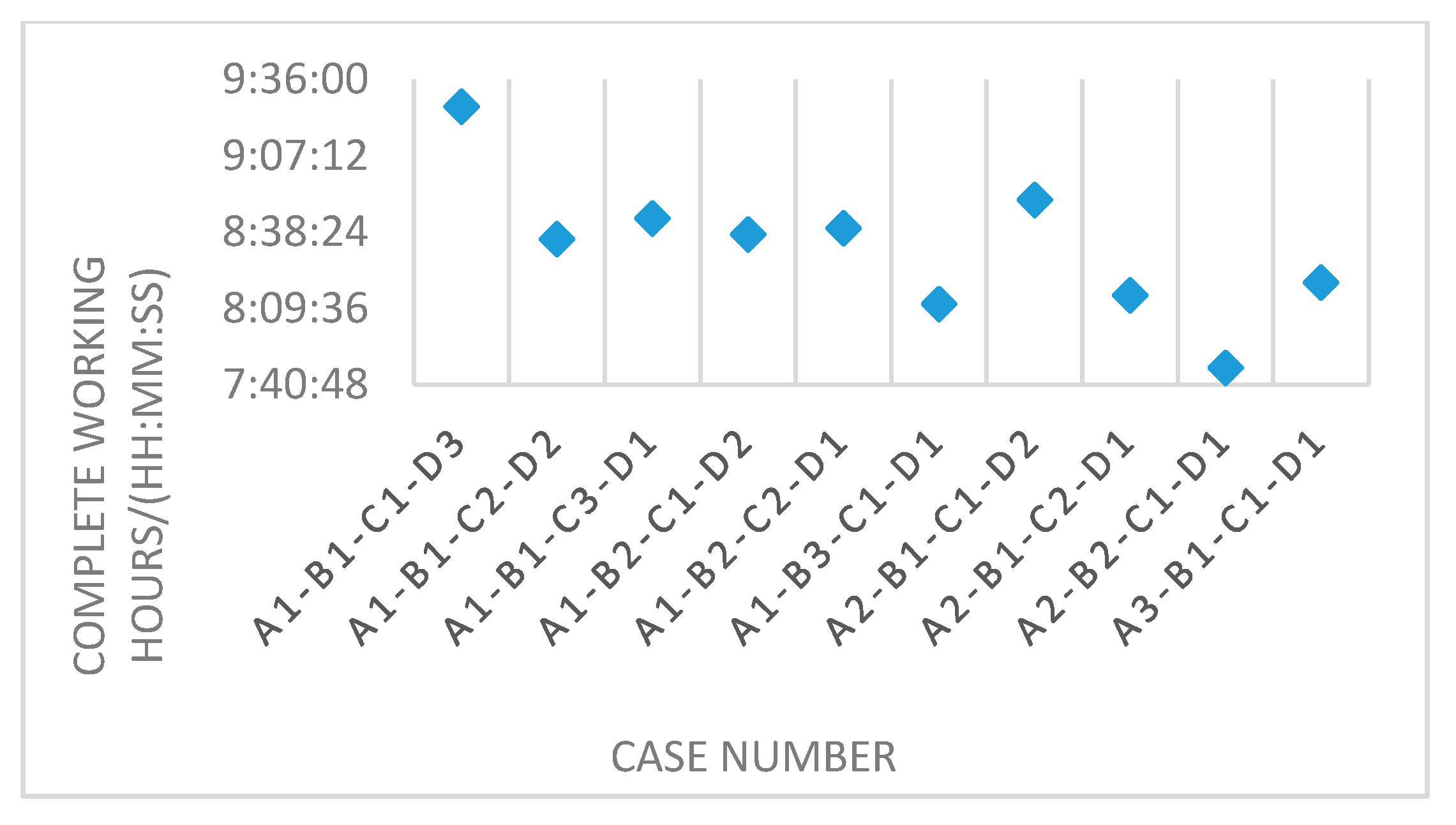

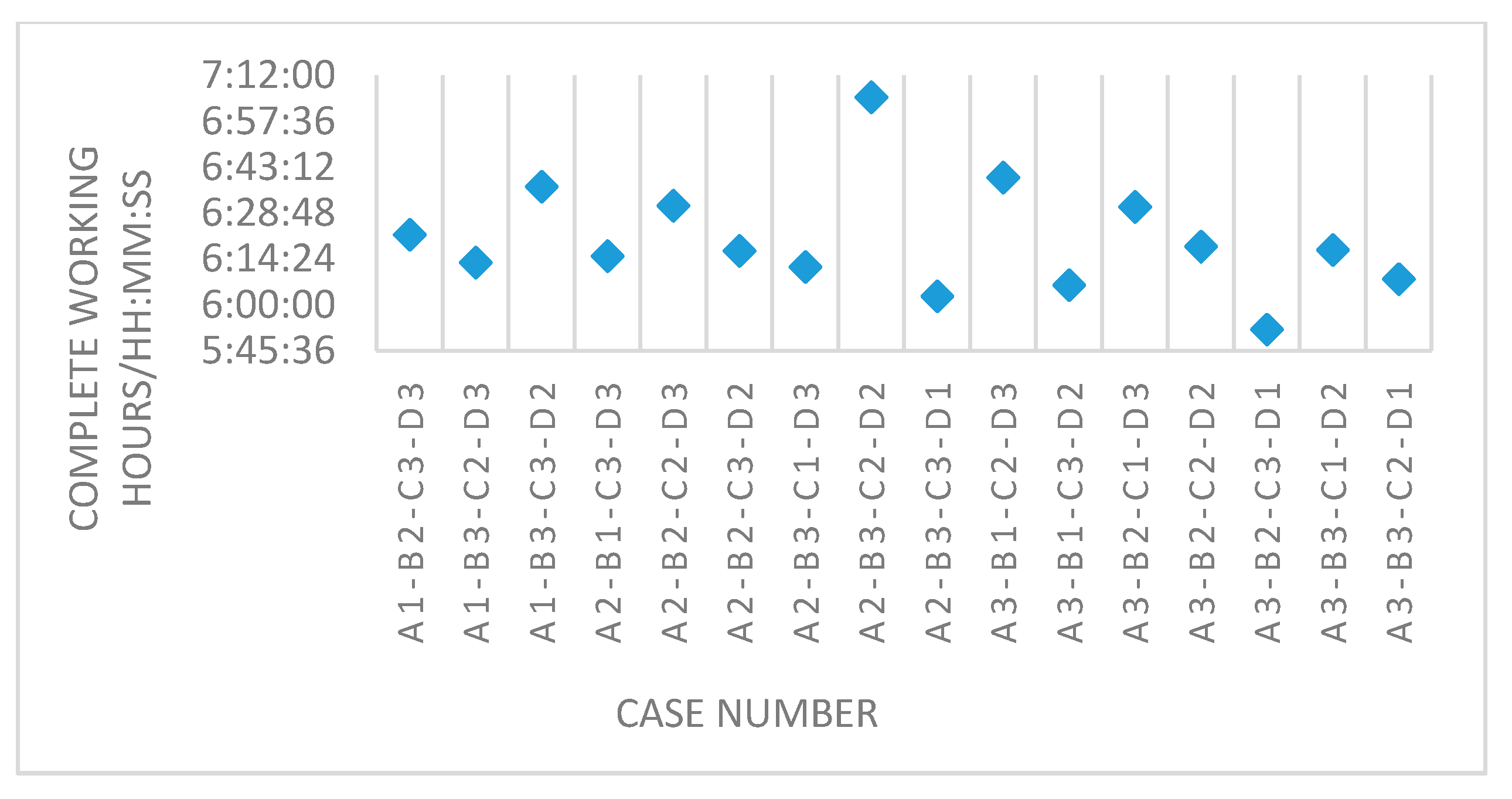

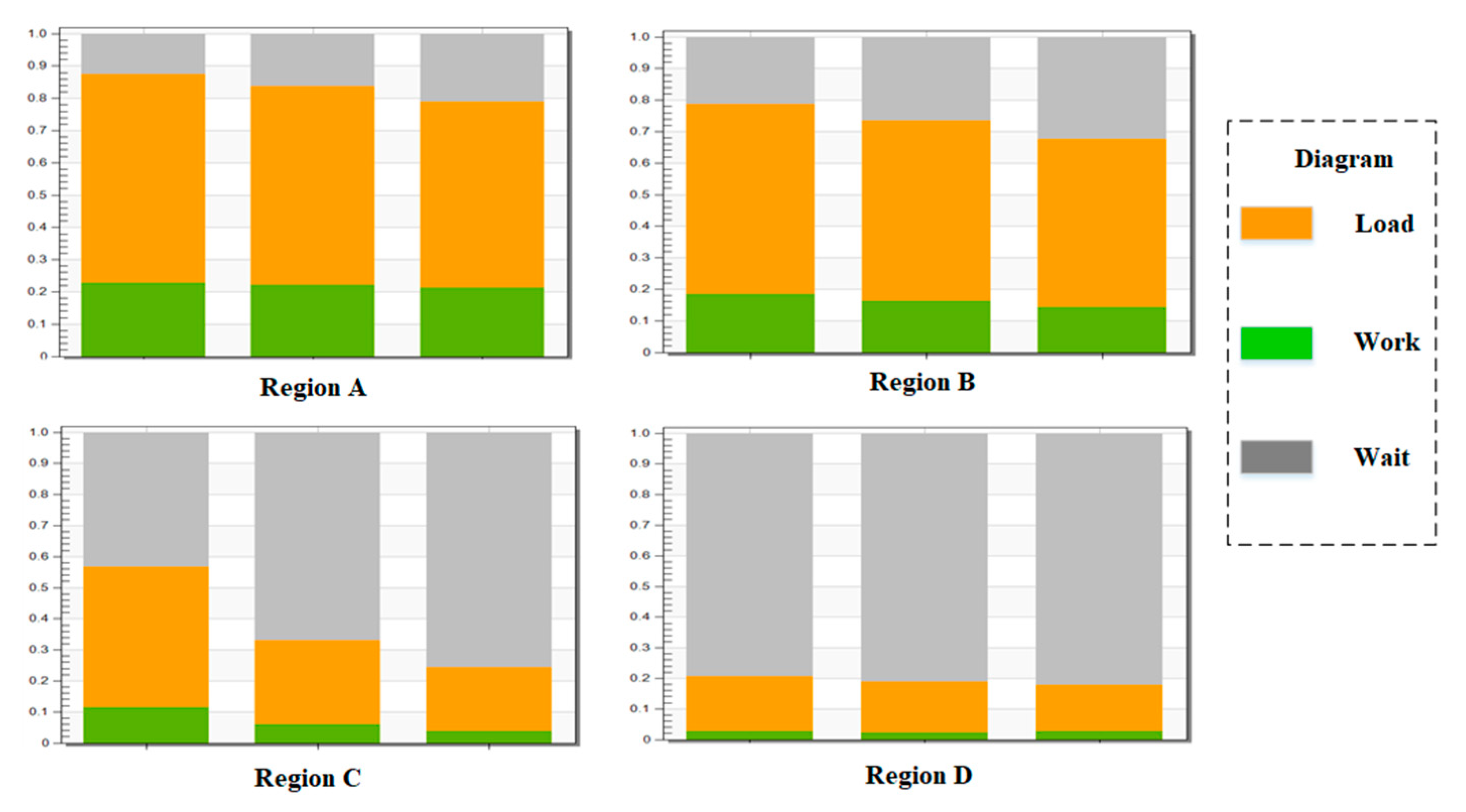

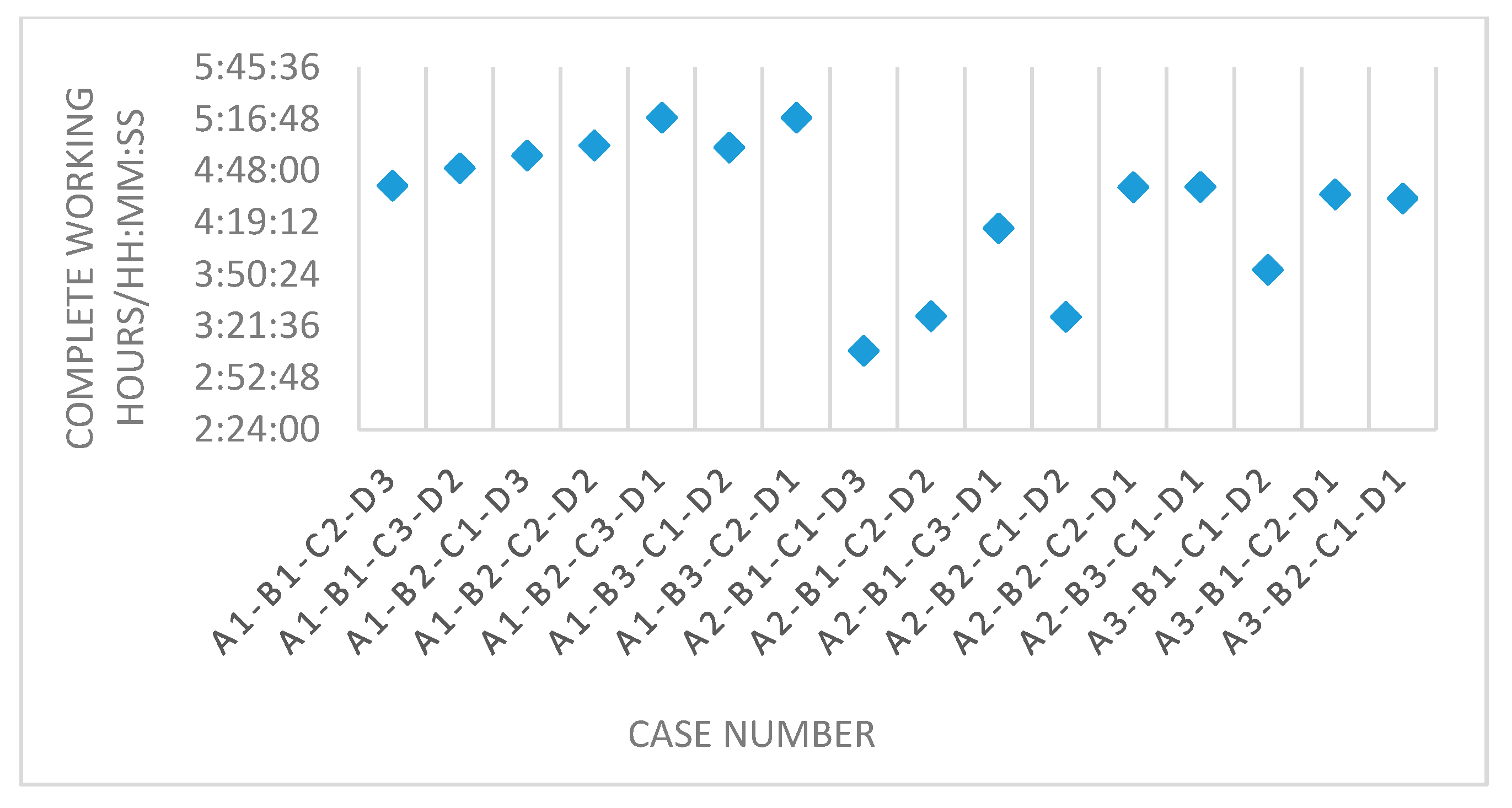

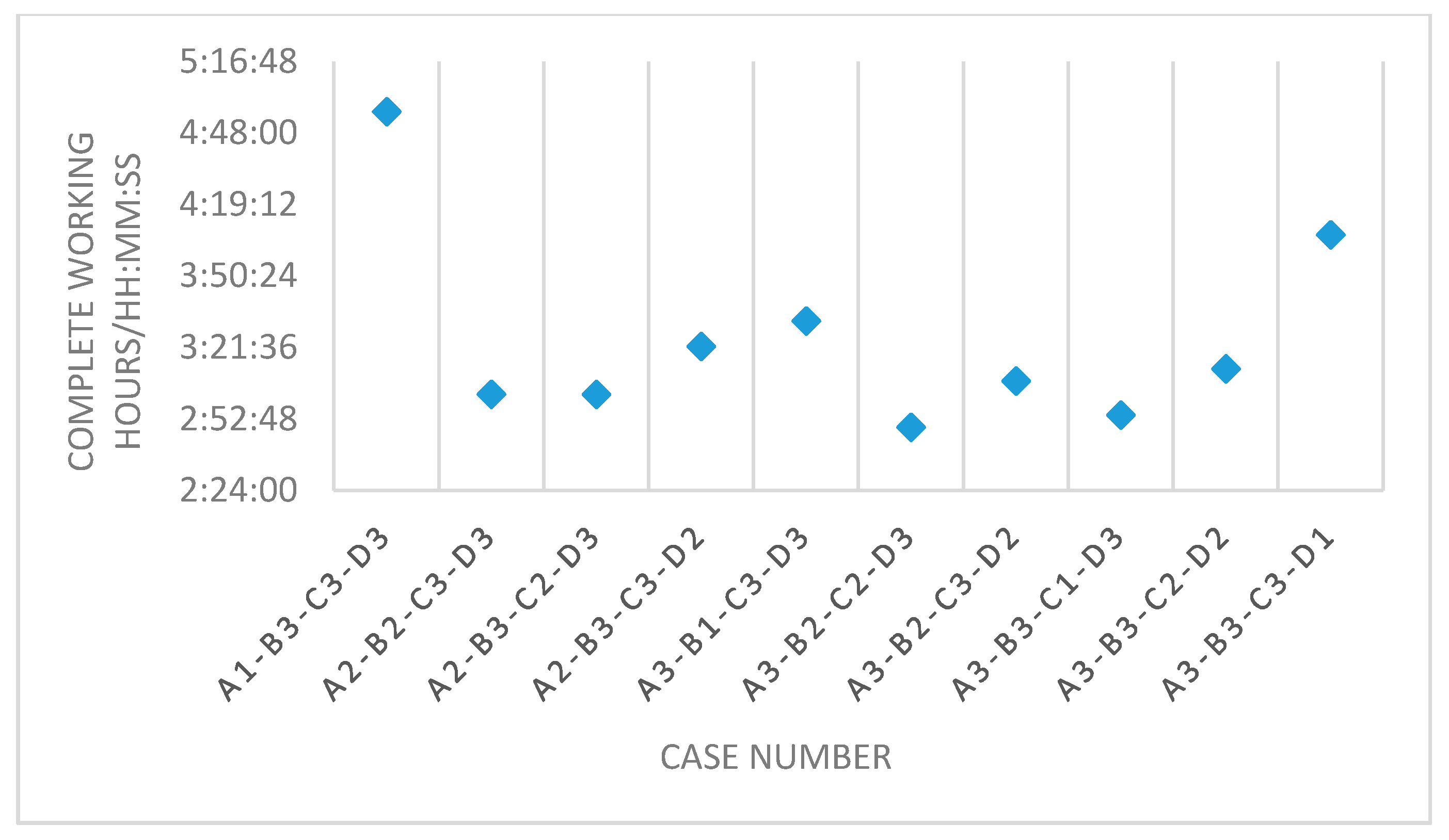

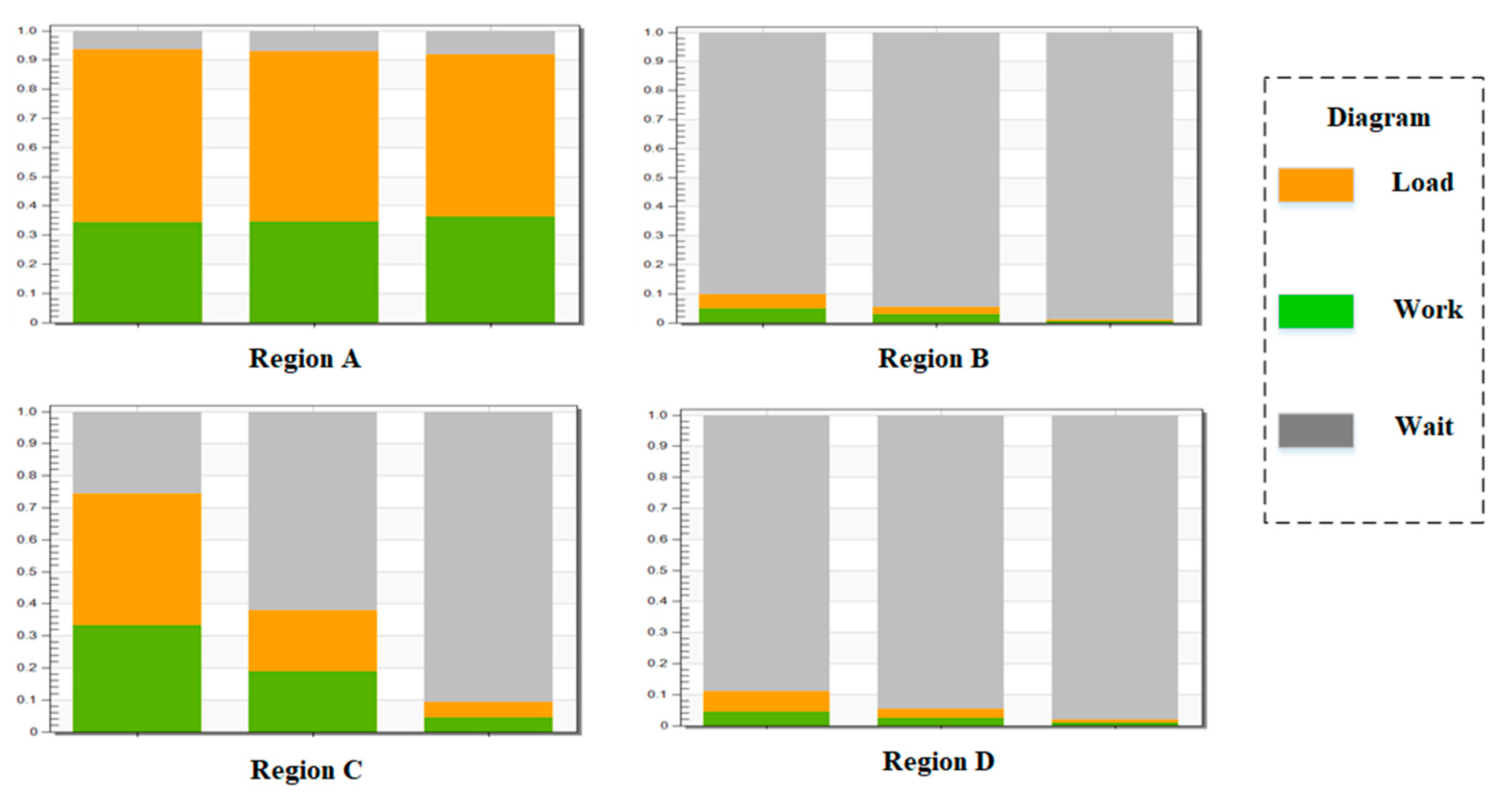

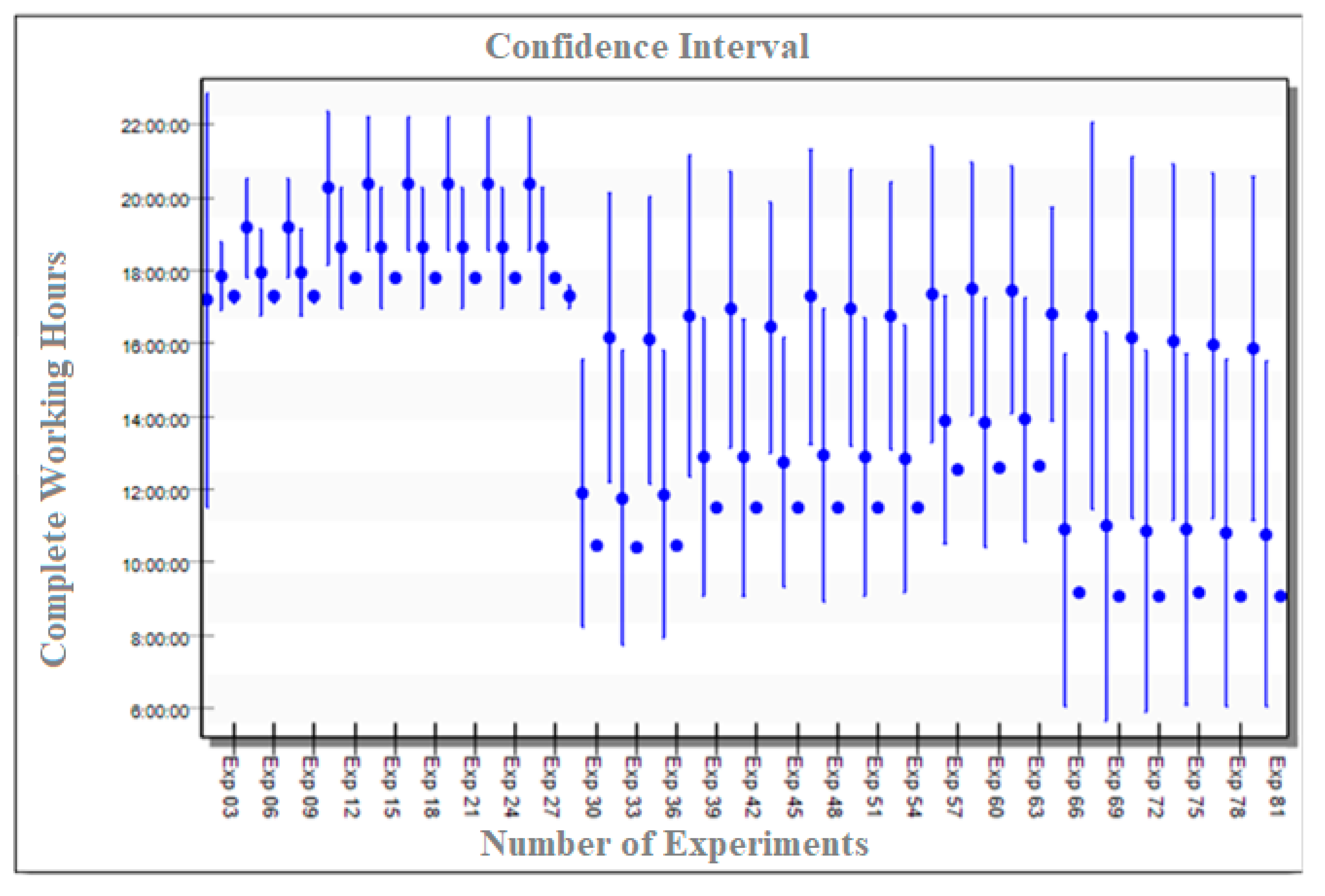

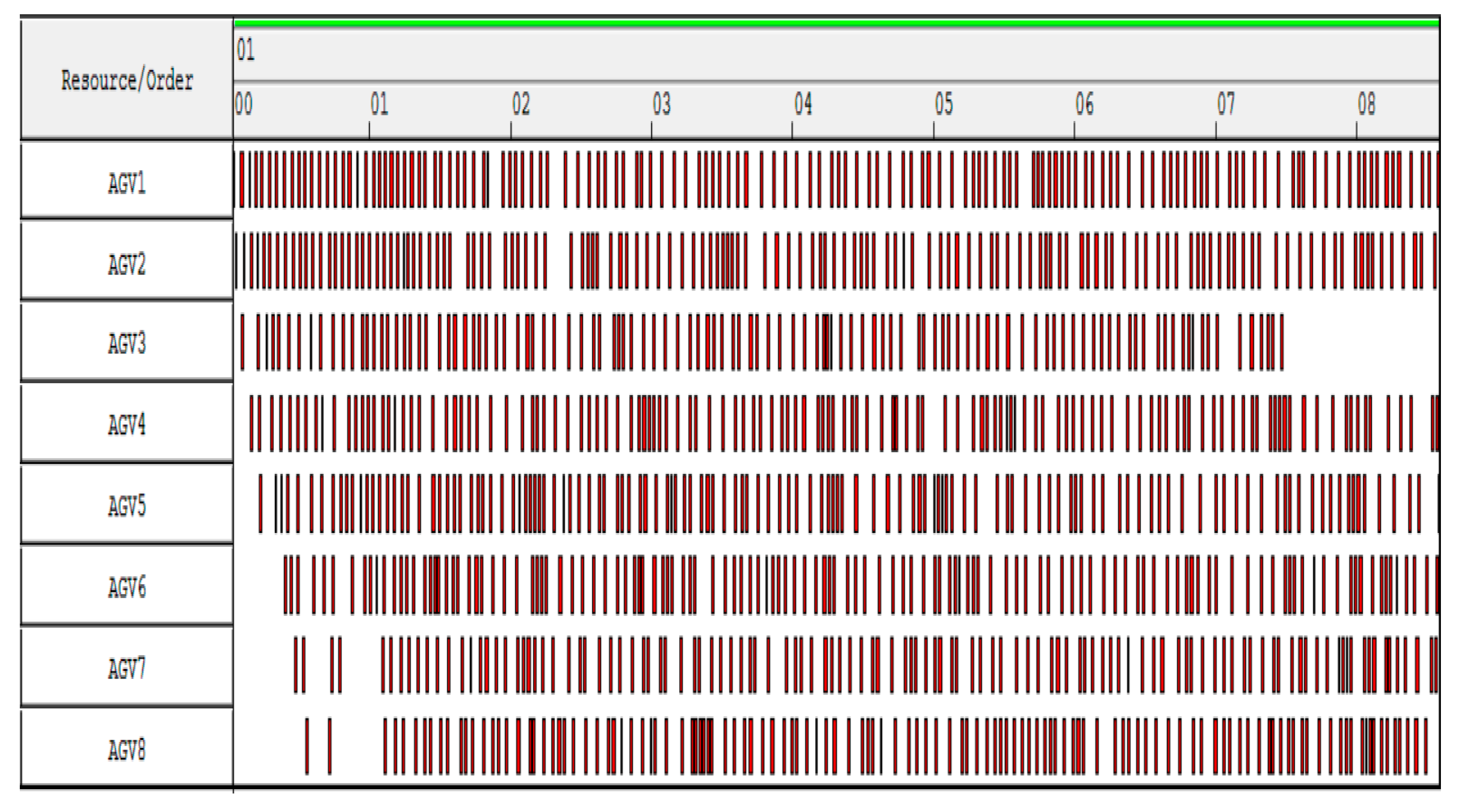

In this paper, we investigated the actual production process parameters and characteristics of highly distributed manufacturing system like textile ring-spinning combing section. This work was inspired to resolve the confronting problems of scheduling, real-time can distribution, and path planning in the continuous production of spinning by benefitting the mixed flow-shop predictive modelling. To effectively reduce the makespans and total completion time, it was vital to define the properties and features of the workshop, equipment, products, and AGVs. Based on the two AGVs scheduling strategies, a novel approach of handling both cross-regional shared resource and cross-regional independent resource pools was analyzed. For the dissimilar cotton and polyester draw-out processing, we established an overall mathematical model of multi-AGV scheduling to solve the problems of can distributions and to prevent conflict and deadlock by assigning different tasks: AGV assignment, AGV sorting, and task source. Moreover, for the intended categories of scheduling tasks, an AGV transportation route strategy was also developed for mass production in a spinning CPPS. The extensive computational experiments were performed using ‘Siemens Tecnomatix Plant Simulation software,’ according to the production of a certain number of products and two scheduling strategies. The simulation results analysis of 81 groups of optimization targets with completion time showed a specific range of AGVs. As the number of AGVs increased, the completion time decreased. The number of AGVs reached a certain threshold, and the completion time stabilized. On this basis, the utilization rate and the completion time of the products were also analyzed. When the number of AGVs rose to a certain extent, the contribution of increasing AGV numbers to the completion time decreased sharply, thus reducing the utilization rate of AGVs. By comparing the results of 81 sets of simulations under the two strategies, it was found that the cross-regional independent resource pool strategy was better than the cross-regional shared resource pool strategy under the actual scenario. These results demonstrated the adequacy of the methods we used and proved that flow-shop predictive modeling for when multi-AGV resources are scarce also produces, for each AGV, a control mode and, if necessary, a preventive maintenance plan. Based on the comparison with our scheduling approach, it was found that the results of multi-AGV scheduling have distinct advantages that can significantly shorten completion time.

In the future, it will be attractive to examine multi-AGV scheduling by applying different scheduling algorithms in order to investigate the potential mechanisms responsible for transportation task set scheduling decisions using a genetic algorithm.