Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows

Abstract

1. Introduction

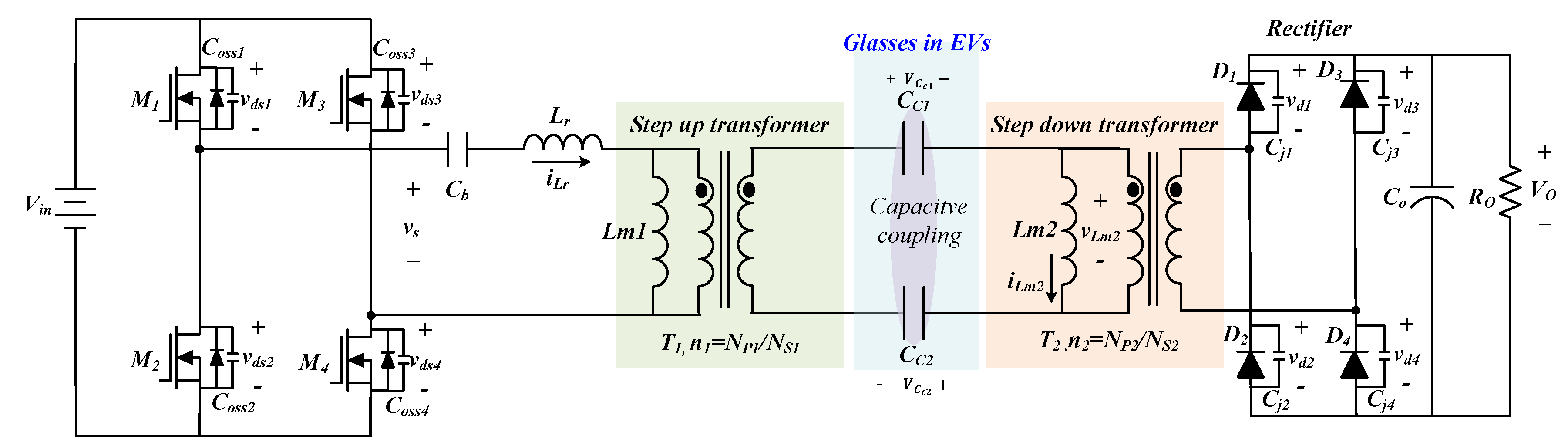

2. The Proposed CCWPT System

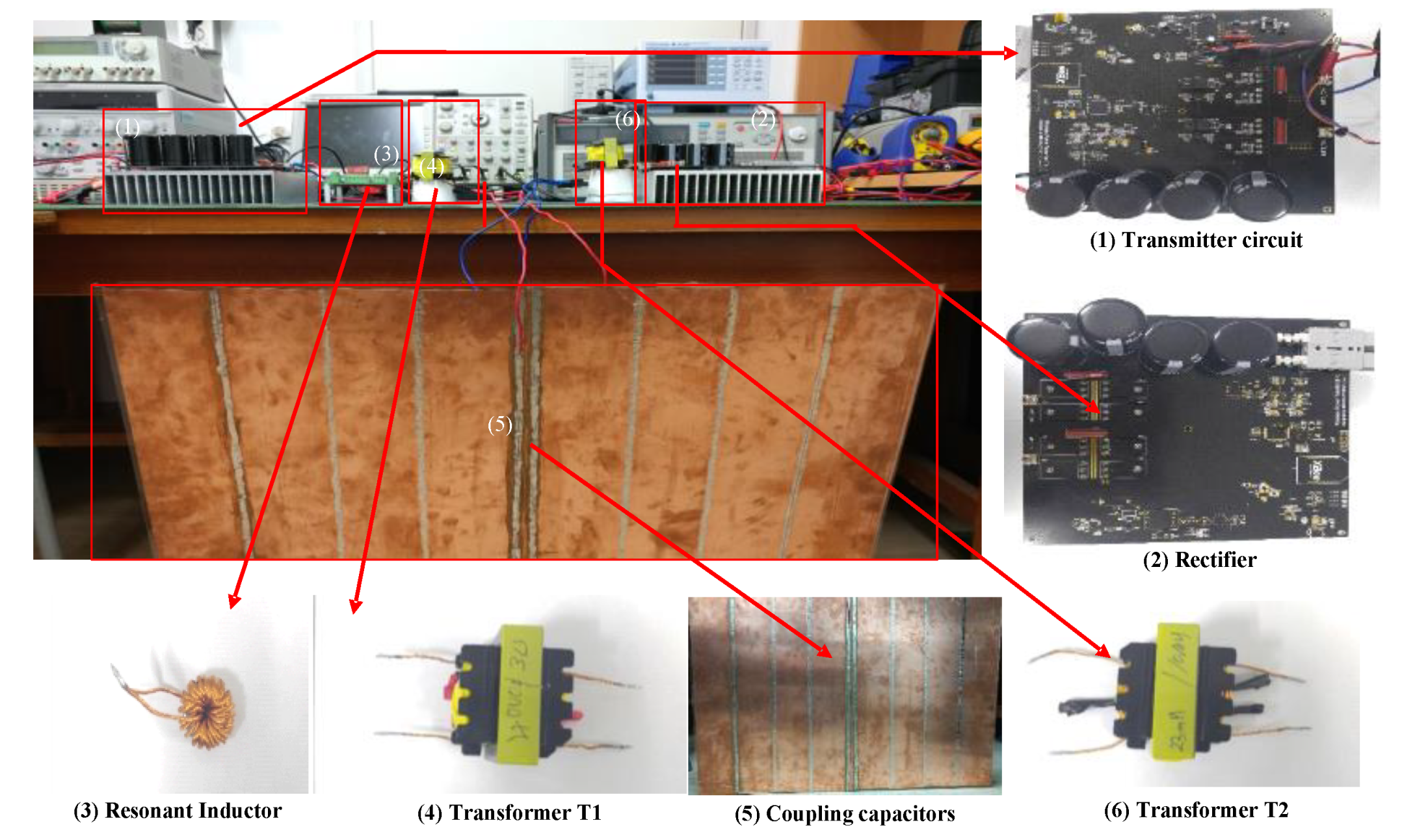

2.1. Substrates for Dielectric Layers in Vehicle

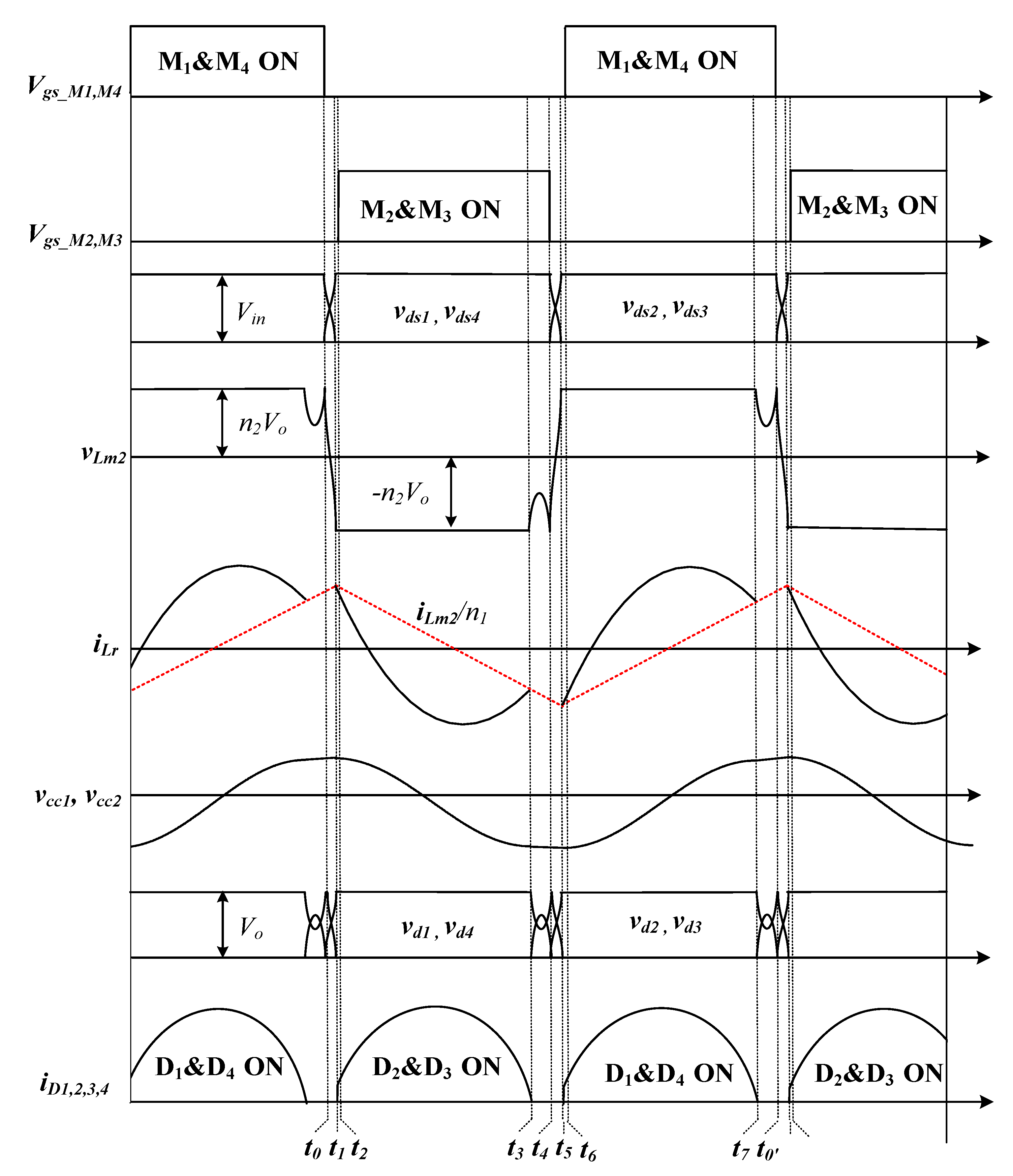

2.2. Quasi-LLC Power Conversion Circuit for Adjusting Impedance of a Coupling Capacitor

- (1)

- All analyses are performed in steady-state operation.

- (2)

- The capacitances of Cb and Co are sufficiently large to make their voltages constant.

- (3)

- M1–M4 are ideal except for their internal diodes and output capacitors.

- (4)

- D1–D4 are ideal except for their junction capacitors.

- (5)

- The inductance of Lm2 is several times greater than the inductance of Lr.

- (6)

- It is assumed that the inductance of Lm1 is large enough and is infinite.

- (7)

- The turn ratio of the step-up transformer T1 is n1.

- (8)

- The turn ratio of the step-down transformer T2 is n2.

3. Design Considerations of the Proposed CCWPT System

3.1. Capacitor Estimation

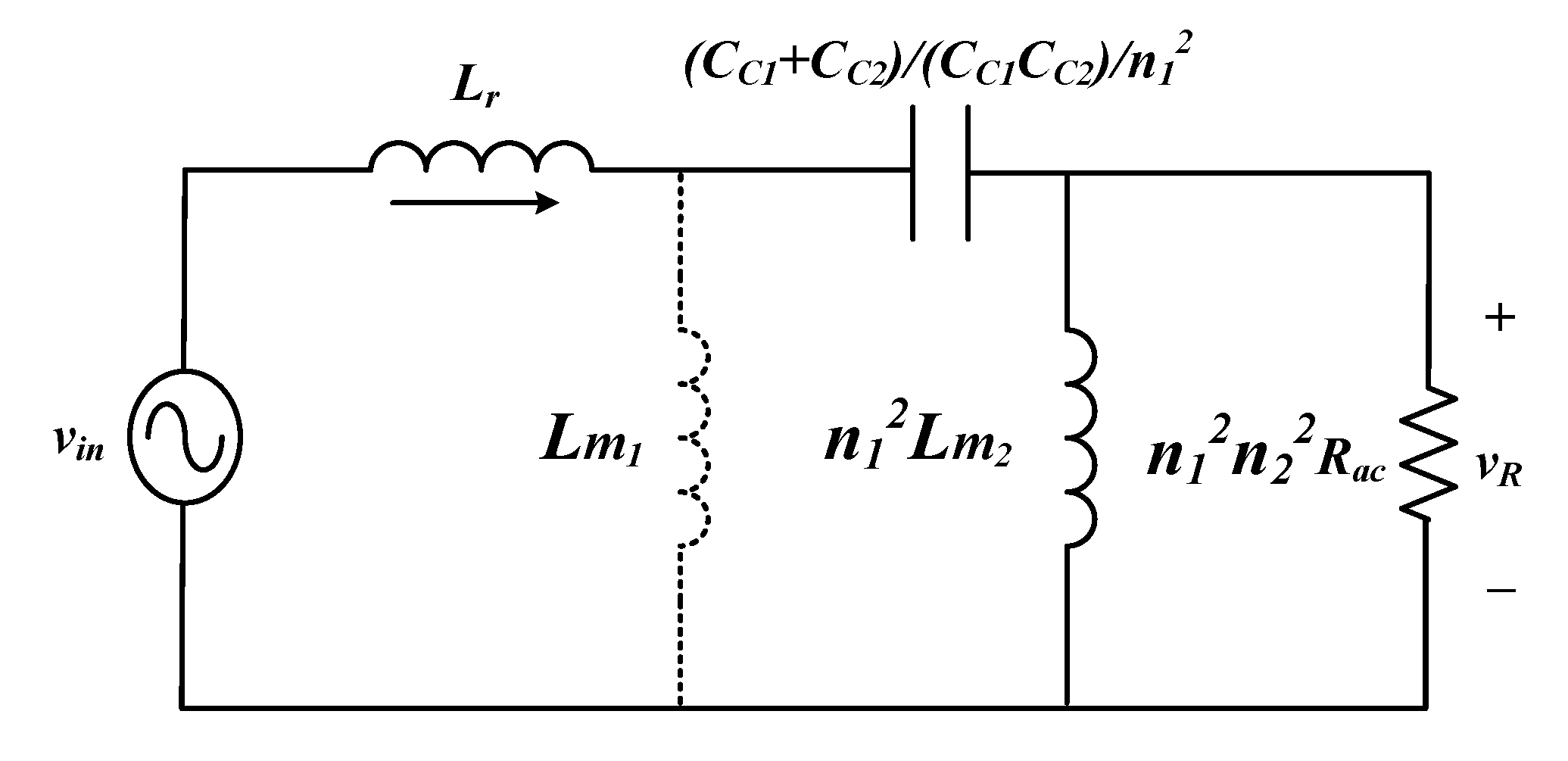

3.2. Output Voltage DC Gain of the Proposed Power Conversion Circuit

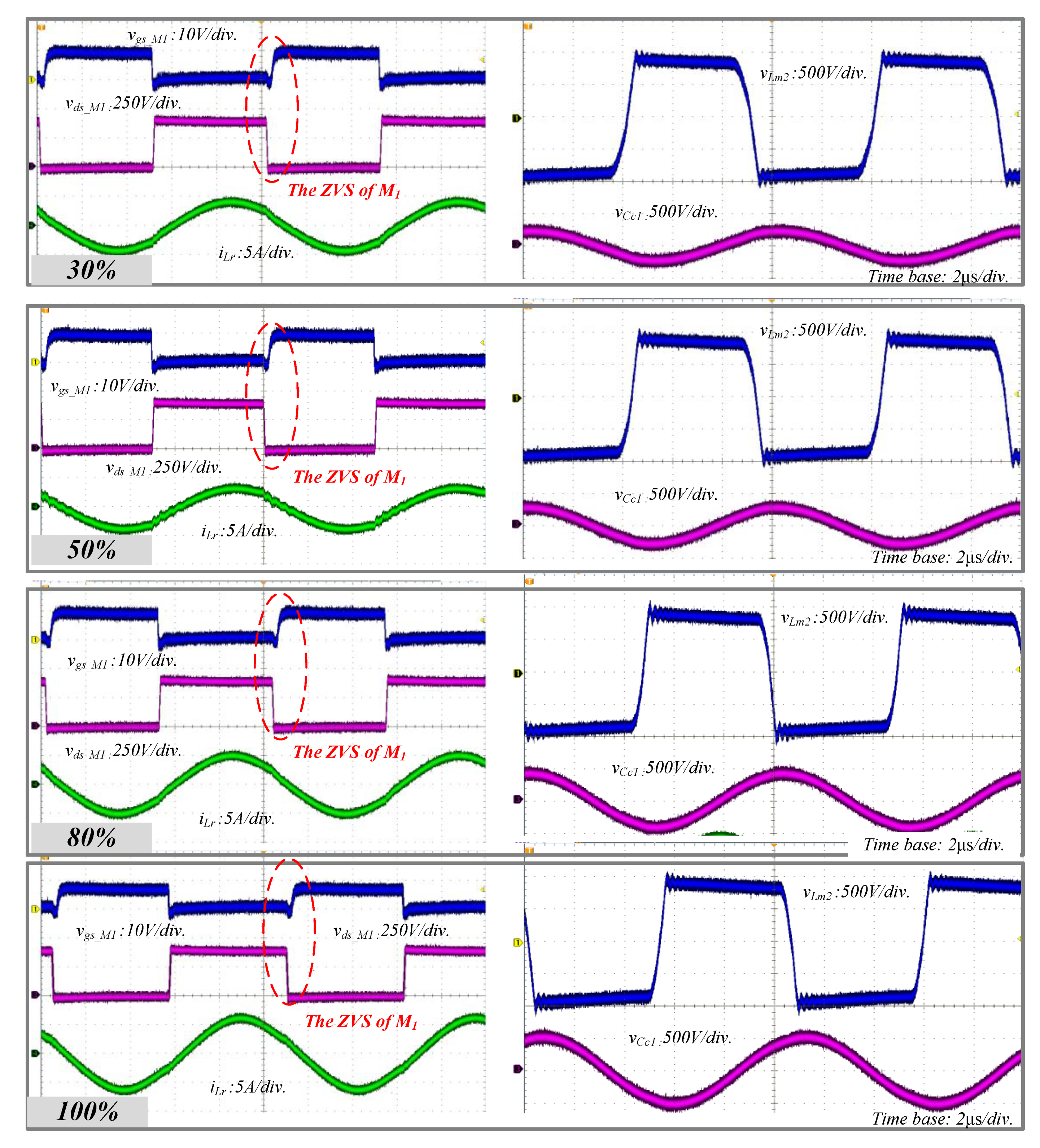

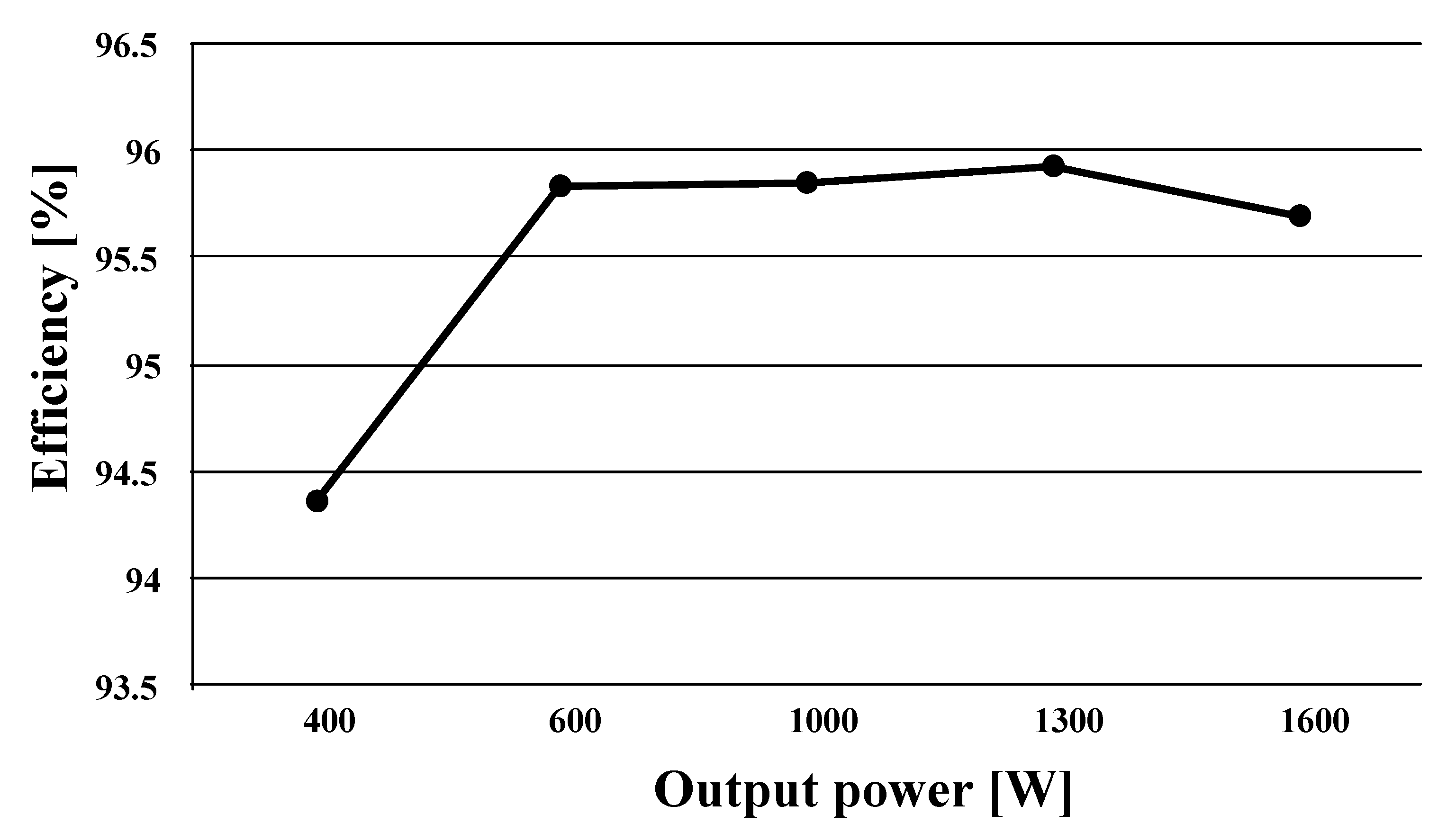

4. Experimental Results

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Gjelaj, M.; Hashemi, S.; Andersen, P.B.; Træholt, C. Optimal infrastructure planning for EV fast-charging stations based on prediction of user behavior. IET Electr. Syst. Transp. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Huang, L.; Hu, A.P.; Swain, A.; Kim, S.; Ren, Y. An overview of capacitively coupled power transfer—A new contactless power transfer solution. In Proceedings of the IEEE Conference on Industrial Electronics and Applications, Melbourne, Australia, 19–21 June 2013; pp. 461–465. [Google Scholar]

- Zhang, H.; Lu, F. An Improved Design Methodology of the Double-Sided LC-Compensated CPT System Considering the Inductance Detuning. IEEE Trans. Power Electron. 2019, 34, 11396–11406. [Google Scholar] [CrossRef]

- Yi, K. High frequency capacitive coupling wireless power transfer using glass dielectric layers. In Proceedings of the 2016 IEEE Wireless Power Transfer Conference, Aveiro, Portugal, 5–6 May 2016; pp. 1–3. [Google Scholar]

- Dai, J.; Ludois, D.C. A survey of wireless power transfer and a critical comparison of inductive and capacitive coupling for small gap applications. IEEE Trans. Power Electron. 2015, 30, 964–969. [Google Scholar] [CrossRef]

- Theodoridis, M.P. Effective capacitive power transfer. IEEE Trans. Power Electron. 2012, 27, 4906–4913. [Google Scholar] [CrossRef]

- Nishiyama, H.; Nakamura, M. Capacitance of disk capacitors. IEEE Tran. Compon. Hybrids. Manuf. Technol. 1993, 16, 306–366. [Google Scholar] [CrossRef]

- Ludois, D.C.; Erickson, M.J.; Reed, J.K. Aerodynamic fluid bearing for translational and rotating capacitors in noncontact capacitive transfer systems. IEEE Trans. Ind. Appl. 2014, 50, 1025–1033. [Google Scholar] [CrossRef]

- Dai, J.; Ludois, D.C. Wireless electric vehicle charging via capacitive power transfer through a conformal bumper. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 15–19. [Google Scholar]

- Zhang, H.; Lu, F.; Hofmann, H.; Liu, W.; Mi, C.C. Six-plate coupler to reduce electric field emission in large air-gap capacitive power transfer. IEEE Trans. Power Electron. 2018, 33, 669–675. [Google Scholar] [CrossRef]

- Yusop, Y.; Husin, H.; Saat, S.; Nguang, S.; Ghani, Z. Class-E LCCL for capacitive power transfer system. In Proceedings of the IEEE 2016 Power and Energy Conference, Melaka, Malaysia, 28–30 November 2016; pp. 428–433. [Google Scholar]

- Narayanamoorthi, R.; Juliet, A.V.; Chokkalingam, B.; Padmanaban, S.; Leonowicz, Z.M. Class E power amplifier design and optimization for the capacitive coupled wireless power transfer system in biomedical implants. Energies 2017, 10, 1409. [Google Scholar]

- Mishra, S.; Adda, R.; Sekhar, S.; Joshi, A.; Rathore, A. Power transfer using portable surfaces in capacitively coupled power transfer technology. IET Power Electron. 2016, 9, 997–1008. [Google Scholar] [CrossRef]

- Rozario, D.; Pathipati, V.; Ram, A.; Azeez, N.; Williamson, S. Modified resonant converters for contactless capacitive power transfer system used in EV charging applications. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4510–4517. [Google Scholar]

- Choi, S.; Choi, H. Capacitive wireless power transfer system with double matching transformers for reduced stress and extended ZVS range. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1–6. [Google Scholar]

- Zhang, H.; Lu, F.; Hofmann, H.; Mi, C. A loosely coupled capacitive power transfer system with LC compensation circuit topology. In Proceedings of the IEEE Energy Conversation Congress Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–5. [Google Scholar]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C. A CLLC-compensated high power and large air-gap capacitive power transfer system for electric vehicle charging applications. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition, Long Beach, CA, USA, 20–24 March 2016; pp. 1721–1725. [Google Scholar]

- Lu, F.; Zhang, H.; Hofmann, H.; Mi, C. A double-sided LCLC-compensated capacitive power transfer system for electric vehicle charging. IEEE Trans. Power Electron. 2015, 30, 6011–6014. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, F.; Hofmann, H.; Liu, W.; Mi, C. A four-plate compact capacitive coupler design and LCL-compensated topology for capacitive power transfer in electric vehicle charging application. IEEE Trans. Power Electron. 2016, 31, 8541–8551. [Google Scholar]

- Li, S.; Liu, Z.; Zhu, L.; Shuai, C.; Chen, Z. Wireless power transfer by electric field resonance and its application in dynamic charging. IEEE Trans. Ind. Electron. 2016, 63, 6602–6612. [Google Scholar] [CrossRef]

- You, Y.S.; Yi, K.H. Capacitive coupling wireless power transfer with glass dielectric layers for electric vehicles. In Proceedings of the IEEE 6th International Conference on Consumer Electronics-Berlin (ICCE-Berlin), Berlin, Germany, 5–7 September 2016. [Google Scholar]

- Yi, K. Research on Glass Dielectric Capacitive Coupling Wireless Power Transfer Using Transparent Electrode. Trans. Korean Inst. Power Electron. 2018, 23, 286–289. [Google Scholar]

- Frontal Vehicle Glass. Available online: https://mechaniclove.com/glass/ (accessed on 6 April 2020).

- Available online: https://www.researchgate.net/figure/Optical-transmittance-spectra-of-ITO-thin-films-deposited-at-different-substrate_fig4_271510410 (accessed on 3 April 2020).

- Kenney, J.B. Dedicated short-range communications (DSRC) standards in the United States. Proc. IEEE 2011, 99, 1162–1182. [Google Scholar] [CrossRef]

| Material | Relative Permittivity |

|---|---|

| Air | 1.0005 |

| Glass | 4–7 |

| Polypropylene | 2.2–2.4 |

| ABS Resin | 2.3–2.5 |

| Parameters | Symbol | Value/Part |

|---|---|---|

| Input voltage | Vin | 400 V |

| Output power | Po | 1.6 kW |

| Resonant inductor | Lr | 63 μH |

| n1 and n2 | Np1:Ns1 and Np2:Ns2 | 1:2.2 and 2.2:1 |

| Magnetizing inductor of T2 | Lm2 | 1600 μH |

| Coupling capacitor | CC1 and CC2 | 16 nF |

| Transformer core | T1 and T2 | EI6044 |

| Primary switches | M1,2,3,4 | STW13NK100Z |

| Diodes | D1,2,3,4 | VS-HFA16PA60C-N3 |

| Width of glass | - | 2 mm |

| Coupling capacitor electrode | - | Copper |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, K. Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows. Electronics 2020, 9, 676. https://doi.org/10.3390/electronics9040676

Yi K. Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows. Electronics. 2020; 9(4):676. https://doi.org/10.3390/electronics9040676

Chicago/Turabian StyleYi, KangHyun. 2020. "Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows" Electronics 9, no. 4: 676. https://doi.org/10.3390/electronics9040676

APA StyleYi, K. (2020). Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows. Electronics, 9(4), 676. https://doi.org/10.3390/electronics9040676