On-Site Lightning Impulse Test and Process Optimization Research on Distribution Network Equipment

Abstract

1. Introduction

2. Distribution of Test Sites and Equipment

2.1. Portable Lightning Impulse Generator

2.2. Usability Analysis of the Lightning Impulse Generator

2.3. Distribution of Test Sites

3. The Generation Principle of Standard Lightning Impulse

3.1. Principle of Lightning Impulse Generator

3.2. The Influence of Wave Modulation Circuit on Lightning Impulse Waveform

4. Experimental Determinations

4.1. Experimental Simulation Analysis

4.2. Experimental Data Management and Automated Test Reporting

- (1)

- Data acquisition module: The voltage signal generated during the test is processed by the signal modulation board, the collected data is cached, the test data is collected through oscilloscope channel 2, and the voltage signal obtained by the oscilloscope is imported into the host computer.

- (2)

- Real-time data analysis module: This module identifies, stores, and optimizes the acquired data stream. Due to the large data interference in field tests, the acquired data is subject to large noise interference. Therefore, an anti-interference method is introduced to smooth and denoise the pre-processed waveform, identify the processed data, and obtain the peak value, front time, time to half-value and other data required for the test.

- (3)

- Communication module: The measurement system uses an oscilloscope as the impact test data acquisition device, and a computer as the control platform. The oscilloscope and the computer are connected through the TCP/IP protocol, and the computer is used to control data acquisition and data management.

- (4)

- Test report generation module: By setting the parameters such as the save data type, save path, format, etc., on the computer, the system will automatically generate the impact test report in sequence according to the test time to facilitate the evaluation and management of the test data results.

4.3. Impulse Test of Common Power Distribution Equipment

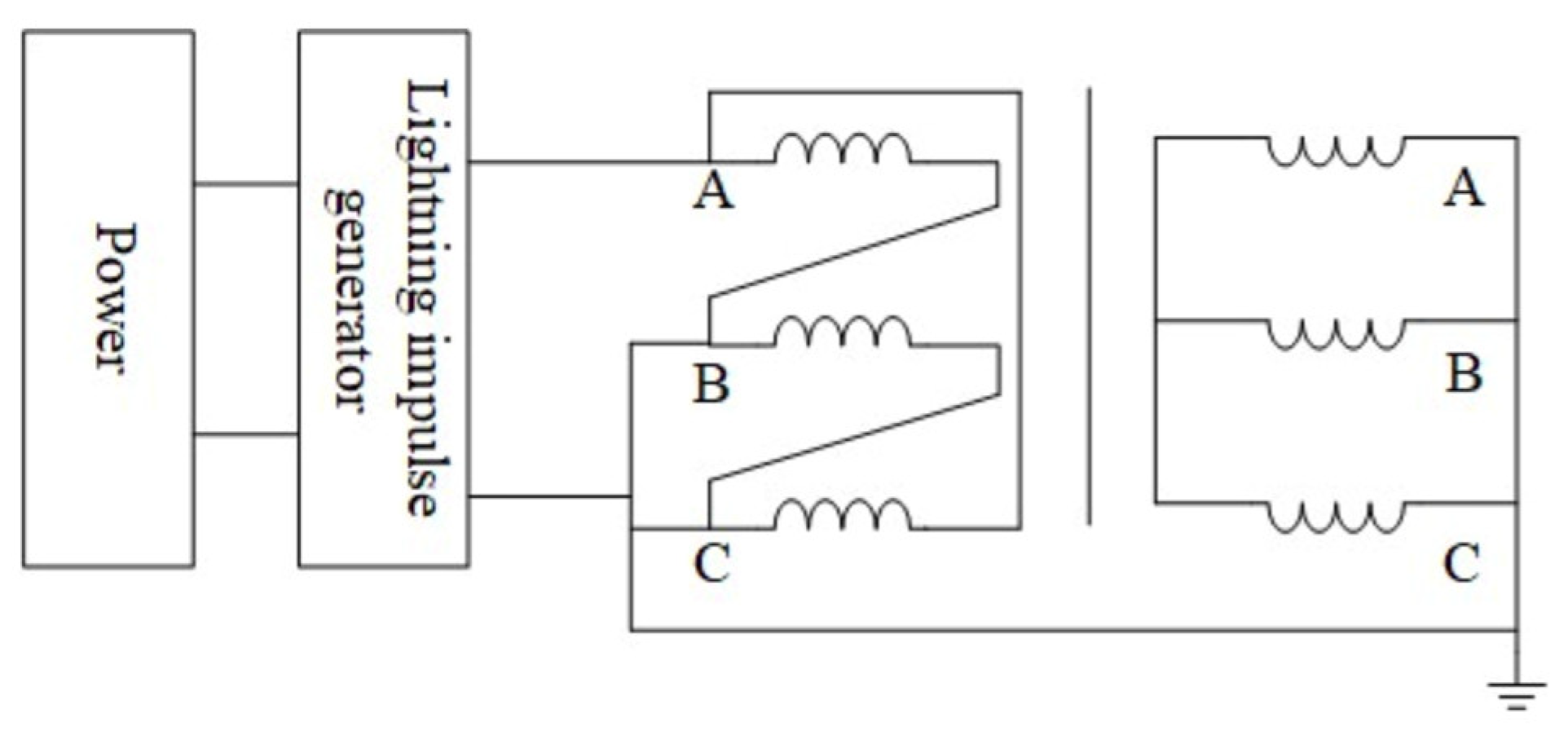

4.3.1. Transformer On-Site Lightning Impulse Test

4.3.2. Lightning Impulse Test for Switchgear

4.4. Analysis of Test Data Errors

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Faria, L.; Silva, E.; Silva, M.; Barbosa, C.; Azevedo, L. Automated evaluation of dynamic performance of impulse voltage measurement systems. J. Phys. Conf. Ser. 2015, 575, 012011. [Google Scholar] [CrossRef]

- Ghosh, P.; Das, A.K.; Dalai, S.; Chatterjee, S. The effects of non-standard lightning impulse on electrical insulation: A review. Electr. Eng. 2022, 104, 4239–4254. [Google Scholar] [CrossRef]

- Hsu, C.-H. Experimental results of electromechanical structure proper ties of noise and vibration on power transformers after lightning impulse test. Int. J. Electr. Power Energy Syst. 2022, 134, 107458. [Google Scholar] [CrossRef]

- Okabe, S.; Tsuboi, T.; Ueta, G. Study on lightning impulse test waveform for uhv-class electric power equipment. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 803–811. [Google Scholar] [CrossRef]

- Pattanadech, N.; Yutthagowith, P. Fast curve fitting algorithm for parameter evaluation in lightning impulse test technique. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2931–2936. [Google Scholar] [CrossRef]

- Perez, J.; Martinez, J. Digitally recorded lightning impulse with overshoot parameter evaluation by using the kalman filtering method. IEEE Trans. Power Deliv. 2002, 13, 1005–1014. [Google Scholar] [CrossRef]

- Petrović, I.; Nikolovski, S.; Baghaee, H.R.; Glavaš, H. Determining impact of lightning strike location on failures in transmission network elements using fuzzy decision-making. IEEE Syst. J. 2019, 14, 2665–2675. [Google Scholar] [CrossRef]

- IEC 60060-1:2025; High-Voltage Test Techniques—Part 1: General Terminology and Test Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2025.

- Smajic, J.; Steinmetz, T.; Ruegg, M.; Tanasic, Z.; Obrist, R.; Tepper, J.; Weber, B.; Carlen, M. Simulation and measurement of lightning-impulse voltage distributions over transformer windings. IEEE Trans. Magn. 2014, 50, 553–556. [Google Scholar] [CrossRef]

- Trkulja, B.; Drandić, A.; Milardić, V.; Župan, T.; Žiger, I.; Filipović-Grčić, D. Lightning impulse voltage distribution over voltage transformer windings—Simulation and measurement. Electr. Power Syst. Re Search 2017, 147, 185–191. [Google Scholar] [CrossRef]

- Ueta, G.; Tsuboi, T.; Okabe, S. Evaluation of overshoot rate of lightning impulse withstand voltage test waveform based on new base curve fitting methods-application to practical diverse waveforms. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 352–362. [Google Scholar] [CrossRef]

- Wen, T.; Zhang, Q.; Ma, J.; Liu, X.; Wu, Z.; Zhang, L.; Zhao, J.; Shimo Mura, N.; Chen, W. Research on the detecting effectiveness of on-site lightning impulse test for gis equipment with insulation defects. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 551–558. [Google Scholar] [CrossRef]

- Wen, T.; Zhang, Q.; Ma, J.; Wu, Z.; Shimomura, N.; Chen, W. A new method to evaluate the effectiveness of impulse voltage for detecting insulation defects in gis equipment. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1301–1307. [Google Scholar] [CrossRef]

- Wen, T.; Zhang, Q.; Qin, Y.; Zhao, J.; Ma, J.; Wu, Z.; Shimomura, N.; Tao, F.; Jia, Y.; Yin, Y.; et al. On-site standard lightning impulse test for 1100 kV gas-insulated switchgear with large capacitance. IEEE Electr. Insul. Mag. 2016, 32, 36–43. [Google Scholar] [CrossRef]

- Şeker, M. Parameter estimation of positive lightning impulse using curve fitting-based optimization techniques and least squares algorithm. Electr. Power Syst. Res. 2022, 205, 107733. [Google Scholar] [CrossRef]

- Lazzaretti, A.E.; Santos, S.L.F.; Küster, K.K.; Toledo, L.F.R.B.; Ravaglio, M.A.; Piantini, A.; da Silva Pinto, C.L. An integrated monitoring system and automatic data analysis to correlate lightning activity and faults on distribution networks. Electr. Power Syst. Res. 2017, 153, 66–72. [Google Scholar] [CrossRef]

- IEC 60076-3:2018; Power Transformers. Part 3: Insulation Levels and Dielectric Tests. International Electrotechnical Commission: Geneva, Switzerland, 2025.

- Mirzaei, H.R. A simple fast and accurate simulation method for power transformer lightning impulse test. IEEE Trans. Power Deliv. 2019, 34, 1151–1160. [Google Scholar] [CrossRef]

- Nicolae, P.-M.T.; Nicolae, I.-D.V.; Nitu, M.-C.; Nicolae, M.-S.P. Analysis and experiments concerning surges transferred between power transformer windings due to lightning impulse. IEEE Trans. Electromagn. Compat. 2023, 65, 1476–1483. [Google Scholar] [CrossRef]

- Nor, N.M.; Abdullah, S.; Rajab, R.; Ramar, K. Field tests: Performances of practical earthing systems under lightning impulses. Int. J. Electr. Power Energy Syst. 2013, 45, 223–228. [Google Scholar] [CrossRef]

- Wen, T.; Zhang, Q.; Zhang, L.; Ma, J.; Guo, C.; Chen, M.; Li, Y.; Shimomura, N.; Chen, W. Discussion on lightning impulse test waveform according to breakdown characteristics of sf6 gas gaps. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2306–2313. [Google Scholar] [CrossRef]

- IEC 62271-1:2017; High-Voltage Switchgear and Controlgear—Part 1: Common Specifications for Alternating Current Switchgear and Controlgear. International Electrotechnical Commission: Geneva, Switzerland, 2025.

- Zhang, X.; Shi, M.; He, C.; Li, J. On site oscillating lightning impulse test and insulation diagnose for power transformers. IEEE Trans. Power Deliv. 2020, 35, 2548–2550. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, S.; Kang, Z.; Wang, Y.; He, T. Effect of residual charges on lightning impulse voltage testing in insulation gaps. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 334–342. [Google Scholar] [CrossRef]

- Kai, N.; Fang-hua, H.; Wei, L.; Hao, N.; Yuan, S.; Xuan-rui, Z.; Jun-hao, L. Research on Oscillating Impulse Voltage Test Technology of Distribution Network Equipment. Adv. Technol. Electr. Eng. Energy 2022, 41, 24–30. [Google Scholar] [CrossRef]

- Radecic, I.; Jancin, S.; Perkovic, M.; Filipovic-Grcic, B.; Jurisic, B.; Filipovic-Grcic, D. Superimposed impulse voltage test on 525 kV HVDC underground cable. Electr. Power Syst. Res. 2026, 251, 112228. [Google Scholar] [CrossRef]

| Index | Item | Parameter |

|---|---|---|

| 1 | Nominal voltage (kV) | ±120 |

| 2 | Rated voltage (kV) | ±120 |

| 3 | Rated energy (kJ) | 11 |

| 4 | Impulse capacitance (μF) | 2 |

| 5 | Number of stages | 1 |

| Rf (Ω) | Rt (Ω) | A | B | /% | /% | EU/% | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tf (μs) | Tt(μs) | Up(kV) | Tf (μs) | Tt(μs) | Up(kV) | |||||

| 860 | 35 | 0.86 | 48.13 | 30.17 | 0.85 | 48.03 | 30.25 | 1.18 | 0.21 | 0.26 |

| 1100 | 1.05 | 48.32 | 30.43 | 1.07 | 48.5 | 30.66 | 1.87 | 0.37 | 0.75 | |

| 1250 | 1.22 | 48.27 | 30.24 | 1.21 | 48.1 | 30.32 | 0.83 | 0.35 | 0.26 | |

| 1400 | 1.36 | 48.59 | 30.54 | 1.37 | 48.83 | 30.76 | 0.73 | 0.49 | 0.72 | |

| 1550 | 1.51 | 48.24 | 30.23 | 1.5 | 48.66 | 30.46 | 0.67 | 0.86 | 0.76 | |

| Name | Wavefront Resistance (Ω) | Wavetail Resistance (Ω) |

|---|---|---|

| Transformer | 120 | 35 |

| Vacuum circuit breaker | 1000 | |

| Disconnect switch | 1000 |

| Rated Capacity (kV·A) | Rated Voltage (kV) | Lightning Impulse Withstand Voltage (kV) | Winding Type |

|---|---|---|---|

| 400 | 10 | 75 | Dyn11 |

| Name | Rated Voltage (kV) | Lightning Impulse Withstand Voltage (kV) |

|---|---|---|

| Vacuum circuit breaker | 12 | 75/85 |

| disconnect switch | 10 | 75/85 |

| Lightning Waveform | A (kV) | B (kV) | C (kV) |

|---|---|---|---|

| 1.2/50 μs (60%) | 45 | 45 | 45 |

| 1.2/50 μs (100%) | 75 | 75 | 75 |

| 1.2/50 μs (100%) | 75 | 75 | 75 |

| 1.2/50 μs (100%) | 75 | 75 | 75 |

| Index | Polarity | Front Time (μs) | Time to Half-Value (μs) | Peak Voltage (kV) |

|---|---|---|---|---|

| 1 | Positive | 1.55 | 48.67 | 46.74 |

| Negative | 1.51 | 47.17 | −49.68 | |

| 2 | Positive | 1.51 | 47.42 | 77.25 |

| Negative | 1.53 | 47.64 | −77.88 | |

| 3 | Positive | 1.53 | 47.01 | 76.95 |

| Negative | 1.52 | 48.32 | −77.33 | |

| 4 | Positive | 1.54 | 47.01 | 77.54 |

| Negative | 1.48 | 47.50 | −77.00 |

| Name | Rated Voltage (kV) | General (kV) | Between Fractures (kV) |

|---|---|---|---|

| Vacuum circuit breaker | 12 | 75 | 85 |

| Disconnect switch | 10 | 75 | 85 |

| Name | Positive | Front Time (μs) | Time to Half-Value (μs) | Peak Voltage (kV) |

|---|---|---|---|---|

| Vacuum Circuit breaker | Positive | 1.25 | 48.95 | 76.91 |

| Negative | 1.24 | 50.11 | −76.68 | |

| Disconnect switch | Positive | 1.11 | 48.30 | 75.55 |

| Negative | 1.08 | 49.09 | −76.40 |

| Name | Front Time (μs) | Time to Half-Value (μs) | ||

|---|---|---|---|---|

| Transformer | 1.51 | 47.42 | 8.0 × 10−5 | 0.06 |

| 1.53 | 47.00 | 8.0 × 10−5 | 0.06 | |

| 1.52 | 47.00 | 8.0 × 10−5 | 0.06 | |

| 1.51 | 47.17 | 8.0 × 10−5 | 0.06 | |

| 1.53 | 47.64 | 8.0 × 10−5 | 0.06 | |

| Vacuum Circuit breaker | 1.25 | 48.73 | 6.4 × 10−5 | 0.08 |

| 1.25 | 49.43 | 6.4 × 10−5 | 0.08 | |

| 1.27 | 48.84 | 6.4 × 10−5 | 0.08 | |

| 1.25 | 48.94 | 6.4 × 10−5 | 0.08 | |

| 1.26 | 49.36 | 6.4 × 10−5 | 0.08 | |

| Disconnect switch | 1.07 | 48.53 | 6.4 × 10−5 | 0.02 |

| 1.08 | 48.25 | 6.4 × 10−5 | 0.02 | |

| 1.07 | 48.50 | 6.4 × 10−5 | 0.02 | |

| 1.09 | 48.53 | 6.4 × 10−5 | 0.02 | |

| 1.07 | 48.26 | 6.4 × 10−5 | 0.02 |

| Name | Peak Voltage (Um/kV) | Set Value (Uset/kV) | Error Rate (Ue/%) |

|---|---|---|---|

| Transformer | 77.25 | 75 | 3.00 |

| 76.95 | 75 | 2.60 | |

| 76.47 | 75 | 1.96 | |

| 76.85 | 75 | 2.47 | |

| 76.76 | 75 | 2.35 | |

| Vacuum circuit breaker | 76.85 | 75 | 2.47 |

| 76.78 | 75 | 2.37 | |

| 76.78 | 75 | 2.37 | |

| 76.66 | 75 | 2.21 | |

| 76.83 | 75 | 2.44 | |

| Disconnect switch | 75.46 | 75 | 0.61 |

| 75.63 | 75 | 0.84 | |

| 75.36 | 75 | 0.48 | |

| 75.42 | 75 | 0.56 | |

| 75.50 | 75 | 0.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, C.; Chen, F.; Chen, H.; Tian, Y.; Zhao, W.; Tian, D.; Li, J.; Ding, Y. On-Site Lightning Impulse Test and Process Optimization Research on Distribution Network Equipment. Electronics 2025, 14, 4846. https://doi.org/10.3390/electronics14244846

Zhong C, Chen F, Chen H, Tian Y, Zhao W, Tian D, Li J, Ding Y. On-Site Lightning Impulse Test and Process Optimization Research on Distribution Network Equipment. Electronics. 2025; 14(24):4846. https://doi.org/10.3390/electronics14244846

Chicago/Turabian StyleZhong, Cheng, Feng Chen, Haifeng Chen, Yu Tian, Wenyan Zhao, Dianxiong Tian, Jin Li, and Yujian Ding. 2025. "On-Site Lightning Impulse Test and Process Optimization Research on Distribution Network Equipment" Electronics 14, no. 24: 4846. https://doi.org/10.3390/electronics14244846

APA StyleZhong, C., Chen, F., Chen, H., Tian, Y., Zhao, W., Tian, D., Li, J., & Ding, Y. (2025). On-Site Lightning Impulse Test and Process Optimization Research on Distribution Network Equipment. Electronics, 14(24), 4846. https://doi.org/10.3390/electronics14244846