Construction of a Machining Process Knowledge Graph and Its Application in Process Route Recommendation

Abstract

1. Introduction

2. Research Framework for Construction and Application of PKG

- (1)

- Well-defined structural form, storing data in a directed graph structure for quick access to data;

- (2)

- Strong reasoning ability to mimic the human mind to deduce implicit knowledge;

- (3)

- Knowledge retrieval with depth and breadth, based on keyword searches can be matched to a complete system of relevance;

- (4)

- (1)

- Advantages:

- (2)

- Disadvantages:

- (1)

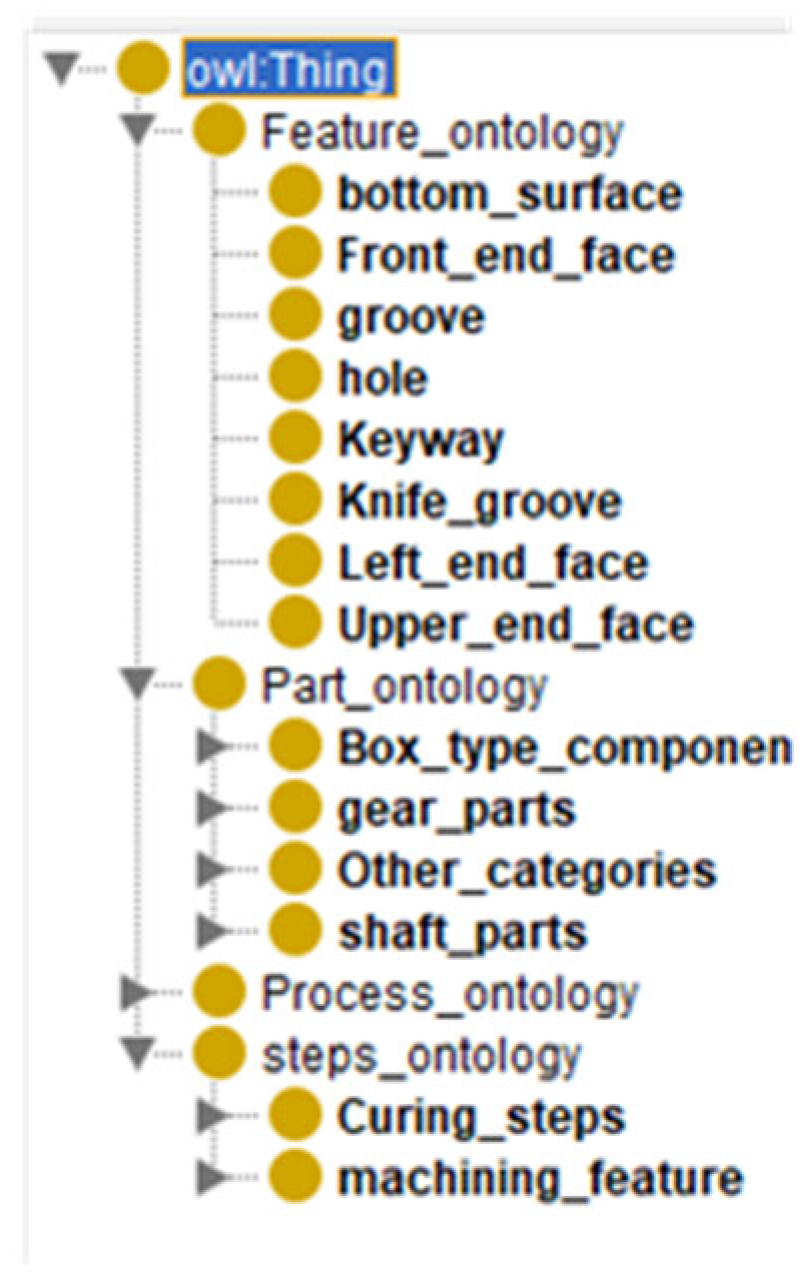

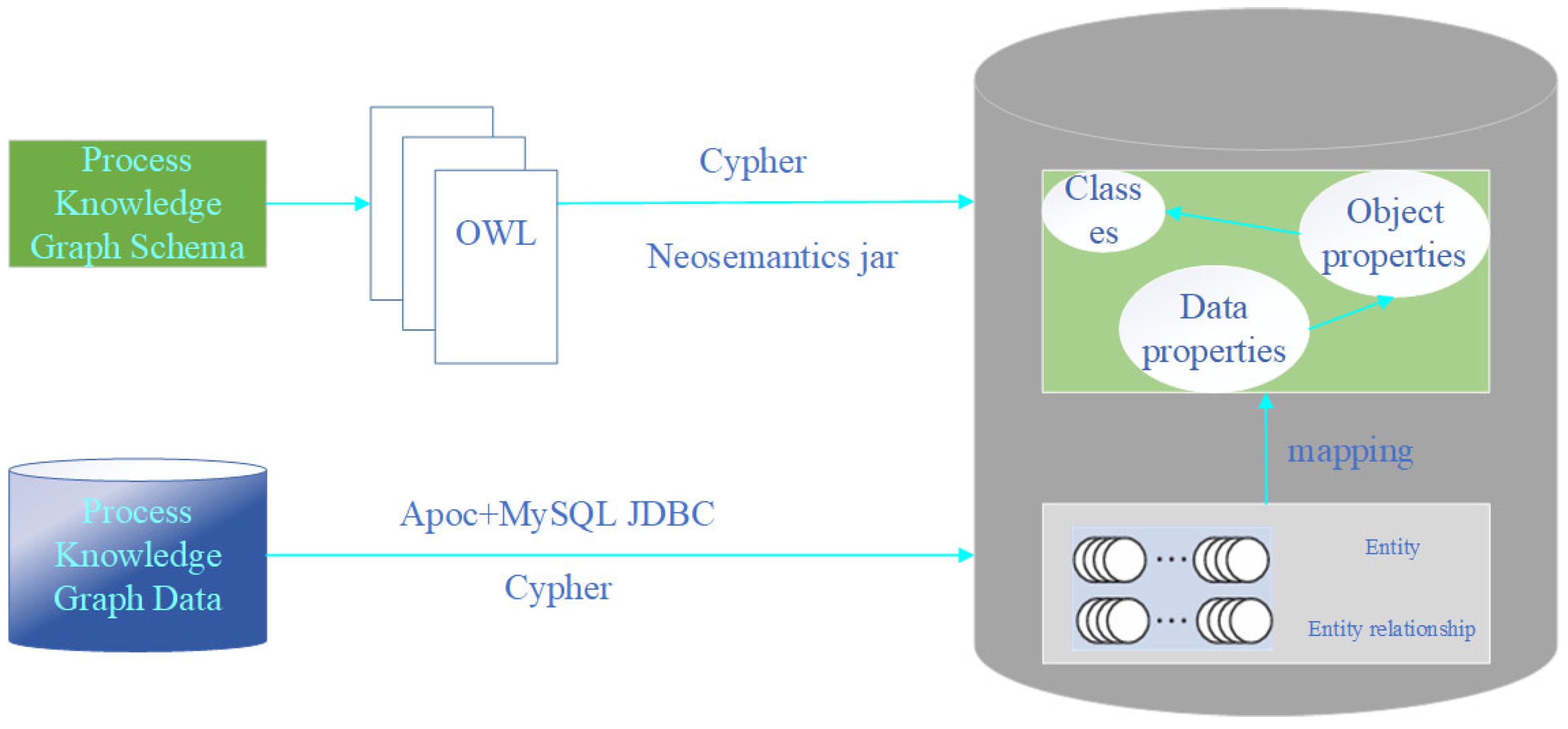

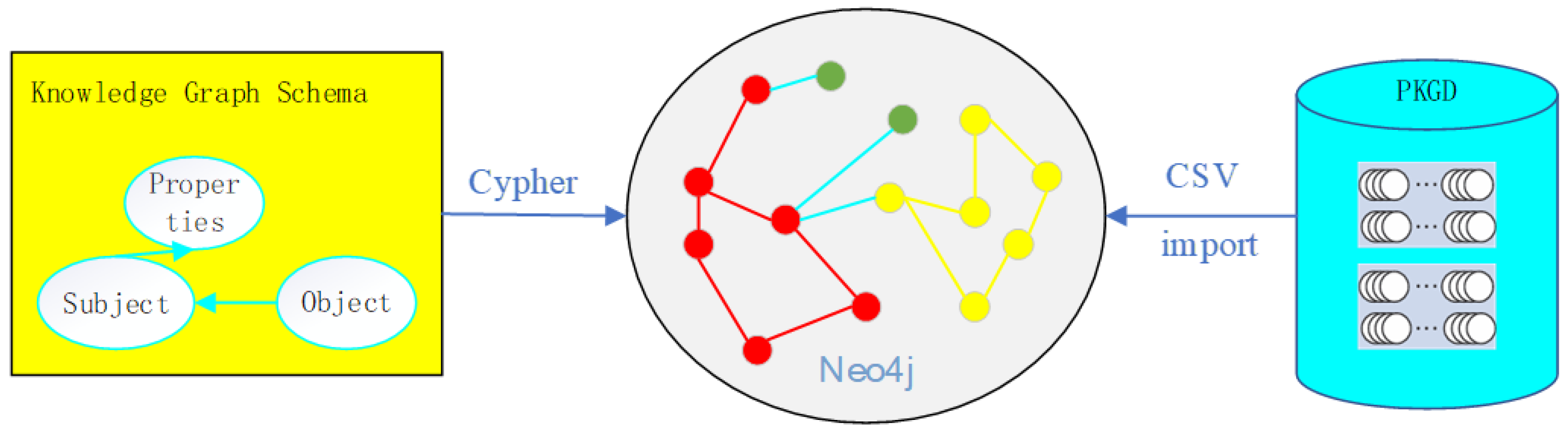

- Ontology construction based on a factory’s machining process cards and historical process data to generate PKGS;

- (2)

- The knowledge extraction process retrieves entity, attribute and relation data to construct the PKGD;

- (3)

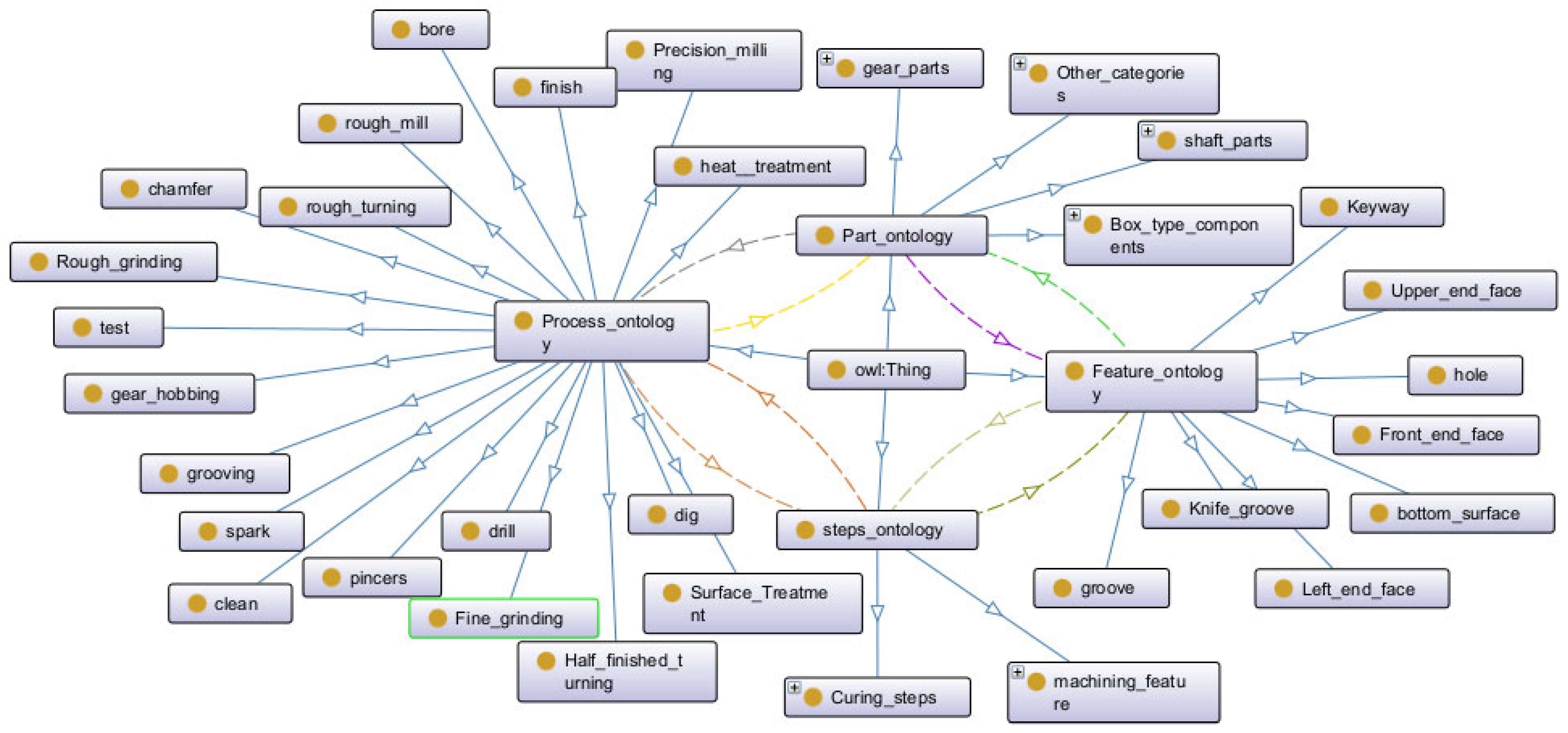

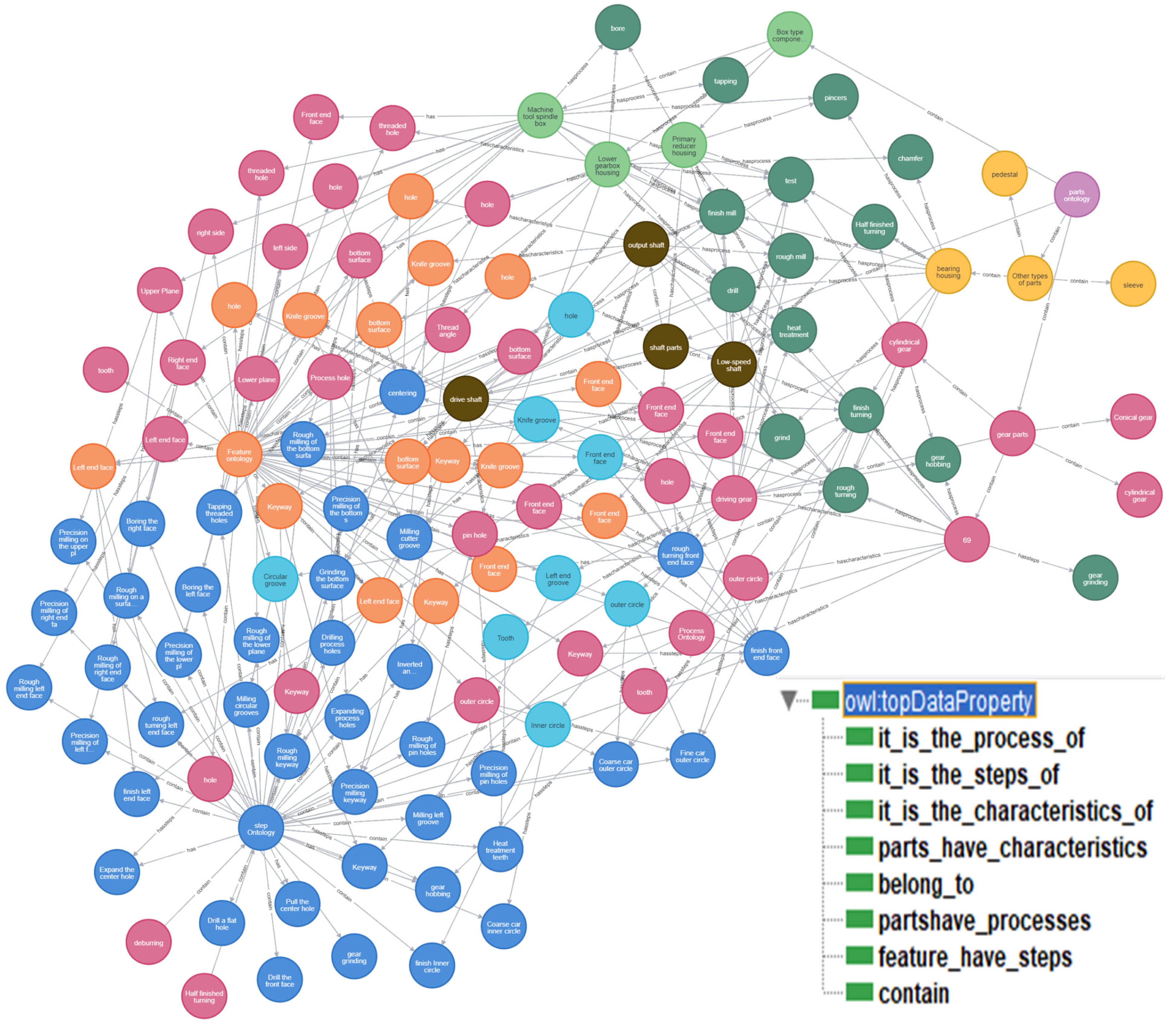

- The schema layer and data layer are correlated and mapped into the Neo4j graph database, resulting in a visual representation of the PKG.

3. Machining PKG for Mechanical Parts

3.1. Construct the Schema Layer of the KG

3.2. KG Data Layer Construction

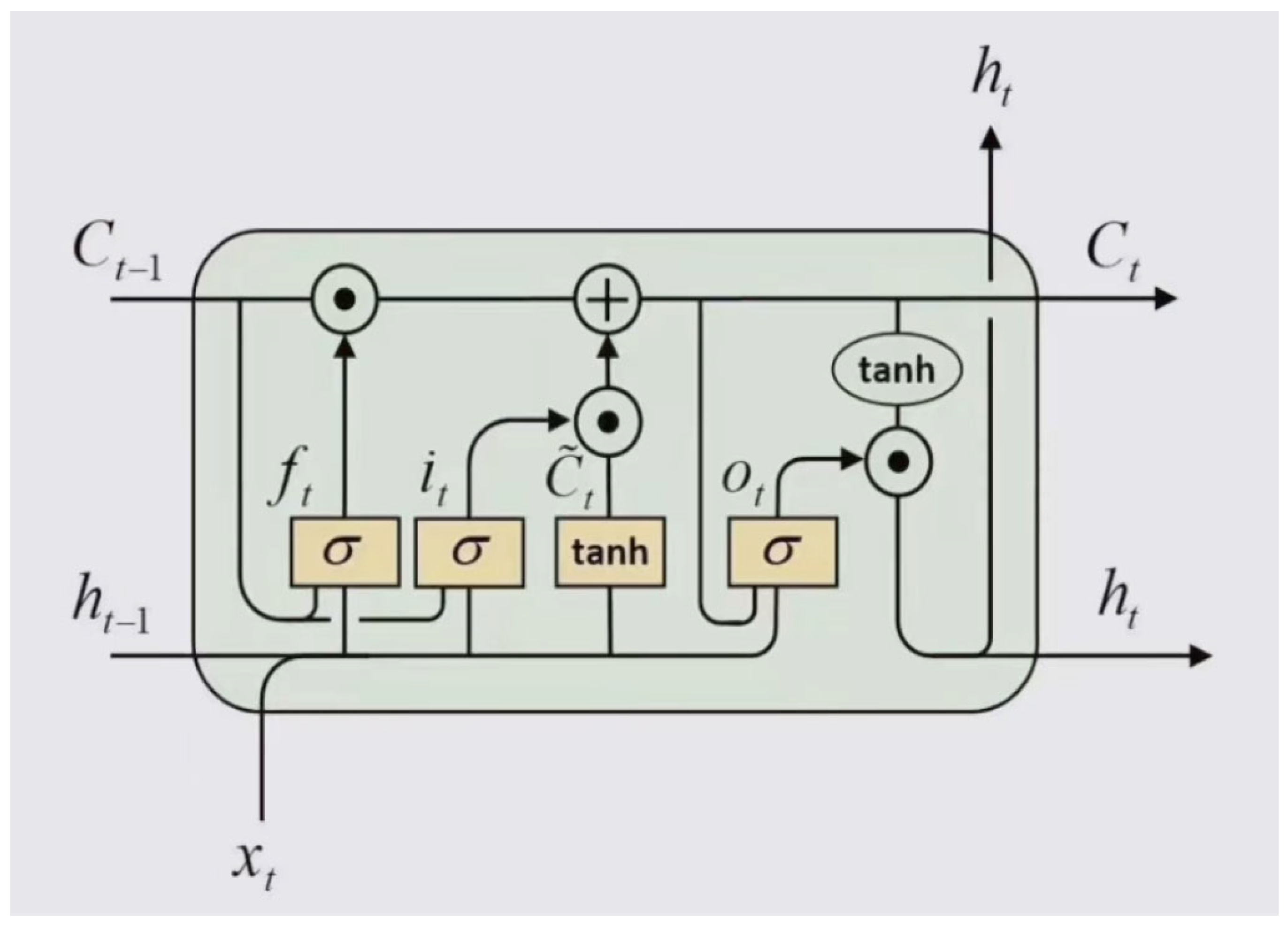

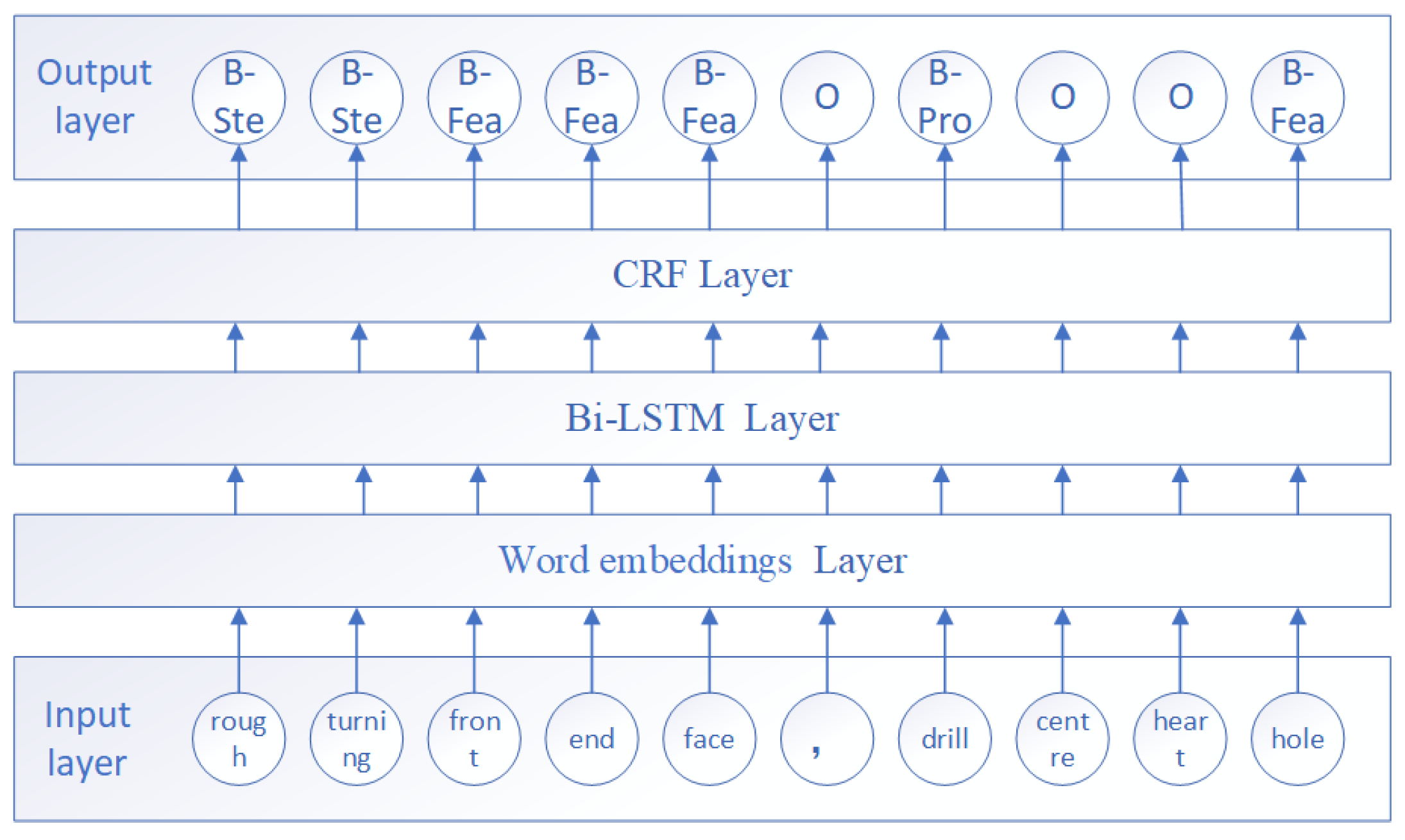

3.2.1. Entity Extraction Based on Bi-LSTM-CRF Architecture

- (1)

- Textual Data Preparation: The unstructured documents representing machining process cards primarily contain string-formatted text. To facilitate computer recognition and algorithmic processing, the textual characters are first converted into numerical representations, typically by transforming words into fixed-dimensional numerical vectors. Word2Vec is a shallow, two-layer neural network and one of the most representative algorithms for distributed text representation. The Word2Vec model maps each word to a low-dimensional, dense vector that captures inter-word relationships, with these vectors constituting the hidden layer of the neural network. This distributed representation method calculates the similarity between words by measuring the distance between their corresponding vectors, effectively solving the dimensionality curse inherent in One-Hot encoding. Our study employs the Skip-gram model from the Word2Vec framework to generate word embeddings, ultimately producing a 300-dimensional vector representation.

- (2)

- Entity Extraction: In constructing the schema layer of the manufacturing process knowledge graph, we integrated four core entity types: part entity (e.g., gear), process entity (e.g., rough turning), operation step entity (e.g., rough turning of outer circle), feature entity (e.g., outer circle). The BIO (Begin-Inside-Outside) annotation framework was implemented with the following tags: B-Par (Begin-Part), B-Pro (Begin-Process), B-Ste (Begin-Step), B-Fea (Begin-Feature), O (Outside/non-entity). This tagging strategy enables subsequent entity recognition where (B- marks the initial character of entity keywords, I- denotes subsequent characters in multi-character entities, O- identifies non-entity terms). The complete annotation scheme is detailed in Table 2.

- (3)

- Relation Extraction (RE) serves as a pivotal natural language processing (NLP) task that identifies and classifies semantic relationships between predefined entity pairs within textual data.

- (4)

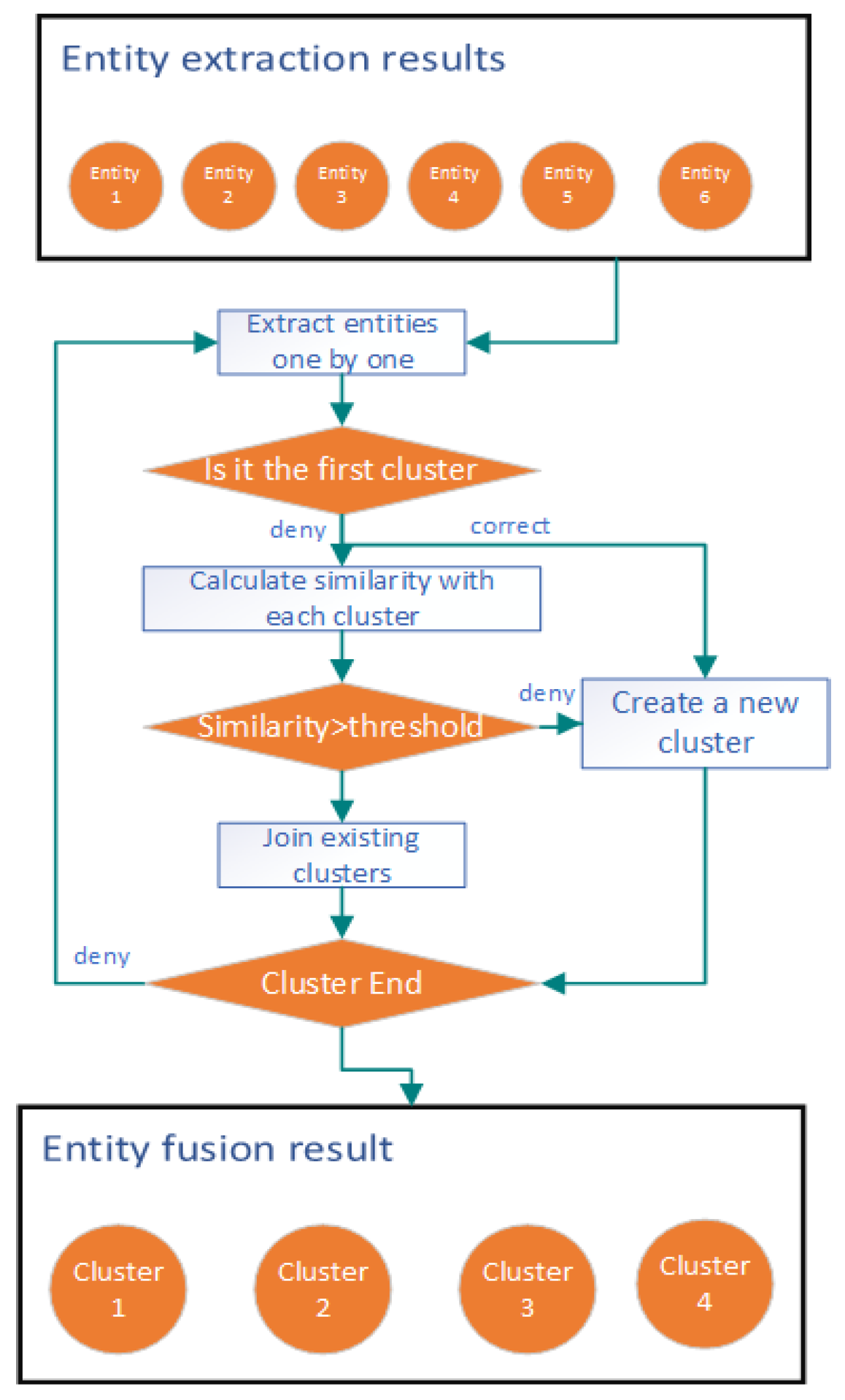

- Entity Alignment is required to resolve duplicated and erroneous entities generated by the aforementioned extraction models. As process documents are authored by different manufacturing engineers, standardization of entity nomenclature cannot be guaranteed. The extracted entities may exhibit coreference issues, where surface orientation descriptors (e.g., “upper surface” vs. “lower surface”) or process granularity terms (e.g., “turning” vs. “rough turning”) refer to the same conceptual entity. Knowledge fusion resolves conceptual ambiguities, eliminates duplicates and corrects erroneous information to ensure KG quality. This process transforms extracted entities into validated triples. Given that machining process ontology attributes are primarily short-text descriptors, this study employs Jaccard similarity coefficient and Levenshtein distance for attribute-level similarity computation.

3.2.2. Ontological Relationship Construction

3.3. Knowledge Storage

- (1)

- Importing Schema Layer to Neo4j Database

- (2)

- Import the data layer into the Neo4j database

3.4. Knowledge Updating

- (1)

- Updates to the schema layer

- (2)

- Updates to the data layer

4. Application of KG for Machining Process

4.1. Visual Presentation of the KG

4.2. Process Knowledge Retrieval Based on KG

4.3. Process Route Recommendation Based on KG

4.3.1. Similarity Calculation

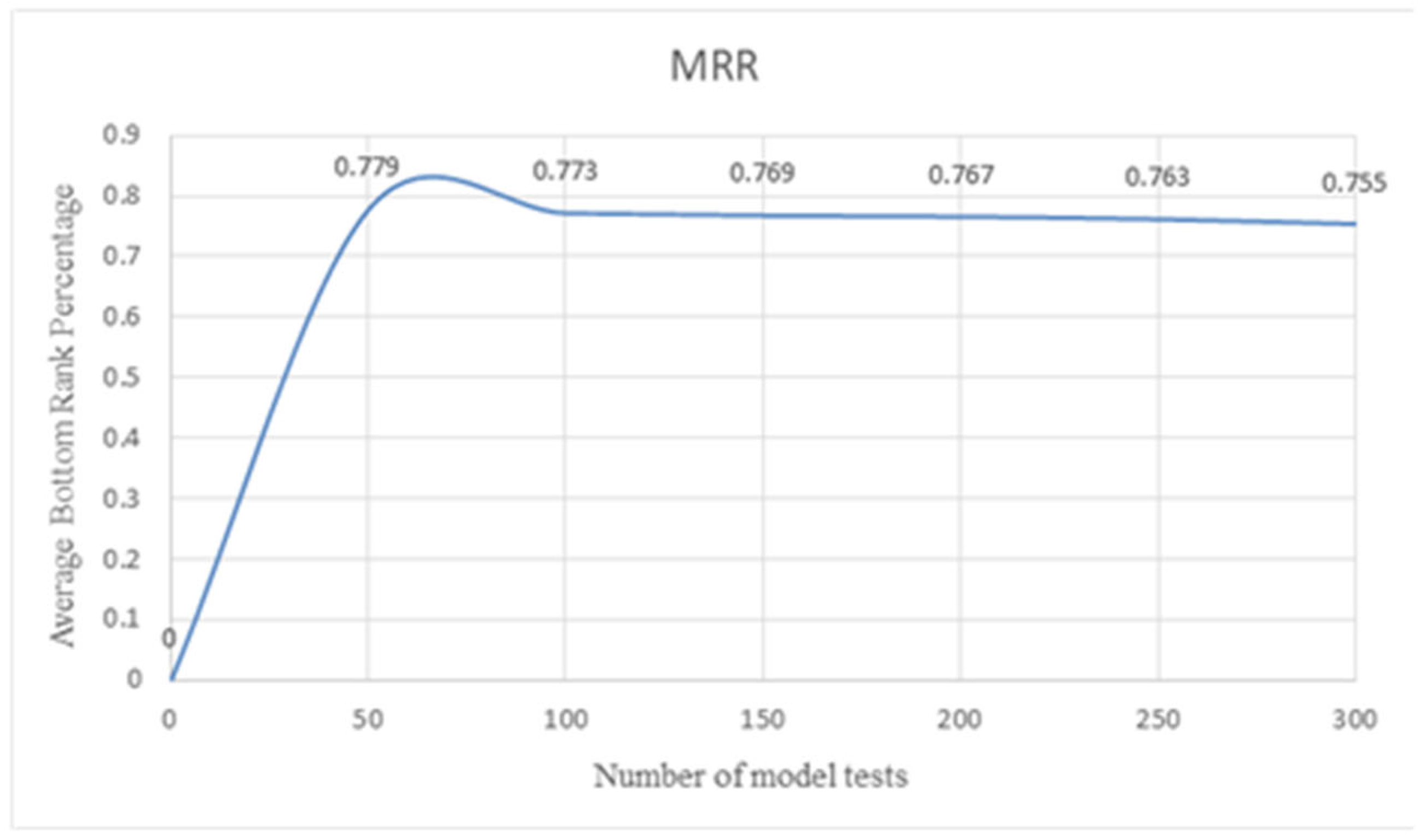

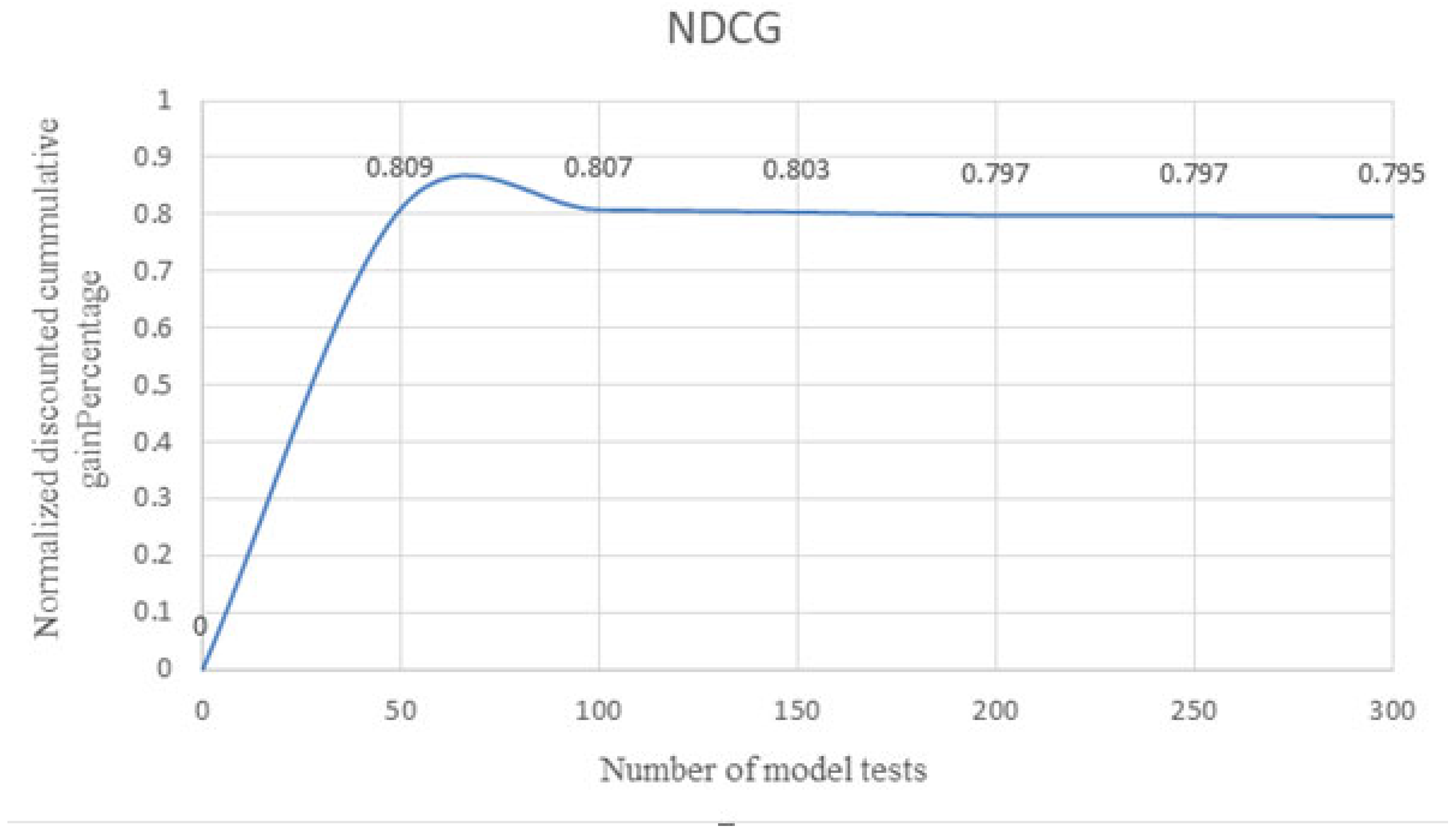

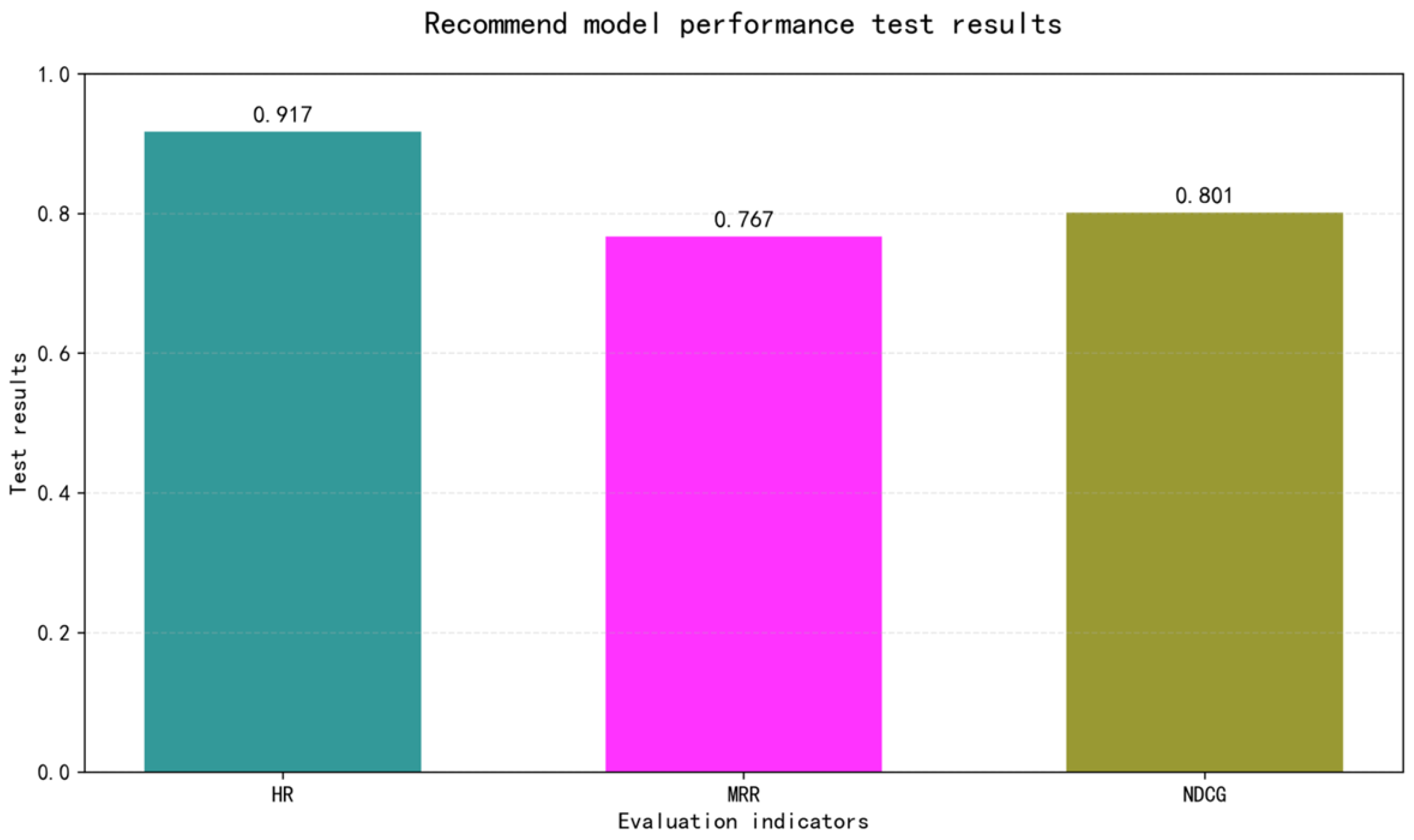

4.3.2. Analyze the Results of the Recommendations

- (1)

- Experimental data selection

- (2)

- Results of the recommended process route based on mapping

5. Concluding Remarks

- (1)

- The KG schema layer and the KG data layer are mapped to each other in the Neo4j graph database to obtain a visualized KG of the parts machining process, which reduces data redundancy and improves retrieval efficiency;

- (2)

- Through the combination of top-down and bottom-up methods combined with deep learning technology, a more accurate KG of part machining process is obtained, and the process knowledge retrieval based on the graph is realized;

- (3)

- By comprehensively calculating the similarity of part attributes (cosine similarity and Jaccard similarity), the process route recommendation based on machining PKG is realized, and the accuracy of the recommendation reached 91.7%.

- (1)

- The data for constructing the KG of part machining process come from the machining process card of the enterprise, which is a relatively single data source with insufficient coverage in the whole machining field, and the knowledge extraction algorithm will be further considered in the subsequent work to expand the coverage of the whole KG of machining process:

- (2)

- Although process knowledge retrieval and process route recommendation based on KG is simply accomplished, it does not fully demonstrate the more powerful reasoning capability of KGs. Therefore, in the subsequent work, the process knowledge reasoning through graph isomorphism, graph matching and other methods will be considered as the key content.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| KG | Knowledge graph |

| PKG | Process Knowledge graph |

| PKGS | Process Knowledge graph Schema |

| PKGD | Process Knowledge graph Data |

| e.g. | exempli gratia |

| NER | Named Entity Recognition |

| LSTM | Long Short-Term Memory |

| Bi-LSTM-CRF | Bidirectional Long Short-Term Memory with Conditional Random Field |

| BIO | Begin-Inside-Outside |

| RE | Relation Extraction RE |

| HR | Hit Rate |

| MRR | Mean Reciprocal Rank |

| NDCG | Normalized Discounted Cumulative Gain |

| DCG | DCG Discounted Cumulative Gain |

| IDCG | Ideal Discounted Cumulative Gain |

References

- Li, C.L. Research on Intelligent Decision-Making and Process Reuse for Machining Process Design. Ph.D. Thesis, Northwestern Polytechnical University, Shaanxi, China, 2017. [Google Scholar]

- Chhim, P.; Chinnam, R.B.; Sadawi, N. Product design and manufacturing process based ontology for manufacturing knowledge reuse. J. Intell. Manuf. 2019, 30, 905–916. [Google Scholar] [CrossRef]

- Song, L.W. Analysis of Hotspots and Frontiers in Google KG and Improvement Research on Co-Word Network Clustering. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2019. [Google Scholar]

- Zheng, P.; Xia, L.; Li, C.; Li, X.; Liu, B. Towards Self-X cognitive manufacturing network: An industrial KG-based multi-agent reinforcement learning approach. J. Manuf. Syst. 2021, 61, 16–26. [Google Scholar] [CrossRef]

- Li, X.L.; Zhang, S.S.; Huang, R. Construction Method of PKG for Process Reuse. J. Northwest. Polytech. Univ. 2019, 37, 1174–1183. [Google Scholar] [CrossRef]

- Li, J.X.; Qu, Y.N.; Qiu, H.H.; Liu, B.; Li, L.; Zhang, J.; Wei, L. Machining Process Design Method for Parts Based on KG and Deep Learning. Comput. Integr. Manuf. Syst. 2024, 30, 3850–3865. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, H.; Wang, R.; Huang, X. Machining Scheme Selection of Features Based on PKG and Improved Cosine Similarity Matching. Machines 2025, 13, 188. [Google Scholar] [CrossRef]

- Jiang, Z.G.; Xie, B.; Zhu, S.; Zhang, H.; Yan, W.; Dai, M. Dynamic Data Flow-Driven KG Construction Method for Remanufacturing Disassembly Process. Comput. Integr. Manuf. Syst. 2024, 30, 879–892. [Google Scholar] [CrossRef]

- Duan, Y.; Hou, L.; Leng, S. Construction and Application of KG for Metal Cutting. J. Jilin Univ. (Eng. Technol. Ed.) 2021, 51, 122–133. [Google Scholar]

- Nie, T.; Zeng, J.; Cheng, Y.; Ma, L. KG Construction Technology and Its Application in Aircraft Power System Fault Diagnosis. Acta Aeronaut. Astronaut. Sin. 2021, 42, 1–19. [Google Scholar]

- Chen, X.; Xiang, Y. Construction and Application of Enterprise Risk KG. Comput. Sci. 2020, 47, 237–243. [Google Scholar]

- Hu, Z.Q.; Liu, M.F.; Li, Q.; Li, X.Y.; Bao, J.S. Modeling of Multi-Modal KG for Assembly Process of Wind Turbines with Multi-Source Heterogeneous Data. J. Shanghai Jiao Tong Univ. 2023, 57, 297–306. [Google Scholar] [CrossRef]

- Rospocher, M.; van Erp, M.; Vossen, P.; Fokkens, A.; Aldabe, I.; Rigau, G.; Soroa, A.; Ploeger, T.; Bogaard, T. Building Event-Centric KG from News. Web Semant. Sci. Serv. Agents World Wide Web 2016, 37–38, 132–151. [Google Scholar] [CrossRef]

- Rotmensch, M.; Halpern, Y.; Tlimat, A.; Horng, S.; Sontag, D. Learning a Health Knowledge Graph from Electronic Medical Records. Sci. Rep. 2017, 7, 5994. [Google Scholar] [CrossRef]

- Li, J.Z.; Hou, L. Review on KG Research. J. Shanxi Univ. (Nat. Sci. Ed.) 2017, 40, 454–459. [Google Scholar] [CrossRef]

- Tao, J.Q.; Li, X.Y.; Zheng, P.; Peng, T.; Xu, K.; Jing, B. State-of-Art and Frontier of Manufacturing KG Application. Comput. Integr. Manuf. Syst. 2022, 28, 3720–3736. [Google Scholar]

- Shen, T.; Zhang, F.; Cheng, J.W. A Comprehensive Overview of KG Completion. Knowl. Based Syst. 2022, 255, 109597. [Google Scholar] [CrossRef]

- Xu, Q.; Niu, N.; Quan, Y.; Jin, Z. Research on the Development of Text Mining Technology Based on Bibliometrics and Knowledge Map Visualization. Sci. J. Inf. Eng. 2017, 7, 51–52. [Google Scholar]

- Xu, Z.L.; Sheng, Y.P.; He, L.R.; Wang, Y. Review on KG Techniques. J. Univ. Electron. Sci. Technol. China 2016, 45, 589–606. [Google Scholar]

- Yang, Y.J.; Xu, B.; Hu, J.W.; Tong, M.; Zhang, P. An Accurate and Efficient Construction Method for Domain KG. J. Softw. 2018, 29, 2931–2947. [Google Scholar]

- Brahimi, M. An Agents’ Model Using Ontologies and Web Services for Creating and Managing Virtual Enterprises. Int. J. Comput. Digit. Syst. 2019, 8, 9–15. [Google Scholar] [CrossRef]

- Yi, L.T.; Zhou, S.Q.; Ding, C.S. Research on Domain Ontology Modeling in Information Extraction. Comput. Technol. Dev. 2011, 21, 5. (In Chinese) [Google Scholar] [CrossRef]

- Martinez-Garcia, J.; Castillo-Barrera, F.E.; Palacio, R.; Borrego, G.; Cuevas-Tello, J.C. Ontology for Knowledge Condensation to Support Expertise Location in the Code Phase during Software Development Process. IET Softw. 2020, 14, 223–241. [Google Scholar] [CrossRef]

- Zhang, B.; Qian, P.; Li, C.; Gao, F.; Yang, N. Research on the Construction Method of Knowledge Ontology Facing the Field of Substation Maintenance. J. Phys. Conf. Ser. 2021, 1971, 012062. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Hong, M.; Man, Y.; He, Z. Cost Optimal Production-Scheduling Model Based on VNS-NSGA-II Hybrid Algorithm—Study on Tissue Paper Mill. Processes 2022, 10, 2072. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Man, Y.; He, Z. Multi-Objective Scheduling in Dynamic of Household Paper Workshop Considering Energy Consumption consumption in production process. J. Smart Environ. Green Comput. 2023, 3, 87–105. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, J.C.; Zhang, J.H.; Zhou, W.; Zhou, X. KG Survey: Representation, Construction, Reasoning and Knowledge Hypergraph Theory. J. Comput. Appl. 2021, 41, 2161–2186. [Google Scholar]

- Kotiranta, P.; Junkkari, M.; Nummenmaa, J. Performance of Graph and Relational Databases in Complex Queries. Appl. Sci. 2022, 12, 6490. [Google Scholar] [CrossRef]

- Guo, R.; Yang, Q.; Liu, S.H.; Li, W.; Yuan, X.; Huang, X. Construction and Application of Power Grid Fault Handling KG. Power Syst. Technol. 2021, 45, 2092–2100. [Google Scholar]

- Guo, X.Y.; Wang, L.; Zhang, Y.J. Machining Process Planning Based on Immune Genetic Algorithm with Rule Constraints. China Mech. Eng. 2020, 31, 482–488. [Google Scholar]

- Han, C.C.; Li, L.; Liu, T.T.; Gao, M. Approaches for Semantic Textual Similarity. J. East China Norm. Univ. (Nat. Sci.) 2020, 5, 95–112. [Google Scholar] [CrossRef]

| Difficulty | Typology |

|---|---|

| Complexity of knowledge | (1) There are many types of equipment and processes, and different equipment and processes can be used for the same process, making it difficult to establish relationships in a uniform manner. (2) Equipment information is fragmented and disorganized, with knowledge of various equipment stored in different databases, online or offline documents, with a low level of structuring. |

| Lack of relevant data | (1) Building a KG requires large labeled datasets. There are many types of processing industries, each with large amounts of data that are underutilized. (2) Poor data interaction. Most plant data are stored only in the plant and is rarely used. |

| Difficulty of knowledge management | (1) Experts are needed to manage the KG, which is very expensive to operate and manage. (2) Devices change and improve rapidly, and the KG requires a mechanism to dynamically update knowledge. |

| Entity Type | Start Marker | Follow-Up Marker |

|---|---|---|

| Parts | B-Par | I-Par |

| Process | B-Pro | I-Pro |

| Step | B-Ste | I-Ste |

| Feature | B-Fea | I-Fea |

| Non-entity | O | O |

| Par-ID | Par-Name | Par-Process |

|---|---|---|

| Par-1 | Drive Shaft | Rough Turning → Drilling → Rough Turning → Finish Turning → Grooving → Heat Treatment → Rough Milling → Finish Milling → Rough Grinding → Finish Grinding → Inspection |

| Par-2 | Low-Speed Shaft | Rough Turning → Drilling → Rough Turning → Semi-Finish Turning → Grooving → Heat Treatment → Finish Turning → Rough Milling → Finish Milling → Deburring → Inspection |

| Par-3 | Output Shaft | Rough Turning → Drilling → Rough Turning → Finish Turning → Heat Treatment → Rough Milling → Finish Milling → Deburring → Inspection |

| Par-4 | Drive Gear | Heat Treatment → Rough Turning → Heat Treatment → Finish Turning → Rough Milling → Finish Milling → Gear Hobbing → Heat Treatment → Deburring → Inspection |

| Par-5 | Cylindrical Gear | Hole Enlarging → Hole Broaching → Rough Turning → Semi-Finish Turning → Gear Hobbing → Deburring → Hole Grinding → Chamfering → Inspection |

| Par-6 | Bevel Gear | Heat Treatment → Rough Turning → Finish Turning → Gear Milling → Hole Enlarging → Hole Broaching → Hole Grinding → Gear Grinding → Heat Treatment → Deburring → Inspection |

| Par-7 | Machine Tool Spindle Housing | Rough Turning → Finish Turning → Rough Milling → Finish Milling → Drilling → Boring → Tapping → Inspection |

| Par-8 | Reducer Lower Housing | Rough Milling → Finish Milling → Drilling → Pilot Hole Enlarging → Drilling → Tapping → Rough Boring → Semi-Finish Milling → Semi-Finish Boring → Finish Milling → Finish Boring → Center Drilling → Chamfering → Tapping → Final Inspection |

| Par-9 | First-Stage Reducer Housing | Heat Treatment → Rough Milling → Rough Grinding → Finish Grinding → Finish Milling → Drilling → Boring → Tapping → Inspection |

| Par-10 | Sleeve | Heat Treatment → Rough Turning → Finish Turning → Drilling → Boring → Deburring → Heat Treatment → Rough Grinding → Finish Grinding → Deburring → Inspection |

| Par-11 | Bearing Seat | Bench Fitting → Rough Milling → Finish Milling → Rough Turning → Finish Turning → Rough Grinding → Finish Grinding → Drilling → Final Inspection |

| Par-12 | Shaft Bracket | Heat Treatment → Rough Milling → Finish Milling → Boring → Drilling → Hole Enlarging → Rough Milling → Finish Milling → Deburring → Inspection |

| Fea-ID | Fea-Name | Fea-Code |

|---|---|---|

| Fea-1 | Drive shaft—front end surface | ZDZ-qdm |

| Fea-2 | Drive shaft—hole feature | ZDZ-k |

| Fea-3 | Drive shaft—left end surface | ZDZ-zdm |

| Fea-4 | Drive shaft—tool relief groove | ZDZ-dc |

| Fea-5 | Drive shaft—bottom surface | ZDZ-dm |

| … | … | … |

| (Process Card 1) | (Process Card 2) | Jaccard Similarity | Levenshtein Similarity |

|---|---|---|---|

| Upper Surface | Lower Surface | 0.615 | 0.75 |

| Rough Turning | Turning | 0.33 | 0.5 |

| Par-ID | Fea-ID |

|---|---|

| Par-1 | Fea-1 |

| Par-1 | Fea-2 |

| … | … |

| Par-2 | Fea-6 |

| Par-2 | Fea-7 |

| … | … |

| Relational Database | RDF Database | Graph Database |

|---|---|---|

| Strengths: high storage efficiency, fast simple queries, easy maintenance | Strengths: intuitive semantic representation, supports schema-based inference | Strengths: high efficiency for deep traversal, optimized for relationship queries, scalable for complex networks |

| Weaknesses: poor join performance, limited real-time analytics, rigid schema | Weaknesses: low design flexibility, large storage footprint, slow complex queries | Weaknesses: high resource consumption |

| Part Name | Material | Feature Information | Process Route |

|---|---|---|---|

| Drive Shaft | 45 Steel | Planar Surfaces, Holes, Tool Grooves, Keyways, Flats, Shoulders | Rough Turning → Drilling → Rough Turning → Finish Turning → Grooving → Heat Treatment → Rough Milling → Finish Milling → Rough Grinding → Finish Grinding → Inspection |

| No. | Part Name | Part ID | Process Route |

|---|---|---|---|

| 1 | Drive Shaft | Par-1 | Rough Turning → Drilling → Rough Turning → Finish Turning → Grooving → Heat Treatment → Rough Milling → Finish Milling → Rough Grinding → Finish Grinding → Inspection |

| 2 | Low-Speed Shaft | Par-2 | Rough Turning → Drilling → Rough Turning → Semi-Finish Turning → Grooving → Heat Treatment → Finish Turning → Rough Milling → Finish Milling → Deburring → Inspection |

| 3 | Output Shaft | Par-3 | Rough Turning → Drilling → Rough Turning → Finish Turning → Heat Treatment → Rough Milling → Finish Milling → Deburring → Inspection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Liang, J.; Li, C.; Liu, Z.; Wei, Y.; Ji, Z. Construction of a Machining Process Knowledge Graph and Its Application in Process Route Recommendation. Electronics 2025, 14, 3156. https://doi.org/10.3390/electronics14153156

Li L, Liang J, Li C, Liu Z, Wei Y, Ji Z. Construction of a Machining Process Knowledge Graph and Its Application in Process Route Recommendation. Electronics. 2025; 14(15):3156. https://doi.org/10.3390/electronics14153156

Chicago/Turabian StyleLi, Liang, Jiaxing Liang, Chunlei Li, Zhe Liu, Yingying Wei, and Zeyu Ji. 2025. "Construction of a Machining Process Knowledge Graph and Its Application in Process Route Recommendation" Electronics 14, no. 15: 3156. https://doi.org/10.3390/electronics14153156

APA StyleLi, L., Liang, J., Li, C., Liu, Z., Wei, Y., & Ji, Z. (2025). Construction of a Machining Process Knowledge Graph and Its Application in Process Route Recommendation. Electronics, 14(15), 3156. https://doi.org/10.3390/electronics14153156