Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine–Human Feedbacks

Abstract

1. Introduction

1.1. Typical Use of Vibrations in Orthopedic Human–Machine–Human Interaction

1.2. Typical Use of Vibrations in Techncial Diagnistics

1.3. Cells and Kinds of Haptic Perception

1.4. Prospective Use of Vibrations in Orthopedic Human–Machine–Human Interaction and Techncial Diagnistics of Prosthetic Implants

1.5. Advantages and Disadvantages of Direct Contact (Exposure) Inbuilt Haptic Vibration Actuators

- A changing vibration frequency and amplitude.

- The possibility to be located stably, be fixed in a firm way in rehabilitation devices (for example, in a tube) or be fixed to various shapes and parts, and the promise to wait for a signal.

- Depending on the mass of the rehabilitation devices, actuators of different capacity are needed.

1.6. Potential Applications

- External prosthetic structures have different masses, components, loading conditions, etc.

- External prostheses are made individually for each patient.

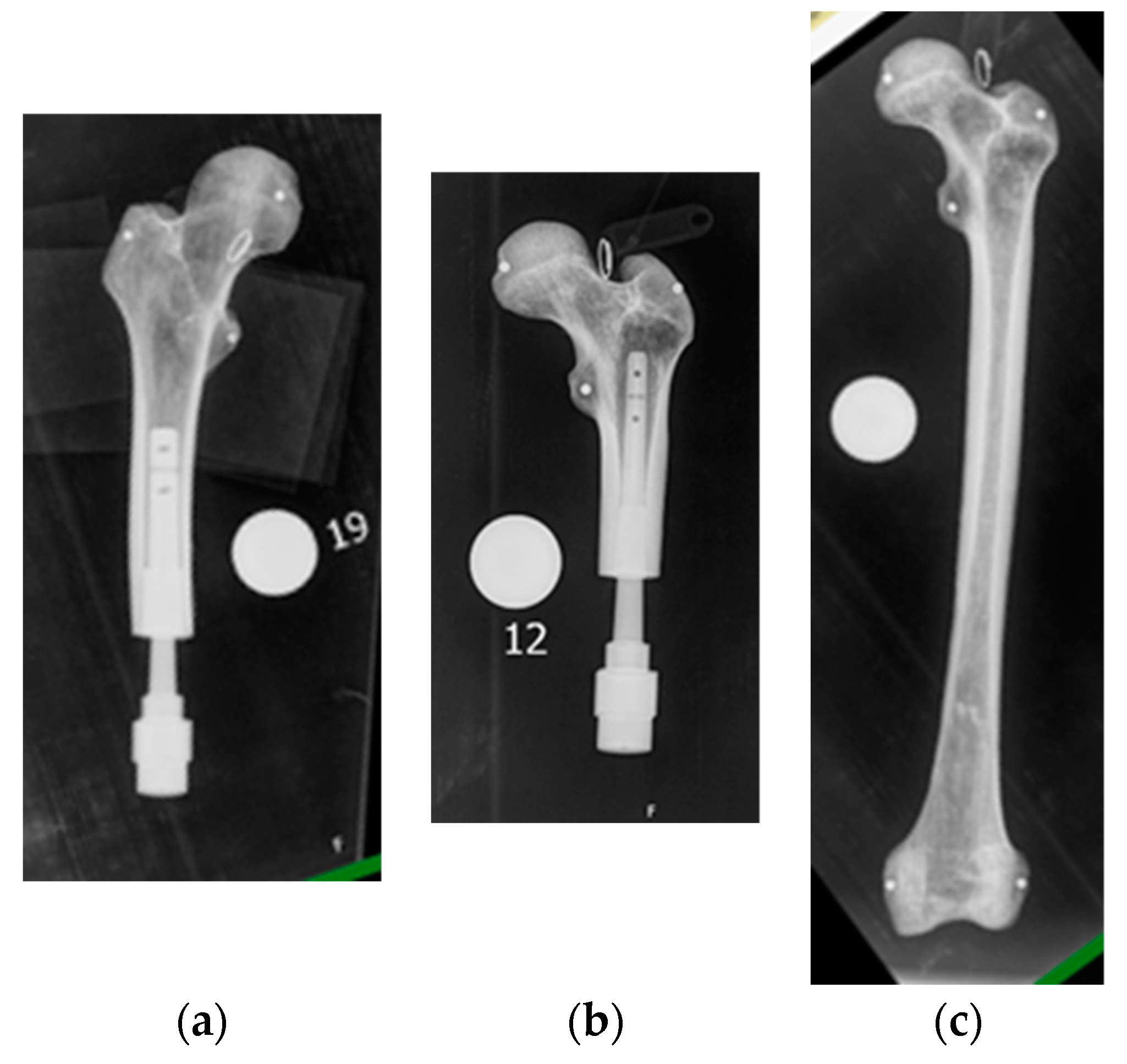

- Amputation stumps for each patient have different masses, bone lengths, diameters, and densities Figure 2a–c.

1.7. Kinds of Vibration Actuators

2. Hypothesis, Methods and Technical Assumptions

2.1. Hypothesis

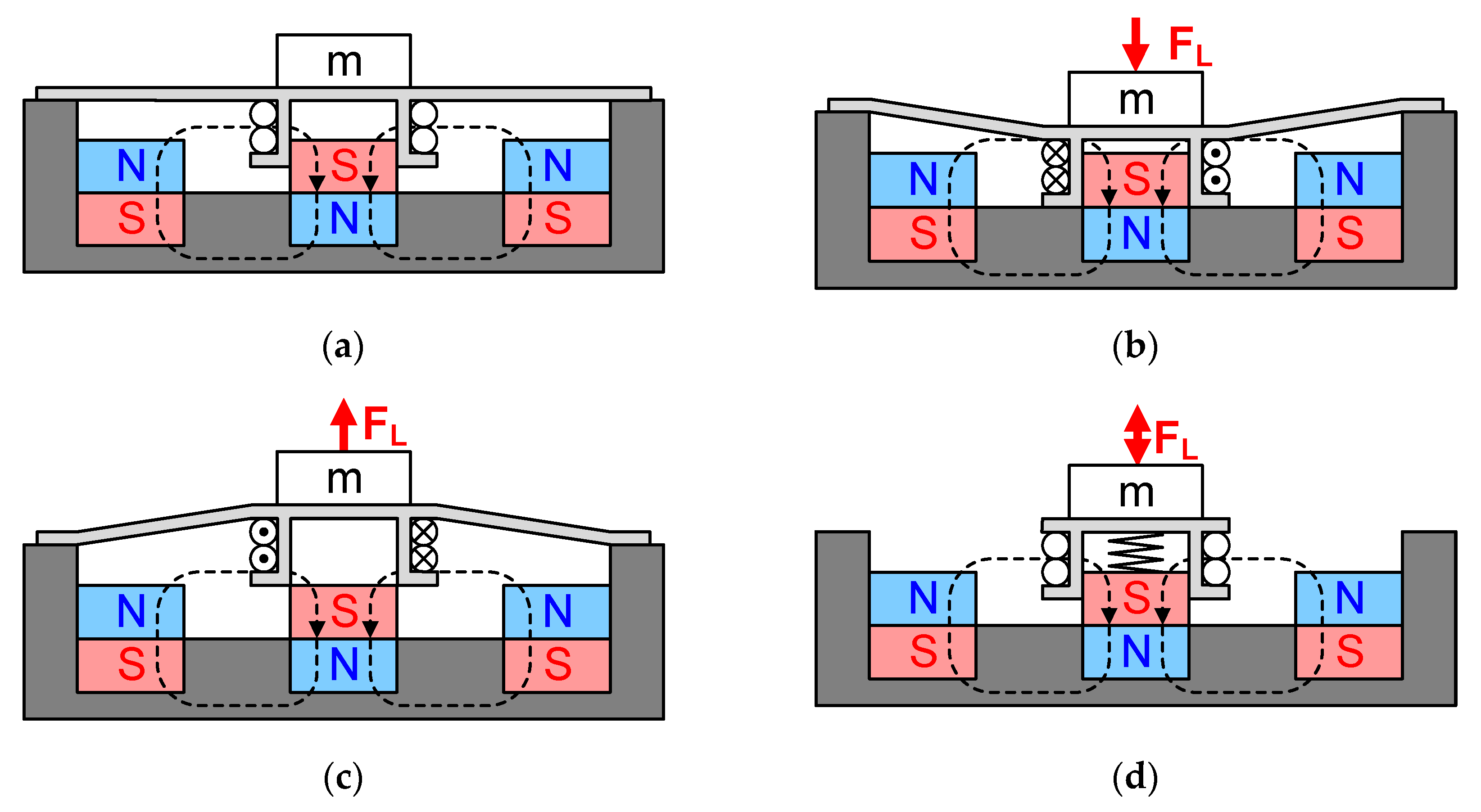

2.2. Construction of Electromagnetic Vibration Actuator

2.3. Mathematical Model of Electromagnetic Vibration Actuator

2.4. Technical Assumptions

- (1)

- The inductance of coil L calculated as coreless coil that significantly reduces its value;

- (2)

- defining the dimensions of the moving part allows for the use of thicker wires with lower R;

- (3)

- the orientation of the actuator and gravitation g9.8 can be ignored if the stiffness of the membrane is high enough to keep the mechanical operation on the linearity range;

- (4)

- the above stated considerations makes the electrical constant of the system much lower than the mechanical one (as it take place in the case of electrical motors, etc.), which allows for the simplification of (15) and (17) into a single 2nd order ODE:where in the tentatively obtained Equation (18) describes a damped spring pendulum system where the frequency of oscillations depends on the stiffness of the membrane (spring) k and accelerated mass m as

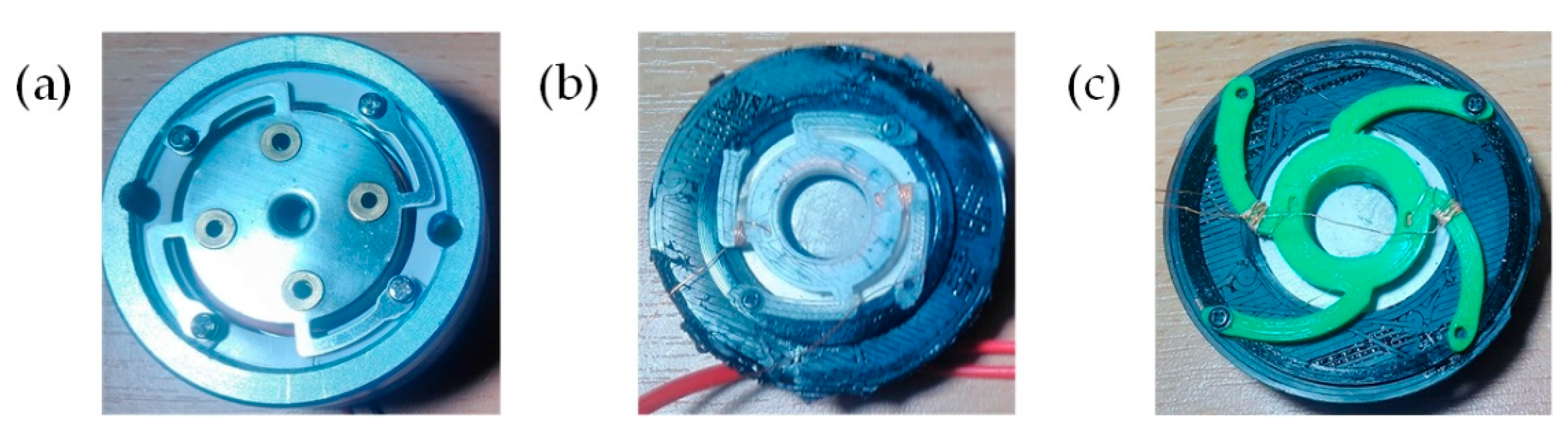

3. 3-D Printed of Vibration Actuators and their Initial Evaluation

4. Discussion on the Combined 3D Printed Design of Vibration Actuators

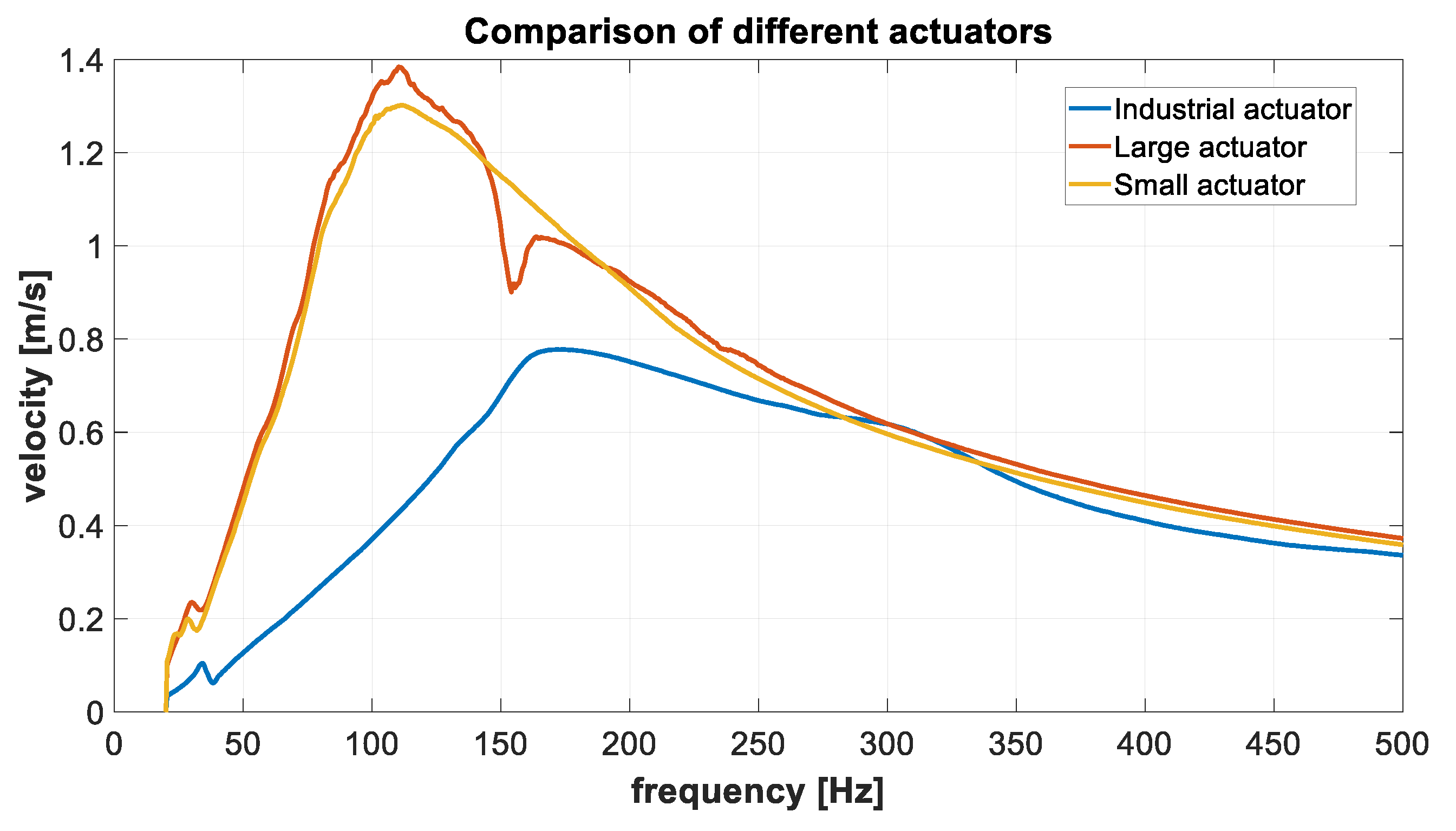

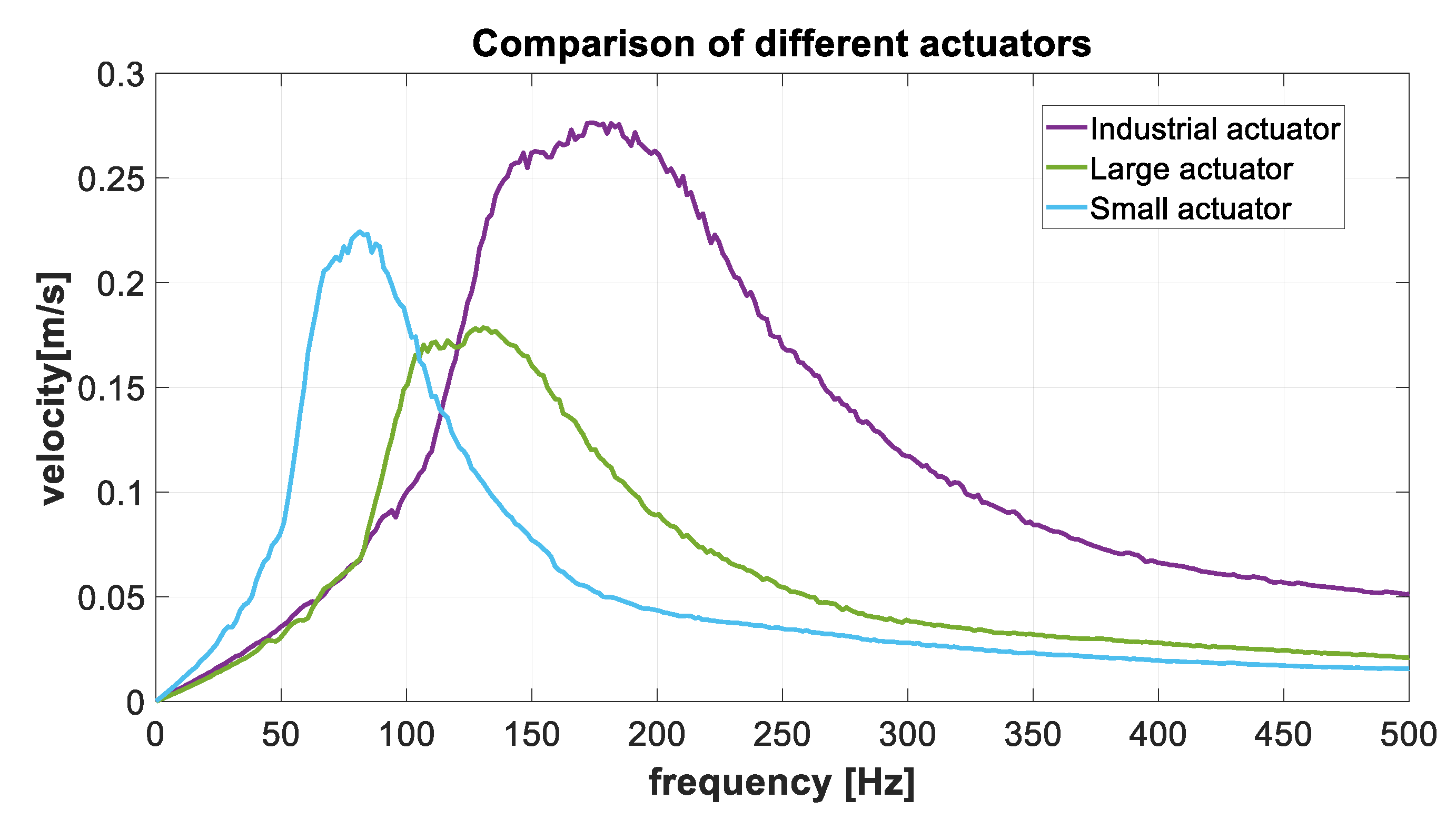

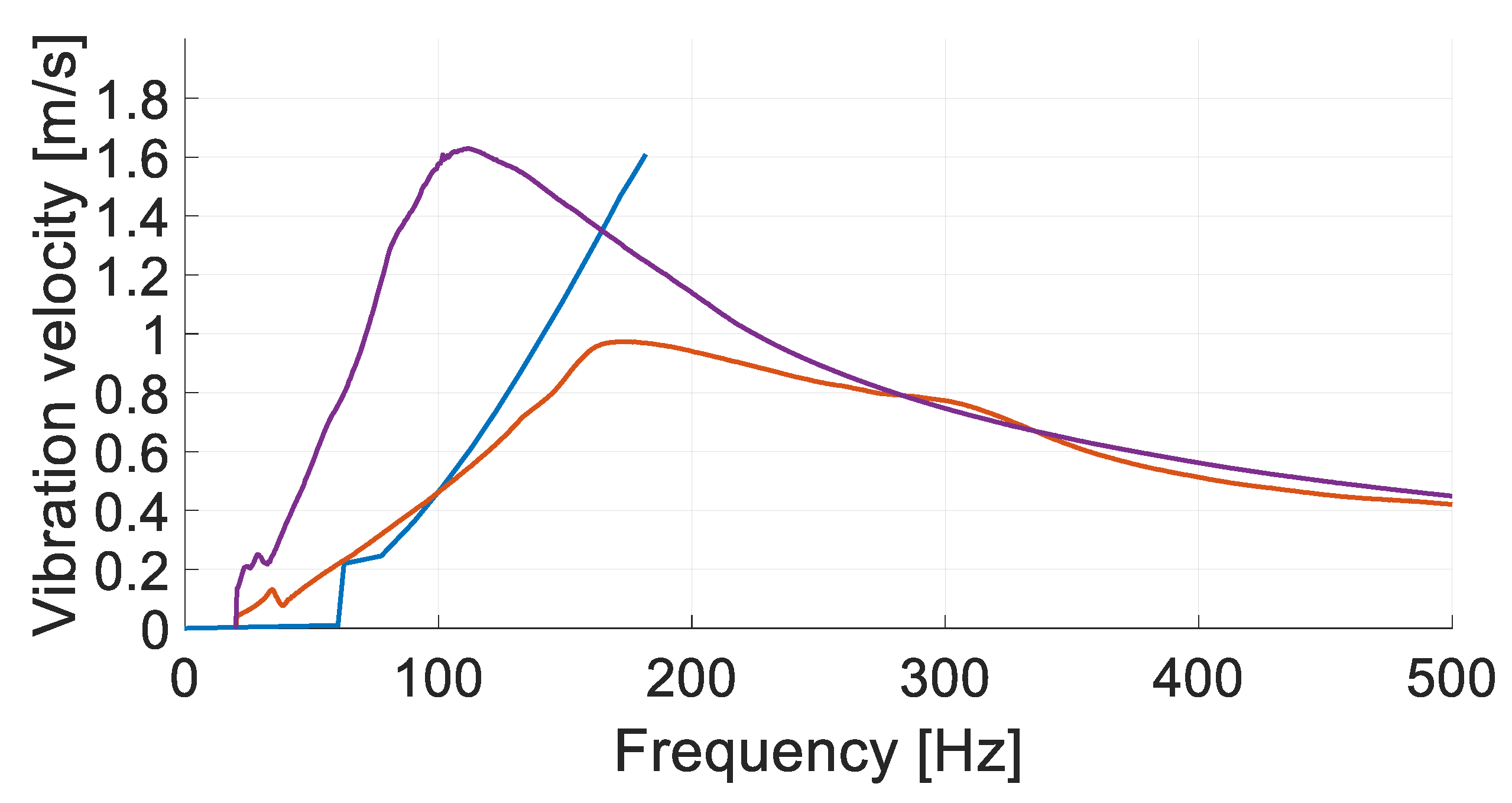

4.1. Comparative Evaluation of Existing and Proposed 3D Printed Vibration Actuators

4.2. Combining of Developed 3D Printed Vibration Actuators in a Single S/W Configurable Design

5. Discussion and Conclusions

- (1)

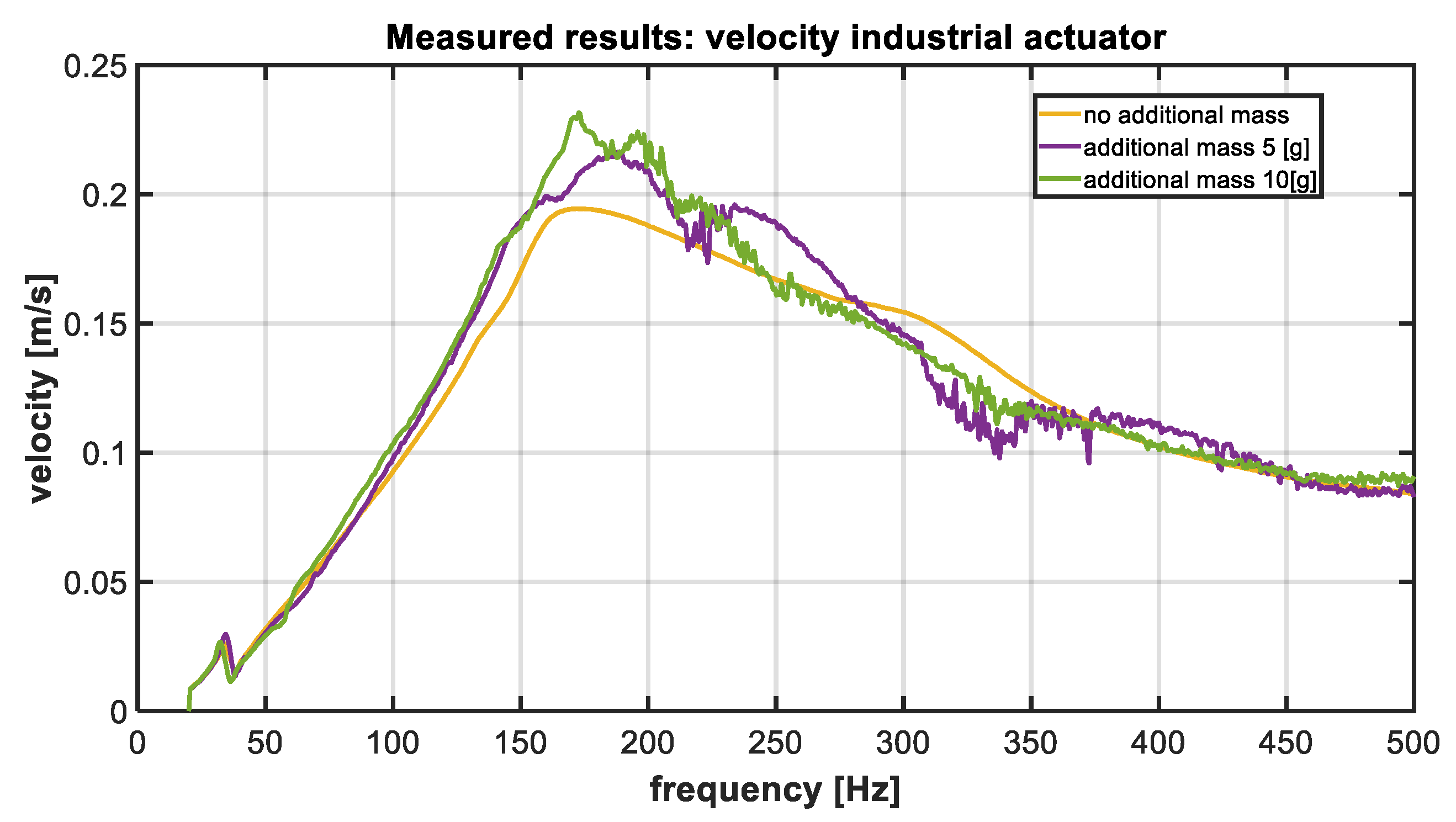

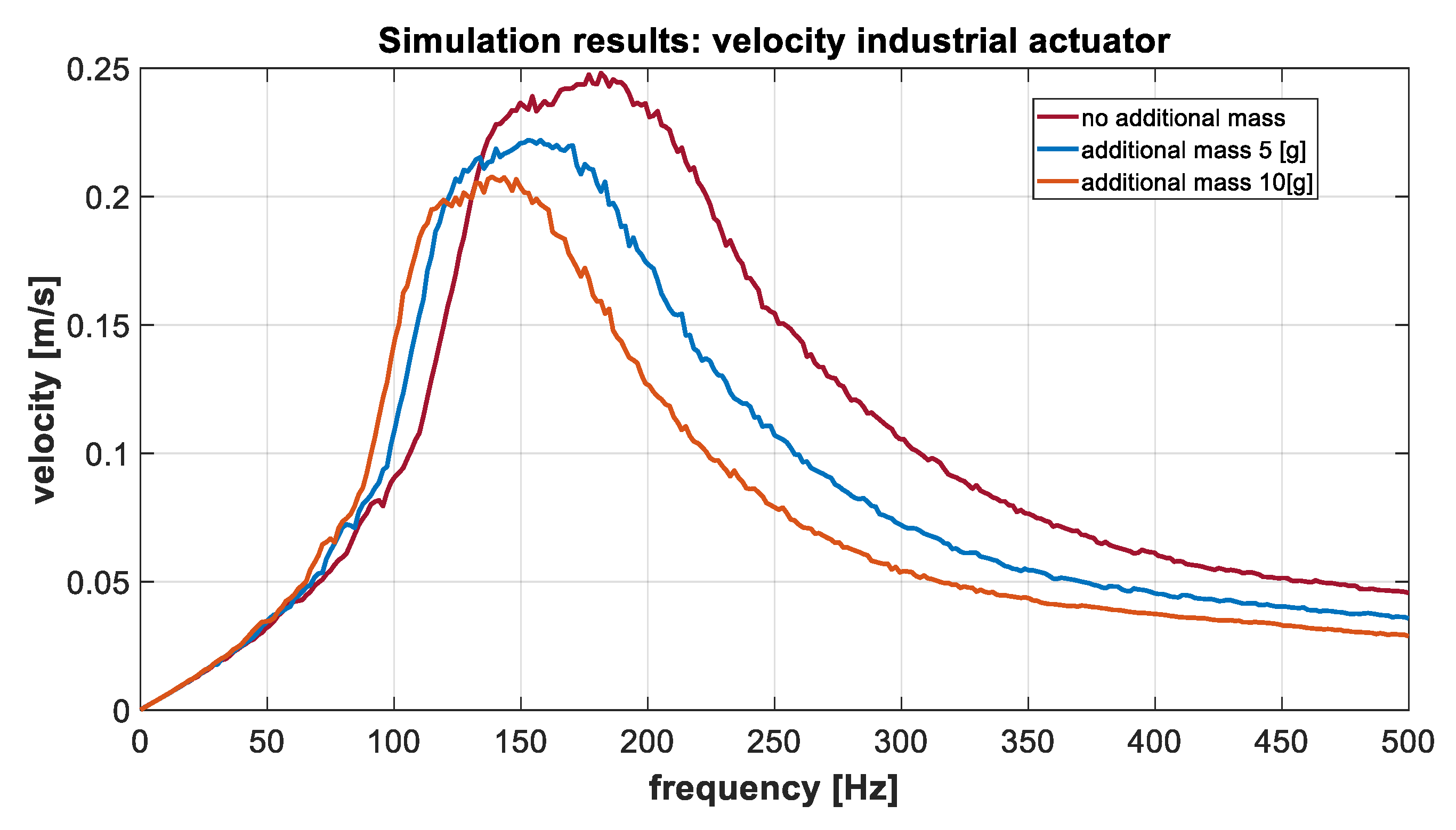

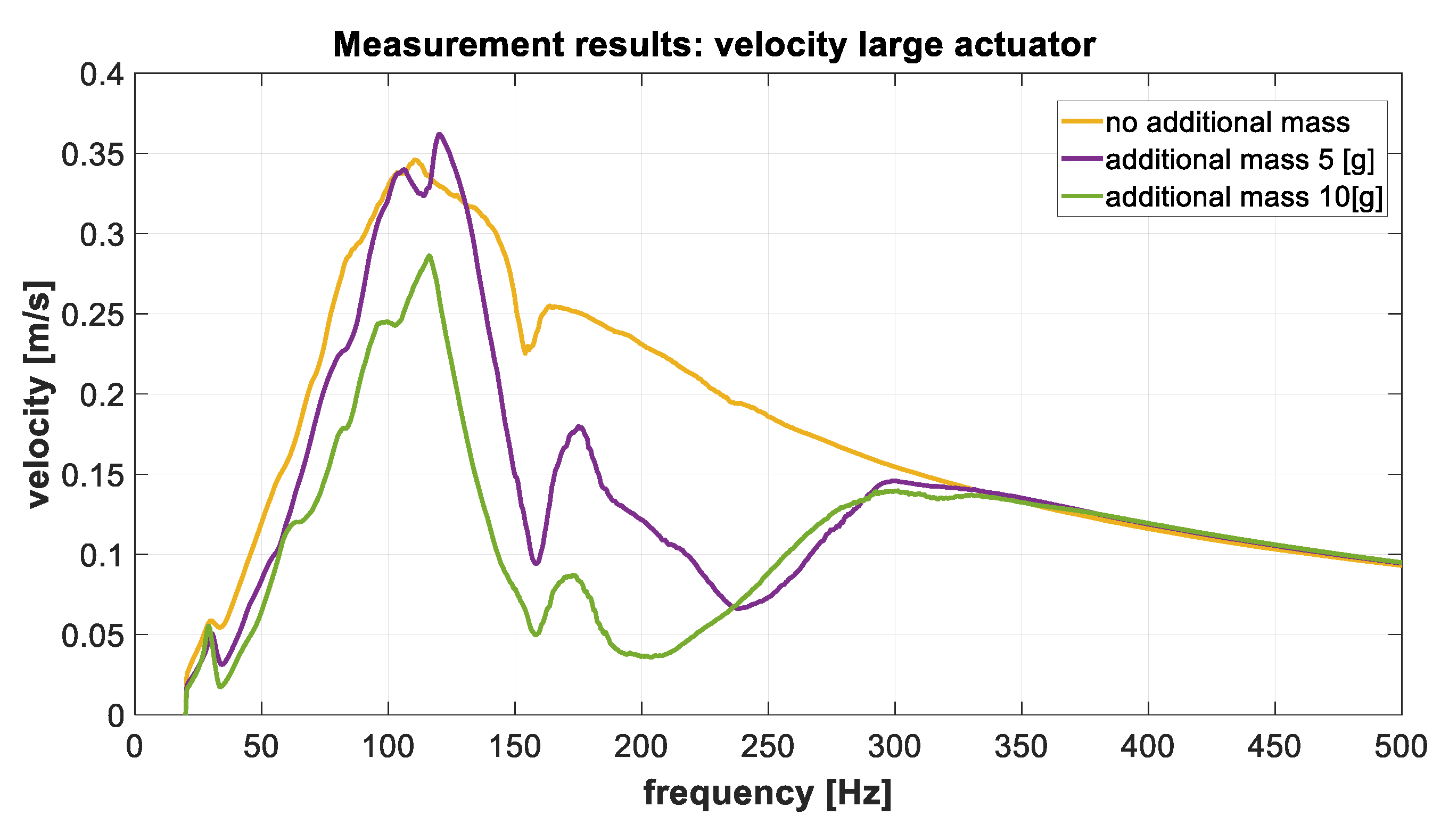

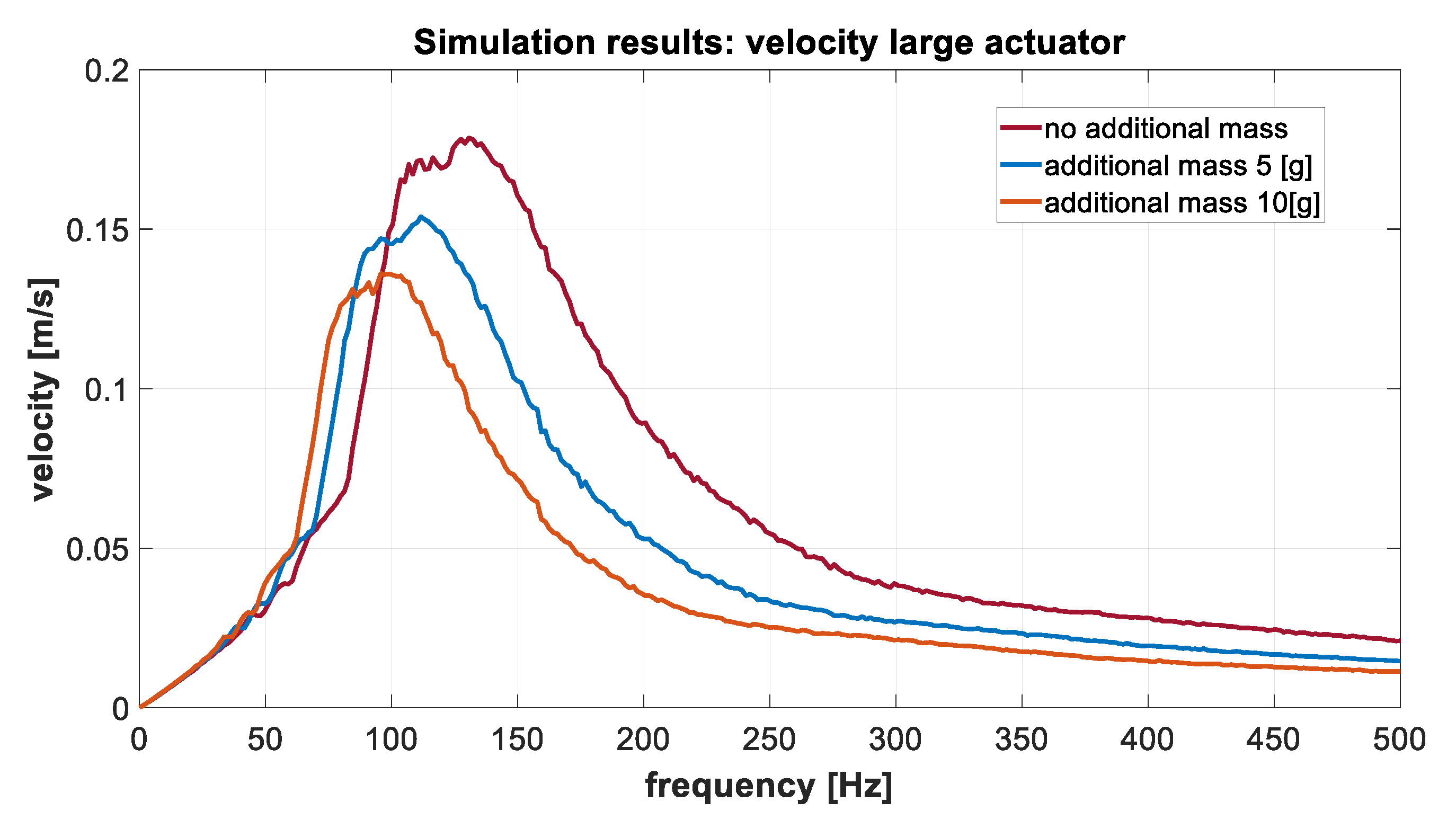

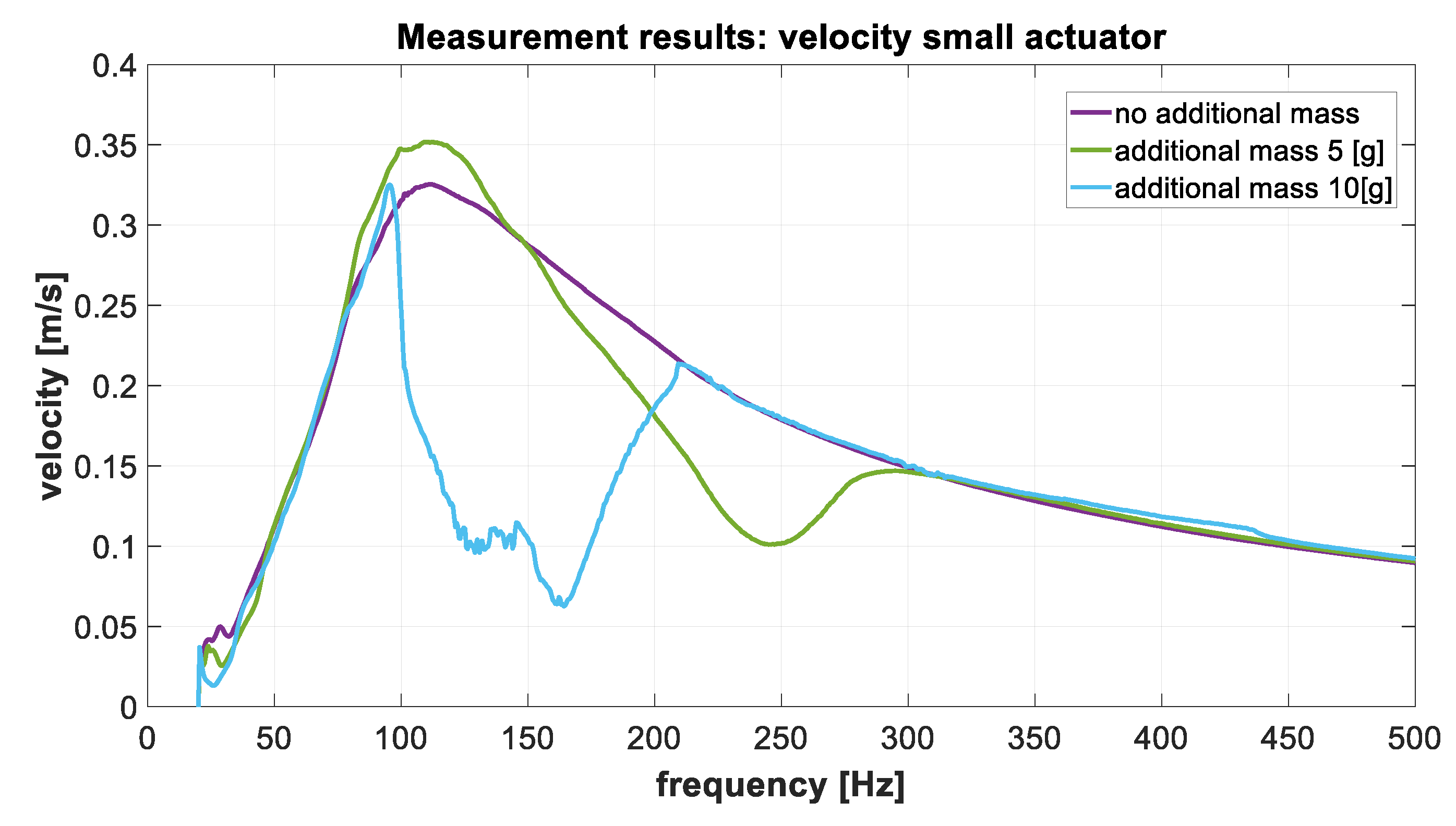

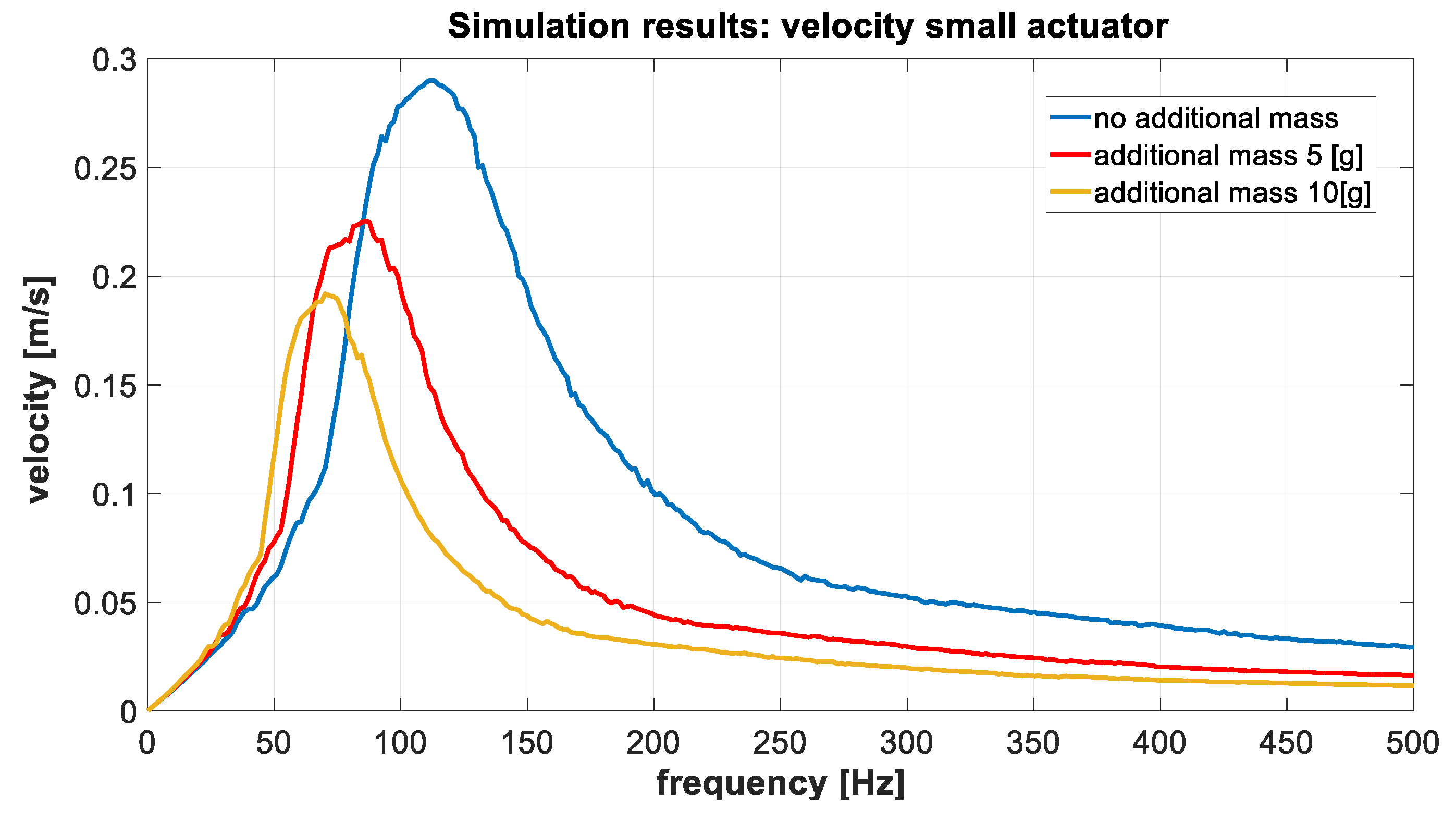

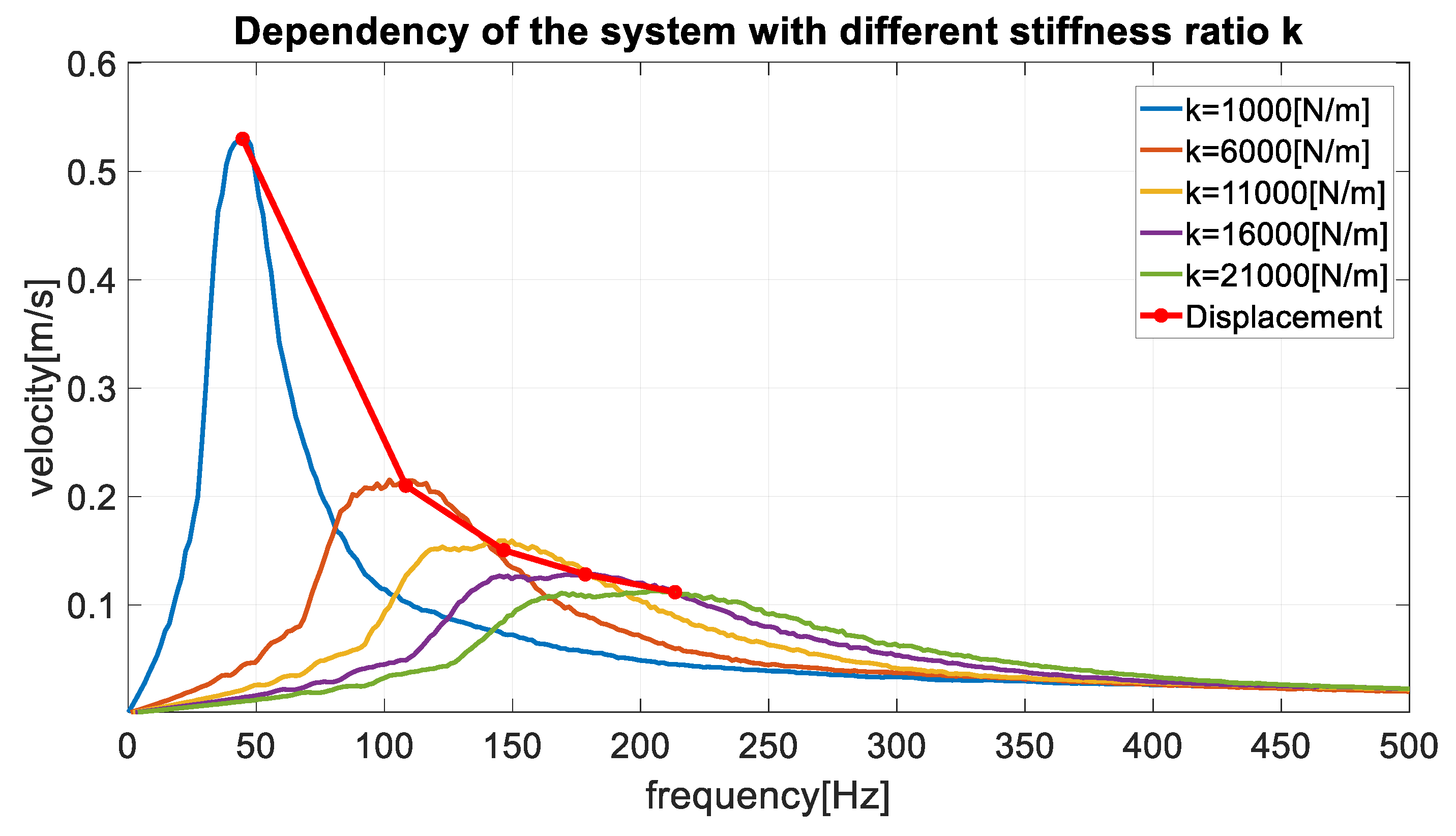

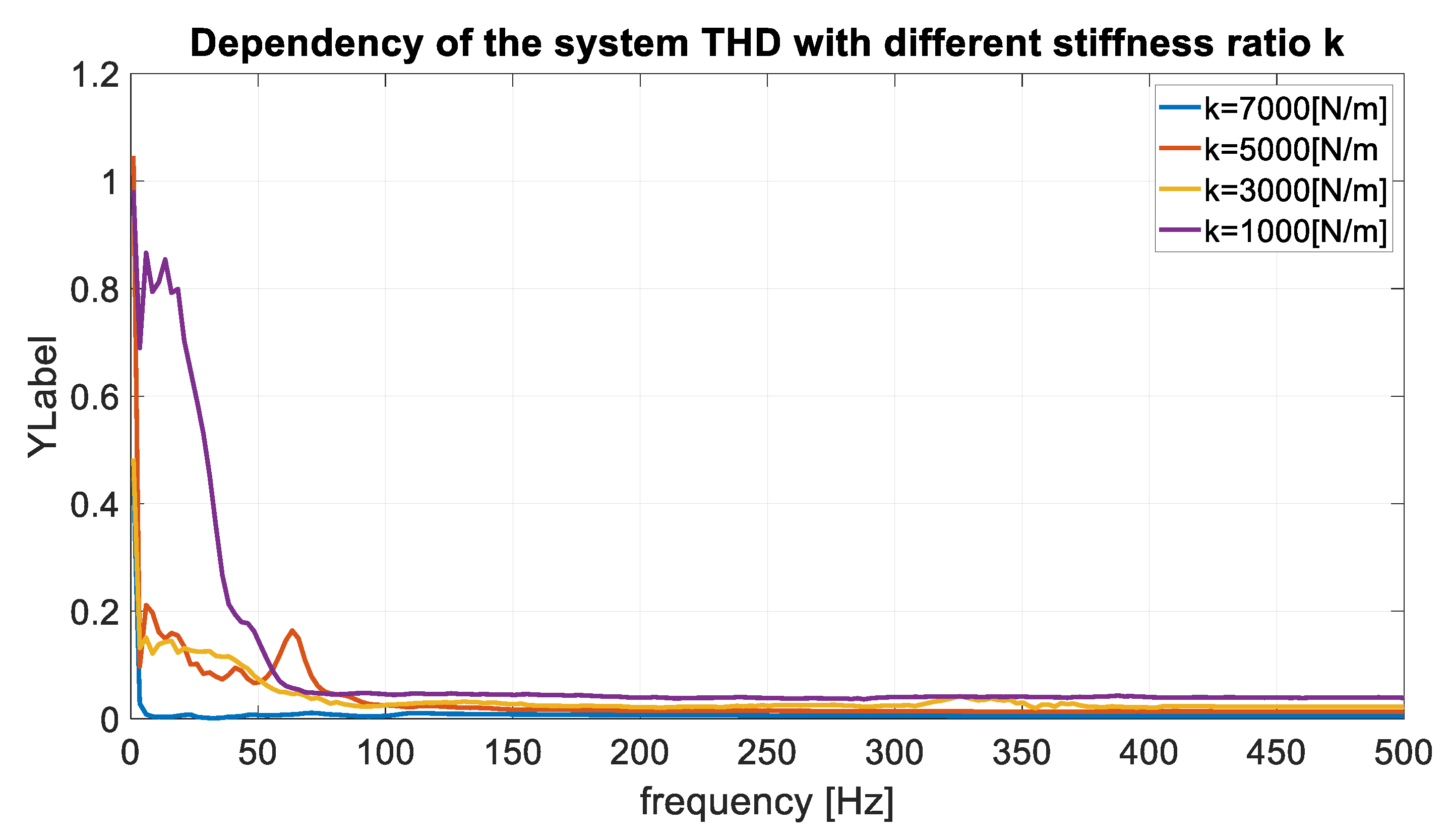

- The simulation with the obtained mathematical model and experiments showed that the point of maximal power output depended on the stiffness coefficient of the membrane of the proposed vibration actuator, as well as on the mass attached to the membrane; the influence of these parameters corresponds to Equation (19) if taking into account measurement declinations;

- (2)

- the provided data about consumed materials and energy, permanent magnets, auxiliary components (required for fastening, connecting, etc.), and invested labor manufacturing confirm that the design of the actuator can be easily modified for a particular frequency at which the power output is maximal; that maximal contribution to the cost of the actuator can be made by permanent magnets;

- (1)

- The real-time programmable modification of stiffness/mass—assuming the change of these parameters with the help of dedicated electronic equipment.

- (2)

- The further is reduction of the cost of actuators; since the most significant contribution to cost is made by magnets, the primary goal of such a reduction of the elaboration of other excitation in schemes, e.g., an electrodynamic scheme in which the excitation magnetic field is produced by an electromagnet.

- (3)

- It is necessary to agree on the mass of the base of the actuator and the membrane parameter to get rid of extra resonances.

Author Contributions

Funding

Conflicts of Interest

References

- Sowe, S.K.; Simmon, E.; Zettsu, K.; de Vaulx, F.; Bojanova, I. Cyber-Physical-Human Systems: Putting People in the Loop. IT Prof. 2016, 18, 10–13. [Google Scholar] [CrossRef] [PubMed]

- Serpanos, D. The Cyber-Physical Systems Revolution. Computer 2018, 51, 70–73. [Google Scholar] [CrossRef]

- Stoker, C.R.; Burch, D.R.; Hine, B.P.; Barry, J. Antarctic undersea exploration using a robotic submarine with a telepresence user interface. IEEE Expert 1995, 10, 14–23. [Google Scholar] [CrossRef]

- Iborra, A.; Pastor, J.A.; Alvarez, B.; Fernandez, C.; Merono, J.M.F. Robots in radioactive environments. IEEE Robot. Autom. Mag. 2003, 10, 12–22. [Google Scholar] [CrossRef]

- Utsumi, M.; Hirabayashi, T.; Yoshie, M. Development for teleoperation underwater grasping system in unclear environment. In Proceedings of the 2002 Internnational Symposium on Underwater Technology (Cat. No.02EX556), Tokyo, Japan, 19 April 2002; pp. 349–353. [Google Scholar]

- Radi, M.; Nitsch, V. Telepresence in Industrial Applications: Implementation Issues for Assembly Tasks. Presence Teleoperators Virtual Environ. 2010, 19, 415–429. [Google Scholar] [CrossRef]

- Hagn, U.; Ortmaier, T.; Konietschke, R.; Kubler, B.; Seibold, U.; Tobergte, A.; Nickl, M.; Jorg, S.; Hirzinger, G. Telemanipulator for remote minimally invasive surgery. IEEE Robot. Autom. Mag. 2008, 15, 28–38. [Google Scholar] [CrossRef]

- Mayer, H.; Nagy, I.; Knoll, A.; Braun, E.U.; Bauernschmitt, R.; Lange, R. Haptic Feedback in a Telepresence System for Endoscopic Heart Surgery. Presence Teleoperators Virtual Environ. 2007, 16, 459–470. [Google Scholar] [CrossRef]

- Chen, Y.; Mazumdar, A.; Brooks, C.F.; Van Bloemen Waanders, B.G.; Bond, S.D.; Nemer, M.B. Remote Distributed Vibration Sensing Through Opaque Media Using Permanent Magnets. IEEE Trans. Magn. 2018, 54, 1–13. [Google Scholar] [CrossRef]

- Lim, W.Q.; Zhang, D.H.; Zhou, J.H.; Belgi, P.H.; Chan, H.L. Vibration-based fault diagnostic platform for rotary machines. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 1404–1409. [Google Scholar] [CrossRef]

- Gai, V.E. Method of diagnostics of the state of rolling element bearing on the basis of the theory of active perception. In Proceedings of the 2014 International Conference on Mechanical Engineering, Automation and Control Systems (MEACS), Tomsk, Russia, 16–18 October 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Vaimann, T.; Sobra, J.; Belahcen, A.; Rassõlkin, A.; Rolak, M.; Kallaste, A. Induction machine fault detection using smartphone recorded audible noise. IET Sci. Meas. Technol. 2018, 12, 554–560. [Google Scholar] [CrossRef]

- Climente-Alarcon, V.; Antonino-Daviu, J.A.; Vedreño-Santos, F.; Puche-Panadero, R. Vibration Transient Detection of Broken Rotor Bars by PSH Sidebands. IEEE Trans. Ind. Appl. 2013, 49, 2576–2582. [Google Scholar] [CrossRef]

- Stone, G.C. Condition monitoring and diagnostics of motor and stator windings—A review. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2073–2080. [Google Scholar] [CrossRef]

- Procházka, P. Methods and Facilities for Calibration of Noncontact Blade Vibration Diagnostic Systems. IEEE Trans. Instrum. Meas. 2018, 67, 2345–2352. [Google Scholar] [CrossRef]

- Boloznev, V.V.; Mirsaitov, F.N.; Noskov, V.Y. Signal and noise characteristics of autodynes in solving problems of gas-turbine engine vibration-based diagnostics. In Proceedings of the 2014 24th International Crimean Conference Microwave and Telecommunication Technology, Sevastopol, Ukraine, 7–13 September 2014; pp. 1019–1022. [Google Scholar] [CrossRef]

- Secic, A.; Kuzle, I. Audio-based On-Load Tap Changer diagnostics: correlation of sound and vibration fingerprints. In Proceedings of the 2018 International Symposium on Industrial Electronics (INDEL), Banja Luka, Bosnia and Herzegovina, 1–3 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Zizins-Malisevs, S.; Poiss, G. Power transformer mechanical condition assessment with a vibration-based diagnostic method. In Proceedings of the 2015 56th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 14 October 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Trendafilova, I.; Cartmell, M.P.; Ostachowicz, W. Vibration-based damage detection in an aircraft wing scaled model using principal component analysis and pattern recognition. J. Sound Vib. 2008, 313, 560–566, ISSN 0022-460X. [Google Scholar] [CrossRef]

- Heirich, O.; Steingass, A.; Lehner, A.; Strang, T. Velocity and location information from onboard vibration measurements of rail vehicles. In Proceedings of the 16th International Conference on Information Fusion, Istanbul, Turkey, 9–12 July 2013; pp. 1835–1840. [Google Scholar]

- Vinet, L.; Zhedanov, A. Engineering Haptic Devices; Springer: London, UK, 2014; Volume 44. [Google Scholar]

- Afzal, M.R.; Oh, M.K.; Lee, C.H.; Park, Y.S.; Yoon, J. A Portable Gait Asymmetry Rehabilitation System for Individuals with Stroke Using a Vibrotactile Feedback. BioMed Res. Int. 2015, 2015, 16. [Google Scholar] [CrossRef] [PubMed]

- Kingma, H.; Felipe, L.; Gerards, M.C.; Gerits, P.; Guinand, N.; Perez-Fornos, A.; Demkin, V.; Van de Berg, R. Vibrotactile feedback improves balance and mobility in patients with severe bilateral vestibular loss. J. Neurol. 2018, 265, 1–8. [Google Scholar]

- Chen, B.; Feng, Y.; Wang, Q. Combining Vibrotactile Feedback with Volitional Myoelectric Control for Robotic Transtibial Prostheses. Front. Neurorobot. 2016, 10, 8. [Google Scholar] [CrossRef] [PubMed]

- Technical Committee CEN/TC 293. European Standard prEN 12184:2004: Electrically Powered Wheelchairs, Scooters and Their Chargers-Requirements and Test Methods; European Standard: Brussels, Belgium, 2004. [Google Scholar]

- Hägström, E.; Hagberg, K.; Rydevik, B.; Brånemark, R. Vibrotactile evaluation: Osseointegrated versus socket-suspended transfemoral prostheses. J. Rehabil. Res. Dev. 2013, 50, 1423–1434. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, R.; Brånemark, R.; Olmarker, K.; Rydevik, B.; Steenberghe, D.V.; Brånemark, P.I. Evaluation of the psychophysical detection threshold level for vibrotactile and pressure stimulation of prosthetic limbs using bone anchorage or soft tissue support. Prosthet. Orthot. Int. 2000, 24, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Uchino, K. Piezoelectric ultrasonic motors: Overview. Smart Mater. Struct. 1998, 7, 273–285. [Google Scholar] [CrossRef]

- Belly, C.; Porchez, T.; Bagot, M.; Claeyssen, F. Improvement of Linear and Rotative Stepping Piezo Actuators using design and control. In Proceedings of the ACTUATOR2012, 13th International Conference on New Actuators, Bremen, Germany, 18–20 June 2012; pp. 246–249. [Google Scholar]

- Rowe, M.J.; Tracey, D.J.; Mahns, D.A.; Sahai, V.; Ivanusic, J.J. Mechanosensory Perception: Are There Contributions from Bone-Associated Receptors? In Proceedings of the Symposium From Osseointegration to Osseoperception: The Functional Translation, (December 2003), Sydney, Australia, 24 February 2005; pp. 100–108. [Google Scholar]

- Available online: https://analogdiscovery.com/ (accessed on 19 March 2019).

- Available online: https://reference.digilentinc.com/reference/software/waveforms/waveforms-3/start (accessed on 19 March 2019).

- Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/adxl335.pdf (accessed on 19 March 2019).

| Cell (Mechanoreceptor) | Adaptation | Perception Area | Sensitivity | f (Hz) | Sensitive to |

|---|---|---|---|---|---|

| Merkel disk (SA-I) | Slow | Small | Distinct | 0–50 | Texture/pressure |

| Ruffini endings (SA-II) | Slow | Large | Diffuse | 0–20 | Texture/pressure |

| Meissner corpuscle (RA-I) | Rapid | Small | Distinct | 10–50 | Vibration |

| Pacinian corpuscle (RA-II) | Rapid | Large | Diffuse | 40–1000 | Vibration |

| Nr. | Rehabilitation Device Goups | Weight (kg) |

|---|---|---|

| 1. | Prostheses of Upper Extremities | 0.5–3 kg |

| 2. | Prostheses of Lower Extremities Above knee prostheses Below knee prostheses | 3–7 kg 1–3 kg |

| 3. | Crutches | 0.5–1 kg |

| 4. | Rollators and walking in a frame | 1.5–5 kg |

| 5. | Wheelchairs without electric drive | 8–25 kg |

| 6. | Wheelchairs with electric drive | –100 kg |

| Type | Independent Control of | Other Remarks | |

|---|---|---|---|

| Frequency | Magnitude | ||

| Eccentric motor | Only together | Most available | |

| Linear motors | + | − | - |

| Electromagnets | + | − | - |

| Voice coil motors | + | + | On market or acoustics (high impedance) |

| Piezoelectric linear | + | + | High voltage required [28] |

| Piezoelectric rotation | + | + | High voltage required [29] |

| Small Actuator | Large Actuator | Industrial Actuator | |

|---|---|---|---|

| Membrane mass (kg) | 0.00203 | 0.00306 | 0.00793 |

| Foot mass (kg) | 0.00063 | 0.00063 | 0.00656 |

| Base mass (kg) | 0.01941 | 0.02920 | 0.22700 |

| Accelerometer mass (kg) | 0.00400 | 0.00400 | 0.00400 |

| Membrane stiffness (N/m) | 3184 | 1639 | 21345 |

| Resistance (Ω) | 4.32 | 4.50 | 3.57 |

| Inductance (µH) | 157.20 | 166.80 | 675.00 |

| Induction (T) | 0.23 | 0.20 | 0.65 |

| Damping ratio (N/m2) | 1.54 | 1.20 | 1.74 |

| Length of wire (m) | 4 | 4 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galkin, I.; Vorobyov, M.; Gainutdinovs, O.; Studers, P. Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine–Human Feedbacks. Electronics 2019, 8, 810. https://doi.org/10.3390/electronics8070810

Galkin I, Vorobyov M, Gainutdinovs O, Studers P. Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine–Human Feedbacks. Electronics. 2019; 8(7):810. https://doi.org/10.3390/electronics8070810

Chicago/Turabian StyleGalkin, Ilya, Maxim Vorobyov, Oskars Gainutdinovs, and Peteris Studers. 2019. "Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine–Human Feedbacks" Electronics 8, no. 7: 810. https://doi.org/10.3390/electronics8070810

APA StyleGalkin, I., Vorobyov, M., Gainutdinovs, O., & Studers, P. (2019). Customized Vibration Generator for State of Health Monitoring of Prosthetic Implants and Pseudo-Bionic Machine–Human Feedbacks. Electronics, 8(7), 810. https://doi.org/10.3390/electronics8070810