Electrical Modeling and Control of a Synchronous Non-Ideal Step-Down Converter Using a Proportional–Integral–Derivative Neural Network Controller

Abstract

1. Introduction

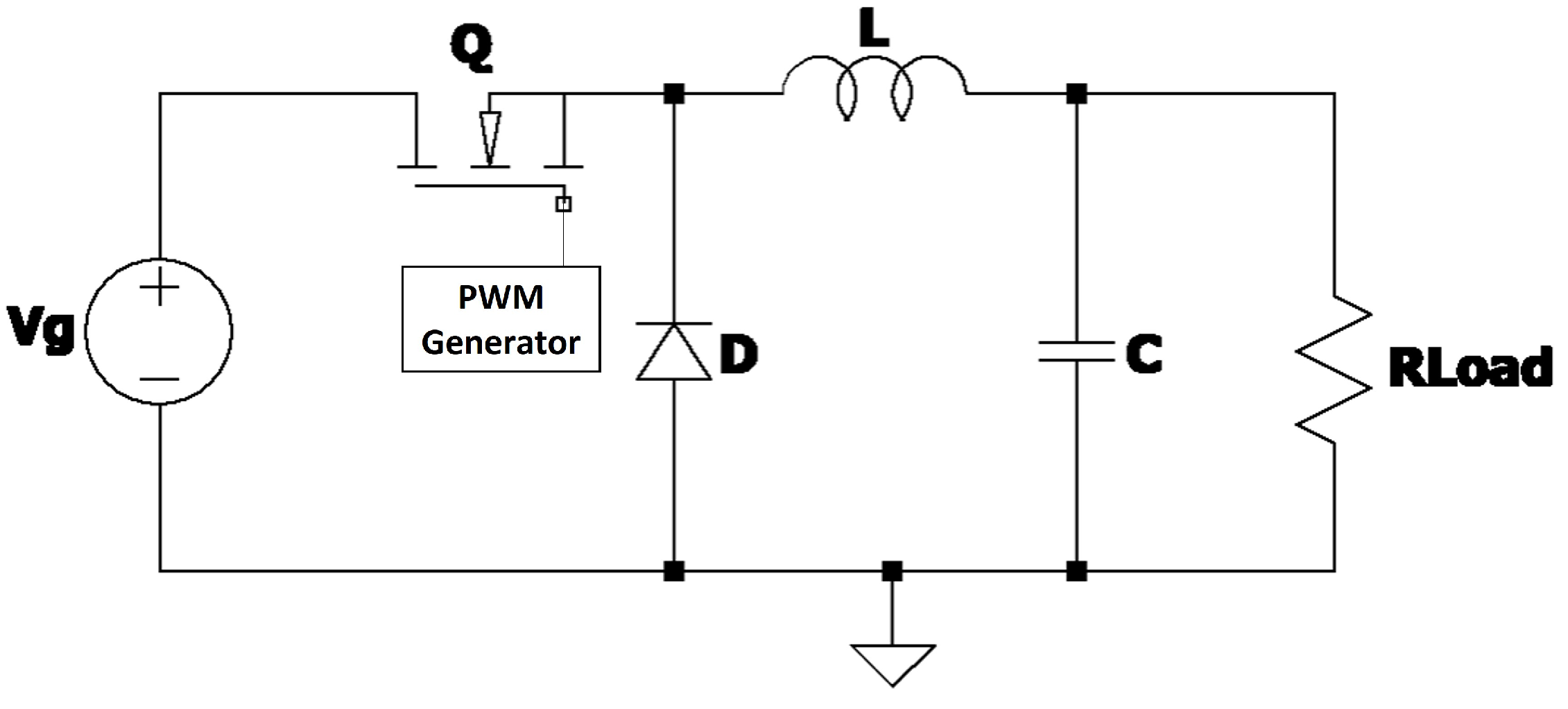

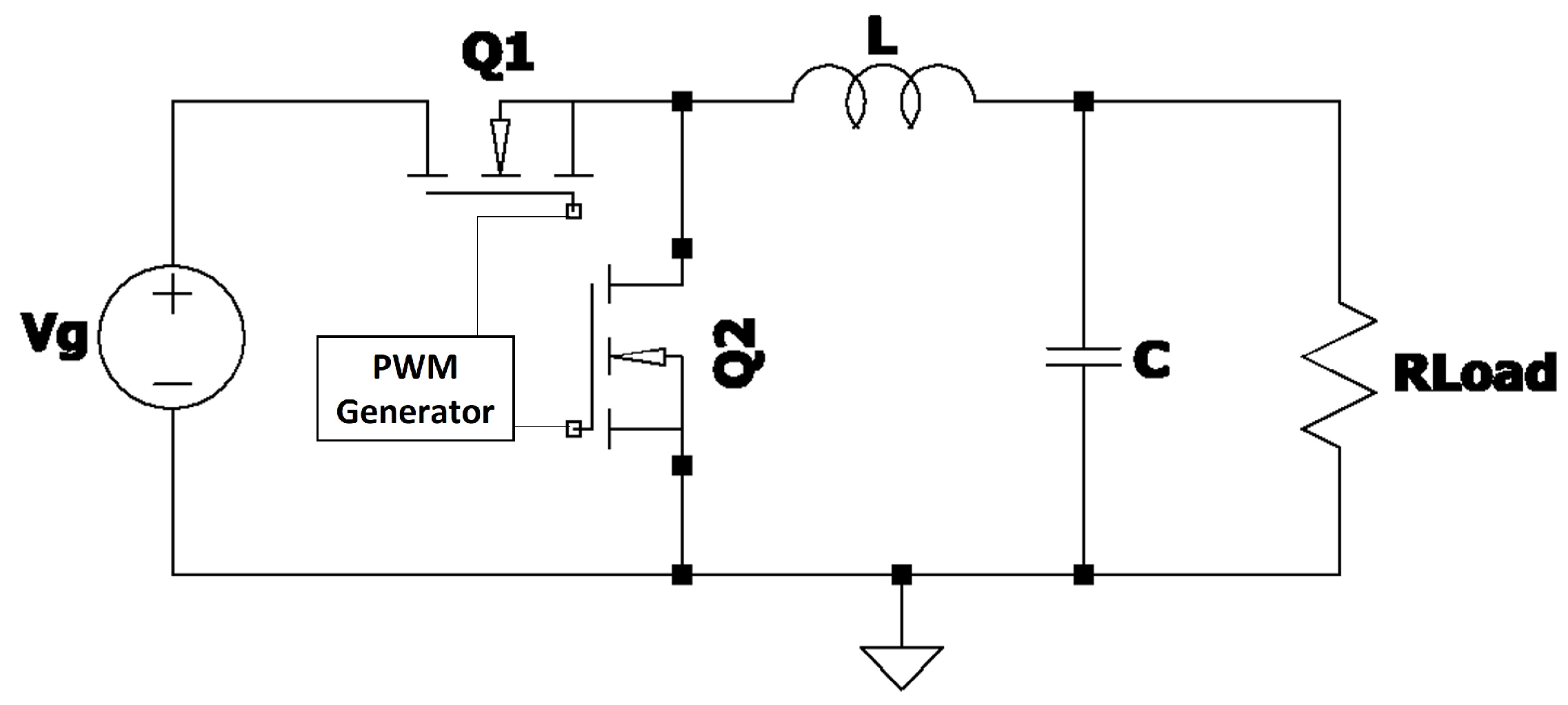

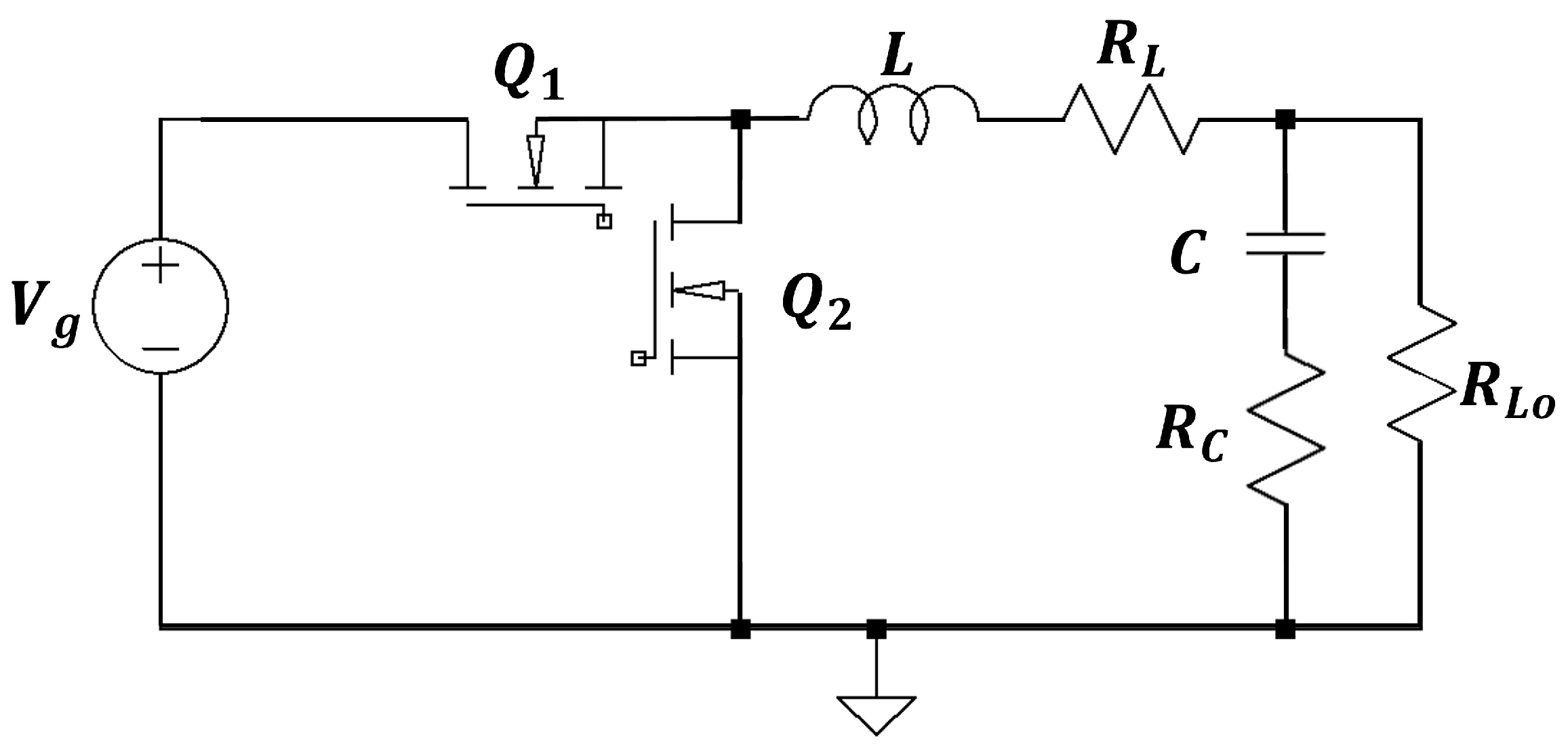

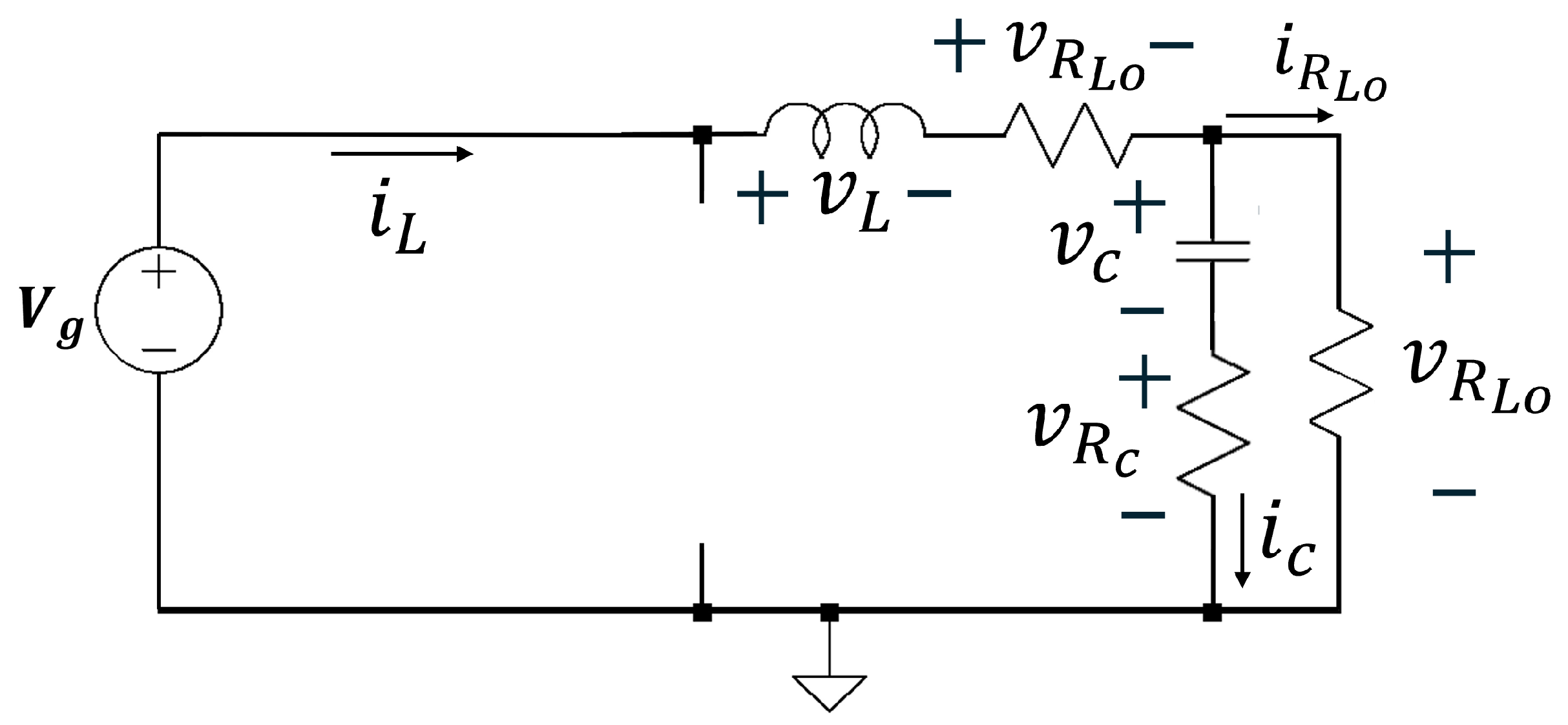

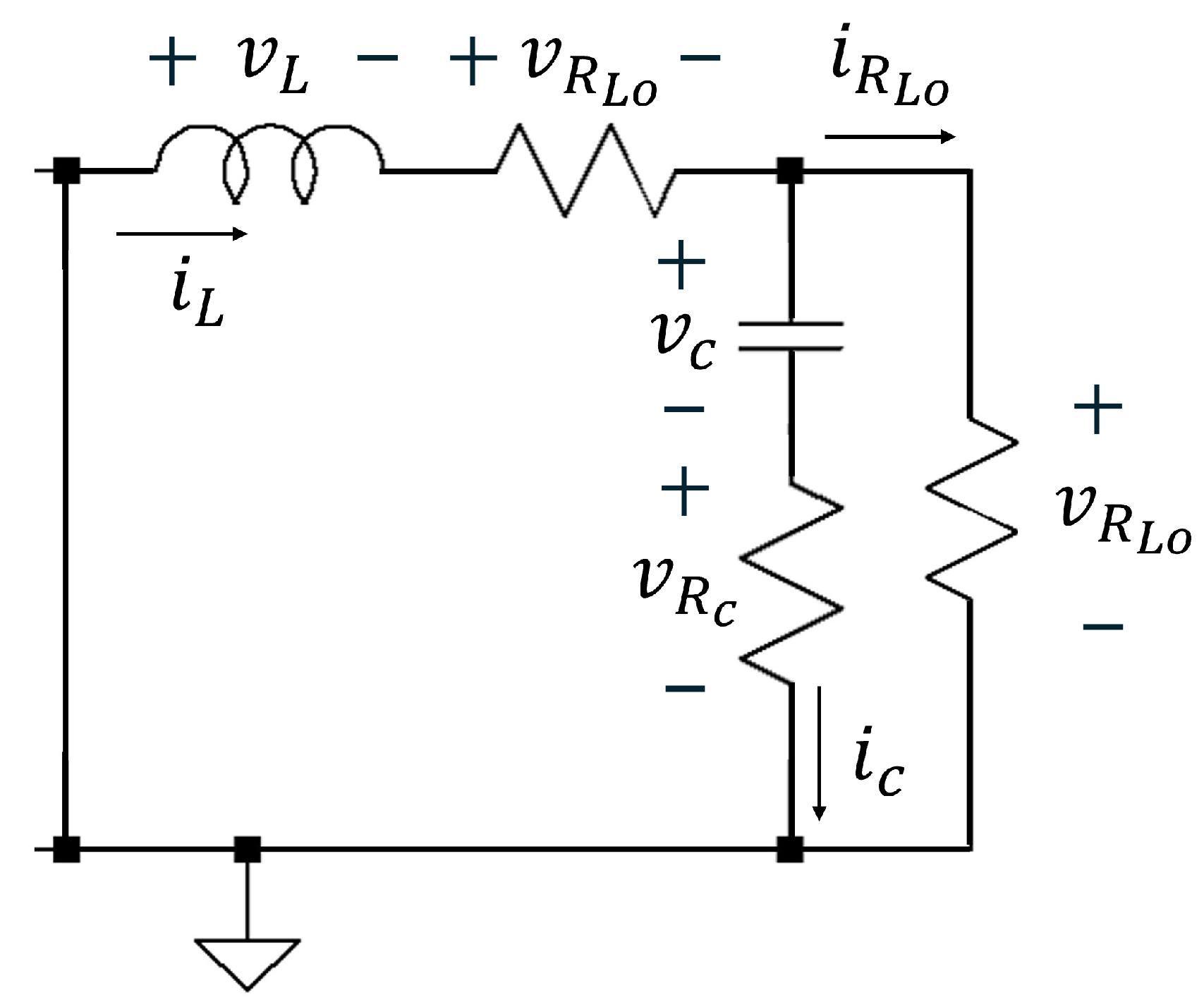

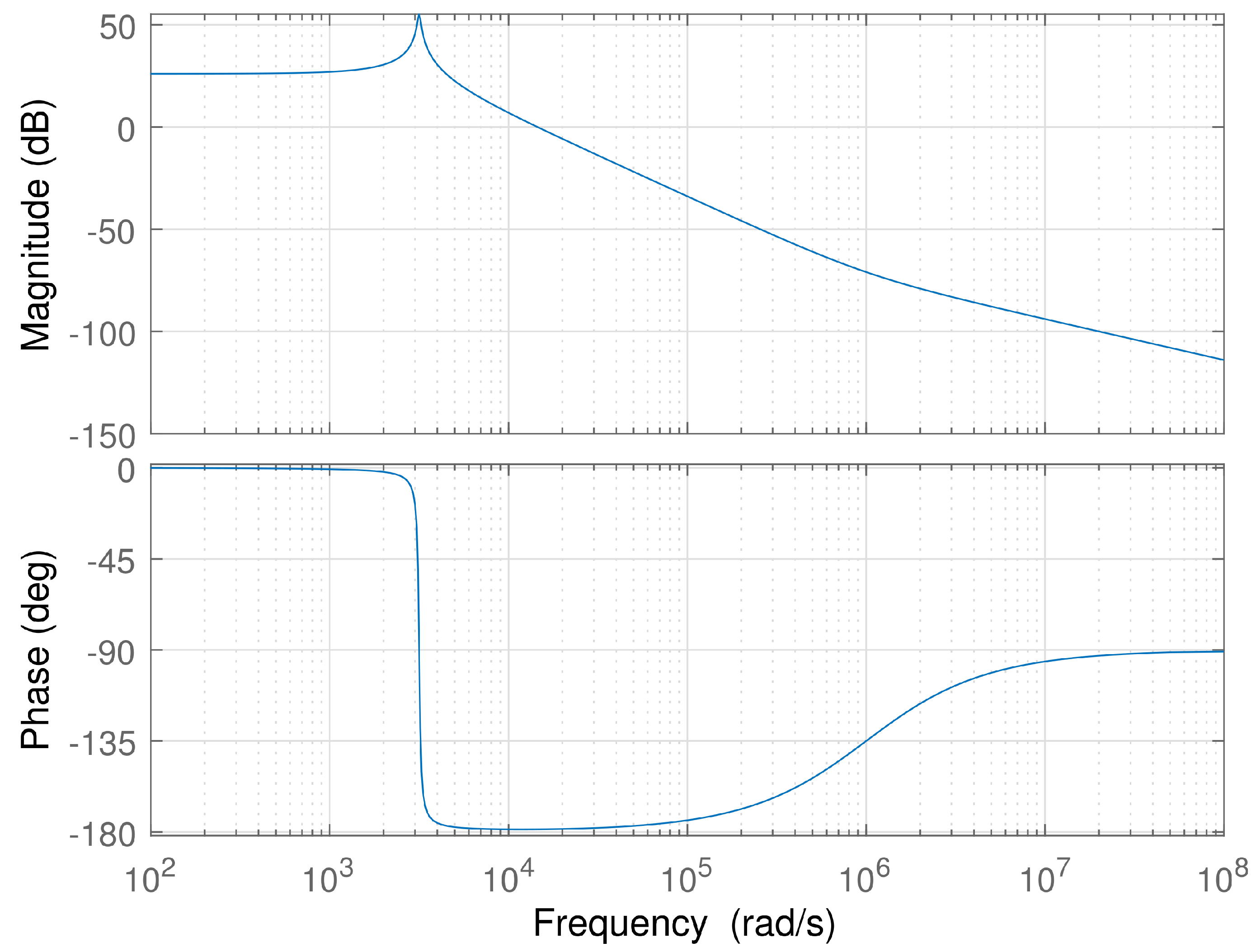

2. Dynamic Modeling of a Synchronous Non-Ideal Buck Converter

- (a)

- State-space averaging method.

- (b)

- Perturbation.

- (c)

- Linearization.

- : on-state resistance of the MOSFET.

- : off-state resistance of the MOSFET.

- : forward voltage drop of the diode.

- Dead-time distortion: delay between switching transitions of the MOSFETs.

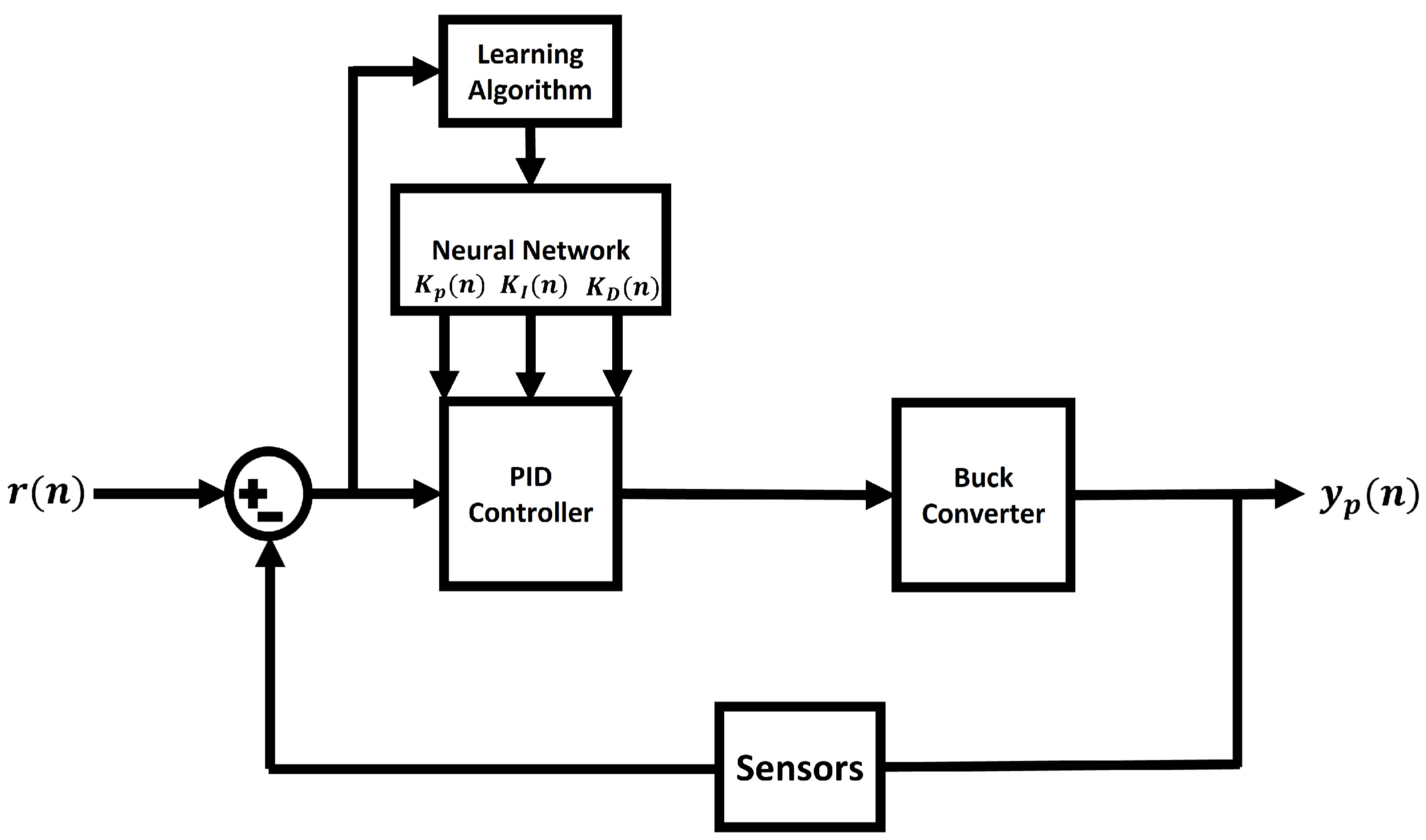

3. PID Neural Network Controller

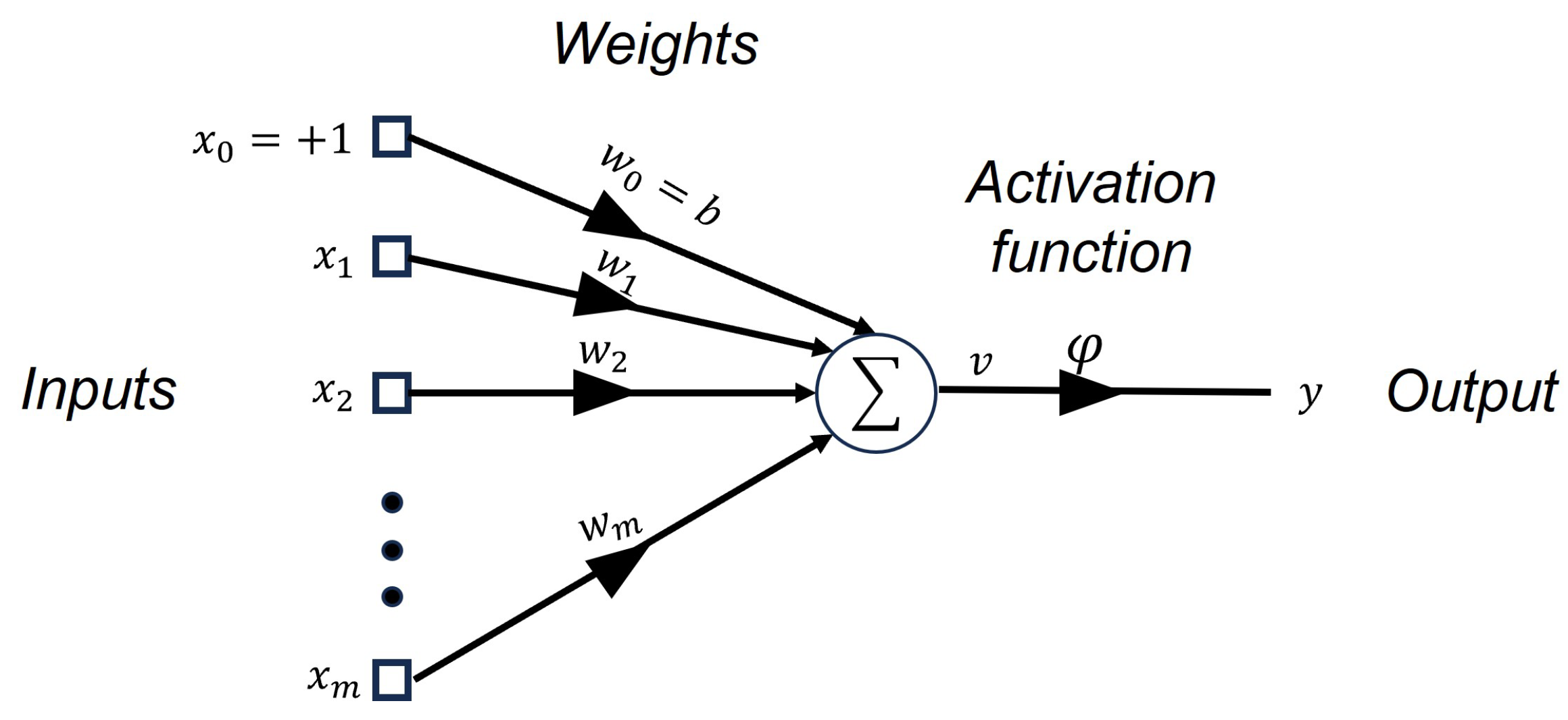

3.1. Artificial Neural Network

3.2. PID Self-Tuning Algorithm Based on ANN

3.3. Derivation of Partial Derivatives in Theorem 1

- Inputs: The ANN receives three inputs:The mentioned inputs represent the error between the system’s output and the reference signal. These inputs require only the errors from previous states to be obtained, simplifying the data acquisition process.

- Outputs: The proposed neural network features three output neurons, which represent the gains , , and of the PID controller, where the control law will be computed asIn other words, each gain of the aforementioned controller will have the architecture shown in Figure 6.

- Activation function: A linear activation function is employed to ensure stability and simplify gradient calculations during weight updates. The output of the neuron is given asHere, are the ANN inputs, and are the network weights.

- Parameter selection ( and ): The Lyapunov candidate function (Equation (21)) includes the parameters and , which play a critical role in ensuring the asymptotic stability of the ANN weights and error signal. The Lyapunov function is defined asThe parameters and are chosen as small positive real numbers () to balance the convergence rate of the error and the weight updates . Specifically,

- −

- A larger value of accelerates the error minimization process.

- −

- moderates the weight updates to prevent instability caused by excessive adjustments.

These parameters are empirically tuned via simulations to achieve fast and stable convergence without overshoot or oscillations.

3.4. Avoiding Natural Resonances

4. Control of a Synchronous Non-Ideal Step-Down Converter Using a PID Neural Network Controller

4.1. Comparison

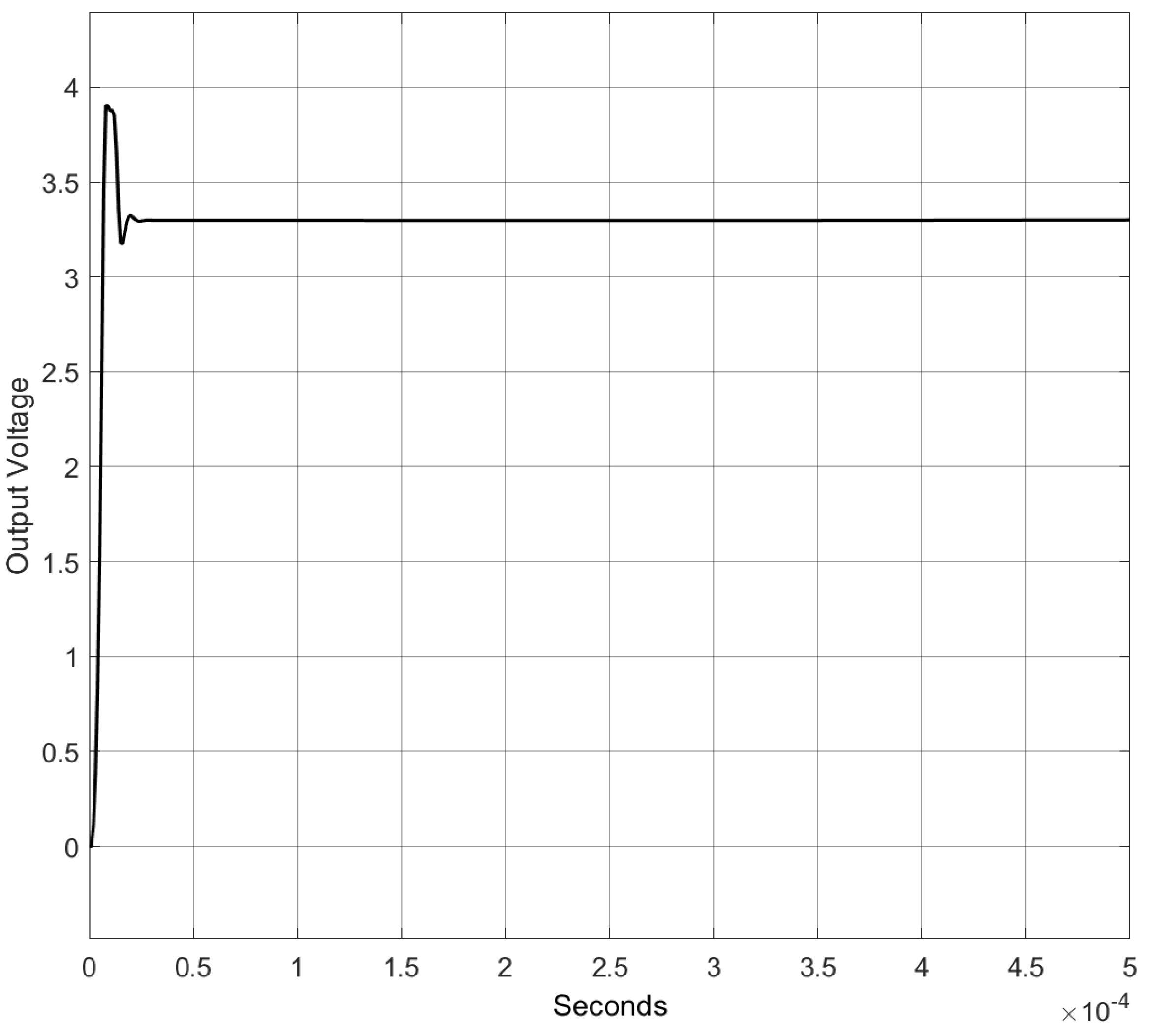

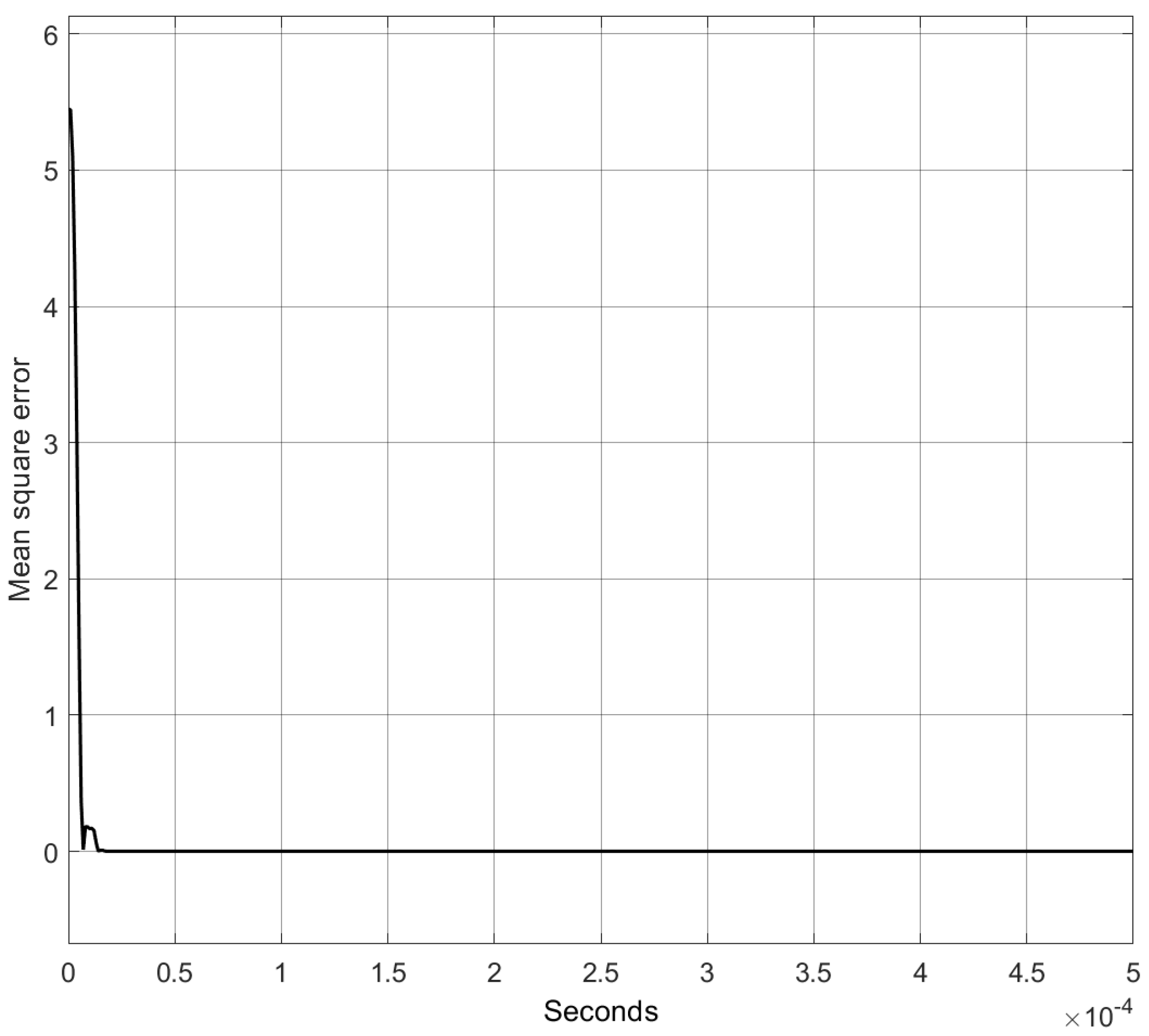

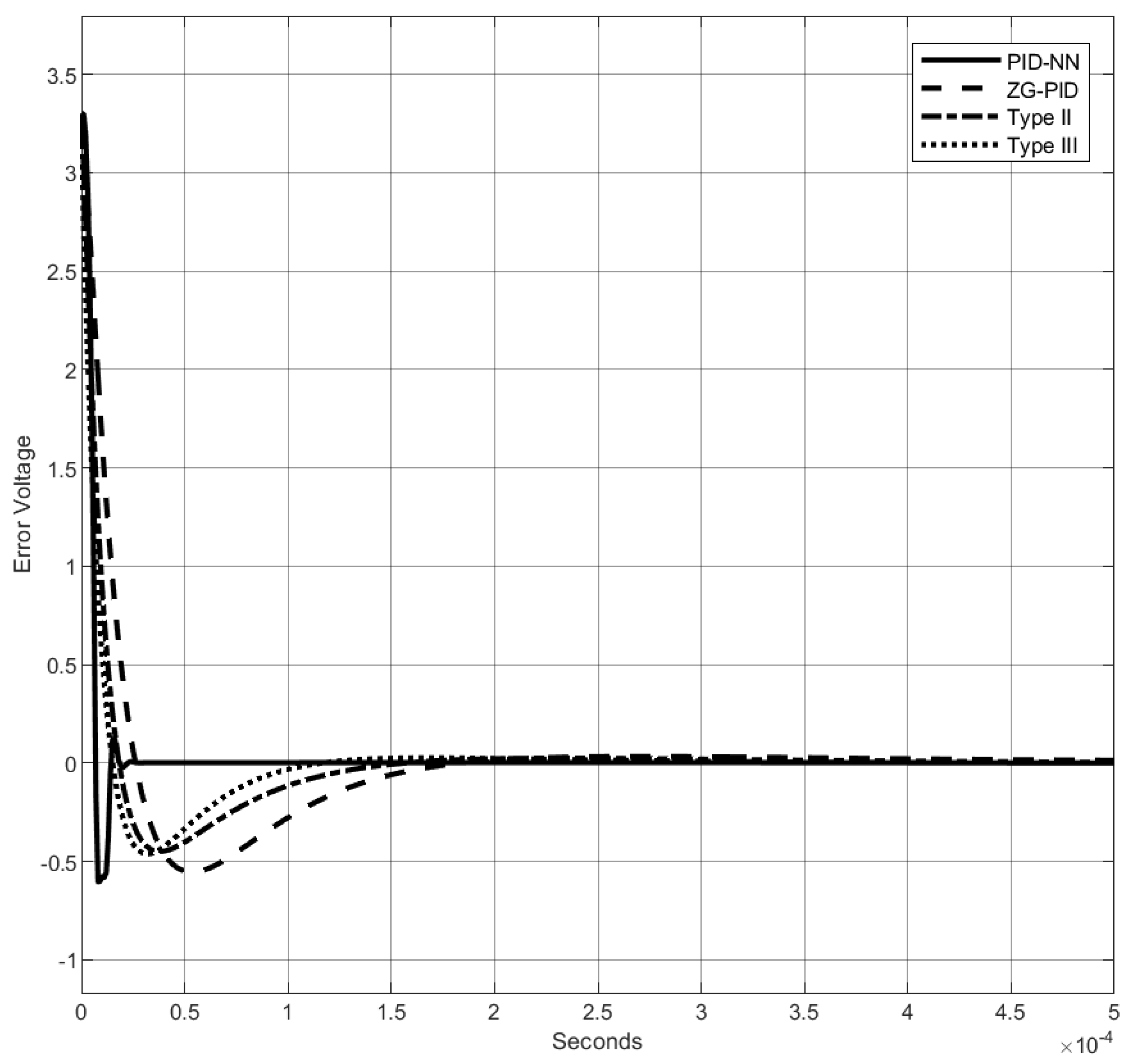

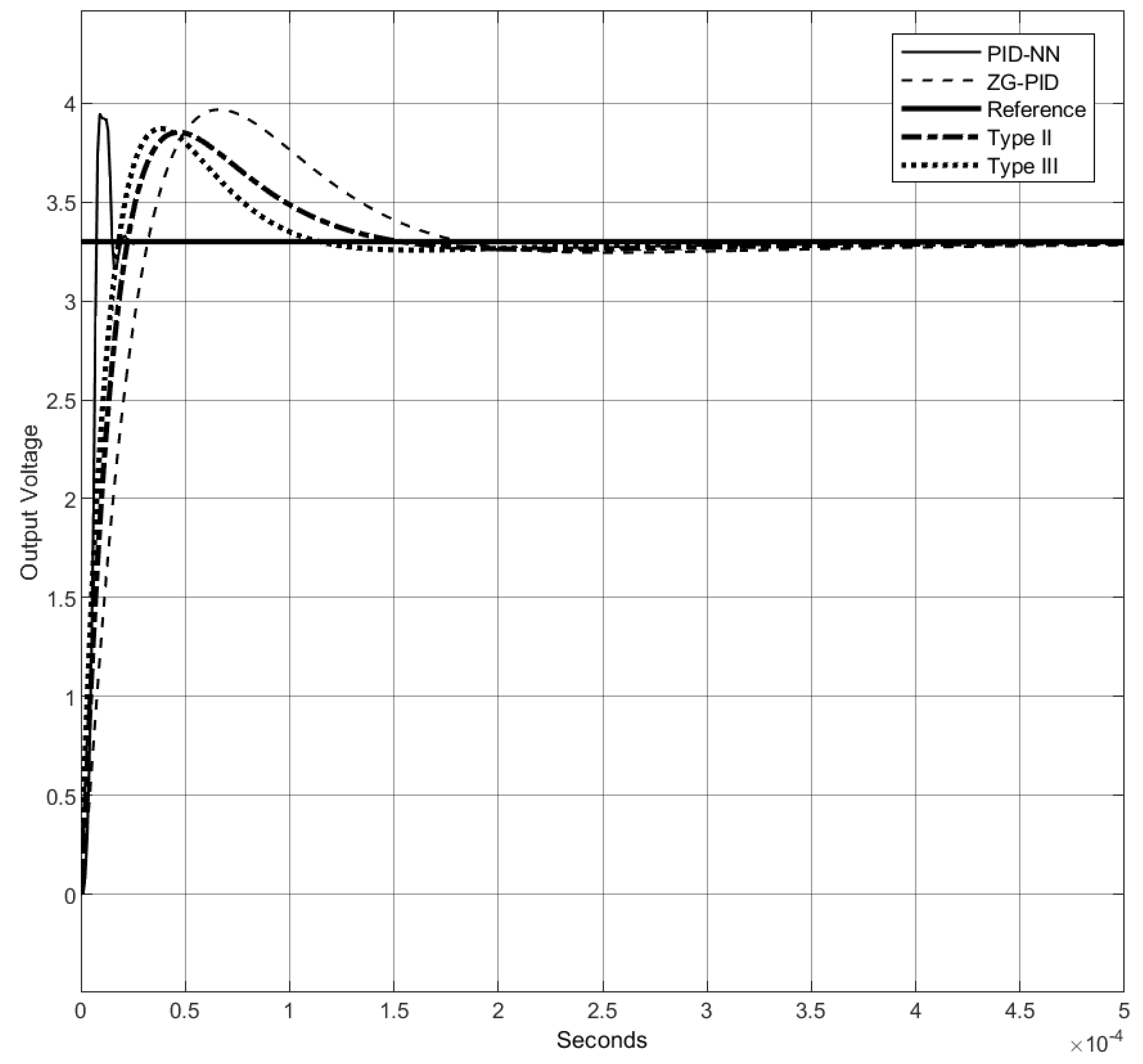

4.1.1. Comparison with the Nominal Model

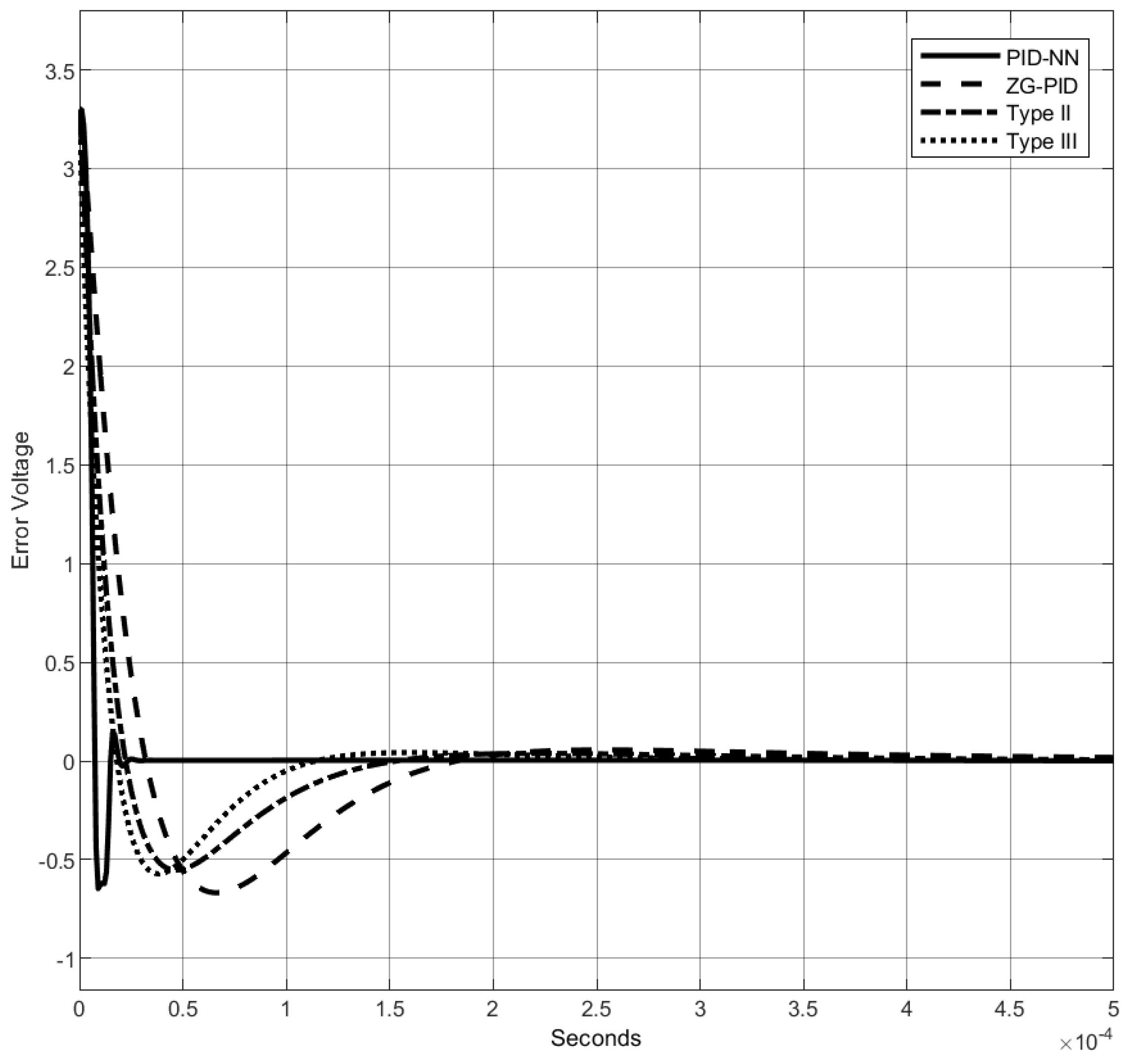

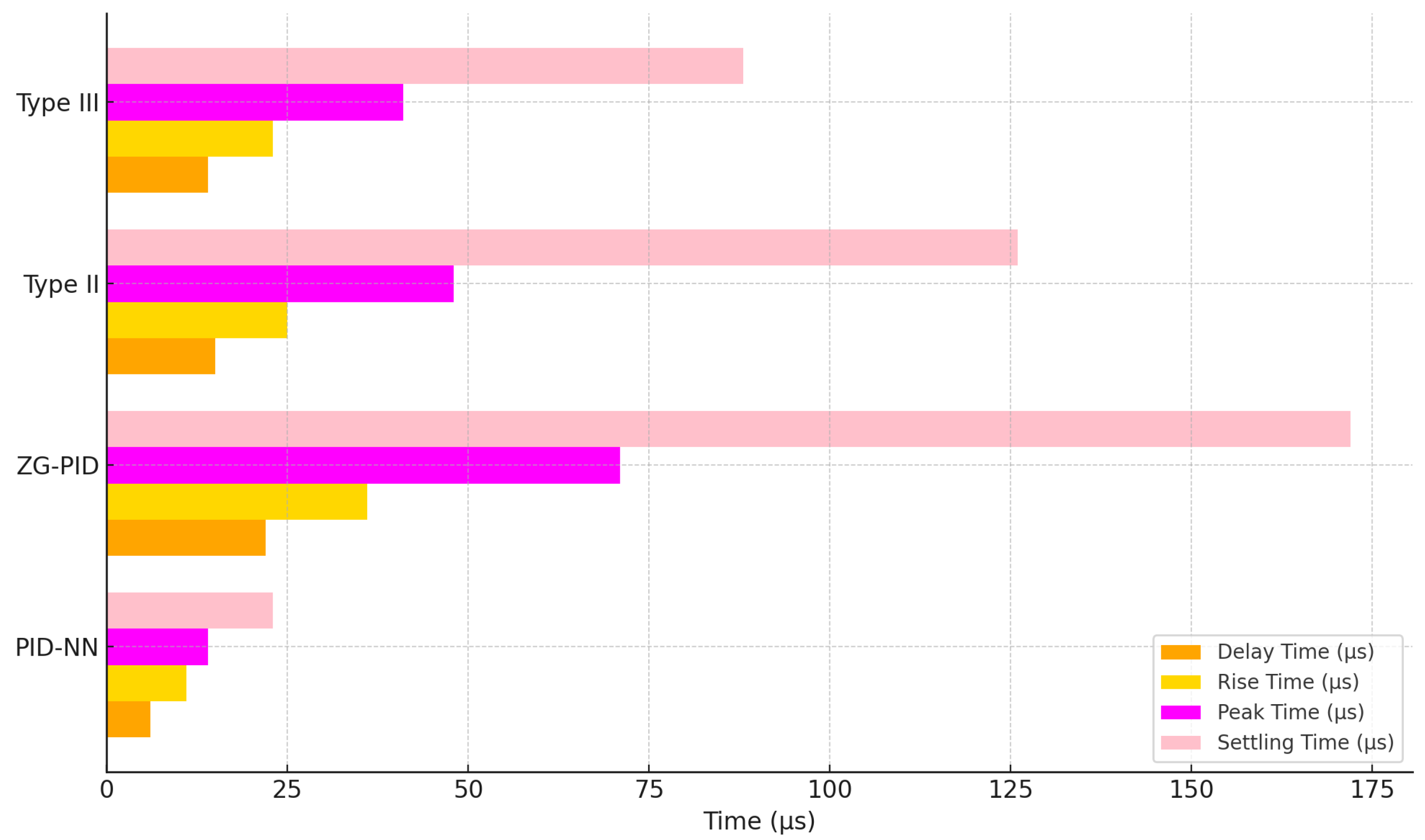

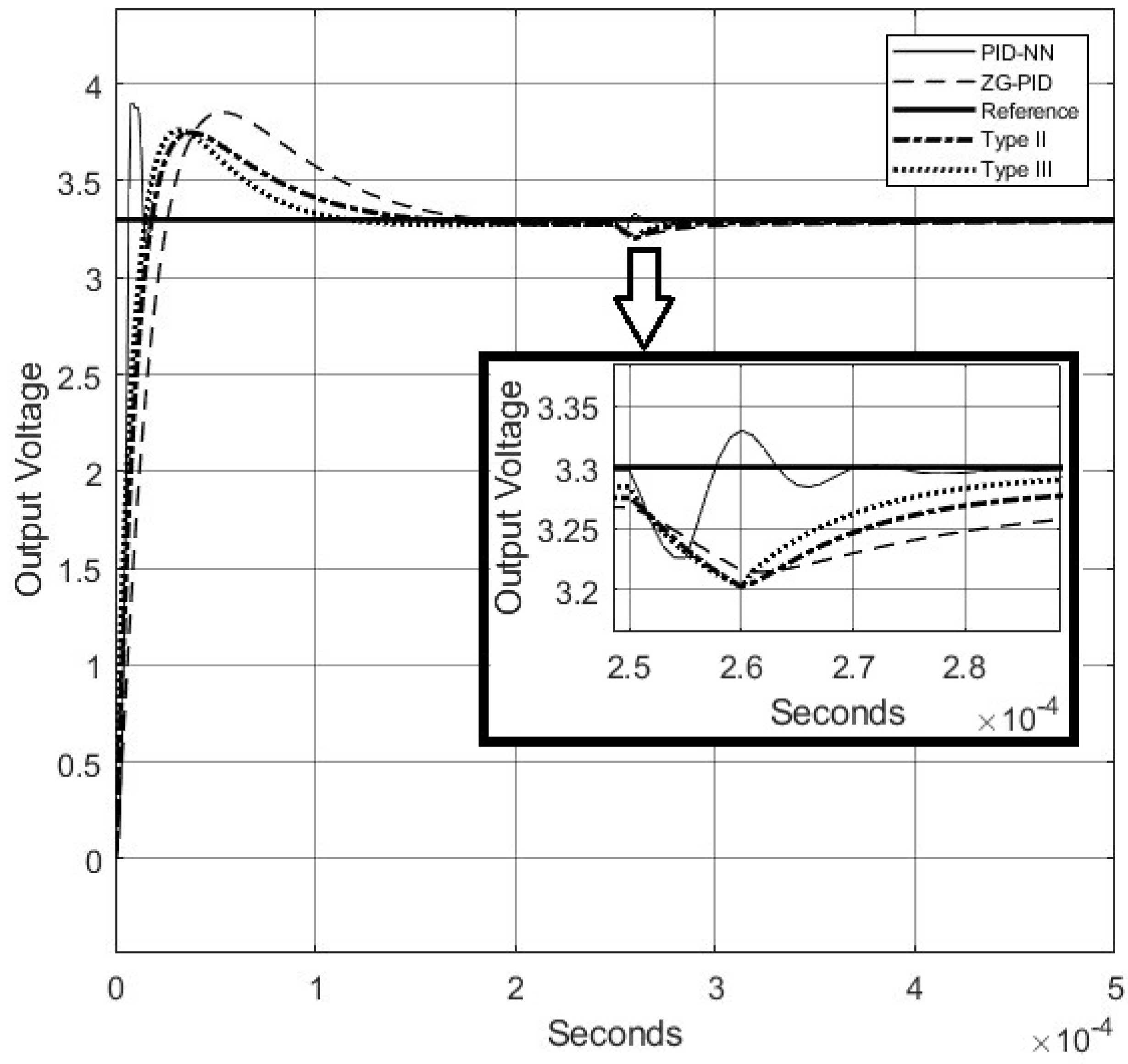

- Delay time (): the time it takes for a system’s response to initially reach a specified percentage (often 50%) of the final value after a step input is applied.

- Rise time (): the time it takes for the system’s response to go from a specified lower percentage (commonly 10%) to a higher percentage (commonly 90%) of the final value.

- Peak time (): the time at which the system’s response reaches its maximum value (peak) after a step input is applied.

- Settling time (): the time it takes for the system’s response to remain within a specified percentage (e.g., 2% or 5%) of the final value without further deviation.

- Peak overshoot (): the maximum deviation of the system’s response above the final value, expressed as a percentage of the final value.

4.1.2. Comparison with Variations in the Input

4.1.3. Comparison with Parametric Variations and a Perturbation in the Input

5. Conclusions and Future Work

Limitations of the Proposed Method

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Erickson, R.; Maksimovic, D. Fundamentals of Power Electronics, 2nd ed.; Springer: New York, NY, USA, 2001. [Google Scholar]

- De Brito, M.; Canesin, C. Design of a High-Efficiency DC-DC Converter for Solar Panels Using a Synchronous Buck Converter. Int. J. Renew. Energy Res. 2010, 1, 17–23. [Google Scholar]

- Rao, K.; Patro, B. Power Electronic Converters for Electric Vehicles: State-of-the-Art and Challenges. J. Power Electron. 2019, 19, 648–665. [Google Scholar]

- Mohan, N. Power Electronics: A First Course, 3rd ed.; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Erickson, R.; Maksimović, D. Fundamentals of Power Electronics; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Isnaeni, M.; Andromeda, T.; Facta, M.; Warsito, A. A Comparison of Synchronous and Nonsynchronous Boost Converter. Proc. Electr. Eng. Comput. Sci. Inform. 2016, 3, 1135–1142. [Google Scholar] [CrossRef][Green Version]

- Tannir, D.; Wang, Y.; Li, P. Accurate Modeling of Nonideal Low-Power PWM DC-DC Converters Operating in CCM and DCM Using Enhanced Circuit-Averaging Techniques. ACM Trans. Des. Autom. Electron. Syst. 2016, 21, 1–15. [Google Scholar] [CrossRef]

- Yue, X.; Wang, X.; Blaabjerg, F. Review of Small-Signal Modeling Methods Including Frequency-Coupling Dynamics of Power Converters. IEEE Trans. Power Electron. 2019, 34, 3313–3328. [Google Scholar] [CrossRef]

- Ravi, D.; Ghosh, A. Voltage Mode Control of Buck Converter using Practical PID Controller. In Proceedings of the International Conference on Intelligent Controller and Computing for Smart Power (ICICCSP), Hyderabad, India, 21–23 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Saurav, S.; Ghosh, A. Design and Analysis of PID, Type II and Type III controllers for Fourth Order Boost Converter. In Proceedings of the 7th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 11–13 February 2021; pp. 323–328. [Google Scholar] [CrossRef]

- Ferahtia, S.; Djeroui, A.; Mesbahi, T.; Houari, A.; Zeghlache, S.; Rezk, H.; Paul, T. Optimal Adaptive Gain LQR-Based Energy Management Strategy for Battery–Supercapacitor Hybrid Power System. Energies 2021, 14, 1660. [Google Scholar] [CrossRef]

- Mamizadeh, A.; Genc, N.; Rajabioun, R. Optimal Tuning of PI Controller for Boost DC-DC Converters Based on Cuckoo Optimization Algorithm. In Proceedings of the 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 677–680. [Google Scholar] [CrossRef]

- Anilkumar, A.; Srikanth, N. Teaching-learning optimization based adaptive fuzzy logic controller for frequency control in an autonomous microgrid. Int. J. Renew. Energy Res. 2017, 7, 1842–1849. [Google Scholar]

- Siddique, A.; Munsi, M.; Sarker, S.; Das, S.; Islam, M. Voltage and current control augmentation of islanded microgrid using multifunction model reference modified adaptive PID controller. Int. J. Electr. Power Energy Syst. 2019, 113, 492–501. [Google Scholar] [CrossRef]

- Rodríguez-Abreo, O.; Rodríguez-Reséndiz, J.; Fuentes-Silva, C.; Hernández-Alvarado, R.; Falcón, M. Self-Tuning Neural Network PID With Dynamic Response Control. IEEE Access 2021, 9, 65206–65215. [Google Scholar] [CrossRef]

- Lee, Y.; Jang, D. Optimization of Neural Network-Based Self-Tuning PID Controllers for Second Order Mechanical Systems. Appl. Sci. 2021, 11, 8002. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Q.; Wu, Q. PID Control Model Based on Back Propagation Neural Network Optimized by Adversarial Learning-Based Grey Wolf Optimization. Appl. Sci. 2023, 13, 4767. [Google Scholar] [CrossRef]

- Ding, Y.; Cheng, S.; Huang, Y.; Hong, D. Deep PID Neural Network Controller for Precise Temperature Control in Plastic Injection-moulding Heating System. IFAC-PapersOnLine 2022, 55, 114–119. [Google Scholar] [CrossRef]

- Ghamari, S.; Khavari, F.; Mollaee, H. Lyapunov-Based Adaptive PID Controller Design for Buck Converter. Soft Comput. 2023, 27, 5741–5750. [Google Scholar] [CrossRef]

- Veeramraju, K.; Cardoza, A.; Sarangapani, J.; Kimball, J. Robust Modifications to Model Reference Adaptive Control for Reference Voltage Tracking in a Dual Active Bridge dc-dc Converter. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–7. [Google Scholar]

- Qureshi, M.; Musumeci, S.; Torelli, F.; Reatti, A.; Mazza, A.; Chicco, G. A novel model reference adaptive control approach investigation for power electronic converter applications. Int. J. Electr. Power Energy Syst. 2024, 156, 109722. [Google Scholar] [CrossRef]

- Kim, J.; Choi, H.; Jung, J. MRAC-Based Voltage Controller for Three-Phase CVCF Inverters to Attenuate Parameter Uncertainties Under Critical Load Conditions. IEEE Trans. Power Electron. 2020, 35, 1002–1013. [Google Scholar] [CrossRef]

- Wu, J.; Luo, A.; Xu, X.; Shuai, Z.; Yang, X.; Peng, S. MRAC method and its application to single phase shunt active power filter. High Volt. Eng. 2010, 36, 507–512. [Google Scholar]

- Ardhenta, L.; Subroto, R. Application of direct MRAC in PI controller for DC-DC boost converter. Int. J. Power Electron. Drive Syst. 2020, 11, 851. [Google Scholar] [CrossRef]

- Khanna, R.; Qinhao, Z.; Stanchina, W.; Reed, G.; Mao, Z. Maximum Power Point Tracking Using Model Reference Adaptive Control. IEEE Trans. Power Electron. 2014, 29, 1490–1499. [Google Scholar] [CrossRef]

- Mabius, L.; Kalnitsky, K.; Kaufman, H. Model reference adaptive control of electric generating plants. In Proceedings of the 19th IEEE Conference on Decision and Control including the Symposium on Adaptive Processes, Albuquerque, NM, USA, 10–12 December 1980; IEEE: Piscataway, NJ, USA, 1980; pp. 286–291. [Google Scholar]

- Saleem, O.; Ahmad, K.; Iqbal, J. Fuzzy-Augmented Model Reference Adaptive PID Control Law Design for Robust Voltage Regulation in DC-DC Buck Converters. Mathematics 2024, 12, 1893. [Google Scholar] [CrossRef]

- Ghamari, S.; Gholizadeh, H.; Mollaee, H. Fractional-order fuzzy PID controller design on buck converter with antlion optimization algorithm. IET Control Theory Appl. 2021, 16, 340–352. [Google Scholar] [CrossRef]

- Kaplan, O.; Bodur, F. Second-order sliding mode controller design of buck converter with constant power load. Int. J. Control. 2023, 96, 1210–1226. [Google Scholar] [CrossRef]

- Nizami, T.; Mahanta, C. An intelligent adaptive control of DC–DC buck converters. J. Frankl. Inst. 2016, 353, 2588–2613. [Google Scholar] [CrossRef]

- Saleem, O.; Rizwan, M. Performance optimization of LQR-based PID controller for DC-DC buck converter via iterative-learning-tuning of state-weighting matrix. Int. J. Numer. Model. Electron. Netw. Devices Fields 2019, 32, e2572. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Sayed-Mouchaweh, M. Adaptive neurofuzzy H-infinity control of DC–DC voltage converters. Neural Comput. Appl. 2020, 32, 2507–2520. [Google Scholar] [CrossRef]

- Ghamari, S.; Khavari, F.; Mollaee, H. Adaptive backstepping controller design for DC/DC buck converter optimised by grey wolf algorithm. IET Energy Syst. Integr. 2024, 6, 18–30. [Google Scholar] [CrossRef]

- Chouya, A.; Boureguig, K. Adaptive Control with MRAC Regulator for DC-DC Buck Converter. Int. J. Control. Syst. Robot. 2022, 7, 13–26. [Google Scholar]

- Surya, S.; Srinivasan, M.; Williamson, S. Modeling of Average Current in Non-Ideal Buck and Synchronous Buck Converters for Low Power Application. Electronics 2021, 10, 2672. [Google Scholar] [CrossRef]

- Tan, R.; Hoo, L. DC-DC converter modeling and simulation using state space approach. In Proceedings of the 2015 IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 19–20 October 2015; pp. 42–47. [Google Scholar] [CrossRef]

- Fang, J.; Tsai, S.; Yan, J.; Chen, P.; Guo, S. Realization of DC–DC buck converter based on hybrid H2 model following control. IEEE Trans. Ind. Electron. 2021, 69, 1782–1790. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, Y.; Zhou, J.; Ding, H.; Guo, X.; Padmanaban, S. Control strategies of mitigating dead-time effect on power converters: An overview. Electronics 2019, 8, 196. [Google Scholar] [CrossRef]

- Iqbal, S.; Xin, A.; Jan, M.; Abdelbaky, M.; Rehman, H.; Salman, S.; Aurangzeb, M.; Rizvi, S.; Shah, N. Improvement of power converters performance by an efficient use of dead time compensation technique. Appl. Sci. 2020, 10, 3121. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson Education: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Borase, R.; Maghade, D.; Sondkar, S.; Pawar, S. A review of PID control, tuning methods and applications. Int. J. Dyn. Control. 2021, 9, 818–827. [Google Scholar] [CrossRef]

- Lu, Y.; Yu, W.; Wang, J.; Jiang, D.; Li, R. Design of PID Controller Based on ELM and Its Implementation for Buck Converters. Int. J. Control. Autom. Syst. 2021, 19, 2479–2490. [Google Scholar] [CrossRef]

- Ghosh, A.; Banerjee, S.; Sarkar, M.; Dutta, P. Design and implementation of type-II and type-III controller for DC–DC switched-mode boost converter by using K-factor approach and optimisation techniques. IET Power Electron. 2016, 9, 938–950. [Google Scholar] [CrossRef]

- Ibrahim, O.; Yahaya, N.; Saad, N. Comparative studies of PID controller tuning methods on a DC-DC boost converter. In Proceedings of the 2016 6th International Conference on Intelligent and Advanced Systems (ICIAS), Kuala Lumpur, Malaysia, 15–17 August 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Khalil, H. Nonlinear Systems; Prentice-Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Ogata, K. Modern Control Engineering; Prentice-Hall: Upper Saddle River, NJ, USA, 2020. [Google Scholar]

| Term/Abbreviation | Definition/Description |

|---|---|

| PID Controller | Proportional–Integral–Derivative controller; a control loop feedback mechanism. |

| ANN | Artificial Neural Network; a machine learning model that adjusts weights based on input-output data. |

| Lyapunov stability | A stability criterion used to prove the convergence of a dynamic system. |

| Current error signal at time step n. | |

| Change in the error signal: . | |

| Squared error signal: . | |

| Gains of the PID controller: proportional, integral, and derivative terms, respectively. | |

| Neural network weights at time step n. | |

| Activation function; in this work, (linear). | |

| Positive parameters of the Lyapunov candidate function used for ANN stability. | |

| Learning rate is one such hyper-parameter that defines the adjustment in the weights of our network with respect to the loss gradient descent. | |

| DC–DC converter | A power converter that regulates DC voltage by stepping it up or down. |

| Buck converter | A type of DC-DC converter where the output voltage is lower than the input voltage. |

| Small-signal analysis | A method to linearize a system model for analyzing its behavior around an operating point. |

| Simulation scenario | A computational test used to validate the performance of the proposed control approach. |

| Performance Parameter | COPID [28] | HOSMC [29] | CNN [30] | LQ-PID [31] | H-inf [32] | Backstepping [33] | MRAC [34] |

|---|---|---|---|---|---|---|---|

| Error minimization | Good | Better | Good | Bad | Good | Fair | Good |

| Asymptotic stability | Yes | Yes | Yes | Yes | Yes | Difficult | Yes |

| Control economy | Fair | Bad | Bad | Better | Fair | Bad | Fair |

| Disturbance rejection | Good | Best | Better | Bad | Good | Fair | Good |

| Chattering suppression | Good | Fair | Fair | Good | Good | Good | Better |

| Mathematical complexity | Medium | High | High | Low | High | High | Low |

| Computation burden | Medium | High | High | Low | High | High | Low |

| Parameter tuning needed | High | Medium | High | Low | High | High | Low |

| Element | Description | Value | Unit |

|---|---|---|---|

| Input voltage | 20 | V | |

| C | Capacitance | 0.1 | mF |

| L | Inductance | 1 | mH |

| Internal resistance | 0.01 | ||

| Internal resistance | 0.1 | ||

| Load | 10 | ||

| r | Desired output voltage | 3.3 | V |

| Method | Delay Time | Rise Time | Peak Time | Settling Time | Peak Overshoot |

|---|---|---|---|---|---|

| PID-NN | 6 s | 10 s | 13.5 s | 22 s | 0.58 V |

| ZG-PID | 16 s | 26 s | 51 s | 125 s | 0.52 V |

| Type II | 13 s | 21 s | 37 s | 88 s | 0.47 V |

| Type III | 11 s | 19 s | 30 s | 80 s | 0.48 V |

| Method | Delay Time | Rise Time | Peak Time | Settling Time | Peak Overshoot |

|---|---|---|---|---|---|

| PID-NN | 6 s | 11 s | 14 s | 23 s | 0.59 V |

| ZG-PID | 22 s | 36 s | 71 s | 172 s | 0.61 V |

| Type II | 15 s | 25 s | 48 s | 126 s | 0.51 V |

| Type III | 14 s | 23 s | 41 s | 88 s | 0.52 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medrano-Hermosillo, J.A.; Rodríguez-Mata, A.E.; Gonzalez-Huitron, V.A.; López-Estrada, F.-R.; Valencia-Palomo, G.; Suarez, O.J. Electrical Modeling and Control of a Synchronous Non-Ideal Step-Down Converter Using a Proportional–Integral–Derivative Neural Network Controller. Electronics 2025, 14, 357. https://doi.org/10.3390/electronics14020357

Medrano-Hermosillo JA, Rodríguez-Mata AE, Gonzalez-Huitron VA, López-Estrada F-R, Valencia-Palomo G, Suarez OJ. Electrical Modeling and Control of a Synchronous Non-Ideal Step-Down Converter Using a Proportional–Integral–Derivative Neural Network Controller. Electronics. 2025; 14(2):357. https://doi.org/10.3390/electronics14020357

Chicago/Turabian StyleMedrano-Hermosillo, Jesús A., Abraham Efraim Rodríguez-Mata, Victor Alejandro Gonzalez-Huitron, Francisco-Ronay López-Estrada, Guillermo Valencia-Palomo, and Oscar J. Suarez. 2025. "Electrical Modeling and Control of a Synchronous Non-Ideal Step-Down Converter Using a Proportional–Integral–Derivative Neural Network Controller" Electronics 14, no. 2: 357. https://doi.org/10.3390/electronics14020357

APA StyleMedrano-Hermosillo, J. A., Rodríguez-Mata, A. E., Gonzalez-Huitron, V. A., López-Estrada, F.-R., Valencia-Palomo, G., & Suarez, O. J. (2025). Electrical Modeling and Control of a Synchronous Non-Ideal Step-Down Converter Using a Proportional–Integral–Derivative Neural Network Controller. Electronics, 14(2), 357. https://doi.org/10.3390/electronics14020357