A Novel MAC Protocol for Low Datarate Cooperative Mobile Robot Teams

Abstract

1. Introduction

- Reliability: automation networks have to provide a suitable reliability level for the transmissions, i.e., a low error probability. To cope with this requirement, some of the mechanisms adopted are retransmissions (with or without acknowledgment), relaying (i.e., the transmission of a message over multiple paths from the source to the destination), and Automatic Repeat reQuests (ARQs) to detect errors.

- Fault-tolerance: the node services have to be always available, as a stop of some hours entails high costs for the industry. For this reason, fault-tolerance mechanisms (such as node redundancy and recovery, replication of functions) have to be provided.

- Real-Time: networks have to meet the timing constraints of the supported applications. This means that the end-to-end delays of messages, i.e., the delivery times from the source to the destination, have to be bounded and predictable. Hence, suitable deadline-aware Medium Access Control (MAC) mechanisms to avoid unpredictability in communications and scheduling policies have to be investigated.

- Low message latency: due to the fast dynamics of this kind of systems, messages not only have to be delivered within a certain deadline (real-time requirement), but also need low message latencies (i.e., from hundreds of microseconds to hundreds of milliseconds).

- Support to multiple traffic classes: the integration of the Internet technologies in robotics applications and also in industrial networks requires the support for the transmission of multiple traffic types [8,9], with different timing constraints, in an efficient way and without compromising the transmission of the control traffic (that is generally the most critical one).

- Mobility: the introduction of mobile robots in the industrial scenario entails additional requirements on the networks. In particular, the standard wireless communication technologies in general do not specifically support node mobility. For these reasons, several mechanisms that modify the standard specifications were proposed [10,11].

- Scalability: cooperative multi-robot networks are typically realized with a high number of nodes. However, some of the most adopted medium access mechanisms in industrial automation are TDMA-based. Such a mechanism is well known to be not very scalable, as a high number of nodes entails a high number of timeslots in the communication cycle, thus increasing the message latency. In order to cope with this issue, several approaches were proposed [12,13].

2. Related Work

3. Design Choices

3.1. Bounded Delays

3.2. Scalability

3.3. Node Mobility

3.4. Advantages of the Proposed Approach

- Predictable and low delays. The TDMA mechanism provides deterministic medium access time. It also allows the use of real-time algorithms to prioritize the messages using either static or dynamic priorities.

- Seamless mobility. The distributed topology management allows that messages can be transmitted by mobile robots regardless of whether they are moving or not, as such an approach enables the knowledge of the link relations among nodes.

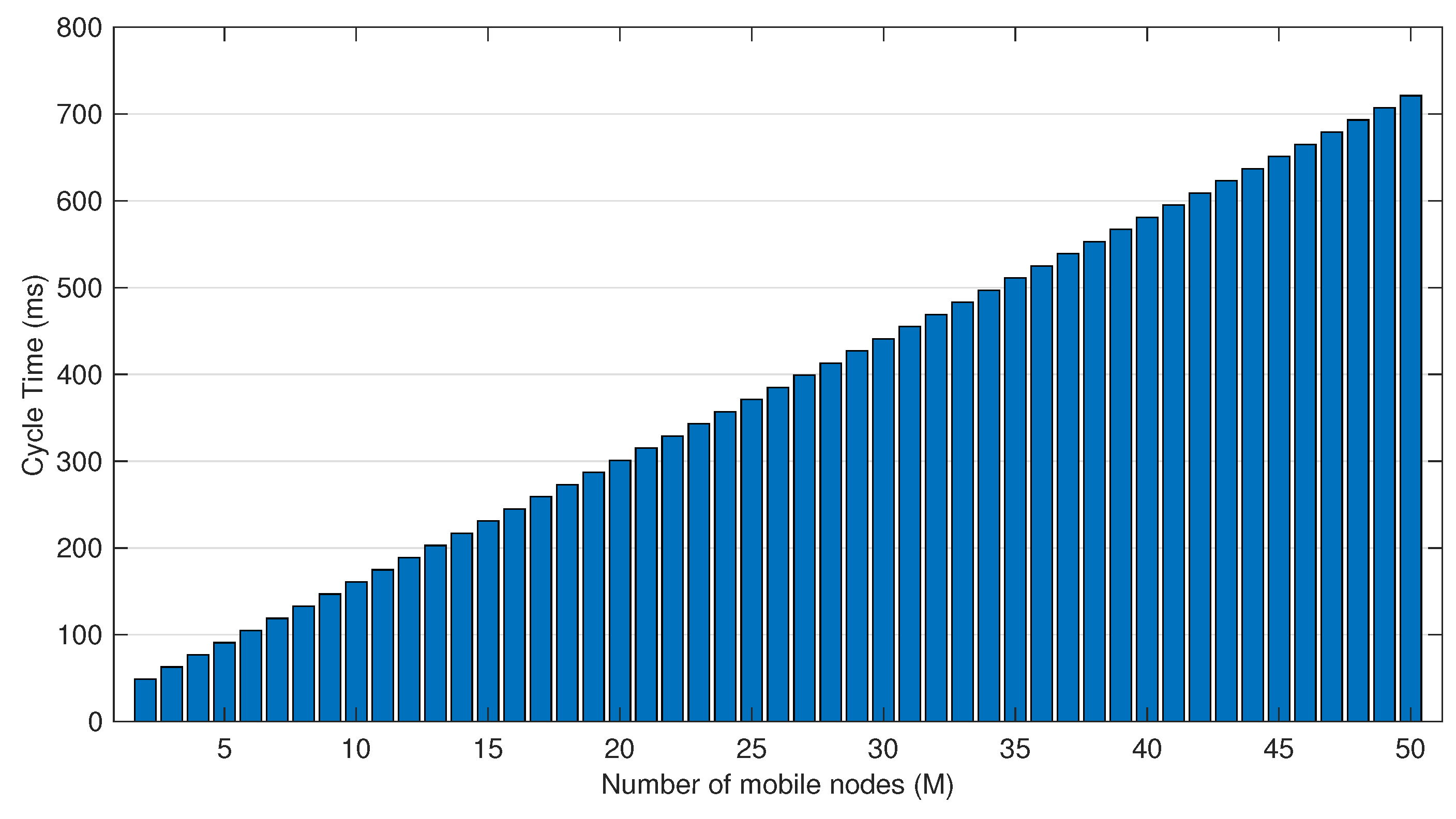

- Improved scalability. Scalability is a known limitation of TDMA-based approaches, as the number of slots grows with the number of nodes, therefore the message delays also grow. To solve this issue, the TDMA-based mechanism, combined with multichannel transmissions and clustering, allows for shorter superframe and simultaneous transmissions on multiple channels, thus supporting tens of nodes while maintaining bounded message delays in the order of hundreds of milliseconds.

4. The RoboMAC Protocol

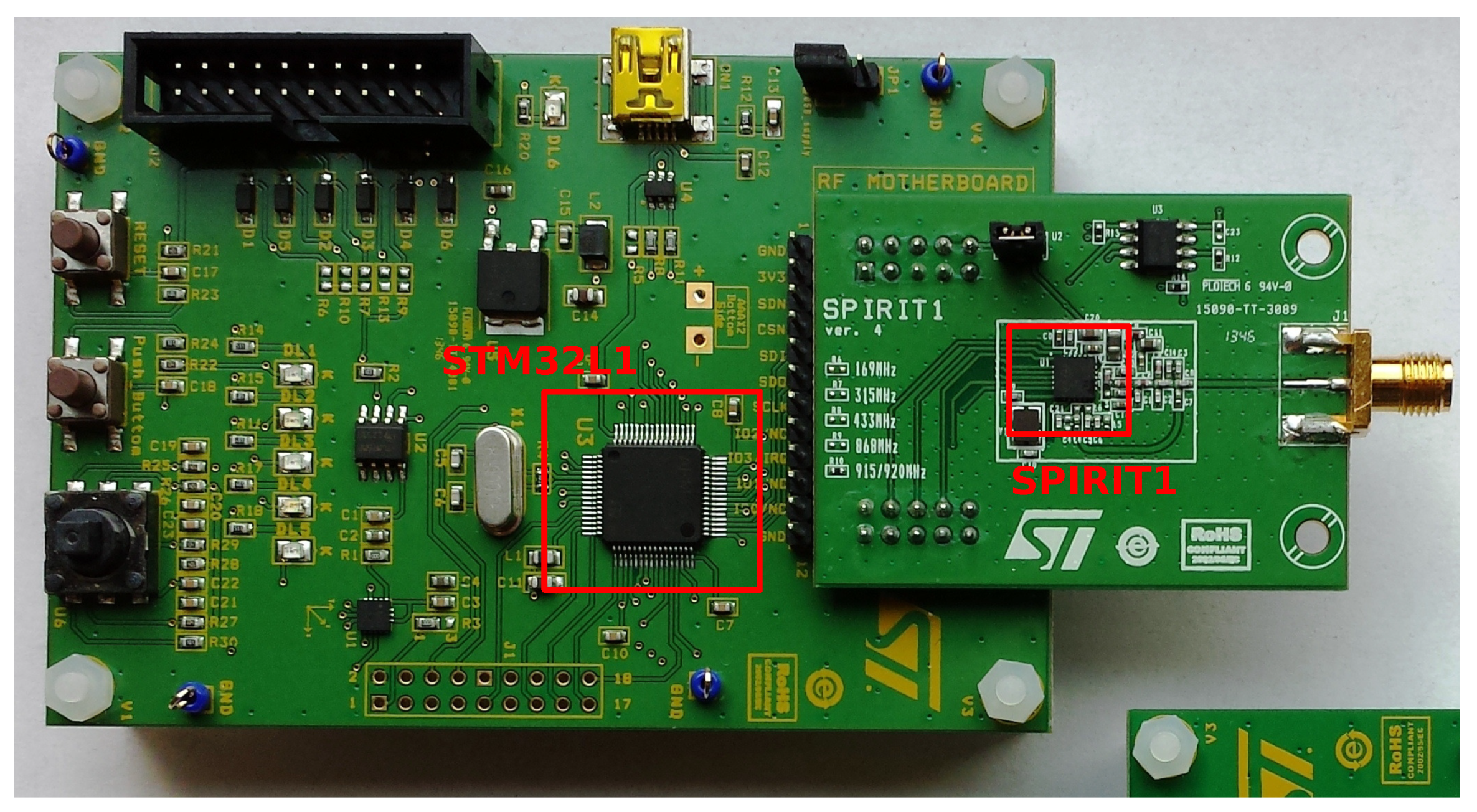

4.1. Physical Layer

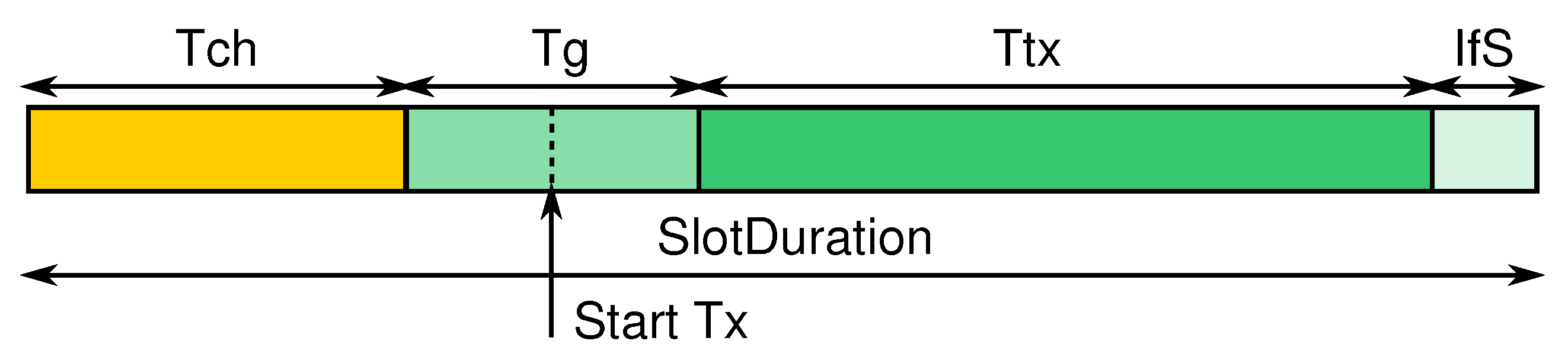

4.2. Medium Access and Synchronization Layer

- The maximum time required for channel switching (), which is equal to 1.92 ms;

- The maximum between the time required to cope with the synchronization accuracy () and the maximum time required to transmit the frame from the microcontroller to the transceiver (i.e., );

- The time needed for data transmission ();

- The Interframe Space (IfS).

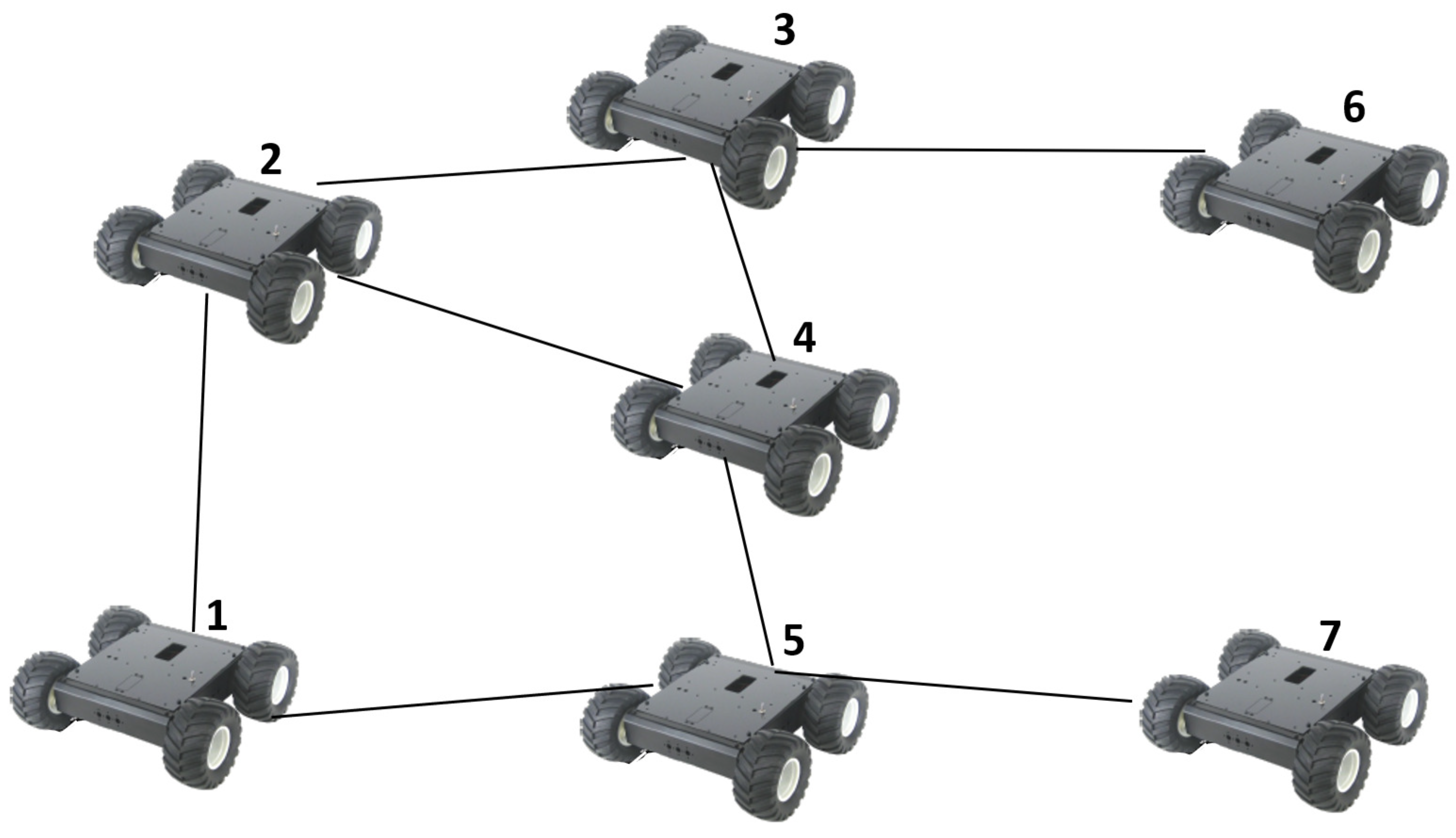

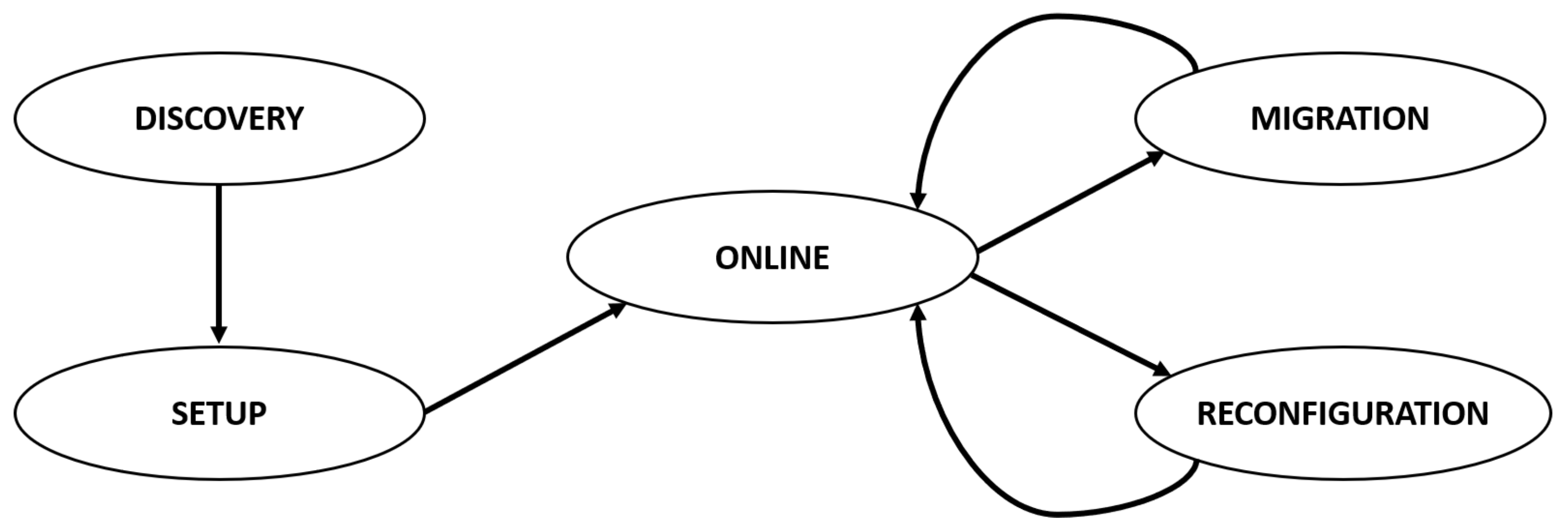

4.3. Clustering and Routing Layer

- Discovery state. This is the initial state in which each node discovers its neighbor nodes. This state has a fixed duration, that is configured offline. The discovery state duration varies according to the number of network nodes.

- Setup state. When the discovery period is elapsed, nodes enter the Setup state. In this phase all the nodes exchange and update the Network Link Matrix (NLM). At the end of the setup state, all the network nodes are aware of the network topology and execute the clustering algorithm, which assigns each node to a cluster. The clustering algorithm runs in each node without message transmissions and takes into account the connectivity relations of nodes provided in the NLM. The result of the clustering algorithm is a vector containing the cluster identifier associated to each node (here called the cluster member vector).

- Online state. In the online state, the clustering and routing layer enables the operations of cluster maintenance and routing. Cluster maintenance is needed to update the information of the cluster member vector and the cluster topology. In the Online state, the nodes transmit in the header of the intracluster messages the NLM of the nodes belonging to a cluster. Such an information is used to discover topology changes and to start the migration or the reconfiguration phase.

- Migration state. A node enters this state when it moves far away from the nodes of its cluster. In this case the node starts the procedure to join another cluster.

- Reconfiguration state. This state is reached when there are not the minimum conditions to maintain a cluster and a new clusterization is required, for instance, when a cluster is composed of a single node. The reconfiguration state involves only two clusters, i.e., the one to which the node requested the reconfiguration and the one chosen by the node based on its position and the number of nodes in the cluster.

5. RoboMAC Assessment

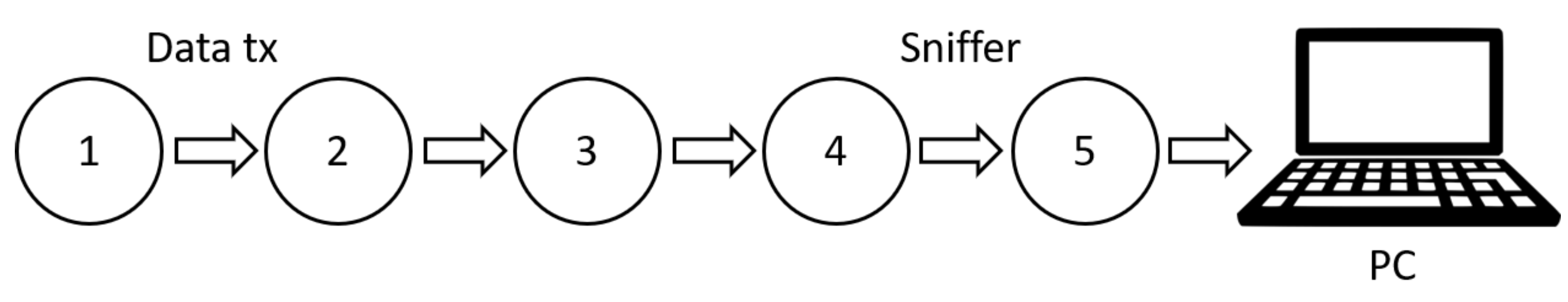

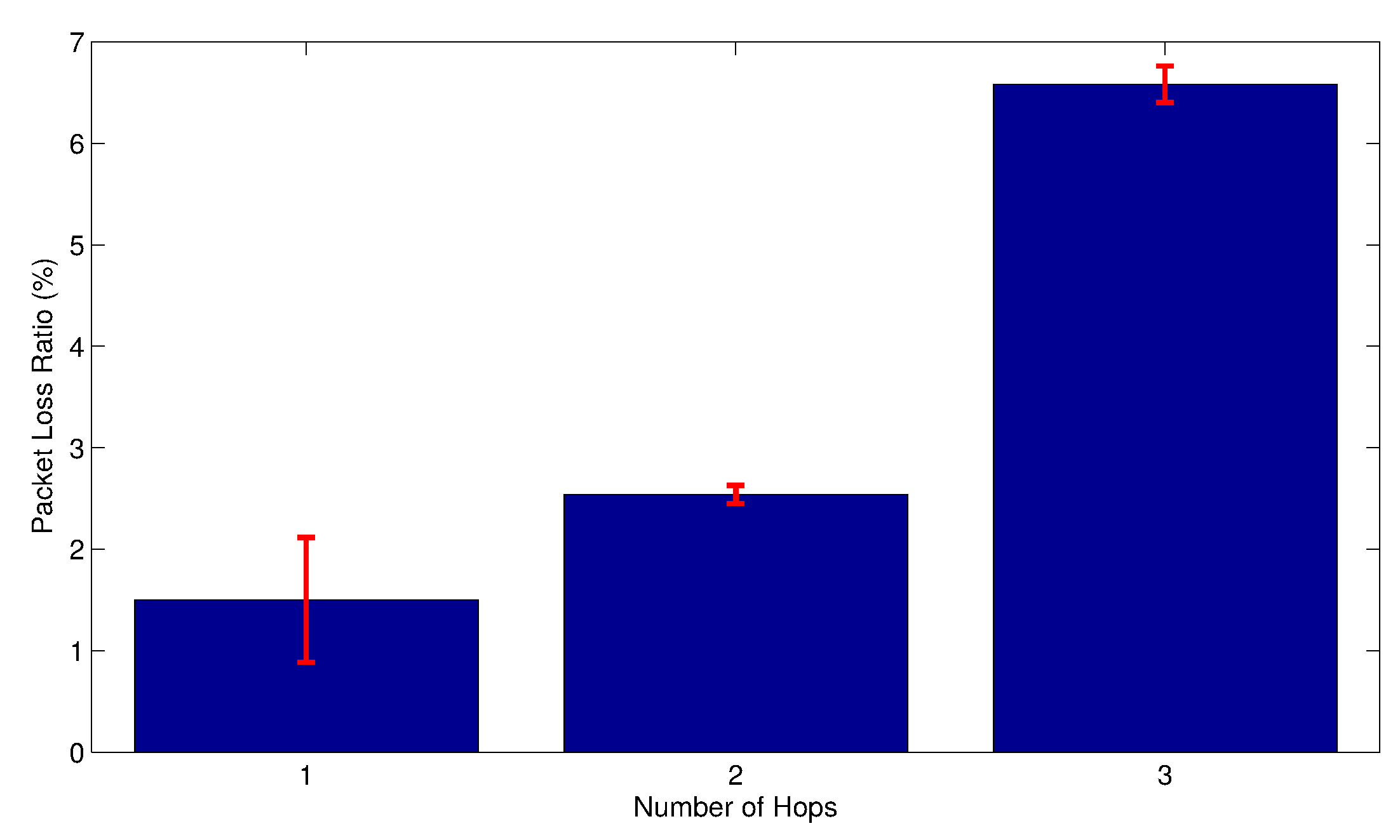

5.1. Packet Loss Ratio Evaluation

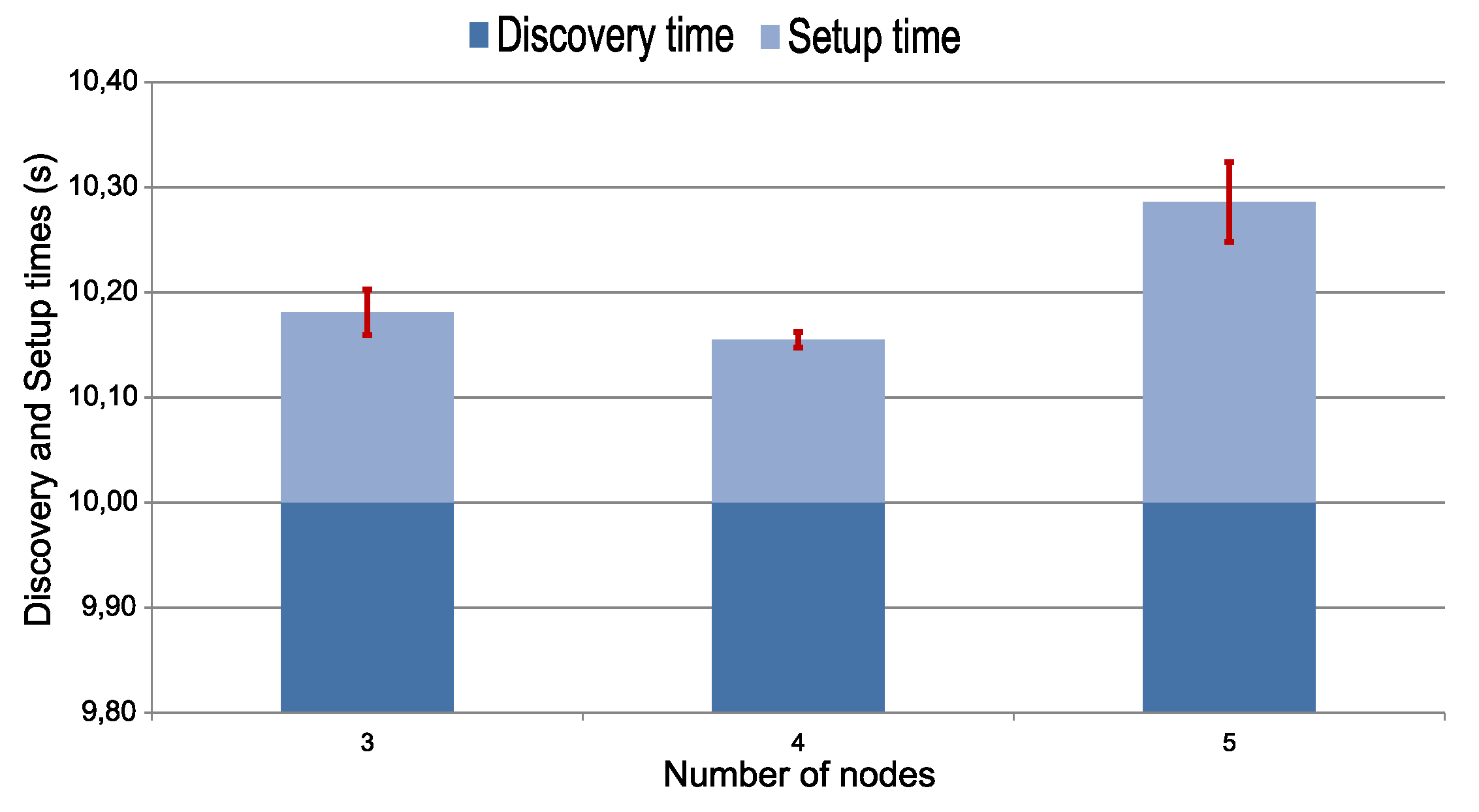

5.2. SetupTime Evaluation with a Varying Number of Nodes

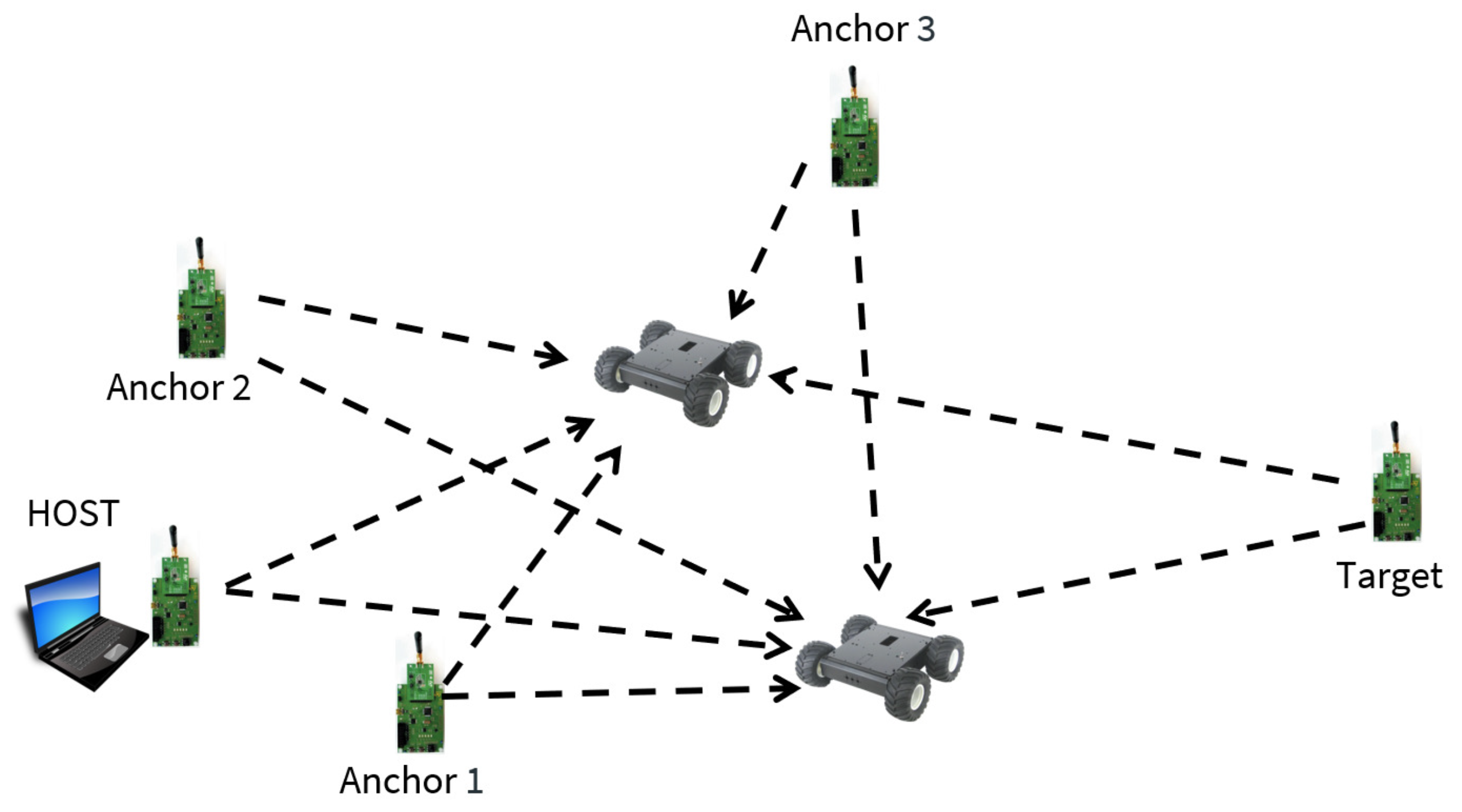

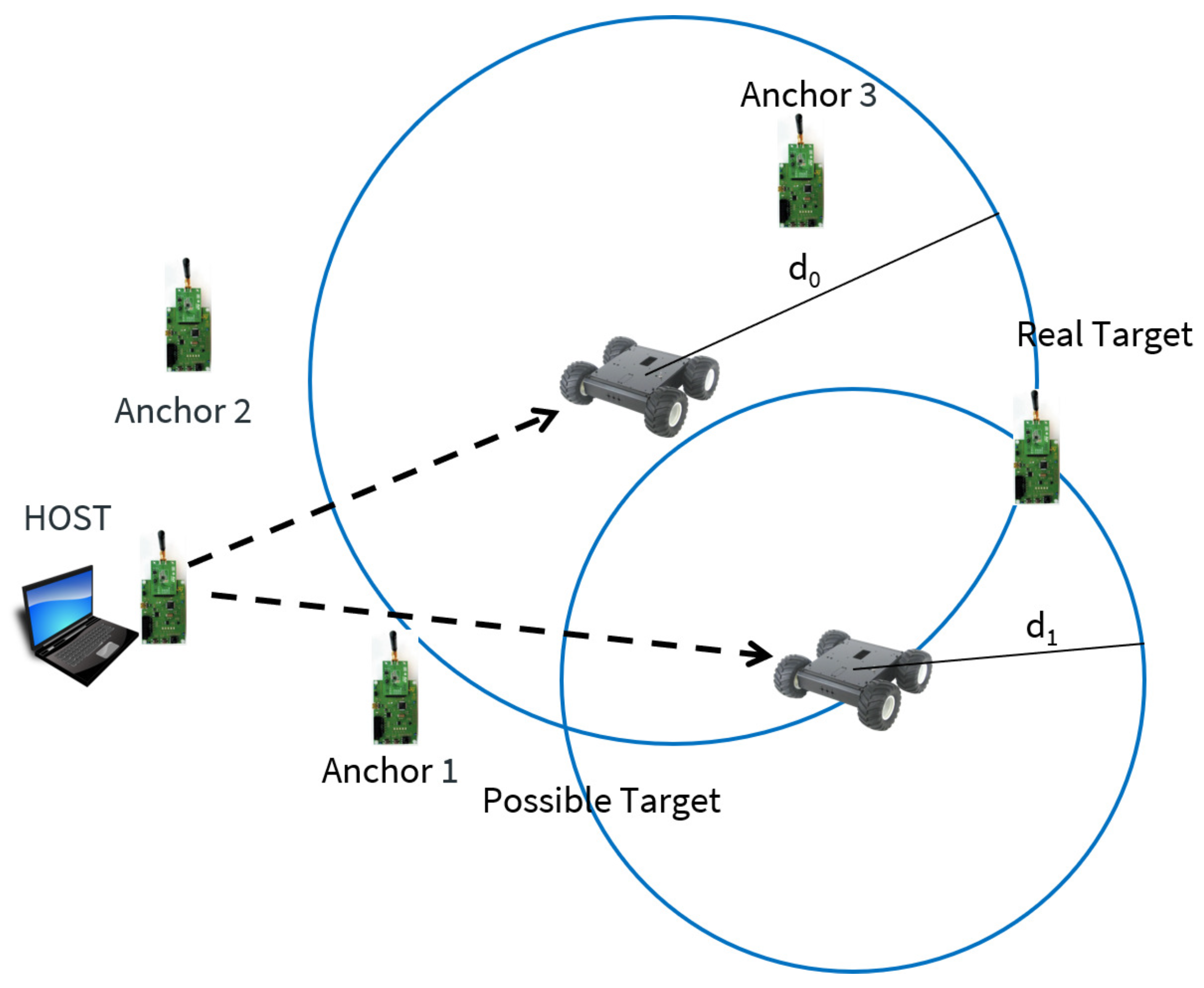

5.3. RoboMAC Test on a Proof-of-Concept Application

- 2 mobile robots equipped with a STEVAL-IKR002V5 communication device, one IMU ST iNemo-M1 (Accelerometer, Gyroscope, Magnetometer), 3 ultrasonic sensors and a STM32F4 microcontroller.

- 3 STEVAL-IKR002V5 nodes, which act as anchors and are placed in defined and fixed positions. Each anchor periodically transmits a frame to the robots, to allow them to retrieve the RSSI and estimate the distance to the anchor.

- 1 Notebook connected to one STEVAL-IKR002V5 that acts as a host controller for the robots.

- 1 STEVAL-IKR002V5 device randomly placed into the test area. Such a device acts as a target for the robots. It periodically transmits a beacon frame to the robots so as to allow them to estimate their distance to the target.

5.4. Scalability Assessment

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, Z.; Jouandeau1, N.; Cherif, A.A. A Survey and Analysis of Multi-Robot Coordination. Int. J. Adv. Robotic Syst. 2013, 10, 1–18. [Google Scholar] [CrossRef]

- Leonardi, L.; Ashjaei, M.; Fotouhi, H.; Lo Bello, L. A Proposal Towards Software-Defined Management of Heterogeneous Virtualized Industrial Networks. In Proceedings of the IEEE 17th International Conference on Industrial Informatics (INDIN 2019), Espoo, Finland, 23–25 July 2019. [Google Scholar]

- Iannizzotto, G.; La Rosa, F.; Costanzo, C.; Lanzafame, P. A multimodal perceptual user interface for collaborative environments. In Lecture Notes in Computer Science; 3617 LNCS; Springer: Berlin, Germany, 2005; pp. 115–122. [Google Scholar]

- Germany Federal Ministry for Economic Affairs and Energy (BMWi). Industrie 4.0—Aspects of the Research Roadmap in Application Scenarios. 2016. Available online: http://www.plattform-i40.de/I40/Redaktion/EN/Downloads/Publikation/aspects-of-the-research-roadmap.html (accessed on 10 December 2019).

- Battaglia, F.; Iannizzotto, G.; Lo Bello, L. JxActinium: A runtime manager for secure REST-ful CoAP applications working over JXTA. In Proceedings of the ACM Symposium on Applied Computing, Pisa, Italy, 4–8 April 2016; pp. 1611–1618. [Google Scholar]

- Fazio, M.; Puliafito, A. Cloud4sens: A cloud-based architecture for sensor controlling and monitoring. IEEE Commun. Mag. 2015, 53, 41–47. [Google Scholar] [CrossRef]

- Vitturi, S.; Zunino, C.; Sauter, T. Industrial Communication Systems and Their Future Challenges: Next-Generation Ethernet, IIoT, and 5G. Proc. IEEE 2019, 107, 944–961. [Google Scholar] [CrossRef]

- Leonardi, L.; Battaglia, F.; Lo Bello, L. RT-LoRa: A Medium Access Strategy to support Real-time flows over LoRa-based networks for Industrial IoT applications. IEEE Internet Things J. 2019, 6. [Google Scholar] [CrossRef]

- Leonardi, L.; Battaglia, F.; Patti, G.; Lo Bello, L. Industrial LoRa: A Novel Medium Access Strategy for LoRa in Industry 4.0 Applications. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4141–4146. [Google Scholar] [CrossRef]

- Al-Nidawi, Y.; Yahya, H.; Kemp, A. Tackling Mobility in Low Latency Deterministic Multihop IEEE 802.15.4e Sensor Network. IEEE Sens. J. 2016, 16, 1412–1427. [Google Scholar] [CrossRef]

- Sauter, T.; Jasperneite, J.; Lo Bello, L. Towards new hybrid networks for industrial automation. In Proceedings of the International Conference on Emerging Technologies and Factory Automation (ETFA), Torino, Italy, 4–7 September 2009. [Google Scholar]

- Battaglia, F.; Collotta, M.; Leonardi, L.; Lo Bello, L.; Patti, G. Novel Extensions to Enhance Scalability and Reliability of the IEEE 802.15. 4-DSME Protocol. Electronics 2020, 9, 126. [Google Scholar] [CrossRef]

- Battaglia, F.; Collotta, M.; Leonardi, L.; Lo Bello, L.; Patti, G. A scalable approach for periodic traffic scheduling in IEEE 802.15.4-DSME networks. In Proceedings of the IEEE 17th International Conference on Industrial Informatics (INDIN 2019), Espoo, Finland, 23–25 July 2019. [Google Scholar]

- Alizadeh Jarchlo, E.; Haxhibeqiri, J.; Moerman, I.; Hoebeke, J. To Mesh or not to Mesh: Flexible Wireless Indoor Communication Among Mobile Robots in Industrial Environments. In Proceedings of the 15th International Conference, ADHOC-NOW 2016, Lille, France, 4–6 July 2016; Volume 9724, pp. 325–338. [Google Scholar] [CrossRef]

- Derbas, A.M.; Al-Aubidy, K.M.; Ali, M.M.; Al-Mutairi, A.W. Multi-Robot System for Real-Time Sensing and Monitoring. In Proceedings of the International Workshop on Research and Education in Mechatronics (REM), El Gouna, Red Sea, Egypt, 9–11 September 2014. [Google Scholar]

- Wichmann, A.; Okkalioglu, B.D.; Korkmaz, T. The integration of mobile (tele) robotics and wireless sensor networks: A survey. Comput. Commun. 2014, 51, 21–35. [Google Scholar] [CrossRef]

- Koubaa, A.; Abdelmajid, K. (Eds.) Cooperative Robots and Sensor Networks 2014; Springer: Berlin, Germany, 2014. [Google Scholar]

- Santos, F.; Almeida, L.; Lopes, L.S. Self-configuration of an adaptive TDMA wireless communication protocol for teams of mobile robots. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2008; pp. 1197–1204. [Google Scholar]

- Tardioli, D.; Sicignano, D.; Villarroel, J.L. A wireless multi-hop protocol for real-time applications. Comput. Commun. 2015, 55, 4–21. [Google Scholar] [CrossRef]

- Patti, G.; Muscato, G.; Abbate, N.; Lo Bello, L. Towards low-datarate communications for cooperative mobile robots. In Proceedings of the 2015 IEEE World Conference on Factory Communication Systems (WFCS), Palma de Mallorca, Spain, 27–29 May 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Kazala, R.; Taneva, A.; Petrov, M.; Penkov, S. Wireless Network for Mobile Robot Applications. IFAC-PapersOnLine 2015, 48, 231–236. [Google Scholar] [CrossRef]

- Dandashy, T.; Al-Mouhamed, M.; Khan, I. A reliable peer-to-peer protocol for multi-robot operating in mobile ad-hoc wireless networks. Int. Arab J. Inf. Technol. 2019, 16, 72–79. [Google Scholar]

- Huang, H.; Savkin, A.V.; Ding, M.; Huang, C. Mobile robots in wireless sensor networks: A survey on tasks. Compute. Netw. 2019, 148, 1–19. [Google Scholar] [CrossRef]

- Doriya, R.; Mishra, S.; Gupta, S. A brief survey and analysis of multi-robot communication and coordination. In Proceedings of the International Conference on Computing, Communication Automation, Greater Noida, India, 15–16 May 2015; pp. 1014–1021. [Google Scholar] [CrossRef]

- Darif, A.; Hasna, C.; Rachid, S. An Energy-Efficient MAC Protocol for Mobile Wireless Sensor Network Based on IR-UWB; Springer: Berlin, Germany, 2018; pp. 1–12. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Yu, L.; Liu, S. Sequential Fusion Estimation for RSS-Based Mobile Robots Localization With Event-Driven WSNs. IEEE Trans. Ind. Inf. 2016, 12, 1519–1528. [Google Scholar] [CrossRef]

- Maxon, S.; Zhang, F. Extending a routing protocol for mobile robot mesh networking. In Proceedings of the 2017 IEEE Conference on Control Technology and Applications (CCTA), Mauna Lani Resort, HI, USA, 27–30 August 2017; pp. 37–42. [Google Scholar] [CrossRef]

- Sharma, H.; Rajesh, M. Design and simulation of WSN for ZigBee based communication in multi-robot system. In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, Tamil Nadu, India, 1–2 October 2017; pp. 1353–1355. [Google Scholar] [CrossRef]

- Gonga, A.; Landsiedel, O.; Johansson, M. MobiSense: Power-efficient micro-mobility in wireless sensor networks. In Proceedings of the International Conference on Distributed Computing in Sensor Systems and Workshops (DCOSS), Barcelona, Spain, 27–29 June 2011. [Google Scholar]

- Jhumka, A.; Kulkarni, S. On the Design of Mobility-tolerant TDMA-based Media Access Control (MAC) Protocol for Mobile Sensor Networks. In Proceedings of the 4th International Conference on Distributed Computing and Internet Technology (ICDCIT), Bangalore, India, 17–20 December 2007; pp. 42–53. [Google Scholar]

- Sudheendran, S.; Bouachir, O.; Moussa, S.; Dahmane, A.O. Review—Challenges of mobility aware MAC protocols in WSN, year=2018. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, UAE, 6–7 February 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Dong, Q.; Dargie, W. A Survey on Mobility and Mobility-Aware MAC Protocols in Wireless Sensor Networks. IEEE Commun. Surv. Tutor. 2013, 15, 88–100. [Google Scholar] [CrossRef]

- Toscano, E.; Lo Bello, L. A multichannel approach to avoid beacon collisions in IEEE 802.15.4 cluster-tree industrial networks. In Proceedings of the IEEE Conference on Emerging Technologies and Factory Automation, (ETFA), Palma de Mallorca, Spain, 22–25 September 2009. [Google Scholar]

- Patti, G.; Alderisi, G.; Lo Bello, L. Introducing multi-level communication in the IEEE 802.15.4e protocol: The MultiChannel-LLDN. In Proceedings of the IEEE Conference on Emerging Technologies and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–8. [Google Scholar]

- Facchinetti, T.; Almeida, L.; Buttazzo, G.C.; Marchini, C. Real-Time Resource Reservation Protocol for Wireless Mobile Ad Hoc Networks. In Proceedings of the IEEE International Real-Time Systems Symposium (RTSS), Lisbon, Portugal, 5–8 December 2004; pp. 382–391. [Google Scholar]

- Trsek, H.; Jasperneite, J. An isochronous medium access for real-time wireless communications in industrial automation systems—A use case for wireless clock synchronization. In Proceedings of the International IEEE Symposium on Precision Clock Synchronization for Measurement Control and Communication (ISPCS), Munich, Germany, 12–16 September 2011; pp. 81–86. [Google Scholar]

- Trsek, H.; Wisniewski, L.; Toscano, E.; Lo Bello, L. A flexible approach for real-time wireless communications in adaptable industrial automation systems. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2011. [Google Scholar]

- Leonardi, L.; Patti, G.; Lo Bello, L. Multi-Hop Real-Time Communications Over Bluetooth Low Energy Industrial Wireless Mesh Networks. IEEE Access 2018, 6, 26505–26519. [Google Scholar] [CrossRef]

- Patti, G.; Leonardi, L.; Lo Bello, L. A Bluetooth Low Energy real-time protocol for Industrial Wireless mesh Networks. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 4627–4632. [Google Scholar] [CrossRef]

- An, P. An Algorithm of Mobile Robot Node Location Based on Wireless Sensor Network. Int. J. Online Eng. 2017, 13, 4. [Google Scholar] [CrossRef][Green Version]

- Liu, W.; Lv, M.; Luo, Y. Sequential Time-of-Flight: Localization of mobile robots with single receiver. J. Harbin Instit. Technol. 2016, 23, 37–43. [Google Scholar] [CrossRef]

- Cadger, F.; Curran, K.; Santos, J.; Moffet, S. A Survey of Geographical Routing in Wireless Ad-Hoc Networks. IEEE Commun. Surv. Tutor. 2013, 15, 621–653. [Google Scholar] [CrossRef]

- Karp, B.; Kung, H.T. Gpsr: Greedy perimeter stateless routing for wireless networks. In Proceedings of the Annual International Conference on Mobile Computing and Networking (MobiCom), Atlanta, GA, USA, 23–28 September 2000; ACM: New York, NY, USA, 2000; pp. 243–254. [Google Scholar]

- STEVAL-IKR002V5: SPIRIT1—Low Data Rate Transceiver—915 MHz—Full Kit. 2014. Available online: https://www.st.com/resource/en/data_brief/steval-ikr002v5.pdf (accessed on 10 December 2019).

- Rizk, Y.; Awad, M.; Tunstel, E.W. Cooperative Heterogeneous Multi-Robot Systems: A Survey. ACM Comput. Surv. 2019, 52, 1–31. [Google Scholar] [CrossRef]

- Khan, A.; Rinner, B.; Cavallaro, A. Cooperative Robots to Observe Moving Targets: Review. IEEE Trans. Cybern. 2018, 48, 187–198. [Google Scholar] [CrossRef] [PubMed]

- Rosa, L.; Cognetti, M.; Nicastro, A.; Alvarez, P.; Oriolo, G. Multi-task Cooperative Control in a Heterogeneous Ground-Air Robot Team. IFAC-PapersOnLine 2015, 48, 53–58. [Google Scholar] [CrossRef]

| Payload (Bytes) | (s) | (s) | (s) | Tot. (s) |

|---|---|---|---|---|

| 87 | 900 | 3400 | 800 | 5100 |

| 75 | 800 | 3100 | 700 | 4600 |

| 63 | 700 | 2700 | 700 | 4100 |

| 51 | 600 | 2300 | 600 | 3500 |

| 39 | 500 | 1900 | 500 | 2900 |

| 27 | 400 | 1500 | 400 | 2300 |

| 15 | 300 | 1100 | 300 | 1700 |

| 3 | 200 | 800 | 200 | 1200 |

| Number of Nodes | Number of Clusters | Superfram Config. | Slot Duration |

|---|---|---|---|

| 3 | 3 | [0, 1, 2] | 9.6 ms |

| 4 | 4 | [0, 1, 2, 3] | 9.6 ms |

| 5 | 5 | [0, 1, 2, 3, 4] | 9.6 ms |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patti, G.; Leonardi, L.; Lo Bello, L. A Novel MAC Protocol for Low Datarate Cooperative Mobile Robot Teams. Electronics 2020, 9, 235. https://doi.org/10.3390/electronics9020235

Patti G, Leonardi L, Lo Bello L. A Novel MAC Protocol for Low Datarate Cooperative Mobile Robot Teams. Electronics. 2020; 9(2):235. https://doi.org/10.3390/electronics9020235

Chicago/Turabian StylePatti, Gaetano, Luca Leonardi, and Lucia Lo Bello. 2020. "A Novel MAC Protocol for Low Datarate Cooperative Mobile Robot Teams" Electronics 9, no. 2: 235. https://doi.org/10.3390/electronics9020235

APA StylePatti, G., Leonardi, L., & Lo Bello, L. (2020). A Novel MAC Protocol for Low Datarate Cooperative Mobile Robot Teams. Electronics, 9(2), 235. https://doi.org/10.3390/electronics9020235