A Study on a Directional Gradient-Based Defect Detection Method for Plate Heat Exchanger Sheets

Abstract

1. Introduction

- (1)

- One-stage algorithms: Liu et al. combined a Single Shot Multi Box Detector (SSD) with Residual Network-50 (ResNet-50) for steel defect detection [23], leveraging residual learning but facing complex parameter optimization. Some researchers adopt variants of the You Only Look Once (YOLO) series for object detection [24,25,26,27,28], despite the loss of shallow features caused by downsampling operations.

- (2)

- Two-stage algorithms: Hao et al. used a Faster Region-Based Convolutional Neural Network (Faster R-CNN) with ResNet-50 [29], enabling multi-scale fusion but risking overfitting with limited data. Zhang et al. employed Mask R-CNN with EfficientNet [30], effective for large objects but missing small defects due to low-resolution features.

- (3)

- End-to-end Transformers: Xing et al. adapted a Vision Transformer (ViT) with ShuffleNet-V2 [31], compensating for missing convolutional priors but losing fine details via self-attention. Zhu et al. combined deformable convolution with a Detection Transformer (DETR) [32], improving key region focus but requiring large datasets unsuitable for industrial constraints.

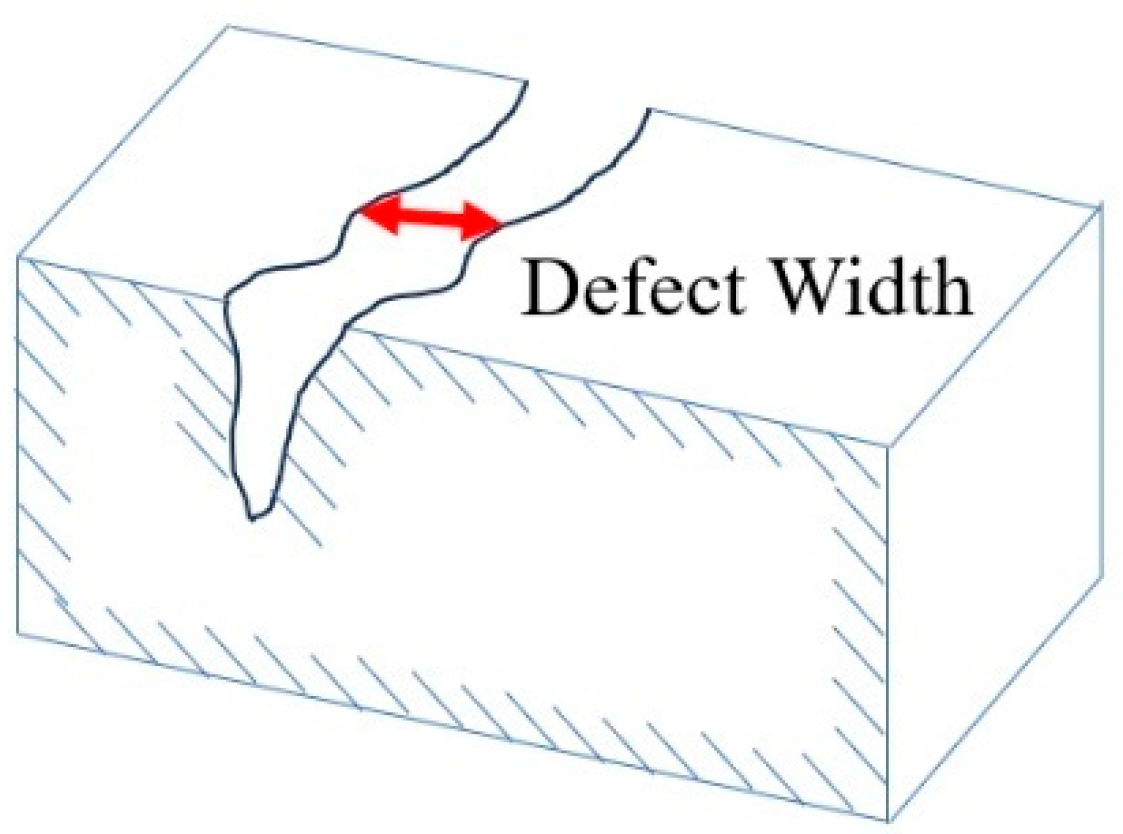

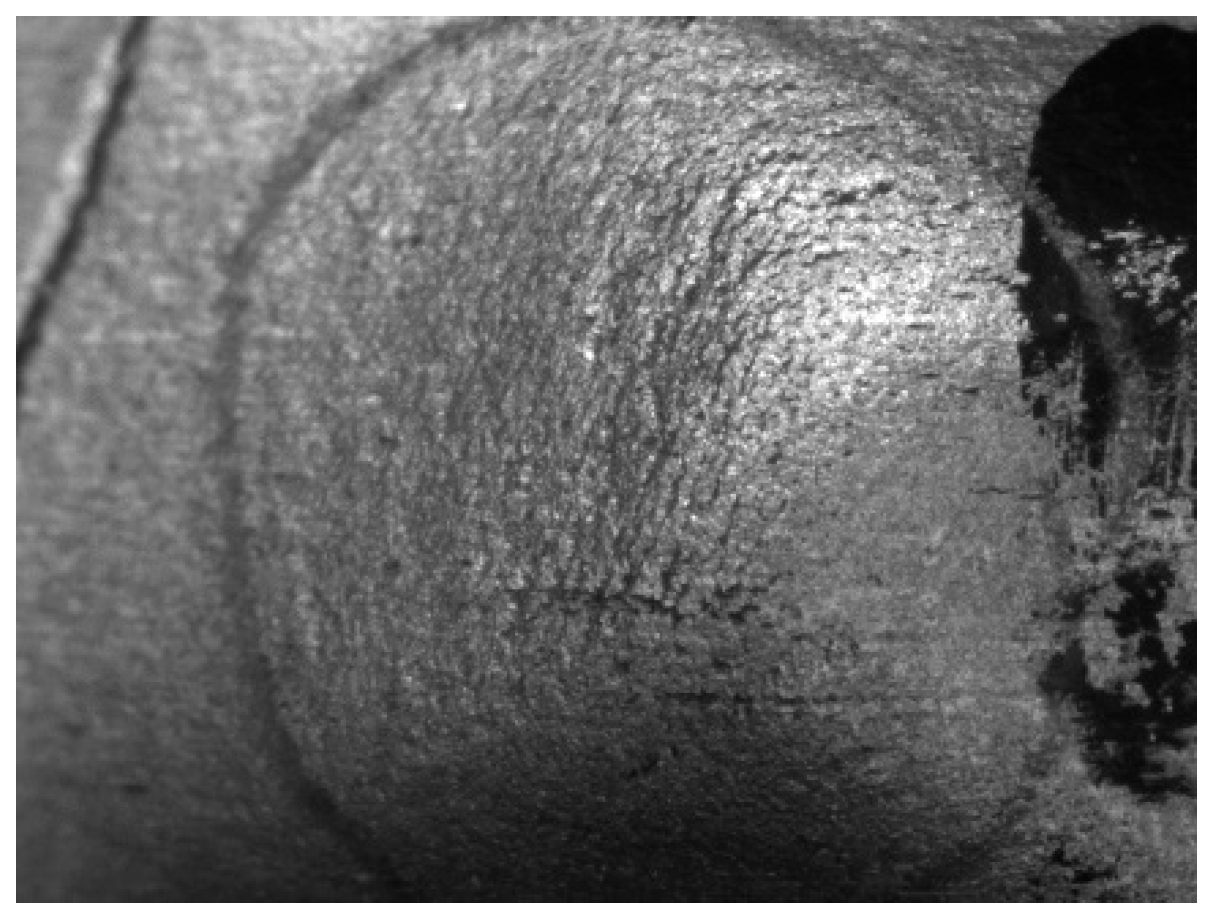

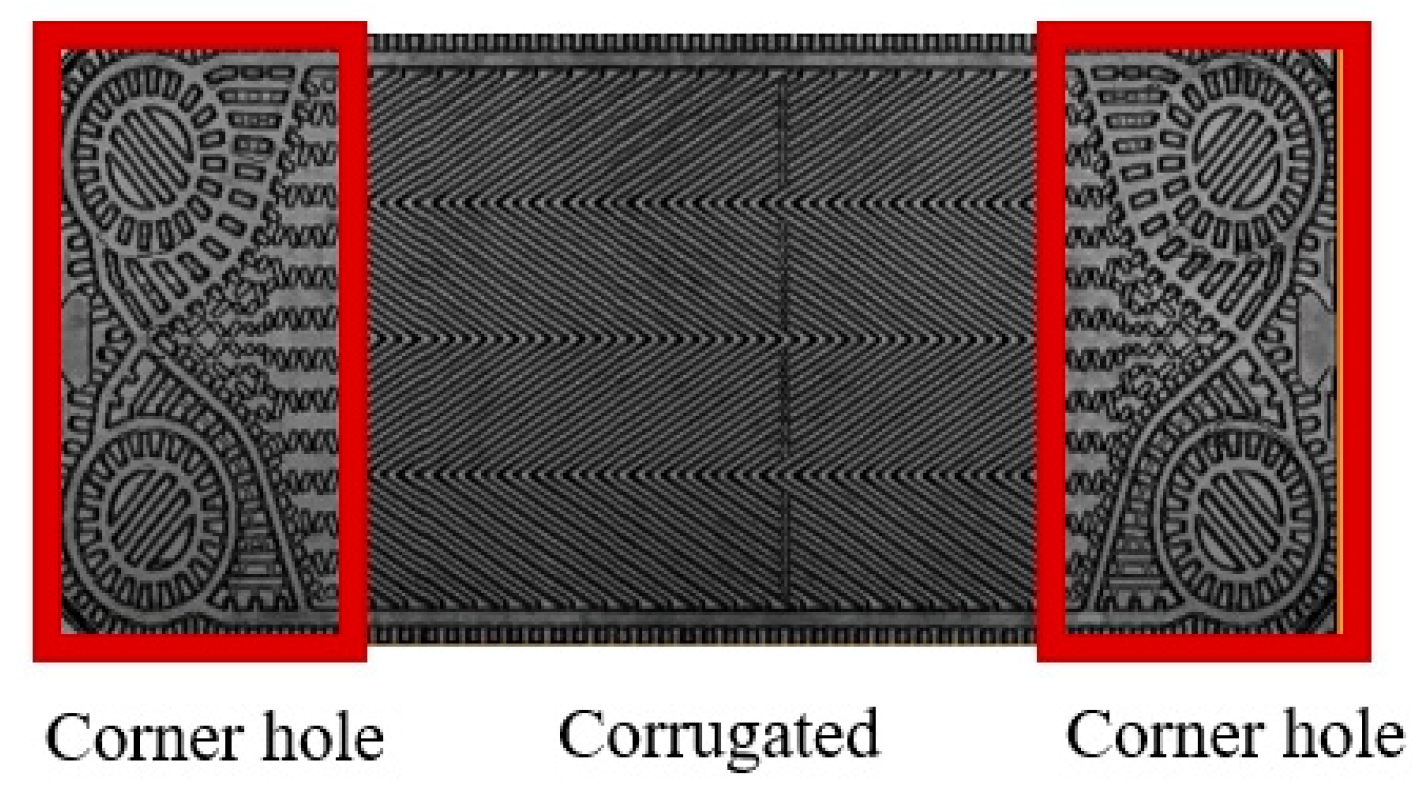

2. Micro-Crack Defect Features

3. Micro-Crack Defect Detection Algorithm Based on Directional Gradient and Gaussian Line Detection

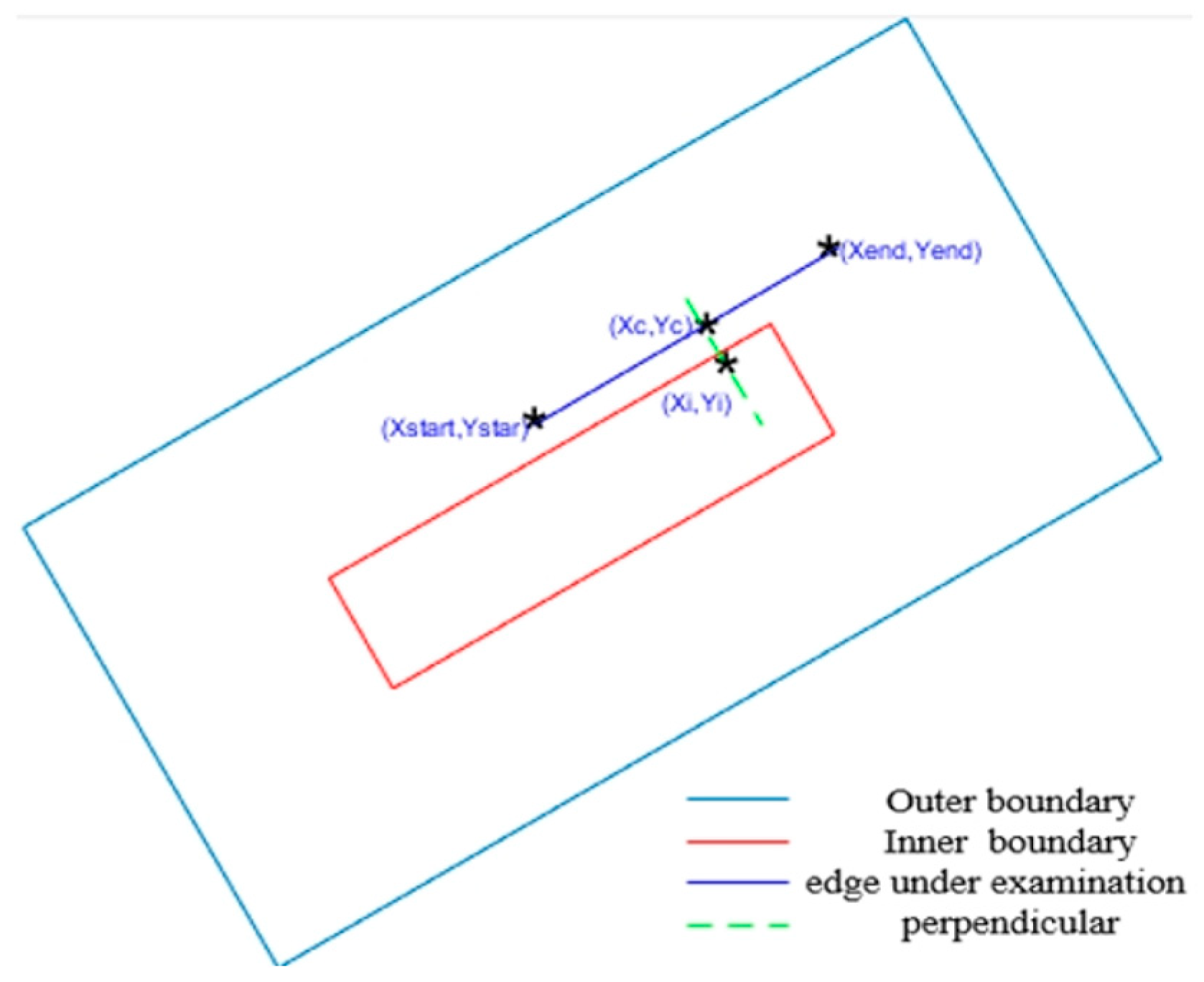

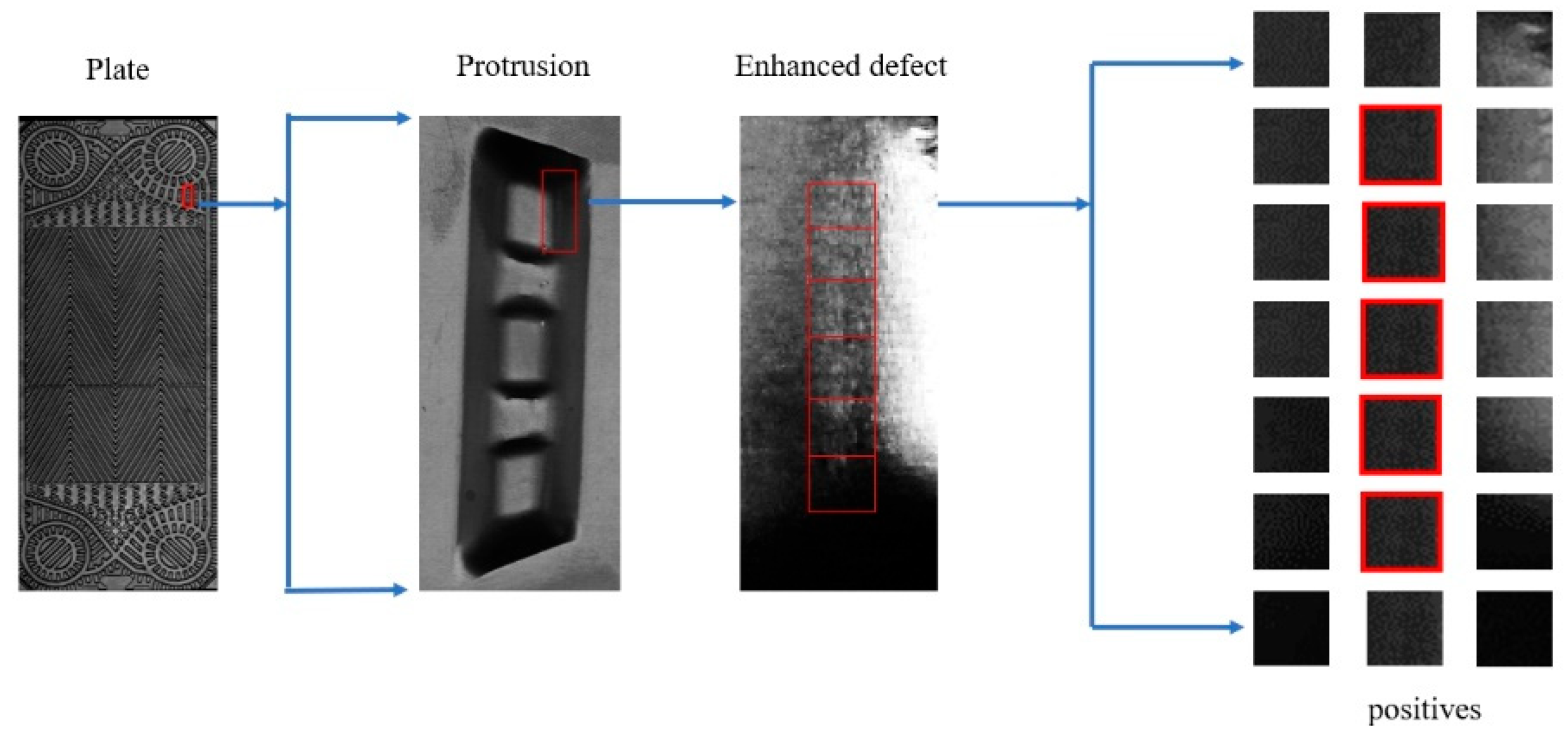

3.1. Extraction of Micro-Crack Defects’ Candidate Regions

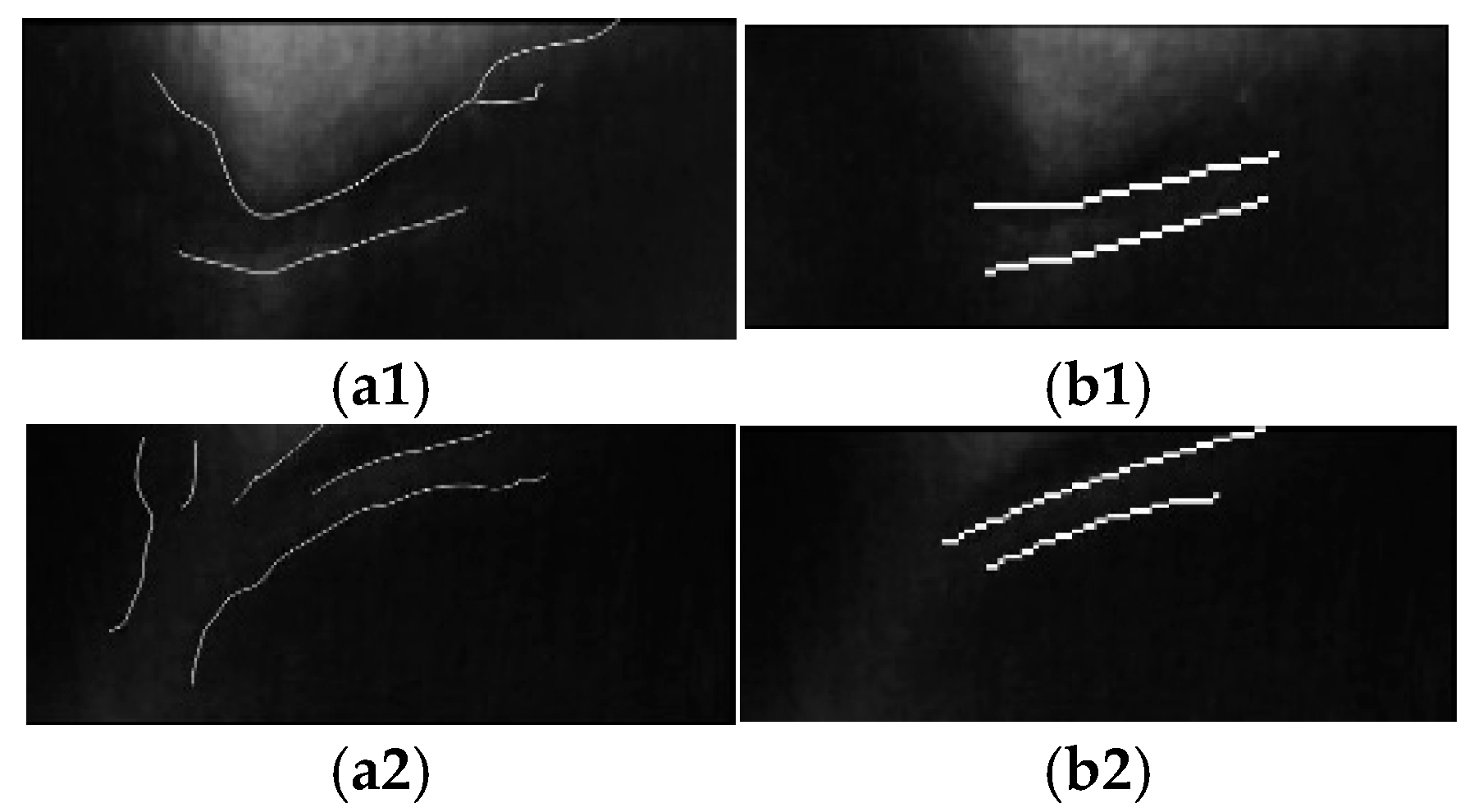

3.2. Sharpening Micro-Crack Defects Using Directional Gradient Operators

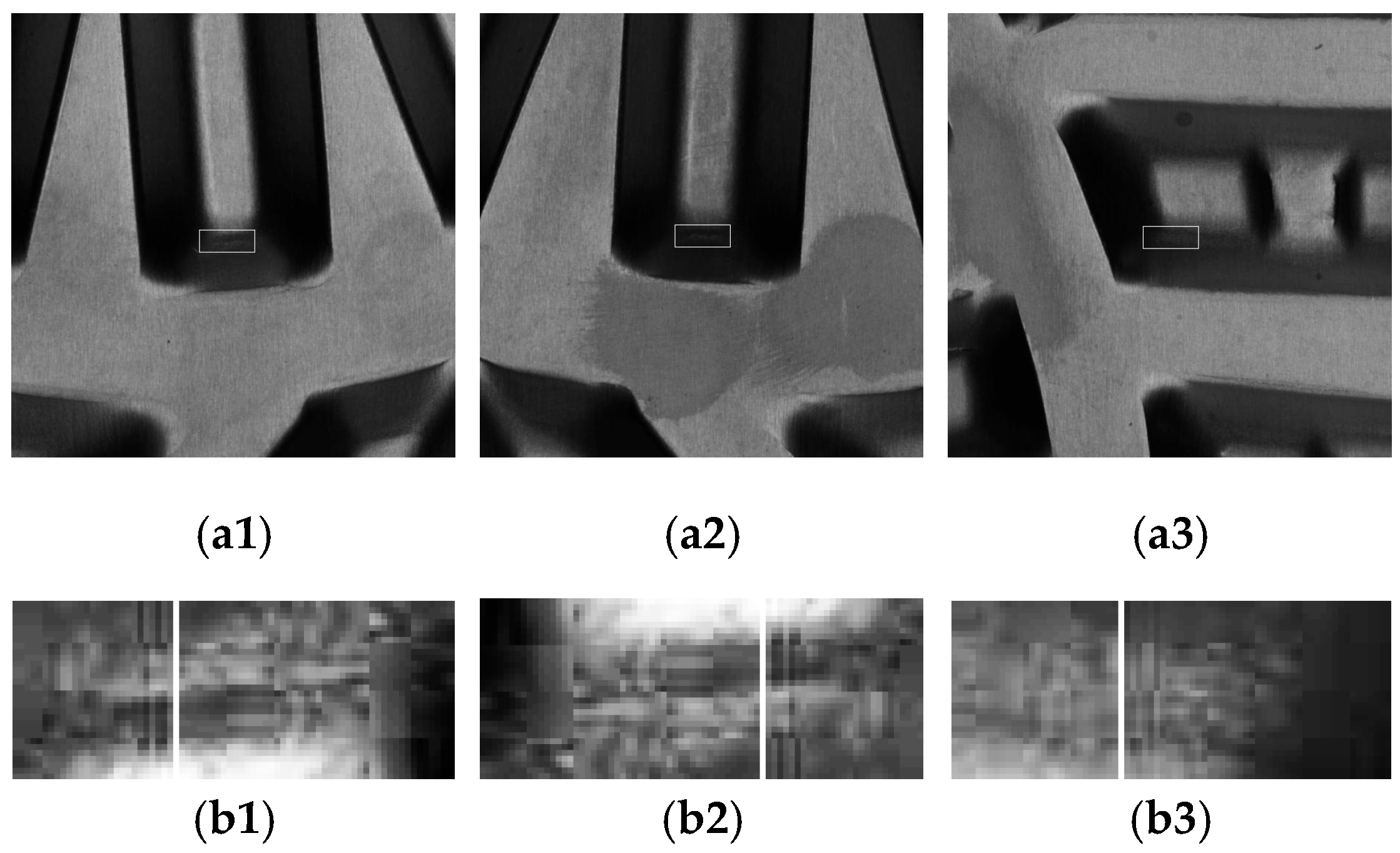

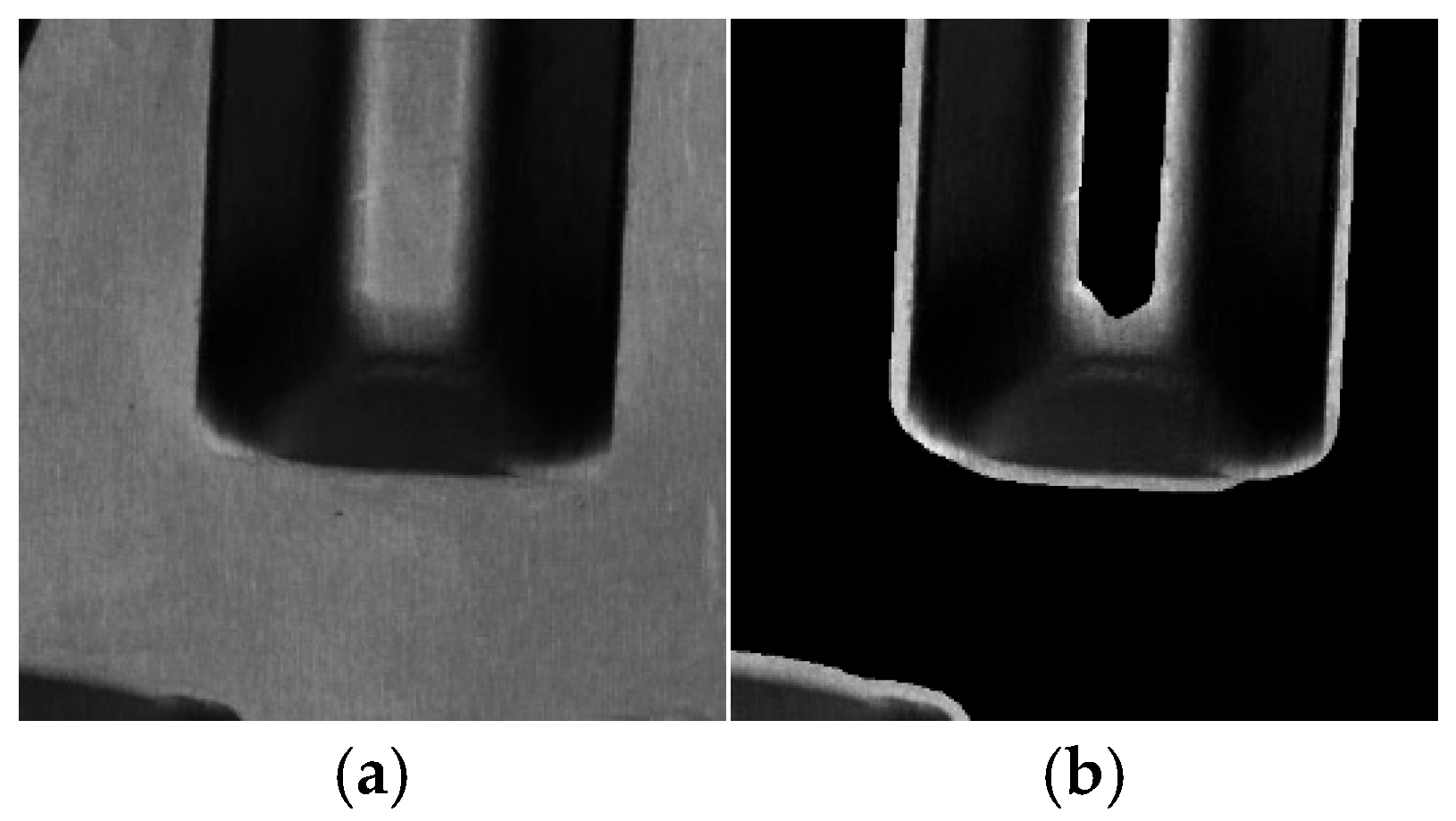

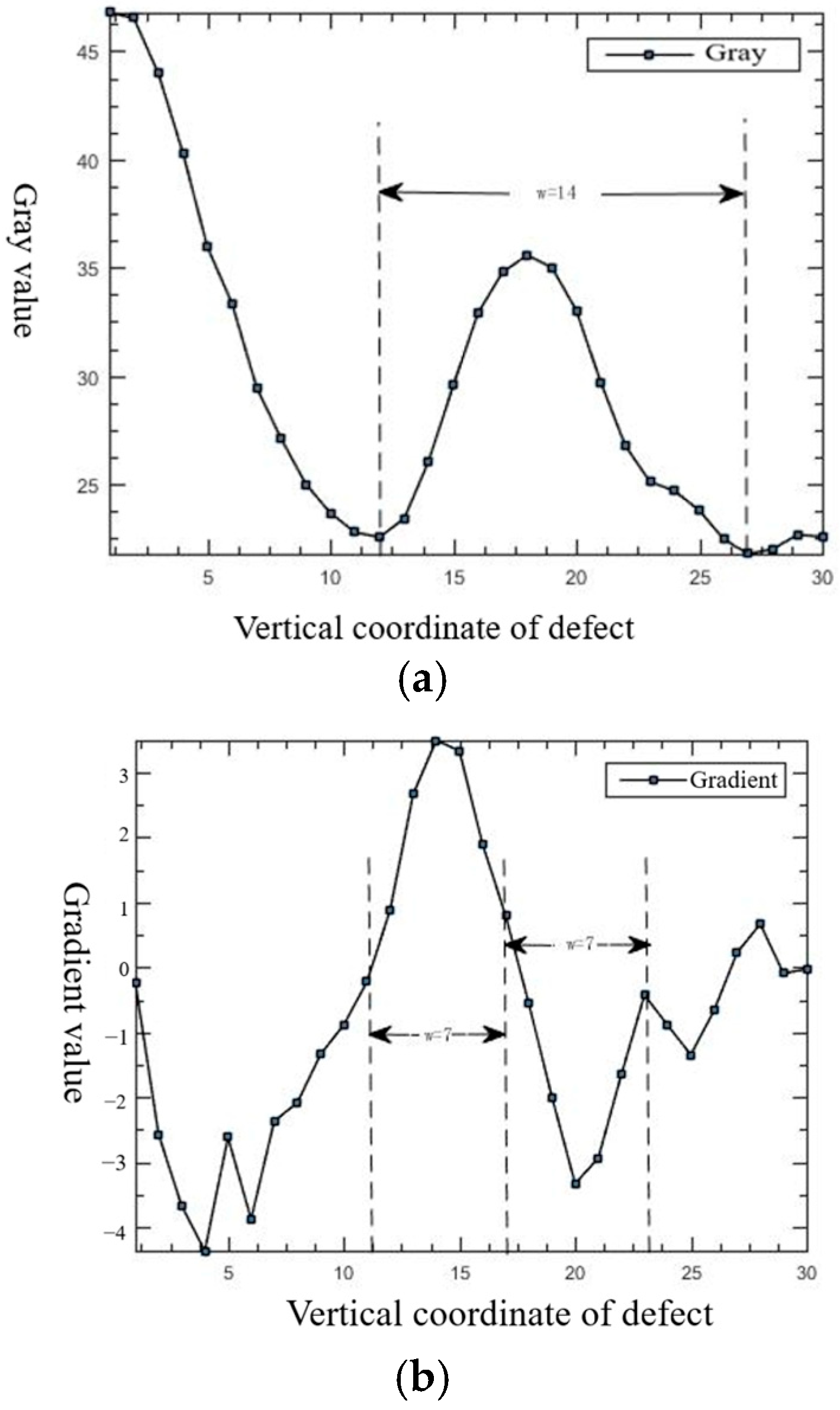

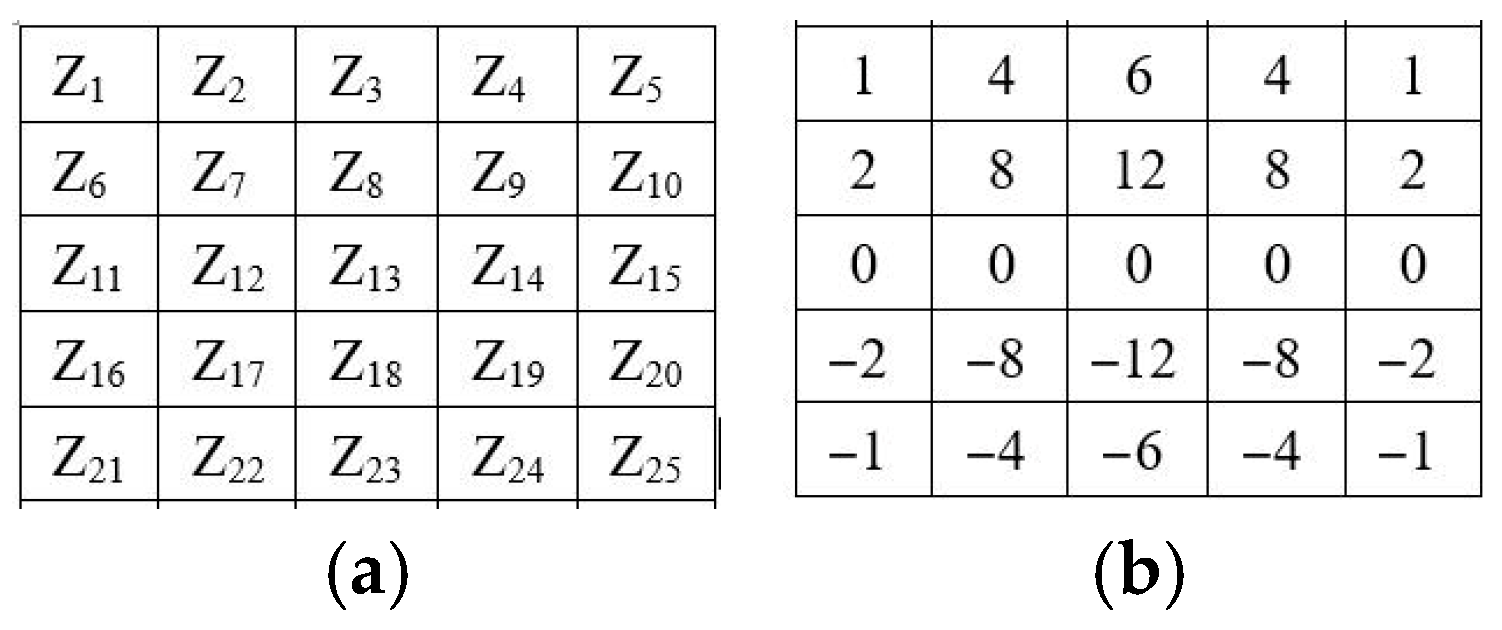

3.2.1. Converting Grayscale Images to Gradient Images

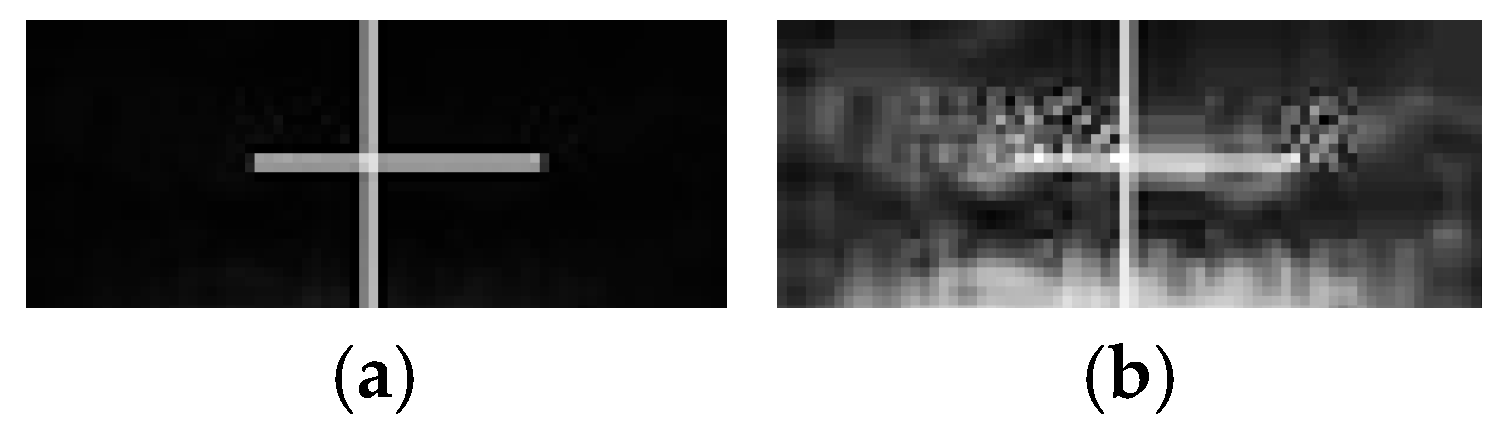

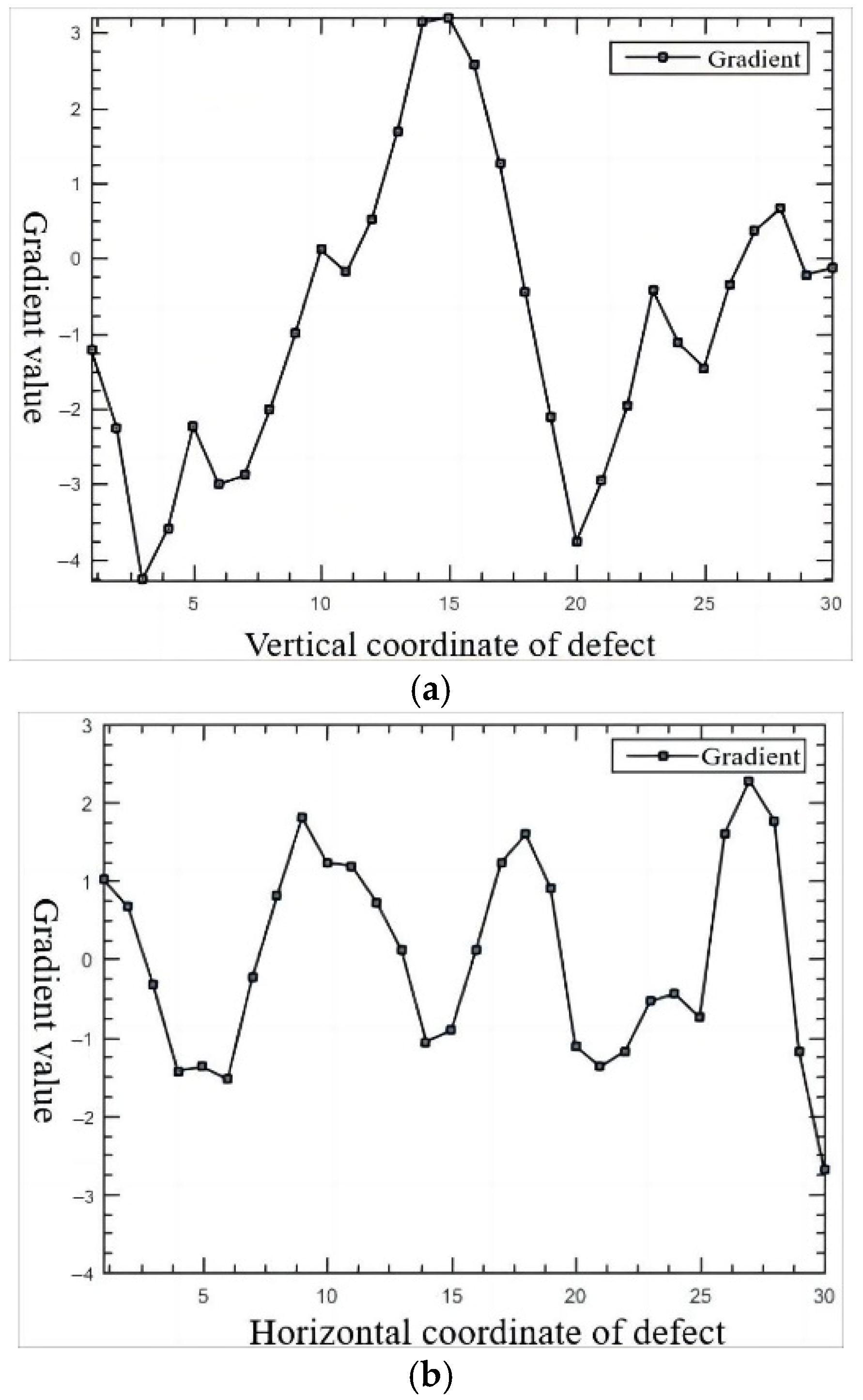

3.2.2. Determination of Template Orientation

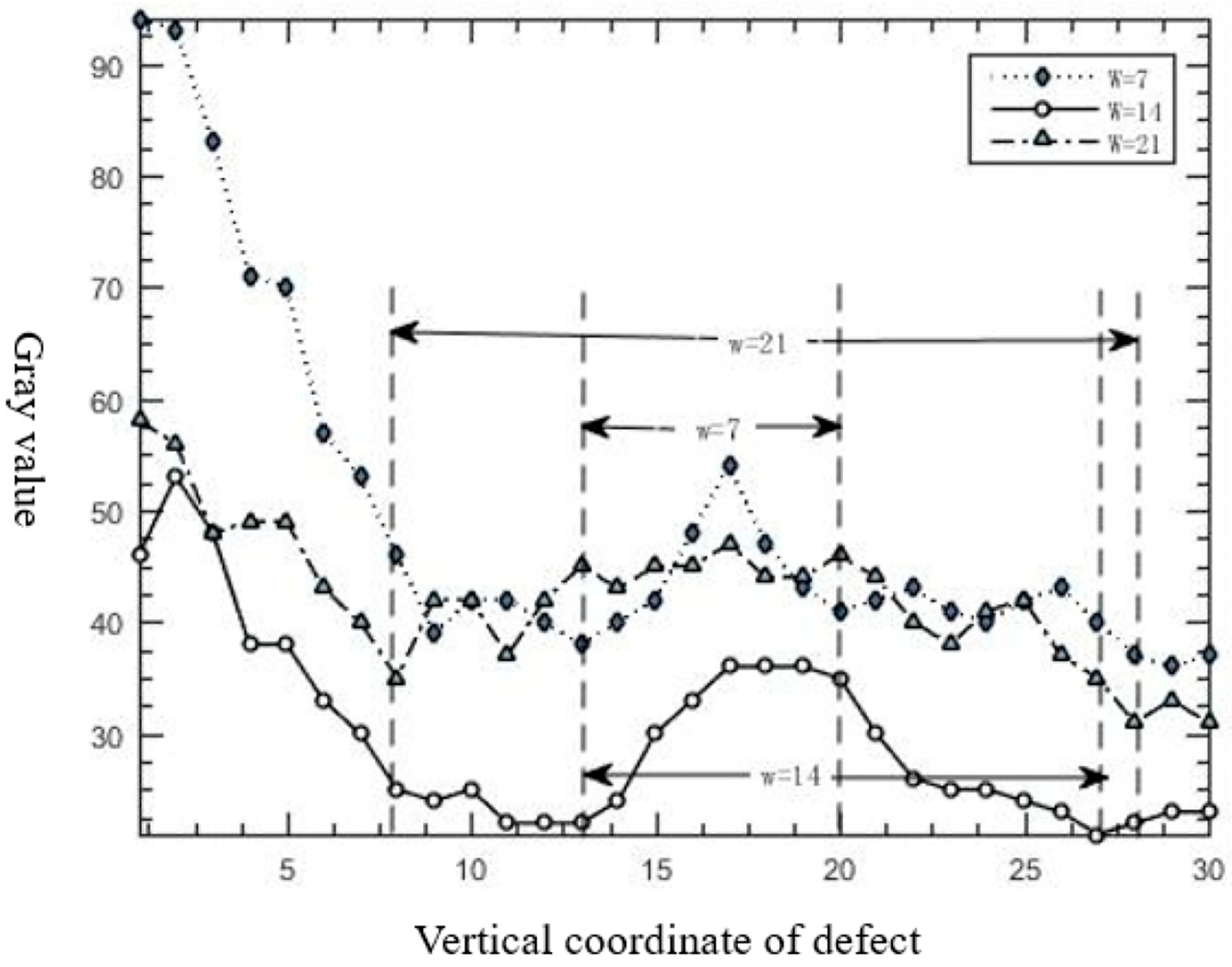

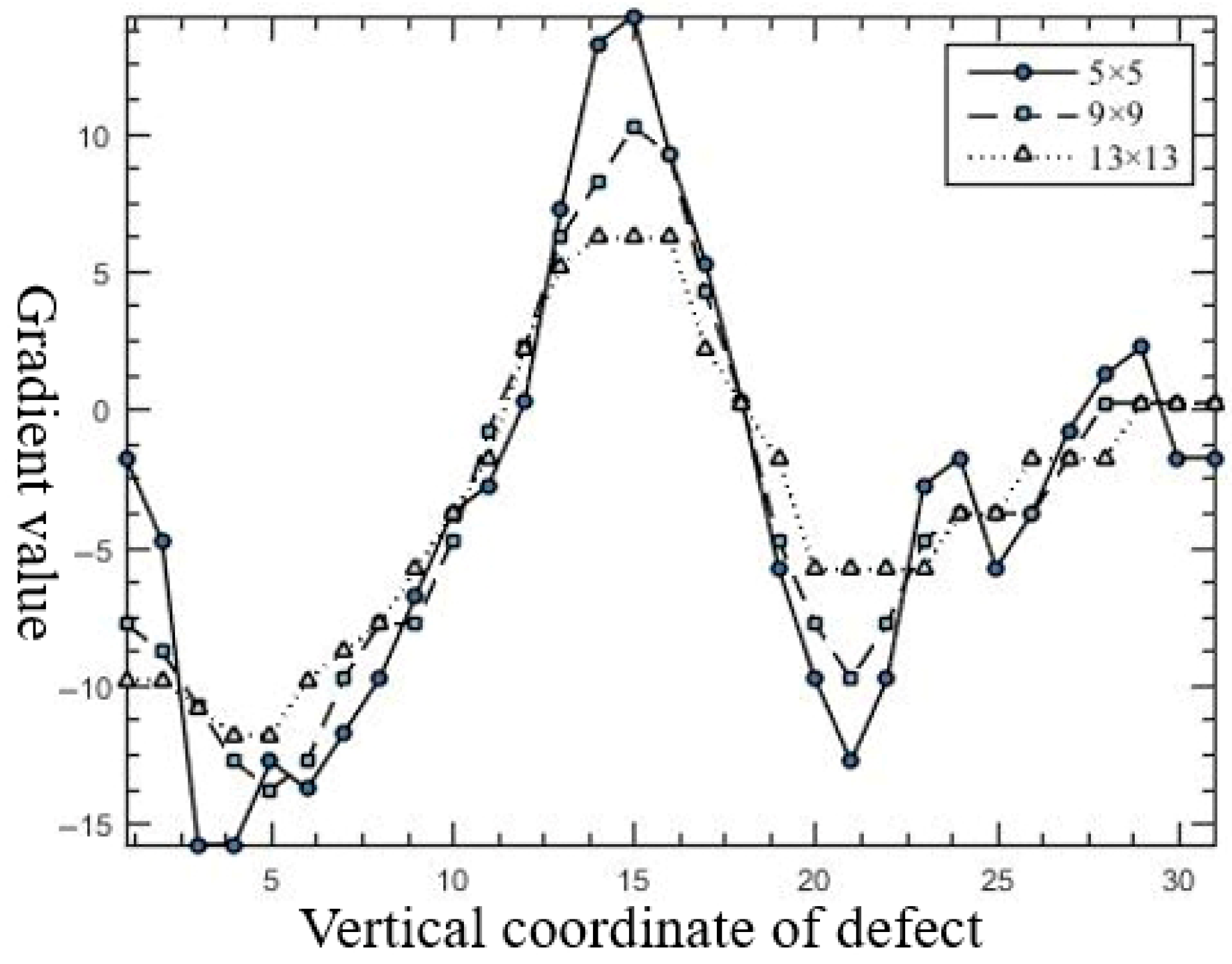

3.2.3. Determination of Template Size

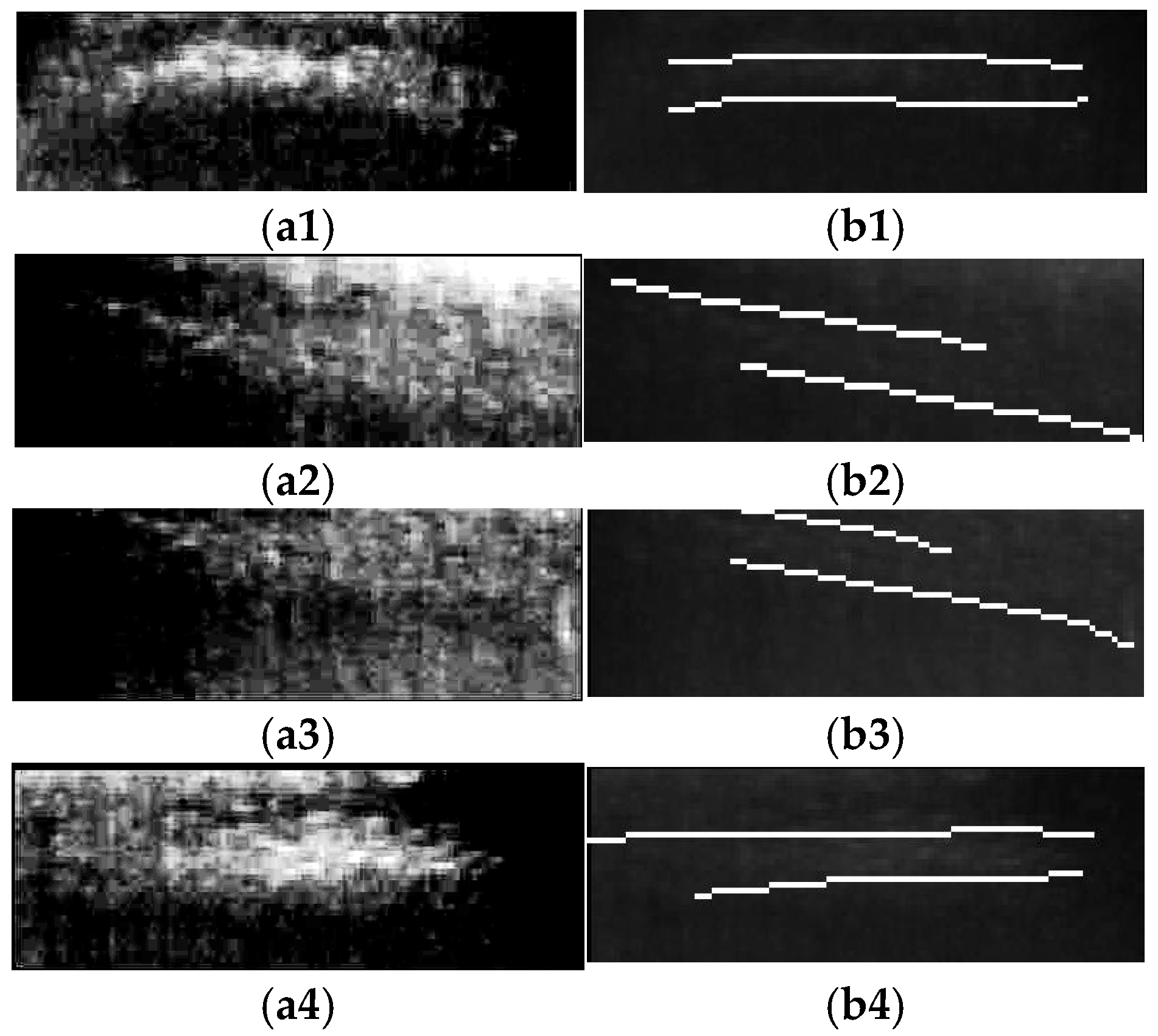

3.3. Extraction of Micro-Crack Defects Using a Gaussian Line Detection Algorithm

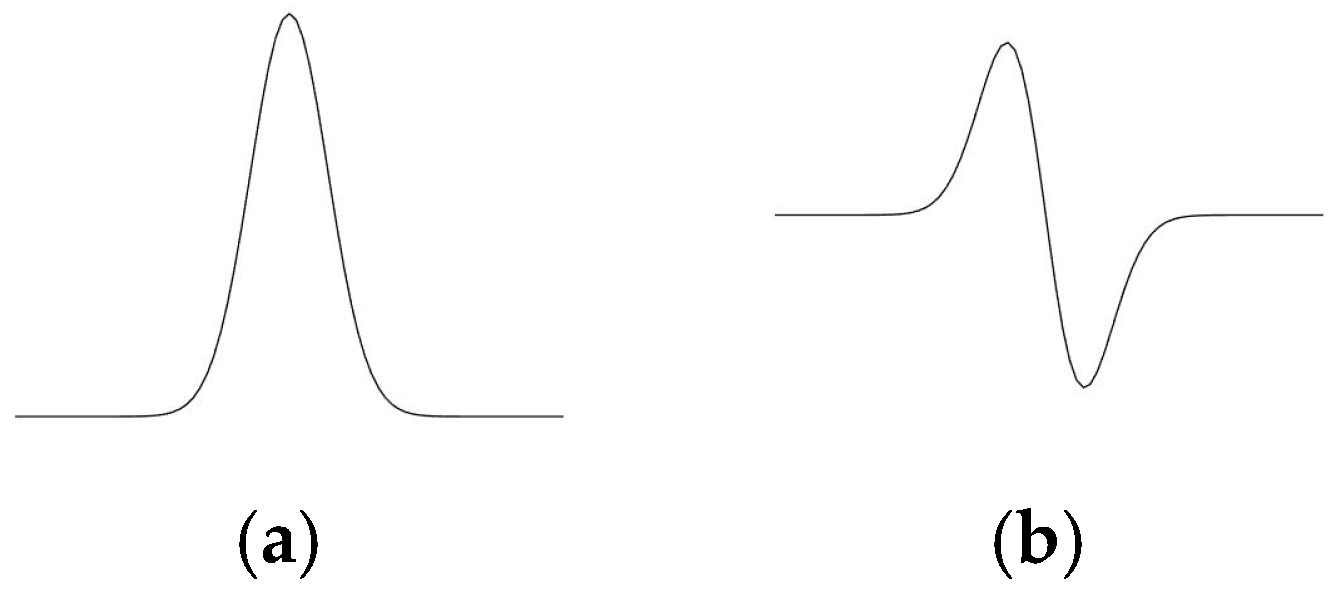

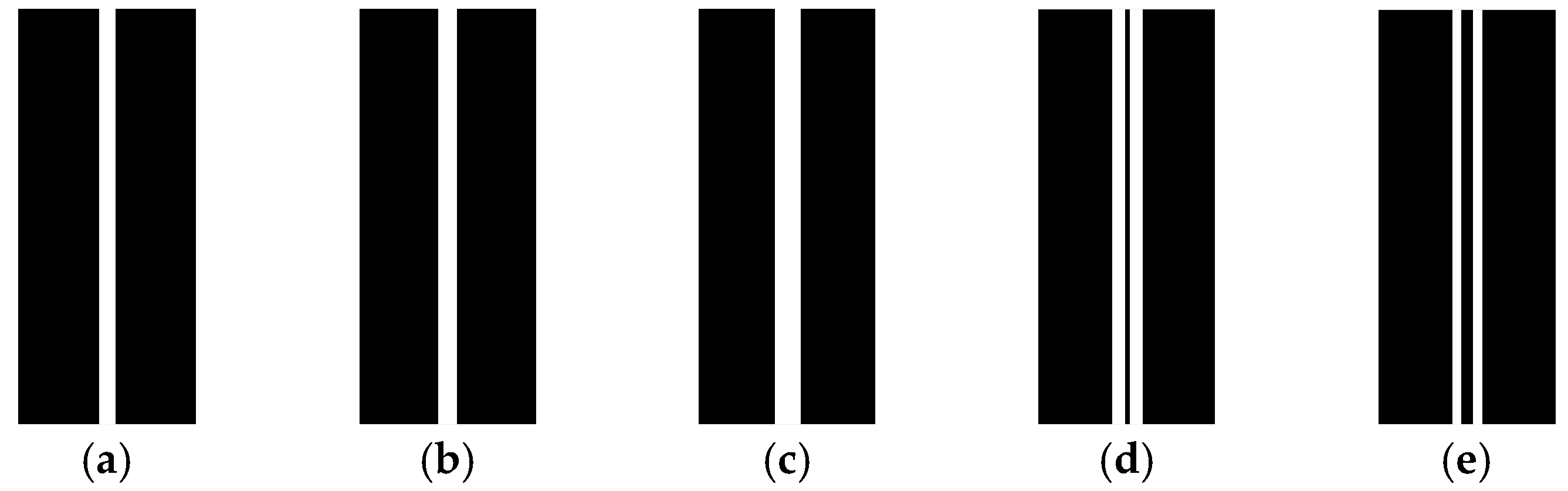

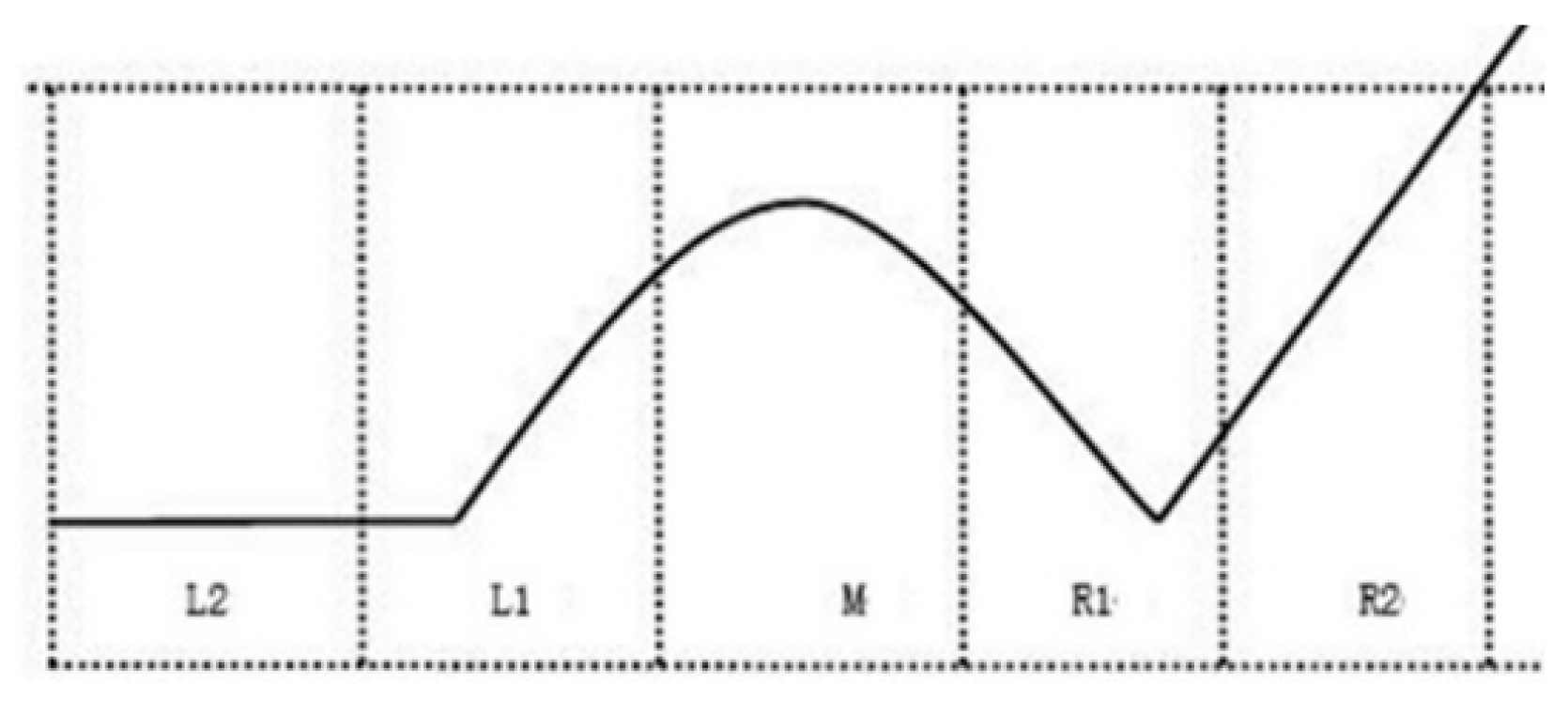

3.3.1. Definition of the Gaussian Line Detection Operator

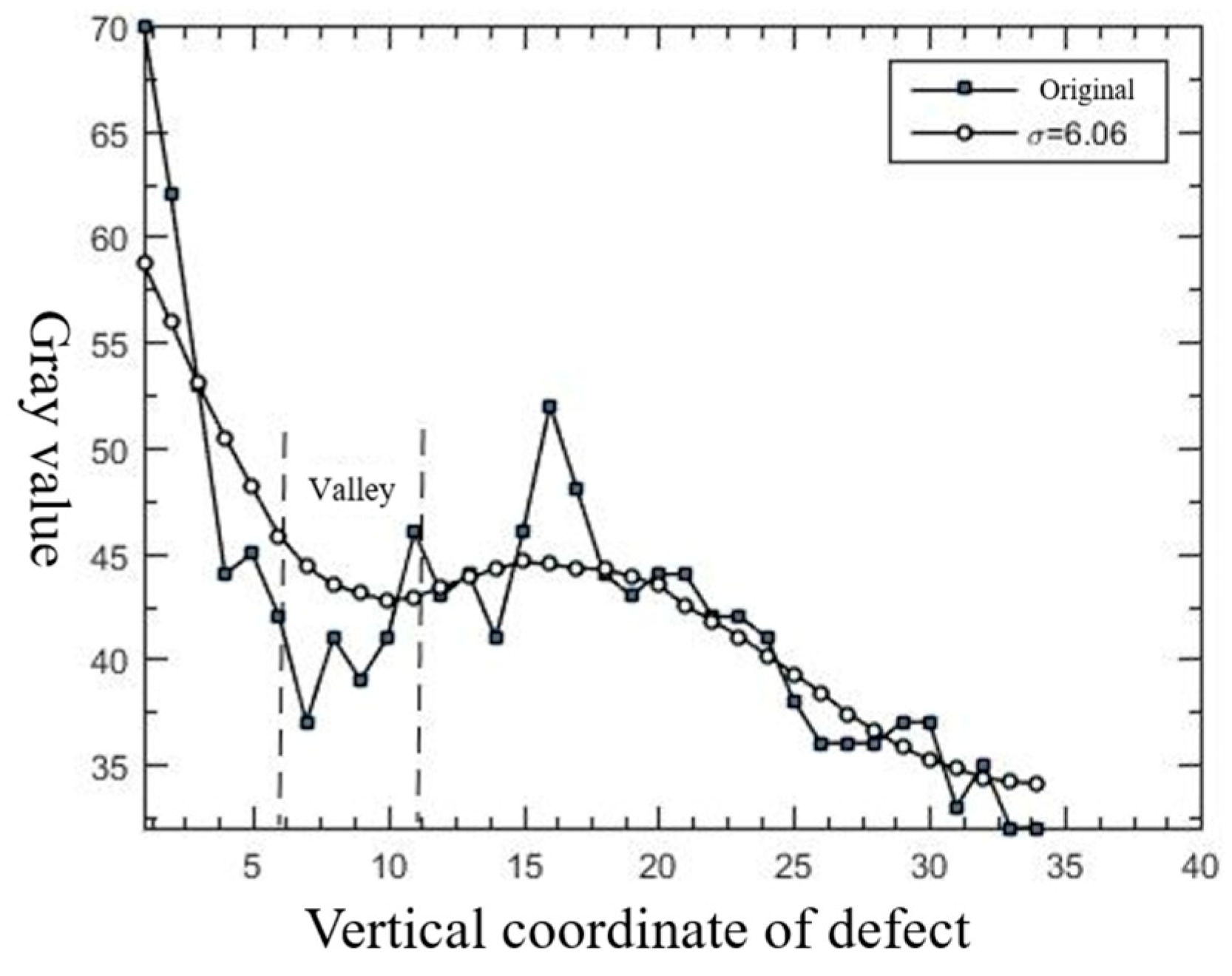

3.3.2. Selection of Gaussian Standard Deviation

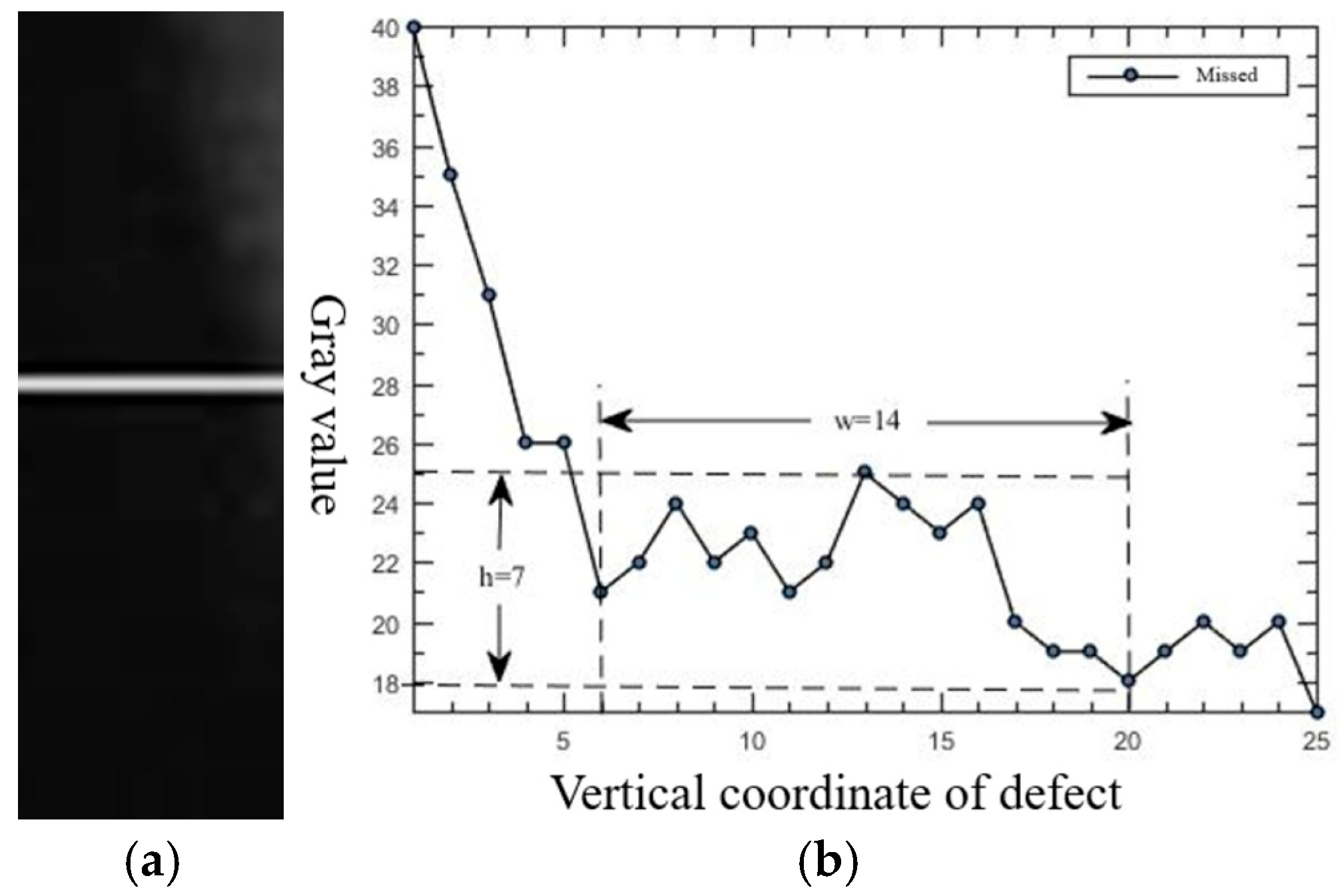

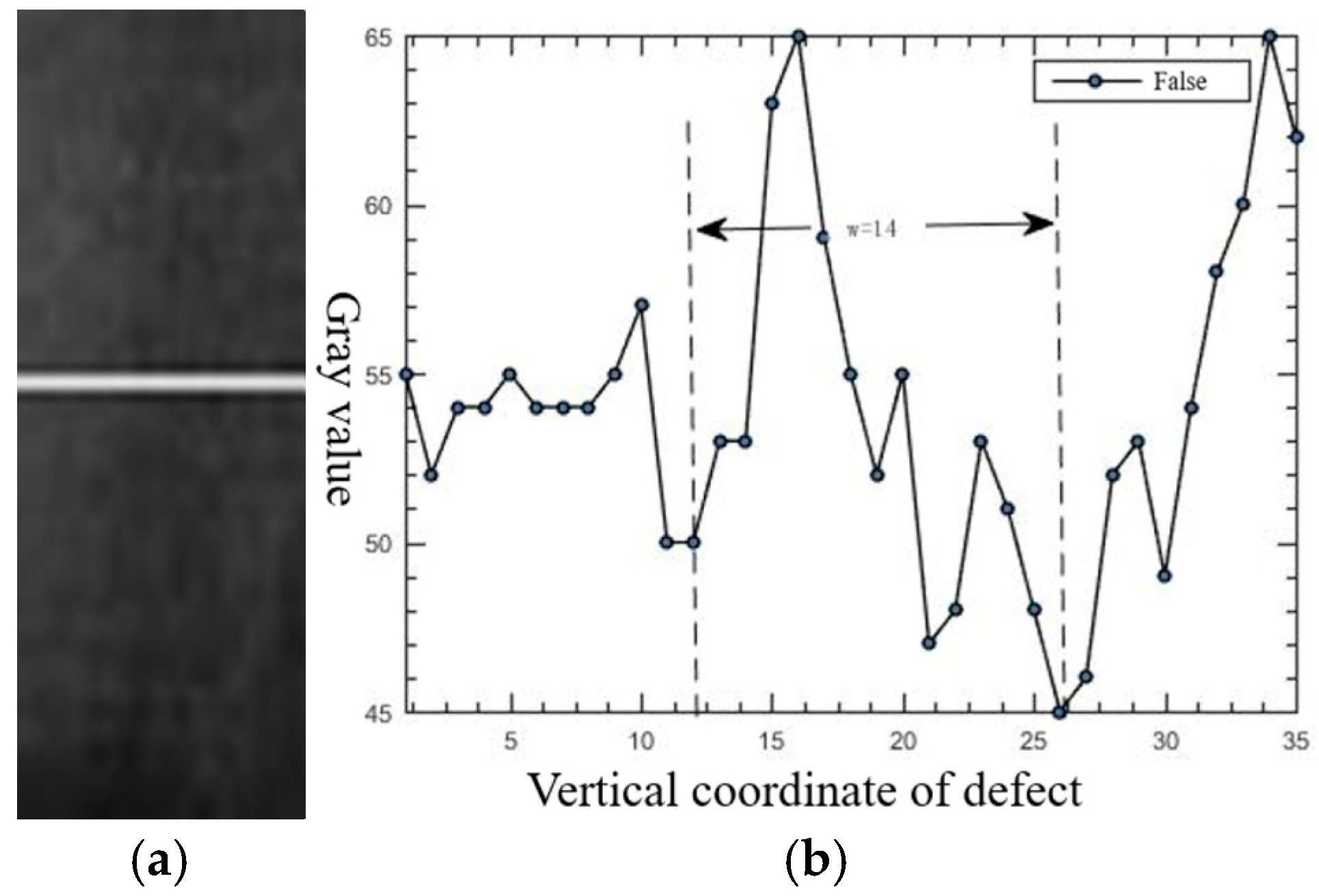

- Template width ≥ defect width: preserved central peak, effective detection.

- Template width < defect width: split dual peaks, missed detection.

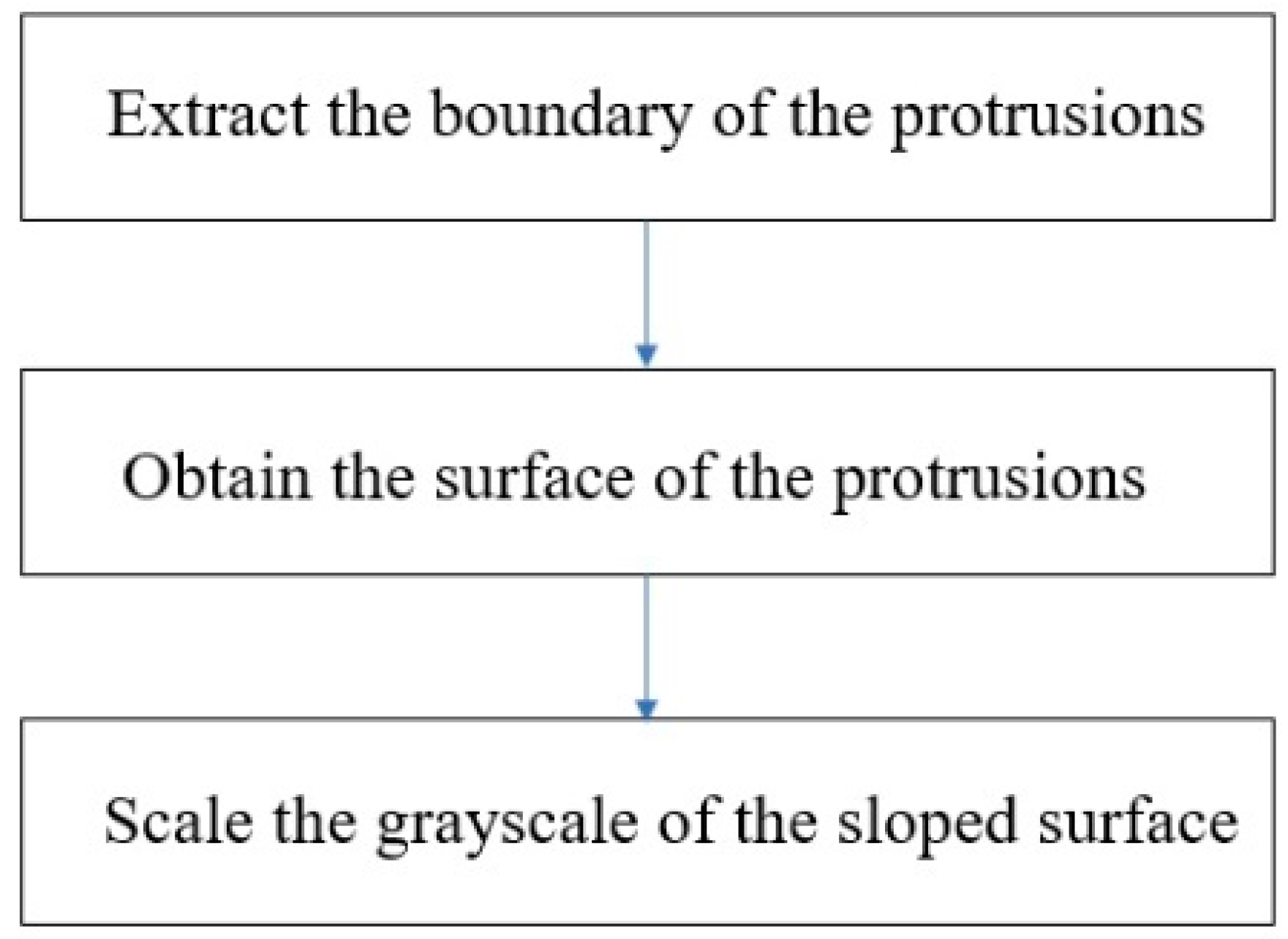

3.4. Steps of the Micro-Crack Defects Detection Algorithm

3.4.1. Extract Candidate Regions

3.4.2. Obtain Gradient Image

3.4.3. Gaussian Line Detection

3.4.4. Recognition

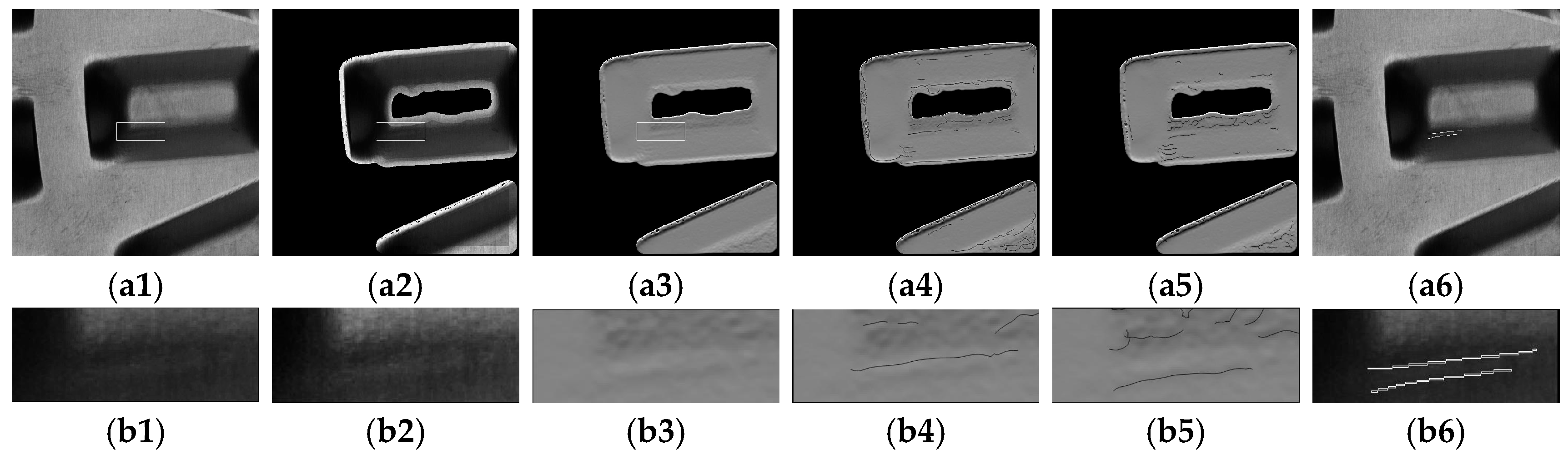

4. Experimental Results and Analysis

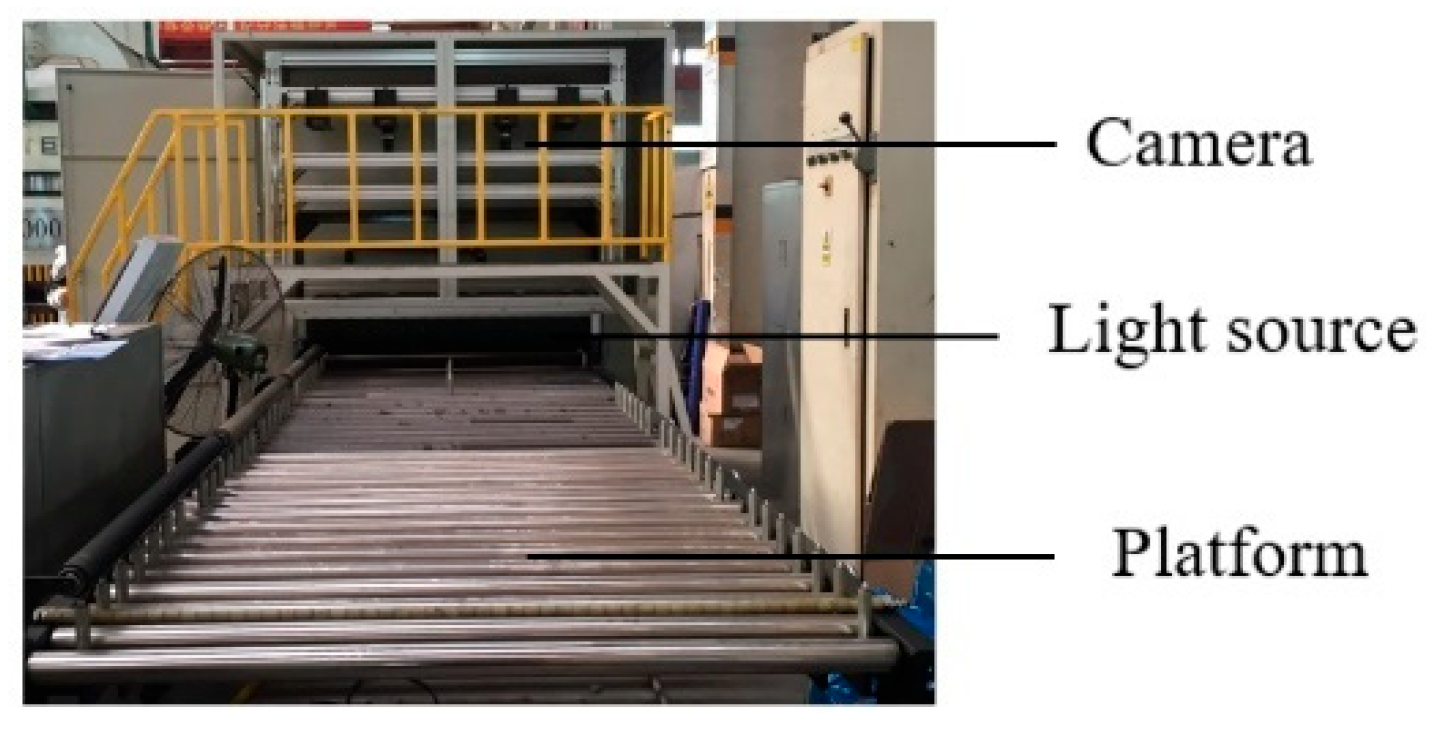

4.1. Construction of the Image Library

4.2. Definition of Evaluation Metrics and Testing Environment

- MDR (missed detection rate) represents the ratio of defects misclassified as background.

- FDR (false detection rate) represents the ratio of background areas misclassified as defects.

- NFR (number of false rejections) is the count of legitimate members wrongly rejected.

- NLA (number of all legal member attempts) is the total count of all legitimate member attempts.

- NFA (number of false accepts) is the count of illegitimate members wrongly accepted.

4.3. Analysis of the Algorithm’s Detection Performance

4.4. Discussion

4.4.1. Comparison with Deep Learning Baseline Models

4.4.2. Comparison with Grayscale-Based Gaussian Line Detection

4.4.3. Comparison with the Non-Directional Canny Operator

4.4.4. Ablation Study on Directional Gradient Templates

4.4.5. Limitations of the Proposed Method

4.4.6. Real-Time Deployment Potential

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- GB/T232-1988; Metallic Materials—Bend Test. Standards Press of China: Beijing, China, 1988.

- NB/T47004.1-2017; Chian Standardization Committee on Boilers and Pressure Vessels. Plate Heat Exchangers—Part 1: Plate-and-Frame Heat Exchangers. Xinhua Publishing House: Beijing, China, 2017.

- Yuan, W.; Zhao, P. An Adaptive Edge Detection Method for Plate of Heat Exchanger Based on Canny. Comput. Technol. Dev. 2021, 31, 81–85+94. [Google Scholar]

- Chen, S. Research on Defect Detection Methods for Plate Heat Exchanger Plates. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2022. [Google Scholar]

- Wang, H.; Wang, T.; Yu, C. CFRP ultrasonic detection defect identification method based on recursive quantitative analysis. J. ZheJiang Univ. (Eng. Sci.) 2024, 58, 1604–1617. [Google Scholar]

- Jin, J.; Zhang, Q.; Han, B.; Yang, S.; Ren, Y. Research on eddy current testing and defect evaluation methods for complex cracks. Chin. J. Sci. Instrum. 2024, 45, 280–288. [Google Scholar]

- Liu, L.; Bao, S. Experimental Research on the Effect of Cracks on Metal Magnetic Memory Signals. Eng. Mech. 2024, 41, 247–256. [Google Scholar]

- Zhang, H.; Liu, S.; Zhu, P. Extraction method for irregular plane path of sensing fiber with Gaussian line method. China Meas. Test 2022, 48, 15–21. [Google Scholar]

- Javeed, M.A.; Ghaffar, M.A.; Ashraf, M.A.; Zubair, N.; Metwally, A.S.M.; Tag-Eldin, E.M.; Bocchetta, P.; Javed, M.S.; Jiang, X. Lane Line Detection and Object Scene Segmentation Using Otsu Thresholding and the Fast Hough Transform for Intelligent Vehicles in Complex Road Conditions. Electronics 2023, 12, 1079. [Google Scholar] [CrossRef]

- Tverdomed, V.; Dmytro, Z.; Kokriatska, N.; Lukoševičius, V. The Detection of Railheads: An Innovative Direct Image Processing Method. Sustainability 2024, 16, 5109. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, Y.; Deng, F.; Mu, Y.; Zhong, Y.; Jiao, D. Detection of bubble defects on tire surface based on line laser and machine vision. Processes 2022, 10, 255. [Google Scholar] [CrossRef]

- Fan, H.; Cosman, P.C.; Hou, Y.; Li, B. High-speed railway fastener detection based on a line local binary pattern. IEEE Signal Process. Lett. 2018, 25, 788–792. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, K.; Xu, J. An improved MB-LBP defect recognition approach for the surface of steel plates. Appl. Sci. 2019, 9, 4222. [Google Scholar] [CrossRef]

- Luo, Q.; Fang, X.; Sun, Y.; Liu, L.; Ai, J.; Yang, C.; Simpson, O. Surface defect classification for hot-rolled steel strips by selectively dominant local binary patterns. IEEE Access 2019, 7, 23488–23499. [Google Scholar] [CrossRef]

- Luo, Q.; Sun, Y.; Li, P.; Simpson, O.; Tian, L.; He, Y. Generalized completed local binary patterns for time-efficient steel surface defect classification. IEEE Trans. Instrum. Meas. 2019, 68, 667–679. [Google Scholar] [CrossRef]

- Huang, D.; Liao, S.; Sunny, A.I.; Yu, S. A novel automatic surface scratch defect detection for fluid-conveying tube of Coriolis mass flow-meter based on 2D-direction filter. Measurement 2018, 126, 332–341. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, T.D.; Lu, R.S. Surface defect inspection of TFT-LCD panels based on 1D Fourier method. In Proceedings of the Seventh International Symposium on Precision Mechanical Measurements, Xia’men, China, 8–12 August 2015; pp. 9903–9908. [Google Scholar]

- Zhang, J.; Cui, Y.; He, G.; Luo, C.; Miao, G. A new image processing enabled approach for detection of scratch defects for wire-type objects. In Proceedings of the International Conference on Information Science & Control Engineering, Beijing, China, 8–10 July 2016; IEEE: Piscataway, NJ, USA, 2016. [Google Scholar]

- Yun, J.P.; Choi, S.; Kim, J.W.; Kim, S.W. Automatic detection of cracks in raw steel block using Gabor filter optimized by univariate dynamic encoding algorithm for searches (uDEAS). NDT E Int. 2009, 42, 389–397. [Google Scholar] [CrossRef]

- Sun, J.; Li, C.; Wu, X.J.; Palade, V.; Fang, W. An effective method of weld defect detection and classification based on machine vision. IEEE Trans. Ind. Inform. 2019, 15, 6322–6333. [Google Scholar] [CrossRef]

- Zhang, H.; Jin, X.; Wu, Q.M.J.; Wang, Y.; He, Z.; Yang, Y. Automatic visual detection system of railway surface defects with curvature filter and improved gaussian mixture model. IEEE Trans. Instrum. Meas. 2018, 67, 1593–1608. [Google Scholar] [CrossRef]

- Zhang, X.P.; Wei, L.F.; Yuan, W.Q.; Ding, Z.B. Microcrack detection method for plate heat exchanger based on machine vision. J. Mech. Electr. Eng. 2020, 37, 856–860. [Google Scholar]

- Liu, X.; Gao, J. Surface defect detection method of hot rolling strip based on improved SSD model. In Database Systems for Advanced Applications. DASFAA 2021 International Workshops: BDQM, GDMA, MLDLDSA, MobiSocial, and MUST, Taipei, Taiwan, 11–14 April 2021, Proceedings 26; Springer International Publishing: Cham, Switzerland, 2021; pp. 209–222. [Google Scholar]

- Zhang, J.; Kang, X.; Ni, H.; Ren, F. Surface defect detection of steel strips based on classification priority YOLOv3-dense network. Ironmak. Steelmak. 2021, 48, 547–558. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, W. LA-YOLO: Bidirectional Adaptive Feature Fusion Approach for Small Object Detection of Insulator Self-explosion Defects. IEEE Trans. Power Deliv. 2024, 39, 3387–3397. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Huang, Q.; Han, Y.; Zhao, M. DsP-YOLO: An anchor-free network with DsPAN for small object detection of multiscale defects. Expert Syst. Appl. 2024, 241, 122669. [Google Scholar] [CrossRef]

- Wang, W.; Meng, Y.; Li, S.; Zhang, C. HV-YOLOv8 by HDPconv: Better lightweight detectors for small object detection. Image Vis. Comput. 2024, 147, 105052. [Google Scholar] [CrossRef]

- Liu, Q.; Lv, J.; Zhang, C. MAE-YOLOv8-based small object detection of green crisp plum in real complex orchard environments. Comput. Electron. Agric. 2024, 226, 109458. [Google Scholar] [CrossRef]

- Hao, R.; Lu, B.; Cheng, Y.; Li, X.; Huang, B. A steel surface defect inspection approach towards smart industrial monitoring. J. Intell. Manuf. 2021, 32, 1833–1843. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, B.; Wang, W. Steel surface defect detection based on improved mask rcnn. In Proceedings of the 2022 IEEE 8th International Conference on Computer and Communications (ICCC), Chengdu, China, 9–12 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 2176–2181. [Google Scholar]

- Xing, L.; Li, T.; Fan, H.; Zhu, H. Defect Detection and Classification of Strip Steel Based on Improved VIT Model. In Proceedings of the International Conference on Intelligent Information Processing, Qingdao, China, 27–30 May 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 327–335. [Google Scholar]

- Zhu, X.; Su, W.; Lu, L.; Li, B.; Wang, X.; Dai, J. Deformable detr: Deformable transformers for end-to-end object detection. arXiv 2020, arXiv:2010.04159. [Google Scholar]

- Steger, C. An Unbiased Detector of Curvilinear Structures. IEEE Trans. Pattern Anal. Mach. Intell. 1998, 20, 113–125. [Google Scholar] [CrossRef]

| Defect | Normal | Miss | False | DR | FDR |

|---|---|---|---|---|---|

| 268 | 400 | 39 | 75 | 14.55% | 21.85% |

| Method | MDR | FDR | Time/s |

|---|---|---|---|

| Ours | 14.55% | 21.85% | 0.1402 |

| Res Net 50 | 46.64% | 12.42% | 0.9562 |

| DenseNet-121 | 20.52% | 24.72% | 1.6875 |

| EfficientNet-B0 | 18.28% | 34.31% | 0.8221 |

| ShuffleNetV2 | 22.01% | 26.17% | 0.1984 |

| Operator | MDR | FDR | Time/s |

|---|---|---|---|

| Vertical Sobel | 14.55% | 21.85% | 0.1402 |

| Horizontal Sobel | 34.70% | 26.58% | 0.1411 |

| Vertical Prewitt | 22.01% | 23.86% | 0.1723 |

| Laplacian | 47.76% | 33.82% | 0.1685 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Z.; Yuan, W. A Study on a Directional Gradient-Based Defect Detection Method for Plate Heat Exchanger Sheets. Electronics 2025, 14, 3206. https://doi.org/10.3390/electronics14163206

Ding Z, Yuan W. A Study on a Directional Gradient-Based Defect Detection Method for Plate Heat Exchanger Sheets. Electronics. 2025; 14(16):3206. https://doi.org/10.3390/electronics14163206

Chicago/Turabian StyleDing, Zhibo, and Weiqi Yuan. 2025. "A Study on a Directional Gradient-Based Defect Detection Method for Plate Heat Exchanger Sheets" Electronics 14, no. 16: 3206. https://doi.org/10.3390/electronics14163206

APA StyleDing, Z., & Yuan, W. (2025). A Study on a Directional Gradient-Based Defect Detection Method for Plate Heat Exchanger Sheets. Electronics, 14(16), 3206. https://doi.org/10.3390/electronics14163206