The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Rectenna Elements: Design, Performance Evaluation, and Fabrication

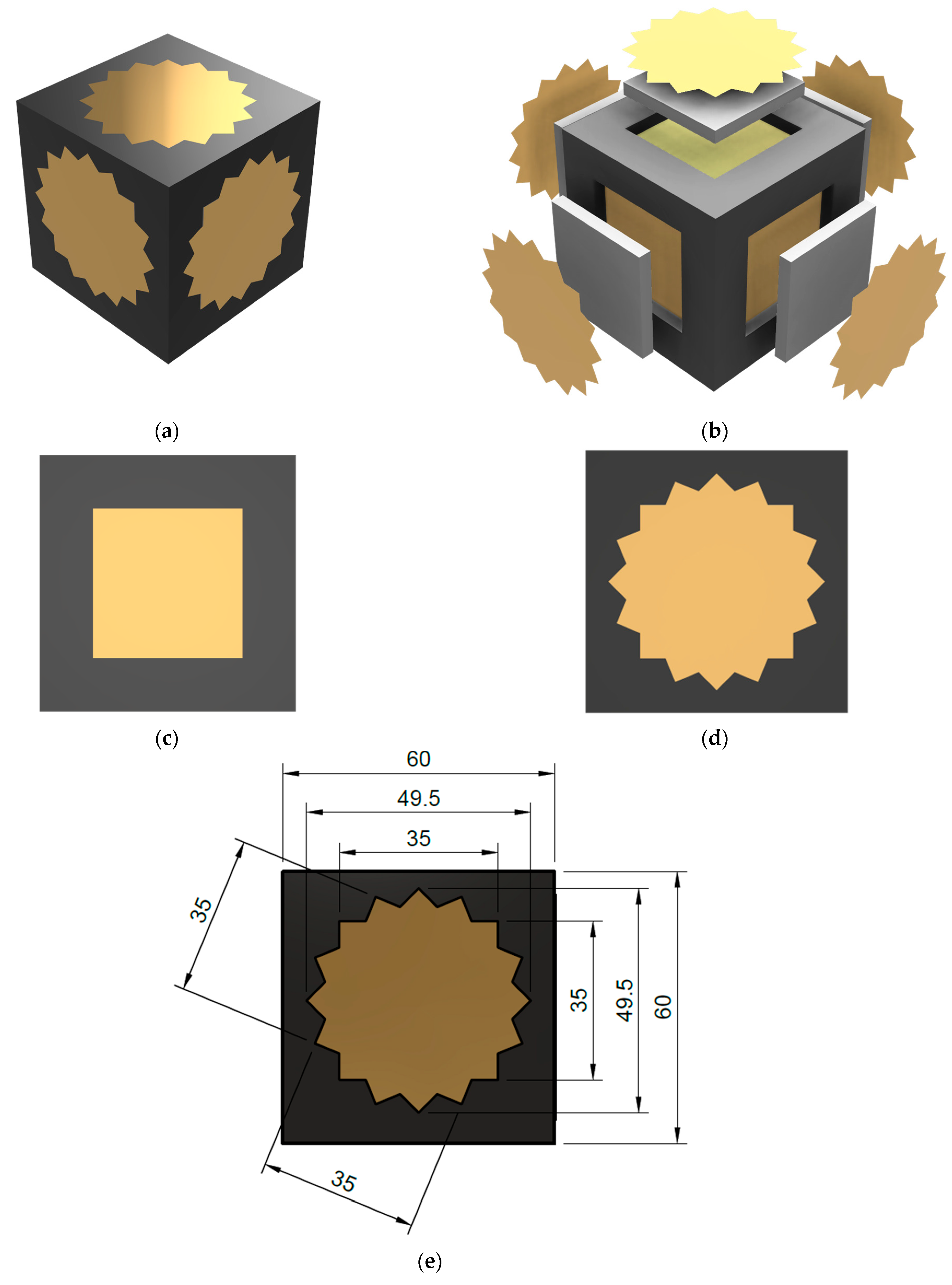

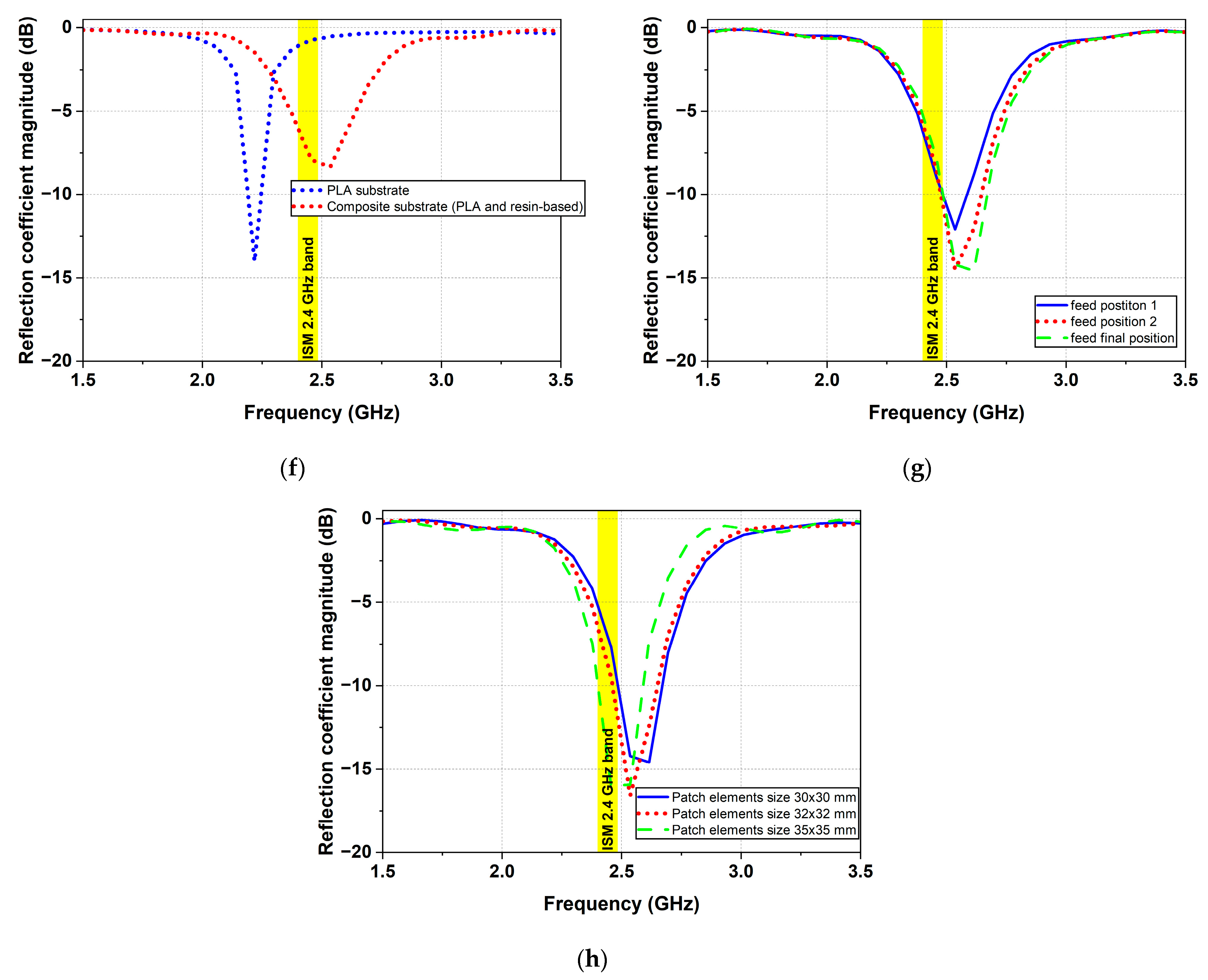

3.1. Antenna Design and Performance Evaluation

3.1.1. Antenna Design

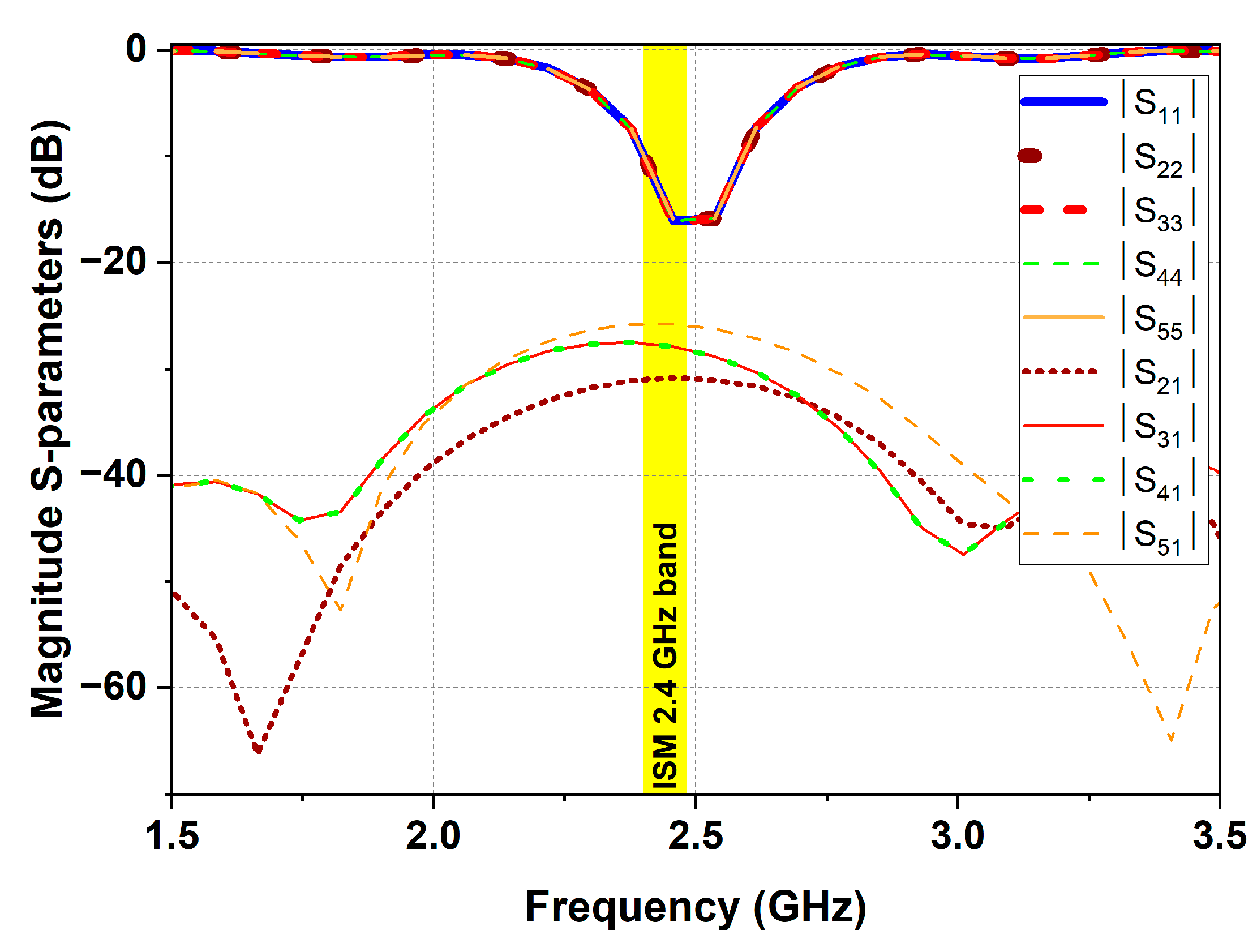

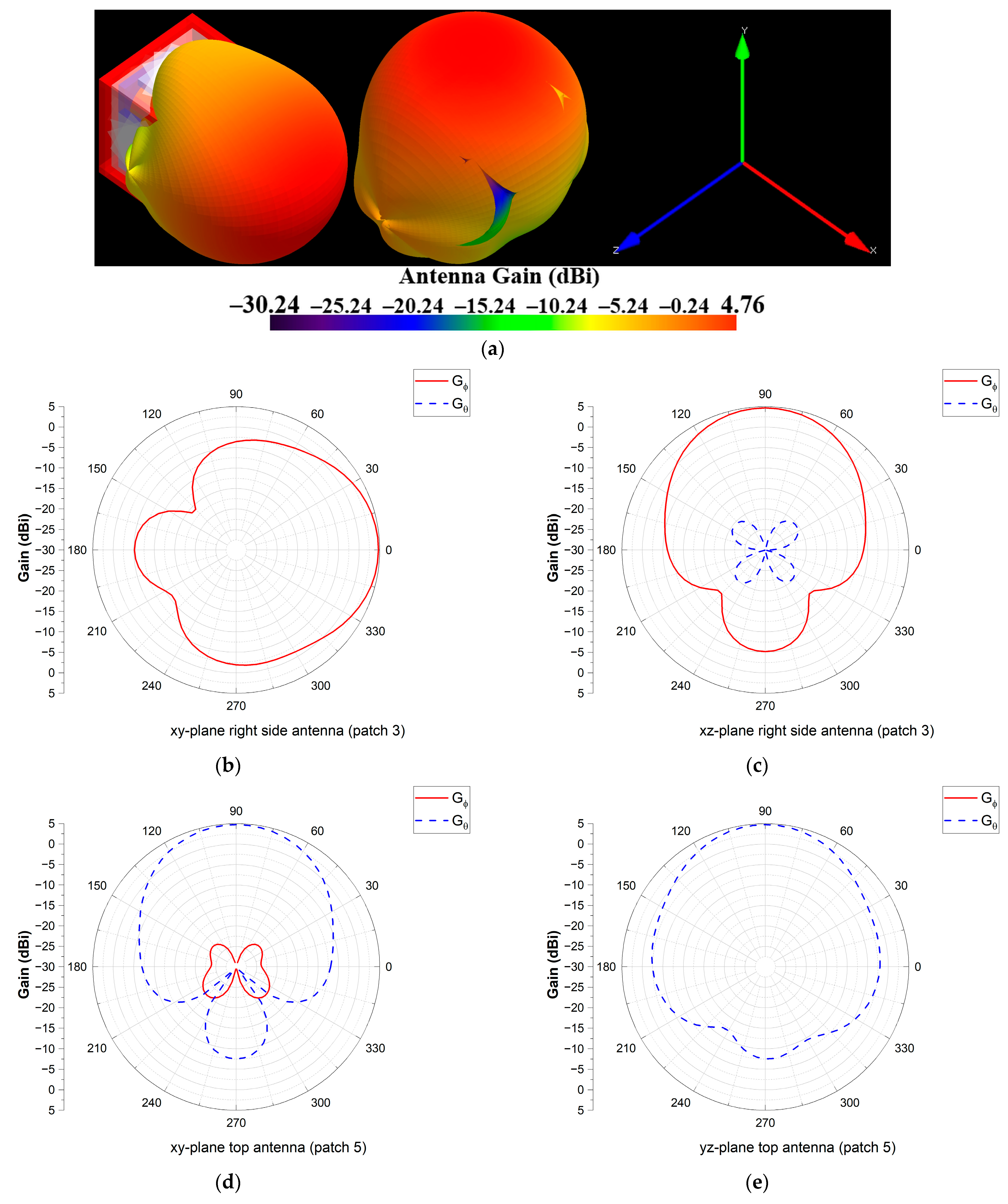

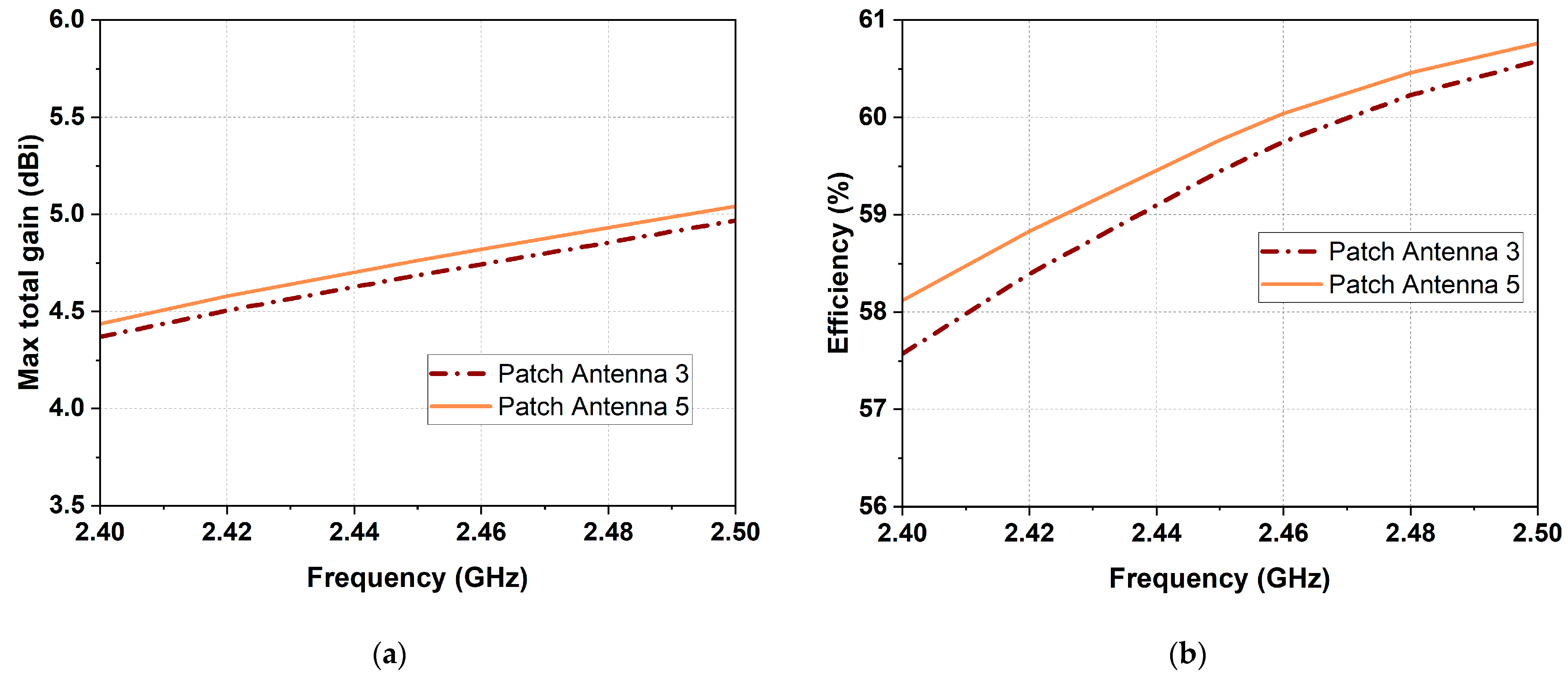

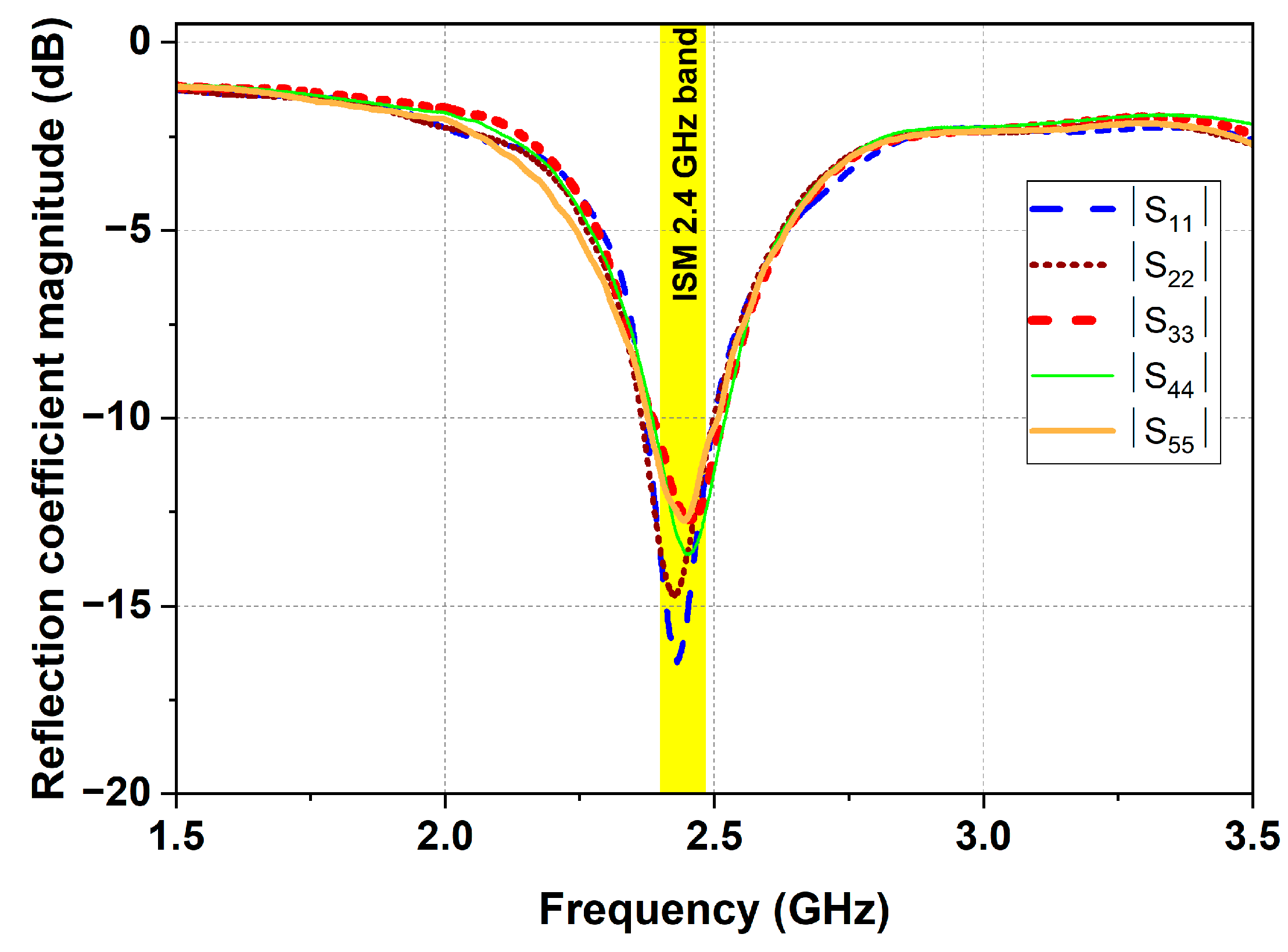

3.1.2. Antenna Performance

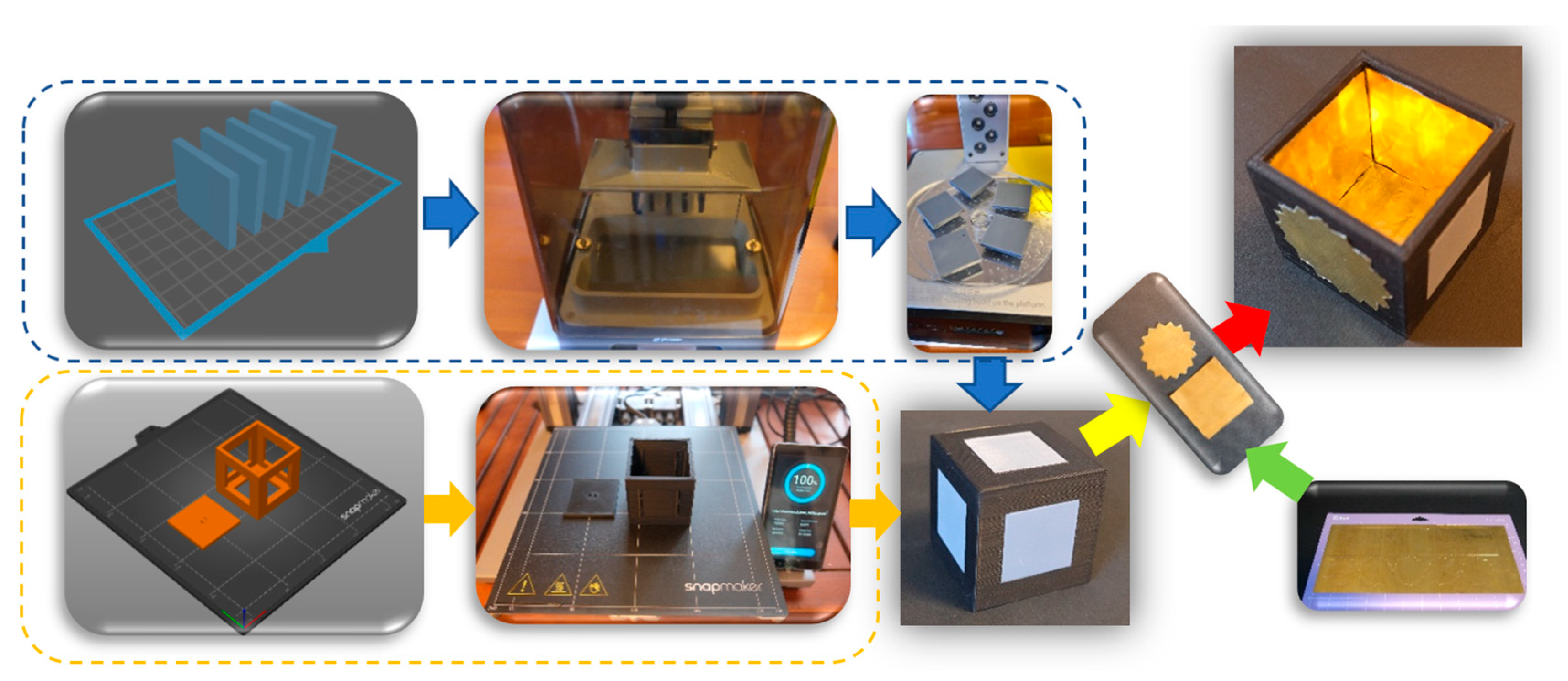

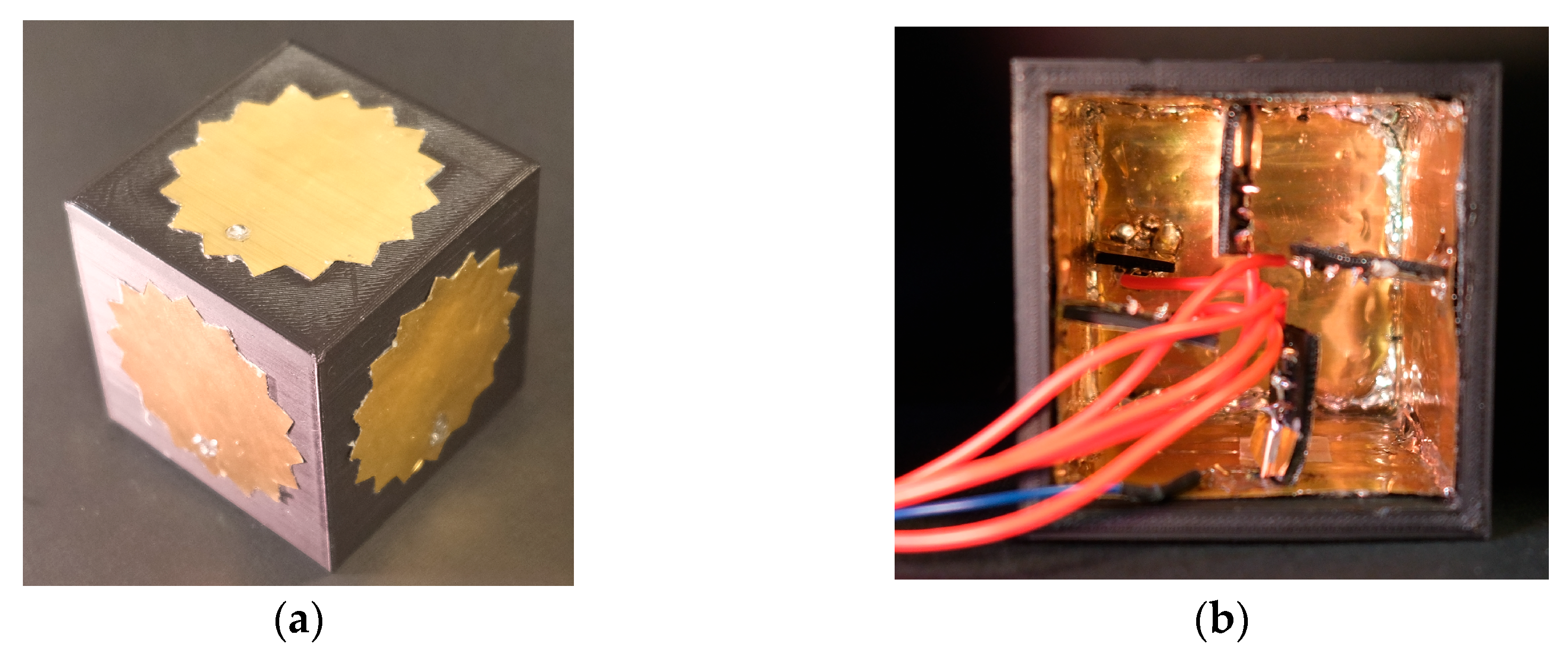

3.1.3. Antenna Prototype Fabrication and Measurements

3.2. Rectifier Design and Performance Evaluation

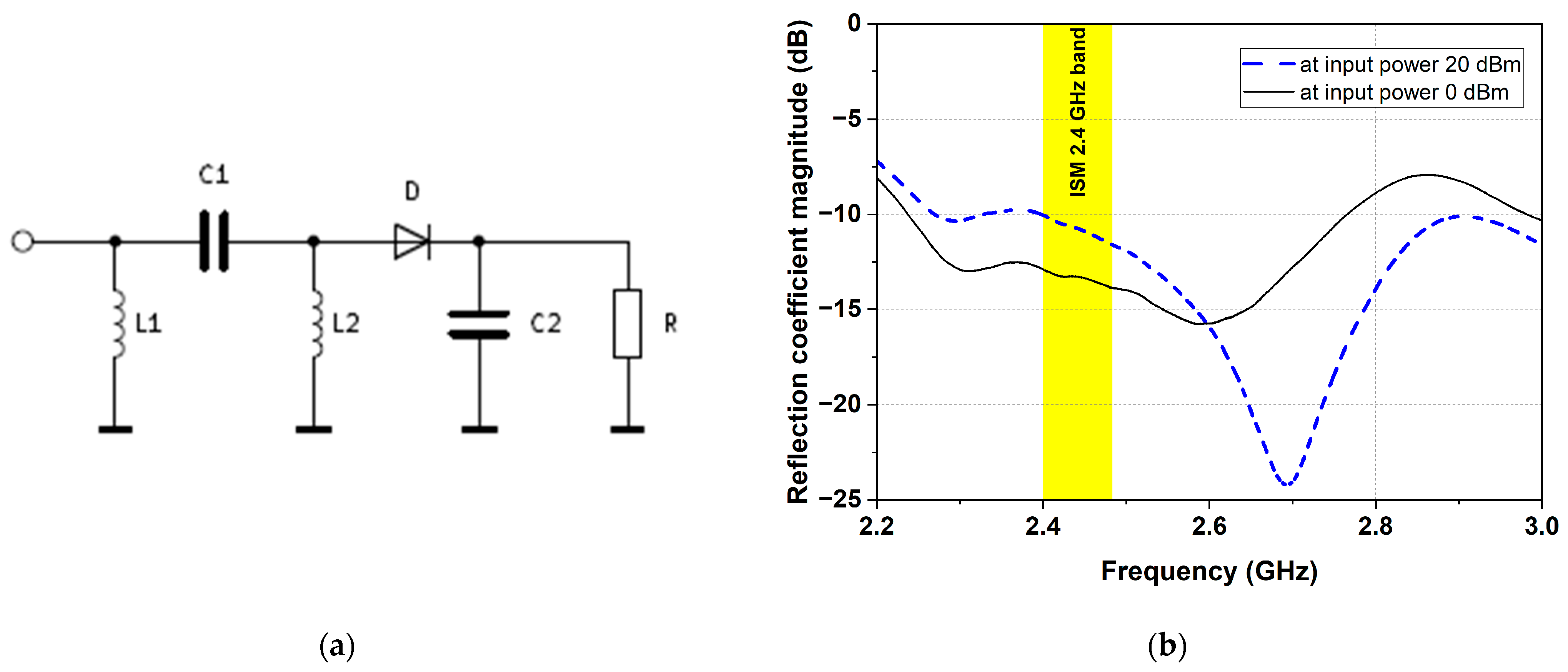

3.2.1. Rectifier Design

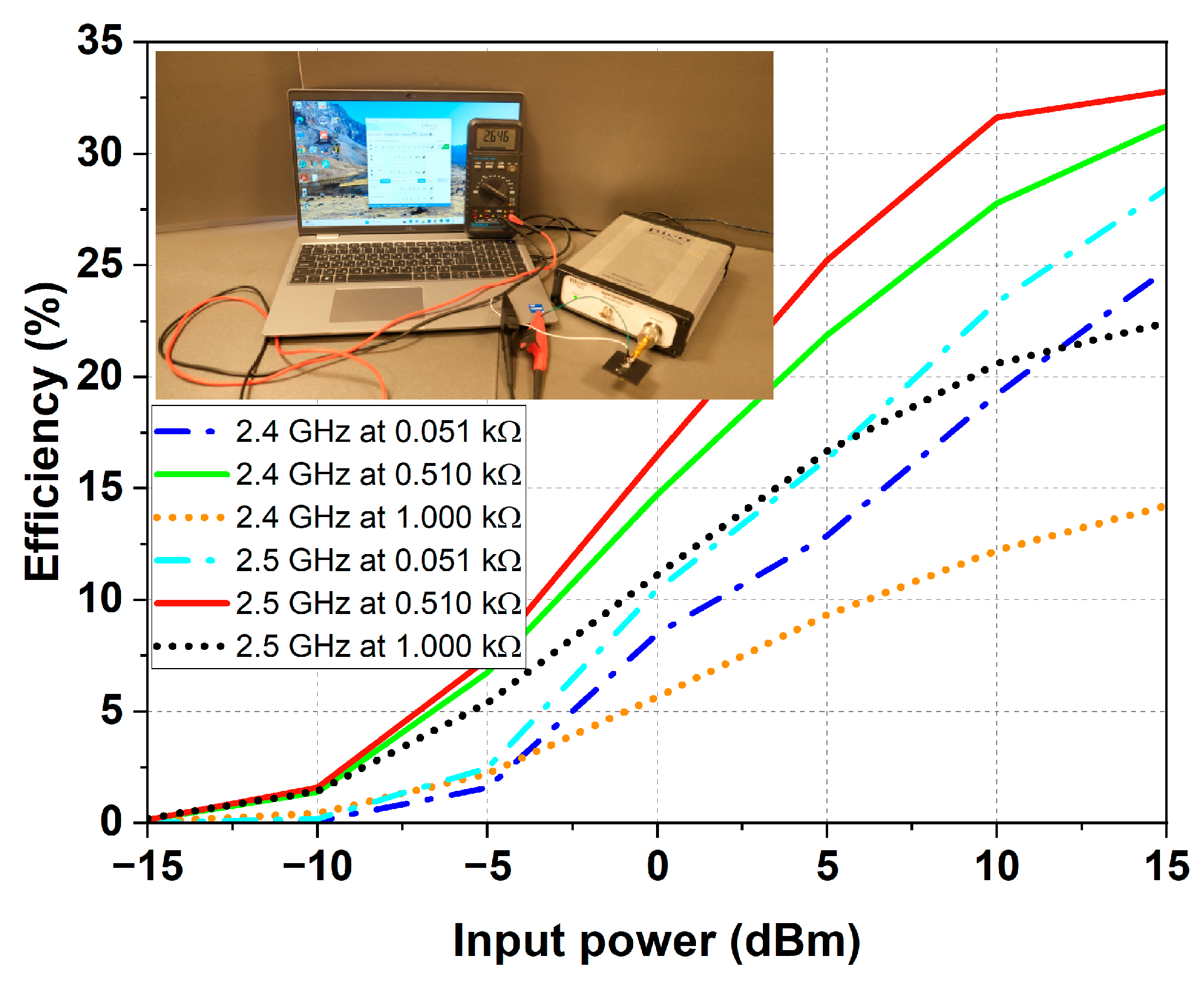

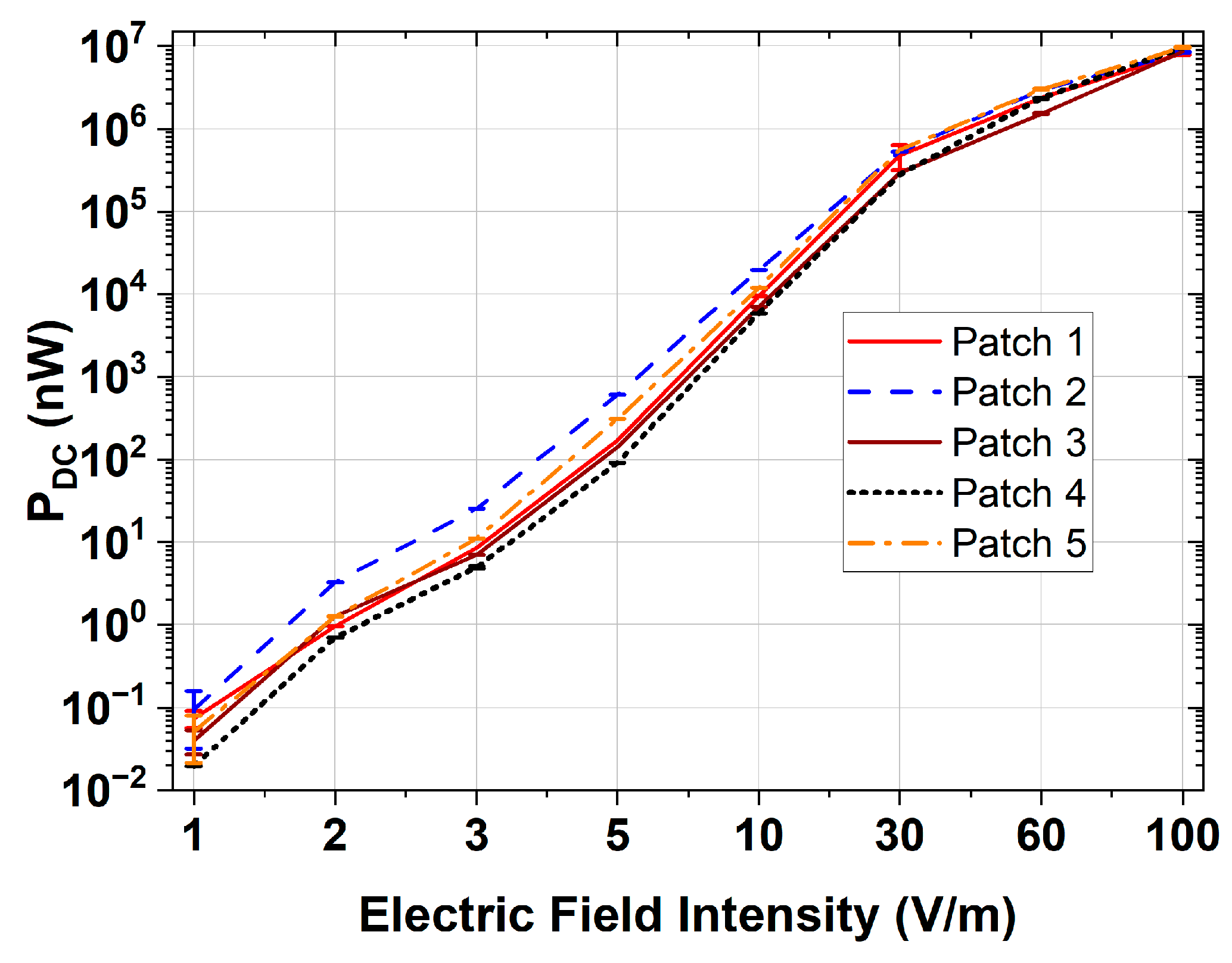

3.2.2. Rectifier Performance Evaluation

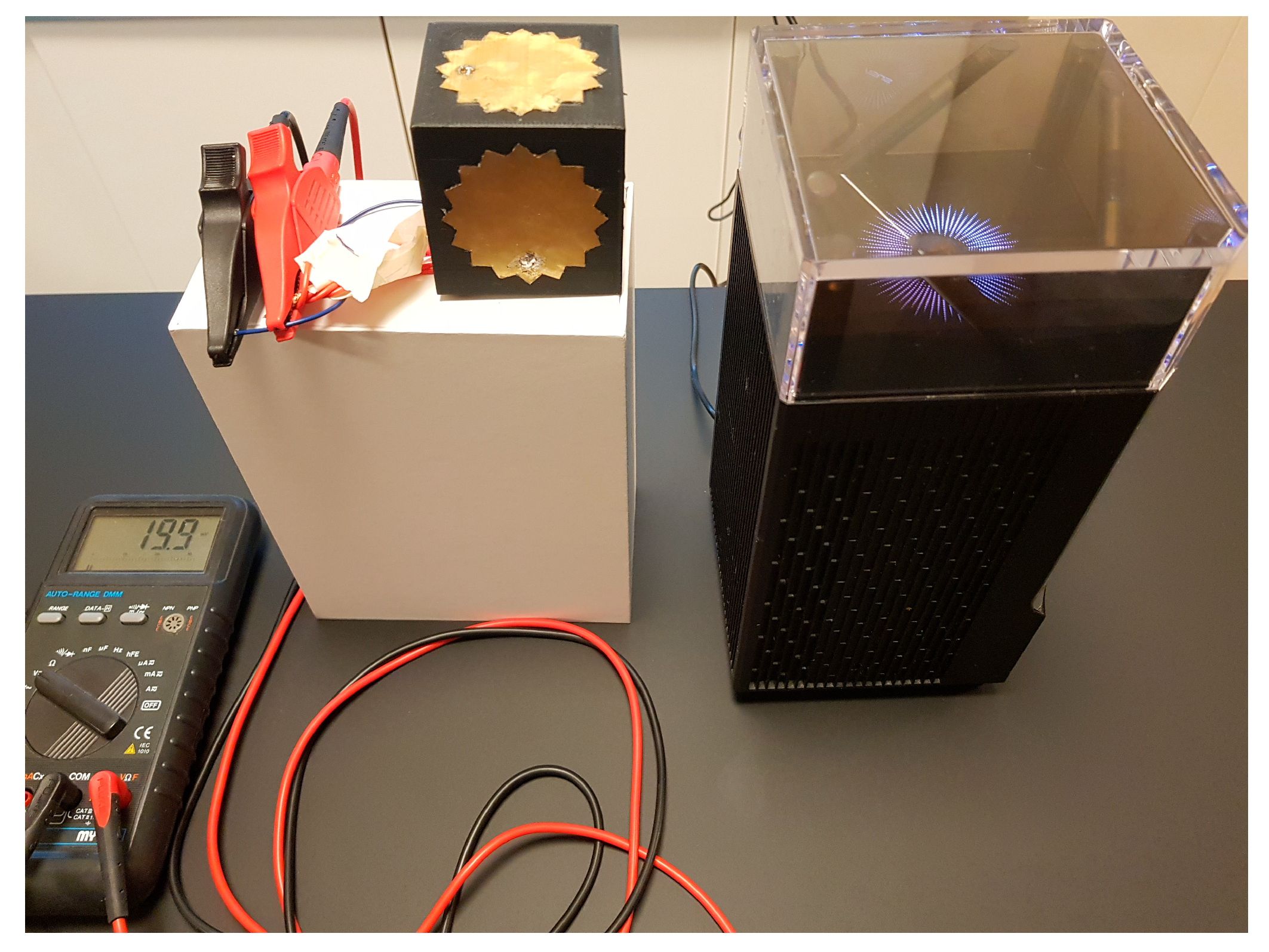

4. Rectenna Measurements

5. Performance Comparison of the Proposed Rectenna with Other 3D-Printed Rectennas

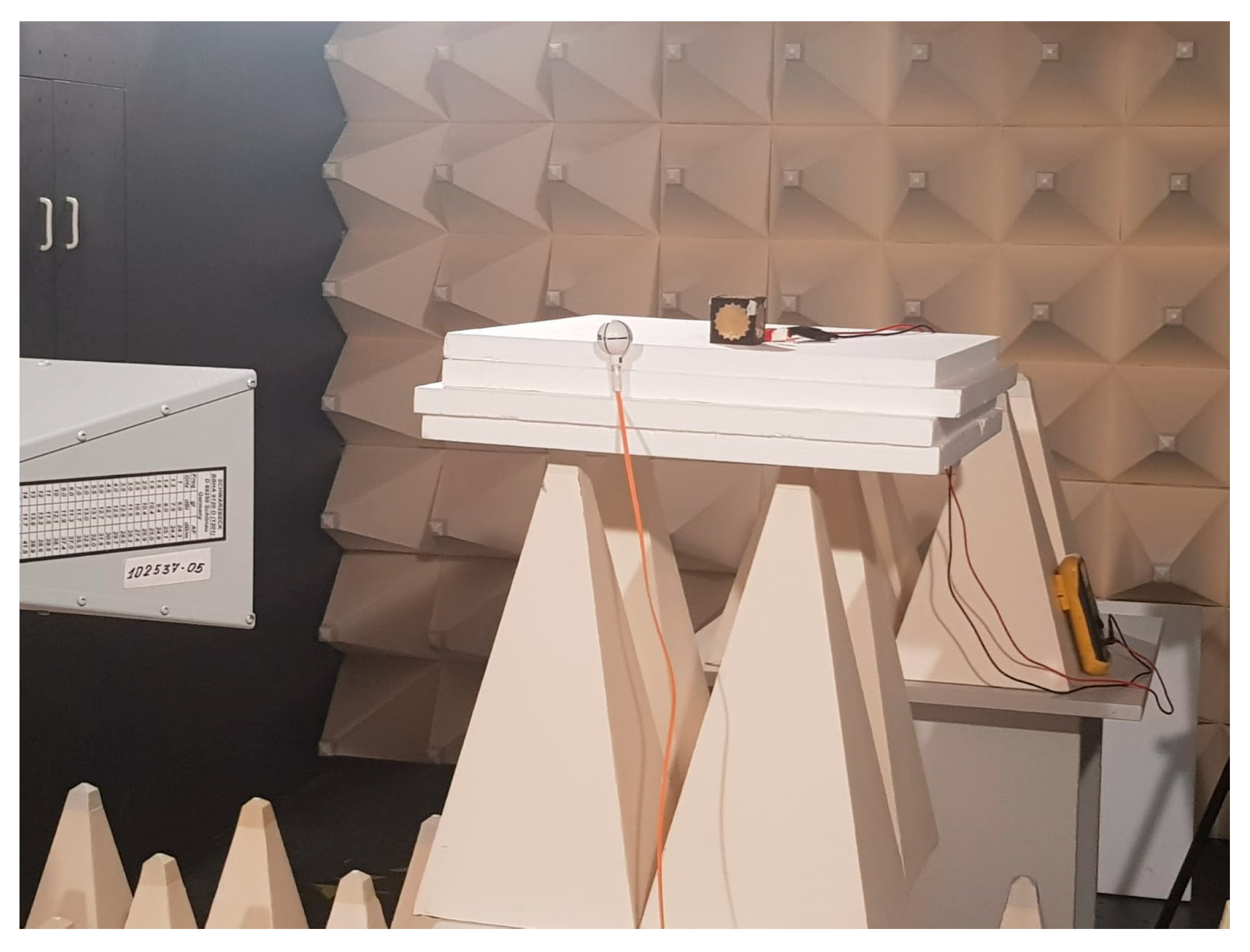

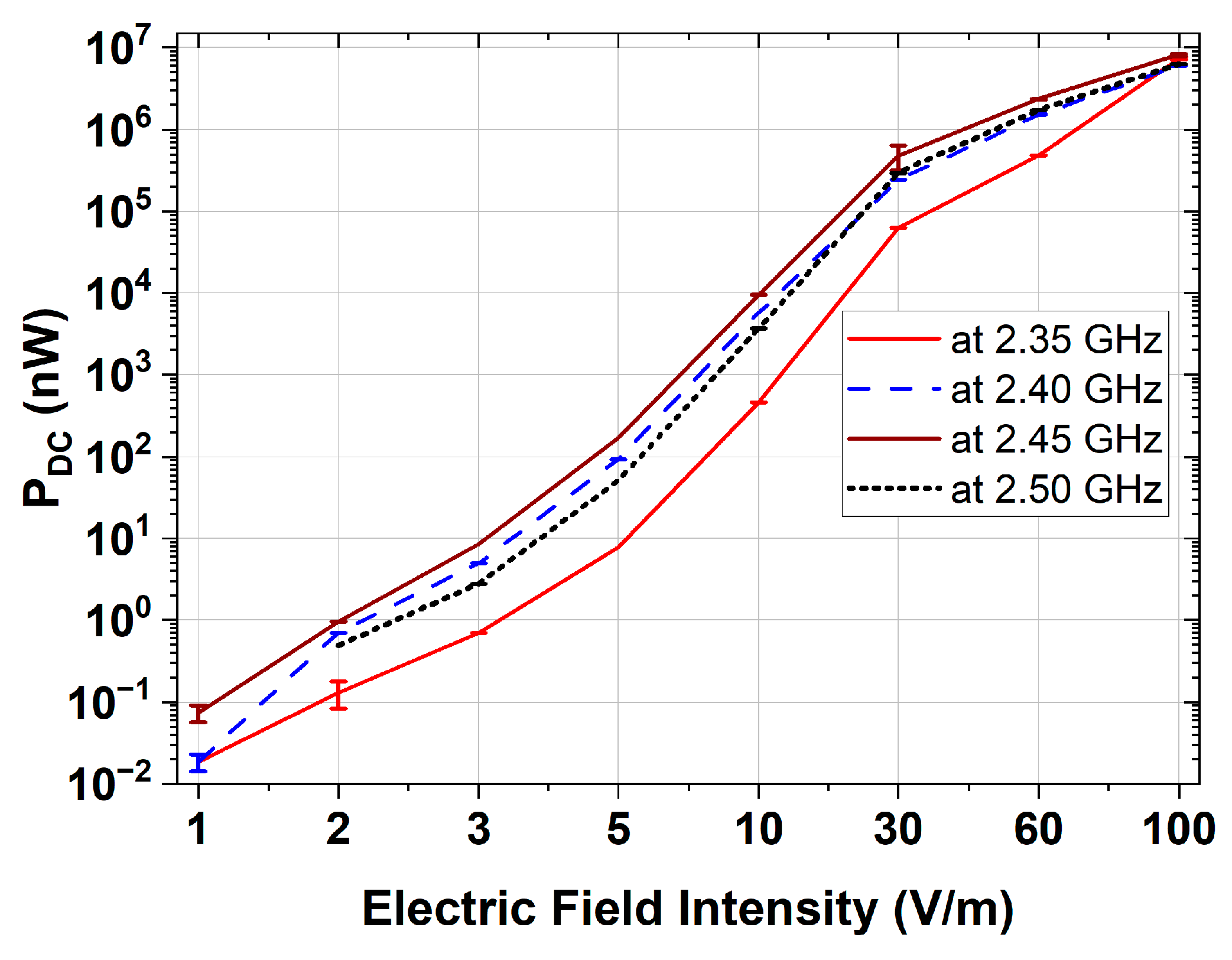

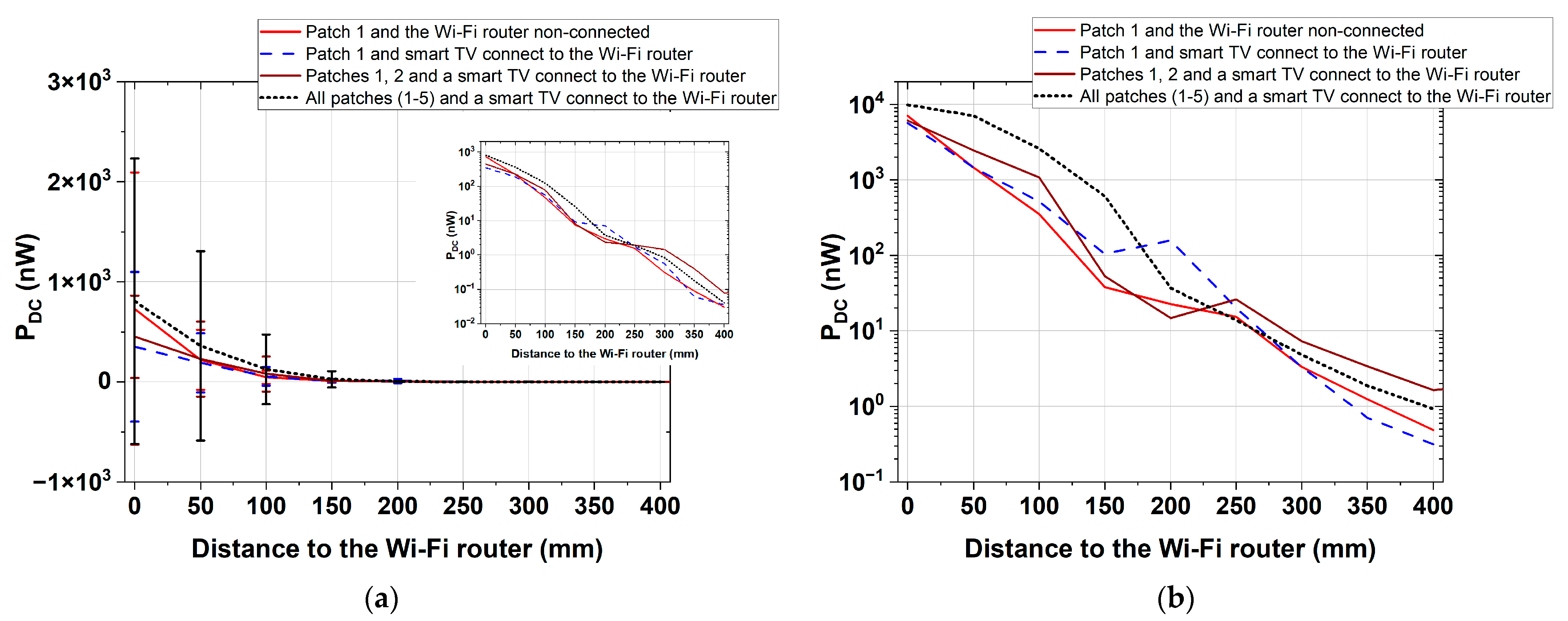

6. Rectenna Testing in a Typical Indoor RF Environment

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| RF-EH | Radio frequency energy harvesting |

| WPT | Wireless power transmission |

| PLA | Polylactic acid |

| 3D | Three dimensional |

| FDTD | Finite-difference time-domain method |

| ISM | Industrial, scientific, and medical |

| FDM | Fused deposition modeling |

| DLP | Digital light processing |

| STL | Standard triangle language |

| RF | Radio frequency |

| DC | Direct current |

| SMD | Surface-mounted device |

References

- Next Generation Internet of Things. Available online: https://digital-strategy.ec.europa.eu/en/policies/next-generation-internet-things (accessed on 5 May 2025).

- Fattahi, A. IoT and Digital Transformation. In IoT Product Design and Development: Best Practices for Industrial, Consumer, and Business Applications; Wiley: Hoboken, NJ, USA, 2023; pp. 9–21. [Google Scholar]

- Zhi, Z.; Wu, Q. Wearable IoT System for Hand Function Assessment Based on EMG Signals. Electronics 2024, 13, 778. [Google Scholar] [CrossRef]

- Atanasova, G.L.; Atanasov, B.N.; Atanasov, N.T. Fully Textile Dual-Band Logo Antenna for IoT Wearable Devices. Sensors 2022, 22, 4516. [Google Scholar] [CrossRef] [PubMed]

- Poyyamozhi, M.; Murugesan, B.; Rajamanickam, N.; Shorfuzzaman, M.; Aboelmagd, Y. IoT—A Promising Solution to Energy Management in Smart Buildings: A Systematic Review, Applications, Barriers, and Future Scope. Buildings 2024, 14, 3446. [Google Scholar] [CrossRef]

- Biswas, A.; Wang, H.-C. Autonomous Vehicles Enabled by the Integration of IoT, Edge Intelligence, 5G, and Blockchain. Sensors 2023, 23, 1963. [Google Scholar] [CrossRef]

- Atanasov, B.N.; Atanasov, N.T.; Atanasova, G.L. Reliable and Resilient Wireless Communications in IoT-Based Smart Agriculture: A Case Study of Radio Wave Propagation in a Corn Field. Telecom 2024, 5, 1161–1178. [Google Scholar] [CrossRef]

- Kamatchi Sundari, V.; Nithyashri, J.; Kuzhaloli, S.; Subburaj, J.; Vijayakumar, P.; Hency Jose, P.S. Comparison analysis of IoT based industrial automation and improvement of different processes—Review. Mater. Today Proc. 2021, 45, 2595–2598. [Google Scholar] [CrossRef]

- Statista. Number of Internet of Things (IoT) Connections Worldwide from 2022 to 2023, with Forecasts from 2024 to 2033. Available online: https://www.statista.com/statistics/1183457/iot-connected-devices-worldwide/ (accessed on 10 May 2025).

- GSMA Intelligence. IoT Connections Forecast to 2030. Available online: https://www.gsmaintelligence.com/research/iot-connections-forecast-to-2030 (accessed on 30 December 2023).

- Atanasov, N.T.; Atanasov, B.N.; Atanasova, G.L. Electromagnetic Properties of Natural Plant Leaves for Eco-Friendly and Biodegradable Substrates for Wireless IoT Devices. Sensors 2025, 25, 1118. [Google Scholar] [CrossRef]

- Sharma, N.; Panwar, D. Green IoT: Advancements and Sustainability with Environment by 2050. In Proceedings of the 2020 8th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 5–6 June 2020. [Google Scholar]

- Tahiliani, V.; Dizalwar, M. Green IoT Systems: An Energy Efficient Perspective. In Proceedings of the Eleventh International Conference on Contemporary Computing (IC3), Noida, India, 2–4 August 2018; pp. 1–6. [Google Scholar]

- López, O.L.A.; Rosabal, O.M.; Ruiz-Guirola, D.E.; Raghuwanshi, P.; Mikhaylov, K.; Lovén, L.; Iyer, S. Energy-Sustainable IoT Connectivity: Vision, Technological Enablers, Challenges, and Future Directions. IEEE Open J. Commun. Soc. 2023, 4, 2609–2666. [Google Scholar] [CrossRef]

- Rahmani, H.; Shetty, D.; Wagih, M.; Ghasempour, Y.; Palazzi, V.; Carvalho, N.B.; Correia, R.; Costanzo, A.; Vital, D.; Alimenti, F.; et al. Next-Generation IoT Devices: Sustainable Eco-Friendly Manufacturing, Energy Harvesting, and Wireless Connectivity. IEEE J. Microw. 2023, 3, 237–255. [Google Scholar] [CrossRef]

- Nusrat, T.; Roy, S.; Lotfi-Neyestanak, A.A.; Noghanian, S. Far-Field Wireless Power Transfer for the Internet of Things. Electronics 2023, 12, 207. [Google Scholar] [CrossRef]

- Liao, L.; Li, Z.; Tang, Y.; Chen, X. Dual-Polarized Stacked Patch Antenna for Wireless Communication Application and Microwave Power Transfer. Electronics 2021, 10, 2988. [Google Scholar] [CrossRef]

- Niotaki, K.; Carvalho, N.B.; Georgiadis, A.; Gu, X.; Hemour, S.; Wu, K.; Matos, D.; Belo, D.; Pereira, R.; Figueiredo, R.; et al. RF Energy Harvesting and Wireless Power Transfer for Energy Autonomous Wireless Devices and RFIDs. IEEE J. Microw. 2023, 3, 763–782. [Google Scholar] [CrossRef]

- Deng, X.; Yang, P.; Chen, S.; Ren, W. Design of a 2.4 & 5.8 GHz Efficient Circularly Polarized Rectenna for Wireless Power Transfer Applications. Electronics 2023, 12, 2645. [Google Scholar] [CrossRef]

- Jing, J.; Yang, B.; Yan, L.; Shinohara, N.; Liu, C. Fully Polarized Wideband Omnidirectional RF Harvester with Highly Efficient DC Power Combination. Electronics 2024, 13, 4891. [Google Scholar] [CrossRef]

- Atanasov, B.; Atanasov, N.; Atanasova, G. A Multi-Band Antenna with an Aesthetic Design for Ambient RF Energy Harvesting. In Proceedings of the 2023 17th European Conference on Antennas and Propagation (EuCAP), Florence, Italy, 26–31 March 2023. [Google Scholar]

- Prashad, L.; Mohanta, H.C.; Mohamed, H.G. A Compact Circular Rectenna for RF-Energy Harvesting at ISM Band. Micromachines 2023, 14, 825. [Google Scholar] [CrossRef]

- Patil, D.D.; Subramanian, K.S.; Pradhan, N.C.; Varadharaj, E.K.; Senthilkumaran, K.; Murugesan, M. 3D-printed dual-band energy harvester for WSNs in green IoT applications. AEU Int. J. Electron. Commun. 2023, 164, 154641. [Google Scholar] [CrossRef]

- Jalali, Z.; Hasani, P.; Hashemi, S.M.; Ghalamkari, B. A multiband coplanar based circularly polarized rectenna with high efficiency for IOT energy harvesting Applications. AEU Int. J. Electron. Commun. 2023, 170, 154796. [Google Scholar] [CrossRef]

- Sang, J.; Qian, L.; Wang, X.; Shi, G. A dual-band omnidirectional rectenna for radio-frequency energy harvesting applications. Microelectron. J. 2025, 156, 106533. [Google Scholar] [CrossRef]

- Shen, S.; Zhang, Y.; Chiu, C.; Murch, R.D. A compact quad-port dual-polarized dipole rectenna for ambient RF energy harvesting. In Proceedings of the 12th European Conference on Antennas and Propagation (EuCAP 2018), London, UK, 9–13 April 2018. [Google Scholar]

- Mansour, M.M.; Torigoe, S.; Yamamoto, S.; Kanaya, H. Compact and Simple High-Efficient Dual-Band RF-DC Rectifier for Wireless Electromagnetic Energy Harvesting. Electronics 2021, 10, 1764. [Google Scholar] [CrossRef]

- Bolognesi, M.; Prosa, M.; Seri, M. Biocompatible and Biodegradable Organic Electronic Materials. In Electronic and Optical Materials, Sustainable Strategies in Organic Electronics; Marrocchi, A., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 297–338. [Google Scholar]

- Atanasov, N.; Atanasov, B.; Atanasova, G. Design, Fabrication and Performance Evaluation of Antennas for Smart Urban Agriculture. In Proceedings of the 2024 Advanced Topics on Measurement and Simulation (ATOMS), Constanta, Romania, 15–17 May 2024. [Google Scholar]

- Jun, S.Y.; Elibiary, A.; Sanz-Izquierdo, B.; Winchester, L.; Bird, D.; McCleland, A. 3-D Printing of Conformal Antennas for Diversity Wrist Worn Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 2227–2235. [Google Scholar] [CrossRef]

- Olan-Nuñez, K.N.; Murphy-Arteaga, R.S. Dual-Band Antenna on 3D-Printed Substrate for 2.4/5.8 GHz ISM-Band Applications. Electronics 2023, 12, 2368. [Google Scholar] [CrossRef]

- The Circular Economy of Brass Recycling. Available online: https://highspeedmachiningbrass.com/the-circular-economy-of-brass-recycling/ (accessed on 1 March 2020).

- Huang, J. Microstrip Antennas: Analysis, Design, and Application. In Modern Antenna Handbook; Balanis, C.A., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; pp. 157–200. [Google Scholar]

- Shen, S.; Chiu, C.-Y.; Murch, R.D. Multiport Pixel Rectenna for Ambient RF Energy Harvesting. IEEE Trans. Antennas Propag. 2018, 66, 644–656. [Google Scholar] [CrossRef]

- Wagih, M.; Weddell, A.S.; Beeby, S. High-Efficiency Sub-1 GHz Flexible Compact Rectenna based on Parametric Antenna-Rectifier Co-Design. In Proceedings of the 2020 IEEE/MTT-S International Microwave Symposium (IMS), Los Angeles, CA, USA, 4–6 August 2020; pp. 1066–1069. [Google Scholar]

- Niotaki, K.; Kim, S.; Jeong, S.; Collado, A.; Georgiadis, A.; Tentzeris, M.M. A compact dual-band rectenna using slot-loaded dual band folded dipole antenna. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 1634–1637. [Google Scholar] [CrossRef]

- Firdaus, A.N.F.; Yulindon; Dewi, R. Measurement of 2.4 GHz Access Point Antenna. IOP Conf. Ser. Mater. Sci. Eng. 2020, 846, 012012. [Google Scholar] [CrossRef]

- Cisco Aironet Antennas. Available online: https://www.industrialnetworking.com/pdf/Cisco-Aironet-Antennas.pdf (accessed on 22 June 2025).

| Material | εr′ | σ 1 | ρ 2 |

|---|---|---|---|

| Sample from PLA | 1.436 | 0.0014 | 1082 |

| Sample from polymer resin | 2.789 | 0.0160 | 780 |

| Reference | Max. Dim. 1 | Max. Rad. Eff. 2 | BW 3 | Max. Conv. Eff. 4 | Aesthetic Design | Complexity | Polarization |

|---|---|---|---|---|---|---|---|

| [21] | 110 × 122 | 32.5 | 220 | - | Yes | Low | Circular |

| [23] | 182 × 182 | - | 580 | 34 | No | Low | Linear |

| [29] | 143 × 64 | 99 | 1200 | - | Yes | Low | Linear |

| [30] | 126 × 9 | - | 350 | - | Yes | Low | Linear |

| [31] | 70 × 70 | 90 | 130 | - | No | Height | Linear |

| This work | 60 × 60 | 60.55 | 170 | 33 | Yes | Low | Linear |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atanasov, B.; Atanasov, N.; Atanasova, G. The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices. Electronics 2025, 14, 2625. https://doi.org/10.3390/electronics14132625

Atanasov B, Atanasov N, Atanasova G. The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices. Electronics. 2025; 14(13):2625. https://doi.org/10.3390/electronics14132625

Chicago/Turabian StyleAtanasov, Blagovest, Nikolay Atanasov, and Gabriela Atanasova. 2025. "The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices" Electronics 14, no. 13: 2625. https://doi.org/10.3390/electronics14132625

APA StyleAtanasov, B., Atanasov, N., & Atanasova, G. (2025). The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices. Electronics, 14(13), 2625. https://doi.org/10.3390/electronics14132625